Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269results about How to "Avoid physical damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

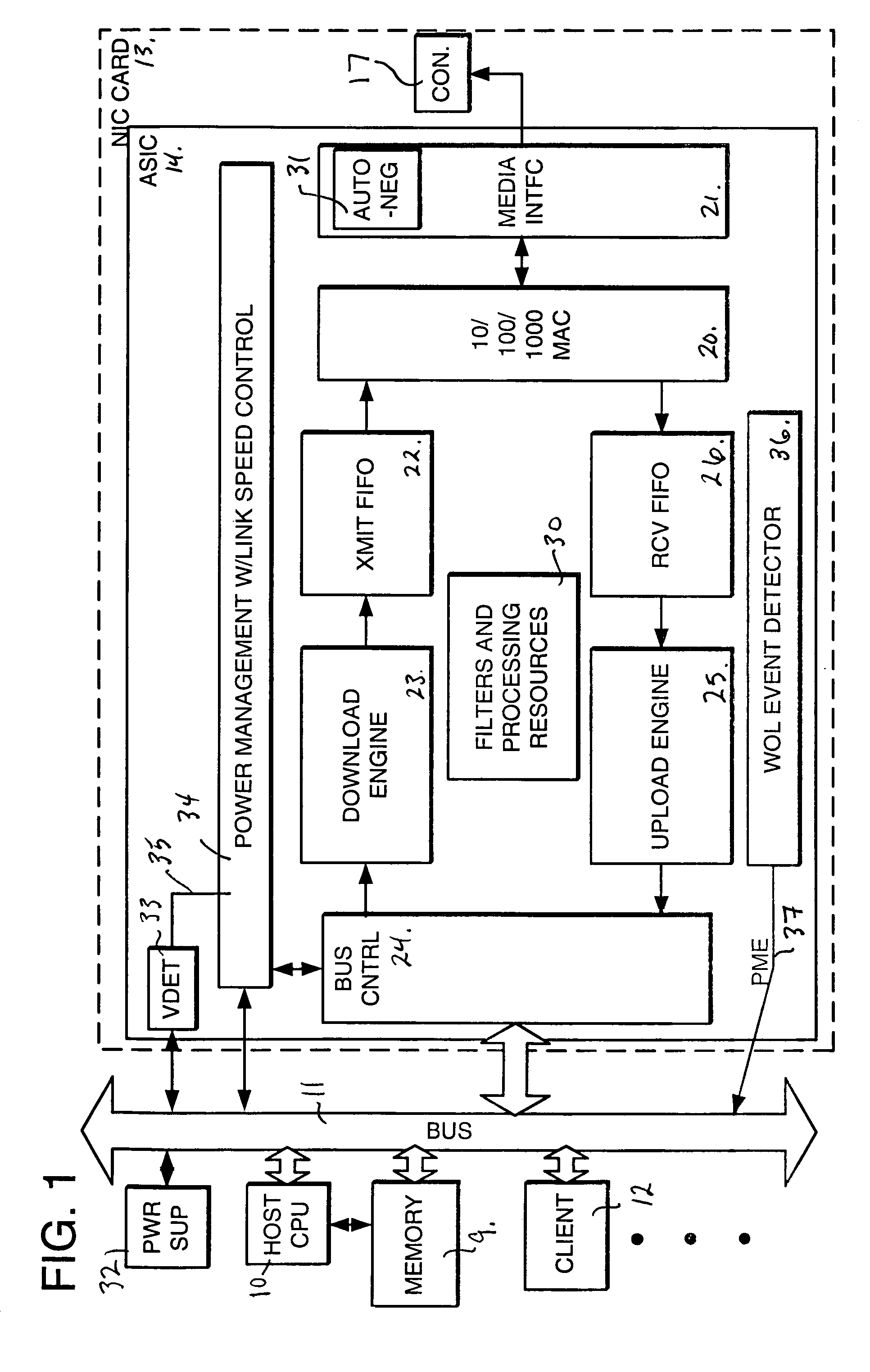

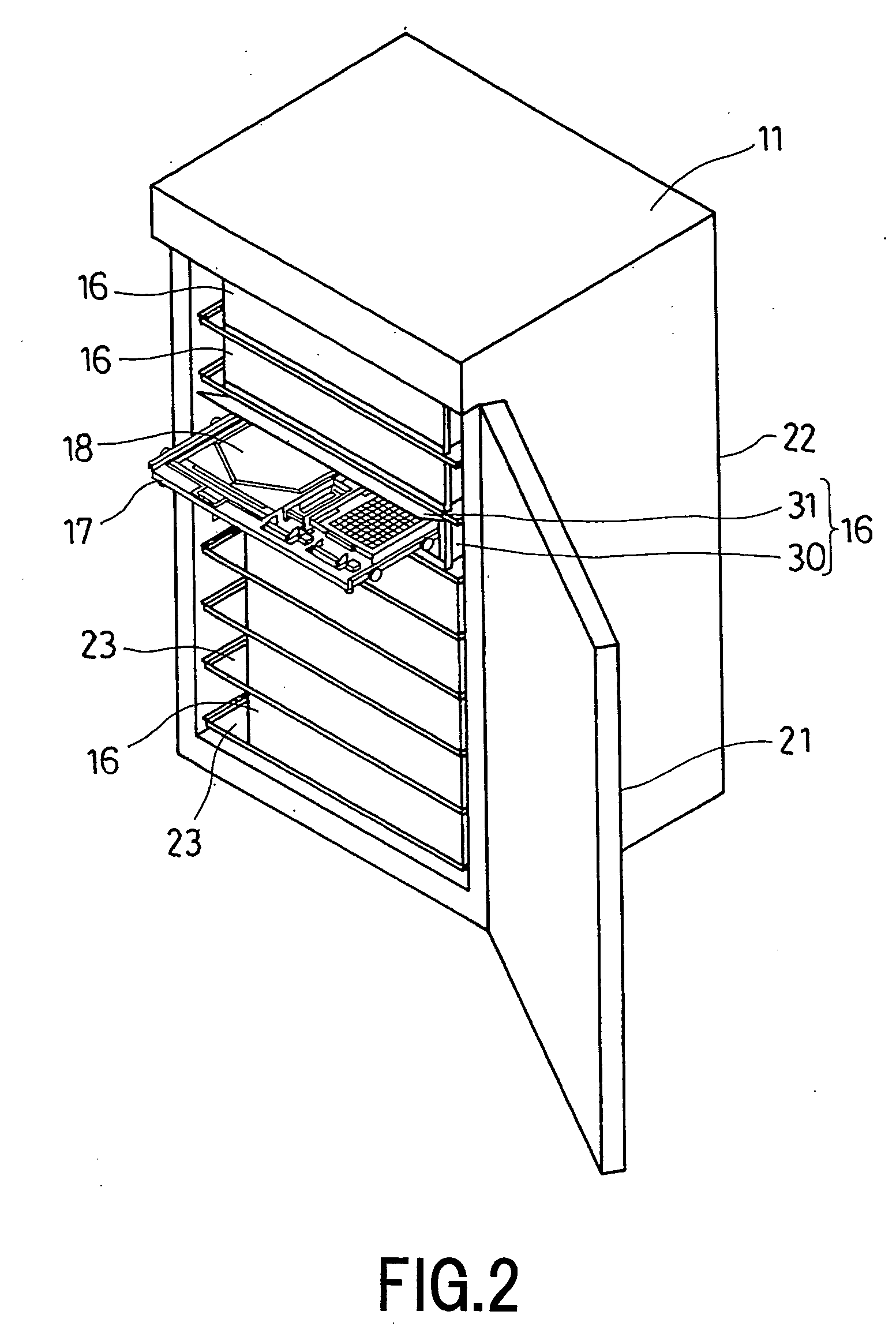

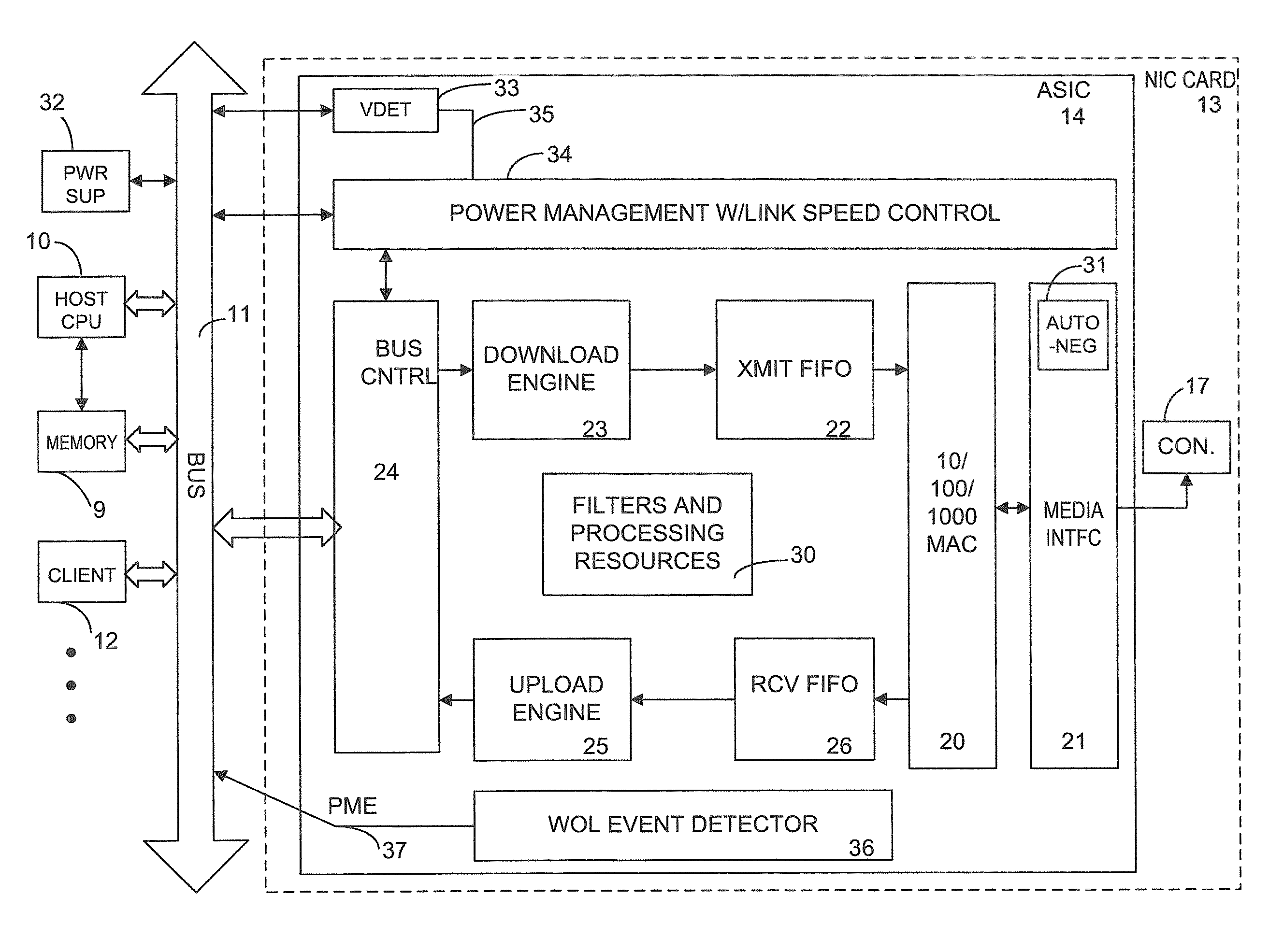

High speed network interface with automatic power management with auto-negotiation

ActiveUS7577857B1Avoid physical damageEnergy efficient ICTVolume/mass flow measurementLow speedNetwork media

A computer system comprises host processor and a network interface, wherein the host processor includes resources supporting a full power mode, a lower power mode and a power down mode, as seen in standard system bus specifications such as PCI and InfiniBand. The network interface includes a medium interface unit coupled to network media supporting a least high speed protocol, such as a Gigabit Ethernet or high-speed InfiniBand, and a lower speed protocol, such as one of 10 Mb and 100 Mb Ethernet or a lower speed InfiniBand. Power management circuitry forces the medium interface unit to the lower speed protocol in response to an event signaling entry of the lower power mode. In the lower power mode, the network interface consumes less than the specified power when executing the lower speed protocol, and consumes greater than the specified power when executing the high speed protocol. Logic in the network interface operates in the lower power mode, and uses the lower speed protocol to detect a pattern in incoming packets. In response to the detection of said pattern, the logic issues a reset signal to the host processor. Thus, the network interface operates as a wake-up device in the lower power mode, using the lower speed protocol.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

