Manufacture method for jointing and reinforcing pipe fitting made from composite materials

A production method and reinforcement technology, applied to household components, other household appliances, household appliances, etc., can solve the problems of long heating time, slow air heat transfer, waste of working hours, manpower, etc., to reduce heating volume and energy consumption , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

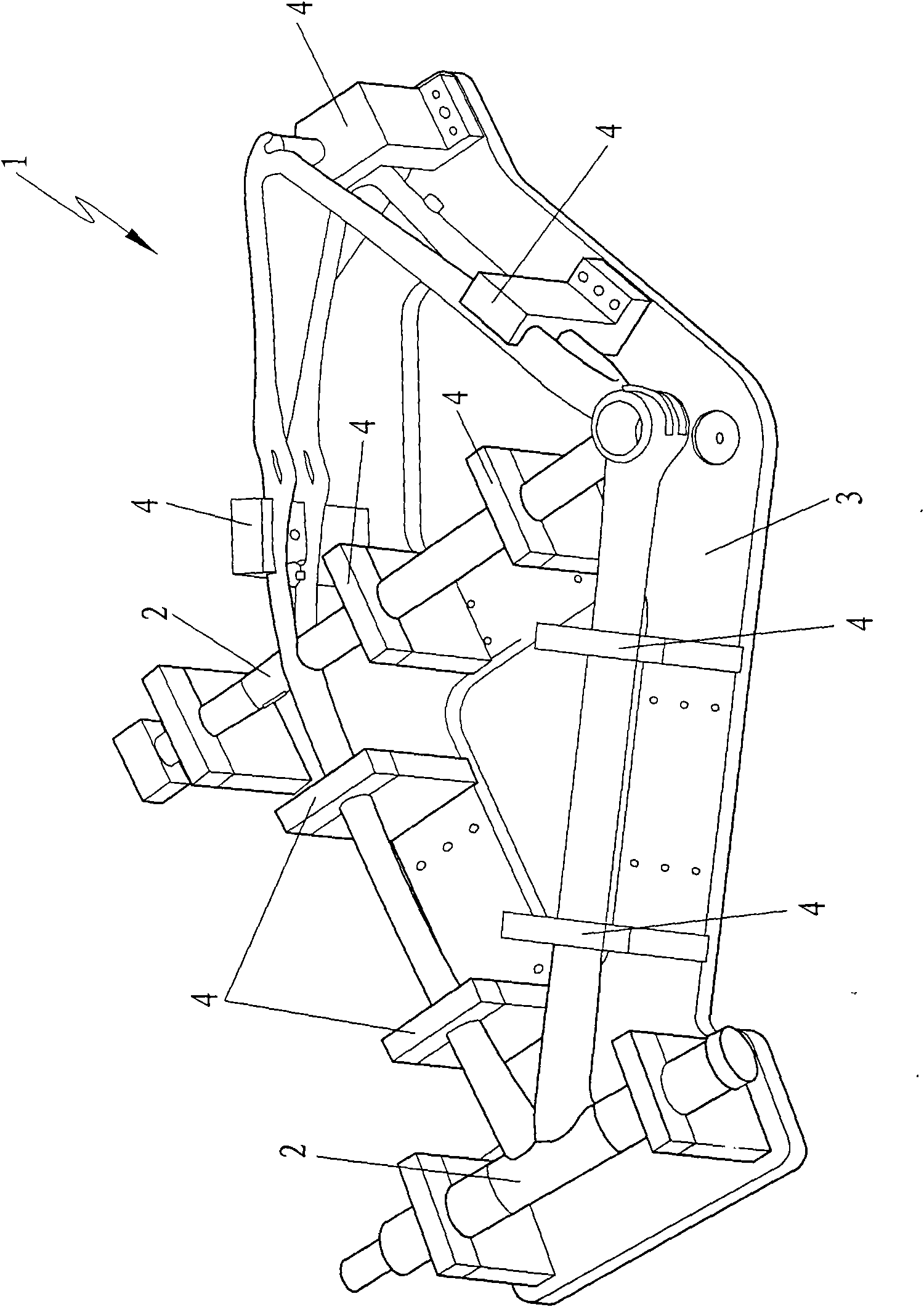

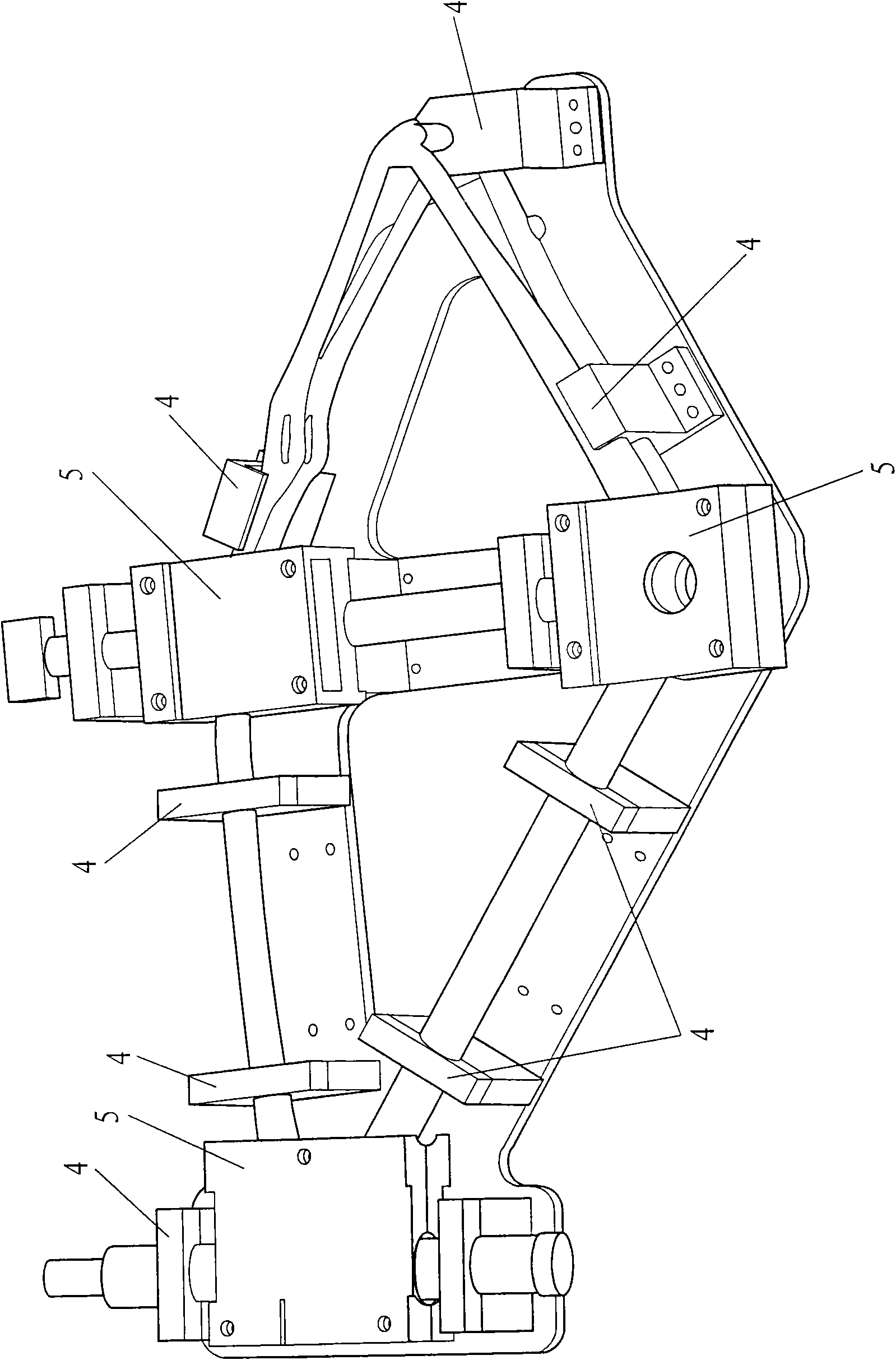

