Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215results about How to "Improve plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature assisted ultrasonic surface rolling intensifying device and processing method

The invention discloses a low-temperature assisted ultrasonic surface rolling intensifying device and a processing method. The device consists of a surface rolling member, a loading member and a heating member, wherein a clamping handle is arranged on the surface rolling member; the loading member is arranged at the tail end of the surface rolling member; a spring, a pressure sensor, a baffle, a transducer and an amplitude-change pole are sequentially arranged on the end face of the loading member; the amplitude-change pole is provided with a rolling head of which the front end is provided with a roller through a guide sleeve; the outer side of the surface rolling member is connected with an ultrasonic generator; and the heating member is provided with a temperature controller and heating wires connected and controlled by the temperature controller According to the processing method disclosed by the invention, an ultrasonic rolling technology and low-temperature heating treatment are combined; on the basis of softening materials by using low temperature heating, an ultrasonic frequency electrical signal is converted into ultrasonic mechanical vibration by using the transducer; and after the ultrasonic mechanical vibration is amplified by the amplitude-change pole, vibration with a certain amplitude is outputted and transmitted to the rolling head, and high-speed vibration between the rolling head and workpieces in the rolling process is realized, thereby better refining material grains on the surface layers of the workpieces, and generating greater residual compressive stress and high surface hardness.

Owner:SOUTH CHINA UNIV OF TECH

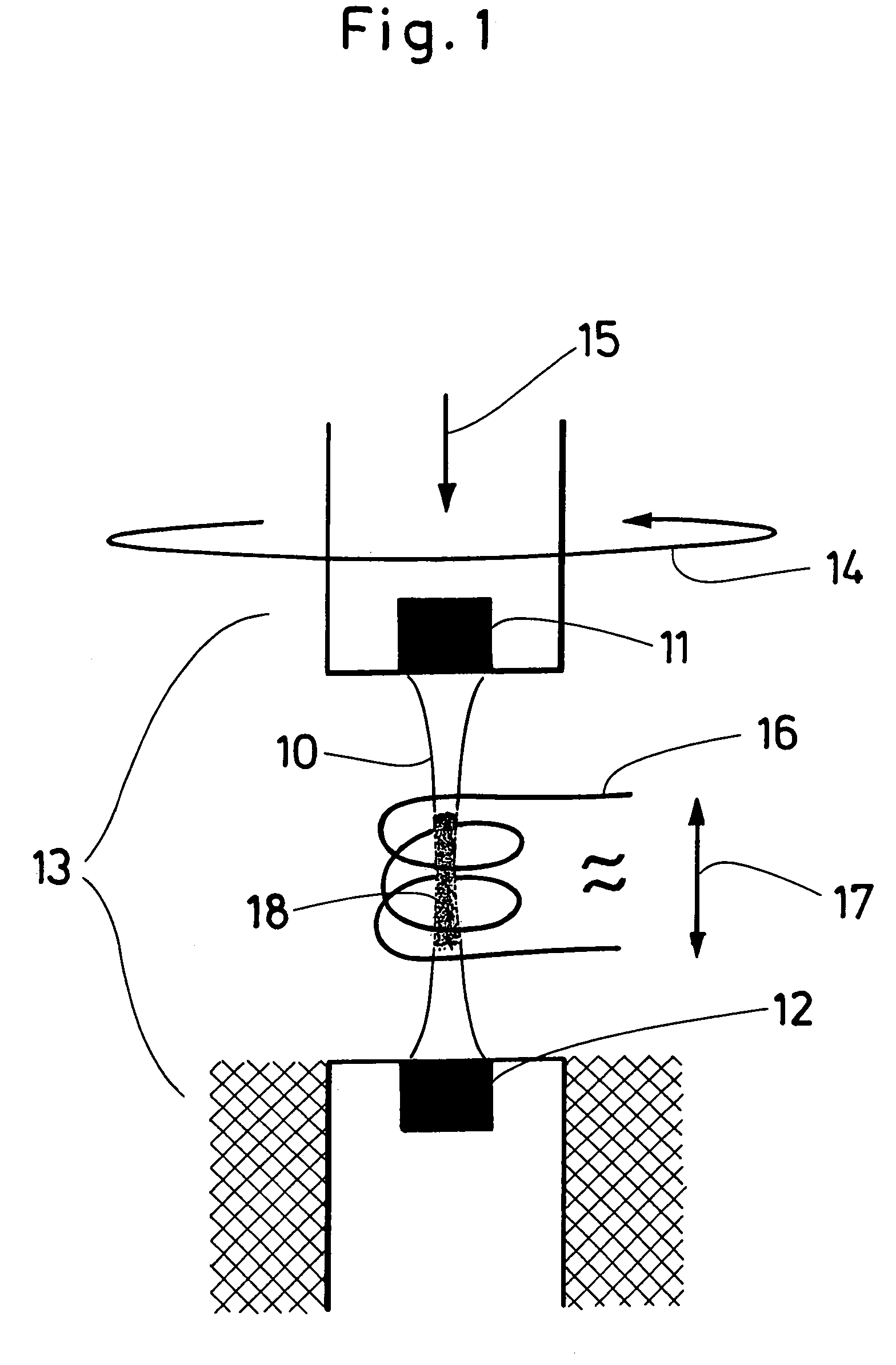

Linear friction welding process between aluminium part and steel part

InactiveCN101020275AAchieve weldingImprove plastic deformationWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingTemperature control

The linear friction welding process between aluminum part and steel part includes the following steps: fixing the steel part in a vibrating fixture; vibrating the steel part vertically by means of a vibrating source and a link rod and at 24-30 Hz frequency and 2.0-2.8 mm amplitude; fixing the aluminum part in a movable fixture; contacting the steel part and the aluminum part mutually with a pushing oil cylinder in the friction pressure of 3.5-5.5 Kg / sq mm for 1.5-2.0 sec; stopping vibration and applying forging pressure of 6.5-12.0 Kg / sq mm for 0.5-1 sec; and cooling naturally to form firm joint between the aluminum part and the steel part. The present invention controls the temperature in friction area at 0.8 time the smelting point of aluminum and applying forging pressure to produce plastic deformation so as to weld by means of re-crystallization and the atomic combination between aluminum and steel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

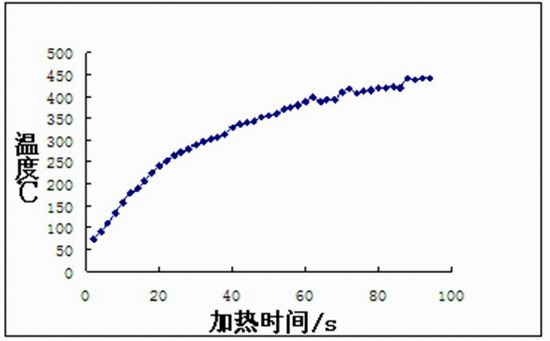

Method fur forming aluminum base composite material thin wall part by current self-resistance heating

The invention relates to a method for forming an aluminum base composite material thin wall part by current self-resistance heating, which belongs to the field of heat processing. The invention aims to solve the problems of poor forming quality of a thin wall part just by heating a blank as well as low heat utilization ratio and great energy consumption by heating the blank together with a die when the stretching formation is carried out on a particle-reinforced aluminum base composite material. The method comprises the following steps of: 1. placing a forming device on a press machine; 2. pressurizing an upper electrode clamping plate, clamping the blank to be formed, switching on a power supply and heating the blank to be formed; 3. measuring temperature in real time by using an infrared thermometer and adjusting an output current parameter of a power supply in real time so that the heating speed of the blank to be formed reaches 5-20 DEG C / s; 4. when the blank to be formed reaches 350-450 DEG C, removing the pressure on the upper electrode clamping plate and pressurizing an edge press ring by the press machine so that the edge press ring compresses the blank to be formed on a lower die; and 5. pressing an upper die for descending and pressing the blank to be formed for forming.

Owner:HARBIN INST OF TECH

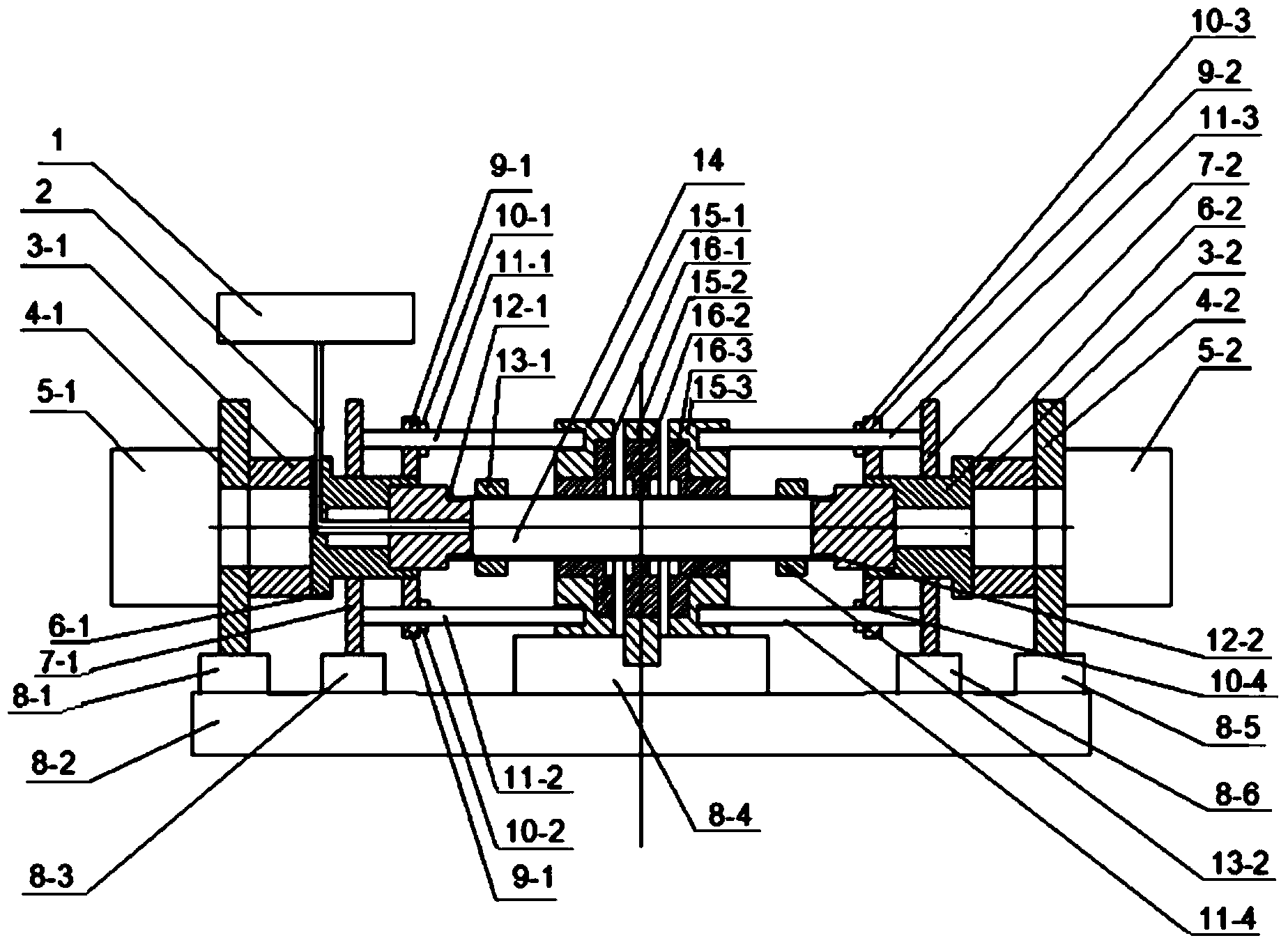

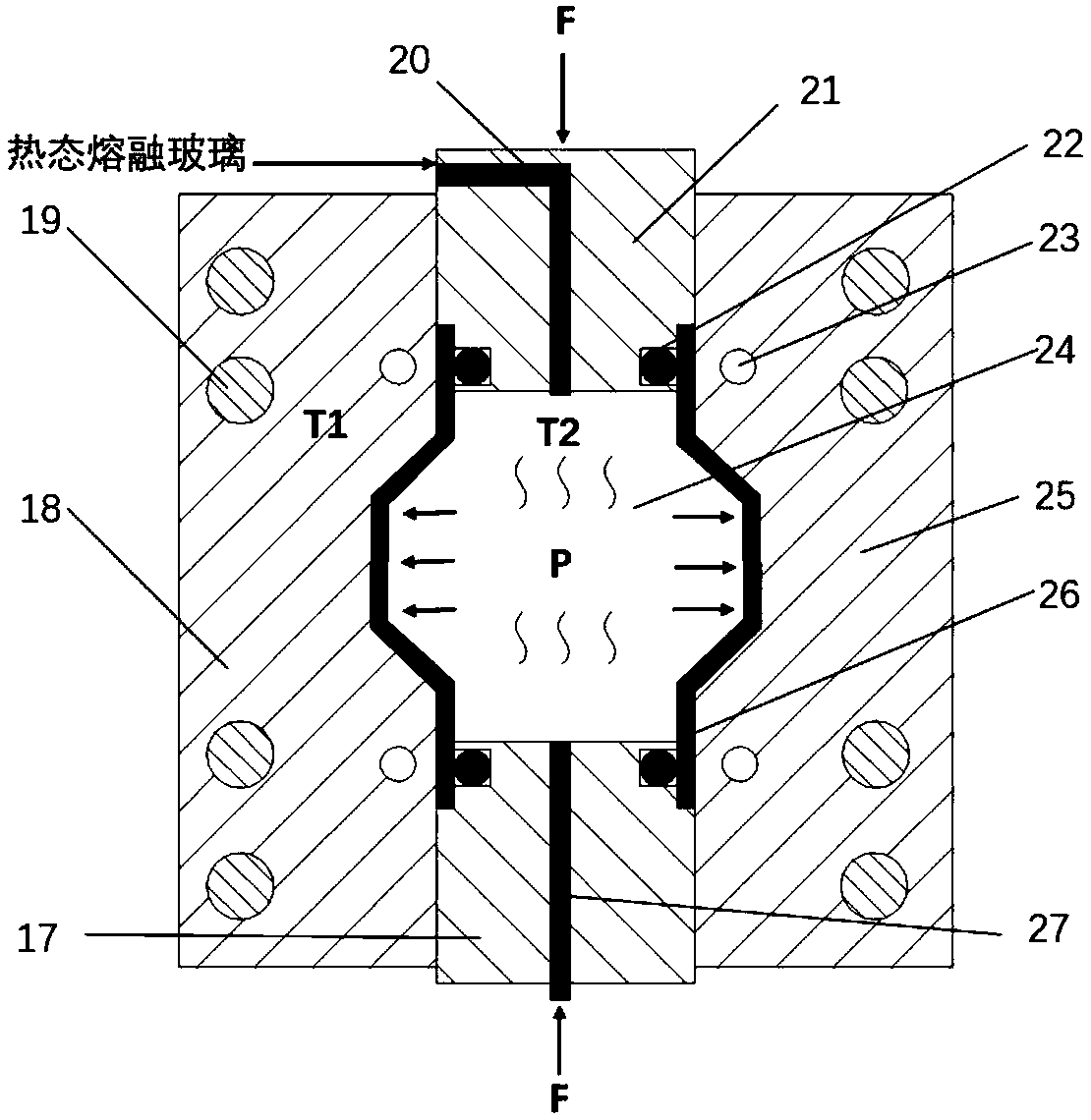

Current-assisted titanium alloy bellows hot-forming tool and method

The invention relates to a current-assisted titanium alloy bellows hot-forming die and method, relates to a bellows hot-forming tool and method and solves the technical problem that integral heating in the plastic hot-forming process causes heat loss. The tool comprises an argon cylinder, a gas pipe, an axial loading shaft, an axial loading device fixing plate, a gas cylinder, an axial loading sleeve, a sleeve support plate, a bench, a positioning plate, positioning nuts, positioning studs, a sealing device, an electrifying device, a metal die frame, and a ceramic die. The method includes: keeping the temperature of 600-900 DEG C and inner air pressure 0.1-0.5MPa of a pipe billet for 100-250s, assembling the die, keeping the inner air pressure 2.0-3.0MPa of the pipe billet for 200-400s, powering off, relieving air pressure, and cooling to obtain a titanium alloy bellows. The die and method belonging to the field of bellows production have the advantages that heat loss consumed for the die during integral heating in the traditional plastic hot-forming process is avoided.