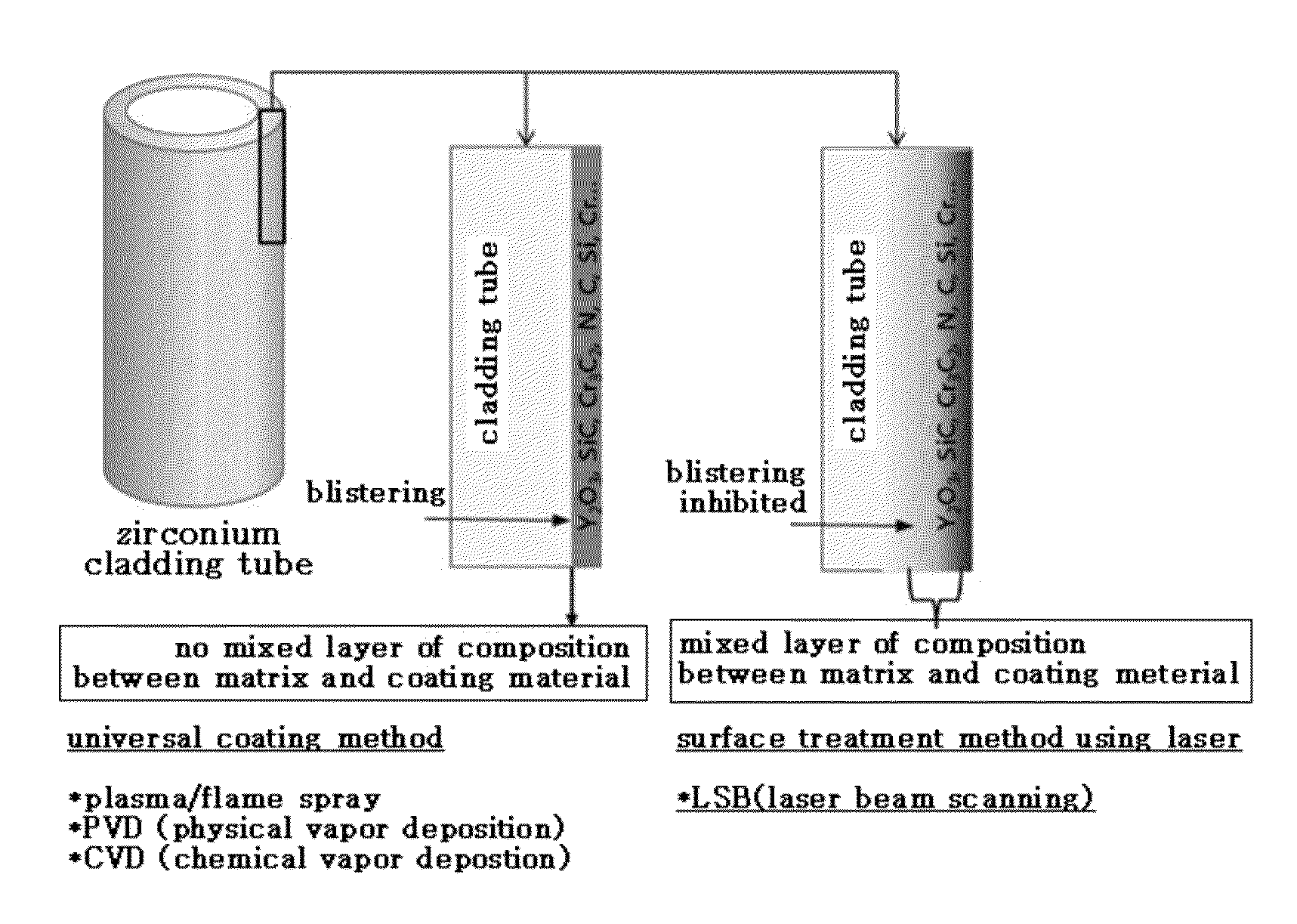

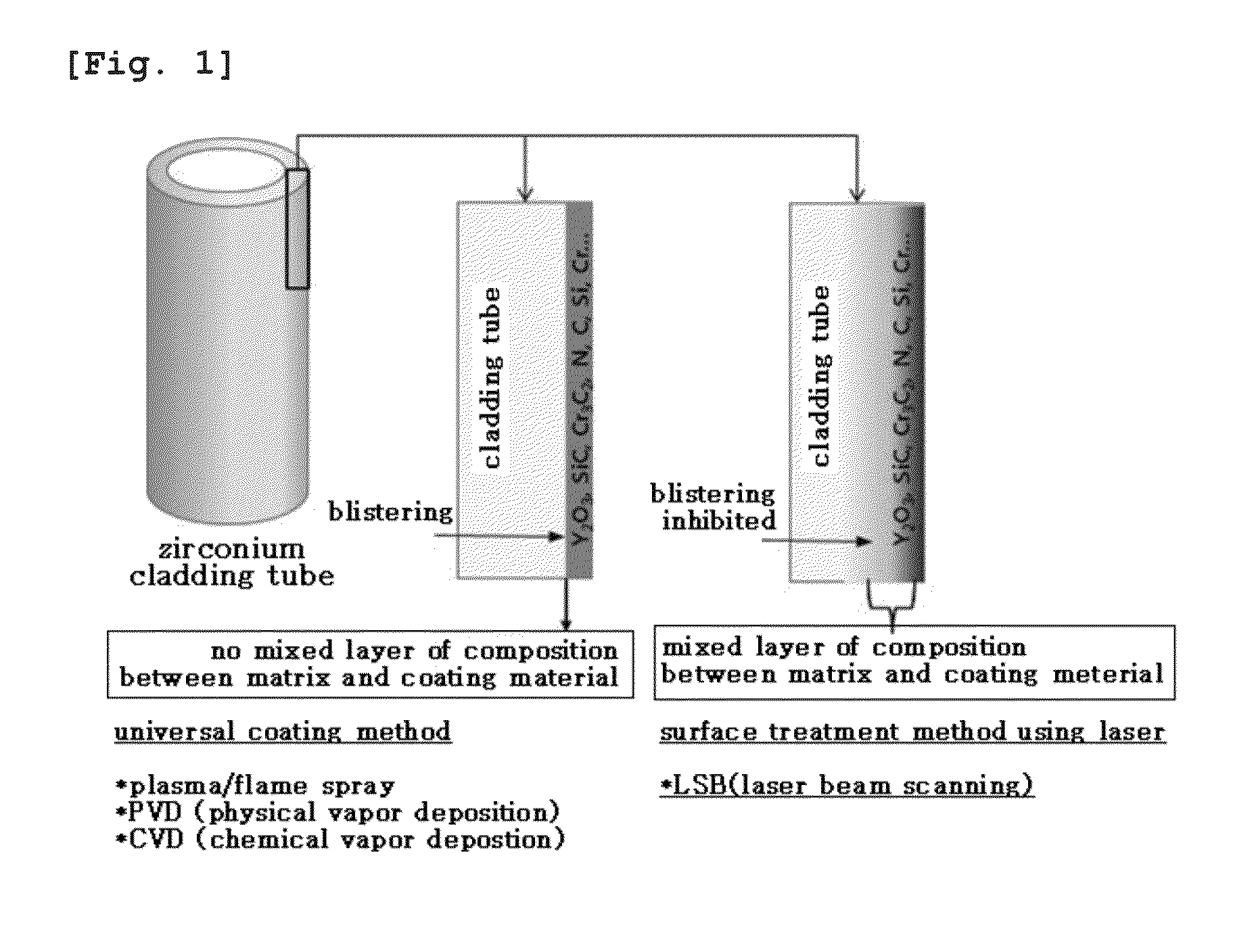

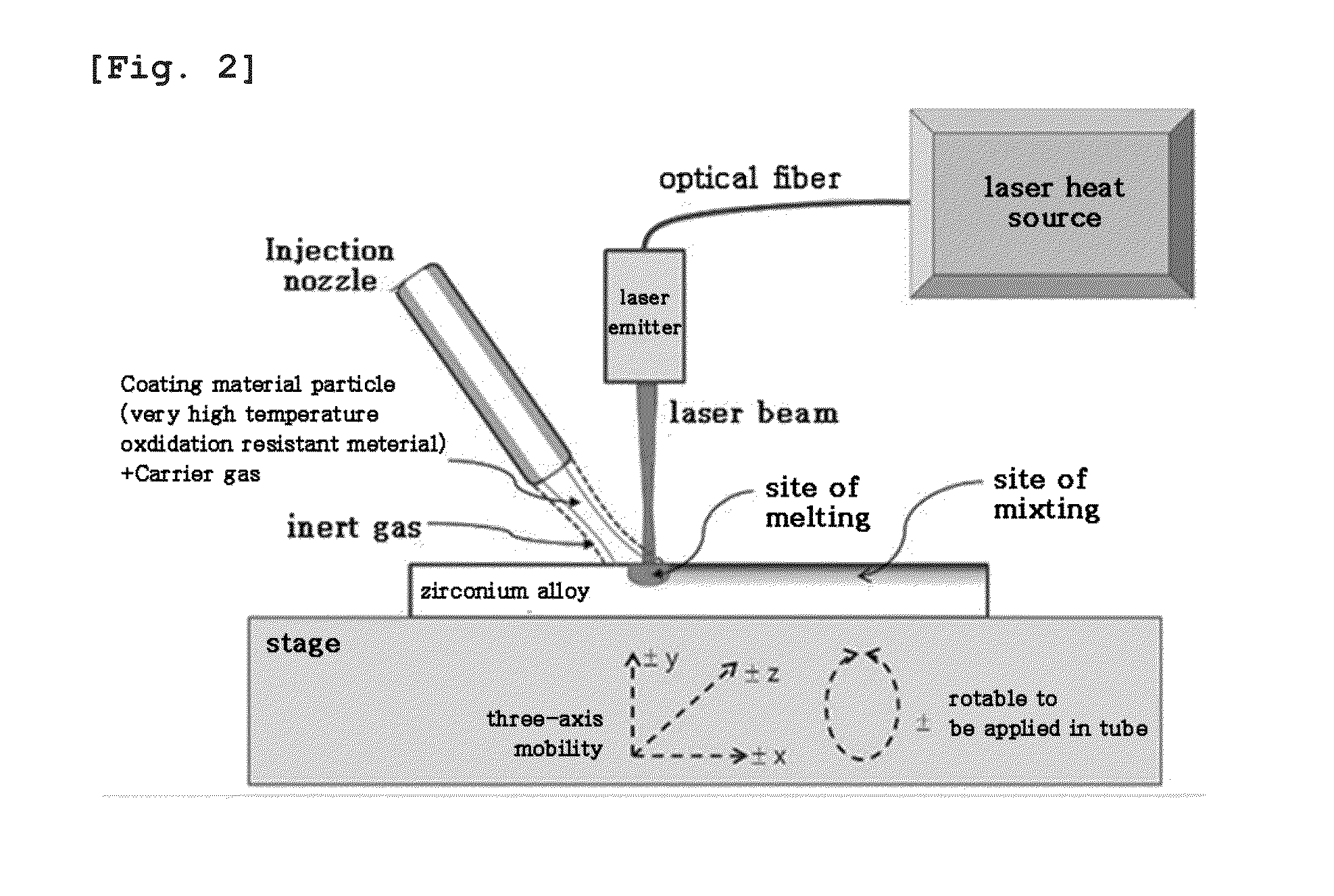

Zirconium alloy with coating layer containing mixed layer formed on surface, and preparation method thereof

InactiveUS20130344348A1High-temperature anticorrosiveAvoid physical damageAdditive manufacturingPretreated surfacesOxidation resistantZirconium alloy

A zirconium alloy with a coating layer formed on a surface comprising a mixed layer, the mixed layer comprises one or more very high temperature oxidation resistant material and zirconium alloy parent material selected from the group consisting of Y2O3, SiO2, ZrO2, Cr2O3, Al2O3, Cr3C2, SiC, ZrC, ZrN, Si and Cr, and in a vertical direction on a boundary between the mixed layer and the zirconium alloy parent material is formed a gradient of compositions between the very high temperature oxidation resistance material and the zirconium alloy parent material.

Owner:KOREA ATOMIC ENERGY RES INST +1

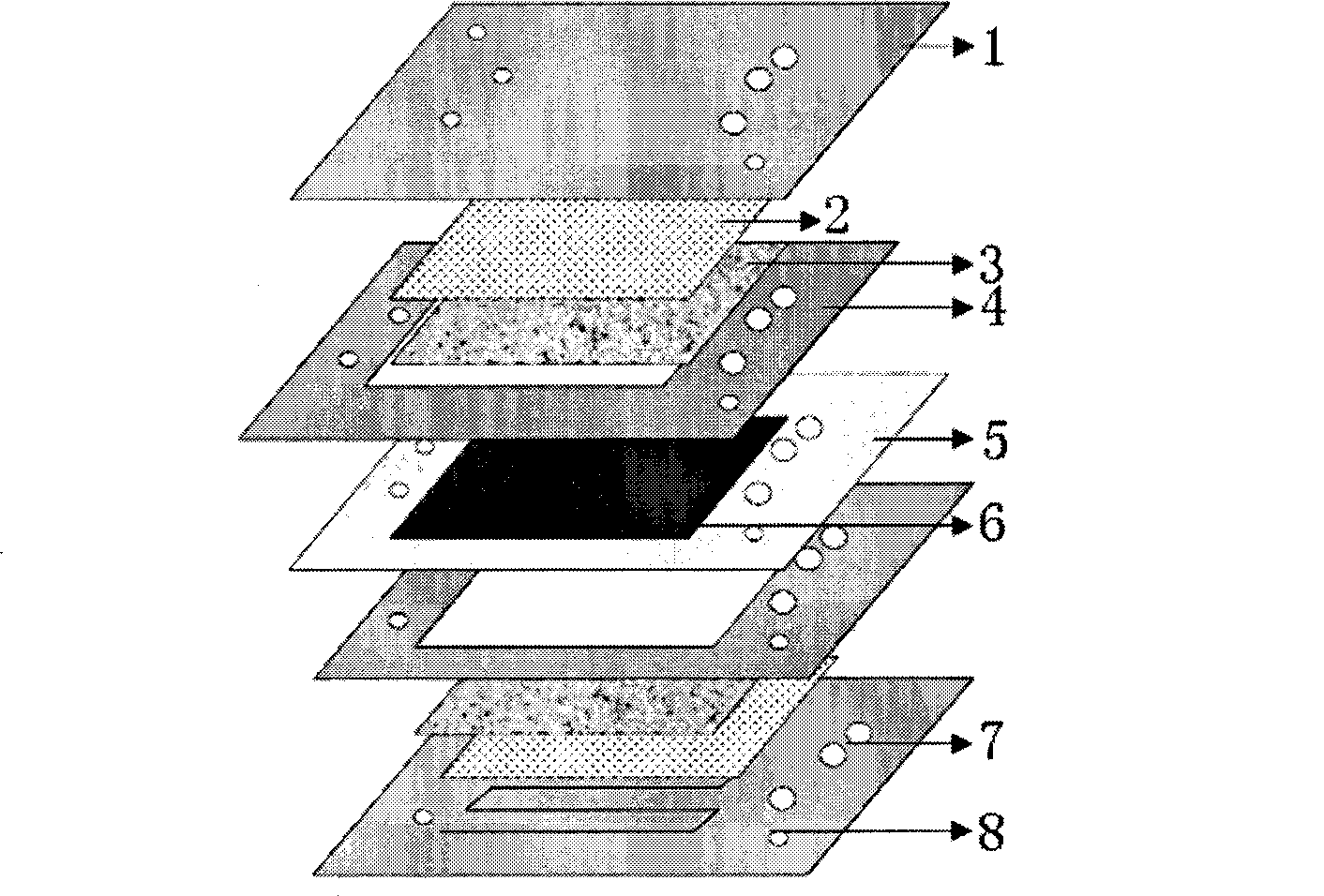

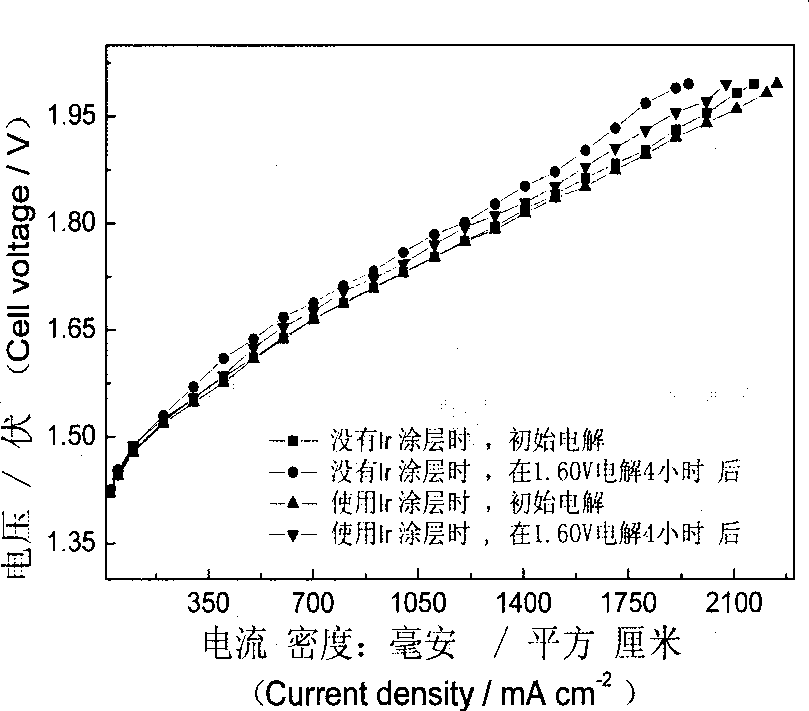

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

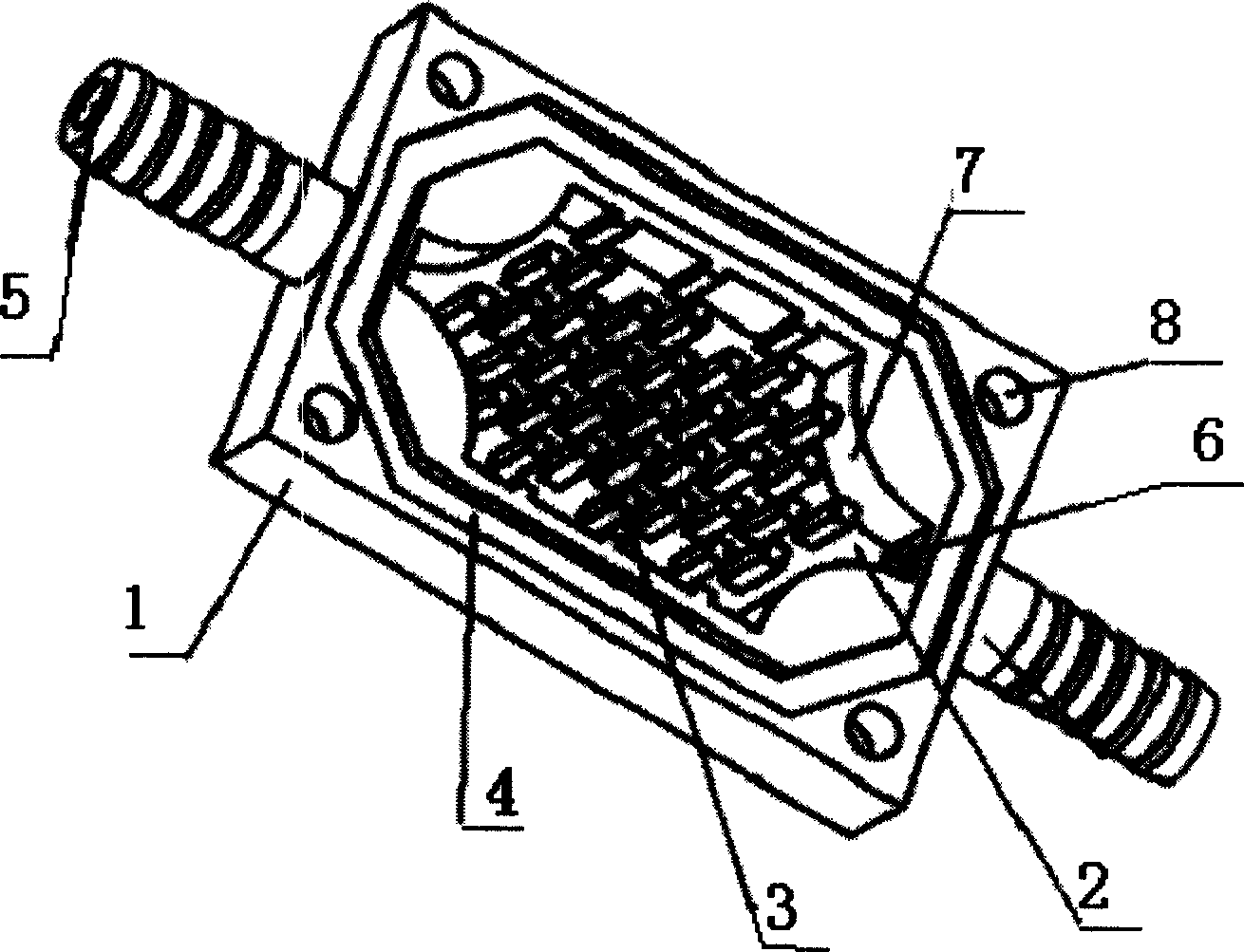

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

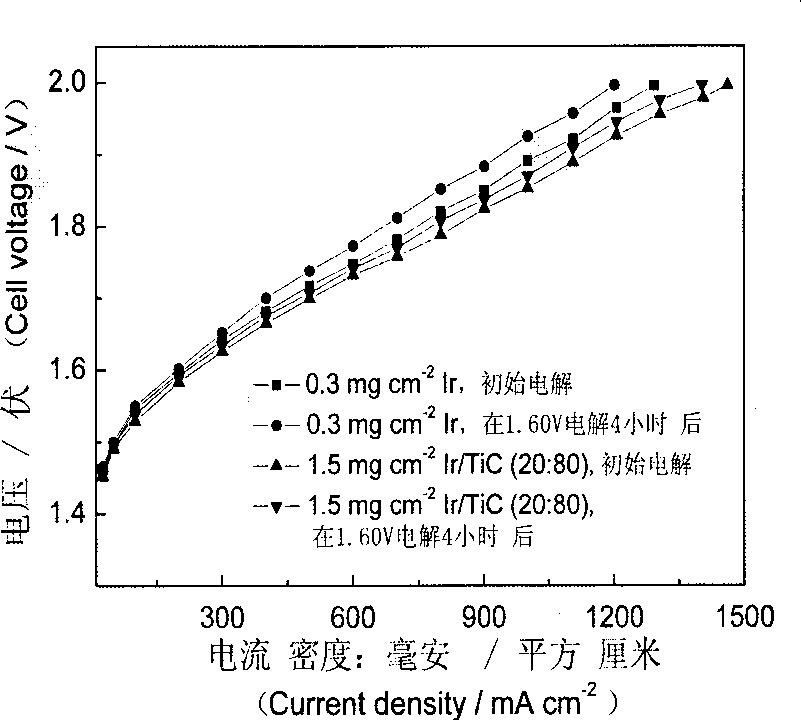

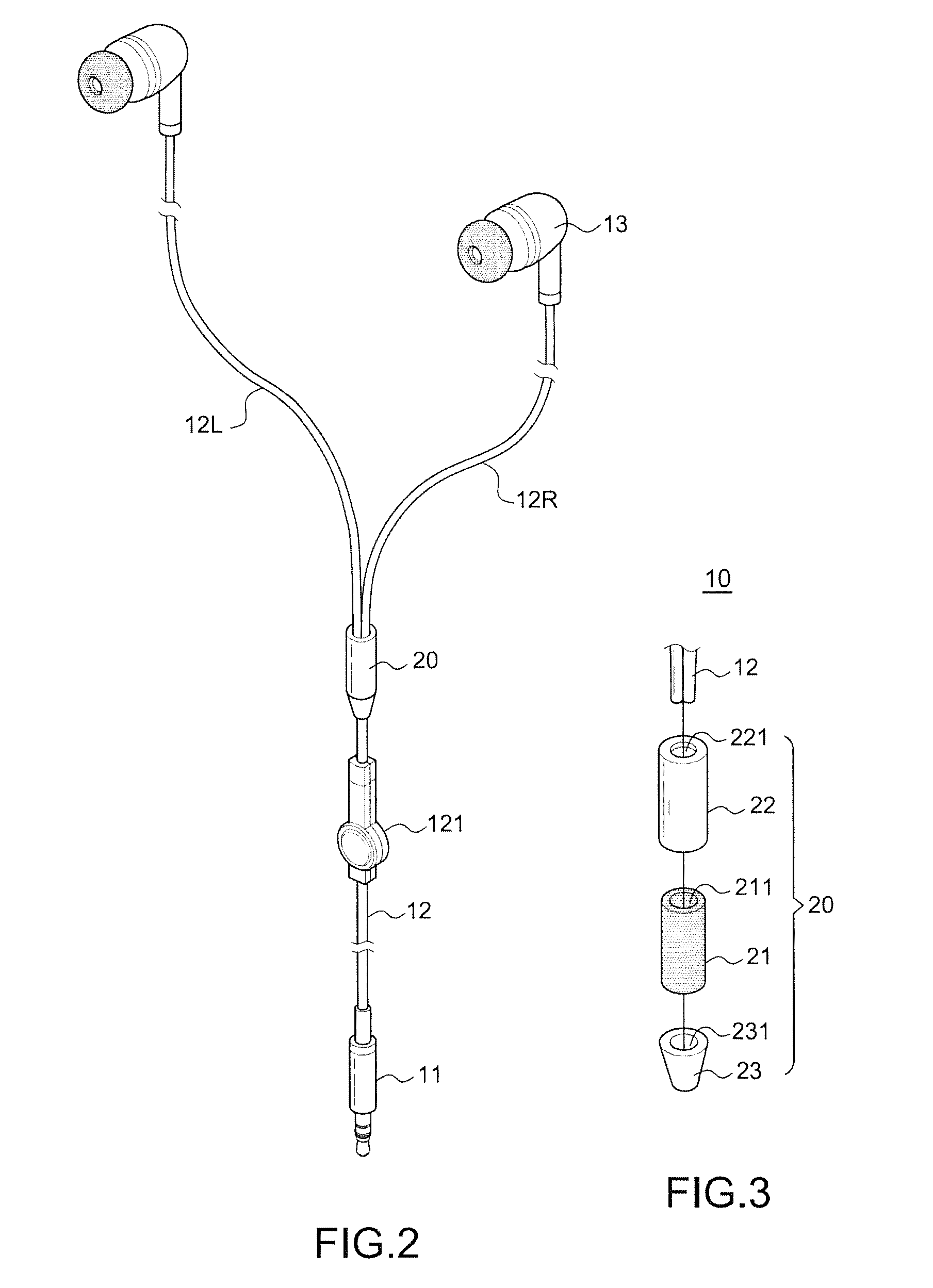

Cell Culture Shaking Device and Shaking Culture Method as Cell Culture Method

ActiveUS20090111179A1Avoid damageEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsCulture cellMicrobiology

The invention intends to provide a cell culture shaking device which is able to improve the efficiency of cell culture while preventing the cells from becoming damaged. The shaking devices used in cell culture apparatuses for culturing cells in flexible culture bags for storing culture suspension having cells inoculated therein includes: shaking mechanisms having operating panels for pressing the culture bags repeatedly, so that the culture suspension in the culture bags is stirred by being pressed by a plurality of projections projecting for the operating panels.

