Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Simple and convenient adjustment steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

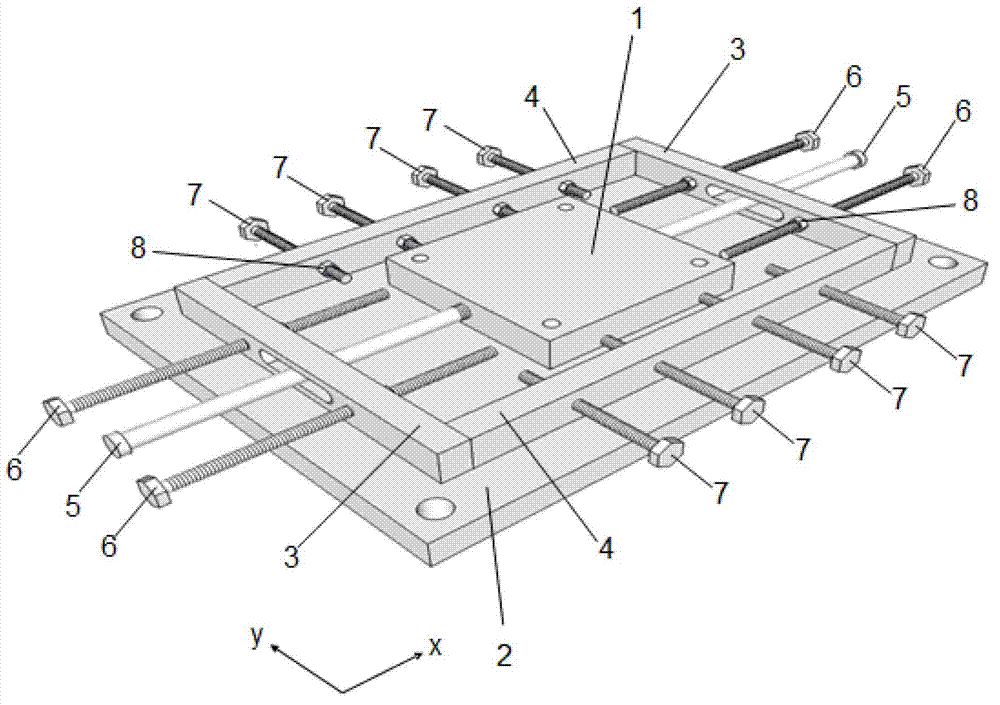

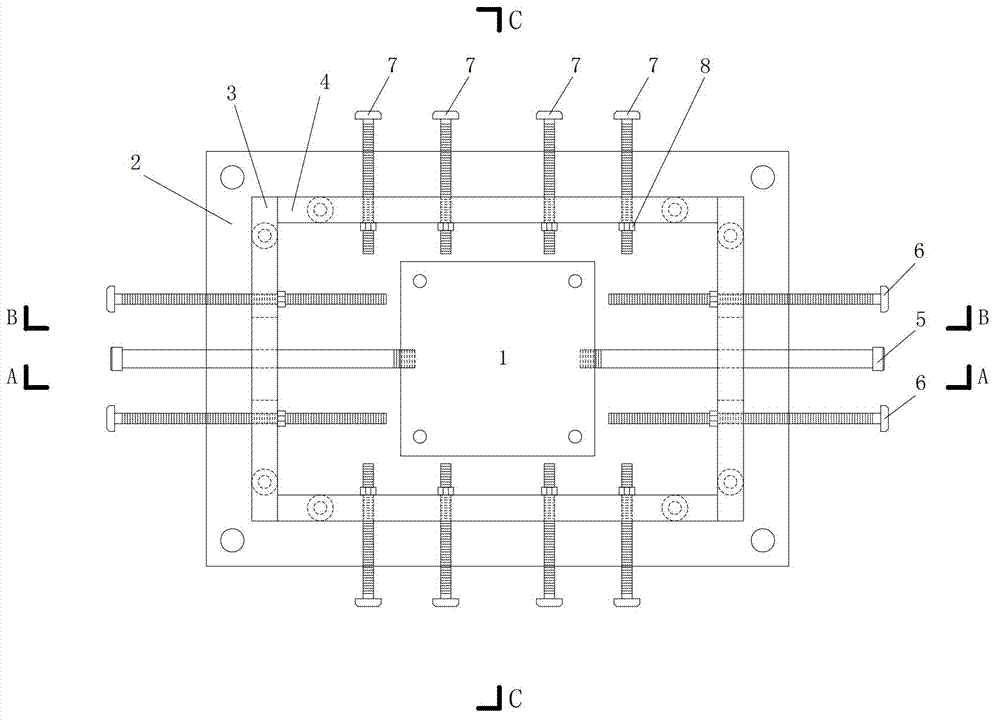

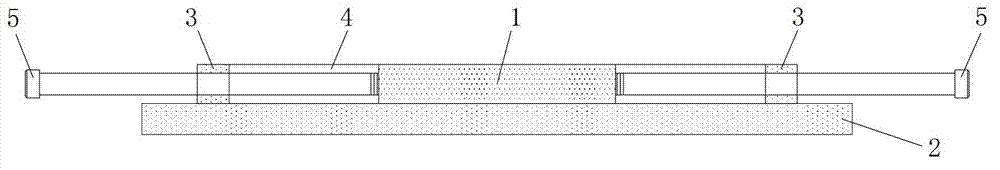

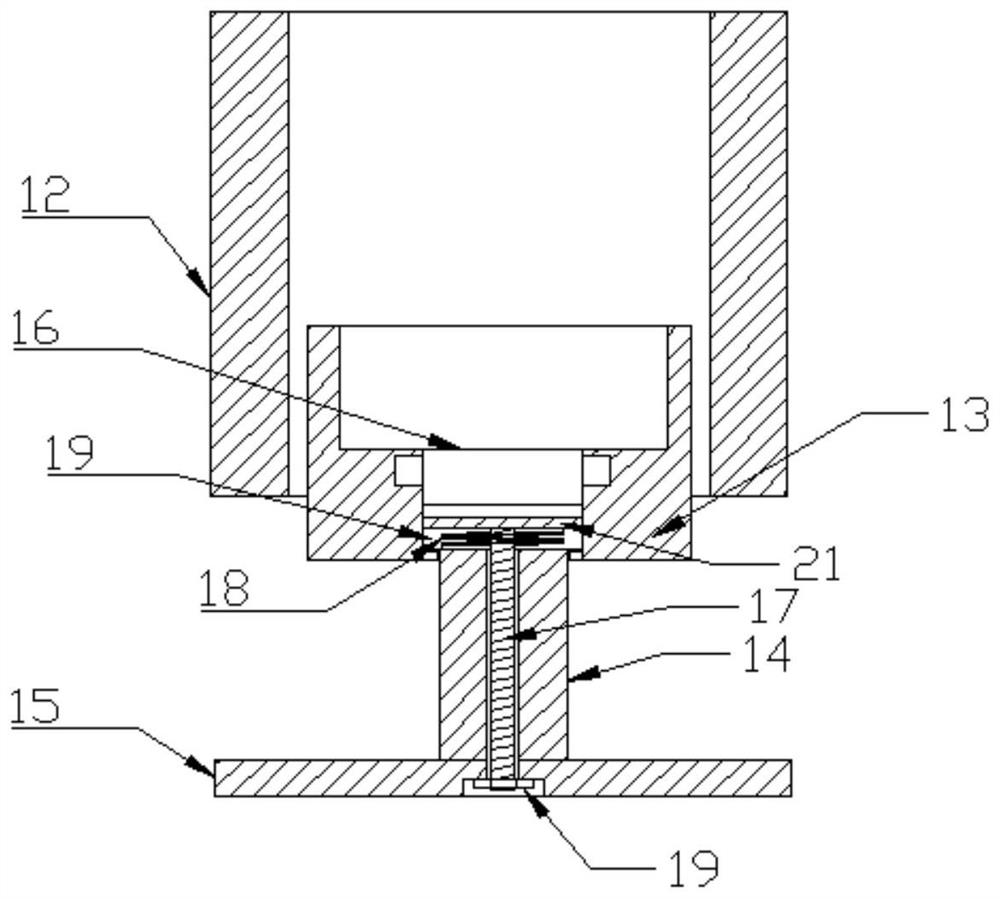

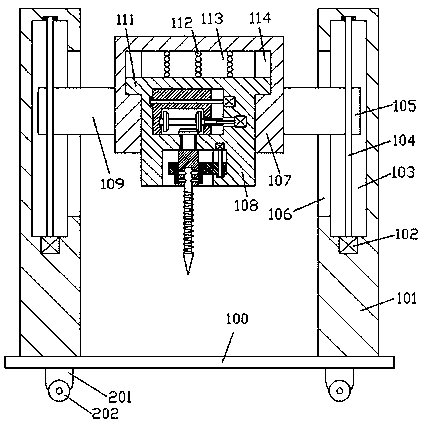

Load positioning device for structural test

InactiveCN102809508AAchieve regulationSimple and convenient adjustment stepsStrength propertiesLocknutEngineering

The invention discloses a load positioning device for a structural test. The device consists of a positioning block, a bottom plate, retaining blocks, an anti-overturn screw, adjusting screws and locknuts. The device is connected and fixed with a steel member or a steel embedded piece of a concrete member through the bottom plate; the positioning block is connected with a jack, is arranged in an area enclosed by the retaining blocks of the surface of the bottom plate, and moves longitudinally and transversely by screwing the adjusting screws; the anti-overturn screw passes through slots on the transverse retaining blocks, and then is anchored into a threaded hole which is formed on the side surfaces of the positioning block so as to prevent the positioning block from being separated from the bottom plate, so that the positioning device is applicable to vertical loading working conditions, and can also be applied to horizontal loading working conditions; scale marks are marked on the upper surface of the bottom plate, and are used for improving the adjusting speed and the adjusting accuracy; and the quantity of the longitudinal adjusting screws is increased and decreased according to the displacement adjustment range. The whole device has a clear principle, can be simply manufactured, is convenient to use, is high in load positioning accuracy, and can be applied to civil engineering teaching and scientific research tests.