Owner:HARBIN INST OF TECH

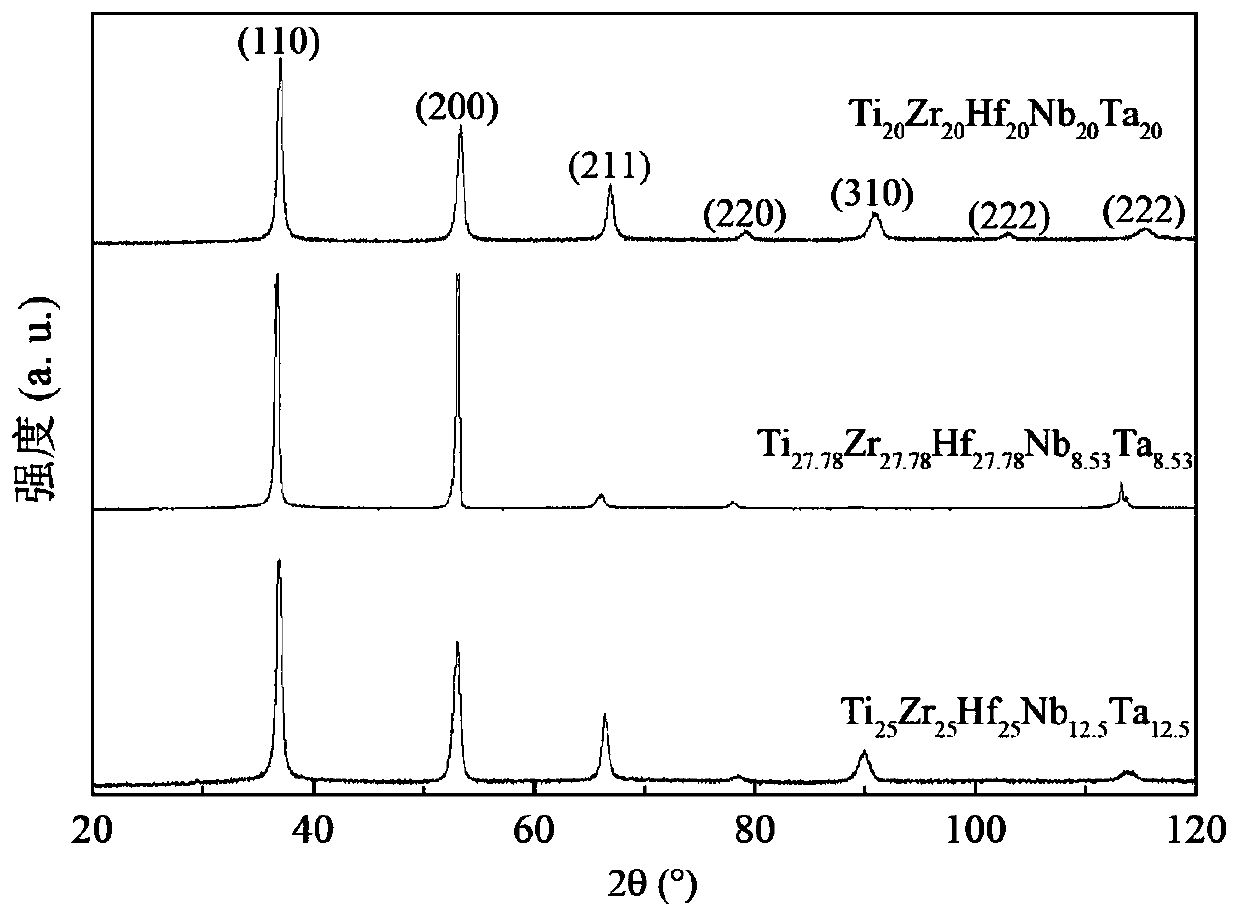

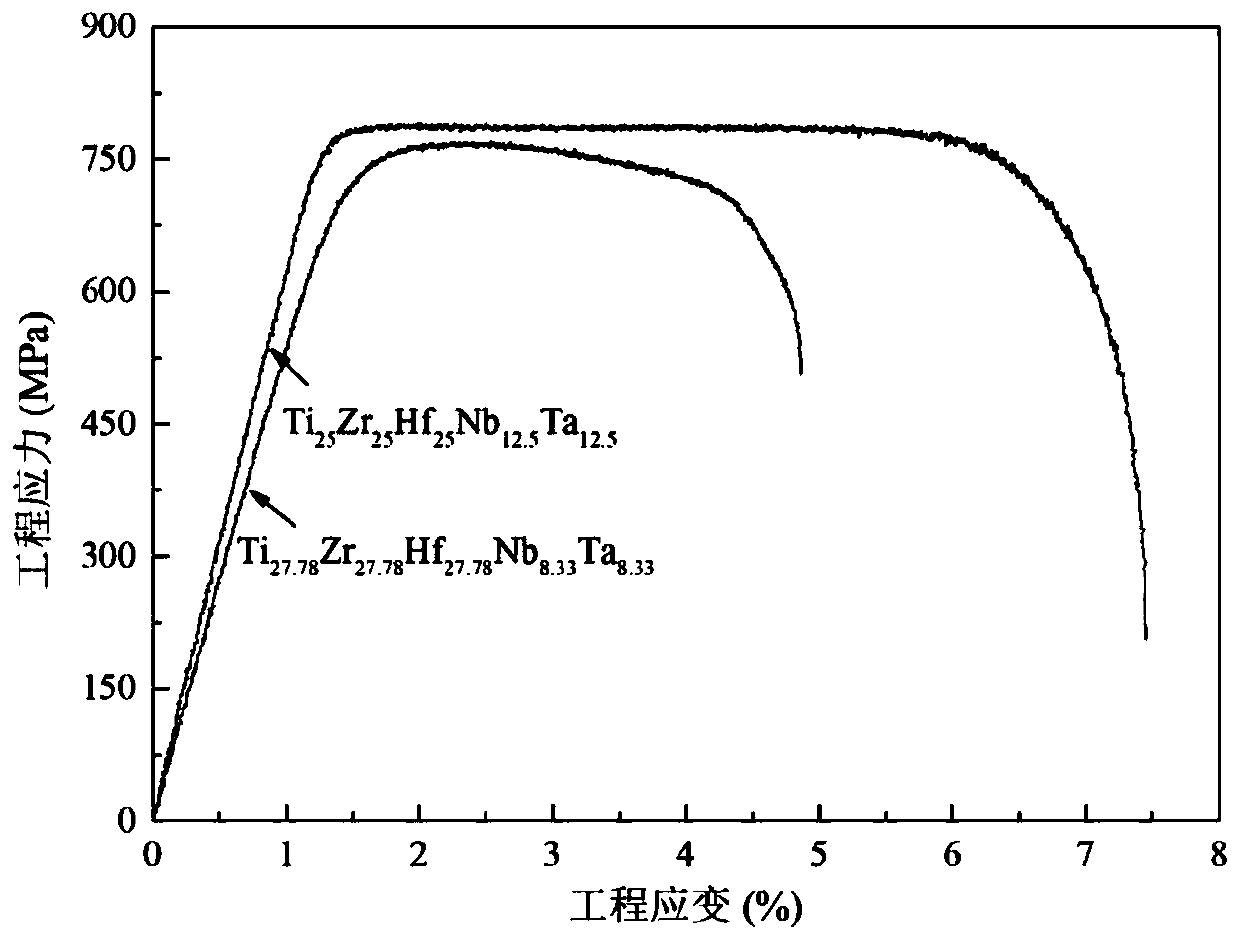

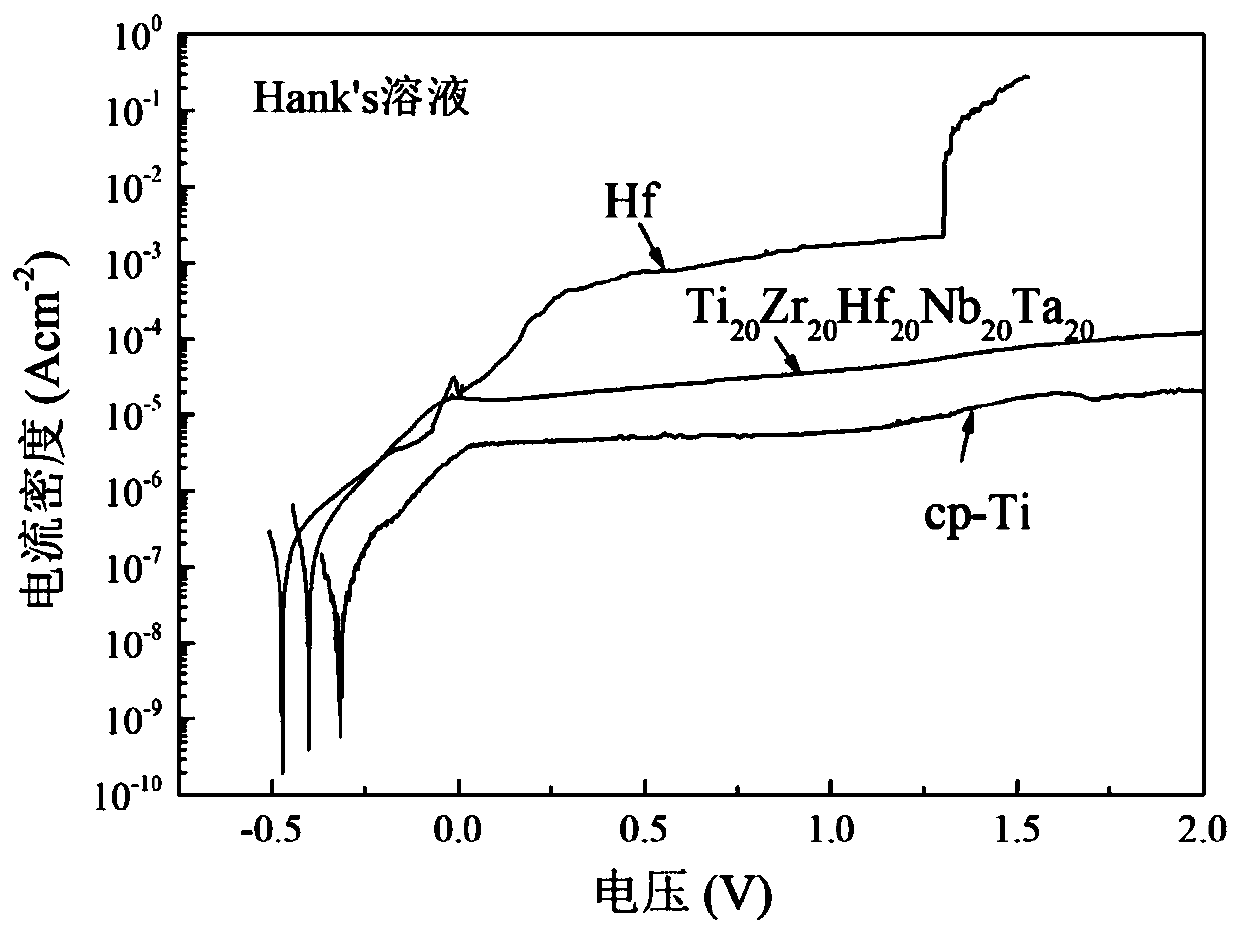

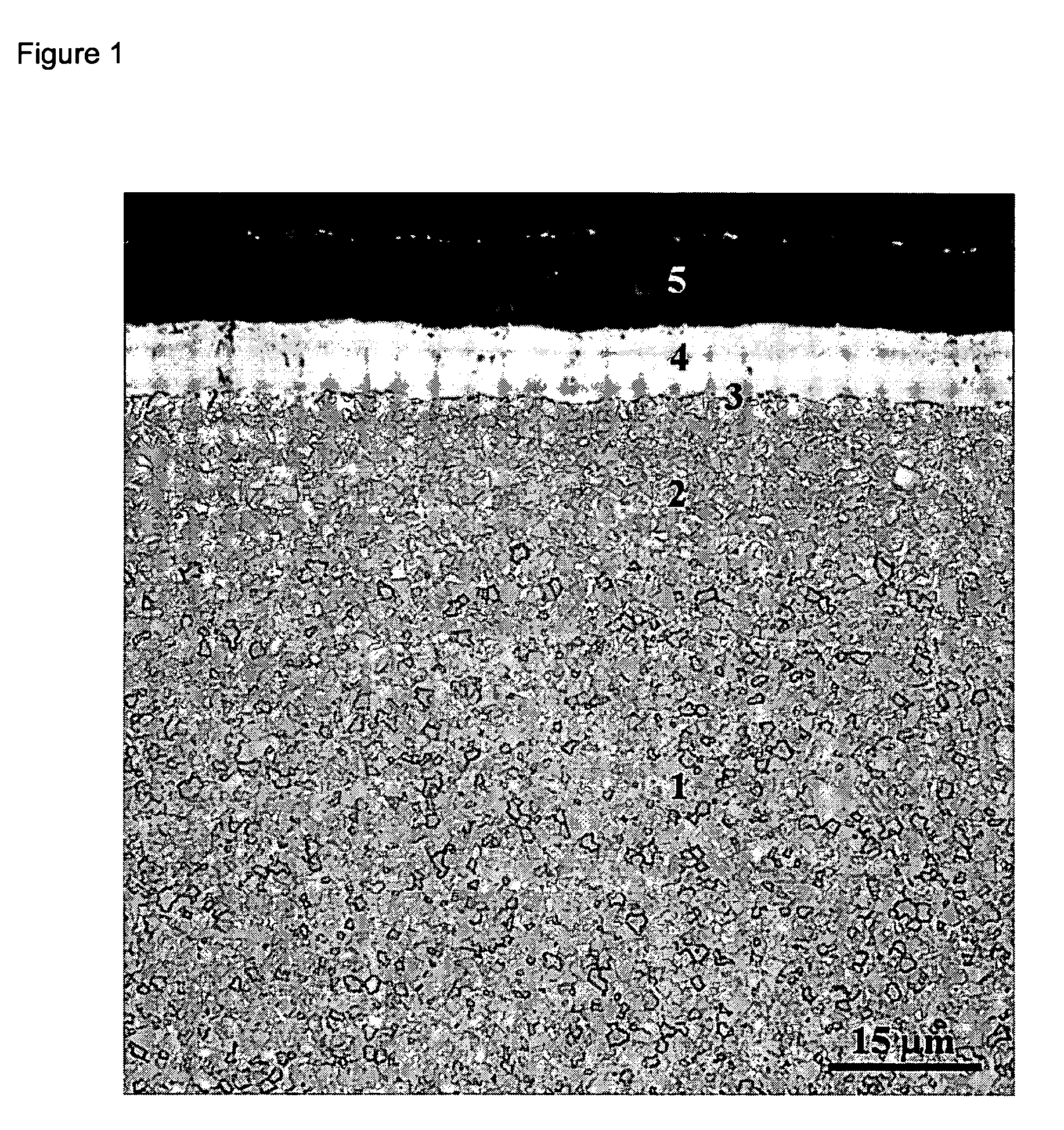

Biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy and preparing method

InactiveCN110423933AHigh elastic modulusLow elastic modulusTissue regenerationProsthesisHigh entropy alloysUnit model

The invention relates to a biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy. The composition general formula of the high-entropy alloy is TiZrHf<c>Nb<d>Ta<e>, wherein a, b, c, d and e are atomic percents, a is larger than or equal to 5 and smaller than or equal to 40, b is larger than or equal to 5 and smaller than or equal to 40, c is larger than or equal to 5 and smaller than or equal to 40, d is larger than or equal to 5 and smaller than or equal to 40, e is larger than or equal to 5 and smaller than or equal to 40, and the sum of a, b, c, d and e is 100. Starting from a TiZr-transition group high-entropy alloy system, a cluster type structure unit model is combined for component design, a low-modulus and high-corrosion-resistance biomedical TiZr-transition group high-entropy alloy with more excellent comprehensive mechanical performance is prepared, and the elasticity modulus of the Ti-Zr-Hf-Nb-Ta series high-entropy alloy is low to 54GPa.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Coated cutting tool insert

InactiveUS7097901B2Improve performanceImprove edge strengthPigmenting treatmentOther chemical processesAlloyCemented carbide

The present invention relates to a coated cemented carbide cutting tool insert particularly useful for turning of cast irons but also low alloyed steels at mediate to high cutting speeds. The cutting tool insert is characterised by a cemented carbide body comprising WC, cubic carbonitrides, a W-alloyed Co binder phase, a surface zone of the cemented carbide body that is binder phase enriched and nearly free of cubic carbonitride phase, and a coating including an innermost layer of TiCxNyOz with equiaxed grains, a layer of TiCxNyOz with columnar grains and at least one layer of Al2O3.

