Electromagnetic impact device for controlling welding heat cracking and deformation

A thermal cracking and electromagnetic technology, applied in the direction of welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems such as the difficulty of quantifying the size of the impact force, the inability to reduce the lateral shrinkage of the weld seam, and the large vibration of the hammerhead deflection. Simple, easy mechanical force transmission, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

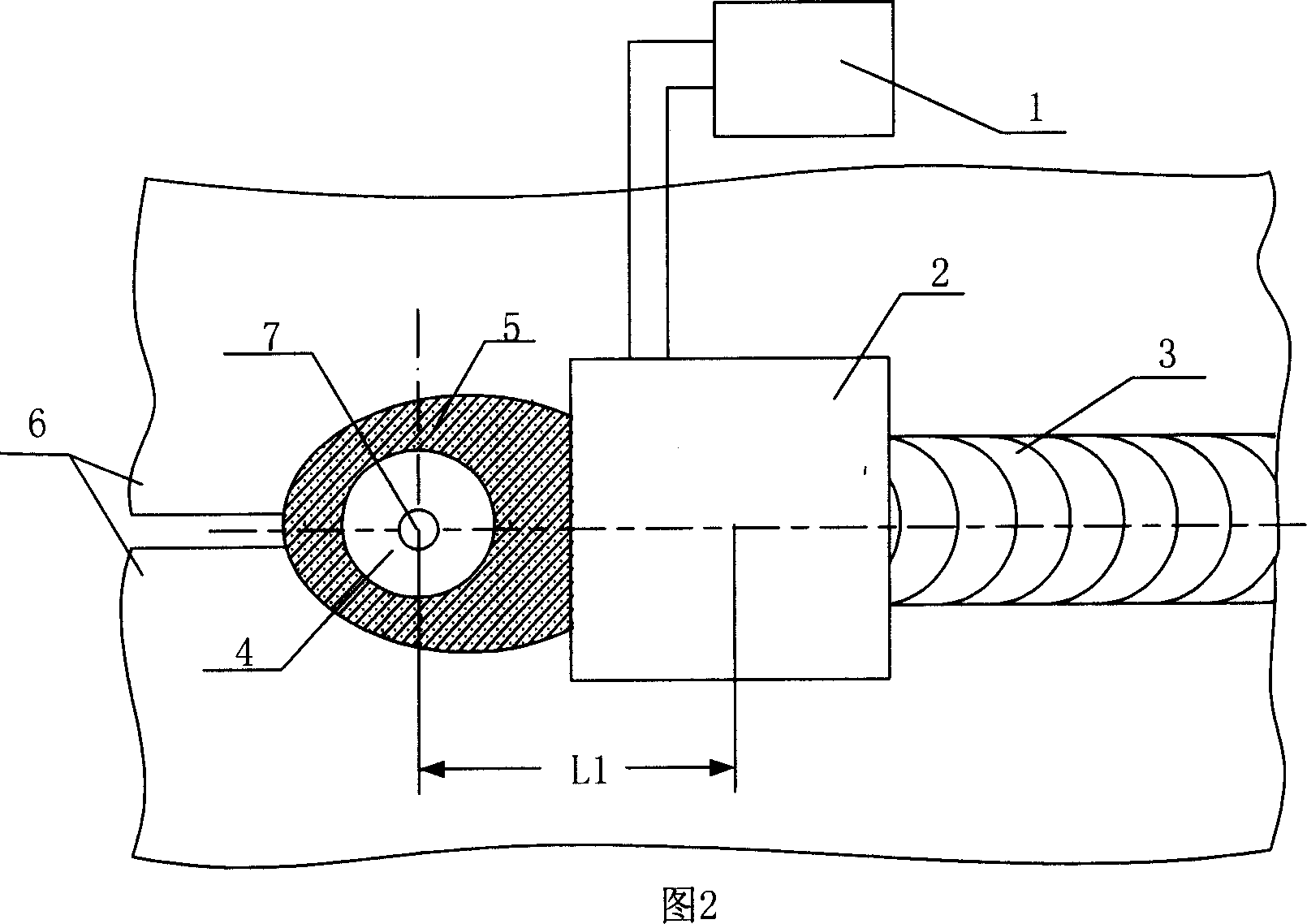

[0007] Specific embodiment one: this embodiment is described in conjunction with Fig. 1, Fig. 2, Fig. 3, Fig. 4, and this embodiment is made up of pulse discharge circuit 1, coil 2; The coil 2 is set directly above the welding seam 3, the distance L2 between the lower surface of the coil 2 and the upper surface of the welding seam 3 is 2-5mm, and the distance L1 between the center of the coil 2 and the center of the welding torch 7 It is 25-60mm.