Owner:MEDINET CO LTD

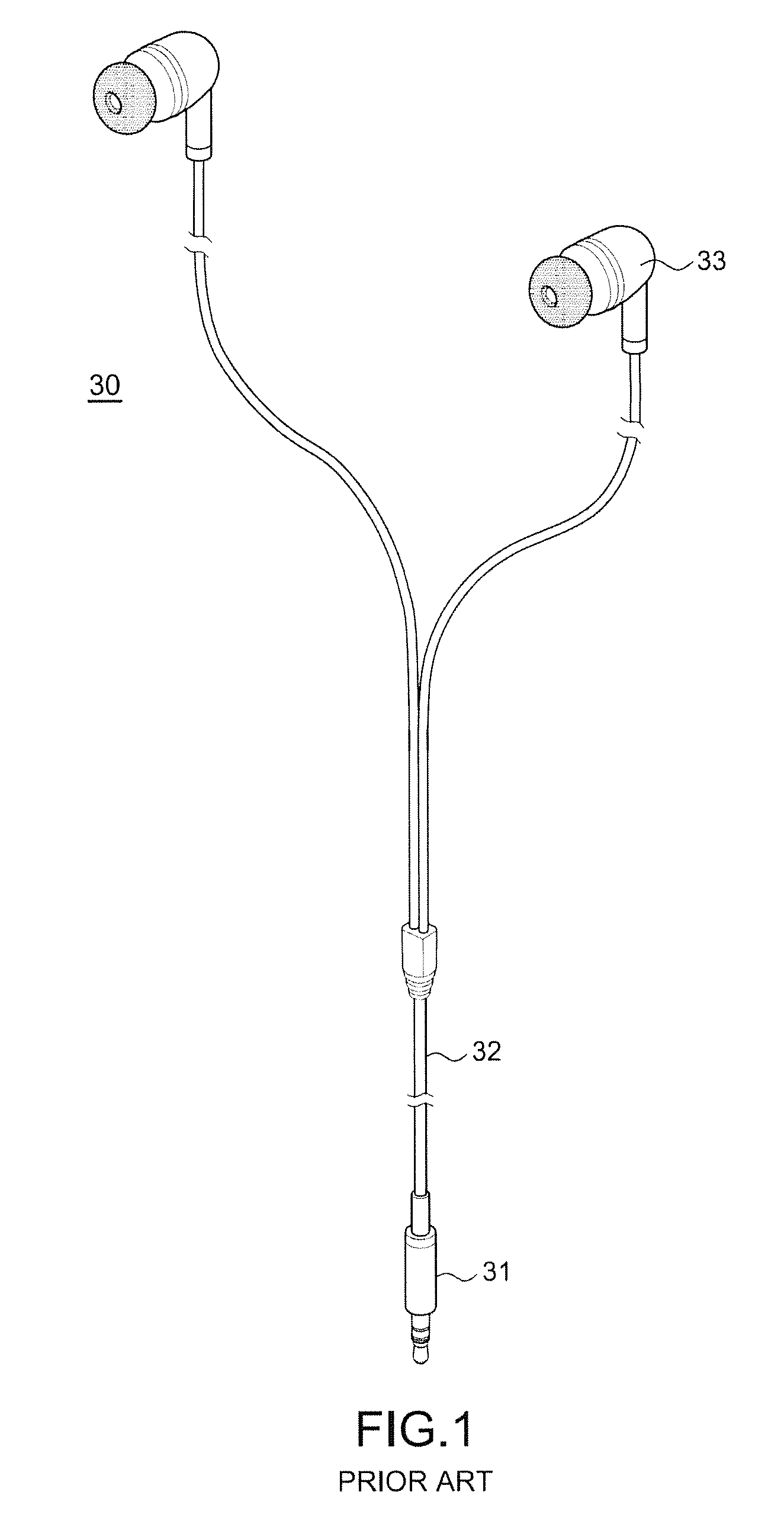

Radiation-resistant earphone wire

InactiveUS9031264B2Reduce electromagnetic interferenceGood signalEarpiece/earphone cablesDeaf-aid setsRadiation resistantMetal

The invention relates to a radiation-resistant earphone wire, particularly to signal lines having at least a radiation-resistant device on a predetermined position thereof and the radiation-resistant device including: a radiation absorber being a cylindrical body, made of a magnetic material with high permeability and having a first through hole in a middle thereof and a radiation blocker made of a metal sleeve body and coating on an outer periphery of the radiation absorber and a top of the radiation blocker corresponding to the first through hole has a second through hole for the signal lines passing through. Based on the features disclosed, the radiation absorber at an inner layer absorbs EMI radiation and the radiation blocker at an outer layer has a shielding effect and both the radiation absorber and the radiation blocker together form an anti-EMI structure, avoiding human brain damage caused by the electromagnetic waves.

Owner:SAMYA TECHNOLOGY CO LTD

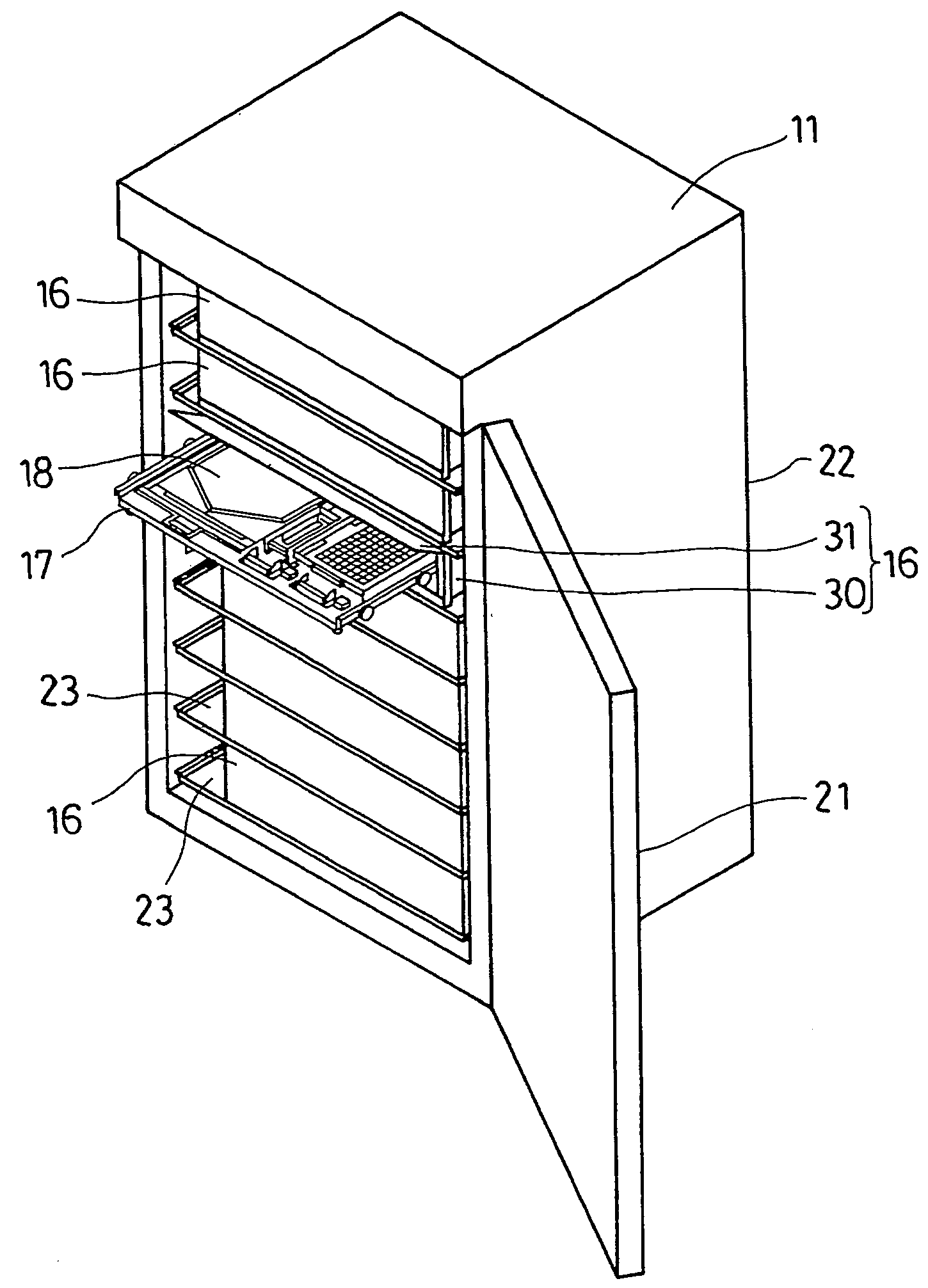

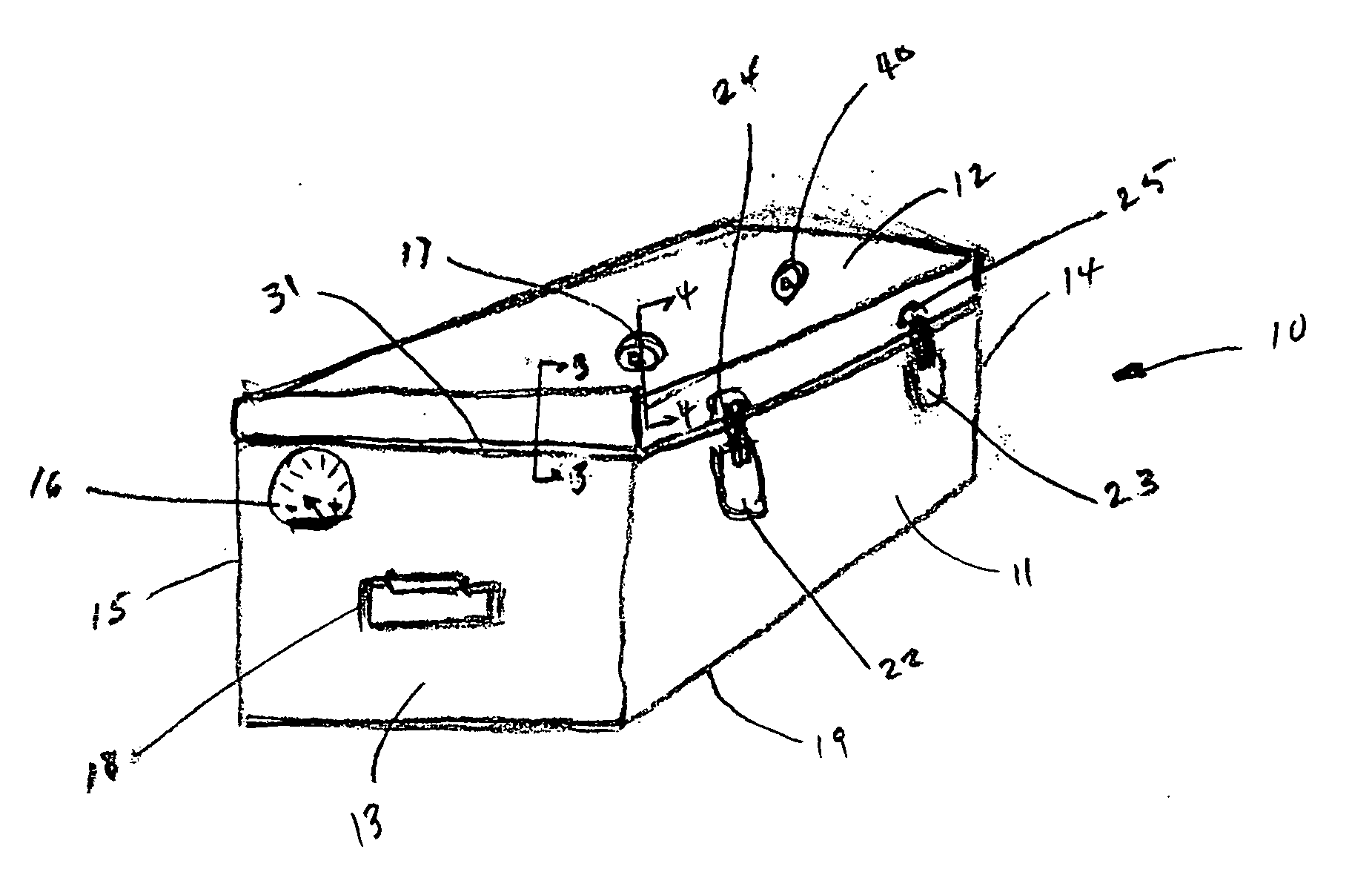

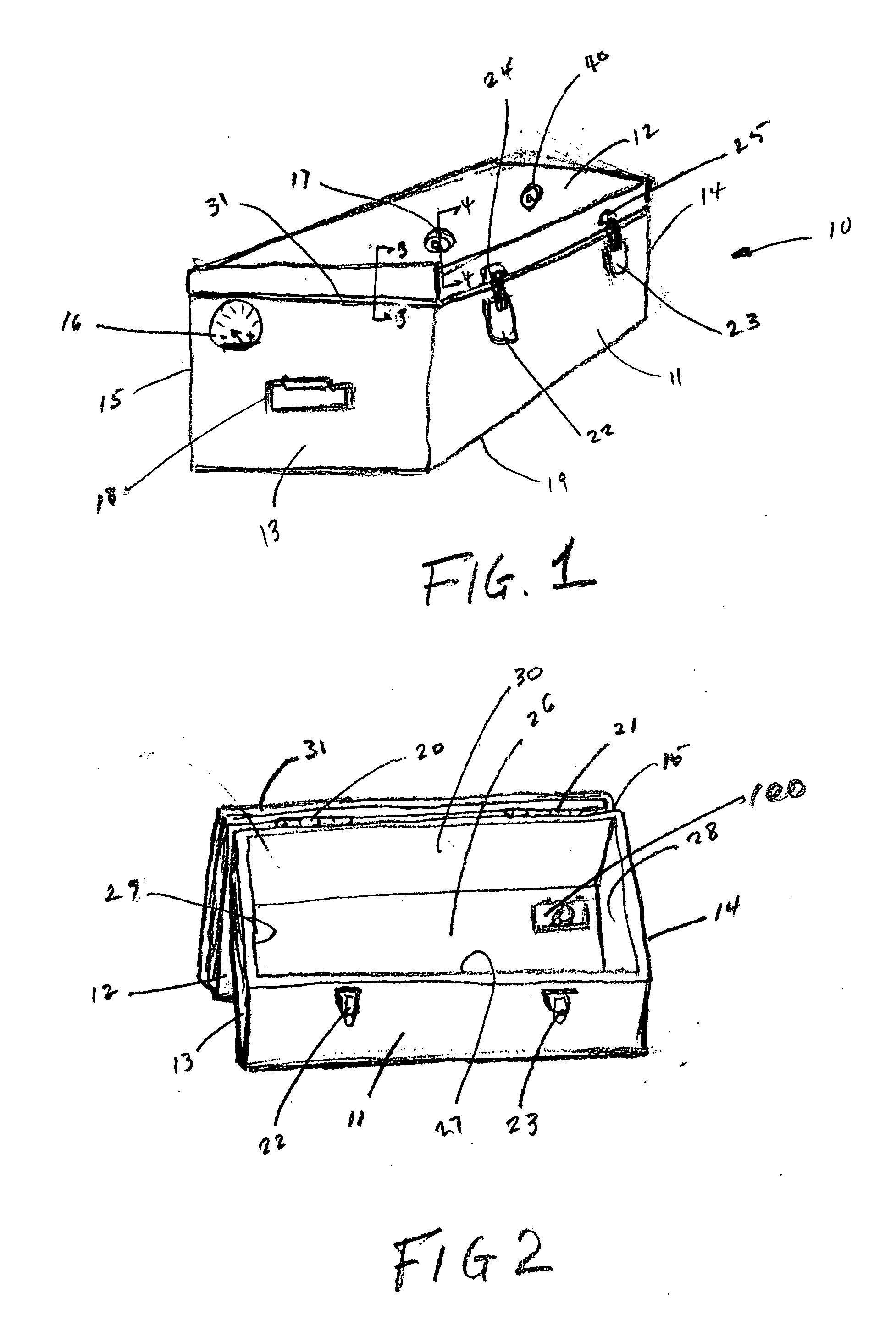

Hermetically sealed storage containers

InactiveUS20060151354A1Maintain internal pressureAdverse atmospheric conditionPackaging under vacuum/special atmosphereHermetic sealDifferential pressure

A storage container for isolating delicate items from harsh environments has a rigid exterior forming a continuous box with an open mouth. A gasketed door is hinged to the box and is provided with catches cooperating with clasps on the box to compress the gasket and close the open mouth forming a hermetic seal. A one-way valve is mounted on the container to subject the sealed interior to a pressure differential from the atmospheric condition. A pressure gauge is mounted on the container to indicate the pressure differential existing in the container.

Owner:AIR TIGHT

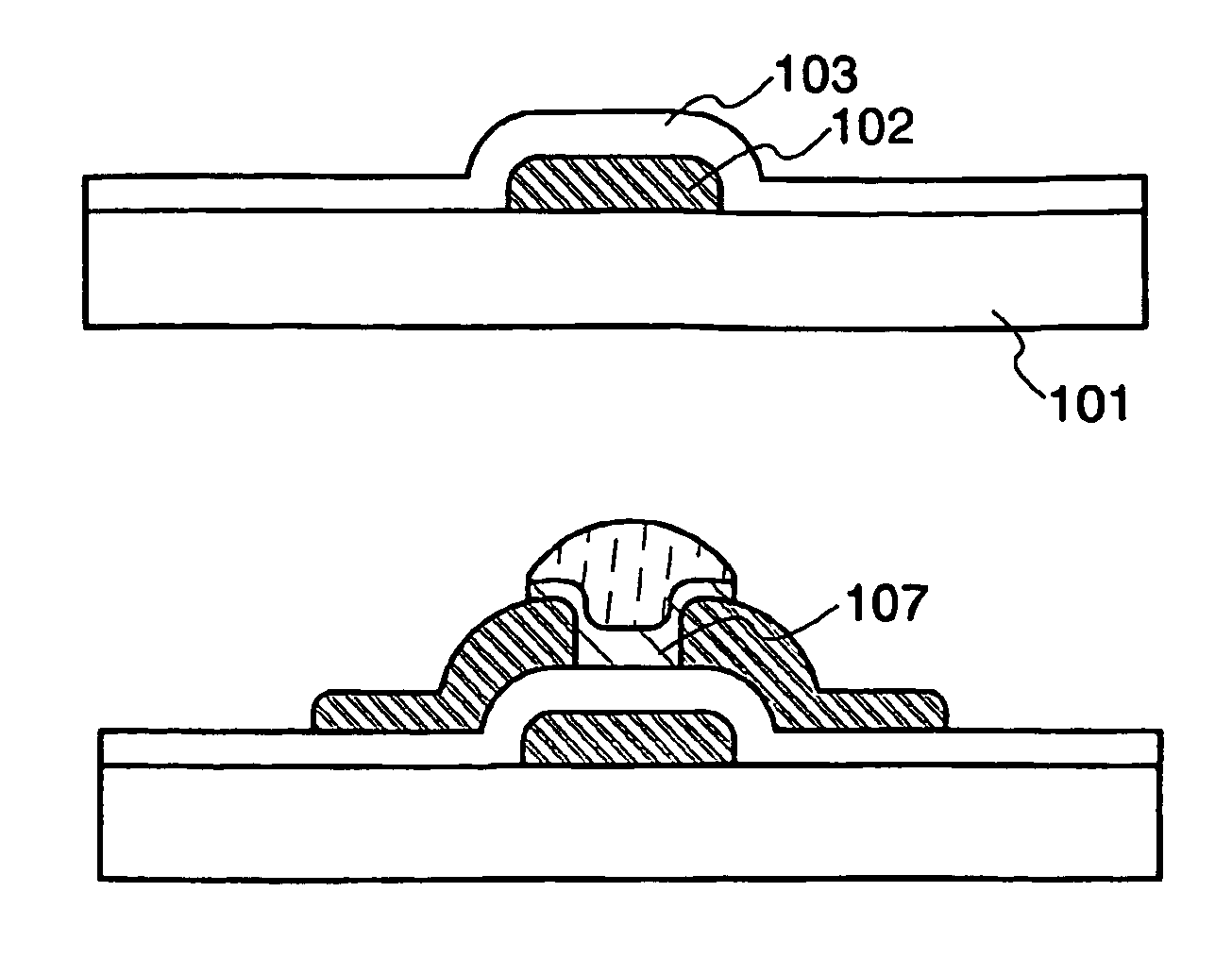

Manufacturing method of semiconductor device

InactiveUS20070031990A1Improve reliabilitySimplify manufacturing stepsTransistorSolid-state devicesDevice materialOrganic semiconductor

In view of the problem that an organic semiconductor layer of an organic TFT is likely to deteriorate due to water, light, oxygen, or the like, it is an object of the present invention to simplify a manufacturing step and to provide a method for manufacturing a semiconductor device having an organic TFT with high reliability. According to the invention, a semiconductor layer containing an organic material is formed by patterning using a mask, and thus an organic TFT is completed in the state where the mask is not removed but to remain over the semiconductor layer. In addition, a semiconductor layer can be protected from deterioration due to water, light, oxygen, or the like by using the remaining mask.