Owner:SECO TOOLS AB

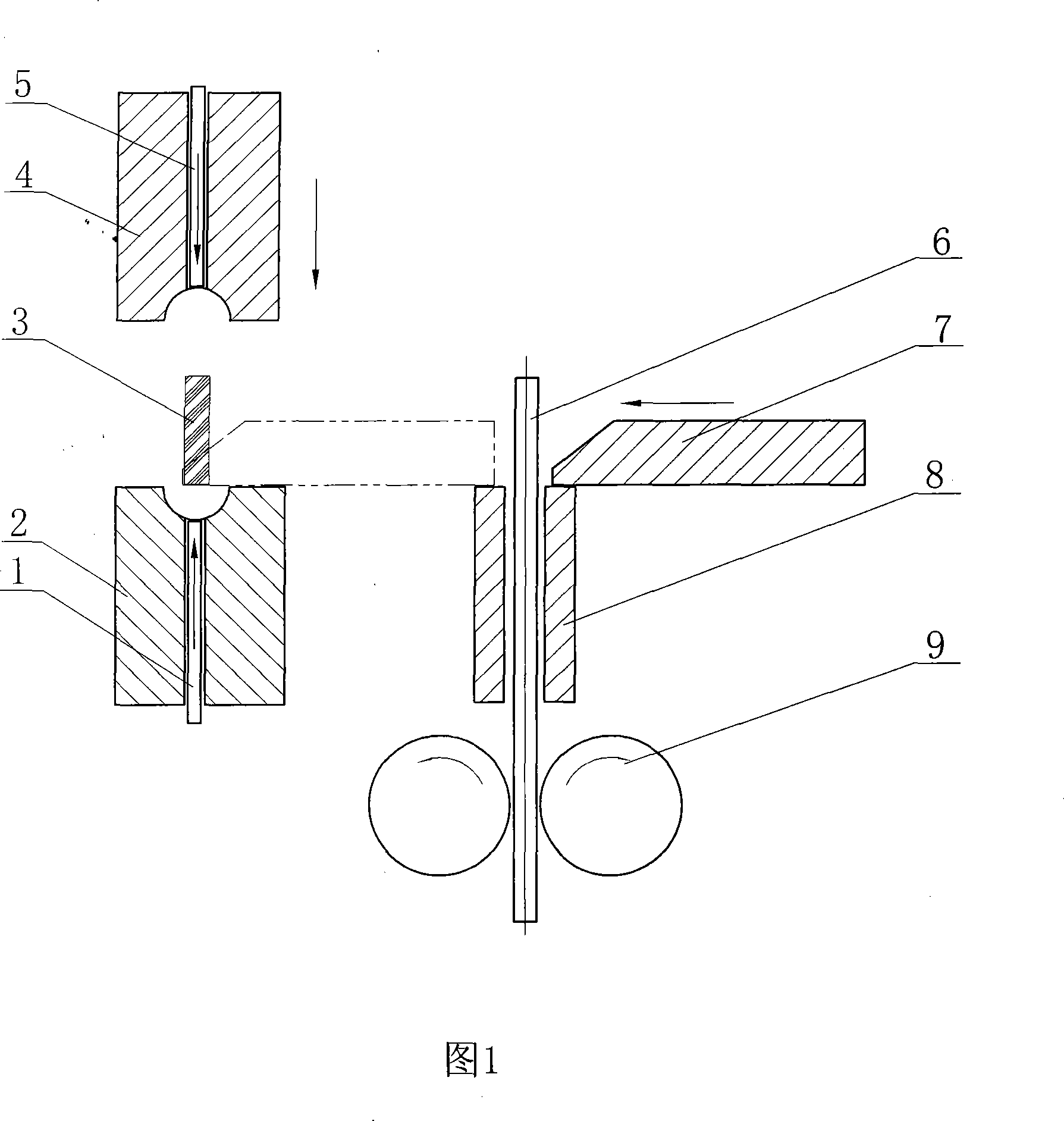

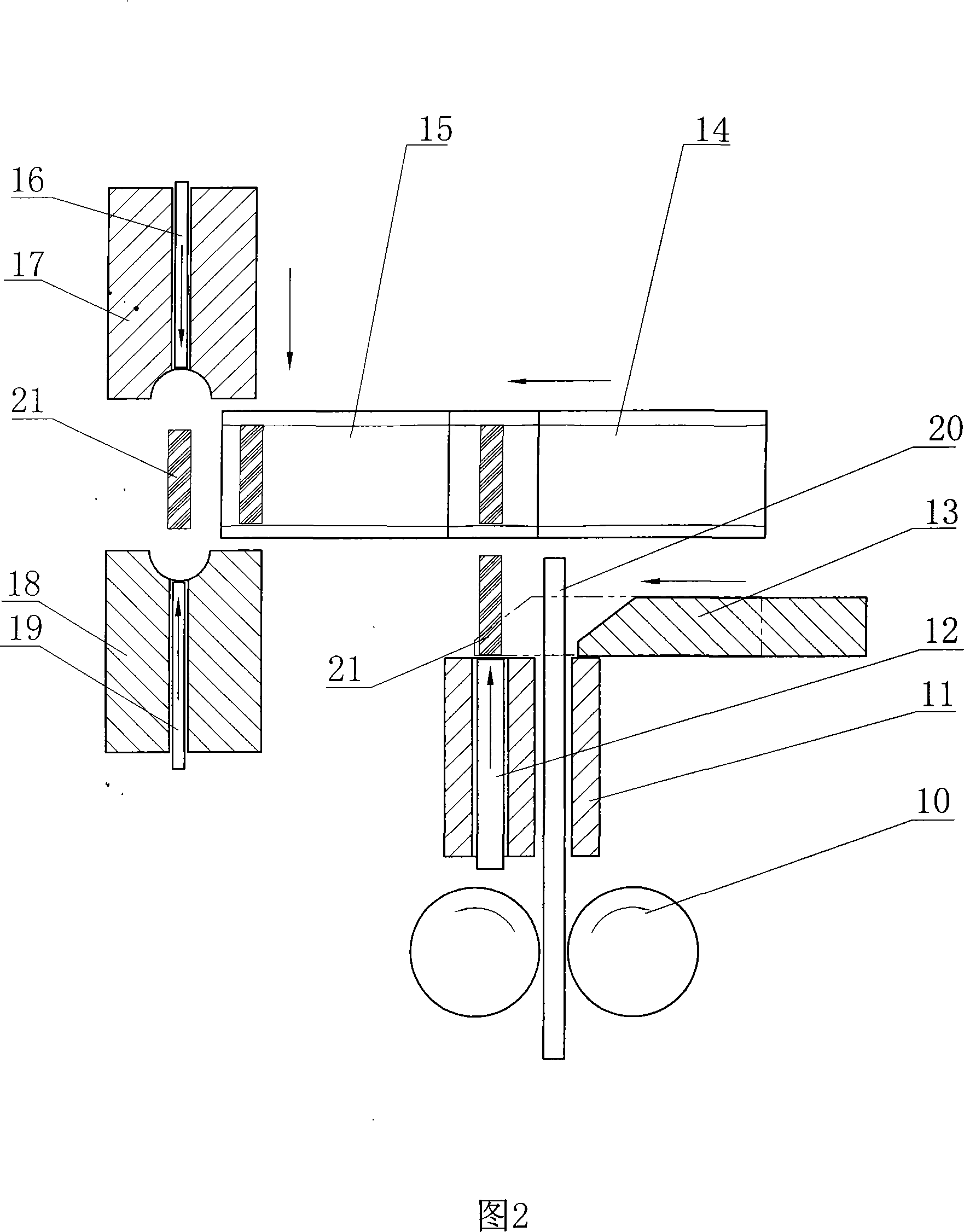

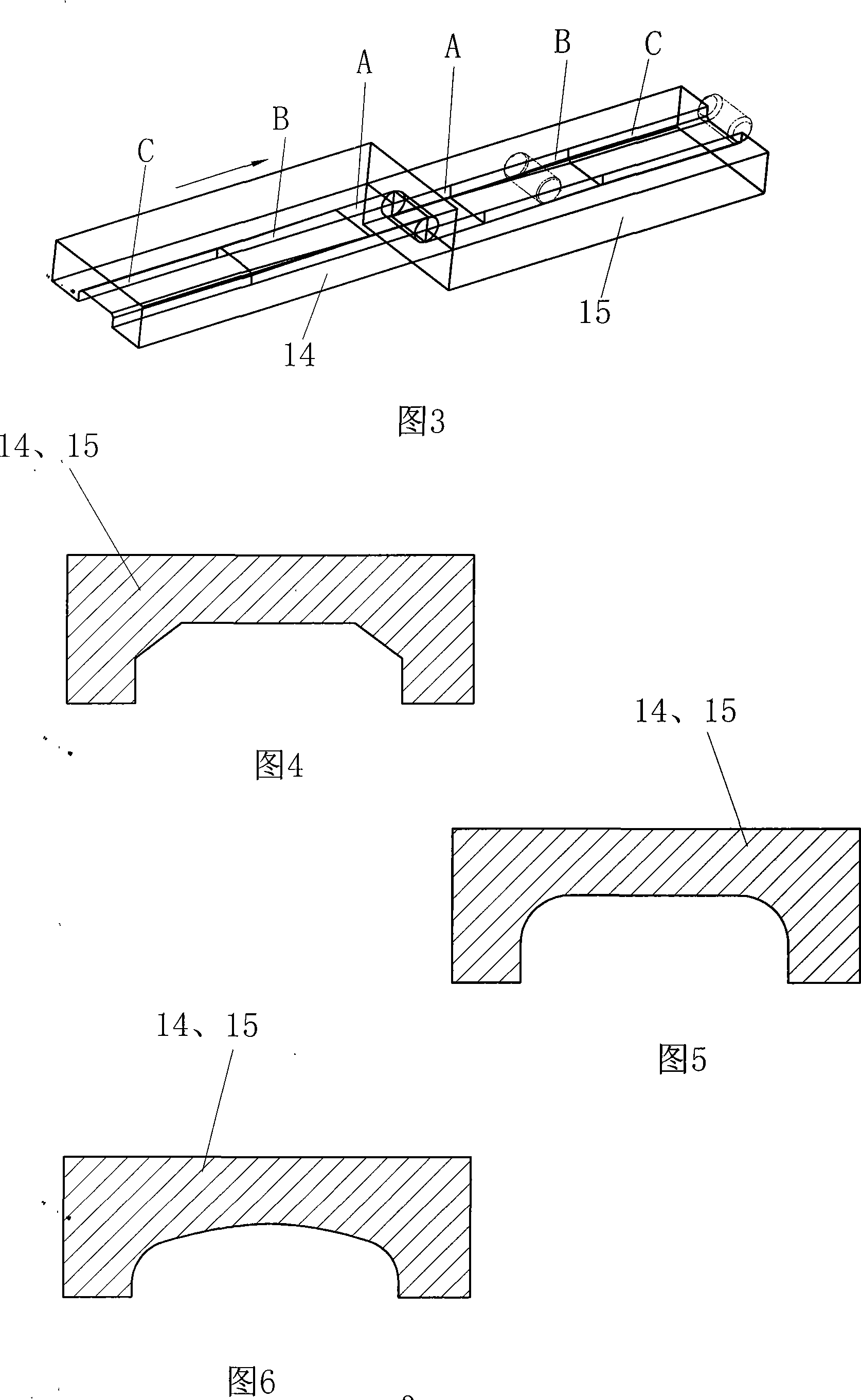

Steel ball cold heading technique and steel ball cold header

InactiveCN101185955AImprove plastic deformationUniform distribution of stress and strainHandling devicesPunchingSteel ball

The invention discloses a steel ball cold heading process and a relevant steel ball cold heading machine. The invention is characterized in that in the steel ball cold heading process, after barstocks are cut into column-shaped blanks, two ends of the column shaped blanks are rubbed and cut into inversed angel or round angle shapes, and then the blanks are transferred to a cold heading mechanism to be headed into steel ball rough cast; a blank rubbing and cutting mechanism is additionally arranged on the corresponding cold heading machine. The rubbing and cutting mechanism consists of an upper rubbing and cutting die and a lower rubbing and cutting die which are provided with formed notches respectively and carry out relative movement. As the rubbing and cutting machining to the blanks is added before the cold heading, the fact that the blanks entering the cold heading mechanism are the cylinders with round angles or inversed angles or the podetiums with other special shapes and no burrs are produced can be guaranteed, and the steel ball rough cast has better plastic transfiguring capability and uniform distribution of stress. The quality and eligibility rate of the steel ball rough cast can be enhanced and the manufacturing cost thereof can be reduced. Furthermore, as the shapes of the blanks entering the cold forging mechanism are regular, the stress born by the cold heading mechanism is equal in the punching process, thus the service life of cold heading dies is prolonged.