Owner:SHANGHAI JIAO TONG UNIV

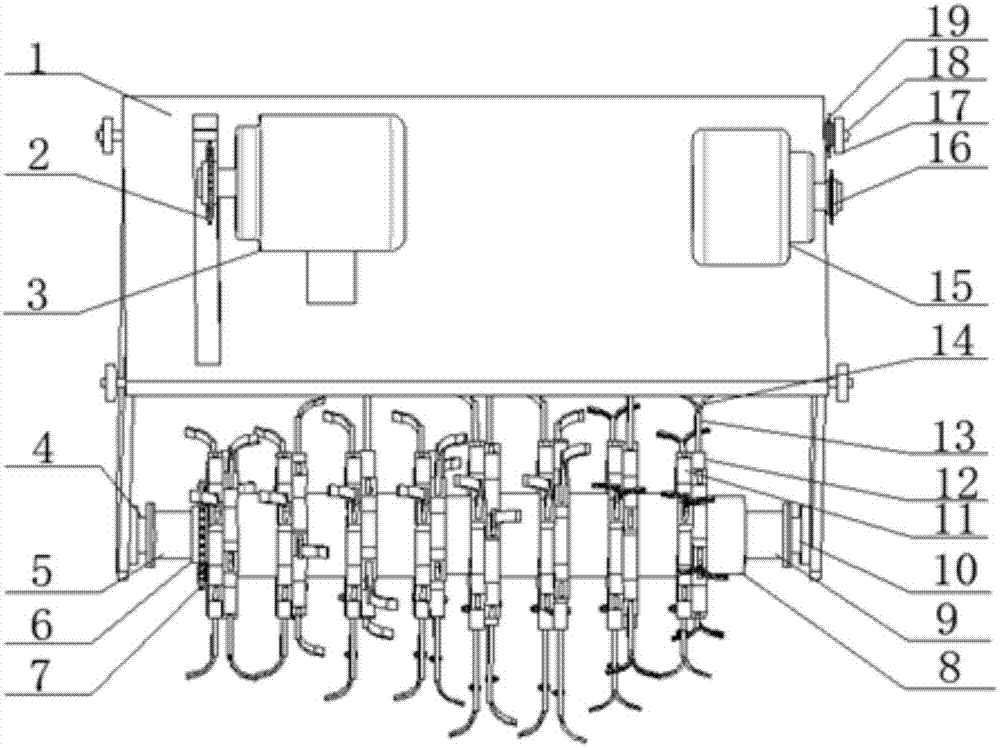

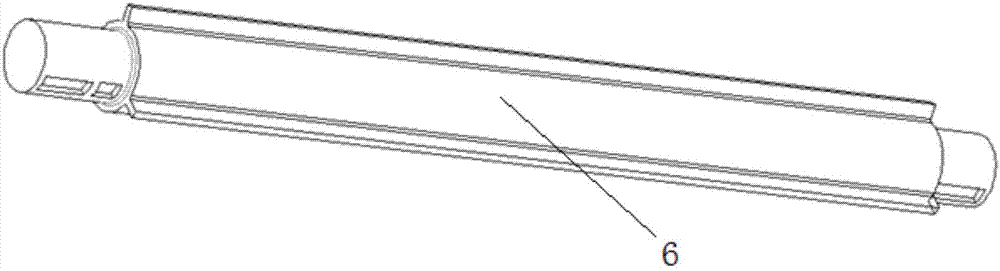

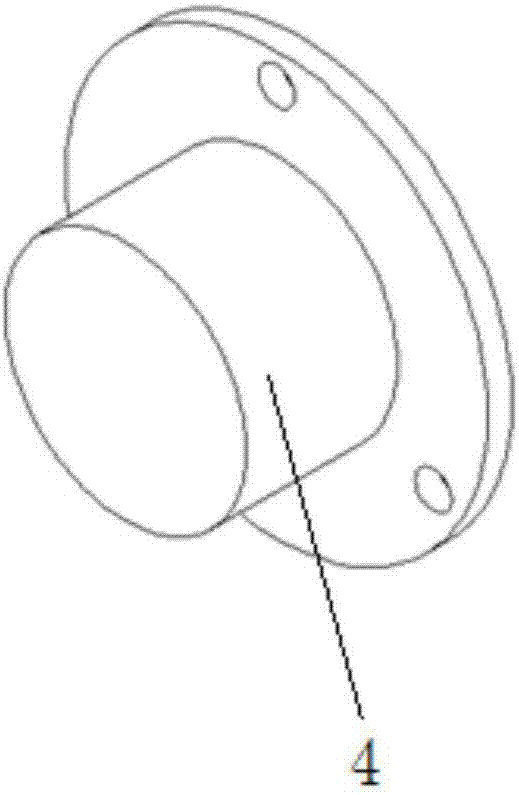

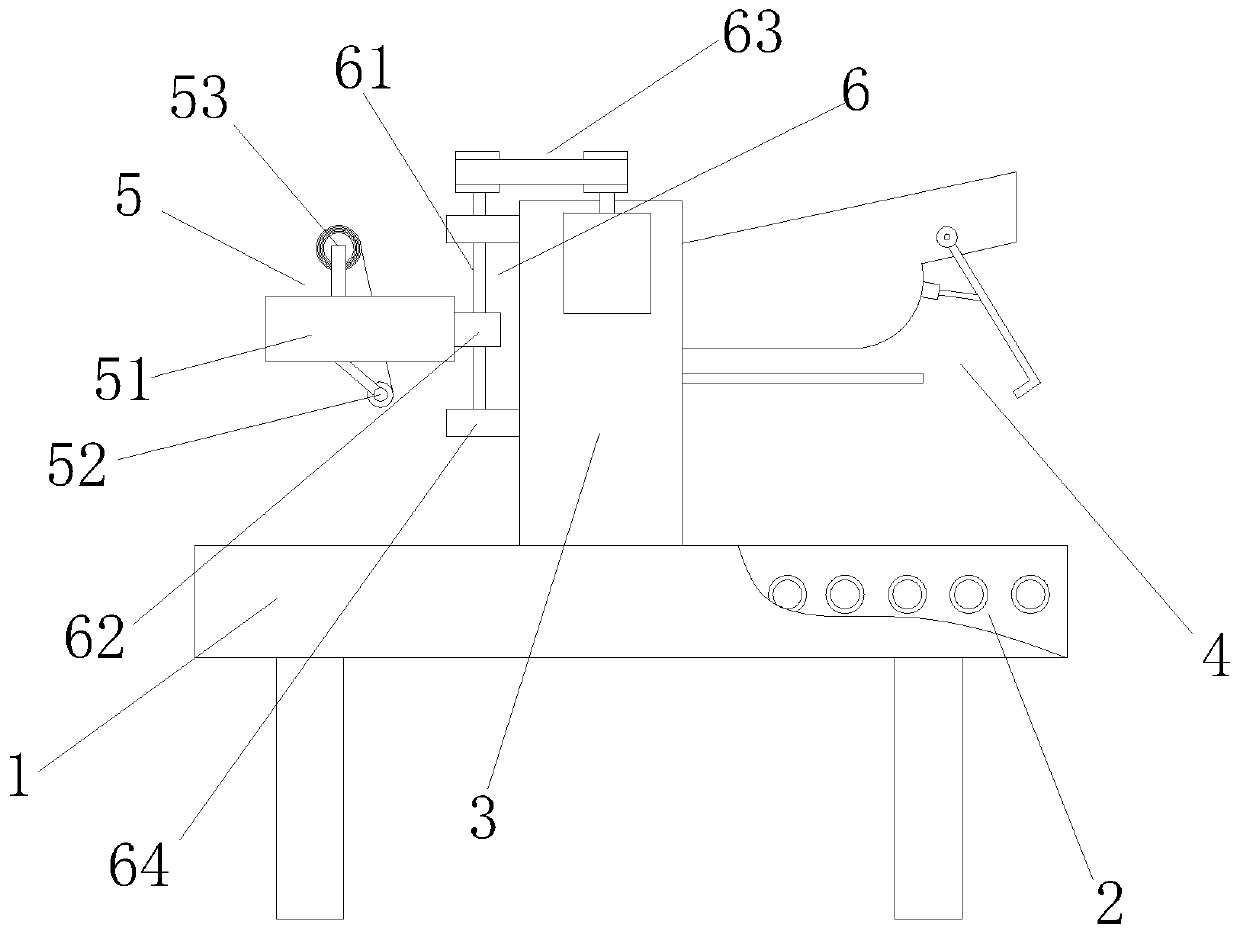

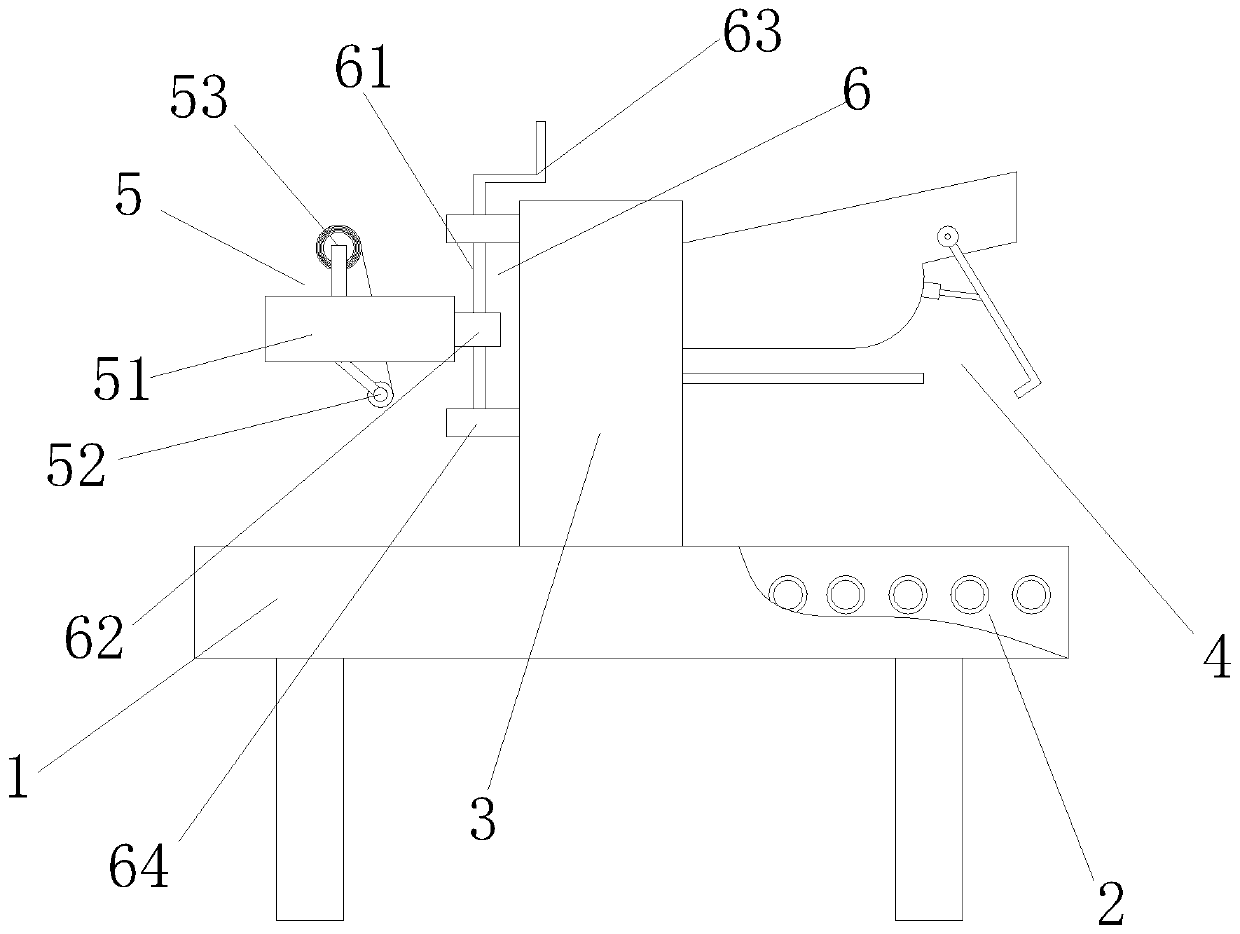

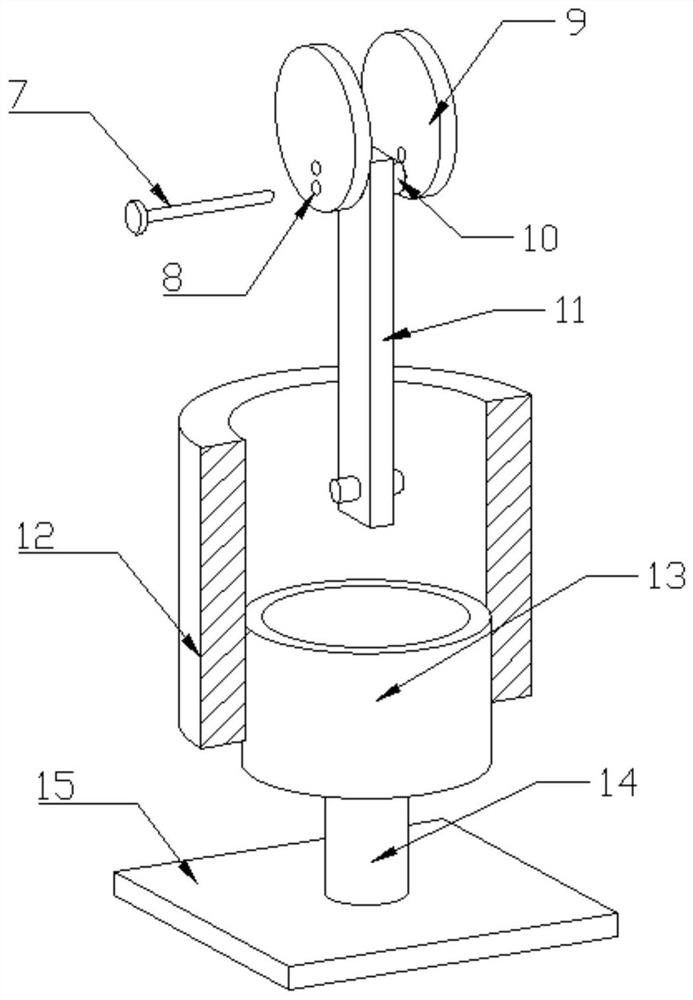

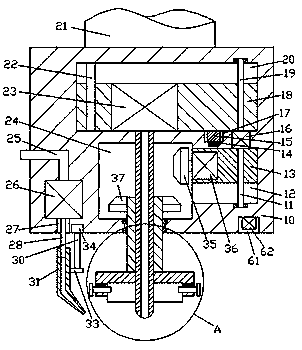

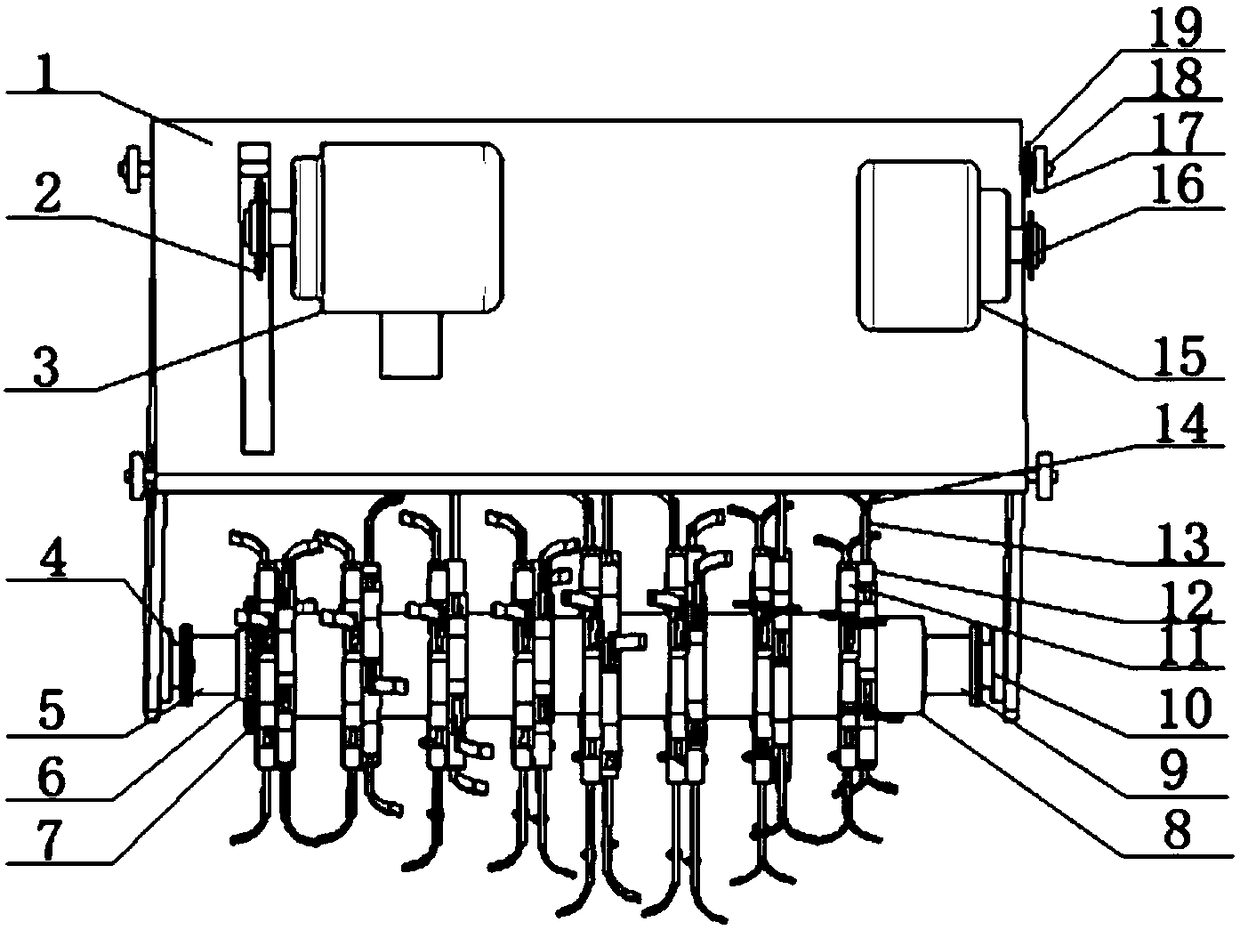

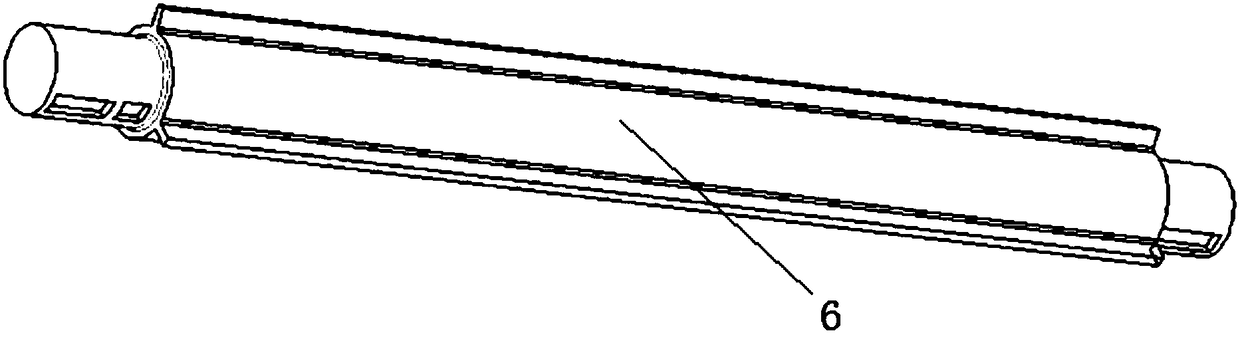

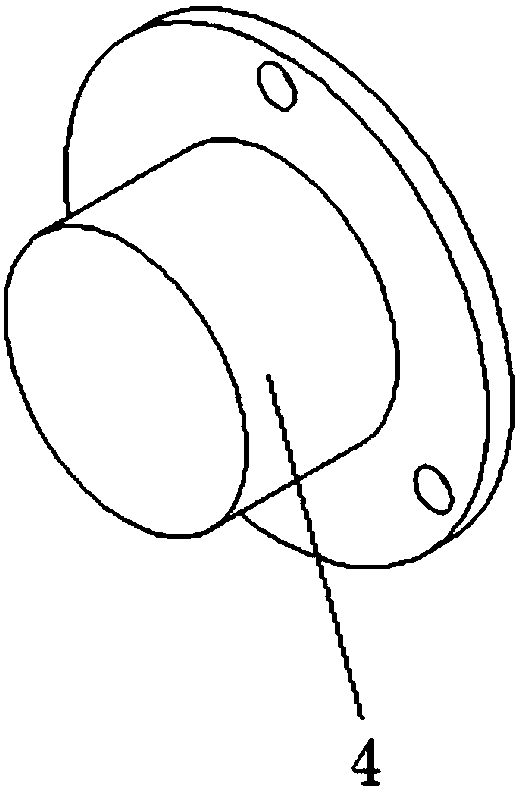

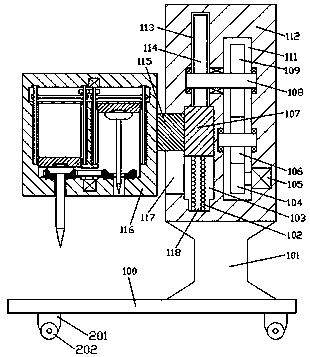

Overturning and throwing machine for producing organic fertilizer and nutritional matrix

ActiveCN107162666AAdaptableAdjustable lengthBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringOrganic fertilizer

The invention relates to an overturning and throwing machine for producing an organic fertilizer and a nutritional matrix. The overturning and throwing machine comprises a frame, a walking mechanism arranged behind the frame and an overturning and throwing mechanism arranged at the lower part of the frame, the walking mechanism is driven by a transmission motor, the overturning and throwing mechanism is driven by an overturning and throwing motor, the overturning and throwing mechanism comprises an overturning and throwing shaft, a plurality of overturning and throwing cutter discs arranged on the overturning and throwing shaft, and overturning and throwing shaft sleeves, the overturning and throwing cutter discs and the overturning and throwing shaft sleeves are alternately distributed, every overturning and throwing cutter disc is provided with a cutter shaft, and a cutter head is arranged at the upper end of every cutter shaft. Compared with overturning and throwing machines in the prior art, the overturning and throwing machine has the following advantages: the diameter of the overturning and throwing cutter discs is adjustable, so the overturning and throwing at different depths are realized according to different material depths; the length of the cutter shafts is adjustable, and can be combined with the diameter of the cutter discs to generate different overturning and throwing depths; the length of the shaft sleeves is adjustable, so the width of an overturning and throwing gap can be adjusted according to the kind of the material, and different shaft sleeve lengths can be set according to the kind and the water content of a fermentation material during the installation of the overturning and throwing shaft; and the type of the cutter heads is adjustable, so different cutter head types can be set according to the characteristics of different fermentation materials.

Owner:TONGJI UNIV

Box sealing machine

InactiveCN110395449ASimple height adjustment structureSimple and convenient adjustment stepsWrapper twisting/gatheringArticle deliveryReciprocating motionEngineering