Owner:SEMICON ENERGY LAB CO LTD

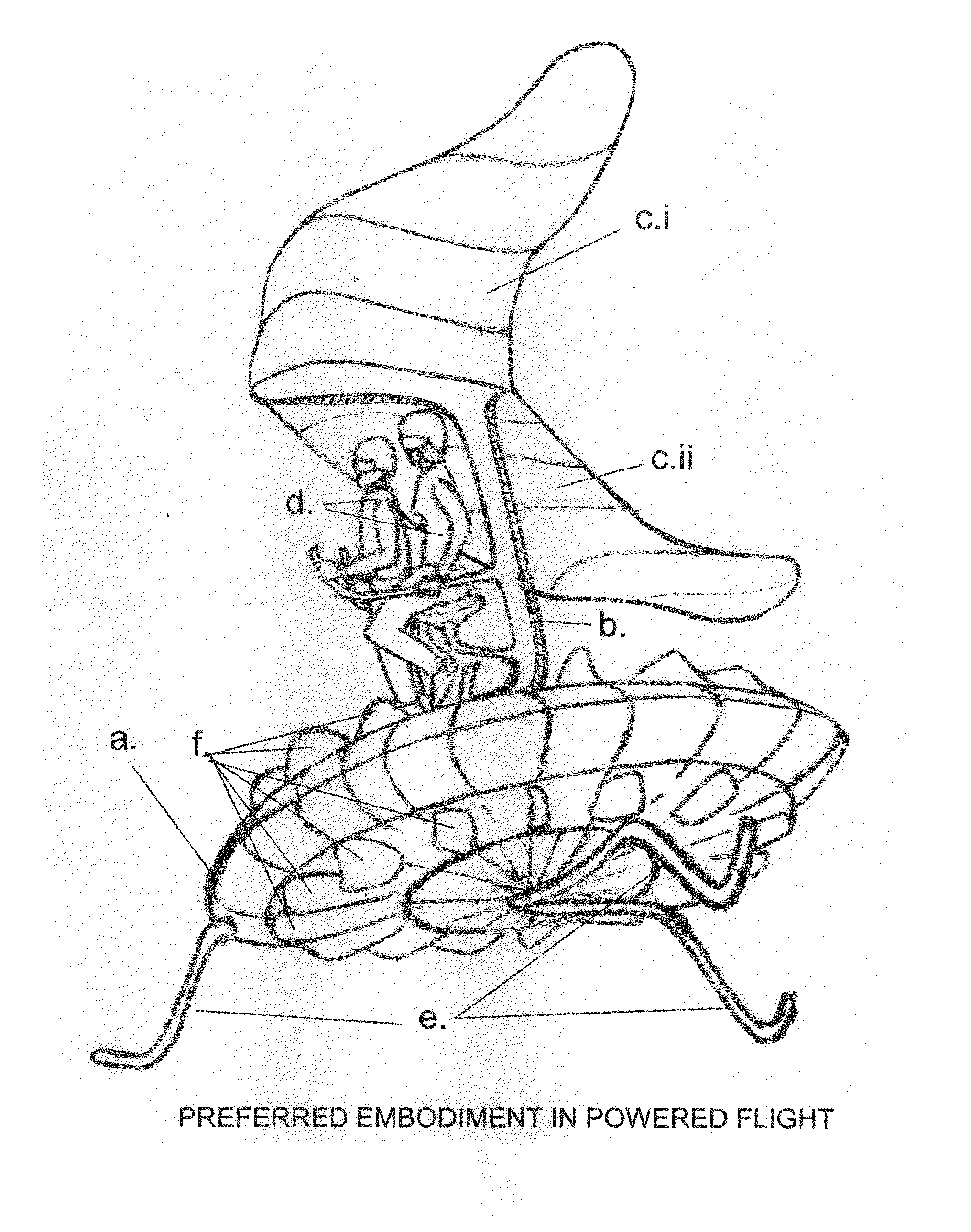

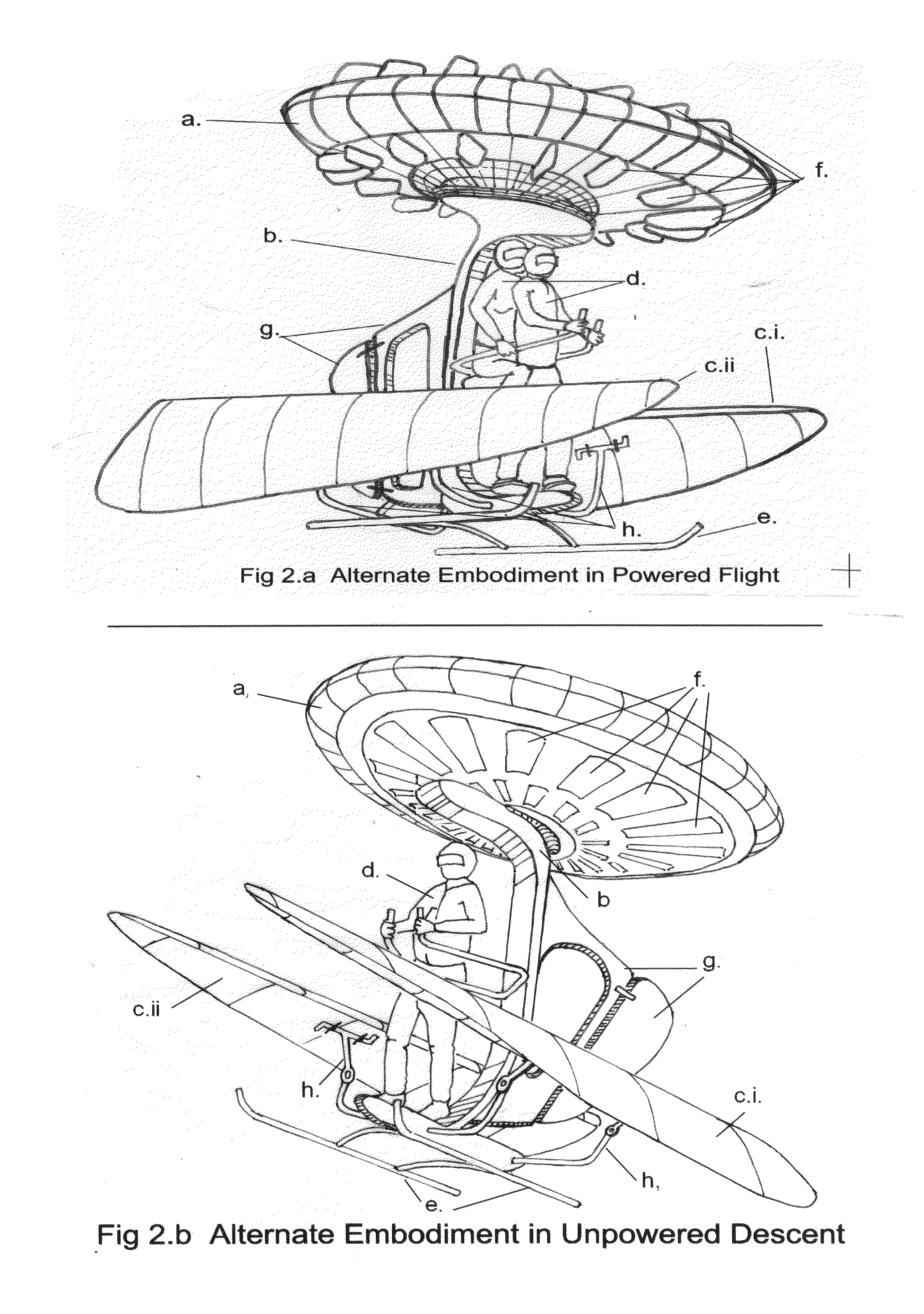

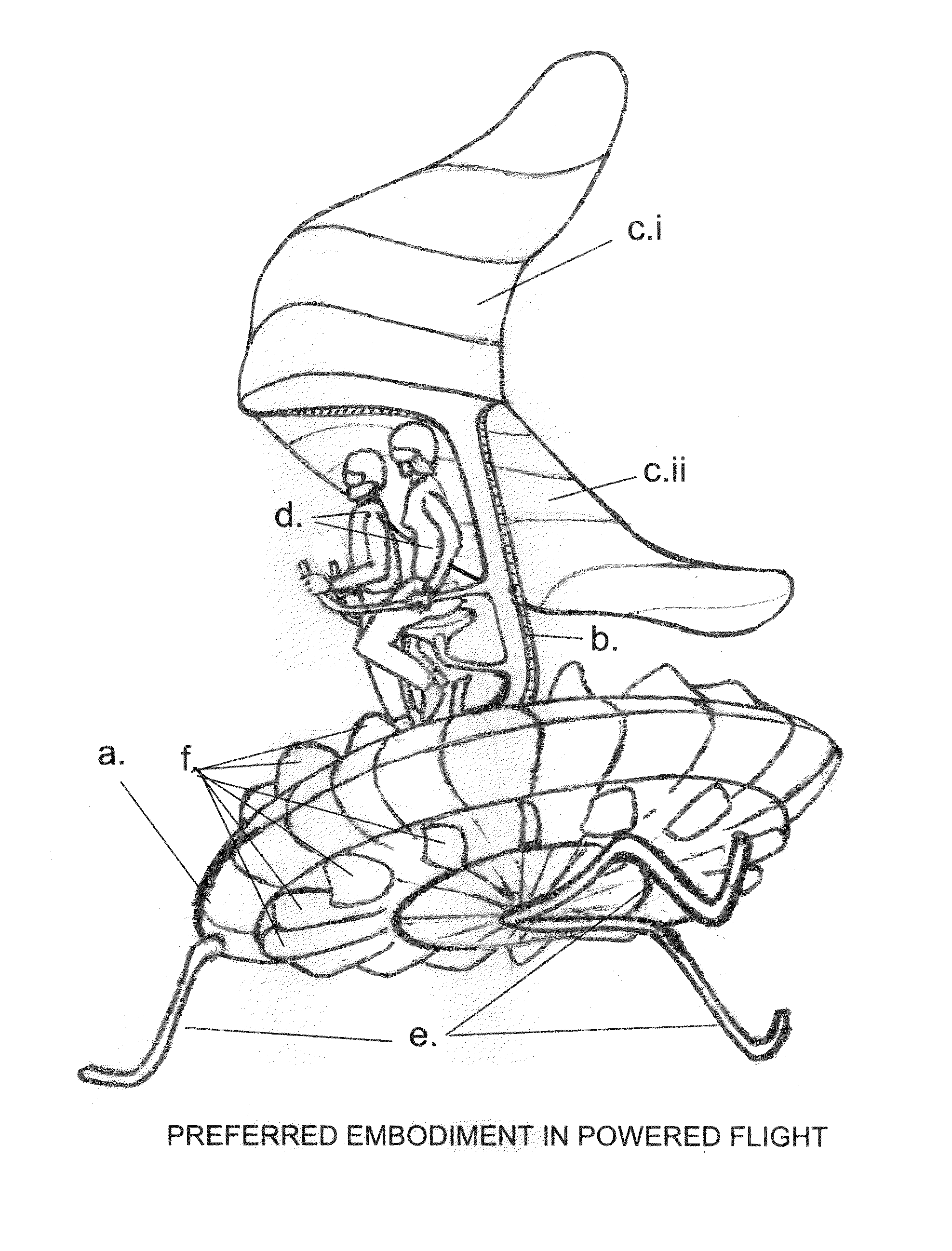

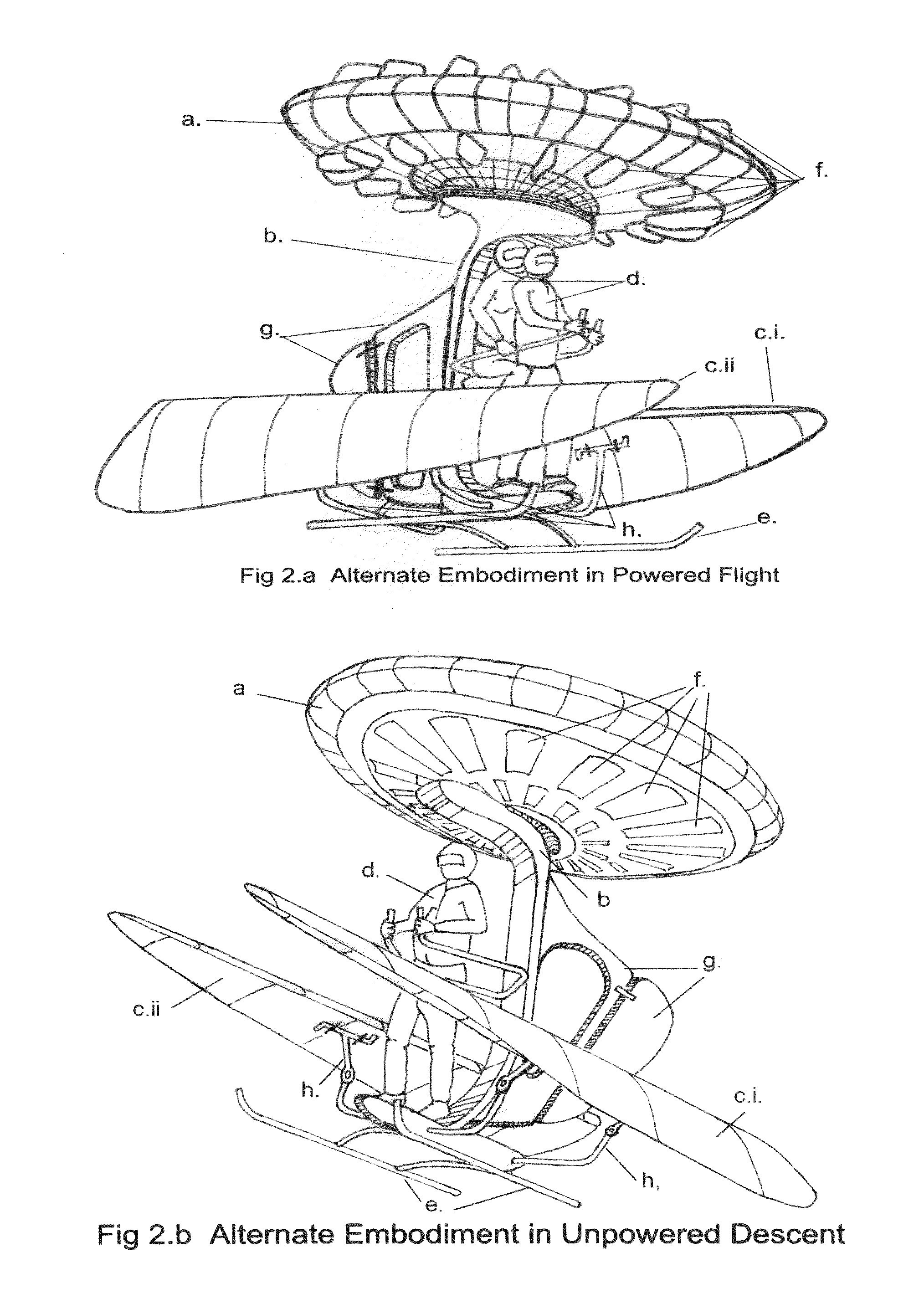

Safety flier--a parachute-glider air-vehicle with vertical take-off and landing capability

ActiveUS20110163198A1Easy to operateAvoid physical damageAircraft navigation controlPropellersRange of motionFlight vehicle

One embodiment of a Vertical Take-off and Landing (VToL) air-vehicle (FIG. 1.) having a horizontal rotor, a. providing lift and propulsion, and communicating at or near its centre to structural elements, or fuselage, b. Upon or within the fuselage structure is attached a platform, to which a payload, or occupant or pilot, d. is secured in such a manner as to permit a movement, or range-of-motion, of the payload, as a means of weight-shifting, or mass-balancing, of the vehicle for stability and control in flight. At least two planar elements, or descent-vanes, c.i & c.ii are connected to a structural element of the fuselage at a location which provides vertical and horizontal separation between the rotor and the descent-vanes, thus creating a tandem, biplane arrangement of two aerodynamically active elements which are aerodynamically balanced to provide stability and controllability in hovering flight, in forward flight, and in un-powered gliding and vertical descents. Other embodiments are described and shown.

Owner:LEAVER GLENN

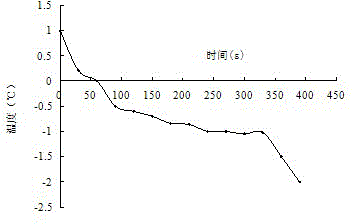

Composite biological coating agent and method for using the same in fresh keeping of blueberry

ActiveCN102940032AHigh tensile strengthAvoid physical damageFruits/vegetable preservation by coatingFlavorChemistry

The invention relates to a composite biological coating agent and a method for using the composite biological coating agent in fresh keeping of blueberry, belonging to the field of food processing. The composite biological preservative film is prepared from biogenetically derived water-soluble chitosan, nisin, lysozyme and nano silicon polyoxide, propylene glycol, glycerin and citric acid in proportion. According to the invention, fresh blueberries are subject to pretreatment, are coated with chitosan composite biological preservative film, dried in cold air, and preserved in a cold storage, wherein the temperature in the cold storage is the freezing point temperature of the blueberry, and the relative humidity is 90-95%; and the blueberries can still keep special flavor, color and nutritional components after being preserved for 50 days under the conditions. The blueberries have high commercial value and good economic benefit. The method disclosed herein has the advantages of mild conditions for preparing the composite biological coating agent, simple operation, and easiness in popularization.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