Owner:JIANGNAN UNIV

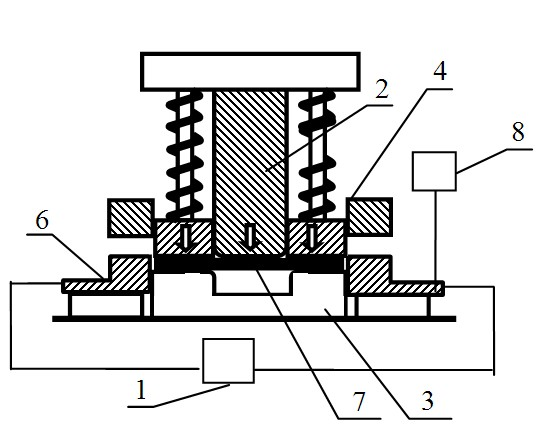

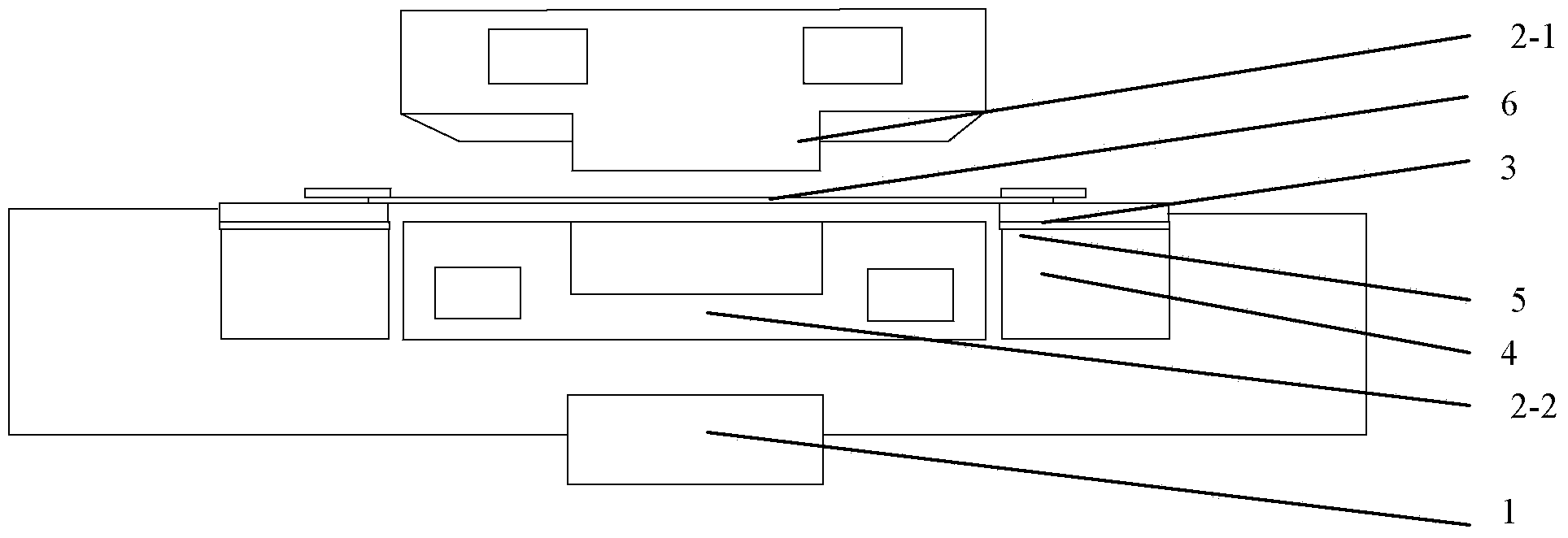

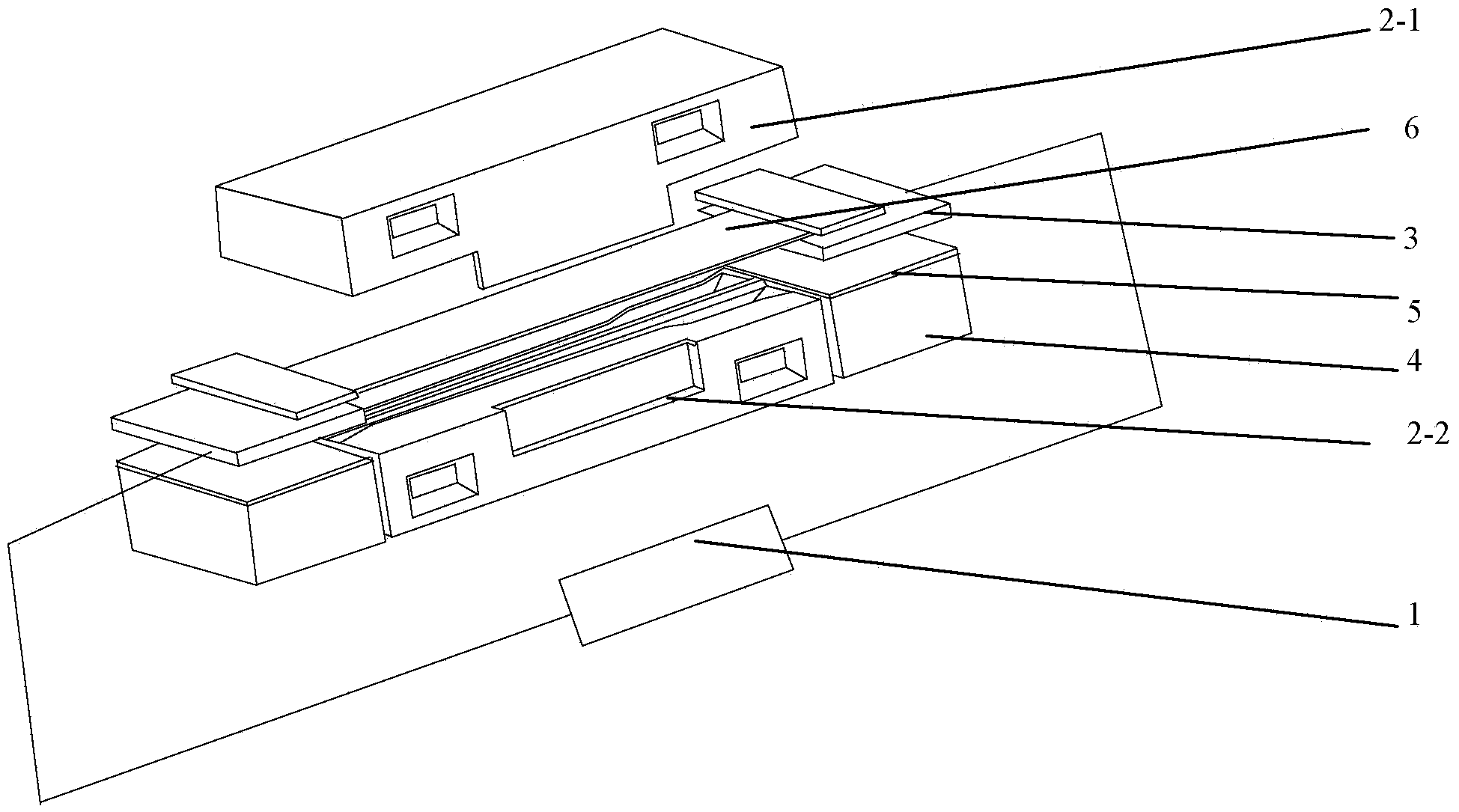

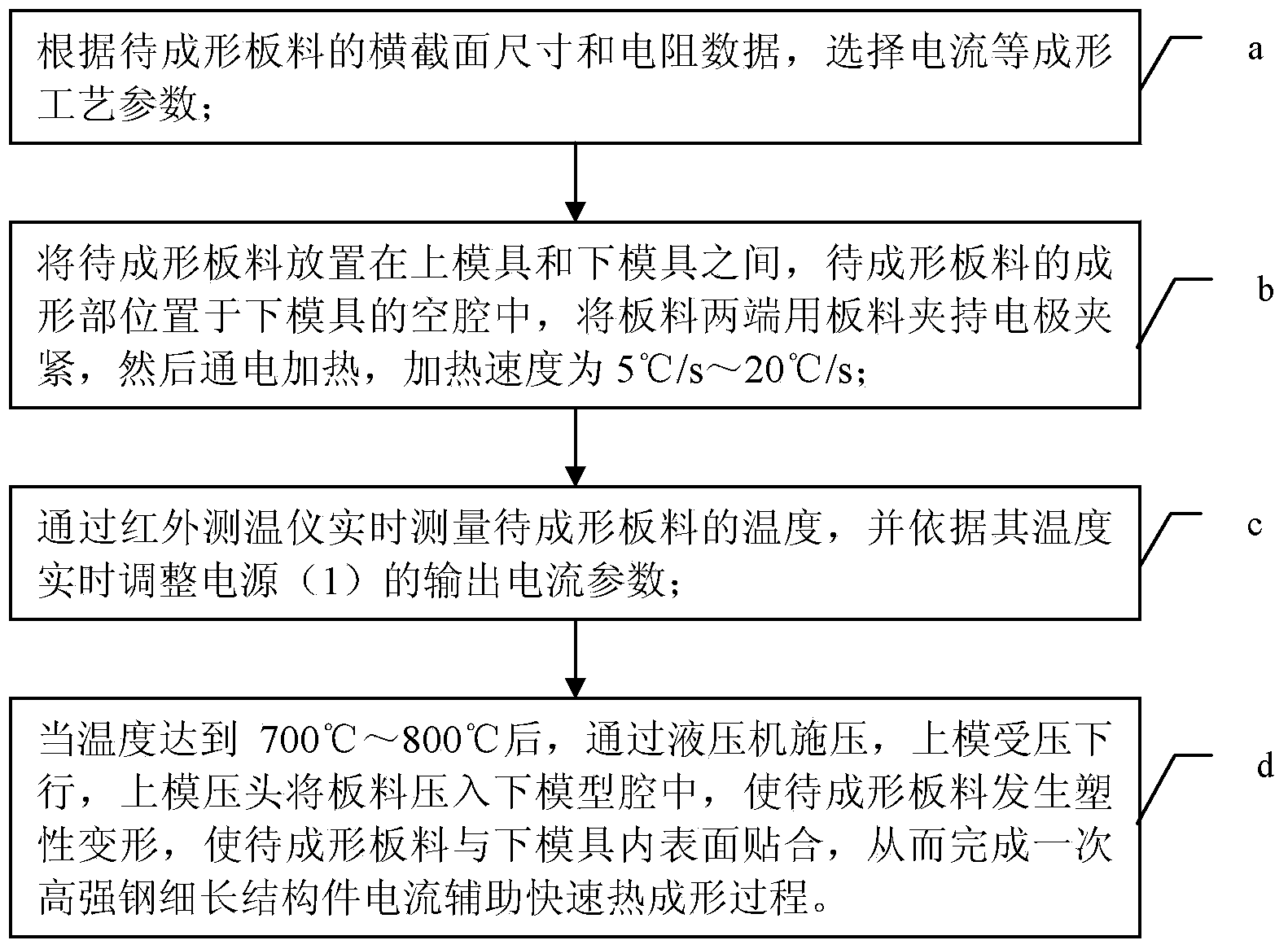

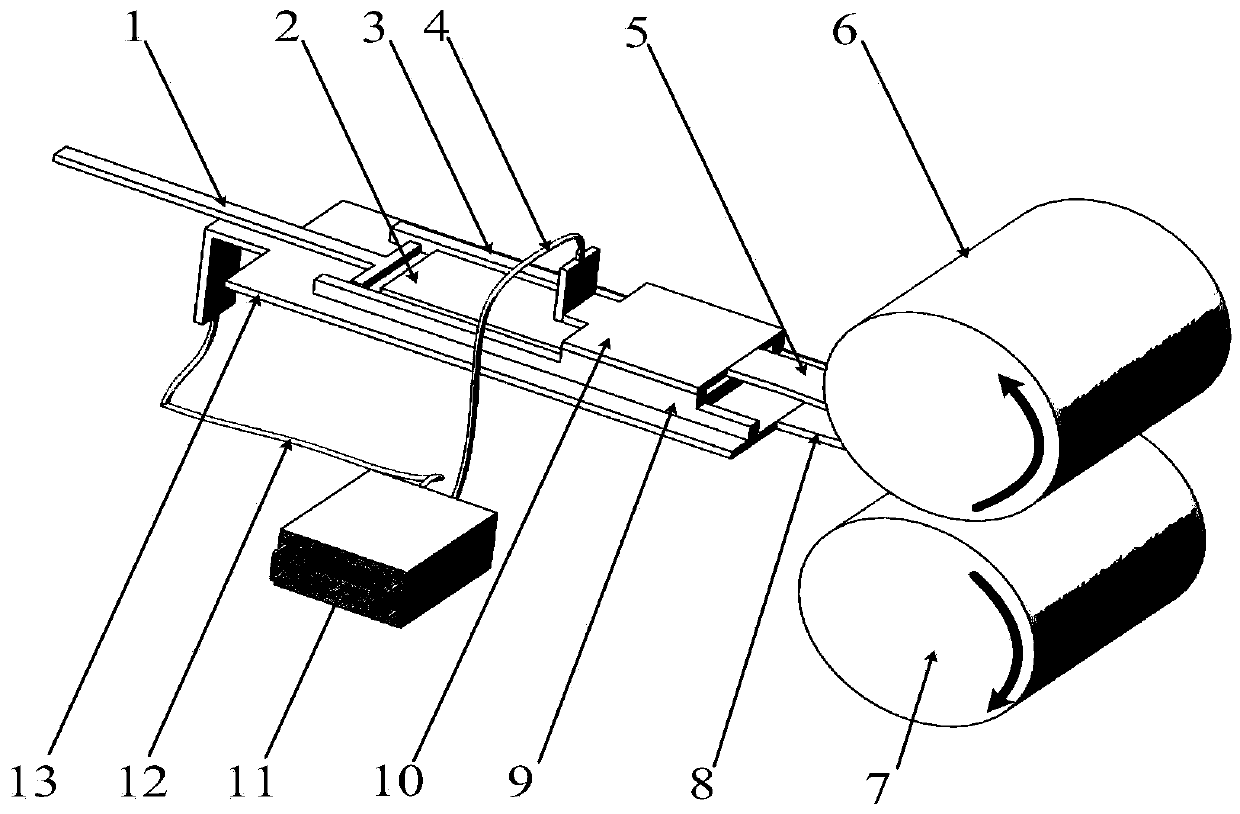

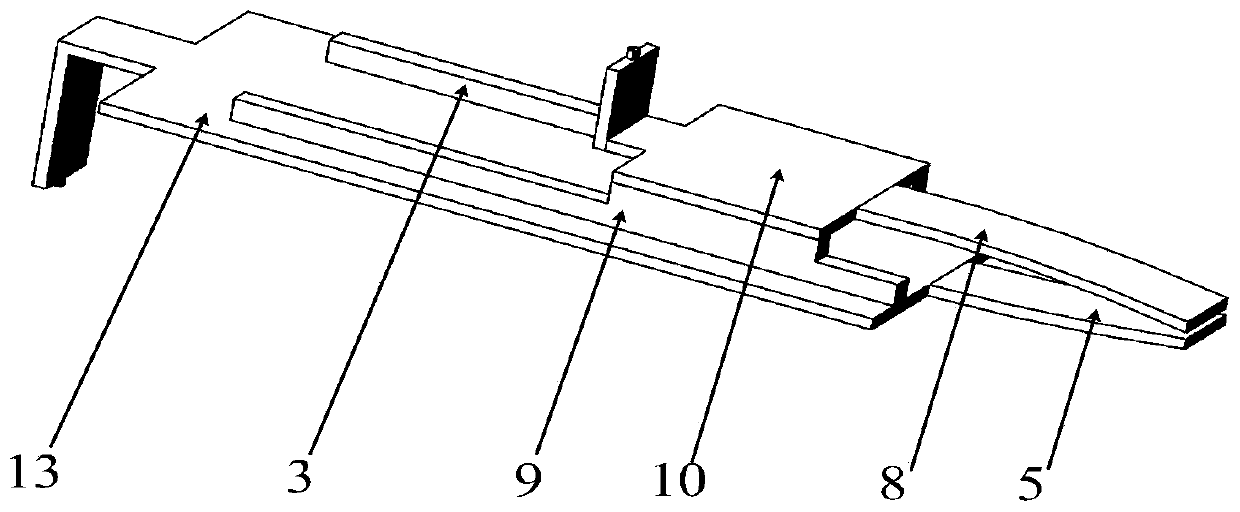

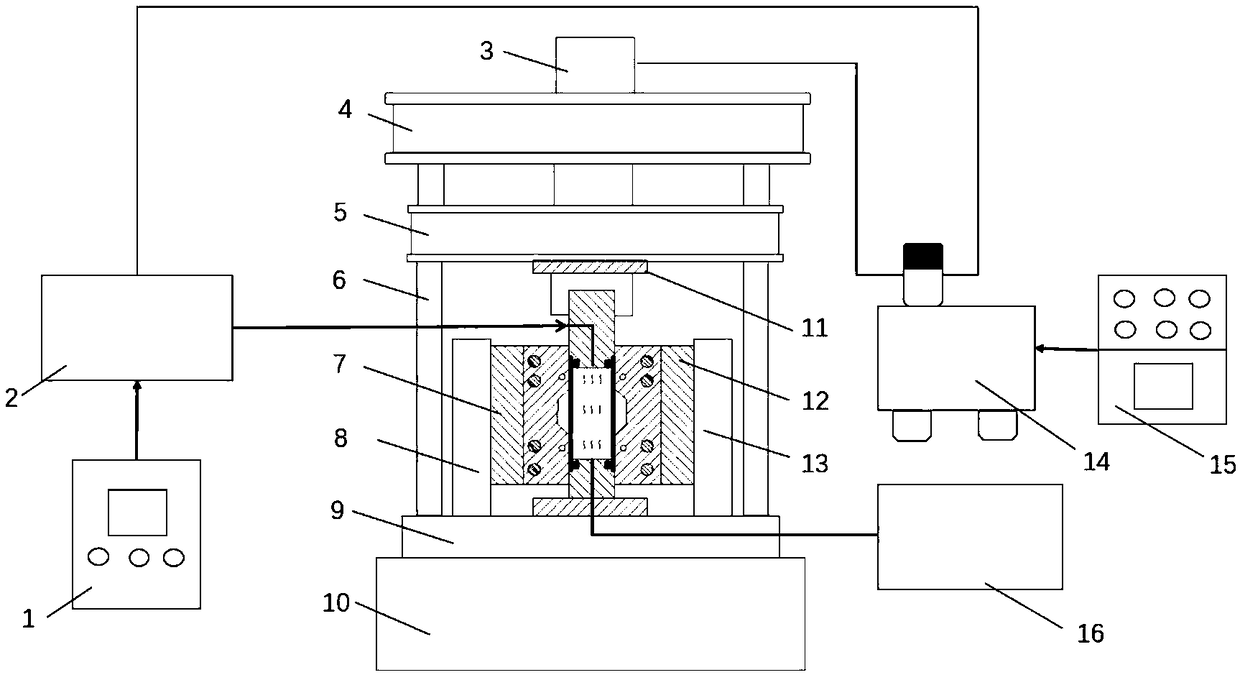

Current-assisted rapid hot forming device and method for long and thin high-strength-steel structural components

InactiveCN103406415AImprove plastic deformationAvoid lostShaping toolsElectricityElectrical resistance and conductance

The invention discloses a current-assisted rapid hot forming device and method for long and thin high-strength-steel structural components, relates to the technical field of high-strength-steel hot forming, particularly relates to a current-assisted self-resistance heating forming device and method and solves the problems that existing rapid hot forming devices are complicated to energize and existing rapid hot forming methods are applied to materials of low melting points and low hardness. The device comprises a power supply, a die, a pair of sheet clamping electrodes, two cushion blocks and two insulating mica sheets, the power supply, the sheet clamping electrodes and a sheet to be formed form an energized loop, the sheet clamping electrodes and the rest part of the die are insulated, insulation is achieved through the high-temperature-resistant insulating mica sheets, and the sheet to be formed is not in contact with the die. The method comprises that joule resistance heat produced by a current passing the sheet is used for heating the sheet directly, and after the forming temperature is reached, the rapid in-situ stamping forming is conducted. The device and the method are used for manufacturing the high-strength-steel structural components for vehicles.

Owner:HARBIN INST OF TECH

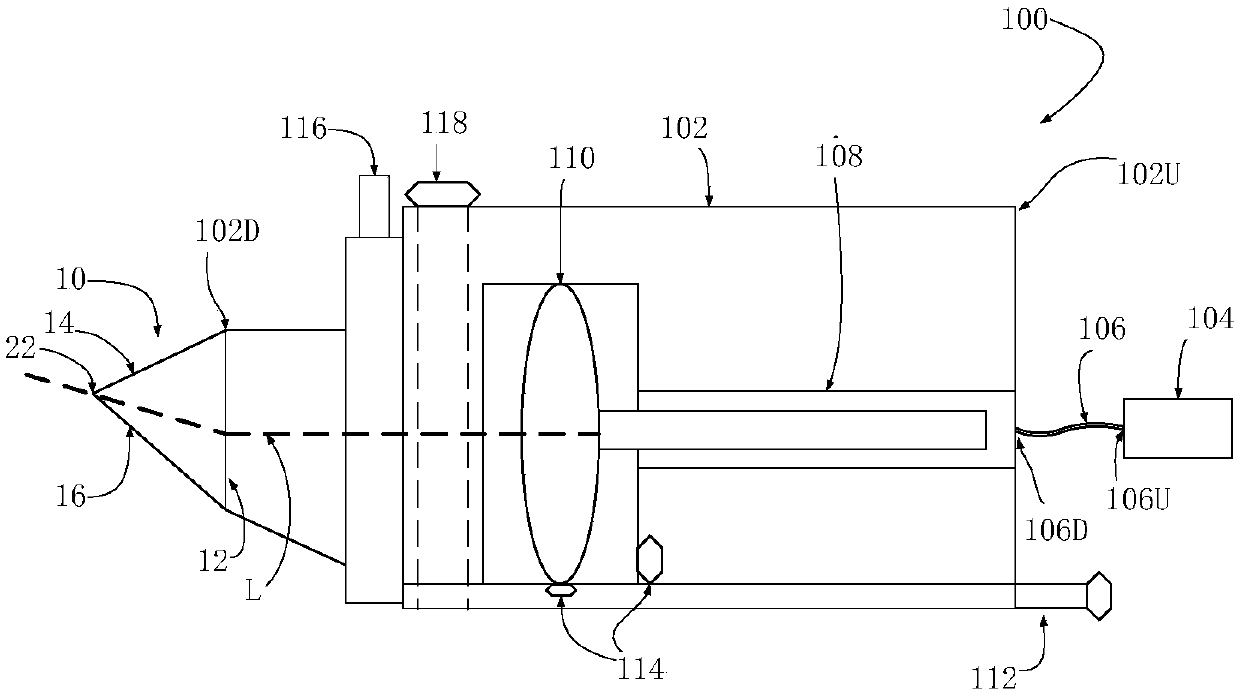

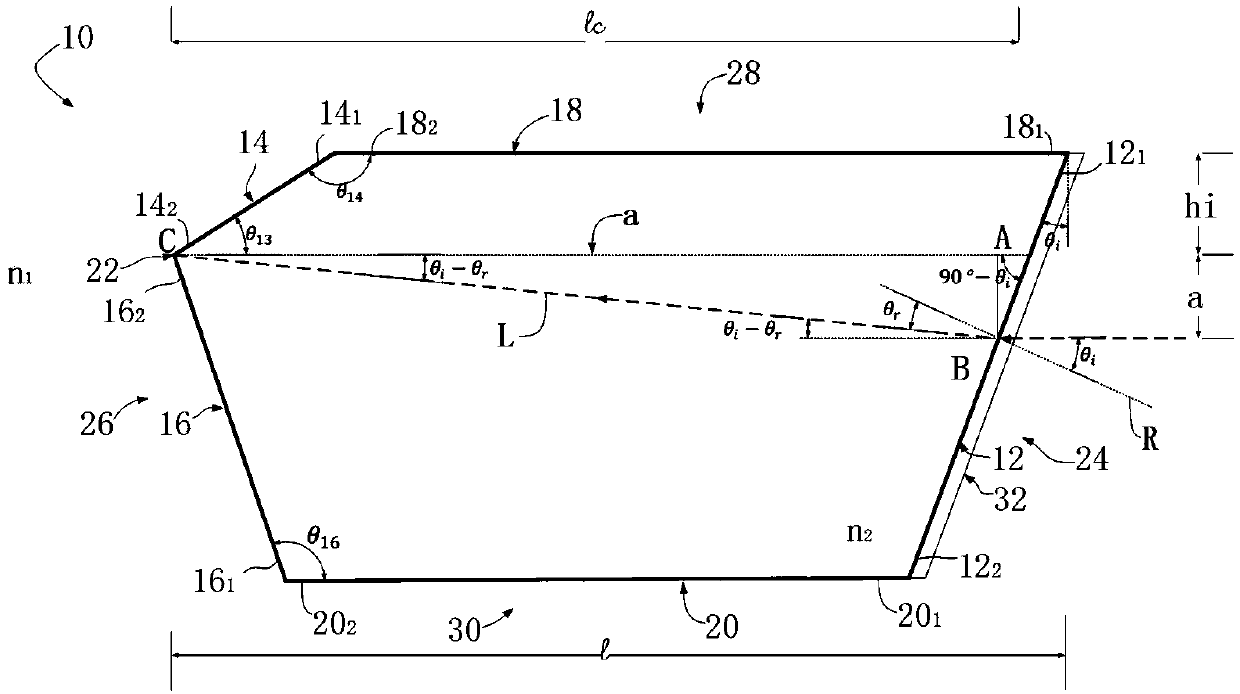

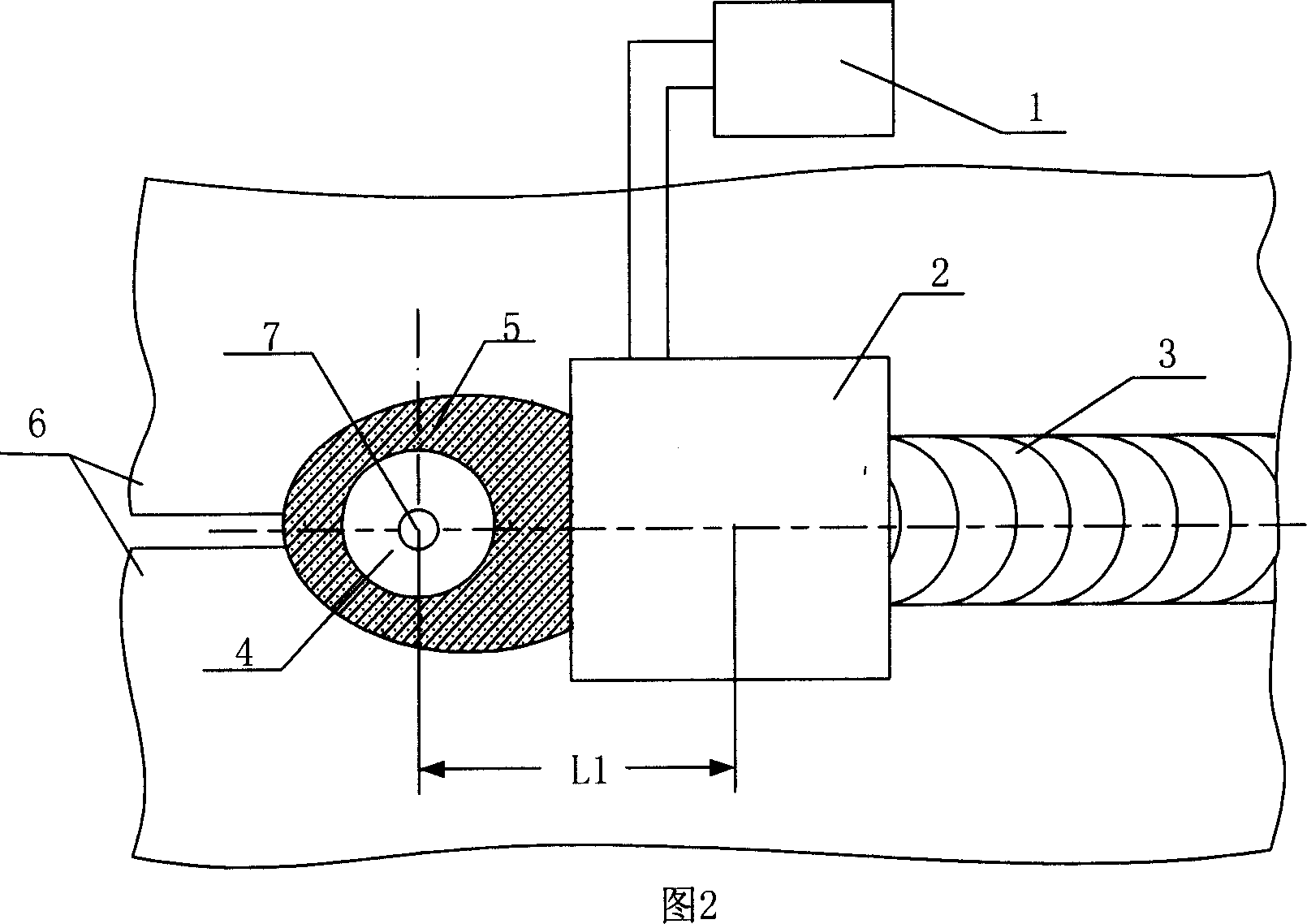

Micro laser auxiliary machining system for optical hard and brittle material and use method thereof

InactiveCN108818983AExtended service lifeHigh removal rateFine working devicesEngineeringMachining system

The invention belongs to the workpiece machining related technical field and discloses a micro laser auxiliary machining system for optical hard and brittle material and a use method thereof. The micro laser auxiliary machining system comprises a laser generator, a shell and a machining cutter. The laser generator is arranged at one end of the shell. The machining cutter is connected to the otherend of the shell and comprises a front cutter face and a rear cutter face which are connected. A cutting edge is formed on the transition part between the front cutter face and the rear cutter face. The laser generator is used for emitting a laser beam. The laser beam penetrates through the shell, then is sent to the machining cutter and is sent out from the cutting edge and at least one of the front cutter face and the rear cutter face, and the sent-out laser beam radiates onto a to-be-machined workpiece so as to soften the workpiece. According to the micro laser auxiliary machining system for the optical hard and brittle material and the use method thereof, laser and single-point turning processes are combined, cost is lowered, efficiency is improved, and service life of the cutter is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

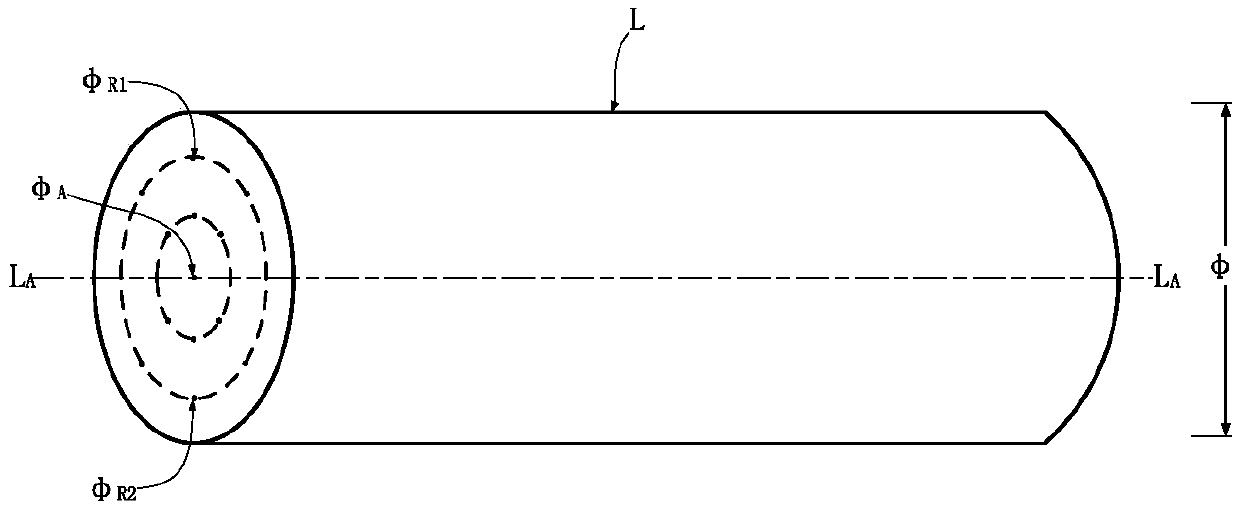

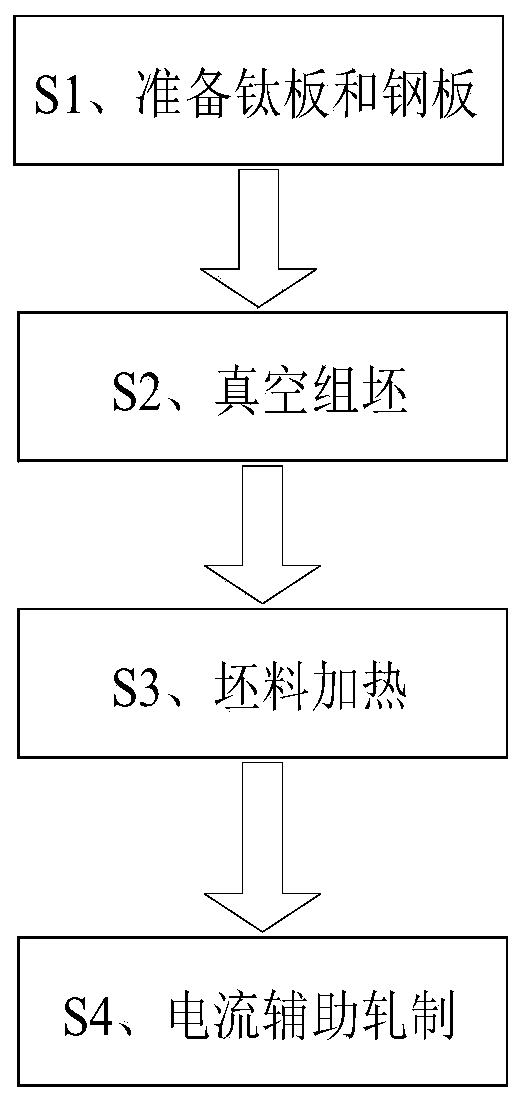

Method for preparing titanium steel composite plate through auxiliary hot rolling of pulse current

InactiveCN110788136AImprove plastic deformationFacilitated DiffusionRoll force/gap control deviceWork cleaning devicesTitaniumComposite plate

The invention provides a method for preparing a titanium steel composite plate through auxiliary hot rolling of pulse current. The method comprises the following steps that S1, a titanium plate, a steel plate and a middle layer material are prepared, and to-be-composited surfaces of the titanium plate, the steel plate and the middle layer material are subjected to treatment and cleaning thoroughly; S2, the titanium plate and the steel plate are subjected to vacuum assembling; S3, a heating device is heated to the designated temperature, a blank is put in the device, and vacuum heat preservation treatment is carried out for a certain time; S4, a roller gap and a rolling speed of a rolling mill are set in advance, the blank obtained after heat treatment is taken out to be put into a rollingmill inlet connected with a pulse power source device, an insulation push plate is used for pushing the blank into the rolling mill, and according to the certain rolling reduction and the rolling speed, rolling is carried out to obtain the titanium steel composite plate. According to the method for preparing the titanium steel composite plate through auxiliary hot rolling of the pulse current, theelectroplastic effect and the tip end effect of the pulse current are used, the two kinds of materials of titanium and steel achieve metallurgical bonding under the small reduction amount, and the titanium steel composite plate good in plate shape and high in combination strength can be obtained.