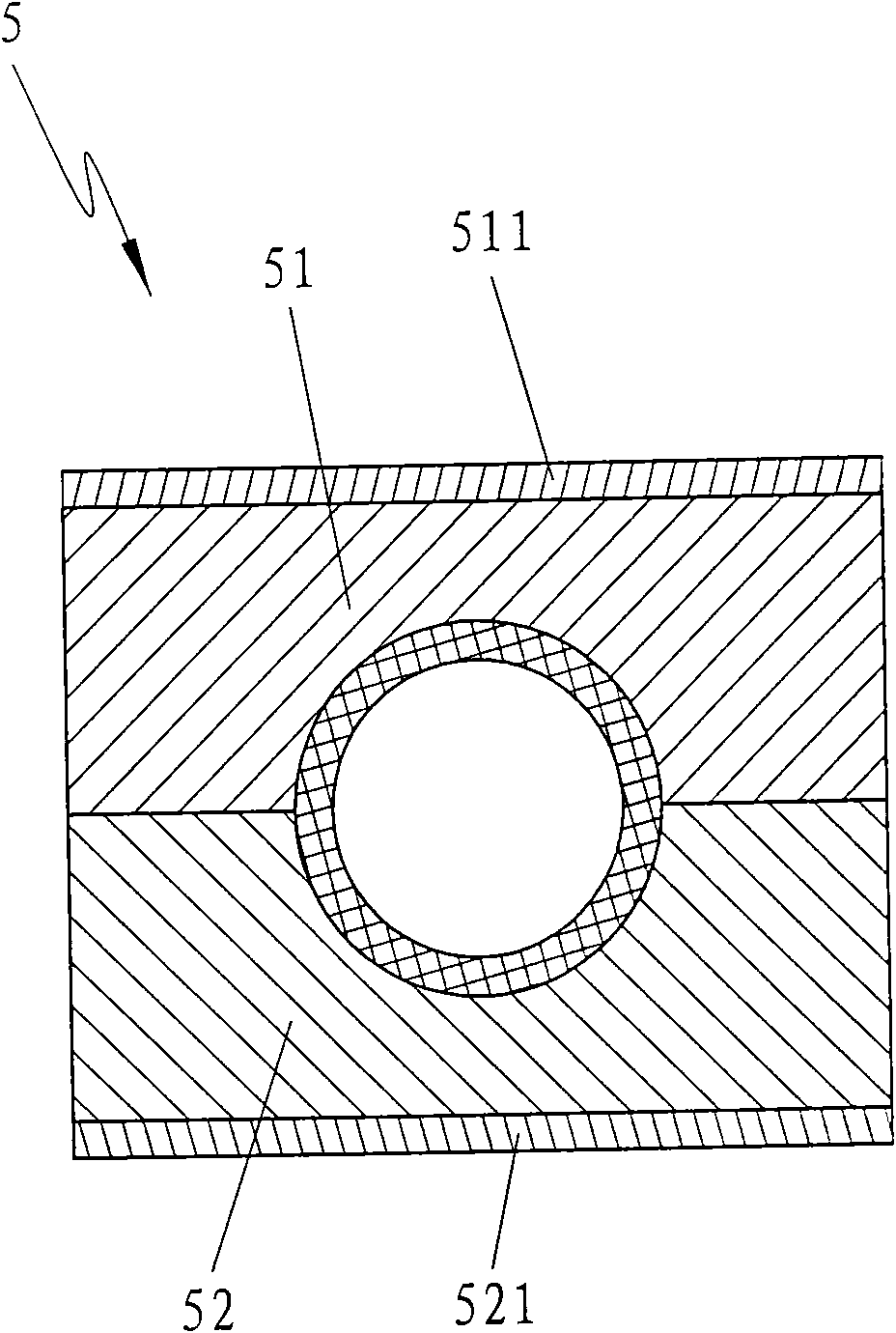

[0015] Such as figure 1 , 2 As shown, the manufacturing method of the joint reinforcement of the composite pipe fittings of the present invention: first, splice the preformed parts of the pipe fittings of the composite material frame body 1, and perform yarn repairing connection at the splicing point 2; then place the spliced frame body 1 on Positioning in the supporting and shaping chassis 3; several supporting and positioning frames 4 are arranged in the chassis 3, and the frame body 1 is positioned and supported by the positioning frames 4; finally, a heating mold 5 is set at the splicing part 2 where yarn mending and reinforcement are required, Cooperate image 3 As shown, the heating mold 5 is composed of an upper mold 51 and a lower mold 52. Here, the structure of the upper and lower molds is exemplified. Of course, the heating mold can also be an independent mold or a left and right mold. The upper mold 51 and the lower mold 52 Heating plates 511, 521 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com