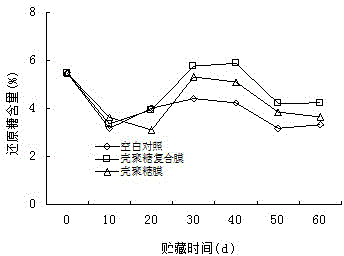

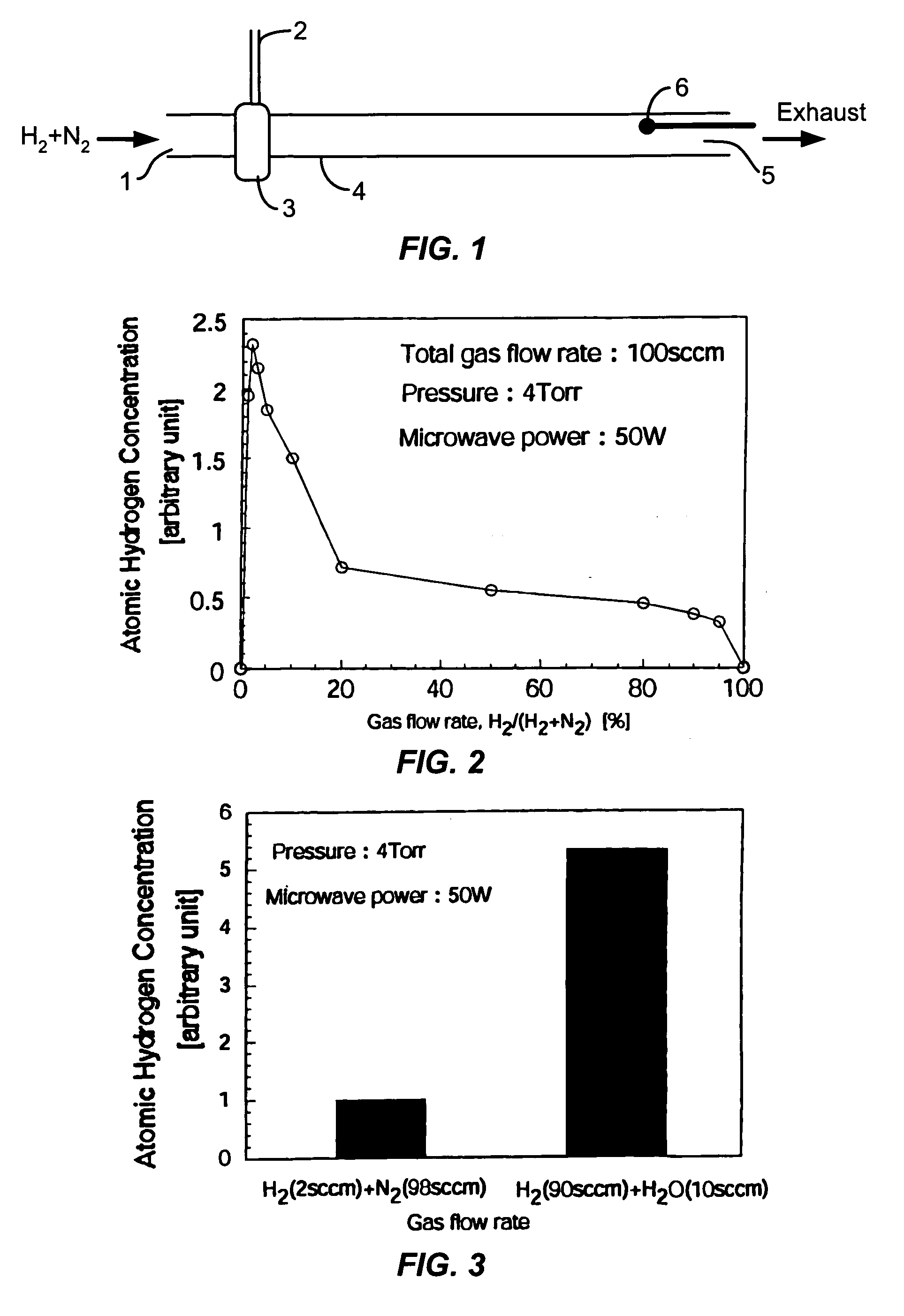

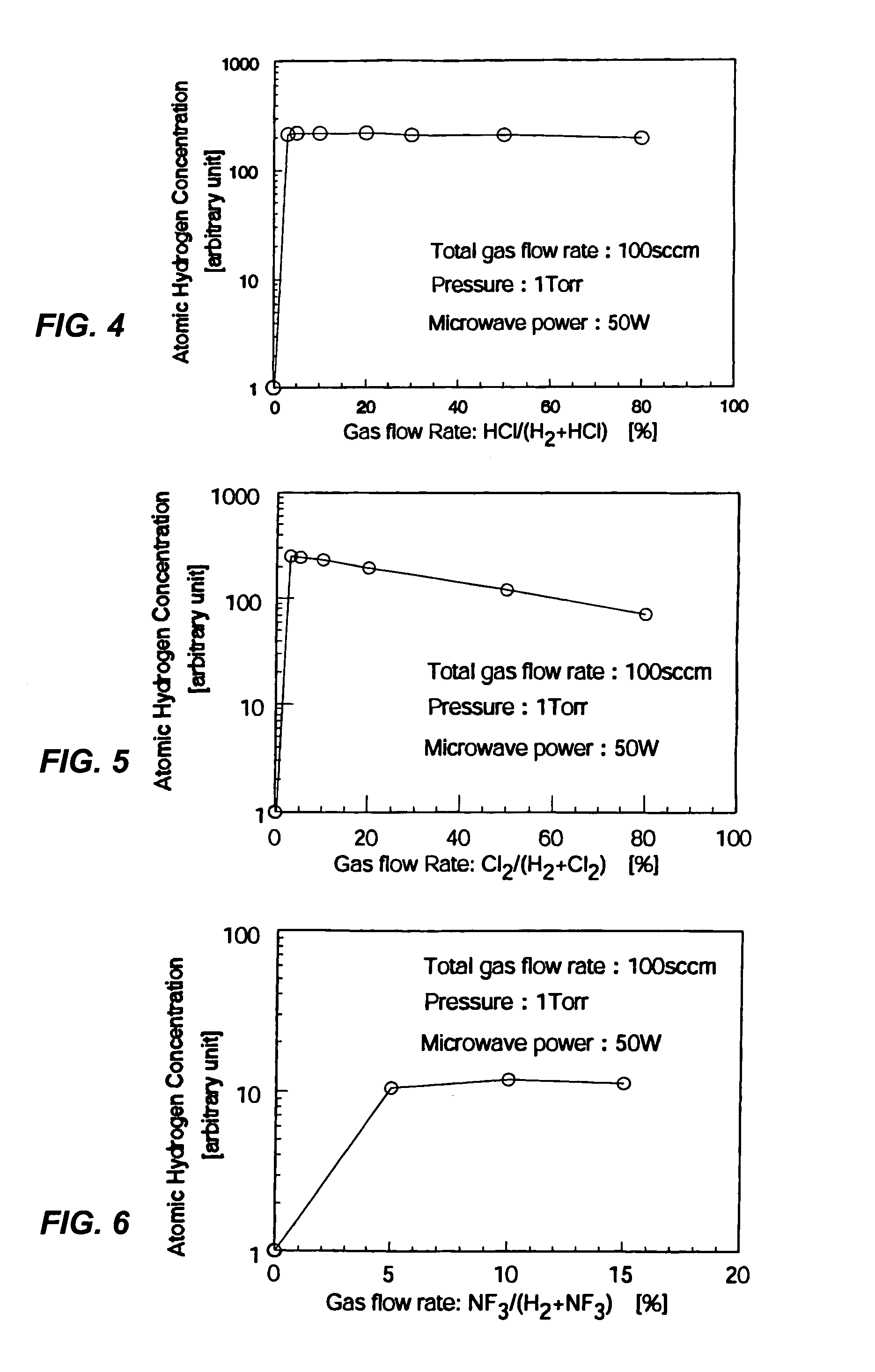

Surface treatment method and equipment

InactiveUS7014788B1Avoid physical damageEasy to implementElectric discharge tubesDecorative surface effectsPresent methodHalide

A method for treating material surface utilizing atomic hydrogen. The method includes utilizing atomic hydrogen by mixing halogen and / or halide to a gas which is used for generating, atomic hydrogen in the plasma. The present method also includes utilizing a characteristics of plasma downstream (11) in which the objective surface is prevented from physical damage caused by high energy particle and undesirable reactive species are controlled so as to avoid their influence. In an alternative embodiment, the present invention includes a method for a material surface treatment utilizing atomic hydrogen without the influence of atomic oxygen by using a gas, as a plasma source, containing the molecule and / or compound of chlorine, bromine and / or iodine and not containing molecules with oxygen atom.

Owner:MITZEL JIM +1

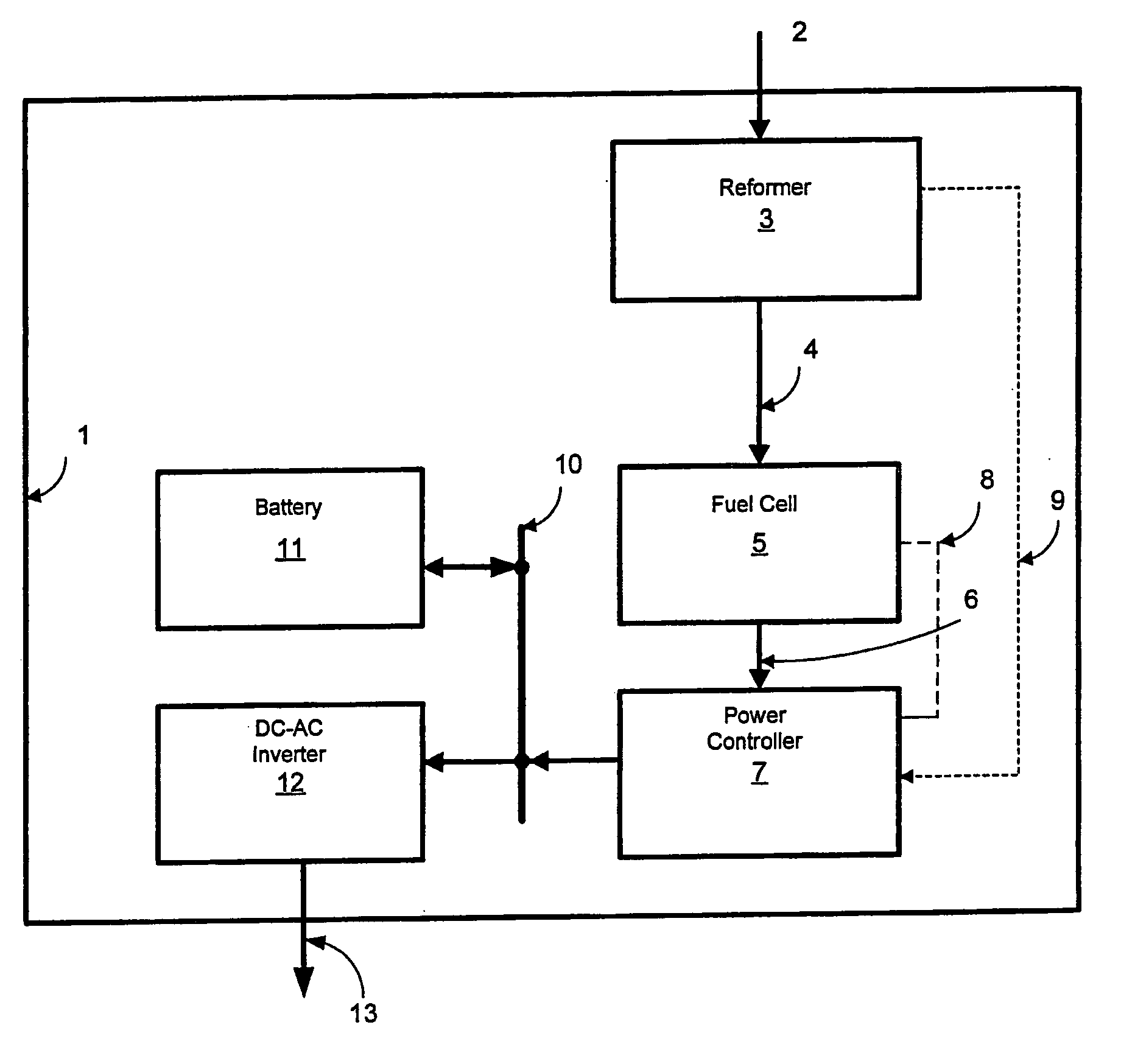

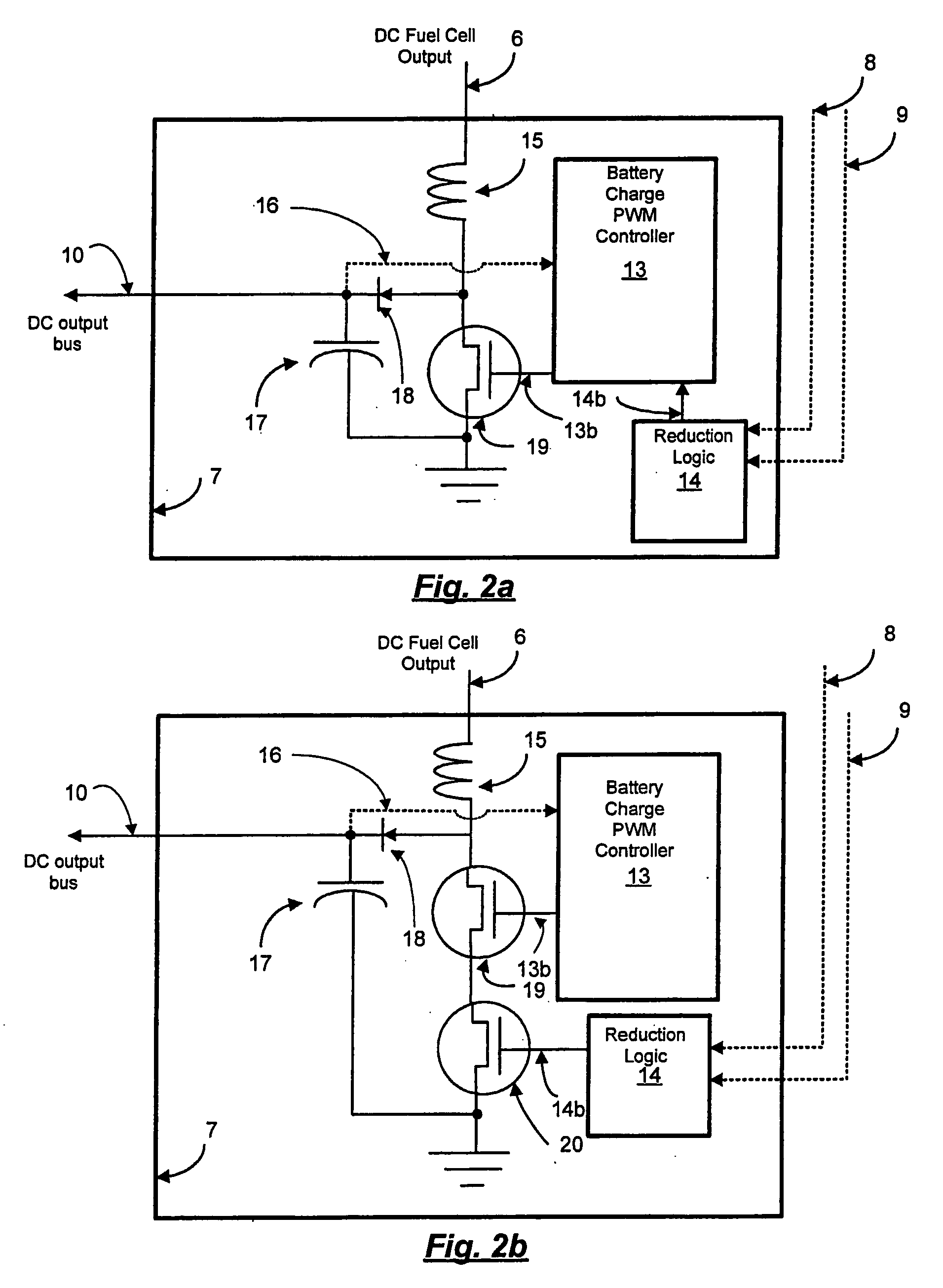

Power controller for fuel cell

InactiveUS20060051634A1Avoid physical damageSmall voltageFuel cells groupingFuel cell auxillariesElectric forcePower controller

A fuel cell power system includes a fuel cell stack having at least two fuel cell groups in series with each other and with each fuel cell group having more than one individual fuel cell, and a power controller which receives electrical power from the fuel cell stack and distributes the electrical power to an output bus. The power controller includes a DC-DC converter, and a reduction logic circuit operative to limit current through the DC-DC converter in response to voltage across each fuel cell group so that a minimum voltage is maintained across each fuel cell group. When used in combination with a hydrogen reformer, the reduction logic circuit is also operative to limit current through the DC-DC converter in response to hydrogen pressure supplied by the reformer to the fuel cell stack so that a minimum pressure is maintained for the hydrogen supplied to the fuel cell stack.

Owner:GENESIS FUEL TECH INC

Safety flier—a parachute-glider air-vehicle with vertical take-off and landing capability

ActiveUS8408488B2Avoid physical damageAircraft navigation controlPropellersRange of motionFlight vehicle

Owner:LEAVER GLENN

Multilayer Thermoformable Materials and Sanitary Food Containers Made Therefrom

PendingUS20140054292A1Easy to peelAvoid contaminationPackage recyclingLarge containersAdhesiveThermoforming

A multilayer stack of polymeric sheets can be used in thermoforming processes to make objects wherein each sheet has substantially the same shape. The stack includes at least one sheet of a thermoformable polymer, and can include many such sheets. A barrier layer is interposed between at least an overlapping portion at least two of the polymeric sheets in order to prevent fusion of the sheets in the overlapping portion during the thermoforming process. The barrier layer can include an adhesive that adheres the sheets in the overlapping portion. In formed articles including such an adhesive, the sheets can be manually peeled from one another if a suitable adhesive is selected. The stack (and object formed using the stack) can include polymeric sheets that are not thermoformable, but are adhered to the surface of a thermoformable sheet. The sheets and objects can include multiple separable and / or peelable sheets. The stack can be used, for example, to make peelable, re-usable food service trays. In such trays, a rigid base has multiple peelable sheets adhered to at least one surface thereof, the sheets being peelable from the surface to reveal a sanitary surface amenable to food contact.

Owner:CONVERTER MFG LLC

Water cooling type CPU radiator

InactiveCN1588267AEven flow distributionAvoid physical damageDigital data processing detailsWater flowDistilled water

It is a water cooling type CPU heat dissipater. It contains heat dissipater body with admitting pipe and exhaust pipe on two stage, a cavity joined with admitting pipe and exhaust pipe inside the heat dissipater body and crossbar interfluent feather array in the cavity. This invention uses distilled water as water cooling type heat dissipater of cooling working substance and quickly transmits CPU's heat to condenser and into the air by this water cooling type heat dissipater; in the mean time, on one hand, crossbar interfluent feather array increases area of dissipation and on the other hand, when water flows through columnar feather array, the columnar feather array has turbulent effect, increases heat emission effect and makes water flows even in the cavity. In this way, great stress raised by great temperature gradient on the CPU's surface can be avoided and CPU's physical damage can also be avoided.

Owner:XI AN JIAOTONG UNIV

High speed network interface with automatic power management with auto-negotiation

InactiveUS20090300392A1Avoid physical damageEnergy efficient ICTVolume/mass flow measurementLow speedNetwork media

A computer system comprises host processor and a network interface, wherein the host processor includes resources supporting a full power mode, a lower power mode and a power down mode, as seen in standard system bus specifications such as PCI and InfiniBand. The network interface includes a medium interface unit coupled to network media supporting a least high speed protocol, such as a Gigabit Ethernet or high-speed InfiniBand, and a lower speed protocol, such as one of 10 Mb and 100 Mb Ethernet or a lower speed InfiniBand. Power management circuitry forces the medium interface unit to the lower speed protocol in response to an event signaling entry of the lower power mode. In the lower power mode, the network interface consumes less than the specified power when executing the lower speed protocol, and consumes greater than the specified power when executing the high speed protocol. Logic in the network interface operates in the lower power mode, and uses the lower speed protocol to detect a pattern in incoming packets. In response to the detection of said pattern, the logic issues a reset signal to the host processor. Thus, the network interface operates as a wake-up device in the lower power mode, using the lower speed protocol.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

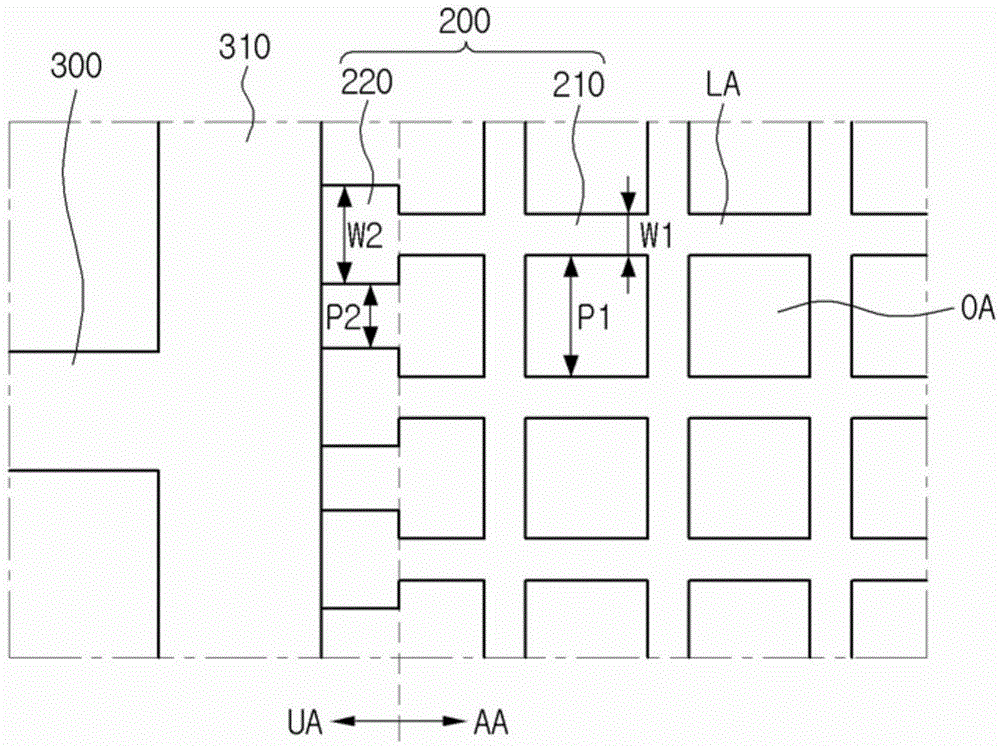

Pixel having an oxide layer with step region

A semiconductor structure, having a doped well region being formed in a substrate layer and a transistor having a terminal provided within said doped well region. The semiconductor structure also includes an oxide layer formed over the substrate layer, the doped well region, a poly silicon region, and the terminal of the transistor. The oxide layer including a step region being located where a height of the oxide layer transitions from a height associated with the doped well region to a height associated with the terminal of the transistor.