Owner:TAIYUAN UNIV OF TECH

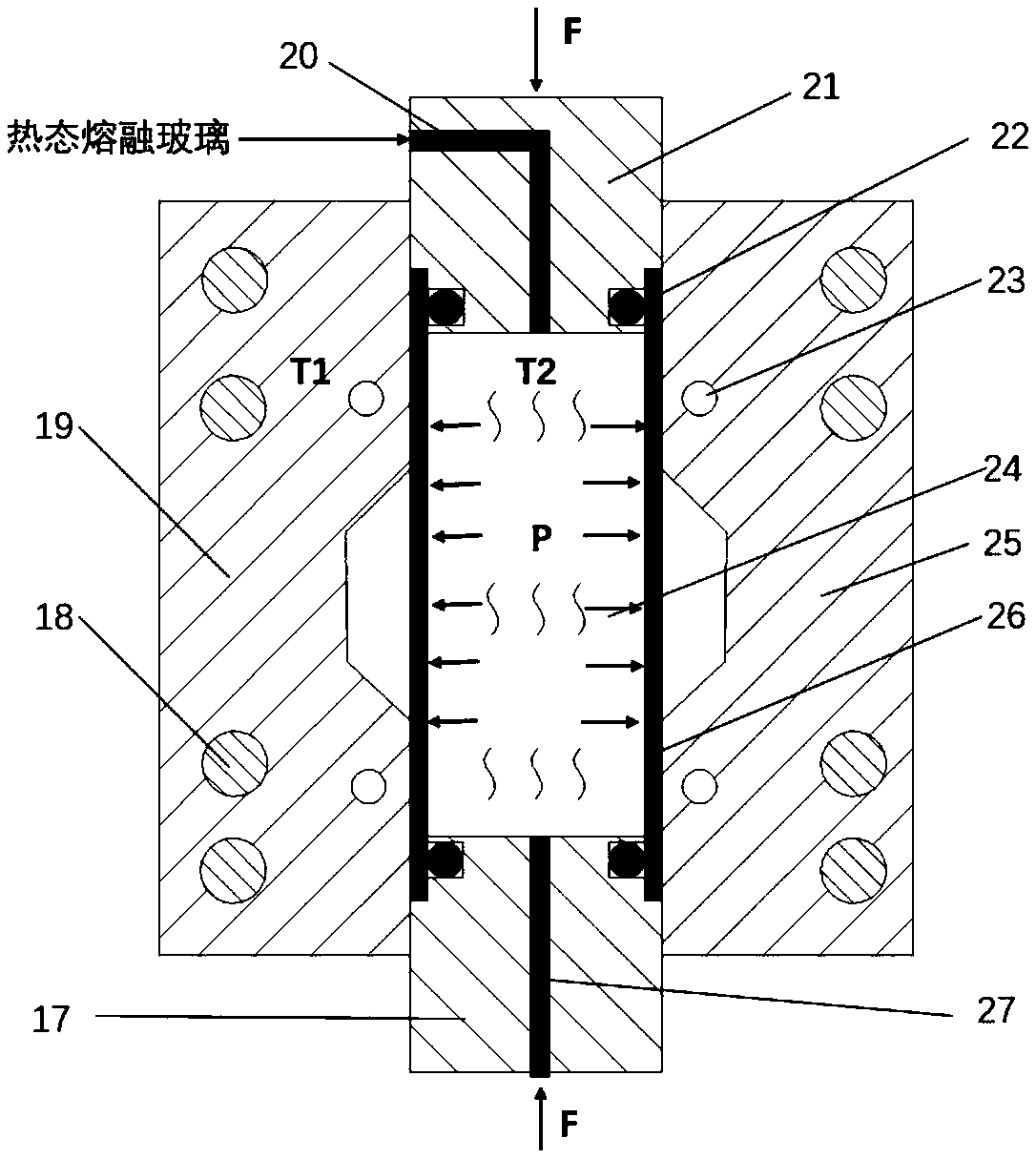

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

Softening method of automobile component part cold extrusion blank

ActiveCN1757765ATo meet the plastic deformation requirementsImprove plastic deformationHeat treatment process controlProduction lineSteel ball

A technology for softening the blank of carí»s part to be cold-extruded includes such steps as blanking the hot-rolled circular steel by needed sizes, putting the blank on the holder of production line, isothermal normalizing for softening whole blank, blasting steel balls for removing oxidized scales, phosphorizing, saponifying and cold extruding.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

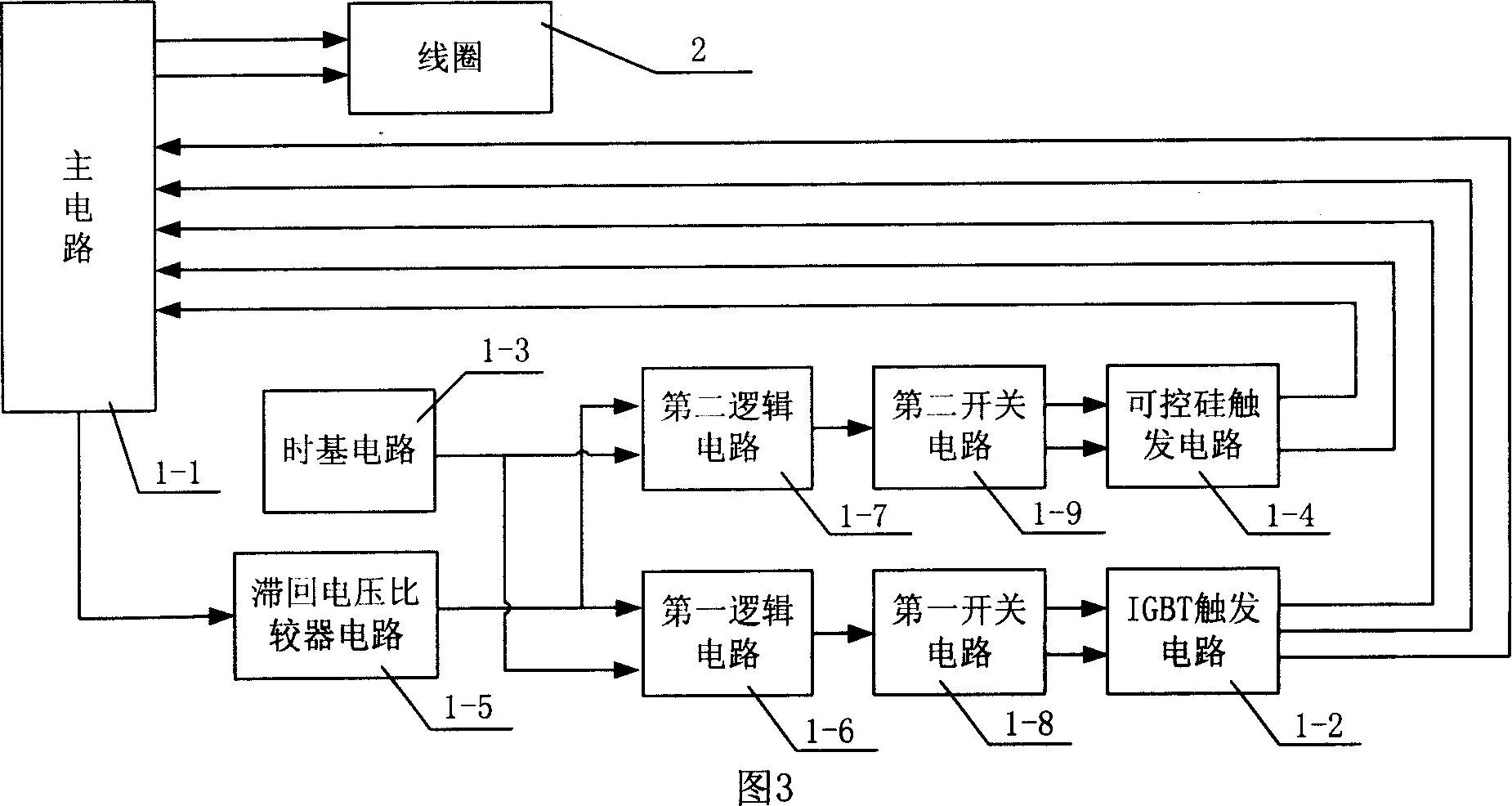

Electromagnetic impact device for controlling welding heat cracking and deformation

InactiveCN1943969ALow costEasy to makeWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The present invention relates to welding technology, and is one kind of electromagnetic impact device for controlling welding heat crack and deformation. The electromagnetic impact device includes one pulse discharge circuit, and one coil with two input ends connected to the output of the pulse discharge circuit. The coil is set over the weld seam, and has lower surface apart from the upper surface of the weld seam by 2-5 mm and center in the distance to the center of the welding torch of 25-60 mm. The present invention has simple operation, easy control on energy, small size, low cost, stereo electromagnetic impact force and no need of contacting the coil with the welded workpiece.

Owner:HARBIN INST OF TECH

Preparation method based on single crystal copper bonding wire

InactiveCN102280388ALow priceImprove plastic deformationPolycrystalline material growthSemiconductor/solid-state device detailsEpoxyMicrocomputer

The invention discloses a preparation method based on single crystal copper bonding wire. The preparation method of the single crystal copper bonding wire is divided into two steps: (1) using continuous casting single crystal copper rod as the single crystal copper The starting material of the bonding wire, at the same time, the single crystal copper bonding wire is drawn by the drawing equipment driven by the AC servo motor with the microcomputer program control, active wire release, and the pulling force accuracy is less than 1mN; (2) The drawn single crystal copper bond The bonding wire is treated with electroplating precious metal palladium with a surface thickness of 0.5um~1um and an organic epoxy coating with a thickness of 1um for double-layer protection; in this way, a single crystal copper bonding wire with multiple protective coatings is finally obtained. Bonding wire has the advantages of low price, high elongation, good mechanical and electrical properties, and good oxidation resistance.

Owner:王一平

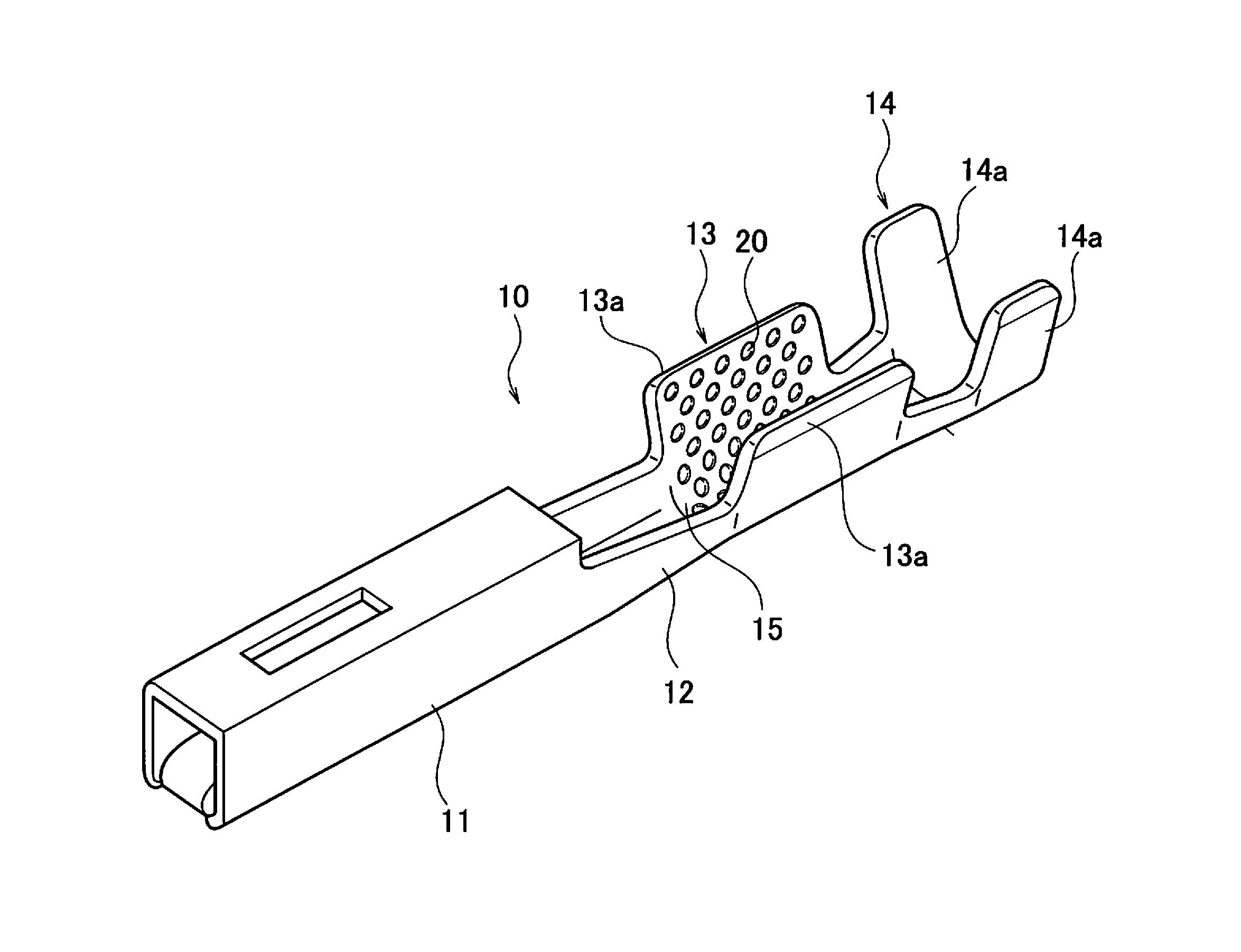

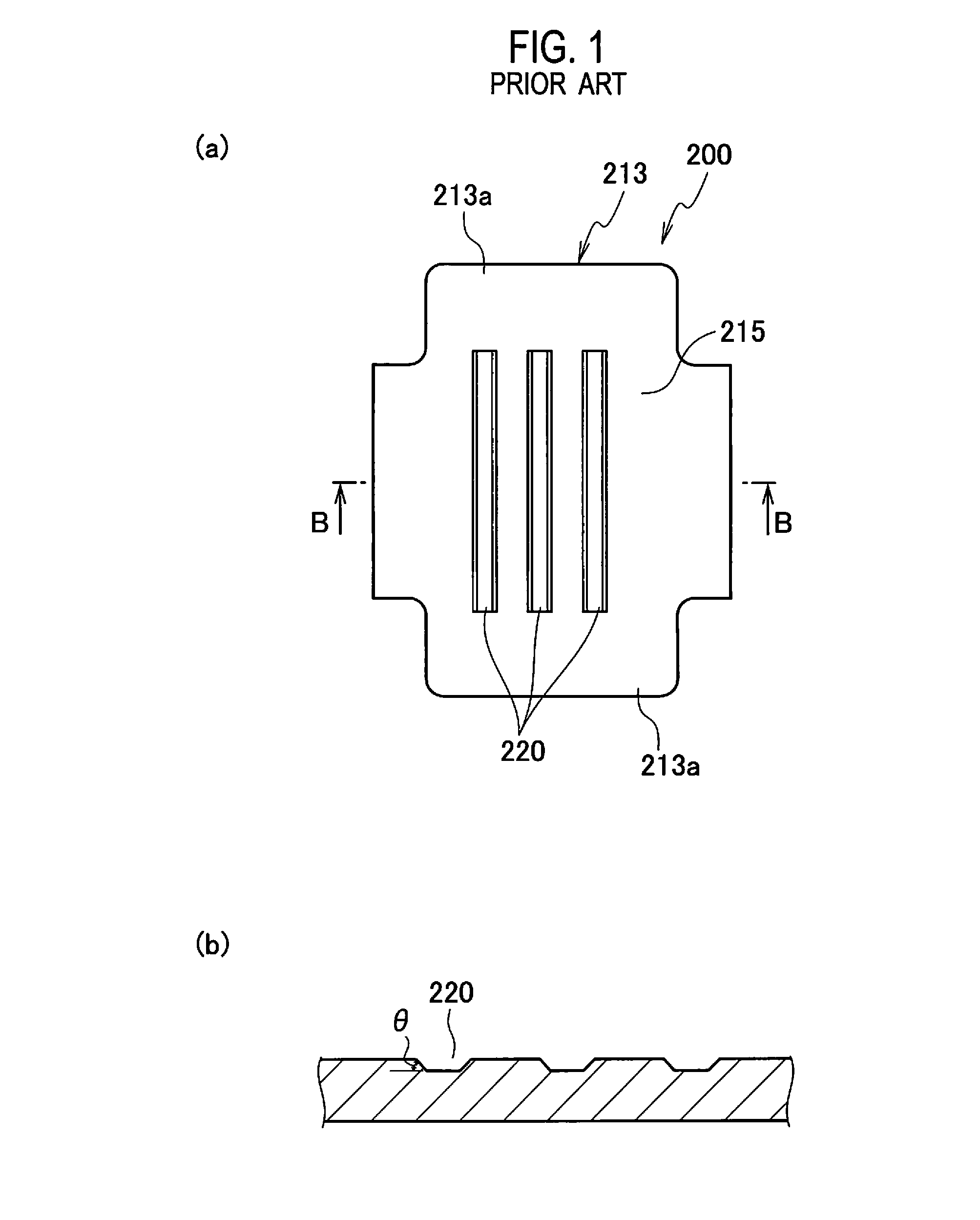

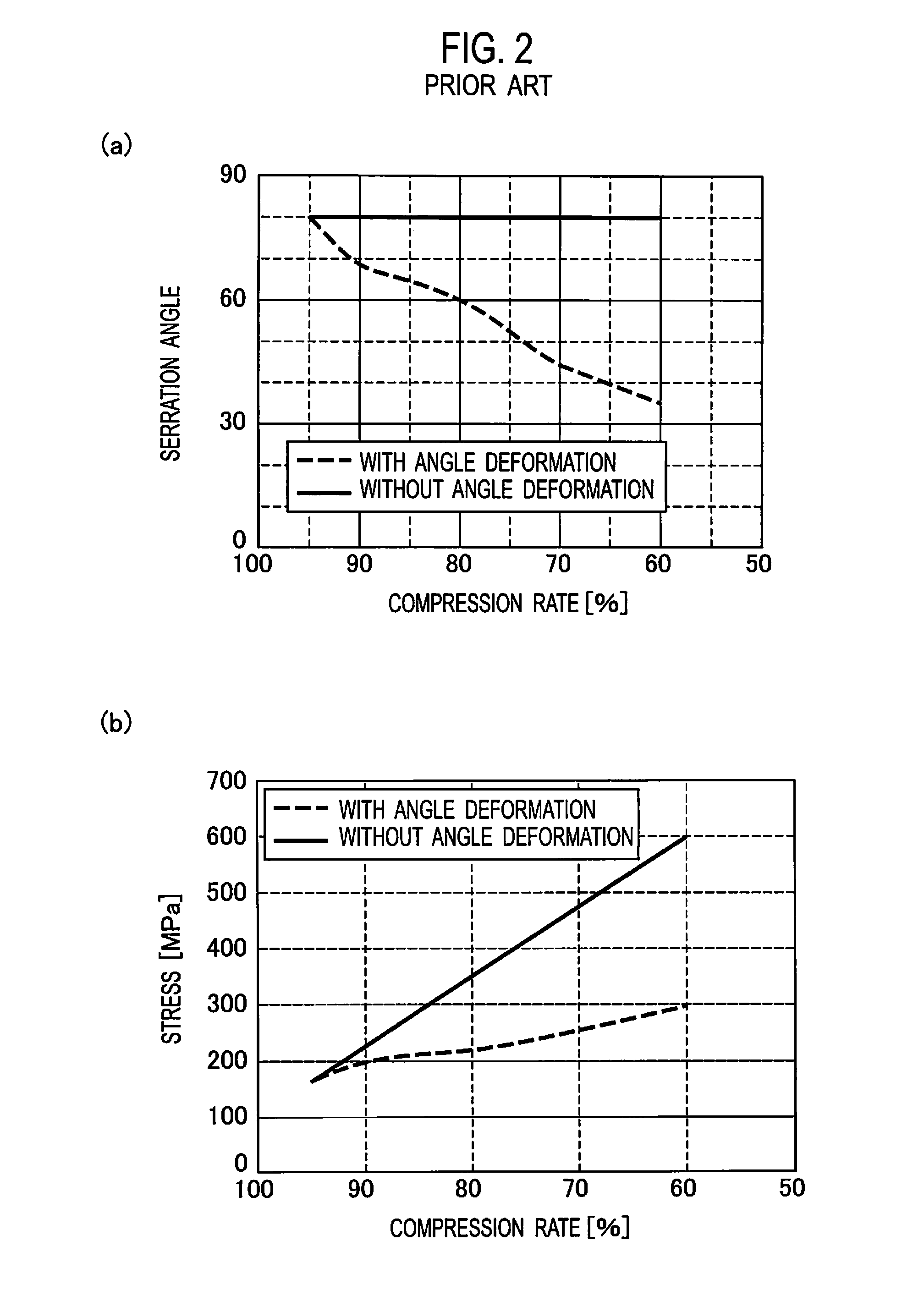

Crimp terminal

ActiveUS20140213123A1Good crimping effectIncrease pressureConnections effected by permanent deformationElectrical conductorShortest distance

Concave serrations are provided in an inner surface of a conductor crimping portion of a crimp terminal. A number of circular concave portions are provided in the inner surface of the conductor crimping portion as the concave serrations so as to be scattered in a state of being spaced aside from one another. A diameter of an inner bottom surface of each circular concave portion is set within a range of 0.15 (an error range is ±0.04) mm to 0.8 (the error range is ±0.04) mm. A serration angle between an extension surface of the inner bottom surface and an inner side surface of each circular concave portion is set within a range of 60 to 90 degrees. A shortest distance of a flat surface portion between peripheries of mutually adjacent circular concave portions is set to be 0.17 (the error range is ±0.09) mm.