The invention discloses a box sealing machine. The box sealing machine comprises a machine frame, a conveying assembly, a support frame, a cap folding assembly and a glue sealing assembly, wherein thesupport frame is located on two sides of the conveying assembly, and in the moving direction of a box body of a box to be sealed, the cap folding assembly and the glue sealing assembly are sequentially arranged at the top of the support frame, and furthermore the glue sealing assembly comprises a box pressing body, a glue sealing roller and a glue supply device, the glue sealing roller is movablyconnected with the box pressing body, the glue supply device is fixedly installed on the box pressing body, the glue sealing roller is connected with the glue supply device through an adhesive tape,the box pressing body is connected with the support frame through height adjustment mechanisms, each height adjustment mechanism comprises a rotation piece vertically installed on the side wall of thesupport frame in a rotation mode, a slide block which performs up-down straight reciprocating motion along the rotation piece and a drive device which drives the rotation piece to rotate, rotation structures are arranged on the surface of each rotation piece and a contact position of each slide block and the surface of each rotation piece, and each slide block is fixedly connected with the box pressing body. Compared with the prior art, the height adjustment mechanisms of the box pressing body are simple in structure, and simple and convenient in adjustment step.

Owner:六安堰山自动化设备销售有限公司

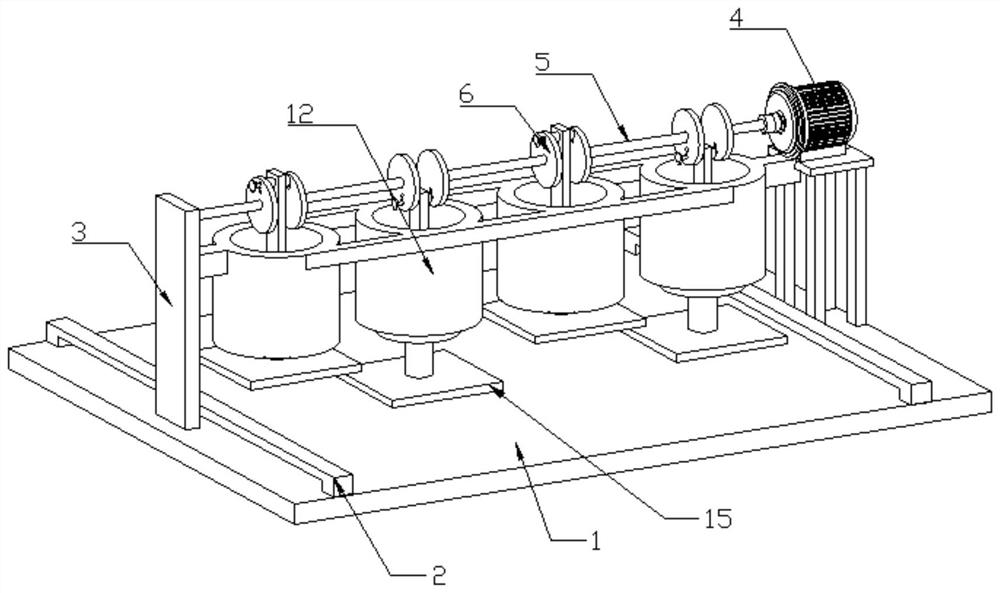

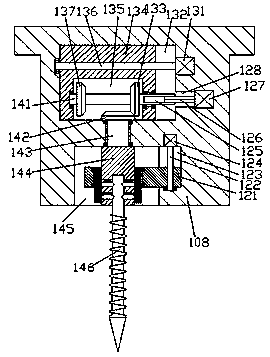

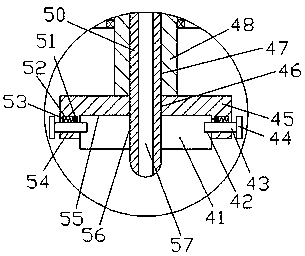

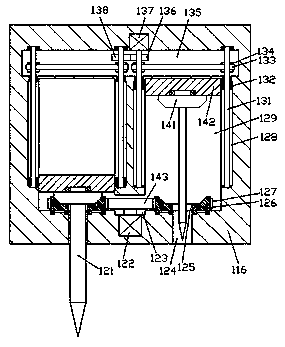

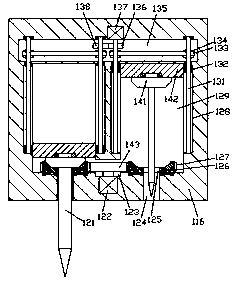

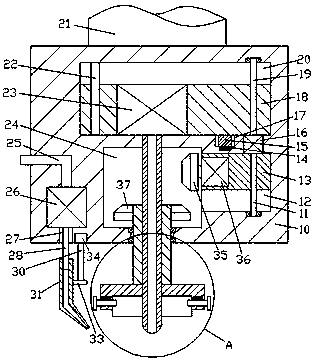

Rubber and plastic product fatigue test device

PendingCN113484168ARealize detectionSimple and convenient adjustment stepsMaterial strength using repeated/pulsating forcesStructural engineeringMechanical engineering

The invention discloses a rubber and plastic product fatigue test device. The device disclosed by the present invention comprises a base and a support, the base is provided with a rotating shaft driven by a starter, the rotating shaft is rotatably connected with connecting rods through connecting mechanisms, the top end of each connecting rod performs eccentric motion by taking the axis of the rotating shaft as the circle center, the bottom of each connecting rod is rotatably connected with a movable part, cavities corresponding to the connecting rods are formed in the movable parts, the outer sides of the movable parts are sleeved with sleeves, the movable parts move up and down along the axes of the sleeves, and lower pressing plates are installed at the bottoms of the movable parts. According to the device, eccentric structures are used for driving a plurality of pressing plates to press downwards to detect rubber and plastic products, connecting positions can be changed, the pressing amplitude correspondingly changes after the positions are changed, the movable parts can move up and down along the axis according to the positions of the nuts, then the positions are changed, and the pressing amplitude correspondingly changes.