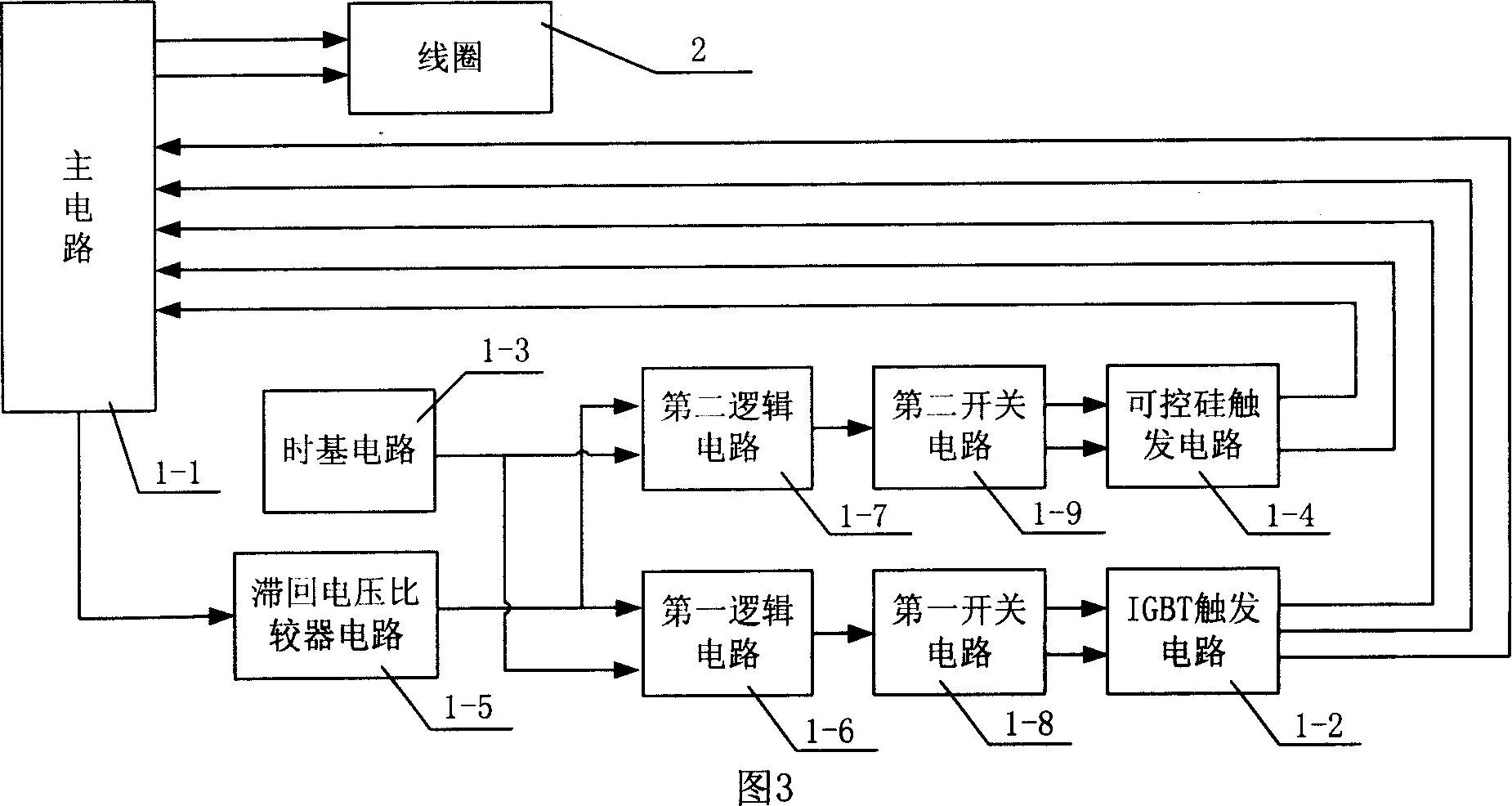

[0008] Pulse discharge circuit 1 is composed of main circuit 1-1, IGBT trigger circuit 1-2, time base circuit 1-3, thyristor trigger circuit 1-4, hysteresis voltage comparator circuit 1-5, first logic circuit 1- 6. The second logic circuit 1-7, the first switch circuit 1-8 and the second switch circuit 1-9 are composed;

[0009]The voltage signal output end of the main circuit 1-1 is connected to the input end of the hysteresis voltage comparator circuit 1-5, and the output end of the hysteresis voltage comparator circuit 1-5 is co...

specific Embodiment approach 2

[0011] Specific Embodiment 2: This embodiment is described in conjunction with Fig. 1 and Fig. 2. The difference between this embodiment and Embodiment 1 is that the distance L1 from the center of the coil 2 to the center of the welding torch 7 is 25-45 mm, and other components and structures are the same as those of Embodiment 1. same.

specific Embodiment approach 3

[0012] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 and Fig. 2. The difference between this embodiment and embodiment two is that the distance L1 from the center of the coil 2 to the center of the welding torch 7 is 26 mm, and other components and structures are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com