Owner:YAZAKI CORP

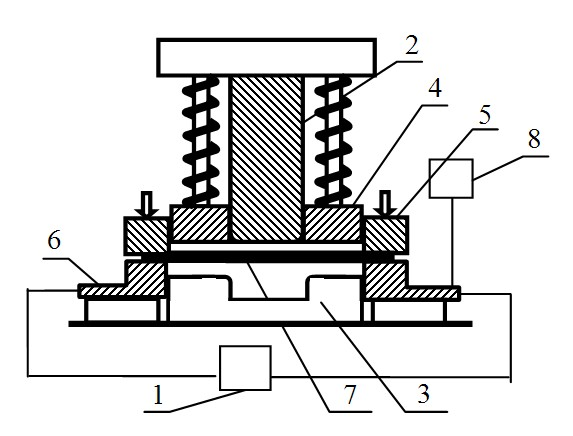

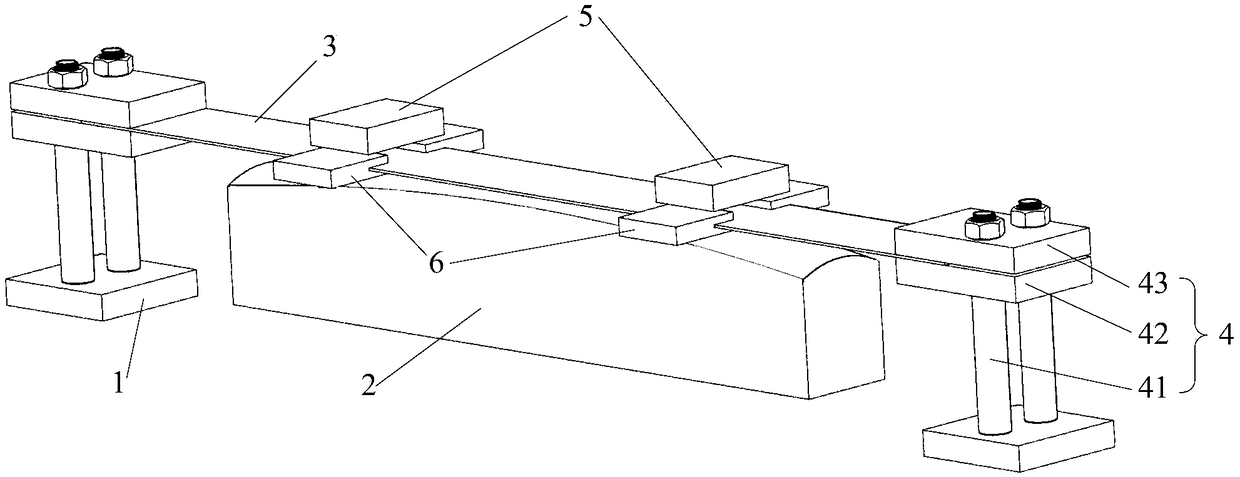

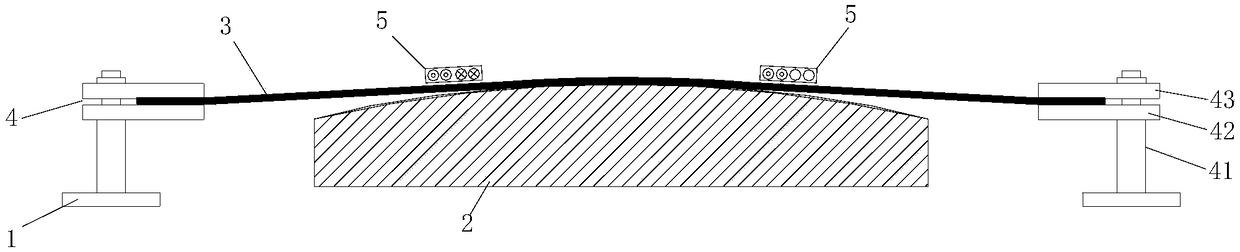

Warm electromagnetic forming device and method of skin piece

ActiveCN108856442AAchieve high rate deformationRaise the forming limitShaping toolsForming faceElectromagnetic forming

The invention discloses a warm electromagnetic forming device of a skin piece. The warm electromagnetic forming device comprises a base plate, a die, a plate material and clamping plate assemblies used for fixedly clamping the plate material, the clamping plate assemblies are arranged on the base plate, the plate material is fixedly clamped between the clamping plate assemblies, the warm electromagnetic forming device further comprises a discharge coil and heating pieces used for heating the plate material, the discharge coil is arranged above the plate material, and the heating pieces are arranged on the two sides of the plate material. The invention further discloses a warm electromagnetic forming method which comprises the steps of plate material fixing, plate material stretch forming,plate material heating, electromagnetic forming and the like; and complete attachment of the plate material and a forming face of a mold is achieved by repeatedly executing plate material stretch forming, heating and electromagnetic forming. The warm electromagnetic forming device has the advantages that the forming accuracy is high, the forming quality is good, the forming efficiency is high, andthe requirement of the equipment for the discharge energy and the coil strengthen is low.

Owner:CENT SOUTH UNIV

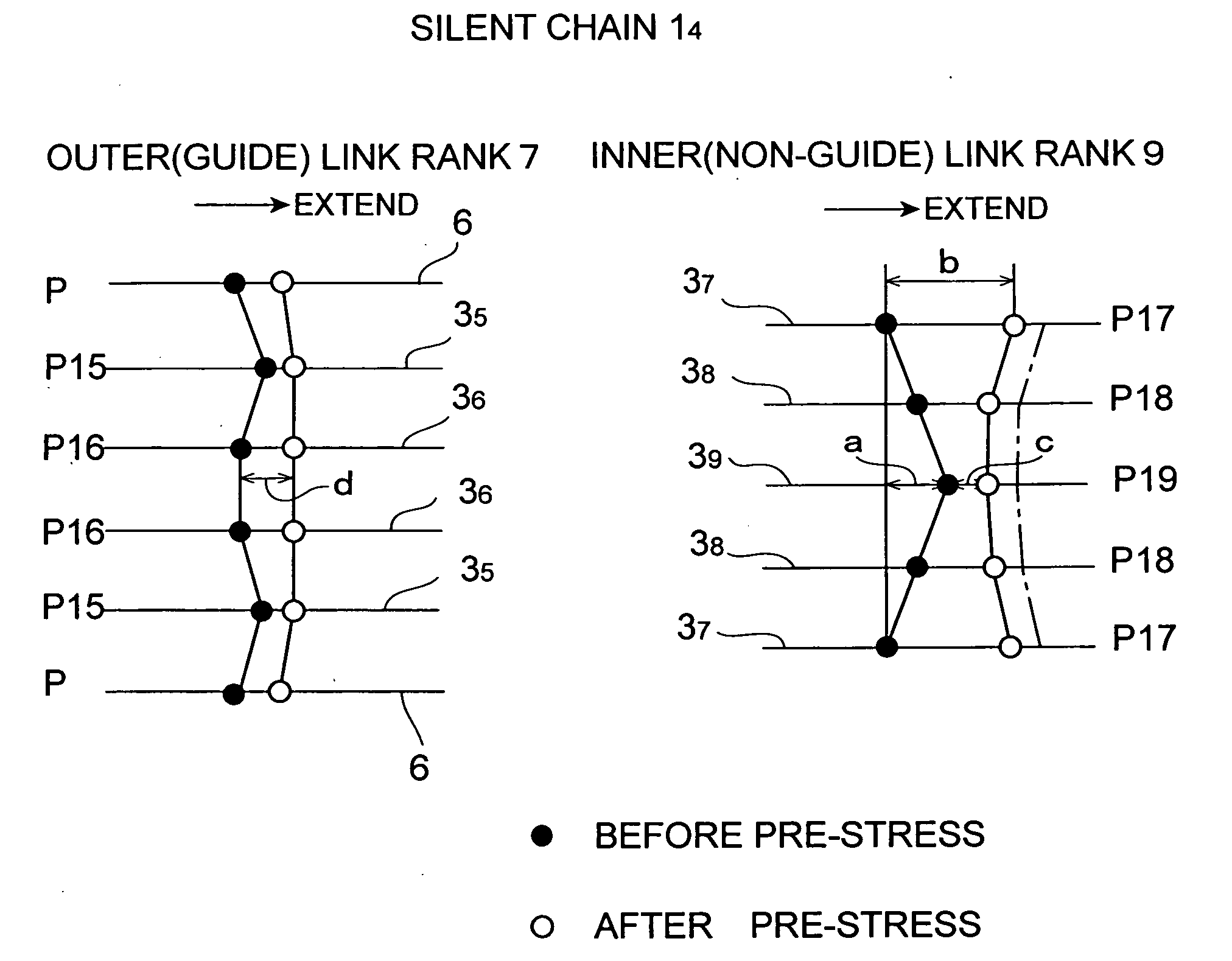

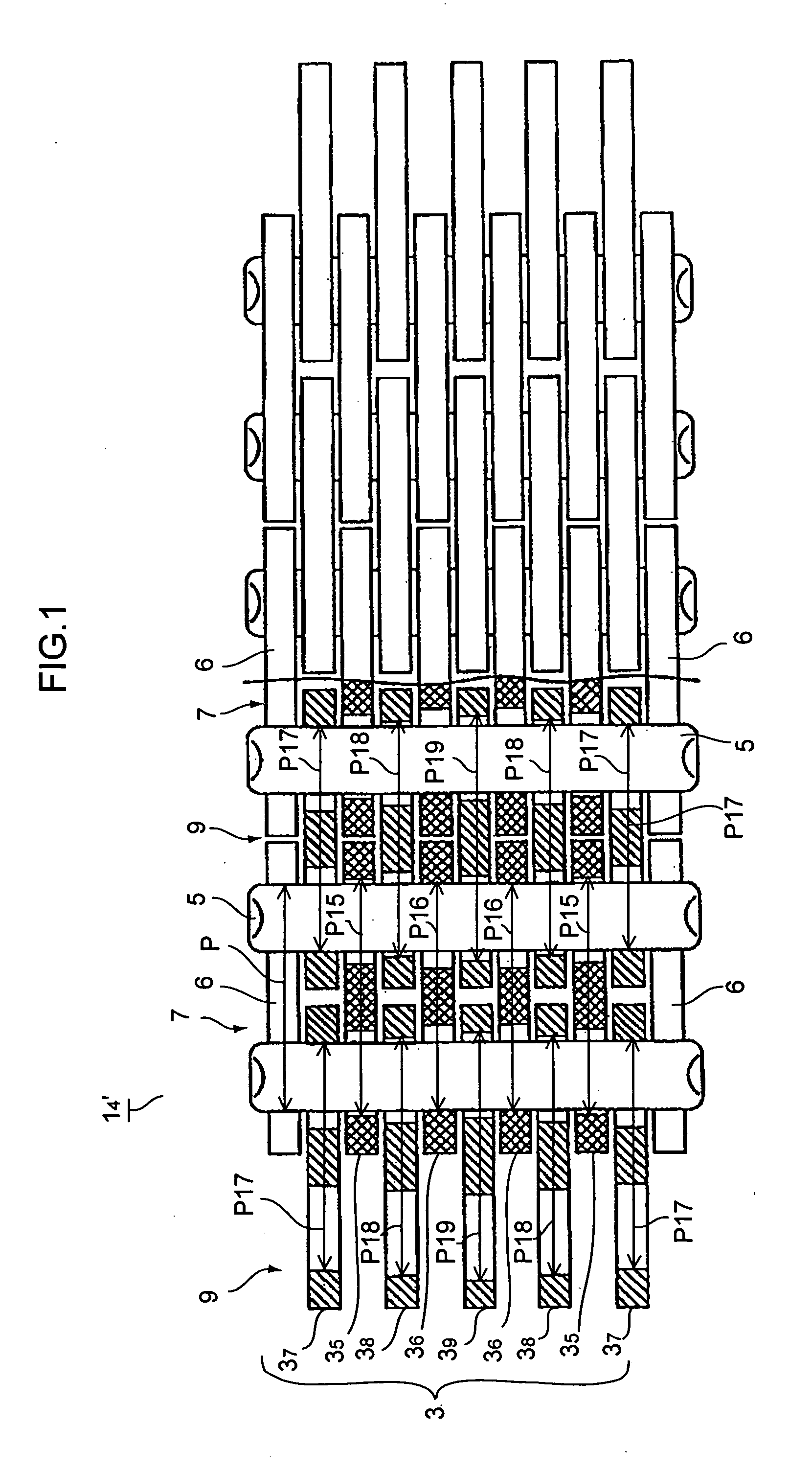

Silent Chain and Manufacturing Method of the Same

InactiveUS20090048047A1Burden of stressImprove fatigue strengthDriving chainsMetal chainsWear resistantPre stress

Owner:DAIDO KOGYO CO LTD

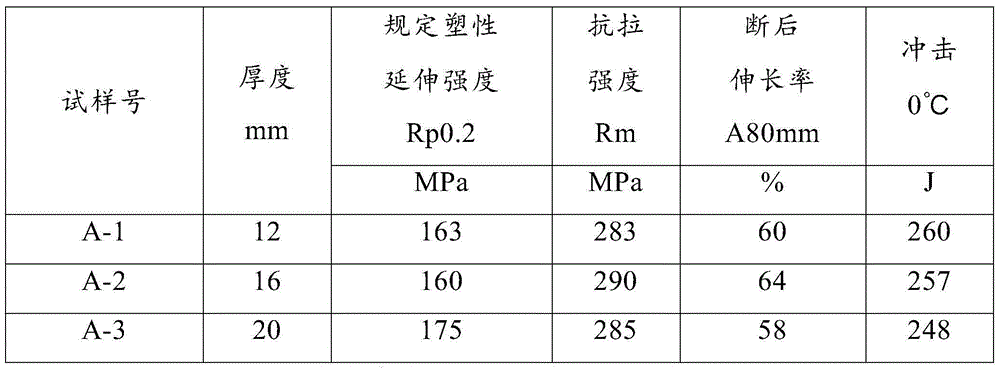

Production method of steel having 225 MPa stage of low yield point and used for building earthquake resistance

The invention discloses a production method of steel having 225 MPa stage of low yield point and used for building earthquake resistance. The steel comprises the following chemical components in percentage by mass: C not more than 0.03%, Si not more than 0.1%, Mn not more than 1%, 0.02-0.06% of Al, P not more than 0.01%, S not more than 0.004%, N not more than 0.004%, 0.01-0.08% of Ti, Nb not more than 0.05%, and the balance of Fe and inevitable impurities. Through a serial of processes of refining, continuous rolling, heating, rough milling, electromagnetic inductive heating, fine milling, laminar cooling and winding, the yielding strength of the steel having 225 MPa stage of low yield point and used for building earthquake resistance reaches 200-240 MPa stage, and the elongation is greater than 50%; and the steel has excellent plastic deformation and impact toughness, and has the advantages of lower alloy cost, easy process realization, excellent weldability and excellent low-cycle fatigue performance.

