Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

A micro-display device and electrode structure technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve problems such as difficult fabrication and high substrate thickness requirements, achieve simple structure, avoid physical damage, and improve uniformity of light emission degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

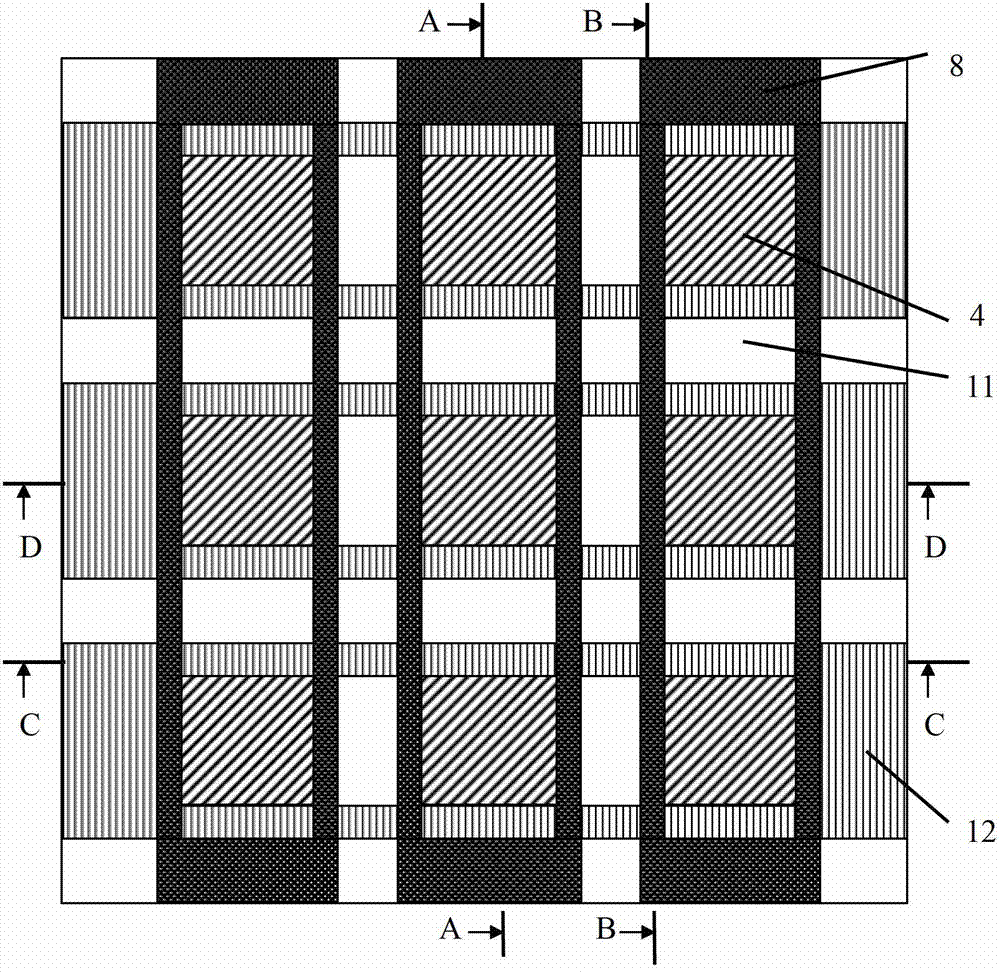

[0033] The inventive concept of the present invention is that for LED array microdisplay devices, the electrode shape is an important factor determining its luminous efficiency and luminous uniformity, and the design of the electrode shape should comprehensively consider the area of the light-transmitting window and the distribution uniformity of the current under the electrode .

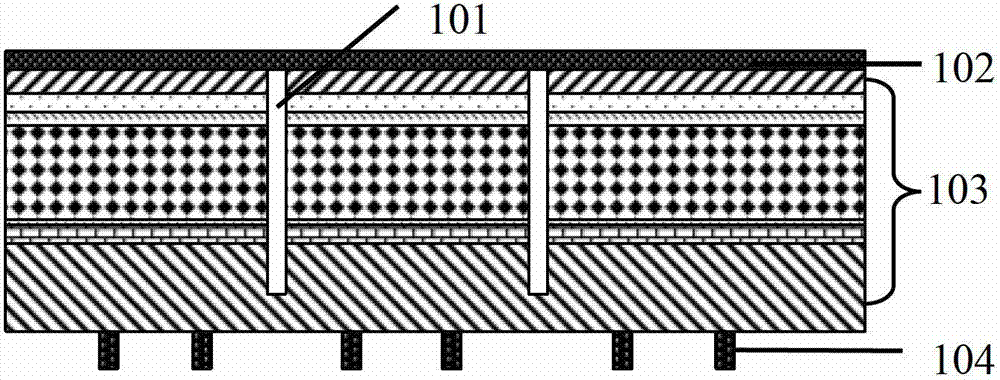

[0034] The manufacturing method of the AlGaInP-LED integrated micro-display device with a single-sided electrode structure proposed by the present invention can avoid the technical difficulties caused by separately making electrodes on the front and back. This manufacturing process is not only simple and easy, but also does not cause damage to the device. Therefore, it will not have any impact on the light emission of the device. The device manufactured by the manufacturing process proposed by the present invention has double-striped upper and lower electrodes perpendicular to different planes, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com