Owner:赵强

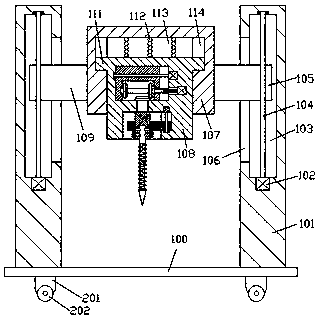

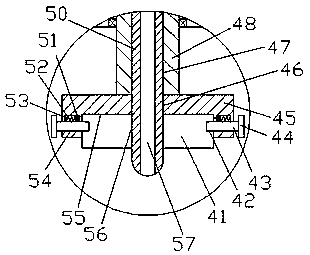

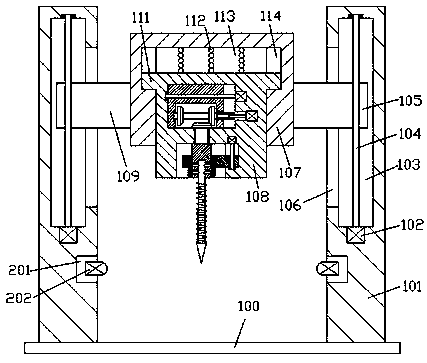

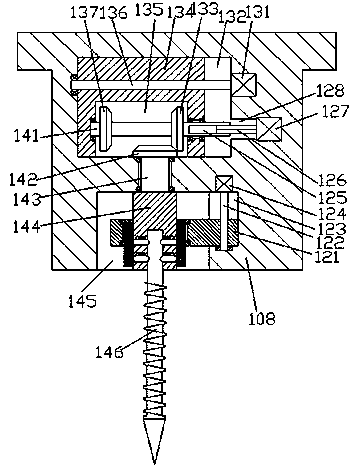

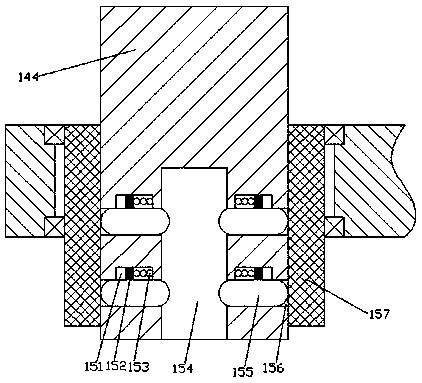

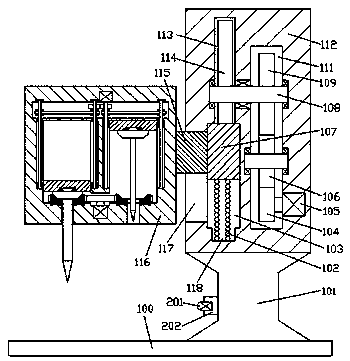

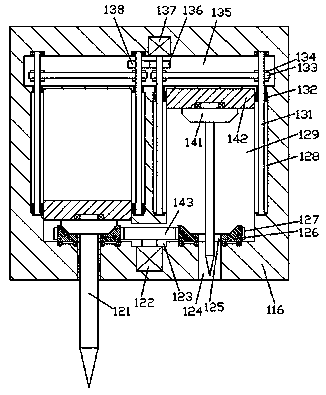

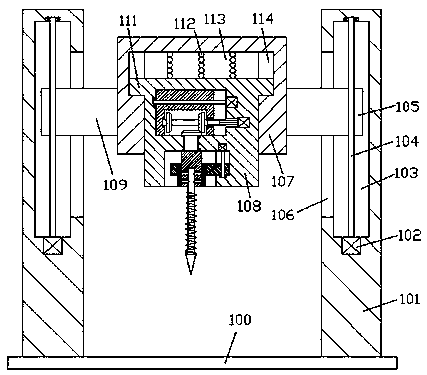

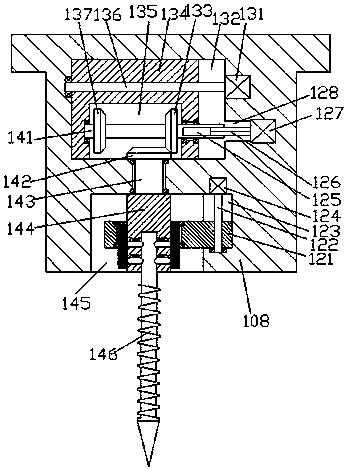

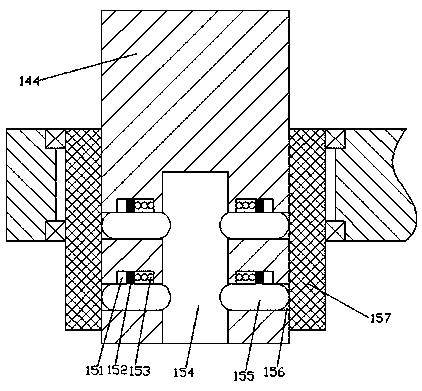

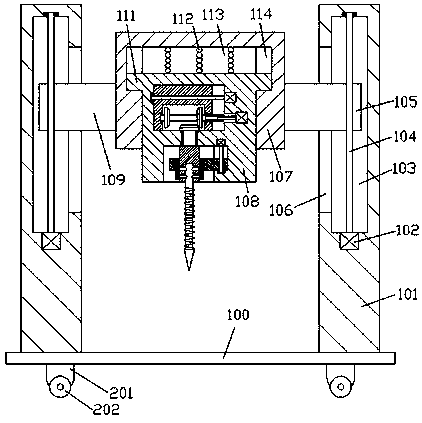

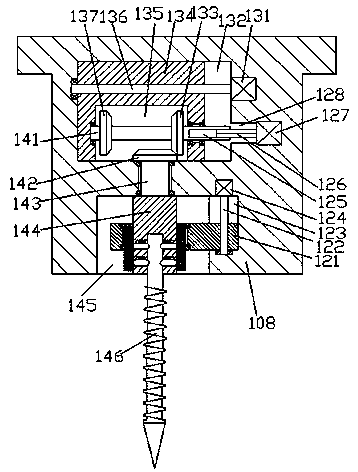

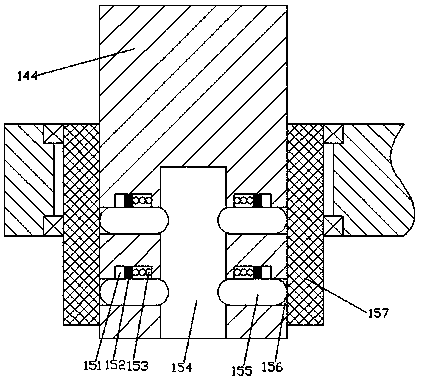

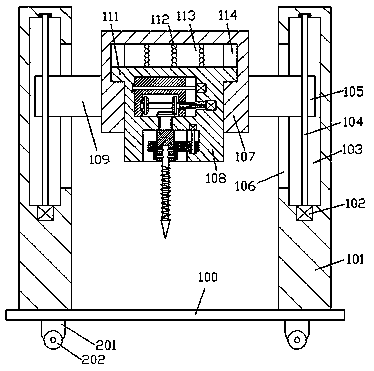

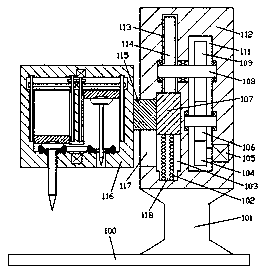

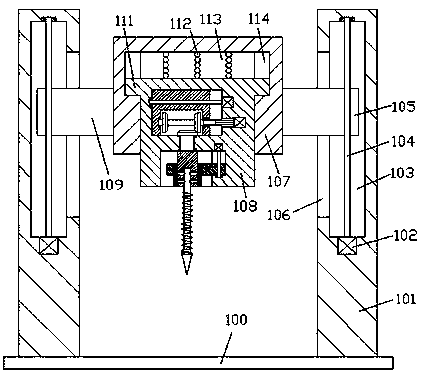

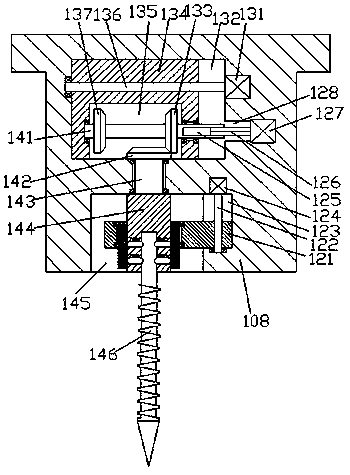

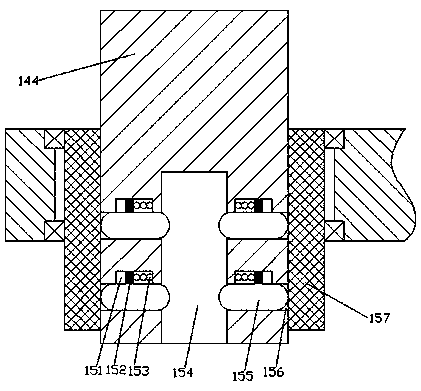

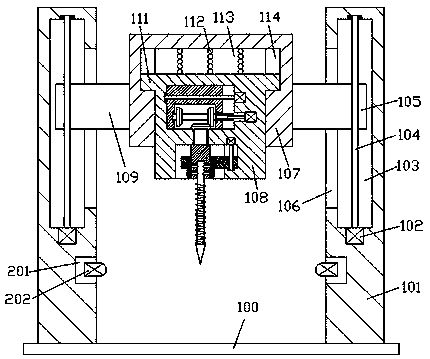

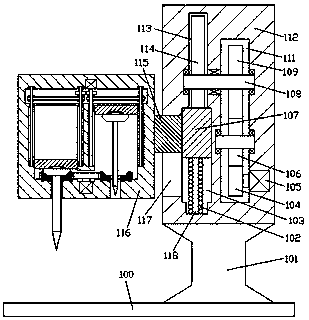

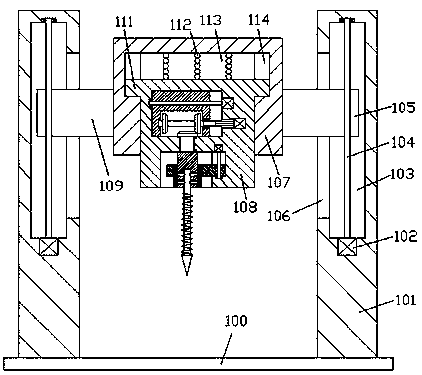

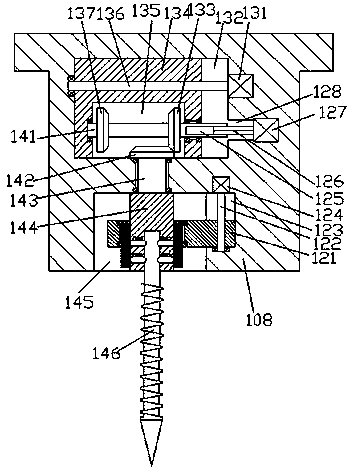

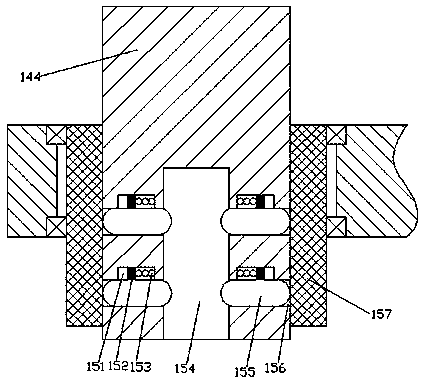

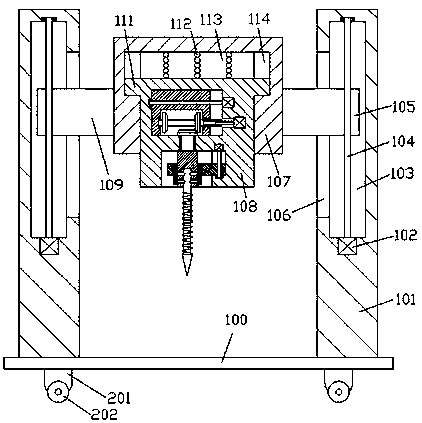

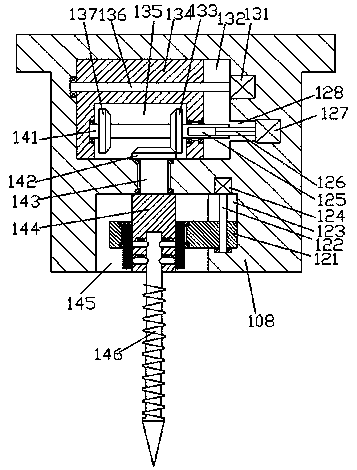

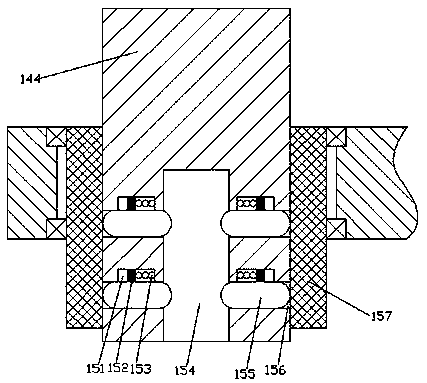

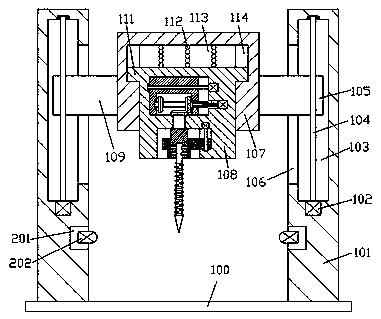

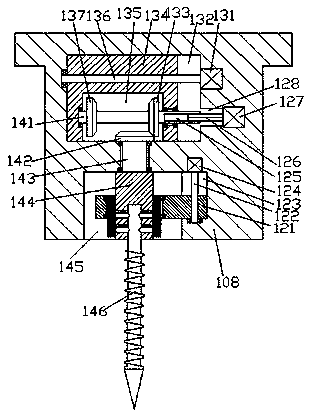

Novel hard alloy pipe fitting

InactiveCN109014296AImprove drilling efficiencyImprove stabilityFeeding apparatusPositioning apparatusPipe fittingAlloy

The invention discloses a novel hard alloy pipe fitting. The novel hard alloy pipe fitting comprises a base, support frames are symmetrically and fixedly arranged on the left side and the right side of the end face of the top of the base, a main base body is arranged between the support frames on the left side and the right side, a first sliding cavity is formed in the end face of the bottom of the main base body, an installing base is installed in the first sliding cavity in a sliding fit mode, and buffering springs are installed between the top end face of the installing base and the top wall of the first sliding cavity in a jacking fit mode; and a first cavity is formed in the end face of the bottom of the installing base, a first transmission cavity is formed in the portion, on the upper side of the first cavity, of the installing base, a first rotation shaft is installed between the first cavity and the first transmission cavity in a rotating fit mode, a first bevel gear is fixedly arranged at the tail end of the top of the first rotation shaft, an installing block is fixedly arranged at the tail end of the bottom of the first rotation shaft, and an inserting cavity is formedin the end face of the bottom of the installing block.