Owner:SHOUGANG CORPORATION

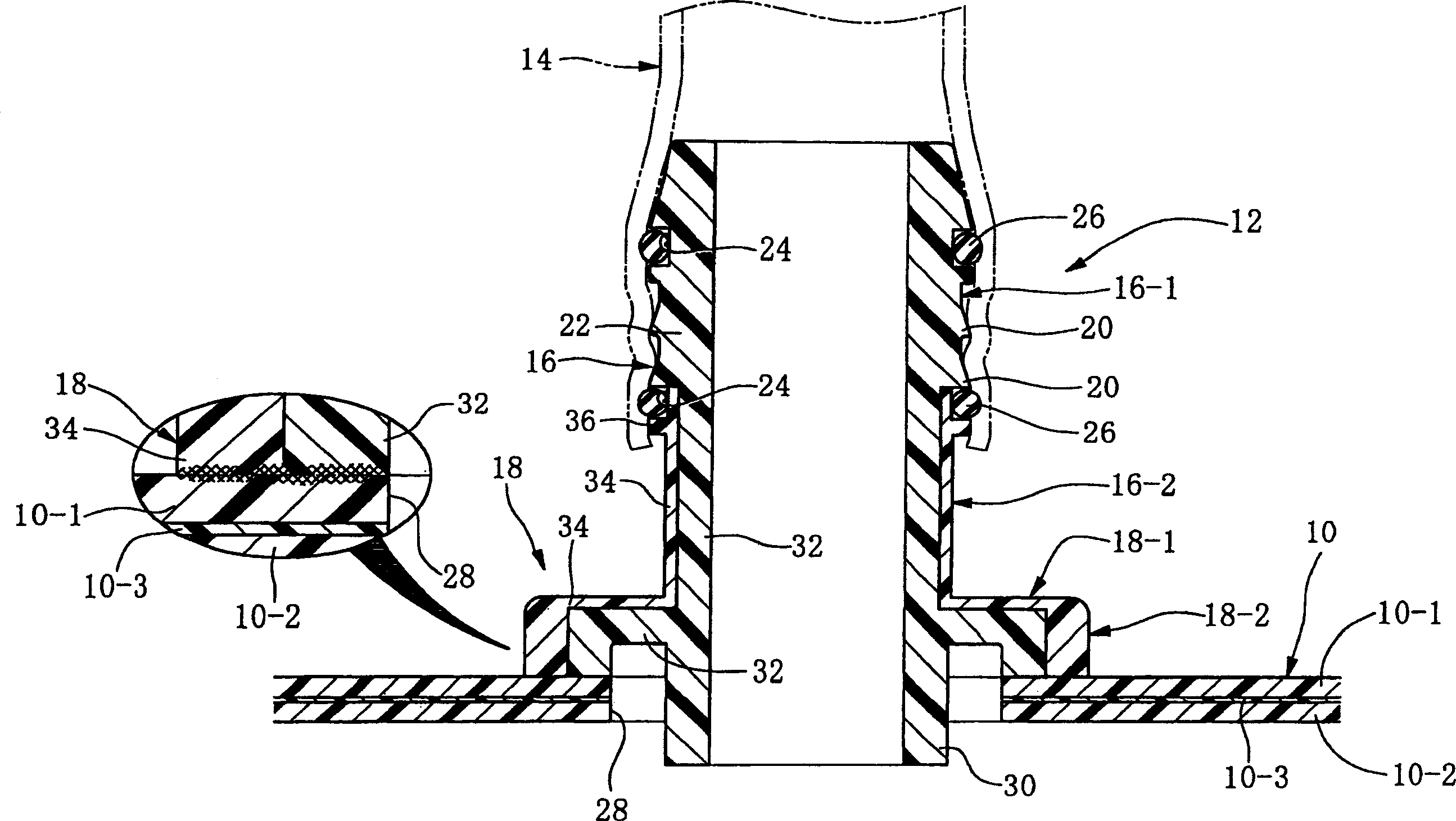

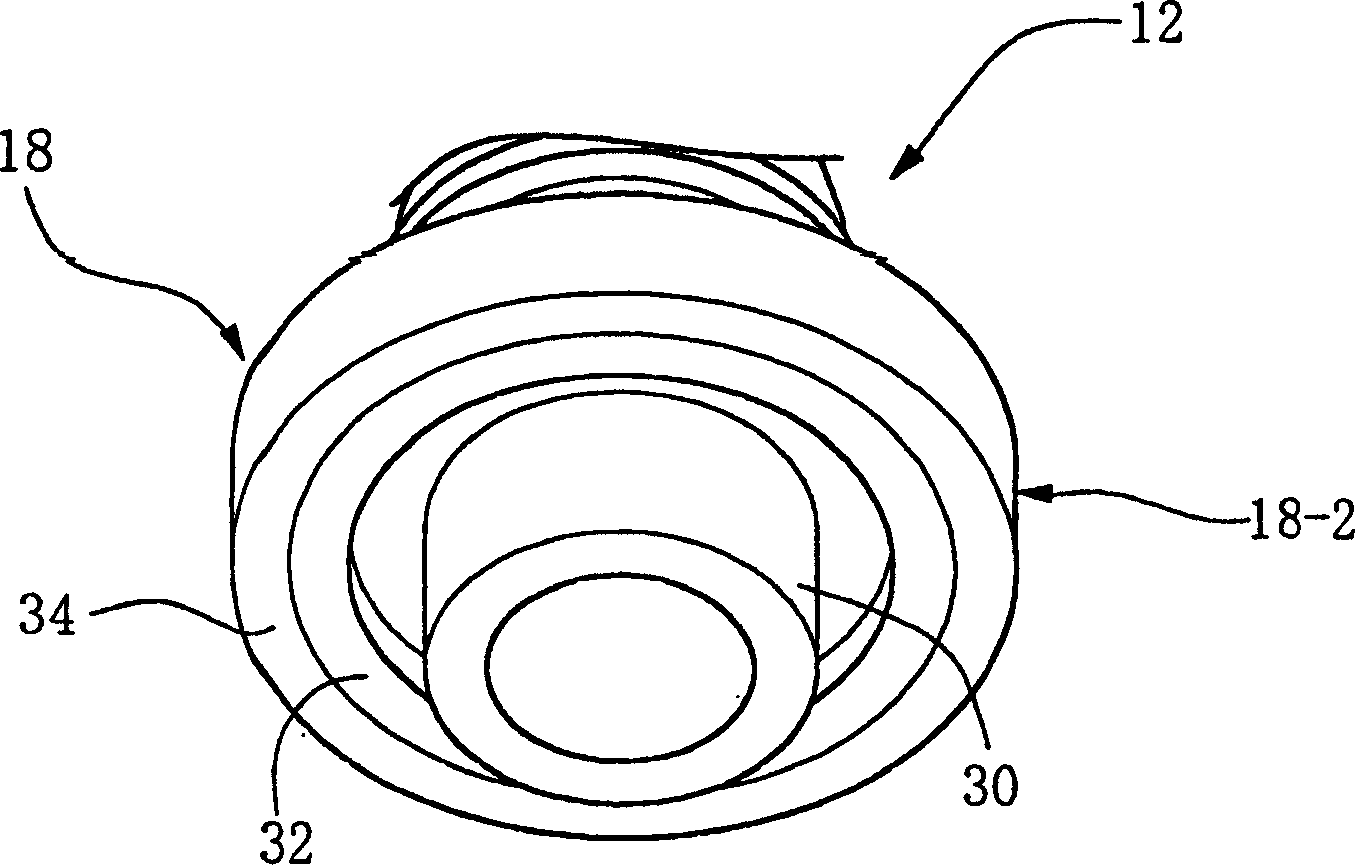

Welding joint of fuel tank

InactiveCN1763407AExcellent resistance to fuel seepageHigh strengthUnderstructuresNon-disconnectible pipe-jointsFuel tankEngineering

A fusion joint has a cylindrical portion as a connecting portion and an annular welded portion arranged at a base end portion of the cylindrical portion, the welded portion configured to be thermally welded to a resin-made fuel tank. The cylindrical portion is constituted by using a resin alloy material in which modified high-density polyethylene obtained by introducing a functional group with a high affinity for the hydroxyl group of an ethylene-vinyl alcohol copolymer and ethylene-vinyl alcohol The copolymer is alloyed, and at least the welded portion includes an inner layer using the resin alloy material and an outer layer using at least one of high-density polyethylene and modified high-density polyethylene and covering the inner layer on the outside.

Owner:SUMITOMO RIKO CO LTD

Method for depositing low-stress coating by utilizing supersonic speed laser

ActiveCN104005021AIncrease spray thicknessIncrease internal stressMetallic material coating processesCrack freeHardness

The invention discloses a method for depositing a low-stress coating by utilizing supersonic speed laser. Hard phase particles and soft phase particles with appropriate particle size and shape are subjected to ball-milling mixing in certain proportion, and the mixed powder particles are subjected to supersonic speed laser deposition on pretreated matrixes of different materials and shapes, so that the low-stress coating is obtained. According to the technical scheme, the soft phase is uniformly distributed in a high hardness coating, great plastic deformation is formed, and internal stress in the coating can be absorbed and eliminated, so that a compact and crack-free coating is obtained; besides, on the interface of the coating and the matrixes, a soft phase enrichment layer is generated in situ, transition action on bonding of the high hardness coating and the matrixes is realized, and interface bonding strength of the coating / matrixes is obviously improved.

Owner:ZHEJIANG UNIV OF TECH +1

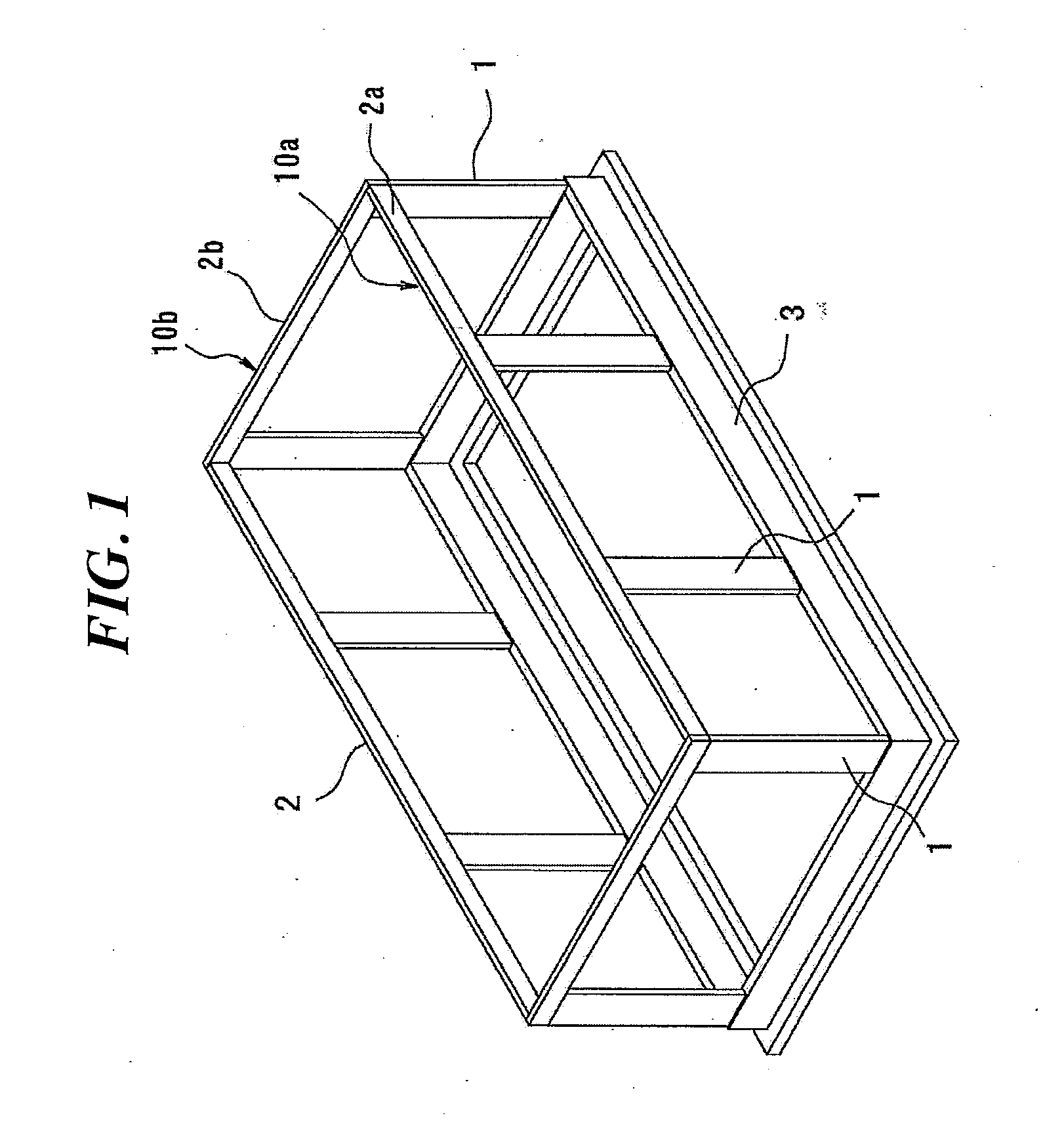

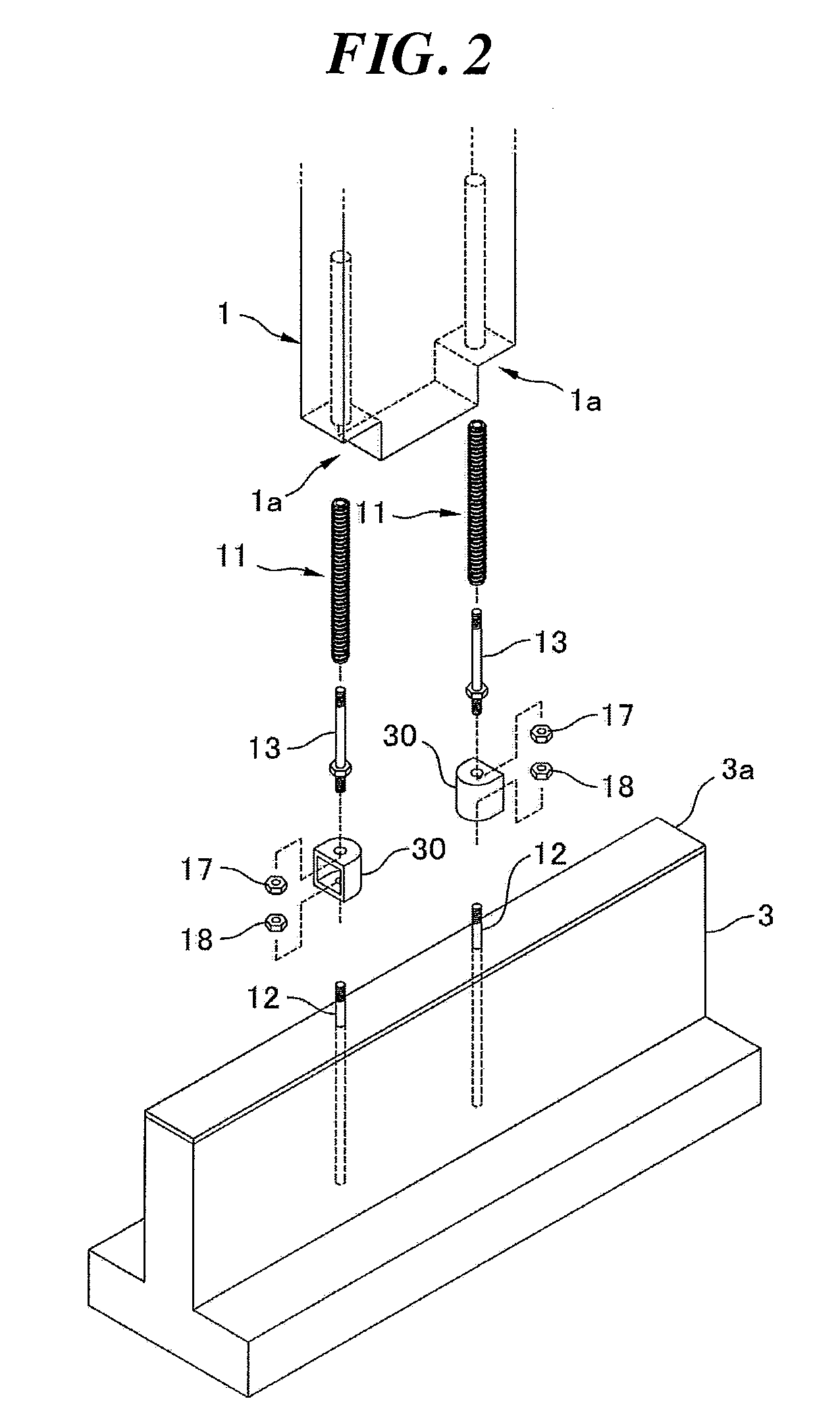

Wooden Member Joint Structure

ActiveUS20140093306A1Prevent large stressImprove load-bearing capacityYielding couplingRopes and cables for vehicles/pulleyEngineeringFlange

A wooden member joint structure having high strength against load repeatedly applied in opposite directions, with improved work efficiency in joining the wooden member to a mating member. A screw member having spiral protrusion on its outer peripheral surface and an axial hollow hole is threaded axially into a wooden column. A distal end of joint bolt is threadedly engaged with bottom of the hollow hole. The joint bolt has an integrally formed flange, and the flange is threaded into the column together with the screw member with its contact surface firmly pressed against end face of the screw member. A joint device is clamped between a fastening nut threadably mounted on a proximal end of the joint bolt and the flange and coupled to the screw member via the joint bolt. The joint device is secured to a foundation by an anchor bolt protruding therefrom and a fastening nut.

Owner:SUMITOMO FORESTRY CO LTD

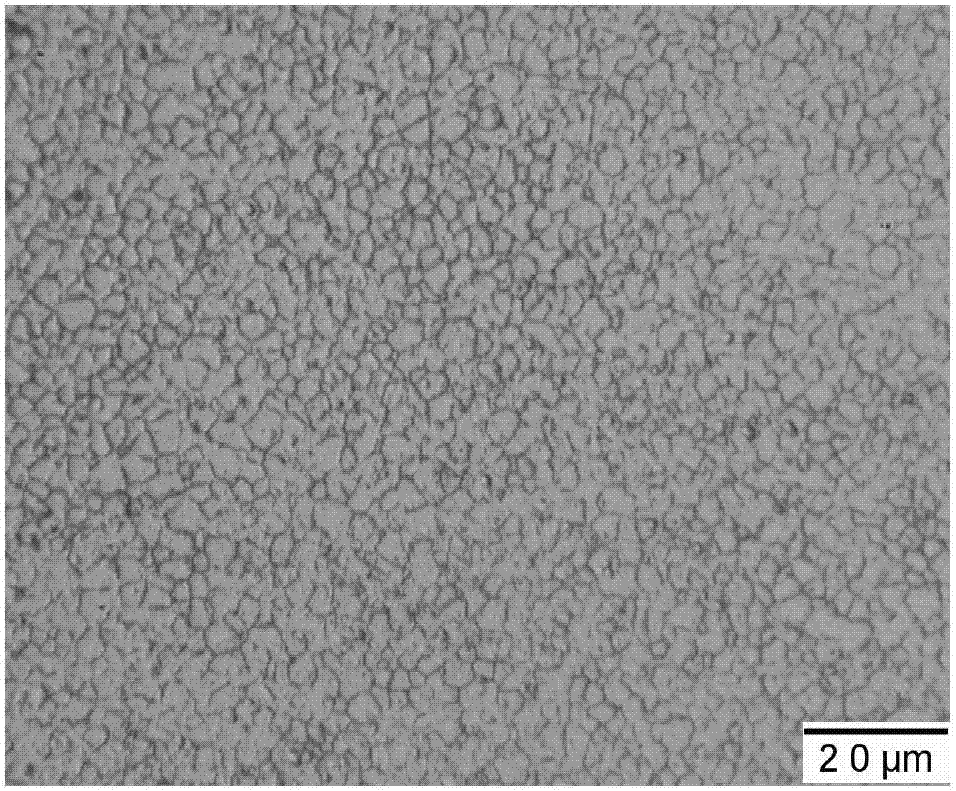

Heat treatment process of bolt processing

InactiveCN102995029AFine grainSmall reduction in areaFurnace typesQuenching agentsThermal insulationUltimate tensile strength

The invention relates to a heat treatment process of bolt processing. The process comprises the following steps: preheating a fastener to be treated, and putting the preheated fastener into a carburizing furnace for carburizing; and thermal insulating in a neutral salt bath furnace, and quenching, wherein the quenching is carried out in two stages, in the first stage, uniform-speed quenching is carried out; and in the second stage, constant-temperature quenching is conducted for tempering treatment; and the tempering treatment is thermal insulation in a tempering furnace and then air cooling to normal temperature. By adopting the above technical scheme, the metallurgical structure is uniform and relatively round and smooth, and crystal grains are small, which is more beneficial to increasing the intensity in cases of plastic deformation, the reduction of cross section is small, and the scrap rate is low.