Owner:SEMICON COMPONENTS IND LLC

Long-distance transportation method of sepia esculenta adults

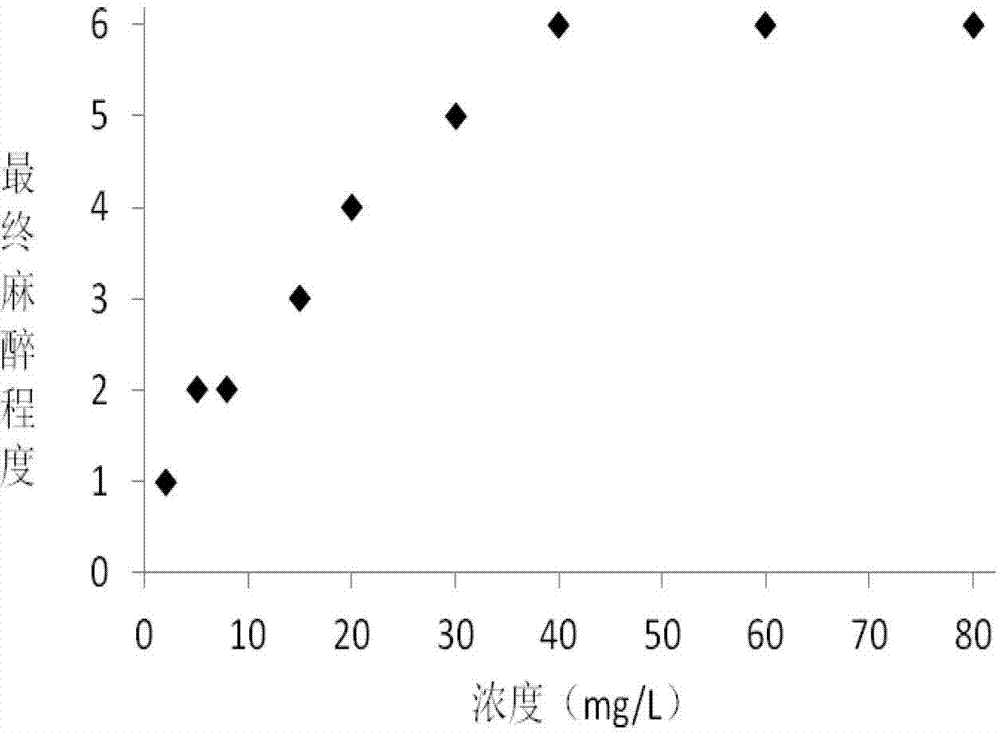

InactiveCN103027004AAppropriate concentrationImprove the survival rate of long-distance transportationClimate change adaptationPisciculture and aquariaEquilibrioceptionTouch Senses

The invention discloses a long-distance transportation method of sepia esculenta adults, and belongs to the field of aquatic product transportation. The long-distance transportation method comprises the steps of two-step oxygenation and two-step anesthetization, wherein the transportation time is not more than 20h; the two-step oxygenation comprises the following steps: oxygenating water for transporting sepia esculenta in a water reservoir with a nano-airstone until saturation, and oxygenating a transportation bag after the sepia esculenta adults are placed into the transportation bag; and the two-step anesthetization comprises the following steps: adding 30-60mg / L of MS-222 anesthetic to a sepia esculenta culture pond without disturbing the sepia esculenta adults, and instantly weighing and packing for transportation when the sepia esculenta adults are anesthetized until the sepia esculenta adults stop swinging the lateral fins and lose the sense of balance; and adding 5-8mg / L of MS-222 anesthetic to the water for transportation, so that the sepia esculenta adults maintain a two-stage anesthetic transportation state, namely, the sepia esculenta adults slightly lose the touch sense, fold the wrists, swing the fins naturally, and changes the body color slightly. With adoption of the long-distance transportation method of the sepia esculenta adults, the survival rate of the sepia esculenta adults during long-distance transportation is significantly increased, and the technical problem about the long-distance transportation of the sepia esculenta adults is solved.

Owner:OCEAN UNIV OF CHINA +1

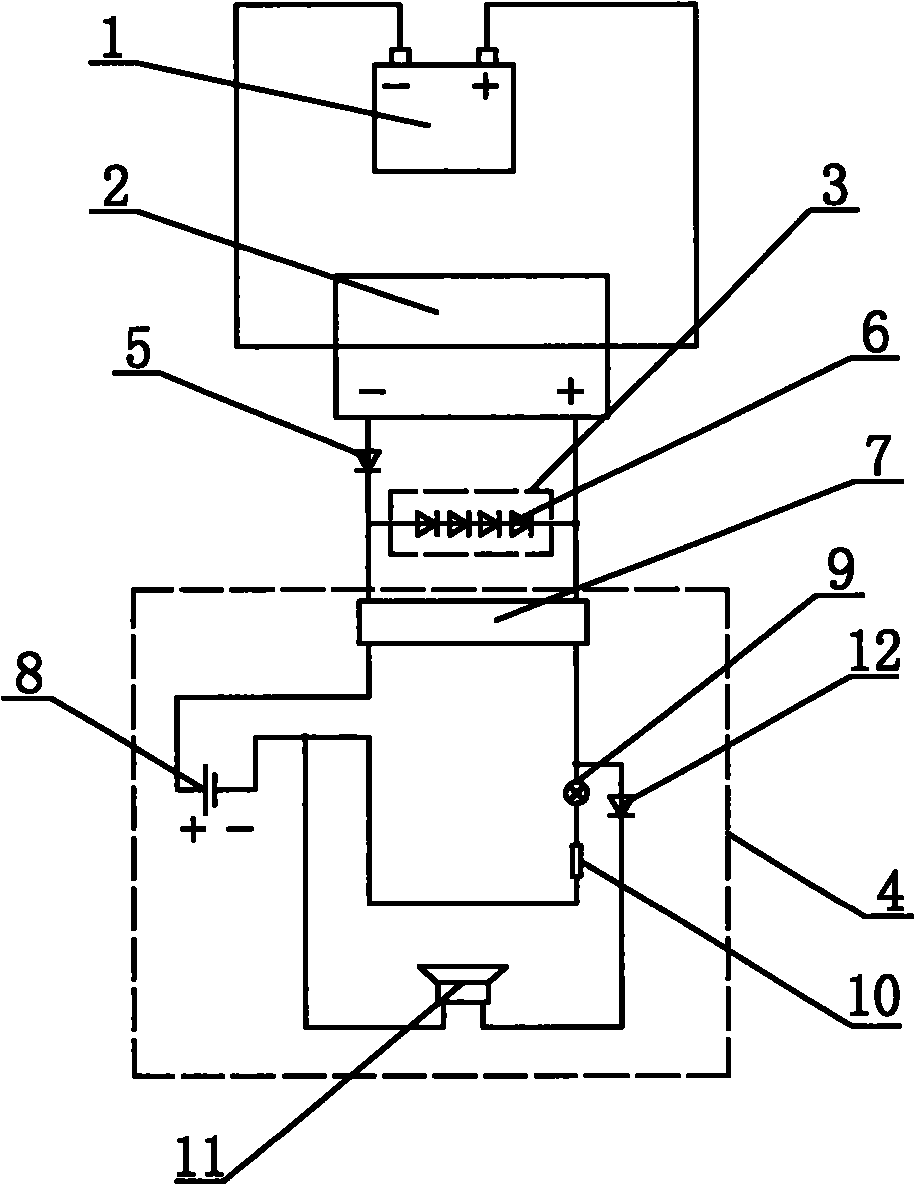

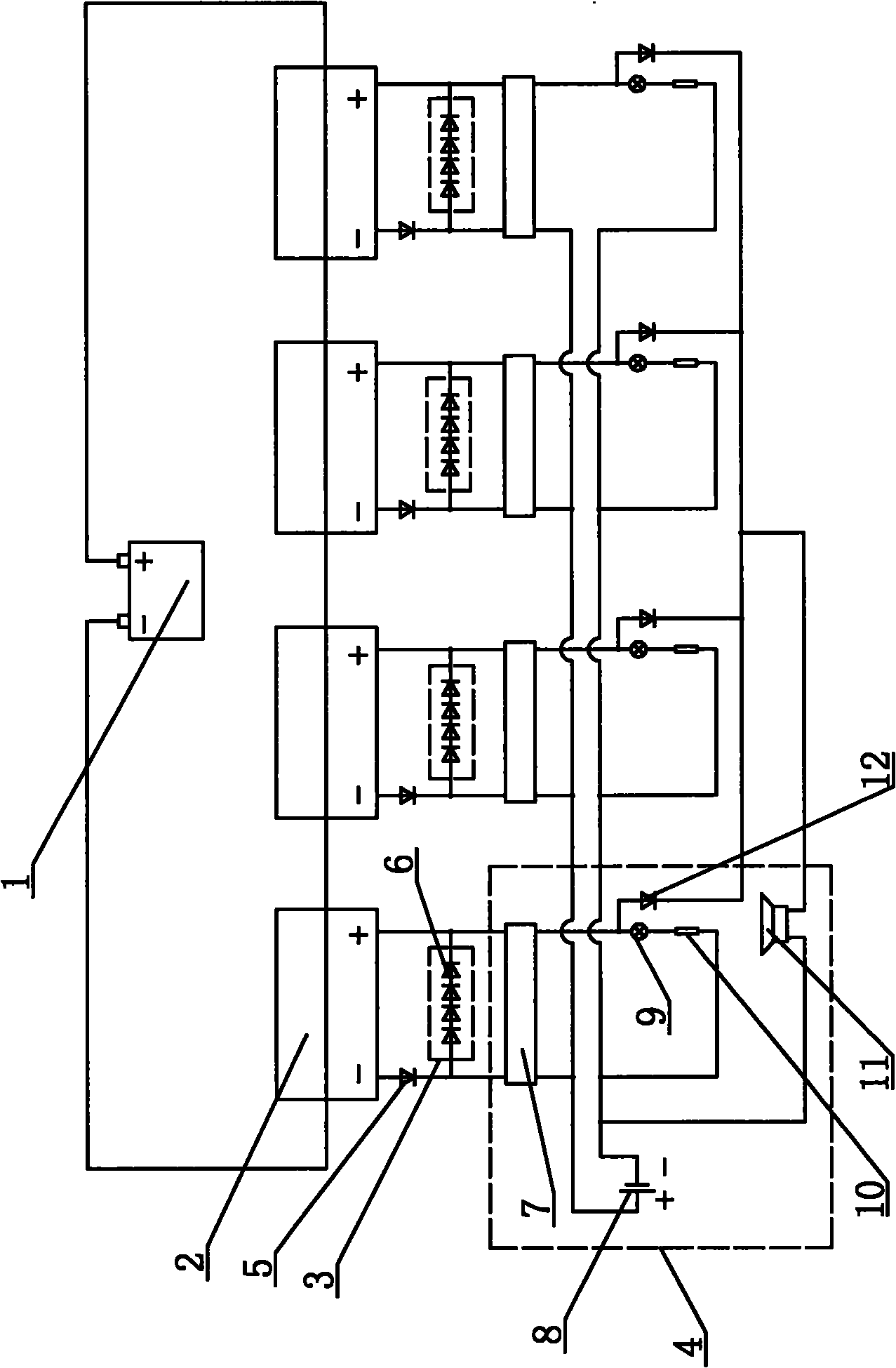

Photovoltaic array component with fault detecting device

InactiveCN101894873AQuick checkReduce waiting timePhotovoltaic monitoringPhotovoltaic energy generationEngineeringDiode

The invention discloses a photovoltaic array component with a fault detecting device. The photovoltaic array component comprises a bypass diode set, a fault detecting device, a storage battery and at least one photovoltaic component, wherein the photovoltaic component is connected with the storage battery in series; the bypass diode set is connected with one diode in series, and the circuit formed by the bypass diode set being connected with one diode in series is connected with the photovoltaic component in parallel; and the fault detecting device is connected with the bypass diode set in parallel. The photovoltaic array component can quickly judge whether the photovoltaic component is in a fault state by detecting whether the current flows in the bypass diode set connected with the photovoltaic component in parallel, and makes people conveniently and quickly know the fault by the fault detecting device connected with the photovoltaic component.

Owner:青岛日月科技发展有限公司

Method for reducing production of preoxidized broken filament during preparation of polyacrylonitrile-based carbon fiber

InactiveCN101760807AAvoid physical damageAvoid breakingFibre chemical featuresWater contentFiber bundle

The invention discloses a method for reducing the production of preoxidized broken filament during the preparation of polyacrylonitrile-based carbon fiber, characterized in that: dipping: polyacrylonitrile-based carbon fiber precursor is dipped with pure water until the water content in the precursor is 5-15wt%; or polyacrylonitrile-based carbon fiber precursor is dipped with epoxy ethane modified silicone oil emulsion or ammonia modified silicone oil emulsion until the water content in the precursor is 5-15wt% and attached amount of oil is 0.5-1wt%; and shaping: the dipped precursor is subject to shaping. Owing to the effect of surface tension of the pure water, a fiber bundle dipped with the pure water is increased in convergence property, and the generated broken filaments are adhered to the fiber bundle; a layer of protective film is formed on the surface of fiber by using the fiber bundle dipped with the oil emulsion, thereby preventing inter-fiber adhesion and doubling and simultaneously avoiding the physical damage to fibers by furnace rollers; and the shaping treatment can effectively relieve the internal stress generated in the production process of the precursor, thereby avoiding fibers from tension fracture in the process of preoxidation.

Owner:ZHONGFU SHENYING CARBON FIBER

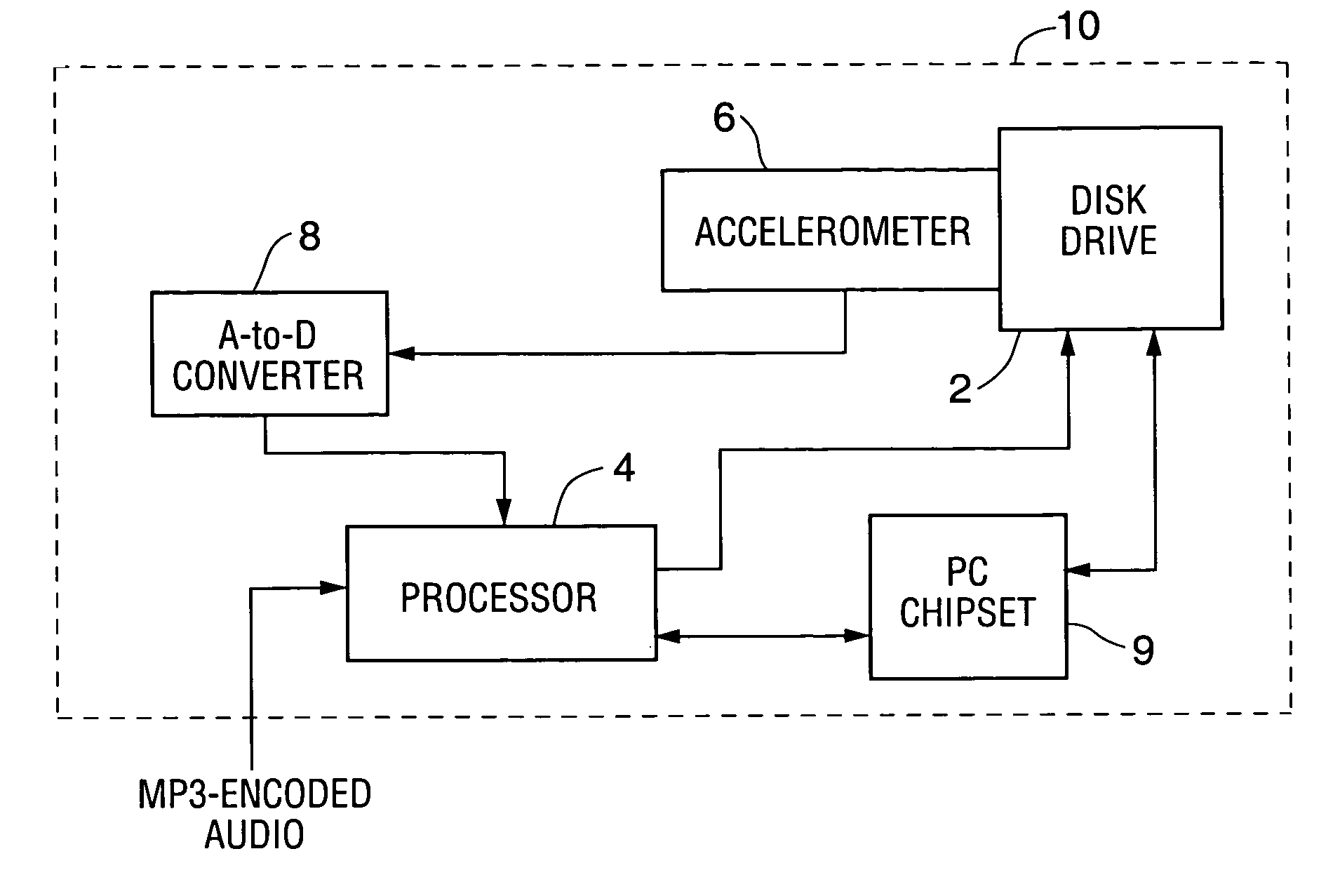

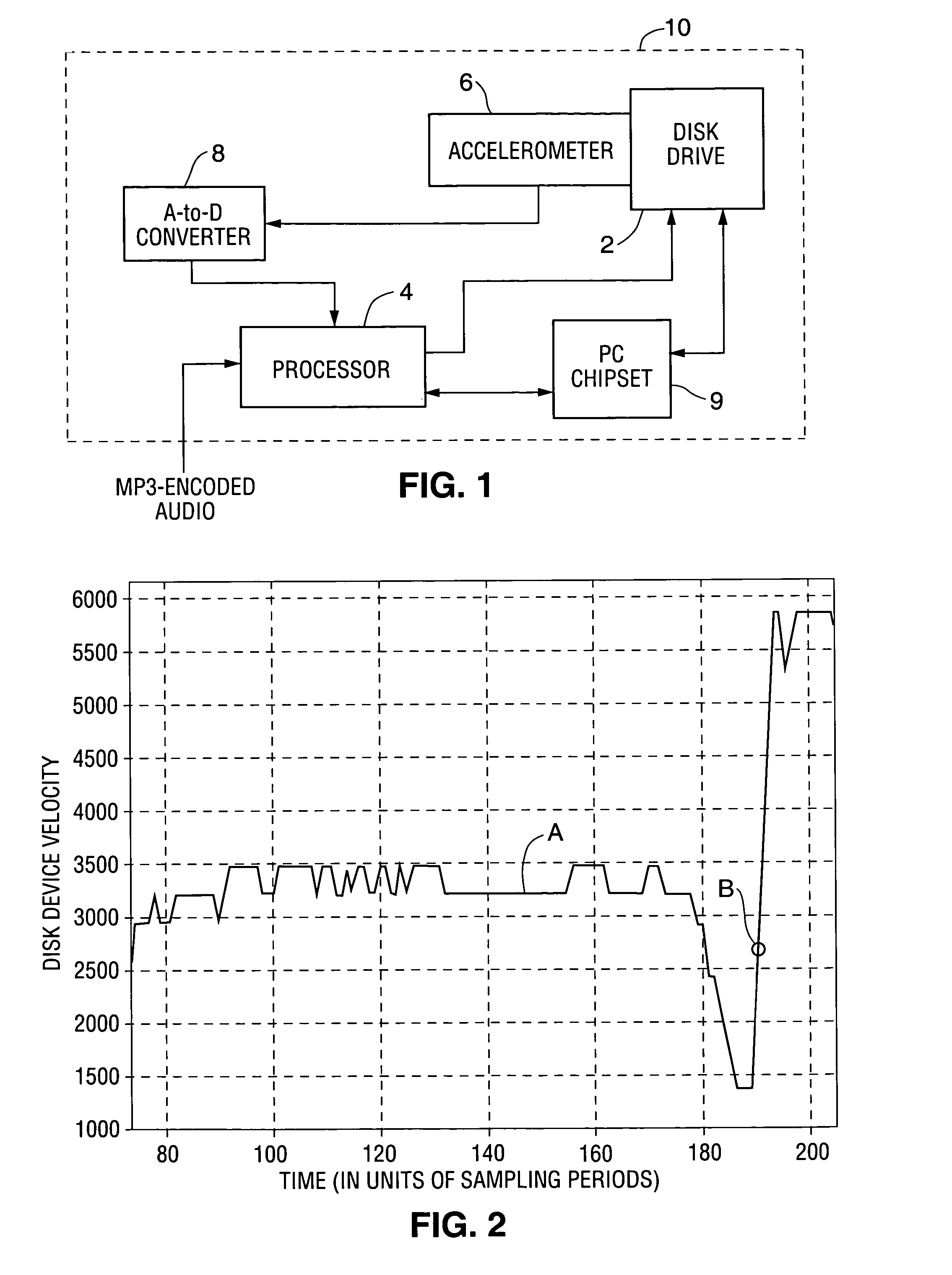

Portable device with freefall detection or audio processing subsystem and freefall detection or audio processing method

ActiveUS7751142B2Avoid physical damageProtection from damageDriving/moving recording headsRecord information storageComputer hardwareAccelerometer

In a class of embodiments, a method and apparatus for detecting freefall of a disk device (thereby predicting that the disk device will likely suffer imminent physical impact) and typically also preventing damage that a disk drive of the device would otherwise suffer if and when a predicted impact occurs. In some embodiments, a disk device includes a freefall detection processor and a CPU. The freefall detection processor is configured to monitor acceleration data to determine whether the disk device is in freefall and to perform at least one other operation (e.g., decoding of MP3-encoded audio data to generate decoded audio data) while the CPU performs at least one other task. Other embodiments pertain to a portable device including a digital audio processing subsystem and an accelerometer. The digital audio processing subsystem is configured to monitor acceleration data to identify any rhythm associated with motion of the portable device and to modify the playback of audio data in response to any such identified rhythm.