Owner:广州峥航机械设备有限公司

A multifunctional laser engraving device

ActiveCN108637688BSimple structureEasy to operateOther manufacturing equipments/toolsLaser beam welding apparatusLaser engravingEngineering

The invention discloses a multifunctional laser carving device. The multifunctional laser carving device comprises a machining body which is fixedly arranged on the lower side of an adjustment arm; atransmission and connection cavity is formed in the inner wall body of the machining body; an adjustment cavity is formed in the machining body on the top of the transmission and connection cavity; anadjustment rack is arranged in the adjustment cavity in a sliding match manner; a sliding cavity is formed in the inner wall of the right side of the transmission and connection cavity in a communication manner; a sliding base is arranged in the sliding cavity in a sliding match manner; a first motor is fixedly arranged in the sliding cavity and the adjustment cavity; the top end of the first motor is connected with an upper threaded rod in a power match manner; the upper threaded rod is connected with the adjustment rack in a thread match manner, and the tail end of the top of the upper threaded rod is connected with the inner top wall of the adjustment cavity in a rotary match manner; the bottom end of the first motor is in power match with a lower threaded rod; and the lower threaded rod is connected with the sliding base in a thread match manner, and the tail end of the bottom of the lower threaded rod is connected with the inner bottom wall of the sliding cavity in a rotary matchmanner.

Owner:CHINA RUILONG TECH CO LTD

Improved flexible circuit board, processing method thereof and mobile terminal

InactiveCN108858439AImprove drilling efficiencyImprove stabilityPrinted circuit manufactureMetal working apparatusFlexible circuitsEngineering

The invention discloses an improved flexible circuit board, a processing method thereof and a mobile terminal. The flexible circuit board comprises a base, supporting bases are symmetrically and fixedly arranged on the end face of the top of the base in the left-and-right direction, a frame is arranged between the supporting bases in the left side and the right side, a first sliding-connecting cavity is formed in the end face of the bottom of the frame, an installing-connecting base is installed inside the first sliding-connecting cavity through sliding fit, a buffering piece is installed between the top end face of the installing-connecting base and the top wall of the first sliding-connecting cavity through abutting-against and pressing fitting, a first hollowed cavity is formed in the bottom end face of the installing-connecting base, a first conveying-connecting cavity is formed in the part, on the upper side of the first hollowed cavity, inside the installing-connecting base, a first rotary connection shaft is rotatably and cooperatively installed at the part between the first hollowed cavity and the first conveying-connecting cavity, a first conical edge wheel is fixedly arranged at the tail end of the top of the first rotary connection shaft, an installing-connecting block is fixedly arranged at the tail end of the bottom of the first rotary connection shaft, and an inserting groove is formed in the end face of the bottom of the installing-connecting block.

Owner:广州弘唷网络科技有限公司

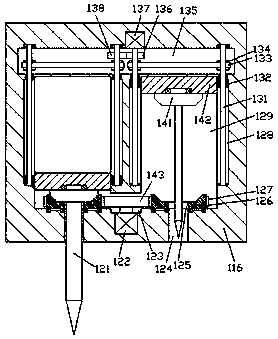

Novel flexible circuit board and processing method thereof and mobile terminal

InactiveCN108943138AImprove punch stabilityAvoid compromising punch qualityMetal working apparatusFlexible circuitsEngineering

The invention discloses a novel flexible circuit board and a processing method thereof and a mobile terminal. The novel flexible circuit board comprises a bed frame, and a supporting column is fixedlyarranged on the top end face of the bed frame. A connecting frame is fixedly arranged on the top end face of the supporting column, and a main seat is arranged on the left side end of the connectingframe. A first penetrating groove is formed in the bottom end face of the main seat in a bilateral symmetry manner, and a transferring groove is formed in the inner top wall of the first penetrating groove in a vertical extending manner. A conical edge frame is mounted on the bottom wall of the transferring groove in a running fit manner, and a toothing ring is fixedly arranged on the periphery ofthe conical edge frame. A second penetrating groove opposite to the first penetrating groove formed in the conical edge frame in a vertical penetrating manner. A transferring frame is mounted in thetransferring groove in a sliding fit manner, and a conical edge wheel for being engaged with the conical edge frame is mounted at the bottom end of the transferring frame in a rotating fit manner. A drill bit is fixedly mounted on the bottom end face of the conical edge wheel, the drill bit penetrates into the second penetrating groove and the first penetrating groove, and a communicating openingis formed between the bottom ends of the transferring groove in the left side and the right side.

Owner:FOSHAN DETAO POWER TECH CO LTD

Flexible circuit board and processing method thereof, mobile terminal

InactiveCN108990282AImprove punch stabilityAvoid compromising punch qualityPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses a flexible circuit board and a processing method thereof, mobile terminal. The flexible circuit board includes a base frame, A support column is fixedly arrange on that top endsurface of the base frame, At that top end surface of the support column, an attachment frame is fixedly arrange, A main seat body is arranged at that left end of the mounting frame, A left-right symmetrical first through groove is arranged in that end face of the bottom of the main seat body, A regulating groove is arranged in the top wall of the first through groove and extends upward and downward, A taper edge frame is rotatably fitted to that bottom wall of the transfer groove, A toothed joint ring is fixedly arranged on the outer periphery of the conical edge frame, A second through-groove opposite to the first through-groove is arranged through the conical edge frame. A transfer rack is slidably fitted and installed in the transfer groove, At that bottom end of the transfer frame, ataper wheel for intermeshing with the taper frame is rotatably fitted, a drill bit is fixedly installed on the bottom end face of the taper wheel, the drill bit is respectively pierced into the second through groove and the first through groove, and the bottom ends of the transfer groove on the left and right sides are communicated with each other through openings.

Owner:FOSHAN DETAO POWER TECH CO LTD

Management system for intelligent packaging box

InactiveCN109049833AImprove drilling efficiencyImprove stabilityPaper-makingBox making operationsRight-SidedManagement system

The invention discloses a management system for an intelligent packaging box. The management system comprises a base frame, wherein the left end surface and the right end surface of the top part of the base frame are symmetrically and fixedly provided with vertical frames; a shell is arranged between the left-sided vertical frame and the right-sided vertical frame; a first sliding slot is formed in the bottom end surface of the shell; a clamping base is mounted in the first sliding slot in a sliding fit manner; a buffer elastic strip is mounted between the top end surface of the clamping baseand the top wall of the first sliding slot in a top pressing fit manner; a first groove is formed in the bottom end surface of the clamping base; a first transmission cavity is formed in the clampingbase and positioned on the upper side of the first groove; a first rotating rod is mounted on the part positioned between the first groove and the first transmission cavity in a rotating fit manner; the tail end of the top part of the first rotating rod is fixedly provided with a first conical angle wheel; the tail end of the bottom part of the first rotating rod is fixedly provided with a clamping block; and an inserting groove is formed in the bottom end surface of the clamping block.

Owner:广州市科卡通信科技有限公司

Novel modified ABS material as well as preparation method and application

The invention discloses a novel modified ABS material as well as a preparation method and application. The novel modified ABS material comprises a base plate, vertical frames are symmetrically and fixedly arranged on the left side and the right side of the top end face of the base plate, and an outer frame is arranged between the vertical frames on the left side and the right side; a first slidingspace is formed in the bottom end face of the outer frame, an embedding base is installed in the first sliding space in a sliding fit mode, and buffering elastic pieces are installed between the topend face of the embedding base and the top wall of the first sliding space in a pressing fit mode; and a first notch is formed in the bottom end surface of the embedding base, a first conduction cavity is formed in the position, on the upper side of the first notch, in the embedding base, a first rotating arm is installed on the part between the first notch and the first conduction cavity in a rotating fit mode, a first bevel wheel is fixedly arranged at the tail end of the top of the first rotating arm, an attachment block is fixedly arranged at the tail end of the bottom of the first rotating arm, and an inserting hole is formed in the bottom end surface of the attachment block.

Owner:广东亚昀五金建材有限公司

Laser engraving device

ActiveCN108326442ASimple structureEasy to operateLaser beam welding apparatusLaser engravingEngineering

The invention discloses a laser engraving device. The laser engraving device comprises a machining main body which his fixedly installed at the lower side of a regulating arm; the inner wall body of the machining main body is internally provided with a passing and receiving chamber; a part, positioned at the top of the passing and receiving chamber, of the machining main body is internally provided with a regulating chamber; a regulating frame is installed inside the regulating chamber in a sliding fit manner; the inner wall of the right side of the passing and receiving chamber is provided with a sliding chamber which communicates with the passing and receiving chamber; a sliding seat is installed inside the sliding chamber in a sliding fit manner; a first motor is fixedly arranged between the sliding chamber and the regulating chamber; the top end of the first motor is in power matched connection with an upper threaded rod; the upper threaded rod is connected with the regulating frame in a thread fit manner; the tail end of the top of the upper threaded rod is connected with the internal top wall of the regulating chamber in a running fit manner; the bottom end of the first motoris in power matched connection with a lower threaded rod; the lower threaded rod is connected with the sliding seat in a thread fit manner; and the tail end of the bottom of the lower threaded rod isconnected with the internal bottom wall of the sliding chamber in a running fit manner.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

Novel image processing method and device

InactiveCN109093145AImprove drilling efficiencyImprove stabilityDriving apparatusPositioning apparatusImaging processingEngineering

The invention discloses a novel image processing method and device. The novel image processing method and device comprises a bottom plate, wherein supporting seats are symmetrically and fixedly arranged on the left side and the right side of the top end face of the bottom plate; a frame body is arranged between the supporting seats on the left side and the right side; a first sliding-moving cavityis formed in the end surface of the bottom of the frame body; a fixing base is arranged in the first sliding-moving cavity in a sliding fit mode; a buffering elastic pressing piece is arranged between the top end face of the fixing base and the top wall of the first sliding-moving cavity in a pressing fit mode; a first sunken cavity is formed in the end surface of the bottom of the fixing base; afirst conveying cavity is formed in the fixing base at the upper side of the first sunken cavity; a first rotating pin shaft is rotationally matched with a part between the first sunken cavity and the first conveying cavity in a rotating mode; a first conical wheel is fixedly arranged at the tail end of the top of the first rotating pin shaft; a fixing block is fixedly arranged at the tail end ofthe bottom of the first rotating pin shaft; and a socket is arranged in the end surface of the bottom of the fixing block.

Owner:广州诗琬家居有限公司

A turning and throwing machine for the production of organic fertilizers and nutrient substrates

InactiveCN107162666BAdaptableAdjustable lengthBio-organic fraction processingOrganic fertiliser preparationOrganic manureAgricultural engineering

The invention relates to an overturning and throwing machine for producing an organic fertilizer and a nutritional matrix. The overturning and throwing machine comprises a frame, a walking mechanism arranged behind the frame and an overturning and throwing mechanism arranged at the lower part of the frame, the walking mechanism is driven by a transmission motor, the overturning and throwing mechanism is driven by an overturning and throwing motor, the overturning and throwing mechanism comprises an overturning and throwing shaft, a plurality of overturning and throwing cutter discs arranged on the overturning and throwing shaft, and overturning and throwing shaft sleeves, the overturning and throwing cutter discs and the overturning and throwing shaft sleeves are alternately distributed, every overturning and throwing cutter disc is provided with a cutter shaft, and a cutter head is arranged at the upper end of every cutter shaft. Compared with overturning and throwing machines in the prior art, the overturning and throwing machine has the following advantages: the diameter of the overturning and throwing cutter discs is adjustable, so the overturning and throwing at different depths are realized according to different material depths; the length of the cutter shafts is adjustable, and can be combined with the diameter of the cutter discs to generate different overturning and throwing depths; the length of the shaft sleeves is adjustable, so the width of an overturning and throwing gap can be adjusted according to the kind of the material, and different shaft sleeve lengths can be set according to the kind and the water content of a fermentation material during the installation of the overturning and throwing shaft; and the type of the cutter heads is adjustable, so different cutter head types can be set according to the characteristics of different fermentation materials.

Owner:TONGJI UNIV

Intelligent image processing method and device

InactiveCN109047822AImprove stabilityAvoid compromising punch qualityBoring/drilling componentsBoring/drilling machinesImaging processingBilateral symmetry

The invention discloses an intelligent image processing method and device. The intelligent image processing device comprises a base, wherein a supporting column is fixedly arranged on the top end surface of the base; an aligning frame is fixedly arranged on the top end surface of the supporting column; a processing seat is arranged at the left side end of the aligning frame; first penetrating cavities which are in bilateral symmetry are formed in the bottom end surface of the processing seat; a debugging cavity which extends up and down is formed in the inner top wall of each first penetratingcavity; a pyramidal frame is mounted on the bottom wall of each debugging cavity in a rotating fit manner; a tooth-shaped ring is fixedly arranged on the periphery of each pyramidal frame; each second penetrating cavity which is opposite to the corresponding first penetrating cavity is formed in the corresponding pyramidal frame in an up and down penetrating manner; a debugging frame is mounted in each debugging cavity in a sliding fit manner; each pyramidal wheel which is mutually meshed with the corresponding pyramidal frame is mounted at the bottom end of the corresponding debugging framein the rotating fit manner; a drilling head is fixedly mounted on the bottom end surface of each pyramidal wheel, and penetrates through the corresponding second penetrating cavity and the corresponding first penetrating cavity; and a through groove communicates with the bottom ends of the debugging cavities on the left side and the right side.

