Modified ABS material and preparation method and application thereof

An ABS material and modification technology, which is applied in metal processing and other directions, can solve the problems affecting the preparation quality of ABS plastic boards, the production speed of ABS plastic boards, the production and processing efficiency of ABS plastic boards, and the inconvenience of adjusting the rotation direction of drill bits, so as to achieve simple and convenient drilling steps , The adjustment steps are simple and convenient, reducing the effect of manual operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

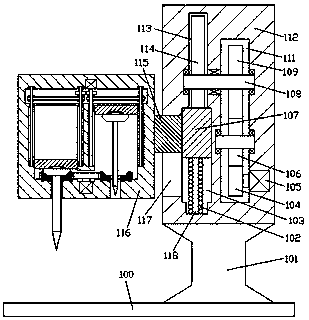

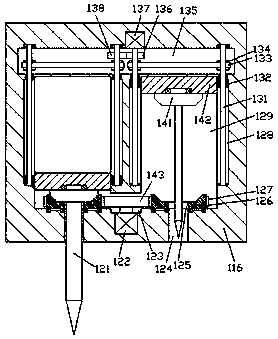

[0013] Combine below Figure 1-3 The present invention will be described in detail.

[0014] refer to Figure 1-3 , a modified ABS material and its preparation method and application according to an embodiment of the present invention, comprising a substrate 100, a column 101 is fixed on the top end of the substrate 100, and a mounting frame 112 is fixed on the top end of the column 101, the The left end of the installation frame 112 is provided with a preparation frame 116, and the bottom end surface of the preparation frame 116 is provided with a first hole 124 symmetrically left and right, and the inner top wall of the first hole 124 is provided with an adjustment cavity 129 extending up and down. , the bottom wall of the adjustment cavity 129 is rotated and installed with a cone frame 126, and the outer circumference of the cone frame 126 is fixed with a ring gear 127, and the inside of the cone frame 126 is provided with a hole opposite to the first hole 124. In the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com