An electromagnetic-fluid impact composite forming device and forming method for pipe fittings

A technology of composite forming and pipe fittings, which is applied in the field of material processing and forming, can solve the problems of difficult to achieve precise shape control of parts, difficult to control the forming process, fast deformation speed, etc., and achieve the effect of improving forming efficiency and increasing forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

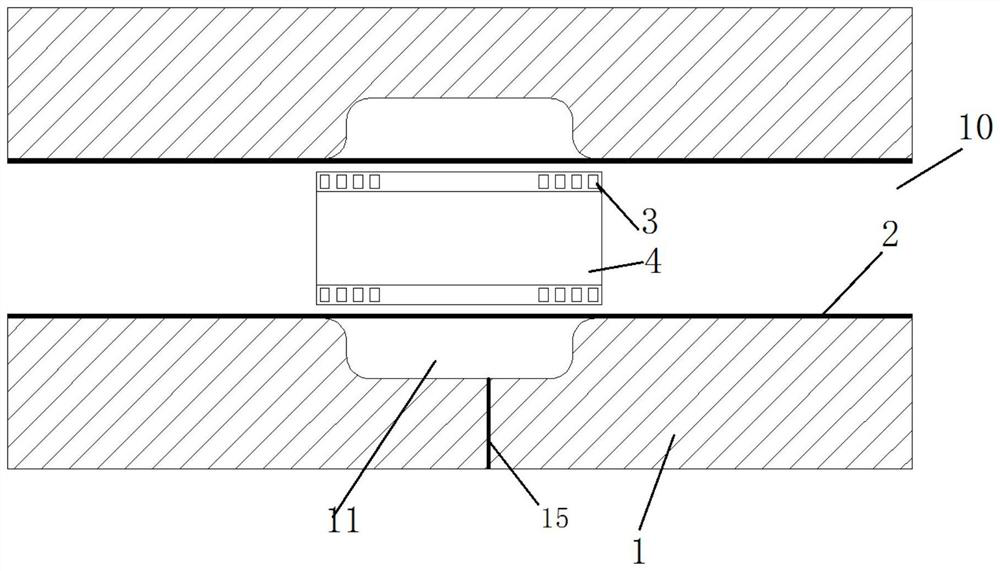

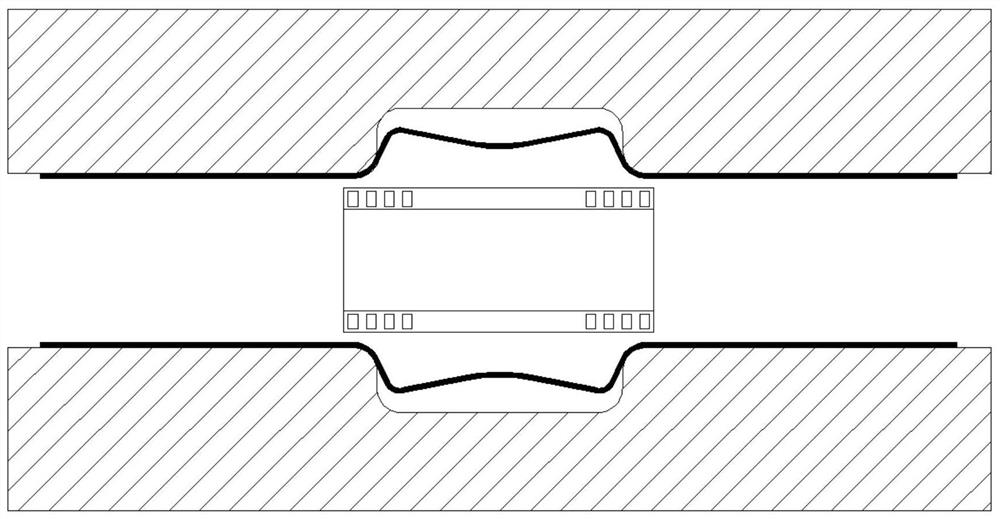

[0039] like Figure 1-5 As shown, the embodiment of the present invention firstly discloses an electromagnetic-fluid impact composite forming device for pipe fittings, comprising a mold 1, wherein a forming hole 10 that can fit the outer wall of the pipe fitting 2 is provided in the mold 1, and the side wall of the forming hole 10 is provided with a forming hole 10. A forming cavity 11 is provided. During the forming process, the inner side wall of the pipe fitting 2 will receive electromagnetic force to expand outward, and finally fit with the bottom surface of the forming cavity 11. The forming cavity 11 is provided with an outwardly penetrating air hole 15 for the pipe fitting. When the wall is expanded outwardly by electromagnetic force, there is exhaust gas. The forming hole 10 is provided with a bulging coil 3 that is installed in the pipe fitting 2 and is opposite to the forming cavity 11. The bulging coil 3 is an electromagnetic forming coil, and at least One side is d...

Embodiment 2

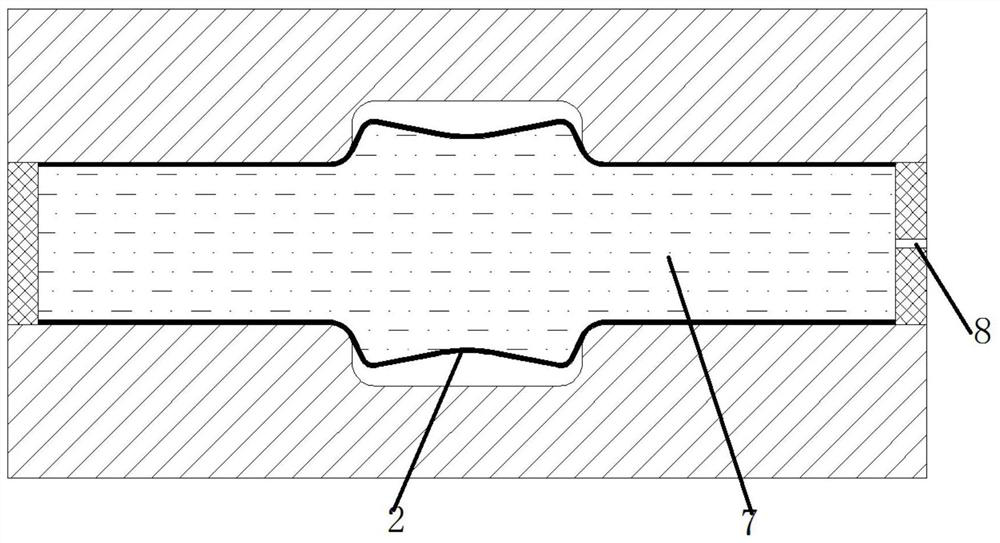

[0043] like Figure 6-9As shown, the electromagnetic-fluid impact composite forming device for pipe fittings according to the embodiment of the present invention is basically the same as that of the first embodiment, except that the sealing member includes a first push block 5 and a second push block 6 made of metal, The first push block 5 and the second push block 6 are sealed and slid on both ends of the forming hole 10 respectively, and a side push coil 9 is provided on the outer side of at least one of the first push block and the second push block 6. In this embodiment Among them, the outer side of the first push block 5 and the second push block 6 are provided with a side push coil 9, and the side push coil 9 is an electromagnetic forming coil, so that when the fluid injection hole 8 is injected with fluid, it can be sealed The pressure exerted by the coil 9 on the first push block 5 and the second push block 6 squeezes the fluid 7, thereby driving the tube 2 to deform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com