Magnesium alloy profile and preparation method and application thereof

A magnesium alloy and profile technology, applied in metal extrusion control equipment, metal processing equipment, metal extrusion, etc., can solve the problems of low tensile strength, low yield strength, poor corrosion resistance of magnesium alloy profiles, etc., to achieve The effect of high tensile strength, high yield strength and high plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention also provides a preparation method of the magnesium alloy profile.

[0040] A method for preparing a magnesium alloy profile, comprising the steps of:

[0041] Provide magnesium alloy blanks,

[0042] The magnesium alloy billet is placed in a mold, and the magnesium alloy billet is reciprocally extruded to obtain a magnesium alloy profile.

[0043] When reciprocating extrusion, the positive pressure is 200KN-500KN, and the back pressure is 200KN-500KN. In this way, the grains can be refined, and the first phase and the second phase can be uniformly redistributed in the magnesium alloy profile.

[0044] Preferably, the magnesium alloy billet is machined before being placed in the mold.

[0045] Wherein, the reciprocating extrusion is extruding with a reciprocating extrusion die containing a necking area inside, so that the magnesium alloy billet is also subjected to the force of the necking area during the reciprocating extrusion process.

[0046] Where...

Embodiment 1

[0066] Mg-Zn-Y-Nd magnesium alloy ingots were prepared by smelting technology. During the smelting process, 1840 g of high-purity magnesium ingots; 60 g of high-purity zinc ingots; 50 g of Mg-25wt% Y master alloy; 50 g of Mg-25wt% Nd master alloy were added. Wherein high purity refers to purity ≥ 99.95%.

[0067] then machined Cylindrical magnesium alloy blanks.

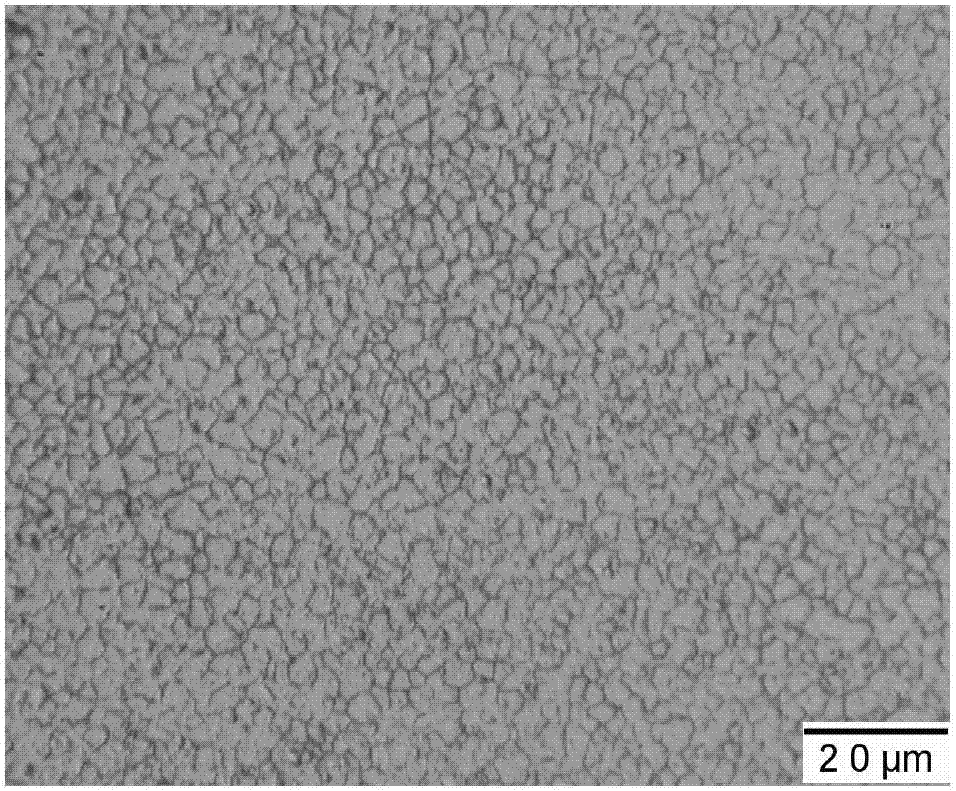

[0068] Then place the magnesium alloy billet in the mold, add an appropriate amount of molybdenum disulfide, and carry out two passes of extrusion processing to obtain the magnesium alloy profile. Wherein, the average grain size of the first phase is 3 μm, and the average grain size of the second phase is 210 nm. The parameters of the reciprocating extrusion process are: the positive pressure is 400KN; the back pressure is 400KN; the extrusion temperature is 543K; the extrusion ratio is 10:1; the extrusion rate is 2mm / s; the mold preheating temperature is 523K.

Embodiment 2

[0070] Utilize smelting technology to prepare the magnesium alloy ingot as in embodiment 1, then machining makes Cylindrical magnesium alloy blanks. Then place the magnesium alloy billet in the mold, add an appropriate amount of molybdenum disulfide, and carry out 4 passes of extrusion processing to obtain the magnesium alloy profile. Wherein, the average grain size of the first phase is 1 μm, and the average grain size of the second phase is 90 nm. The parameters of the reciprocating extrusion process are: the positive pressure is 300KN; the back pressure is 300KN; the extrusion temperature is 600K; the extrusion ratio is 25:1; the extrusion rate is 4mm / s; the mold preheating temperature is 640K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com