Owner:NVIDIA CORP

Touch window and touch device including the same

ActiveCN104571687AExcellent electrical propertiesImprove reliabilityInput/output processes for data processingComputer scienceElectrode

Owner:LG INNOTEK CO LTD

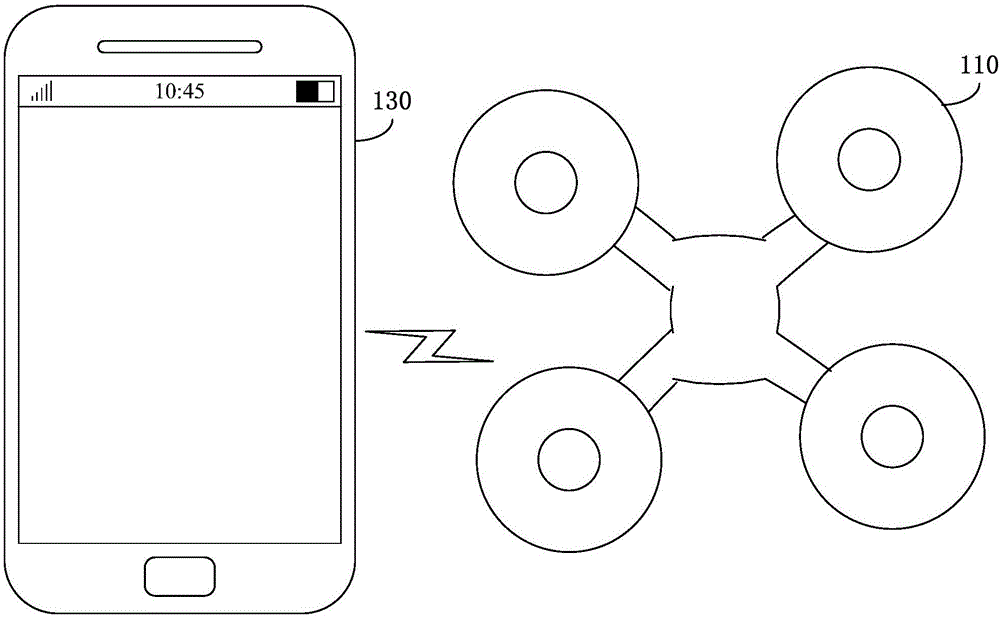

Unmanned aerial vehicle control method and unmanned aerial vehicle control device

InactiveCN106054915AAvoid physical damageIncrease the level of autonomous controlActuated automaticallyRemote controlled aircraftEmergency treatmentFlight level

The invention relates to an unmanned aerial vehicle (UAV) control method and a UAV control device. The method comprises the steps as follows: when a UAV is in a first flight state, acquiring meteorological data of the current location of the UAV, wherein the first flight state is a state showing that the UAV is flying stably or is about to take off; determining the current dangerous flight level of the UAV according to the acquired meteorological data, wherein the dangerous flight level represents the level of danger caused by different weather conditions to the flight of the UAV; and if the dangerous flight level is a first preset level, switching the UAV to a second flight state, wherein the first preset level is a level at which the UAV is unable to fly safely, and the second flight state is a state showing that the UAV flies under emergency or stops flying. According to the technical scheme, a UAV can acquire meteorological data automatically and in real time and perform emergency treatment, so physical damage to the UAV caused by dangerous weather is avoided.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

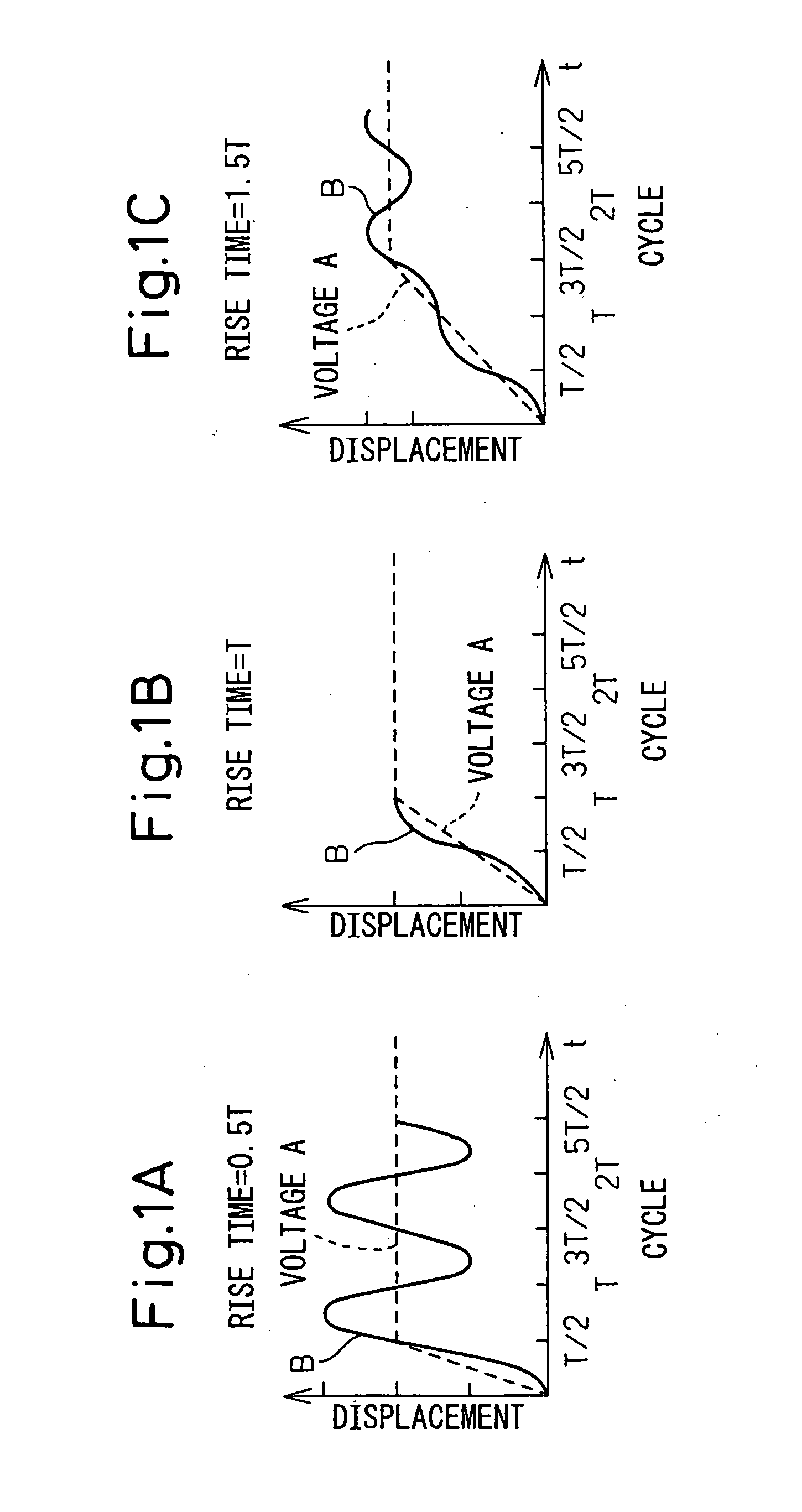

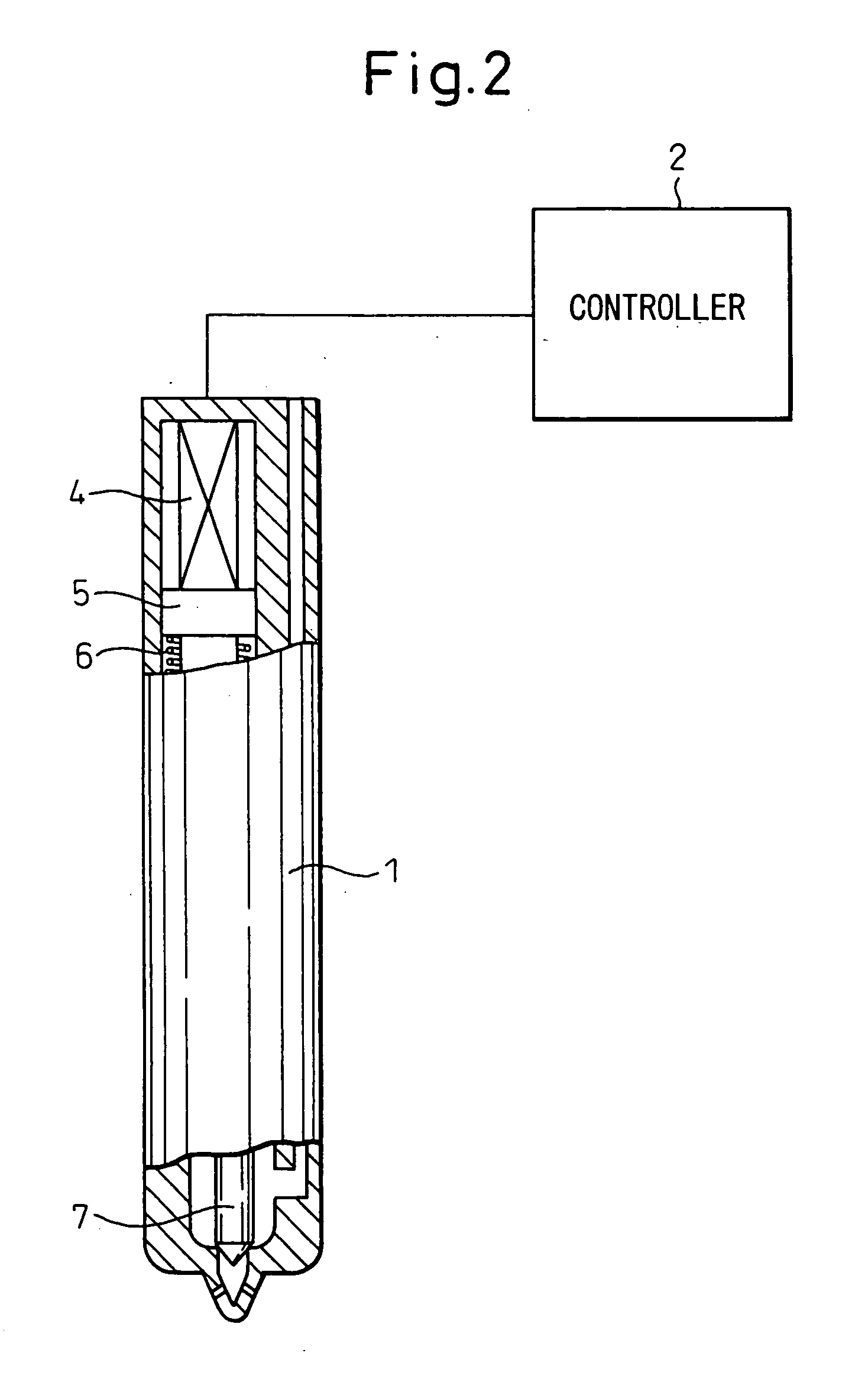

Fuel injection device for internal combustion engine

InactiveUS20060231311A1Dropping loadIncreased durabilityElectrical controlVehicle fittings for lifting and manoeuvringInternal combustion engineFuel injection

A fuel injection device wherein when the combined natural resonant period of a piezo stack and a driving member constituting part of a piezo injector of a fuel injection device is denoted by T, and the voltage rise time taken from the moment the charging to the piezo stack is initiated until the piezo stack is charged to a target charge voltage is denoted by t, then, in order to prevent oscillating loads from being applied to the piezo stack after elapse of the voltage rise time t when t≦0.5 T±0.1 T, the voltage rise time t that satisfies the relation 0.6T≦t is set in a controller for the piezo injector and, thus, the voltage rise slope of the piezo stack immediately before reaching the end of the voltage rise time t is made gentler to suppress the expansion and contraction force occurring in the piezo stack and thereby enhance the long-term reliability of the piezo stack.

Owner:DENSO CORP +2

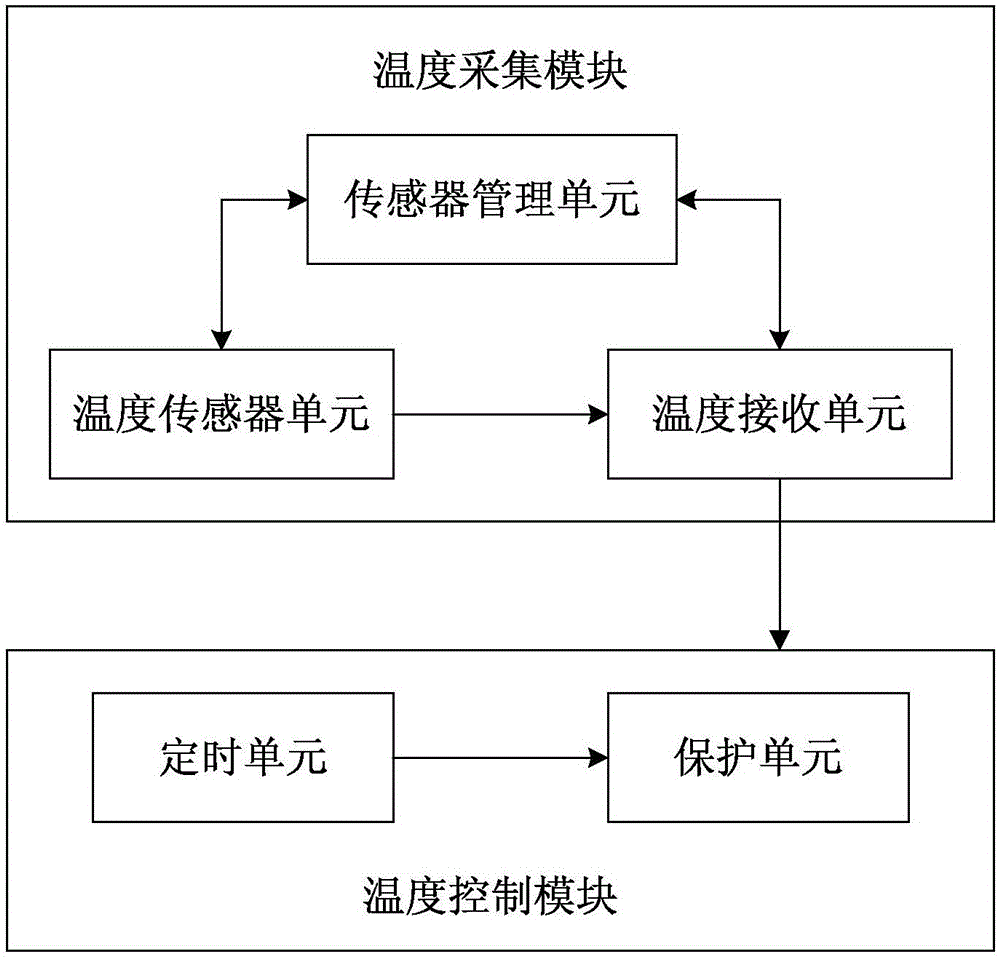

Temperature-based CPU dynamic frequency modulation apparatus and method

InactiveCN106598200APlay a protective effectAvoid physical damagePower supply for data processingTemperature controlFrequency modulation

The invention discloses a temperature-based CPU dynamic frequency modulation apparatus and method, and relates to the CPU frequency modulation field of an Android mobile phone. The apparatus comprises a temperature collection module used for obtaining a CPU temperature of the Android mobile phone in real time, and a temperature control module which has four built-in temperature ranges and is used for dynamically switching the CPU to a corresponding working mode according to the temperature range of the CPU. The CPU working mode of the Android mobile phone is automatically adjusted through the temperatures; and when the temperature is too high, the CPU working frequency is lowered to protect the mobile phone, so that physical damage of the mobile phone caused by the too high temperature can be avoided.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

