Centrifugal casting process for main pipeline of million kilowatt-grade nuclear power plant

A centrifugal casting, nuclear power plant technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problem that the centrifugal casting process cannot be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

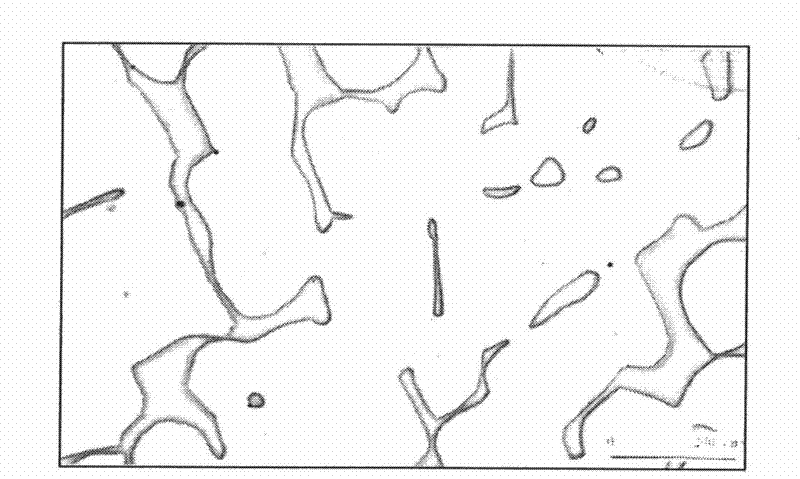

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the drawings and embodiments.

[0038] The following are specific examples of the centrifugal casting process of the present invention.

[0039] 1. Smelting

[0040] Smelting uses 5t electric arc furnace + 15t electric arc furnace + AOD furnace, or 15t electric arc furnace + AOD furnace.

[0041] 1. When using 5t electric arc furnace + 15t electric arc furnace + AOD furnace for smelting,

[0042] (1) When the 5t electric arc furnace supplies low-phosphorus molten steel to the 15t electric arc furnace, the 5t electric arc furnace uses oxidation method for smelting, and the 5t electric arc furnace uses pure iron, scrap steel pipe heads, carbon blocks and other raw materials to ensure that the composition of the 15t electric arc furnace meets the relevant requirements. Requirements, where P≤0.003%;

[0043] (2) When a 5t electric arc furnace is used to provide molten steel to the AOD furnace, the weight of the 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com