Preparation method of graphene ultra-high molecular weight polyethylene hybrid fiber

An ultra-high molecular weight, hybrid fiber technology, applied in the field of high-performance fiber preparation, can solve the problems of reducing the collective strength of fibers, easy creep and heat resistance of fibers, etc., and achieve good lipophilicity, high fiber matrix strength, and improved stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

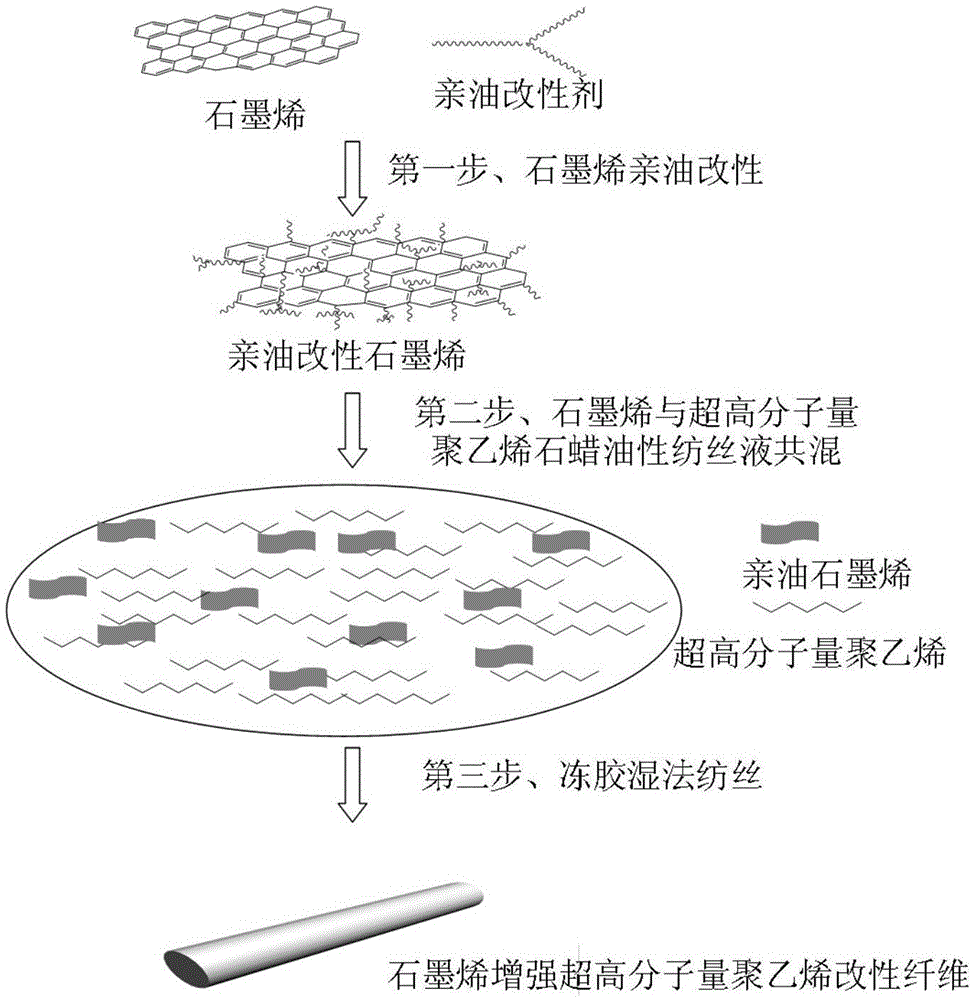

[0014] The preparation process steps of the graphene ultra-high molecular weight polyethylene hybrid fiber involved in this embodiment include: graphene (or graphene oxide) lipophilic modification, lipophilic modified graphene dispersion liquid and ultra-high molecular weight polyethylene paraffin oily Three process steps for preparing graphene-reinforced ultra-high molecular weight polyethylene hybrid fibers by spinning solution blending and gel wet spinning:

[0015] (1) Graphene (or graphene oxide) lipophilic modification: the graphene or graphene oxide raw material is uniformly dispersed in the ethanol solution first to prepare graphene or graphene oxide with a concentration of 0.1-10% by weight of graphite Graphene or graphene oxide ethanol dispersion; then graphene or graphene oxide ethanol dispersion is added to the lipophilic modifier (oleylamine or oleic acid) in a weight ratio (1:10—10:1) for blending Obtain a blended solution; then, control the temperature of the bl...

Embodiment 2

[0020] The present embodiment is prepared according to the process steps of Example 1, wherein the raw material adopts graphene powder, and the graphene ethanol dispersion in step (1) has a weight percentage concentration of 1%, and the graphene ethanol dispersion and lipophilic modifier oil Amines are blended at a weight ratio of 1:1 to obtain a blended solution, and the blended solution is subjected to lipophilic grafting modification at a high temperature of 90°C, and the prepared lipophilic modified graphene dispersion has a weight percentage concentration of 0.5% ; The lateral size of the graphene is 5 microns, and the thickness is 10 nanometers;

[0021] In step (2), the antioxidant butyl hydroxyanisole and ultra-high molecular weight polyethylene with a molecular weight of 2 million are added in a ratio of 1:1000 to a dissolution kettle filled with paraffin wax, and the temperature is raised to 100° C. The molecular weight polyethylene is completely swollen; the lipophi...

Embodiment 3

[0024] This example is prepared according to the process steps of Example 1, wherein the raw material is graphene oxide powder, and other parameters are the same as those of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com