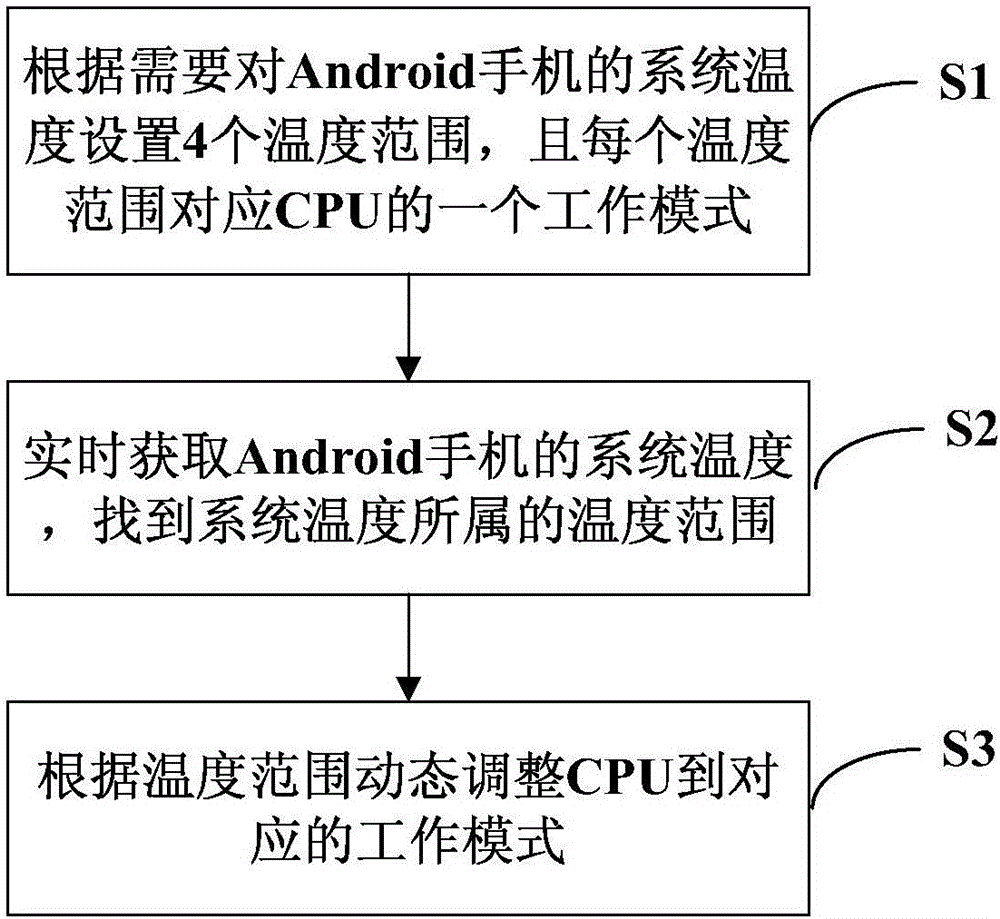

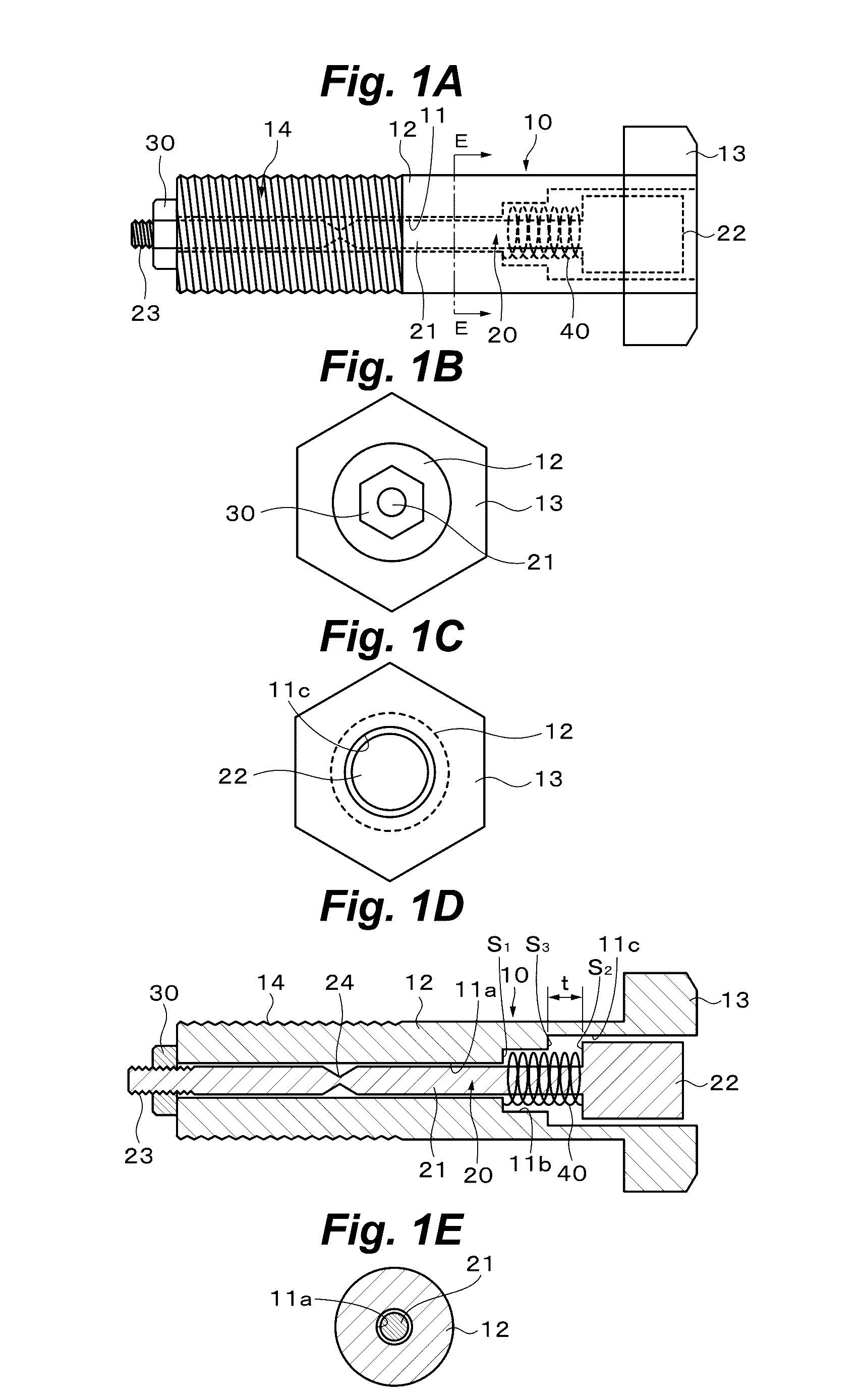

Failure detection sensor, failure detection system, and structure

ActiveUS20160370268A1Easy to detectLow priceLoad modified fastenersMaterial strength using tensile/compressive forcesStress concentrationPull force

Provided is a failure detection sensor which, when attached to structural members of various structures such as buildings can easily detect the risk of the failure of the structural members, and thus the structure, before such failure occurs and has a simple structure, which leads to realization at a low price.The failure detection sensor comprises: the first member 10 and the second member 20 provided in parallel with the first member 10 such that one end of the second member 20 is fixed to or restricted by the first member 10 and the other end of the second member 20 is not fixed to or restricted by the first member 10, having fracturing characteristics such that the second member 20 fractures during elastic deformation or plastic deformation of the first member 10. The failure detection sensor may have a compression coil spring 40 which applies a tensile force to the other end of the second member 20 on the opposite side of the one end. The first member 10 and the second member 20 are constituted of, for example, a round rod or a square rod and the first member 10 is constituted of, for example, a hollow rod. The second member 20 has a notch 24 which is a stress concentration site between the one end and the other end. The second member 20 is made of brittle materials.

Owner:HIEI KENSETSU

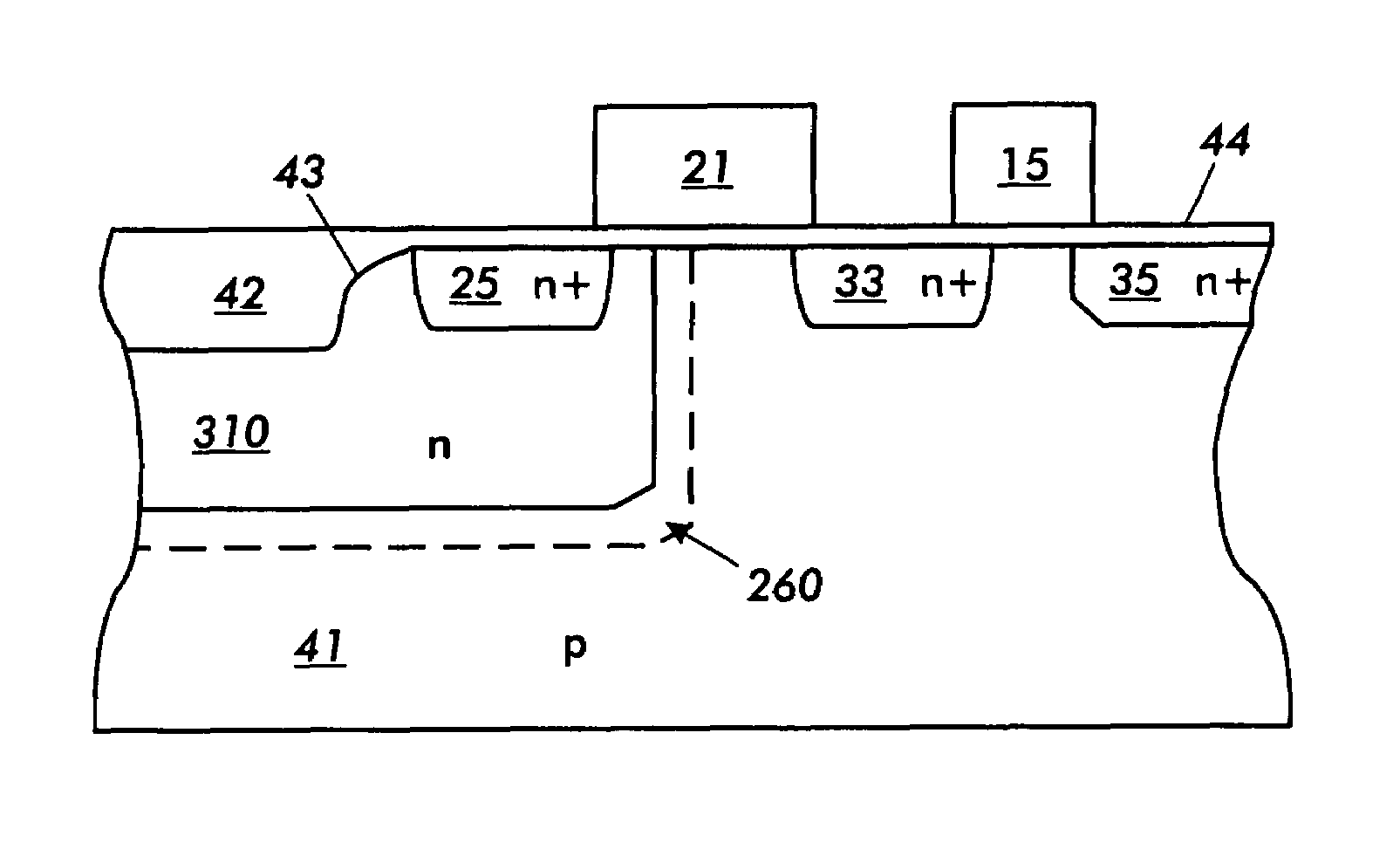

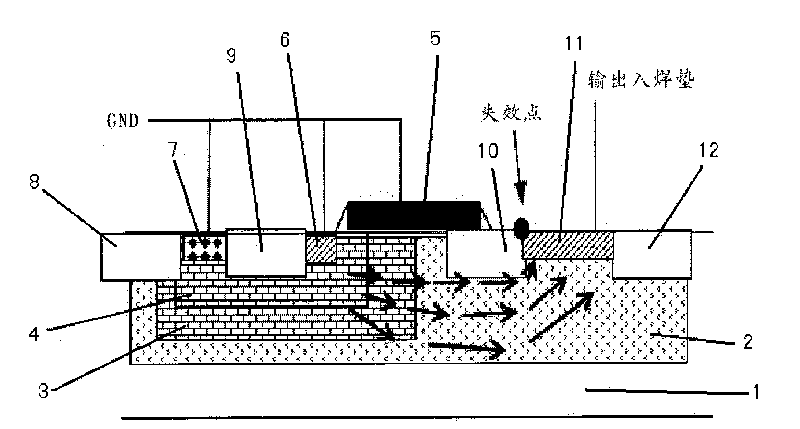

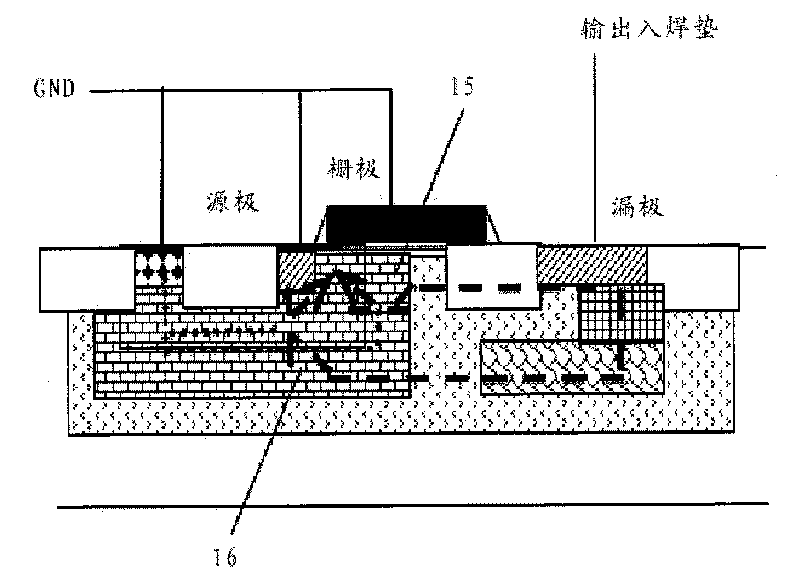

Electrostatic protection structure and manufacturing method thereof

ActiveCN101752347AEvenly distributedImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringIon implantation

The invention discloses an electrostatic protection structure, which comprises a P-type substrate and an N-type deep well on the P-type substrate, wherein an N well is further arranged below a second N+ diffusion region and a fourth field oxide region and in the range of the N-type deep well; and an N-type secondary diffusion region is further arranged below the N well. The invention further discloses a manufacturing method for the electrostatic protection structure, wherein the N-type secondary diffusion region is formed by an ion implantation process after the formation of the field oxide region and before the formation of the N well. The electrostatic protection structure and the manufacturing method can ensure uniform distribution of current during current discharge by arranging the N-type secondary diffusion region under the N-type well, so physical damage caused to the electrostatic protection structure is avoided and the stability of the device is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

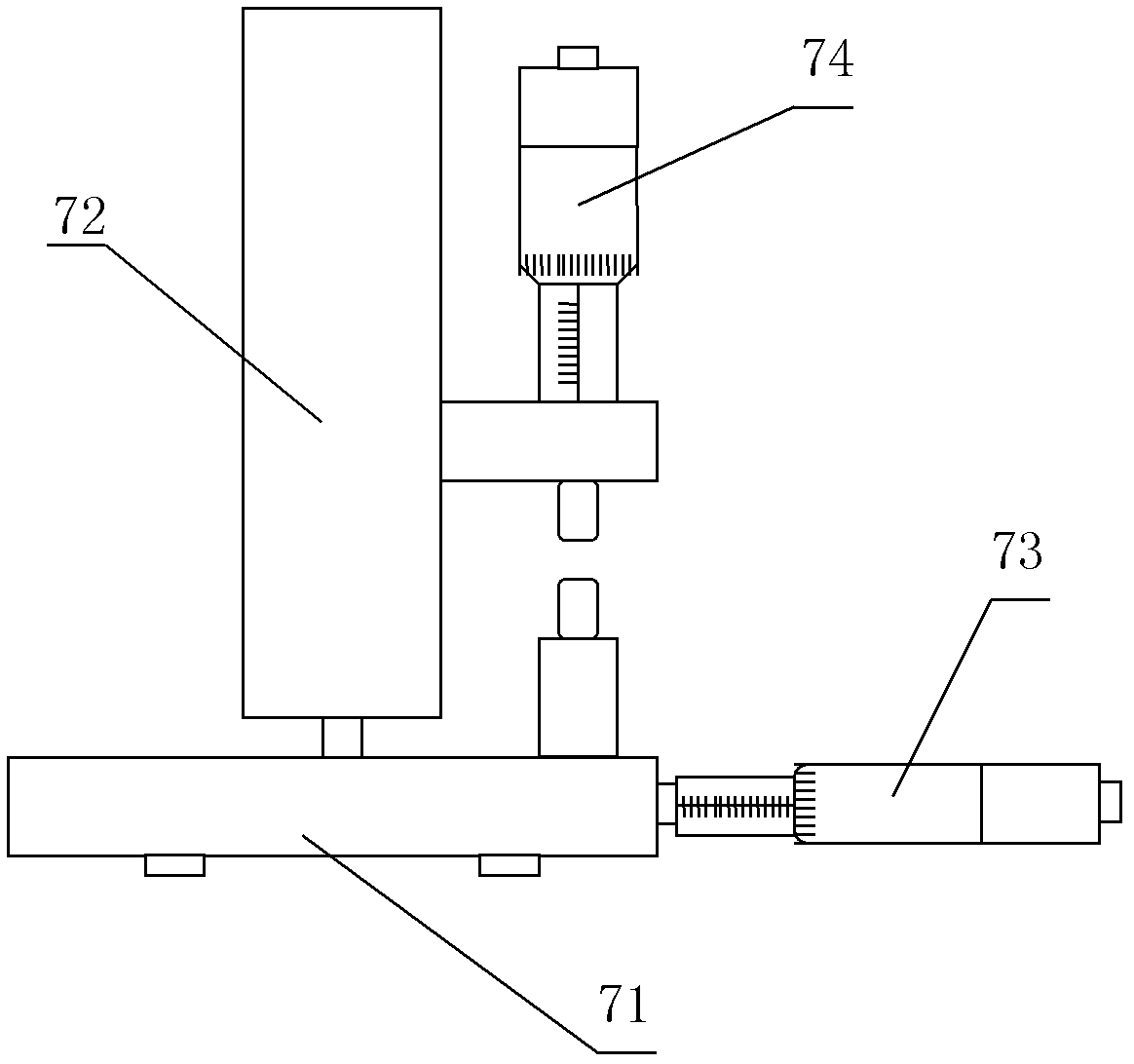

Device and method for manufacturing tapered optical fiber

InactiveCN102565947AAvoid physical damageReduce processing timeCoupling light guidesGalvanometerEngineering

The invention discloses a device and a method for manufacturing a tapered optical fiber. The device comprises an optical flat, a computer terminal, a carbon dioxide laser, a scanning galvanometer, a metal film plated reflector, a placing platform, two bi-dimensional accurate adjusting brackets, two optical fiber fixing parts and a plurality of pairs of weights. The placing platform is used for placing the metal film plated reflector, the two bi-dimensional accurate adjusting brackets are respectively arranged on two sides of the placing platform, the two optical fiber fixing parts are respectively fixed on the two bi-dimensional accurate adjusting brackets and are respectively used for fixing one of two ends of the processed optical fiber, the plurality of pairs of weights are used for suspending on the two ends of the processed optical fiber, the mirror surface of the reflector is right against an output end of the carbon dioxide laser, during usage, a portion to be processed with a coating layer removed in the processed optical fiber is enabled to tightly cling to the mirror surface of the reflector and is located on a focal plane of a focusing lens of the carbon dioxide laser, output laser spots of the carbon dioxide laser are controlled by the computer terminal, and the weights are quickly pulled after one scanning is completed to obtain the tapered optical fiber. Not onlythe processing time is shortened, but also physical damage to the optical fiber caused by long time action of the output laser spots on the optical fiber is avoided.

Owner:NINGBO UNIV

Fiber grating sensor based on composite grating linear array and sensing method

The invention provides a fiber grating sensor based on a composite grating linear array. The fiber grating sensor comprises fibers and a composite grating linear array, and the composite grating linear array comprises a tilted grating and a Bragg reflection grating group which are connected to the fiber in series connection in order; wherein, one group of the tilted grating is provided, and the included angle between a cross section of the fiber and the tilted grating is 3-15 degrees; the Bragg reflection grating group comprises two or more groups of Bragg reflection gratings which are etchedalong the cross section of the fiber, and Bragg reflection wavelengths of each group of Bragg reflection gratings are different; wavelengths of cladding mode of the tilted grating and Bragg reflectiongrating reflection peak are synchronously influenced by temperature and strain, and the cladding mode of the tilted grating and the Bragg reflection gratings have same temperature and strain sensitivity coefficient. Grafting writing and fabricating technology is used for periodical rewriting of refractive index of a fiber core, in order to perform sensitivity characteristic of refractive index ofthe titled grafting, and realize a refractive index fiber sensing scheme without physical structure damage and mechanical property damage, and output an environmental refractive index sensitive reflection spectra without temperature and strain influences.

Owner:WUHAN UNIV OF TECH

Method for promoting female and male parent giant salamanders to synchronously mature

InactiveCN103238563APromote maturationAvoid physical damageAnimal husbandryBroodstockArtificial rearing

The invention belongs to the field of animal husbandry, and particularly relates to a method for promoting female and male parent giant salamanders to synchronously mature. The method is suitable for artificial rearing of giant salamanders. The method is characterized by being realized through the following mode: firstly, selecting sexually-mature parent giant salamanders, and artificially domesticating the parent giant salamanders to enable the same to be capable of taking in food initiatively; and secondly, feeding spawning-inducing medicine to the artificially-domesticated parent giant salamanders from the middle of August to the beginning of September in each year, wherein the spawning-inducing medicine is prepared by mixing luteinizing hormone releasing hormone analogs (LHR-A), human chorionic gonadotrophin (HCG) for fishes and carp pituitary glands. The method of feeding the spawning-inducing medicine is adopted to promote sexual glands of the parent giant salamanders to mature, so that sperm producing amount of male parent giant salamanders is increased by at least 35%, sperm activity is improved by more than 40%, egg laying amount of female parent giant salamanders is increased, and success rate of artificial fertilization is increased by more than 85%.

Owner:赵道全

Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

ActiveCN102790144AAdvantages of production methodSimple structureSolid-state devicesSemiconductor devicesPlanar electrodeLed array

The invention discloses a method for manufacturing an AlGaInP-LED (Light Emitting Diode) integrated micro display component with a single-side electrode structure, wherein the steps comprises: etching multiple first grooves which are mutually intersected on a device body; growing a lower electrode metal layer on the bottom part of each groove to form the lower electrode metal layer; growing an insulating medium layer above a lower electrode; corroding an area of the lower electrode metal layer outside a lower electrode diagram downward till reaching a certain depth in an N-shaped substrate layer in order to form multiple second grooves; filling opaque diaphragms into the second grooves and the upper part of a protection medium of the lower electrode; manufacturing an upper electrode above a light emitting unit; and electroforming upper and lower electrode leads. With the adoption of the method for manufacturing the LED array micro display device with the planar electrode structure disclosed by the invention, the process difficulty resulting from the manufacturing of the electrodes on the front face and the back face respectively can be prevented; since the manufactured micro display device is provided with the double bar type upper and lower electrodes of which the different faces are perpendicular to each other, the more even current distribution can be obtained; and therefore, the micro display device available for even luminance is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com