Owner:广州同轩信息科技有限公司

Automated laser engraving device

InactiveCN109108469ASimple structureEasy to operatePolishing machinesLaser beam welding apparatusLaser engravingEngineering

The invention discloses an automated laser engraving device. The automated laser engraving device comprises a machining main body fixedly mounted on the lower side of an adjustment arm hand. A passingand receiving cavity is formed in an inner wall body of the machining main body. An adjustment cavity is formed inside the machining main body and at the top of the passing and receiving cavity. An adjustment bracket is mounted in the adjustment cavity in a sliding-fit manner. A sliding cavity is formed in an inner wall of the right side of the passing and receiving cavity in a communicating manner. A sliding seat is mounted in the sliding cavity in a sliding-fit manner. A first motor is fixedly arranged between the sliding cavity and the adjustment cavity. An upper threaded rod is connectedto the top end of the first motor in a power-fit manner. The upper threaded rod is connected to the adjustment bracket in a screw-thread fit manner, and the top tail end of the upper threaded rod is connected to an inner top wall of the adjustment cavity in a running-fit manner. The bottom end of the first motor is connected with a lower threaded rod in a power-fit manner. The lower threaded rod is connected with the sliding seat in a screw-thread fit manner, and the bottom tail end of the lower threaded rod is connected to an inner bottom wall of the sliding cavity in a running-fit manner.

Owner:张金莲

Intelligent packaging box management system

InactiveCN109176706AImprove punch stabilityAvoid compromising punch qualityMetal working apparatusFixed frameEngineering

The invention discloses an intelligent packaging box management system. The intelligent packaging box management system comprises a base, a vertical rod is fixedly arranged on the end face of the topof the base, an installing and fixing frame is fixedly arranged on the end face of the top of the vertical rod, and a main frame body is arranged on the left side end of the installing and fixing frame; first hole cavities are formed in the end face of the bottom of the main frame body in a bilateral symmetry mode, a distance adjusting cavity is formed in the inner top wall of each first hole cavity in a vertical extending mode, a conical corner bracket is installed on the bottom wall of each distance adjusting cavity in a rotating fit mode, a meshing ring is fixedly arranged at the peripheryof each conical corner bracket, and second hole cavities opposite to the first hole cavities are formed in the conical corner brackets in a vertical penetrating mode; and a distance adjusting frame isinstalled in each distance adjusting cavity in a sliding fit mode, a conical corner wheel meshing with the corresponding conical corner bracket is installed at the bottom end of each distance adjusting frame in a rotating fit mode, a drill bit is fixedly installed on the bottom end face of each conical corner wheel, the drill bits penetrate into the second hole cavities and the first hole cavities, and an open cavity is formed between the bottom end of left-side distance adjusting cavity and the bottom end of the right-side distance adjusting cavity in a communicating mode.

Owner:广州利萨智能化科技有限公司

Plastic plate processing equipment

InactiveCN109176702AImprove drilling efficiencyImprove stabilityMetal working apparatusEngineeringBilateral symmetry

The invention discloses plastic plate processing equipment. The plastic plate processing equipment comprises a base plate, the top end face of the base plate is fixedly provided with vertical racks ina bilateral symmetry manner, an outer frame is arranged between the left side vertical rack and the right side vertical rack, the bottom end face of the outer frame is internally provided with a first sliding space, the first sliding space is internally provided with an installation inlay seat in a sliding fit manner, buffer springing pieces are installed between the top end face of the installation inlay seat and the top wall of the first sliding space in a jacking pressing fit manner, the bottom end face of the installation inlay seat is internally provided with a first notch, the part, onthe upper side of the first notch, of the installation inlay seat is internally provided with a first conduction cavity, the part between the first notch and the first conduction cavity is provided with a first rotating arm in a rotating fit manner, the top tail end of the first rotating arm is fixedly provided with a first cone wheel, the bottom tail end of the first rotating arm is fixedly provided with an installation closing block, and the bottom end face of the installation closing block is internally provided with an insert hole.

Owner:广东亚昀五金建材有限公司

Improved modified ABS material, preparation method and application

InactiveCN109049123AImprove drilling efficiencyImprove stabilityMetal working apparatusEngineeringMechanical engineering

The invention discloses an improved modified ABS material, a preparation method and application. The improved modified ABS material comprises a substrate. Vertical frames are symmetrically and fixedlyarranged on the end surface of the top of the substrate left and right. An outer frame is arranged between the vertical frames on the left and right sides. A first sliding space is arranged in the end surface of the bottom of the outer frame. A mounting and embedding seat is installed in the first sliding space in a sliding fit mode. A buffering elastic piece is installed between the top end surface of the mounting and embedding seat and the top wall of the first sliding space in an abutting fit mode. A first notch is formed in the end surface of the bottom of the mounting and embedding seat.A first conducting cavity is arranged in the portion, on the upper side of the first notch, of the mounting and embedding seat. A first rotating arm is rotatably installed between the first notch andthe first conducting cavity in a matched mode. A first conical gear is fixedly arranged at the tail end of the top of the first rotating arm. A fitting block is fixedly arranged at the tail end of the bottom of the first rotating arm. An insertion hole is formed in the end surface of the bottom of the fitting block.

Owner:广东亚昀五金建材有限公司

Novel flexible circuit board and processing method thereof, mobile terminal

InactiveCN108990281AImprove punch stabilityAvoid compromising punch qualityPrinted circuit manufactureFlexible circuitsComputer terminal

The invention discloses a novel flexible circuit board and a processing method thereof, mobile terminal. The flexible circuit board includes a base frame, A support column is fixedly arrange on that top end surface of the base frame, At that top end surface of the support column, an attachment frame is fixedly arrange, A main seat body is arranged at that left end of the mounting frame, A left-right symmetrical first through groove is arranged in that end face of the bottom of the main seat body, A regulating groove is arranged in the top wall of the first through groove and extends upward anddownward, A taper edge frame is rotatably fitted to that bottom wall of the transfer groove, A toothed joint ring is fixedly arranged on the outer periphery of the conical edge frame, A second through-groove opposite to the first through-groove is arranged through the conical edge frame. A transfer rack is slidably fitted and installed in the transfer groove, At that bottom end of the transfer frame, a taper wheel for intermeshing with the taper frame is rotatably fitted, a drill bit is fixedly installed on the bottom end face of the taper wheel, the drill bit is respectively pierced into thesecond through groove and the first through groove, and the bottom ends of the transfer groove on the left and right sides are communicated with each other through openings.

Owner:FOSHAN DETAO POWER TECH CO LTD

A laser engraving device

ActiveCN108326442BSimple structureEasy to operateLaser beam welding apparatusLaser engravingEngineering

The invention discloses a laser engraving device. The laser engraving device comprises a machining main body which his fixedly installed at the lower side of a regulating arm; the inner wall body of the machining main body is internally provided with a passing and receiving chamber; a part, positioned at the top of the passing and receiving chamber, of the machining main body is internally provided with a regulating chamber; a regulating frame is installed inside the regulating chamber in a sliding fit manner; the inner wall of the right side of the passing and receiving chamber is provided with a sliding chamber which communicates with the passing and receiving chamber; a sliding seat is installed inside the sliding chamber in a sliding fit manner; a first motor is fixedly arranged between the sliding chamber and the regulating chamber; the top end of the first motor is in power matched connection with an upper threaded rod; the upper threaded rod is connected with the regulating frame in a thread fit manner; the tail end of the top of the upper threaded rod is connected with the internal top wall of the regulating chamber in a running fit manner; the bottom end of the first motoris in power matched connection with a lower threaded rod; the lower threaded rod is connected with the sliding seat in a thread fit manner; and the tail end of the bottom of the lower threaded rod isconnected with the internal bottom wall of the sliding chamber in a running fit manner.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

Modified ABS material and preparation method and application thereof

InactiveCN109129687AImprove punch stabilityAvoid compromising punch qualityMetal working apparatusEngineeringDrill bit

The invention discloses a modified ABS material and a preparation method and application thereof. A structure includes a substrate, the top end surface of the substrate is fixedly provided with a column, the top end surface of the column is fixedly provided with an installation frame, a manufacture frame is arranged at that left end of the installation frame, a left-right symmetrical first hole groove is arranged in the bottom end face of the manufacture frame, a position adjusting cavity is arranged in the top wall of the first hole groove and extends upward and downward, a taper frame is rotatably matched with the bottom wall of the position adjusting cavity, a gear ring is fixedly arranged on the outer periphery of the taper frame, a second hole groove opposite to the first hole grooveis arranged in the taper frame, a position adjusting frame is slidably fitted and installed in the position adjusting cavity, a taper wheel for intermeshing with the taper frame is rotatably fitted and installed at the bottom end of the position adjusting frame, a drill bit is fixedly installed at the bottom end face of the taper wheel, the drill bit respectively passes into the second hole grooveand the first hole groove, and a groove is arranged between the bottom ends of the position adjusting cavity on the left and right sides.

Owner:广州猎狗信息咨询有限公司

Product housing sleeve equipment

InactiveCN109016647AImprove drilling efficiencyImprove stabilityBox making operationsPaper-makingEngineeringMechanical engineering

The invention discloses product housing sleeve equipment. The product housing sleeve equipment comprises a base frame, wherein vertical frames are symmetrically and fixedly arranged on the top end surface of the base frame left and right; a housing is arranged between the vertical frames at left and right sides; a first slide slot is formed in the bottom end surface of the housing; a clamping baseis mounted in the first slide slot in a sliding fit mode; a buffer elastic strip is mounted between the top end surface of the clamping base and the top wall of the first slide slot in a jacking-pressing matched mode; a first groove is formed in the bottom end surface of the clamping base; a first transmission cavity is arranged in the clamping base at the upper side of the first groove; the portion, between the first groove and the first transmission cavity, is rotatably equipped with a first rotary rod; the tail end of the top of the first rotary rod is fixedly equipped with a first conicalangle wheel; the tail end of the bottom of the first rotary rod is fixedly equipped with a clamping block; and an insertion slot is formed in the bottom end surface of the clamping block.

Owner:广州市科卡通信科技有限公司

Novel intelligent packaging box management system

InactiveCN109016649AImprove drilling efficiency and stabilityAvoid deviationBox making operationsPaper-makingManagement systemMechanical engineering

The invention discloses a novel intelligent packaging box management system. The novel intelligent packaging box management system comprises a base rack, the top end face of the base rack is fixedly provided with vertical racks in a left and right symmetrical manner, a shell is arranged between the left side vertical rack and the right side vertical rack, the bottom end face of the shell is internally provided with a first sliding groove, the first sliding groove is internally provided with an installing clamping seat in a sliding matching manner, buffer spring strips are installed between thetop end face of the installing clamping seat and the top wall of the first sliding groove in a jacking-pressing matching manner, the bottom end face of the installing clamping seat is internally provided with a first groove, the part, on the upper side of the first groove, of the installing clamping seat is internally provided with a first transmission cavity, the part between the first groove and the first transmission cavity is provided with a first rotating rod in a rotating matching manner, the tail end of the top of the first rotating rod is fixedly provided with a first cone angle wheel, the tail end of the bottom of the first rotating rod is fixedly provided with an installing clamping block, and the bottom end face of the installing clamping block is internally provided with an insert closing slot.

Owner:广州市科卡通信科技有限公司

Positioning and calibration method and mobile terminal equipment

InactiveCN109047818AImprove drilling efficiencyImprove stabilityBoring/drilling machinesRight-SidedTerminal equipment

The invention discloses a positioning and calibration method and mobile terminal equipment. The mobile terminal equipment comprises an underframe, wherein the left end surface and the right end surface of the top part of the base frame are symmetrically and fixedly provided with supports; a main frame is arranged between the left-sided support and the right-sided support; a first sliding cavity isformed in the bottom end surface of the main frame; a clamping base is mounted in the first sliding cavity in a sliding fit manner; a buffer elastic strip is mounted between the top end surface of the clamping base and the top wall of the first sliding cavity in a top pressing fit manner; a first concave embedding cavity is formed in the bottom end surface of the clamping base; a first transmission cavity is formed in the clamping base and positioned on the upper side of the first concave embedding cavity; a first steering shaft is mounted on the part positioned between the first concave embedding cavity and the first transmission cavity in a rotating fit manner; the tail end of the top part of the first steering shaft is fixedly provided with a first conical wheel; the tail end of the bottom part of the first steering shaft is fixedly provided with a clamping block; and an inserting groove is formed in the bottom end surface of the clamping block.

Owner:广州雅松商贸有限公司

Novel hard alloy pipe fitting

InactiveCN109014277AImprove punch stabilityAvoid compromising punch qualityFeeding apparatusDriving apparatusPipe fittingAlloy

The invention discloses a novel hard alloy pipe fitting which comprises a bottom frame. A column rod is fixedly arranged on the top end face of the bottom frame. An installation frame is fixedly arranged on the top end face of the column rod. A machining frame is arranged at the left side end of the installation frame. First penetrating ports are bilaterally symmetrically formed in the bottom endface of the machining frame. Adjustment and control cavities extending up and down are formed in the inner top walls of the first penetrating holes. Conic frames are installed on the bottom walls of the adjustment and control cavities in a running fit mode. Toothed rings are fixedly arranged on the peripheries of the conic frames. Second penetrating ports opposite to the first penetrating ports are formed in the conic frames in an up-down run-through mode. Adjustment and control frames are installed in the adjustment and control cavities in a sliding fit mode. Conic wheels used for being engaged with the conic frames are installed at the bottom ends of the adjustment and control frames in a running fit mode. Drill bits are fixedly installed on the bottom end faces of the conic wheels and extend into the second penetrating ports and the first penetrating ports. A through hole is formed between the bottom ends of the adjustment and control cavities in the left side and the right side ina communicating mode.

