Thermally conductive adhesive tape

An adhesive tape, electrical and thermal conductivity technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor high temperature resistance of PE film, poor strength of PE film, affecting thermal conductivity, etc., and achieve good insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

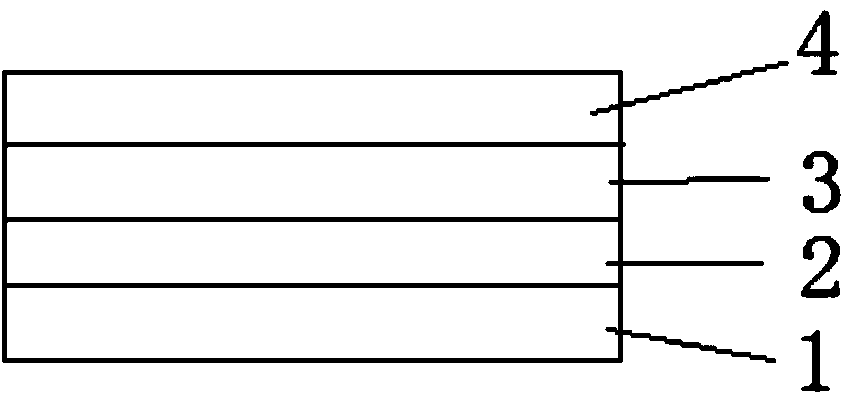

[0014] Such as figure 1 A heat-conducting adhesive tape shown includes a PET transparent film layer 1, and a graphite coating layer 2 is provided on one side of the PET (polyethylene terephthalate) transparent film layer 1, and the graphite coating layer 2 is black. The thermally conductive graphite layer is called black thermally conductive film. The surface of the graphite coating layer 2 is coated with an acrylic pressure-sensitive adhesive layer 3 , and the surface of the acrylic pressure-sensitive adhesive layer 3 is covered with a release film layer 4 . The graphite coating layer 2 is an electrically and thermally conductive layer. The release film layer 4 is a PET release film layer.

[0015] The tape is designed to be ultra-thin without affecting the thermal conductivity of the graphite layer. The graphite film layer can be designed with hemming when die-cutting, so that the graphite film layer has good insulation. It has good insulation for graphite film, mobile p...

Embodiment 2

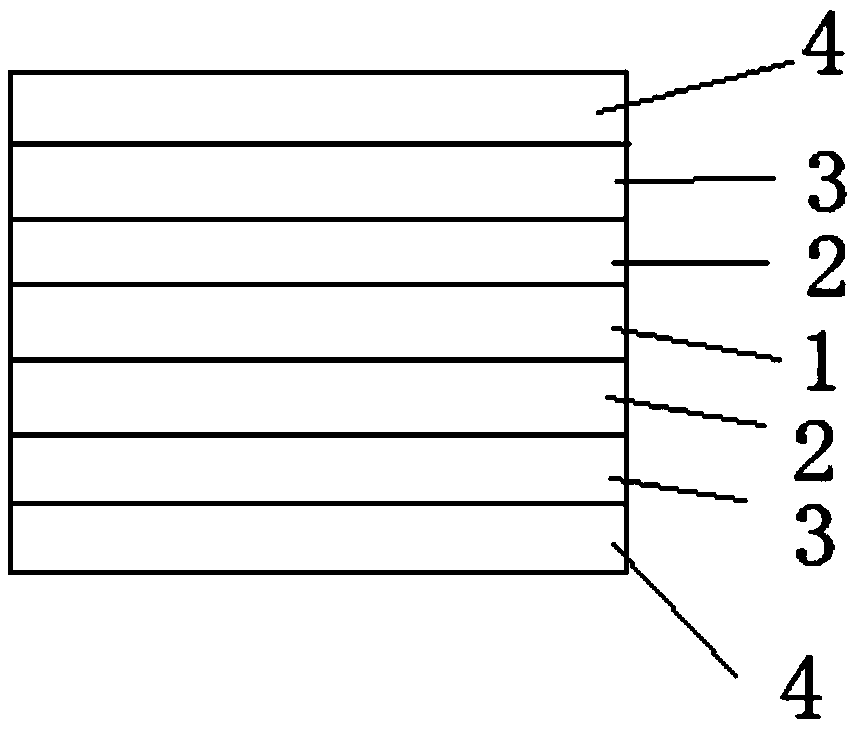

[0017] Such as figure 2 A heat-conducting adhesive tape shown includes a PET transparent film layer 1, and a graphite coating layer 2 is provided on one side of the PET (polyethylene terephthalate) transparent film layer 1, and the graphite coating layer 2 is black. The thermally conductive graphite layer is called black thermally conductive film. The surface of the graphite coating layer 2 is coated with an acrylic pressure-sensitive adhesive layer 3 , and the surface of the acrylic pressure-sensitive adhesive layer 3 is covered with a release film layer 4 . The other side of the PET transparent film layer is also provided with another graphite film layer, and the surface of the graphite film layer is coated with another layer of acrylic pressure-sensitive adhesive layer, and the surface of the acrylic pressure-sensitive adhesive layer is pasted There is another layer of release film. The graphite coating layer 2 is an electrically and thermally conductive layer. The rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com