Warm electromagnetic forming device and method of skin piece

A technology for electromagnetic forming and skin parts, which is applied in the field of sheet metal forming, can solve problems such as the forming of skin parts that are not suitable for double curvature or multi-curvature, and achieves less energy required for equipment, high forming efficiency, and good forming accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

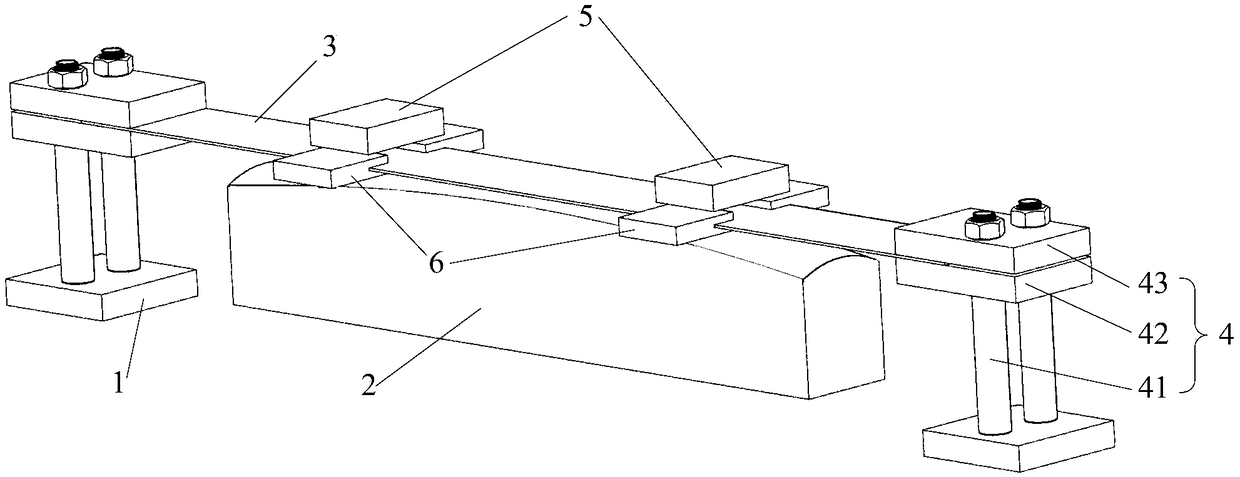

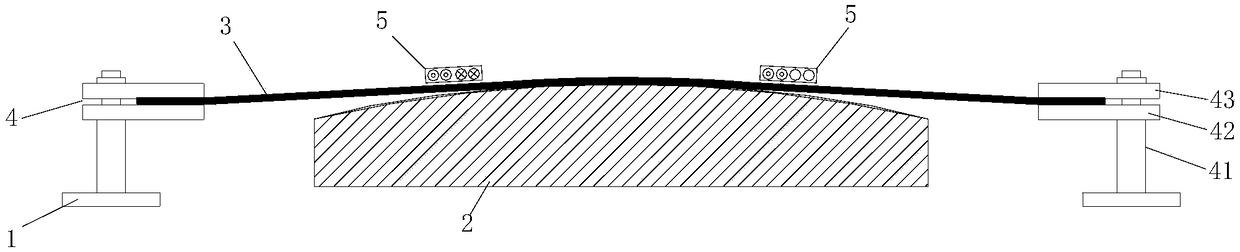

[0039] Such as Figure 1 to Figure 7 As shown, the warm electromagnetic forming device for skin parts of this embodiment includes a base plate 1, a mold 2, a sheet material 3 and a splint assembly 4 for fixing and clamping the sheet material 3. The splint assembly 4 is arranged on the base plate 1, The plate 3 is fixedly clamped between the splint components 4, and also includes a discharge coil 5 and a heating element 6 for heating the plate 3, the discharge coil 5 is arranged above the plate 3, and the heating element 6 is arranged on the plate 3 sides. The combination of stretching and electromagnetic forming does not require the complex stretching structure and complicated process required by traditional stretching, and can reduce the requirements of equipment for discharge energy and coil strength. The heating element can increase the local temperature of the sheet metal, which is conducive to plastic deformation. , not easy to rebound, easy to control the forming accura...

Embodiment 2

[0054] Such as Figure 8 As shown, the warm electromagnetic forming device of the skin part of this embodiment is basically the same as that of Embodiment 1, the main difference is that in this embodiment, the mold 2 is a concave mold with a single curved surface, and during the forming process, The blank 3 flows into the die and adheres to the forming surface of the die.

[0055] In other embodiments, the forming surface of the mold 2 may be multi-curved.

[0056] In other embodiments, the heating element 6 can also be a thermal radiation heating device or an electromagnetic induction heating device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com