Owner:广州犀鸟工业设计有限公司

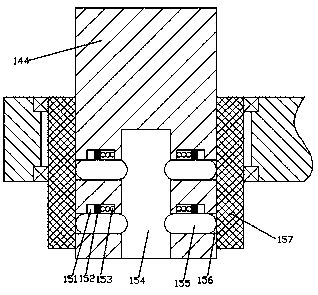

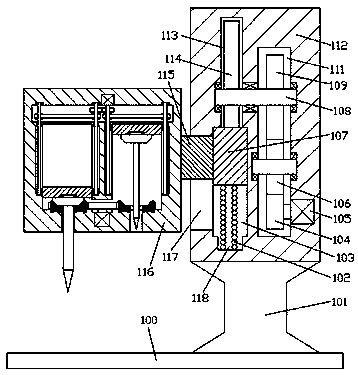

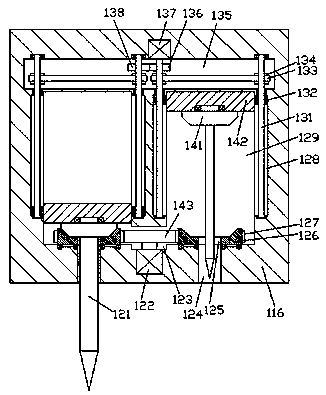

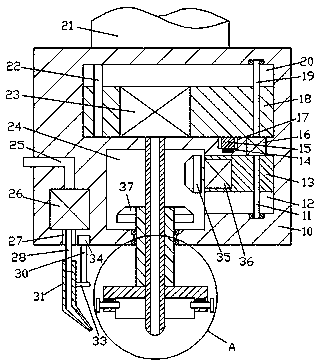

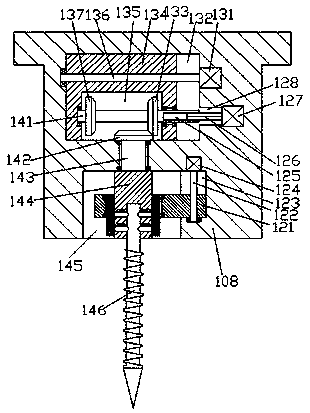

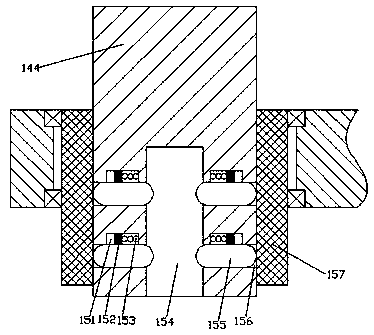

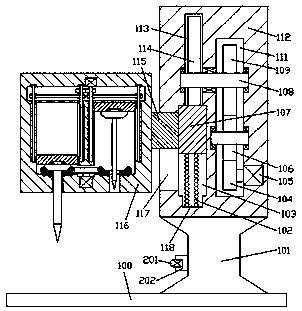

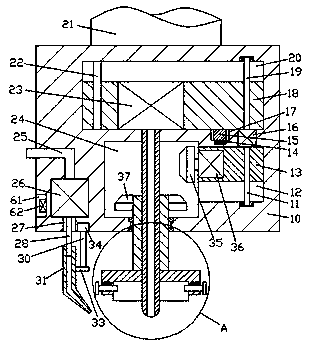

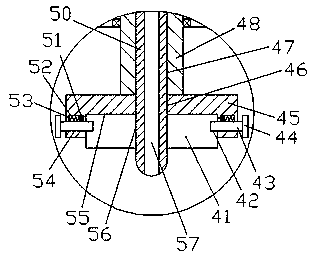

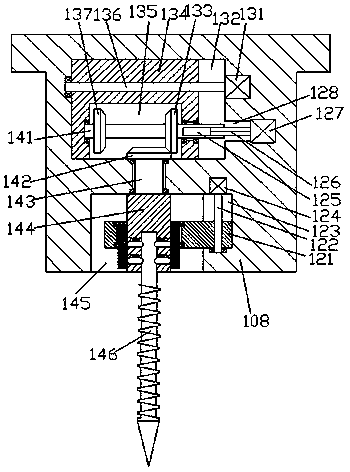

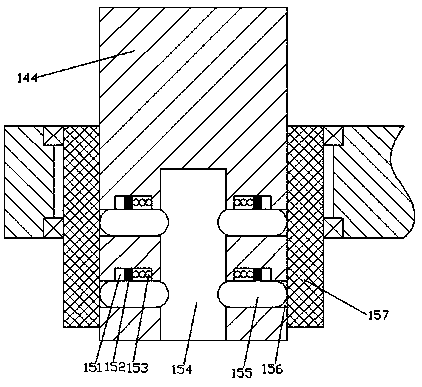

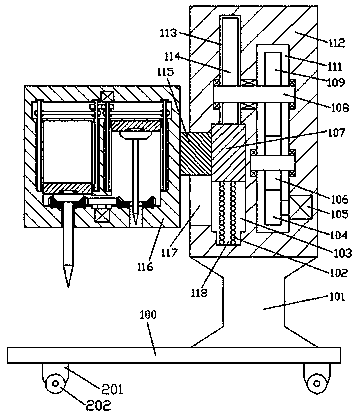

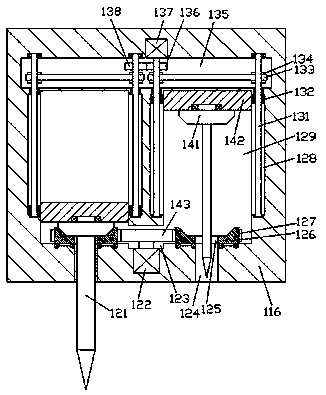

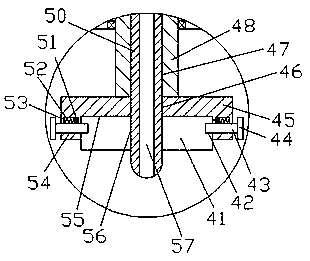

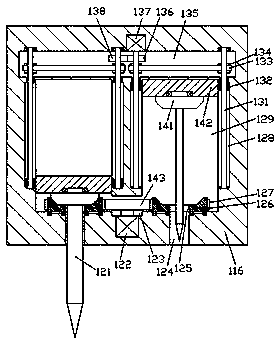

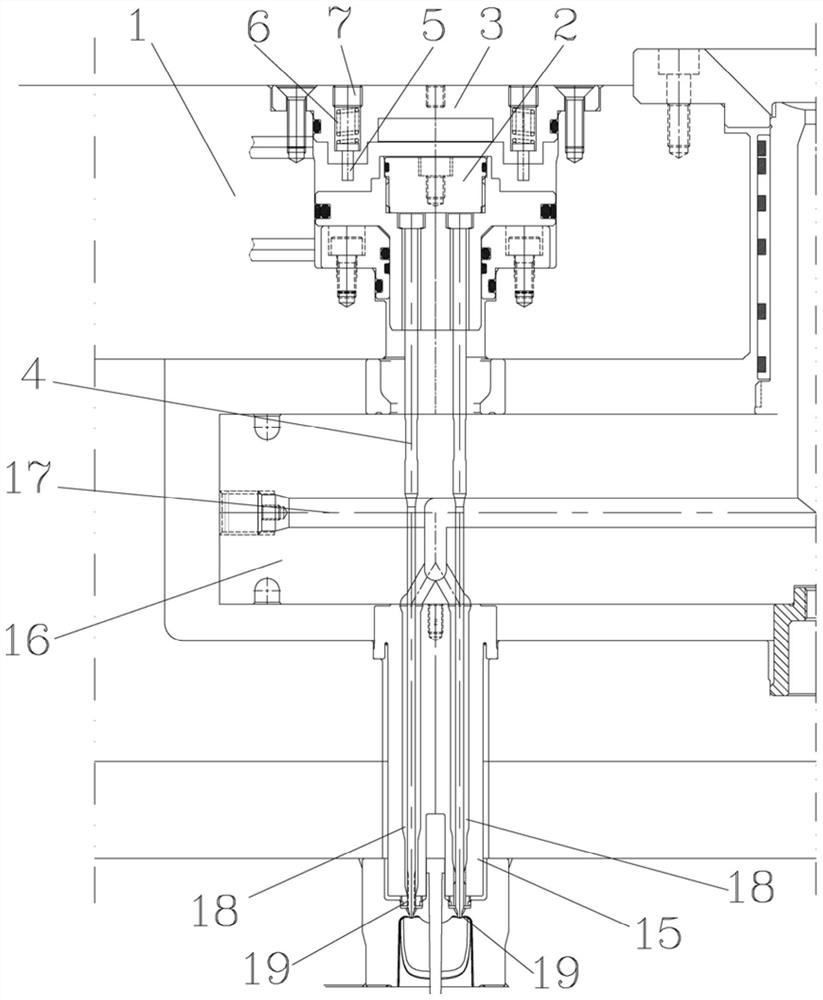

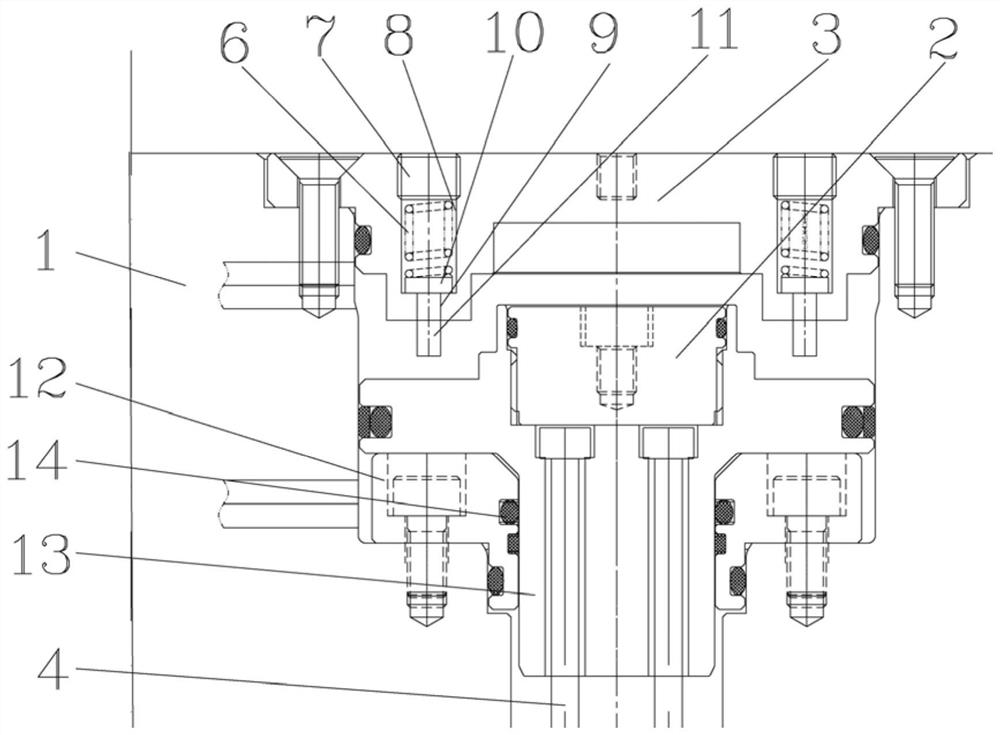

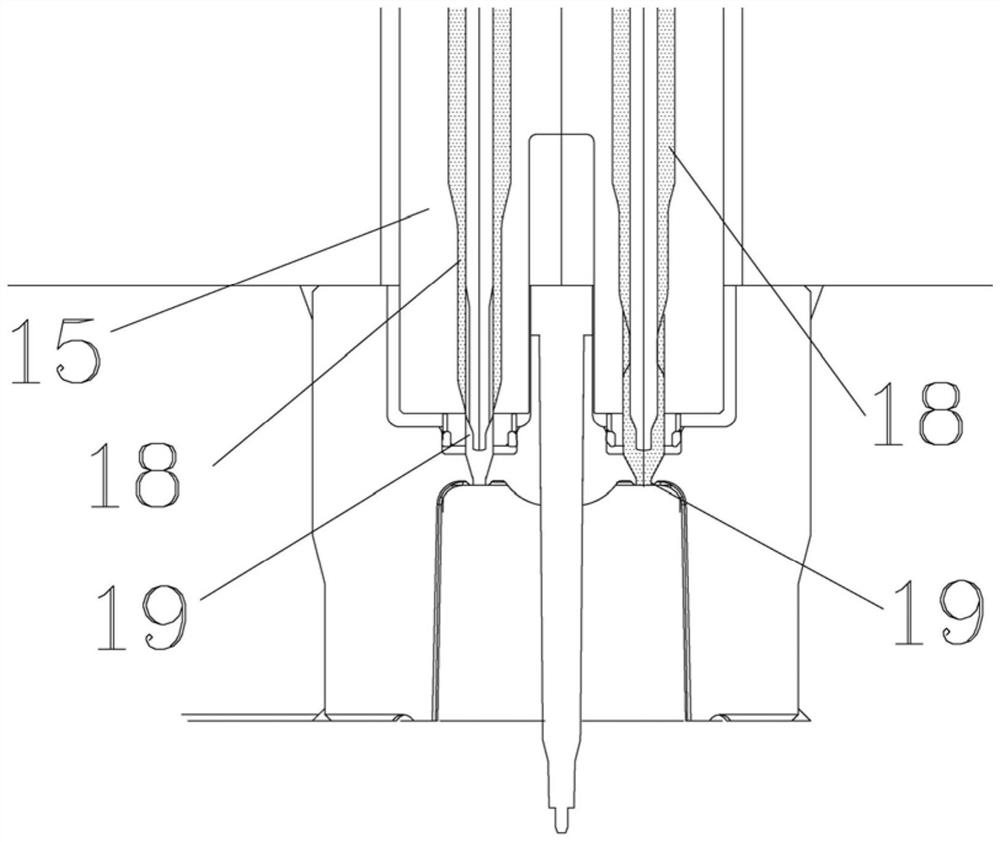

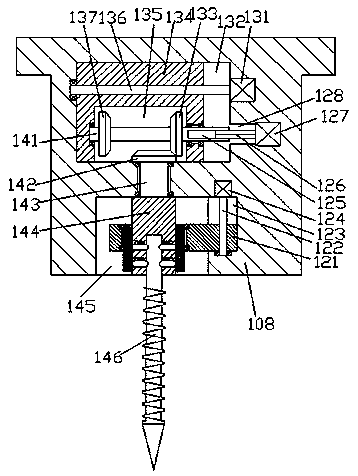

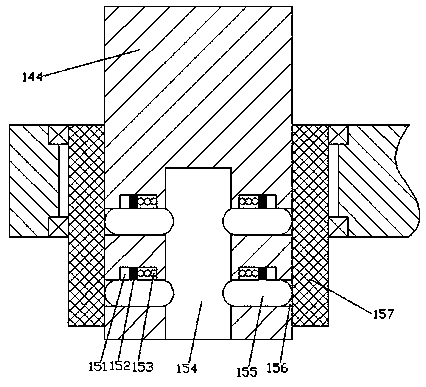

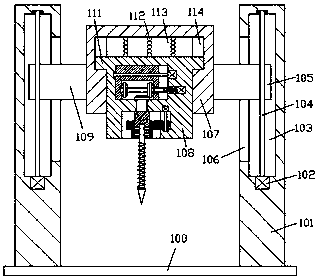

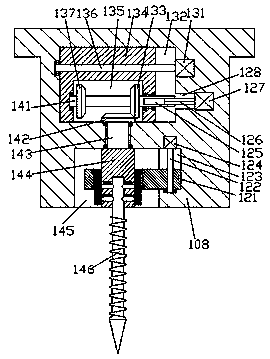

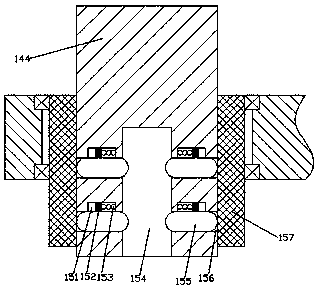

Air cylinder and hot runner system with same

PendingCN114683494AAvoid Rigid CollisionsSimple and convenient adjustment stepsNon-rotating vibration suppressionPhysicsHot runner

The invention relates to the technical field of hot runner injection molding, in particular to an air cylinder and a hot runner system with the air cylinder, the air cylinder comprises a cylinder body, a piston, a cylinder cover, a valve needle connected with the piston, and an abutting piece, an elastic piece and an adjusting piece which are movably arranged in the cylinder cover, and the abutting piece can protrude to the cylinder body and abut against the piston; the elastic piece is connected to the adjusting piece and the abutting piece. And the adjusting piece can adjust the tightness of the elastic piece. The elastic piece applies downward buffering force to the piston through the abutting piece, rigid collision between the piston and the abutting piece or / and the cylinder cover is avoided, and therefore the service life of the piston, the service life of the abutting piece and the service life of the cylinder cover are prolonged. The tightness degree of the elastic piece can be adjusted without detaching the cylinder cover from the cylinder body, so that the buffering force borne by the piston can be conveniently and quickly adjusted; the piston ingeniously changes or controls the glue discharging sequence of the second glue channels through the valve needle, and the injection molding quality of products is improved.

Owner:东莞市热恒注塑科技有限公司

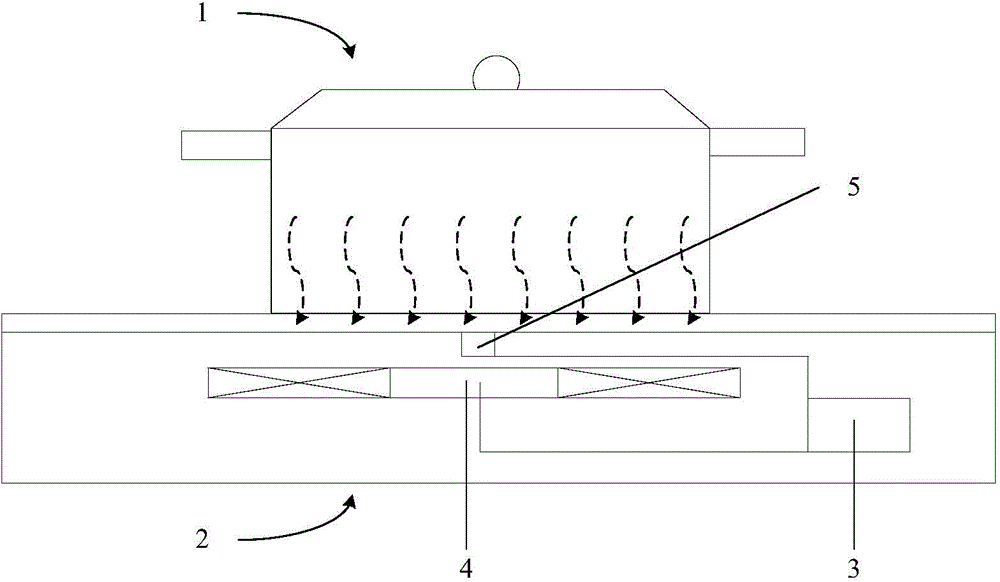

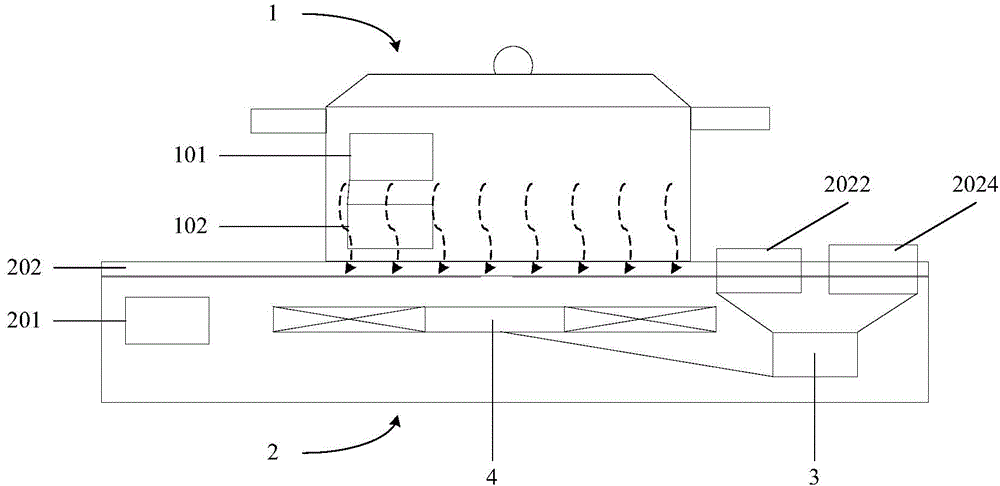

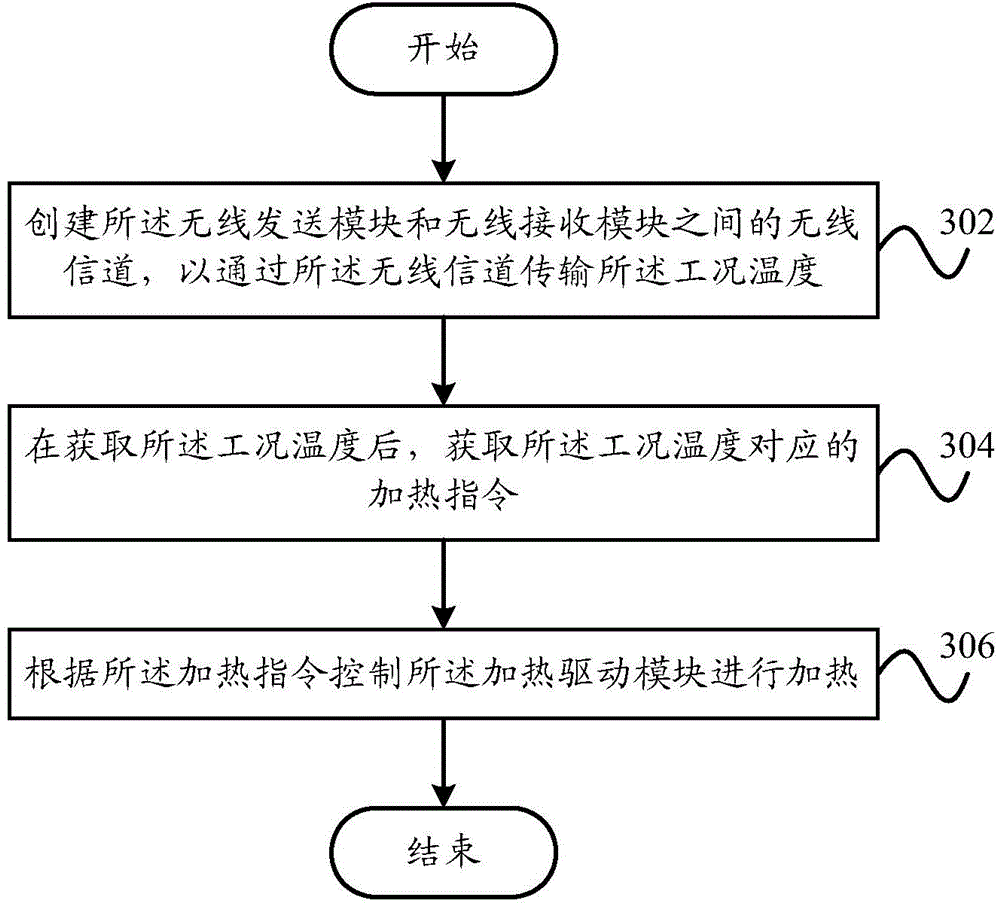

Cooking appliance provided with wireless temperature measuring device, control method and system

ActiveCN106136839ARealize the wireless sensing processHigh sensitivityWarming devicesWorking temperatureElectrical and Electronics engineering

The invention provides a cooking appliance provided with a wireless temperature measuring device, a control method and a system. The cooking appliance provided with the wireless temperature measuring device comprises a cooking container and a cooking stove, wherein the cooking container comprises a temperature measuring module used for testing the working temperature of the cooking container, and a wireless sending module connected to the temperature measuring module and used for sending the working temperature to a corresponding wireless receiving module; the cooking stove comprises the wireless receiving module