Owner:NINGBO TENGLING IND & TRADE

Magnesium alloy profile and preparation method and application thereof

PendingCN107999551AImprove organizational structureImprove corrosion resistanceSurgeryExtrusion control devicesUltimate tensile strengthMaterials science

The invention relates to a magnesium alloy profile and a preparation method and application thereof. Grains in the magnesium alloy include first phase grains and second phase grains dispersely distributed between the first phase grains. The first phase grains are micro grains. The size of the second phase grains is 50-230 nm. Compared with a profile prepared through a traditional casting method, the magnesium alloy profile has the characteristics that the tissue structure is refined, the first phase grains and the second phase grains are uniform, and the size of the second phase grains is 50-230 nm. The magnesium alloy profile has the advantages of high corrosion resistance, high tensile strength, high yield strength and high plastic deformation and can meet the requirement for medical instruments implanted in human bodies.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

Low-cast and superplasticity titanium alloy

A low-cost super-plastic titanic alloy consists of Al 3.0-6.0wt%, V 2.0-4.0wt%, Mo 1.0-3.0wt%, iron 0.5-2.0wt%, Cr 0.5-2.0wt%. It achieves low cost and easy plastic deformation.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

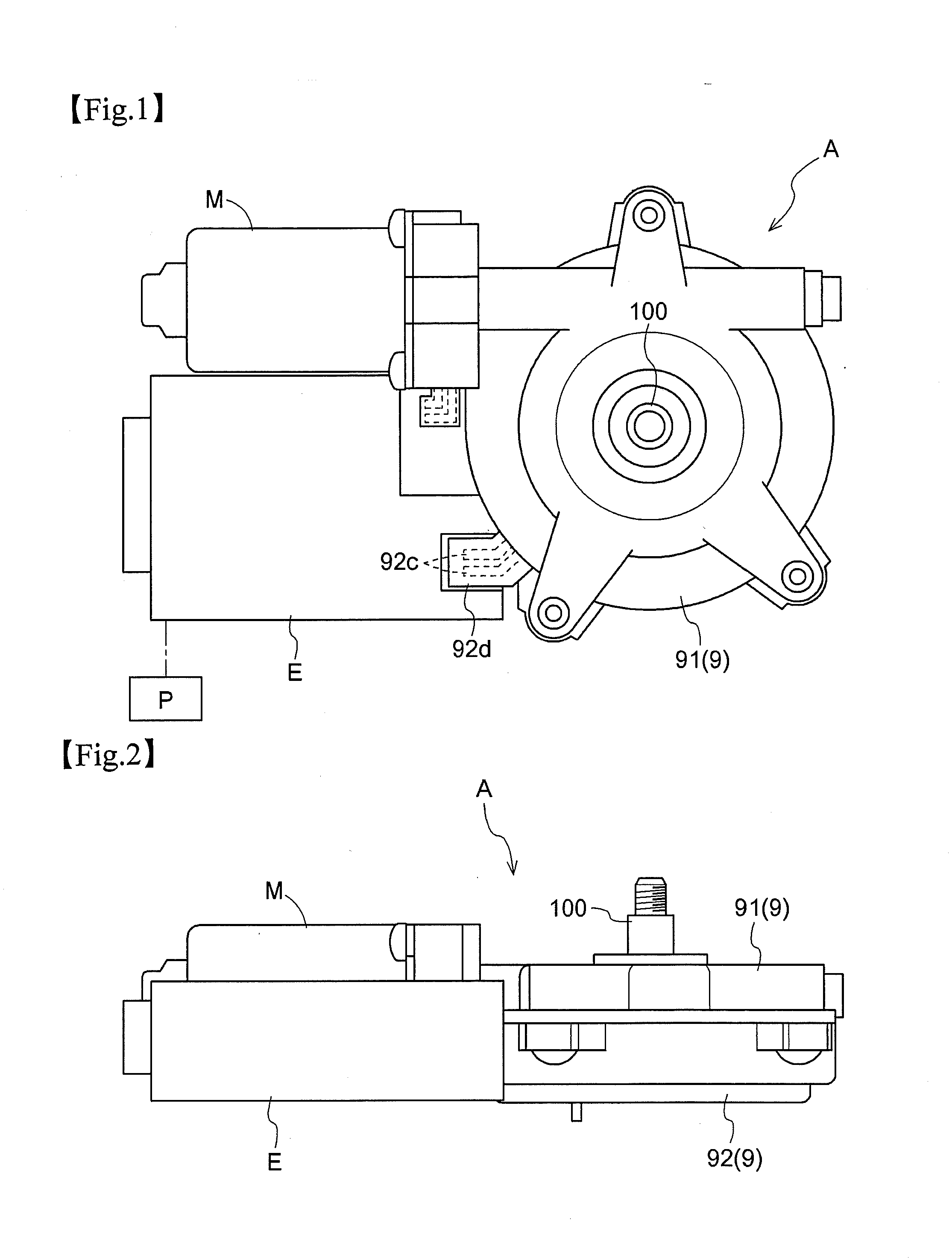

Electromagnetic clutch

InactiveUS20110227436A1Improve plastic deformationDelay minimizationMagnetically actuated clutchesPower-operated mechanismRotational axisElectromagnetic clutch

An electromagnetic clutch includes a motor, a worm wheel rotatably driven by a motor, a rotor having an electromagnetic coil and rotatable about a same rotational axis as the worm wheel, an armature that is mounted to the worm wheel and is pulled into contact with the rotor upon application of electric power to the electromagnetic coil, so that the armature is rotated with the rotor, a cover member configured to cover the rotor and the armature, and a power supply mechanism disposed between the cover member and the rotor and connected to a power source for supplying power to the electromagnetic coil. The power supply mechanism includes a fixed frame body having a first power supply portion for receiving the power from the power source and fixed to the cover member, a rotary frame body having a second power supply portion in contact with the first power supply portion for supplying the power to the electromagnetic coil, the rotary frame body being fixed to the rotor and rotatably engaged with the fixed frame body; and a plate-like conducting member provided in the cover member, the conducting member coming into contact with a portion of the first power supply portion projecting from the fixed frame body.

Owner:AISIN SEIKI KK

Method for preparing 160MPa grade low-yield-point building aseismicity steel

ActiveCN104087830ASolve heatingSolve the contradiction between high temperature final rolling and coilingChemical compositionLaminar cooling

The invention discloses a method for preparing 160MPa grade low-yield-point building aseismicity steel. The steel comprises the following chemical components in percentage by mass: 0.001-0.005% of C, less than or equal to 0.02% of Si, 0.10-0.8% of Mn, 0.01-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, 0.01-0.08% of Ti, 0.0005-0.001% of B, and the balance of Fe and inevitable impurities. Through a series of processes of fine smelting, continuous casting, heating, rough rolling, electromagnetic sensation heating, fine rolling, laminar cooling, coiling and the like, the yield strength of the 160MPa grade low-yield-point building aseismicity steel achieves the 140-180MPa grade, the ductility is greater than 50%, good plastic deformation and impact toughness are achieved, and meanwhile an alloy is relatively low in cost and good in welding performance and low-cycle fatigue property, and the process is easy to achieve.

Owner:SHOUGANG CORPORATION

Manufacturing method of carbon steel wire with diameter of 0.05 mm

ActiveCN109940054AImprove plastic deformationInhibit expansionFurnace typesHeat treatment furnacesWork in processUltimate tensile strength

The invention discloses a manufacturing method of a carbon steel wire with a diameter of 0.05 mm. The manufacturing method comprises the steps of raw material selection-primary semi-finished steel wire cold drawing-primary semi-finished steel wire continuous heat treatment-secondary semi-finished steel wire cold drawing-secondary semi-finished steel wire continuous heat treatment-ternary semi-finished steel wire cold drawing-ternary semi-finished steel wire continuous heat treatment-finished steel wire drawing-finished steel wire inspection. The stress is eliminated to recover plasticity through the drawing combination mode and three times of heat treatment; through optimization of heat treatment parameters and specific drawing routes, the metal deformation under high compression ratio isadapted to, so that the smooth drawing process can be effectively guaranteed; through plastic deformation in the whole process, the diameter of the steel wire can be smoothly reduced; meanwhile, the tensile strength of a product is continuously improved, and the strength reaches above 2300 MPa to meet the requirements of appearance, surface quality, mechanical performances and toughness of the steel wire product; and meanwhile, the batch production is realized, and the product quality is guaranteed.

Owner:GUIZHOU WIRE ROPE

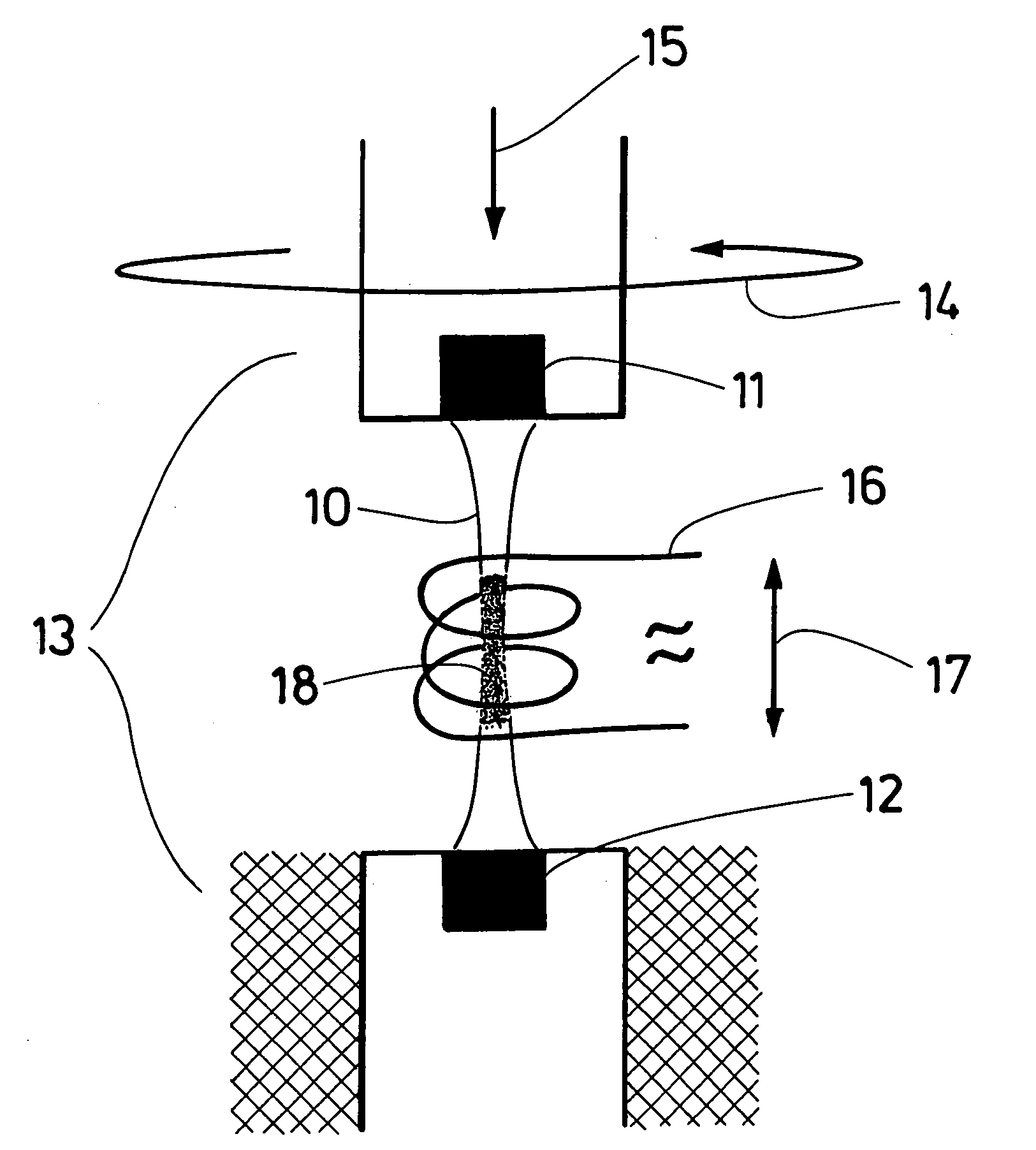

Method for the treatment of metallic materials

InactiveUS7115177B2Improve textureImproved texture consolidationForging press detailsMetallic materialsTransition temperature

In a method for the treatment of metallic materials especially for the consolidation of the texture of the materials, a blank of the metallic material is heated to a transformation temperature and the blank is then subjected to twisting preferably while, at the same time, being compressed. In this way, the texture can be refined to a large degree in a simple and inexpensive manner.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

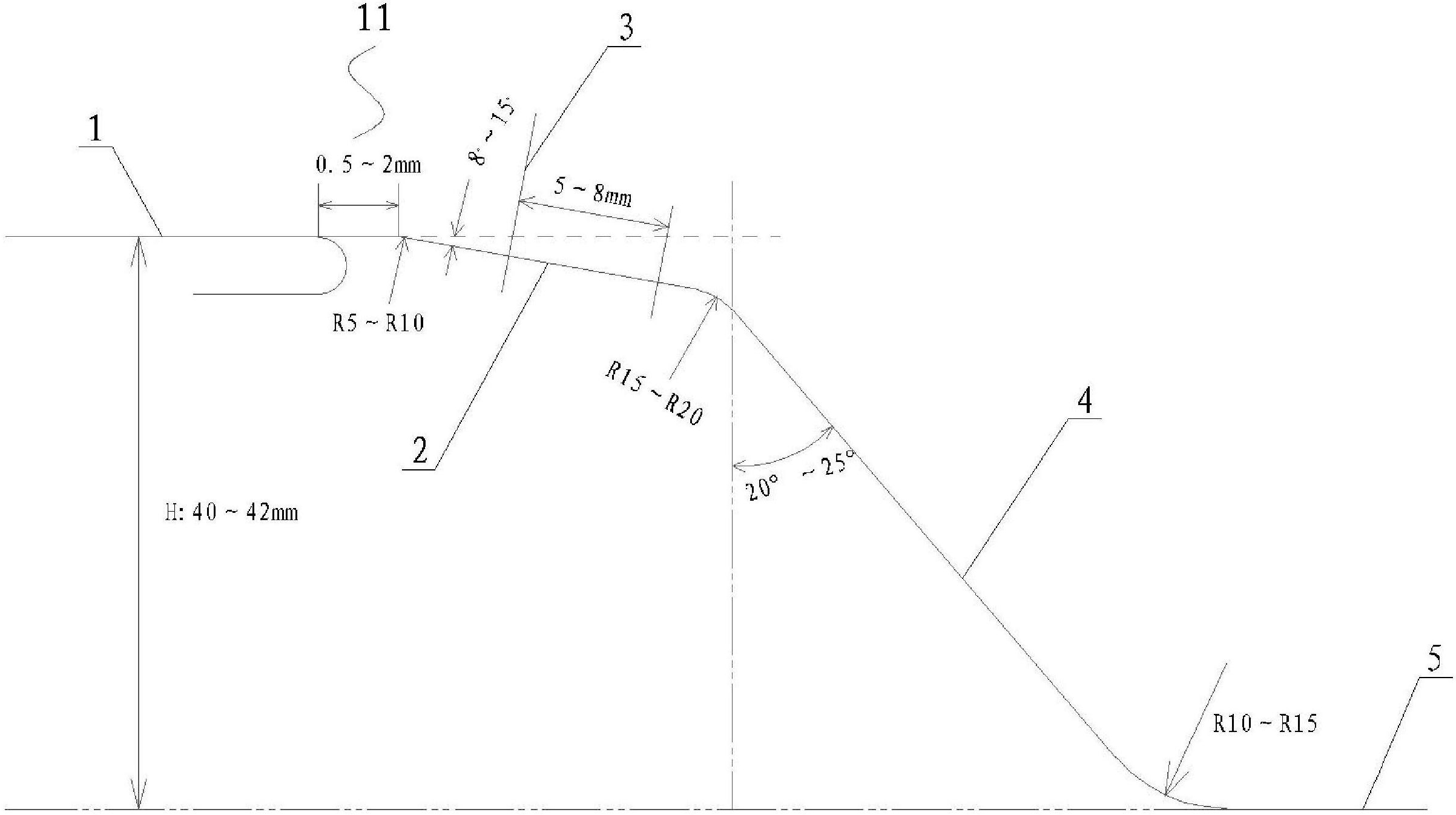

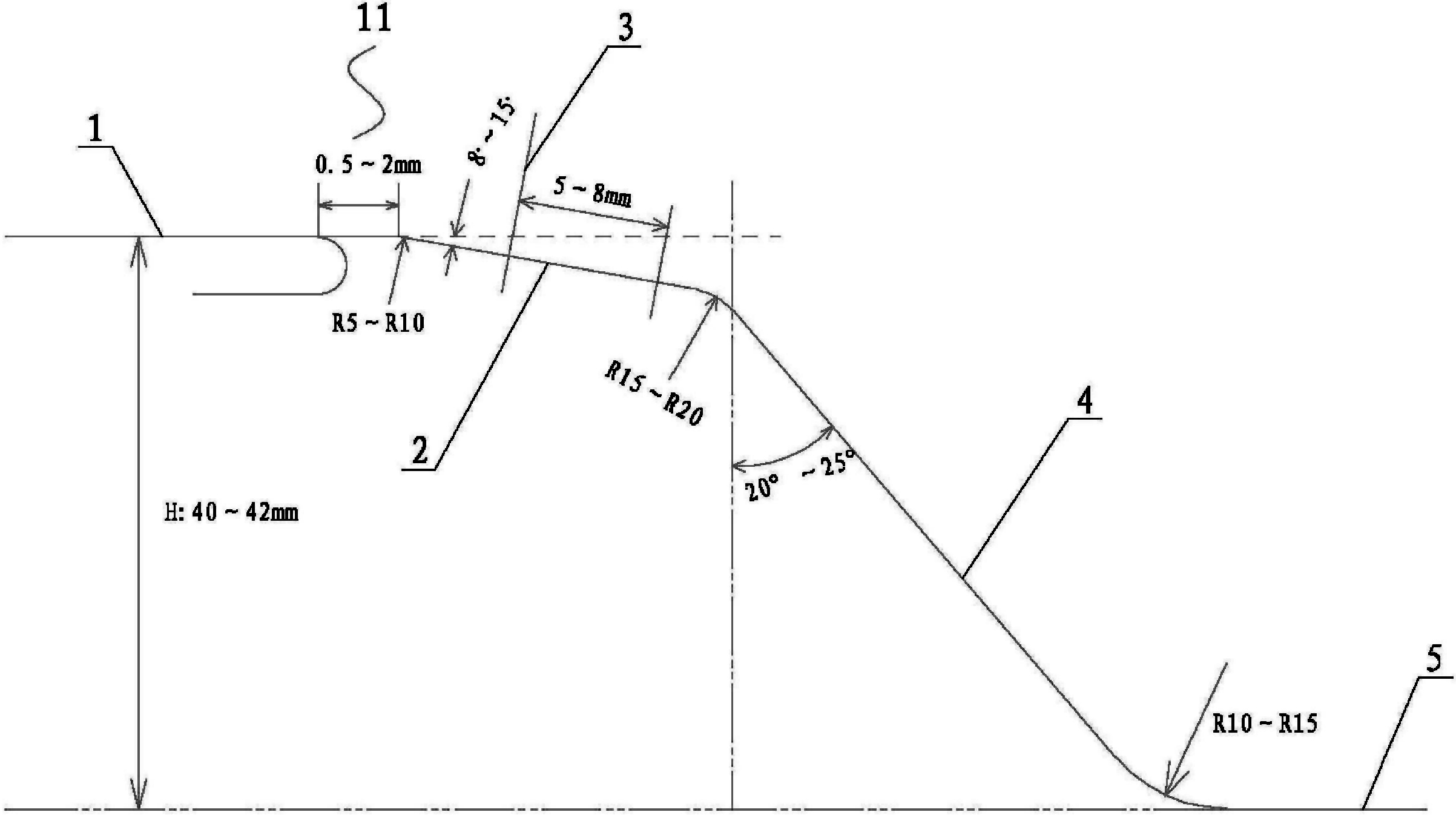

Manufacturing method of drawing die face on handle of outboard door panel of automobile and outboard door panel of automobile

The invention discloses a manufacturing method of a drawing die face on a handle of an outboard door panel of an automobile. The manufacturing method comprises the following steps that: when the drawing die face on the handle of the outboard door panel of the automobile is manufactured, a border of an A face (1) of an area of the handle of the outboard door panel is extended along self curvature to form a border extending section (11); the border extending section (11) is intersected with a straight-line section (2) which forms an included angle of 8 degrees-15 degrees with the A face (1); the straight-line section (2) is continuously extended to form a drawing wall (4); the drawing wall (4) and a punching direction form an included angle of 20 degrees-25 degrees; and the drawing wall (4) is extended to be intersected with a binder face (5). The drawing die face belongs to the field of components of the outboard door panel of the automobile. The invention also disclosed the outboard door panel of the automobile. The phenomenon that the A face on the handle of the outboard door panel is easy to deform is effectively improved, the plasticity deformation rate of the outboard door panel is improved, and the rigidity is improved.

Owner:CHERY AUTOMOBILE CO LTD

Thermal magnetic multi-field coupling electronic control magnetofluid compression molding 3D printing forming device and method

The invention discloses a thermal magnetic multi-field coupling electronic control magnetofluid compression molding 3D printing forming device and a method. The device is mainly composed of a conveying system, a temperature control system, a control system, a printing system and the like. The conveying system is composed of a motor, a conveying belt, a conveying guide rail and the like. The temperature control system is composed of an electromagnetic heater and a temperature sensor, the temperature sensor is connected with the electromagnetic heater, the temperature of magnetofluid is controlled by the temperature sensor, and the magnetofluid is made to reach optimized thermal molding forming temperature. The control system achieves control of an integrated system. The printing system is composed of a drawing meter, a permanent magnet, a magnetofluid vessel, the magnetofluid and the like. According to the thermal magnetic multi-field coupling electronic control magnetofluid compression molding 3D printing forming device and the method adopting the device, thermal molding forming is carried out on foam materials through high-temperature magnetofluid wave crests generated with the drawing meter as the center, the 3D printing technology is adopted, a compacting tool set or roller embossing equipment is avoided, cost is reduced, efficiency is improved, and patterns in any complex shape can be formed.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com