Optical structure film for carrying out electrode patterning on silver nanowire transparent conductive film and patterning method of optical structure film

A technology of transparent conductive film and optical structure, applied in electrical digital data processing, data processing input/output process, coating and other directions, can solve the problems of serious etching marks and silver migration of nano silver wire transparent conductive film, and achieve good Optical performance and stability, enhanced fluidity, and the effect of eliminating silver migration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The UV hardening solution formula used in this embodiment is as follows:

[0077]

[0078] The specific preparation method is: weigh each raw material according to the proportion, first add pentaerythritol tetraacrylate to CN8885NS resin, stir at 500r / min for 25min, then add dodecyl mercaptan, light stabilizer 292, BYK- 333 and photoinitiator 754, continue to stir for 20 minutes to obtain UV hardening solution.

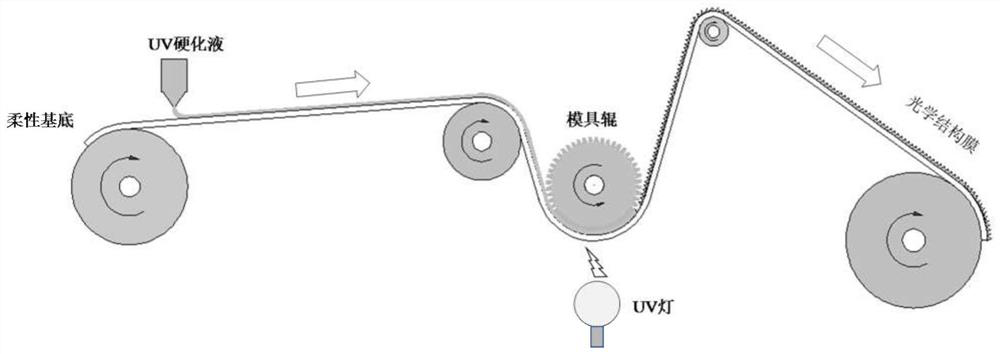

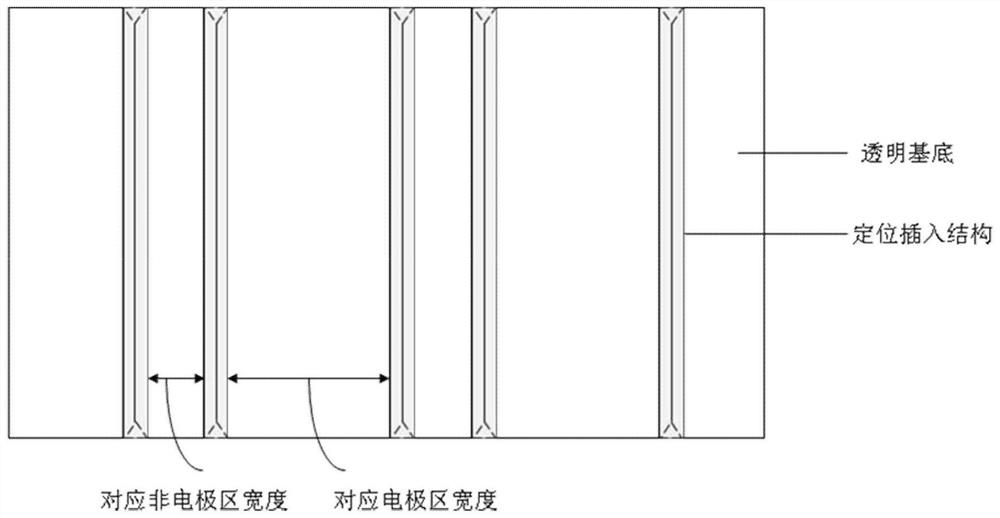

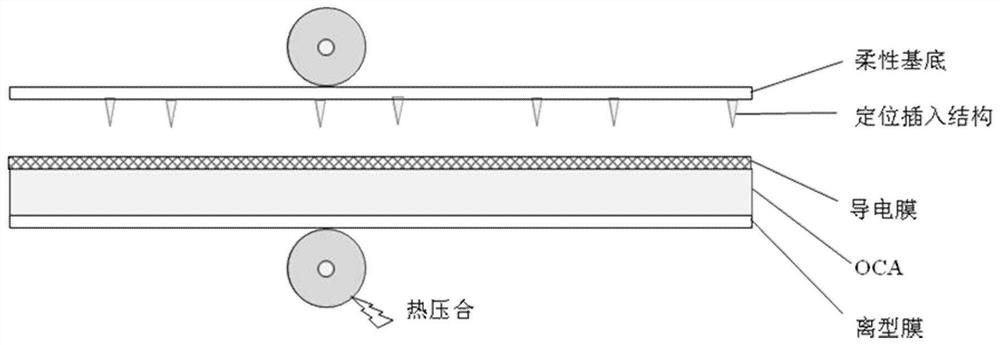

[0079] Such as figure 1 As shown, based on the above-mentioned UV hardening solution, an optical structure film is produced in this embodiment:

[0080] Firstly, the UV hardening solution is coated on the surface of the flexible substrate PET through the dimple coating process;

[0081] The UV hardening solution on the surface of the flexible substrate is then embossed using a mold roll with the desired pattern (made in advance by an electron beam etching process) to form a positioning insertion structure of the desired pattern;

[0082] Finally, UV curin...

Embodiment 2

[0088] This embodiment is the same as Embodiment 1, the only difference is that the UV hardening liquid formula used is as follows:

[0089]

Embodiment 3

[0091] This embodiment is the same as Embodiment 2, the only difference is that the UV hardening liquid formula used is as follows:

[0092]

[0093] Table 1 shows the performance comparison results of the silver nanowire transparent conductive film obtained in the above examples and comparative examples after electrode patterning.

[0094] Table 1: Comparison of the performance of the patterned conductive film obtained in the comparative example and each embodiment

[0095]

[0096]

[0097] It can be seen from Table 1 that the optical structure layer in the silver nano wire flexible transparent conductive film of the present invention does not affect the performance of the conductive film, and the etching marks of the silver nano wire conductive film of the embodiment are obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com