connected to the wireless sending module via a wireless channel and used for receiving the working temperature, and a display control panel connected to the wireless receiving module; the display control panel comprises a prompting module used for prompting a user for the working temperature. According to the cooking appliance, the control method and the system, the control process of the cooking appliance is more accurate, simpler and more convenient, so that the user's experience is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Novel flexible circuit board and processing method thereof, and mobile terminal

InactiveCN109005642AImprove drilling efficiencyImprove stabilityPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses a novel flexible circuit board and a processing method thereof, and a mobile terminal. The novel flexible circuit board includes a base, support seats are symmetrically fixedlyarranged on the top end face of the base, a frame is arranged between the support seats on the left and right sides, a first sliding connection cavity is arranged in the bottom end face of the frame,a mounting connection seat is arranged in sliding fit in the first sliding connection cavity, a buffering piece is mounted between the top end surface of the mounting connection seat and the top wallof the first sliding connection cavity in push press fit, a first indent cavity is arranged in the bottom end face of the mounting connection seat, a first transmission connection cavity is arrangedin the mounting connection seat on the upper side of the first indent cavity, a first adapter shaft is mounted on a part between the first indent cavity and the first transmission connection cavity inrunning fit, a first conical edge wheel is fixedly arranged at the tail end of the top of the first adapter shaft, a mounting connection block is fixedly arranged at the tail end of the bottom of thefirst adapter shaft, and an insertion connection groove is arranged in the bottom end face of the mounting connection block.

Owner:广州弘唷网络科技有限公司

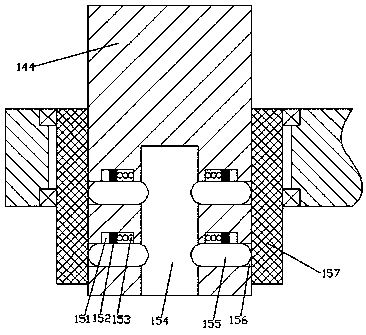

Hard alloy pipe fitting

InactiveCN109047829AImprove drilling efficiencyImprove stabilityFeeding apparatusDriving apparatusPipe fittingEngineering

The invention discloses a hard alloy pipe fitting. The hard alloy pipe fitting comprises a base. Supporting frames are symmetrically and fixedly arranged on the top end surface of the base left and right. A main seat body is arranged between the supporting frames on the left and right sides. A first sliding cavity is arranged in the bottom end surface of the main seat body. A mounting seat is installed in the first sliding cavity in a sliding fit manner. A buffer spring is installed between the top end surface of the mounting seat and the top wall of the first sliding cavity in an abutting fitmanner. A first concave cavity is formed in the bottom end surface of the mounting seat. A first transmission cavity is arranged in the portion, on the upper side of the first concave cavity, of themounting seat. A first rotating shaft is rotatably arranged between the first concave cavity and the first transmission cavity in a matched mode. A first bevel gear is fixedly arranged at the tail endof the top of the first rotating shaft. A mounting block is fixedly arranged at the tail end of the bottom of the first rotating shaft. An insertion cavity is formed in the bottom end surface of themounting block.

Owner:广州峥航机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com