Uranium dioxide core aging tank, and system and method for aging, cleaning and drying

A uranium dioxide, washing and drying technology is applied in the field of uranium dioxide core aging, washing and drying systems, and can solve the problems of unfavorable industrial scale production, complicated operation process, health of operators, and environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

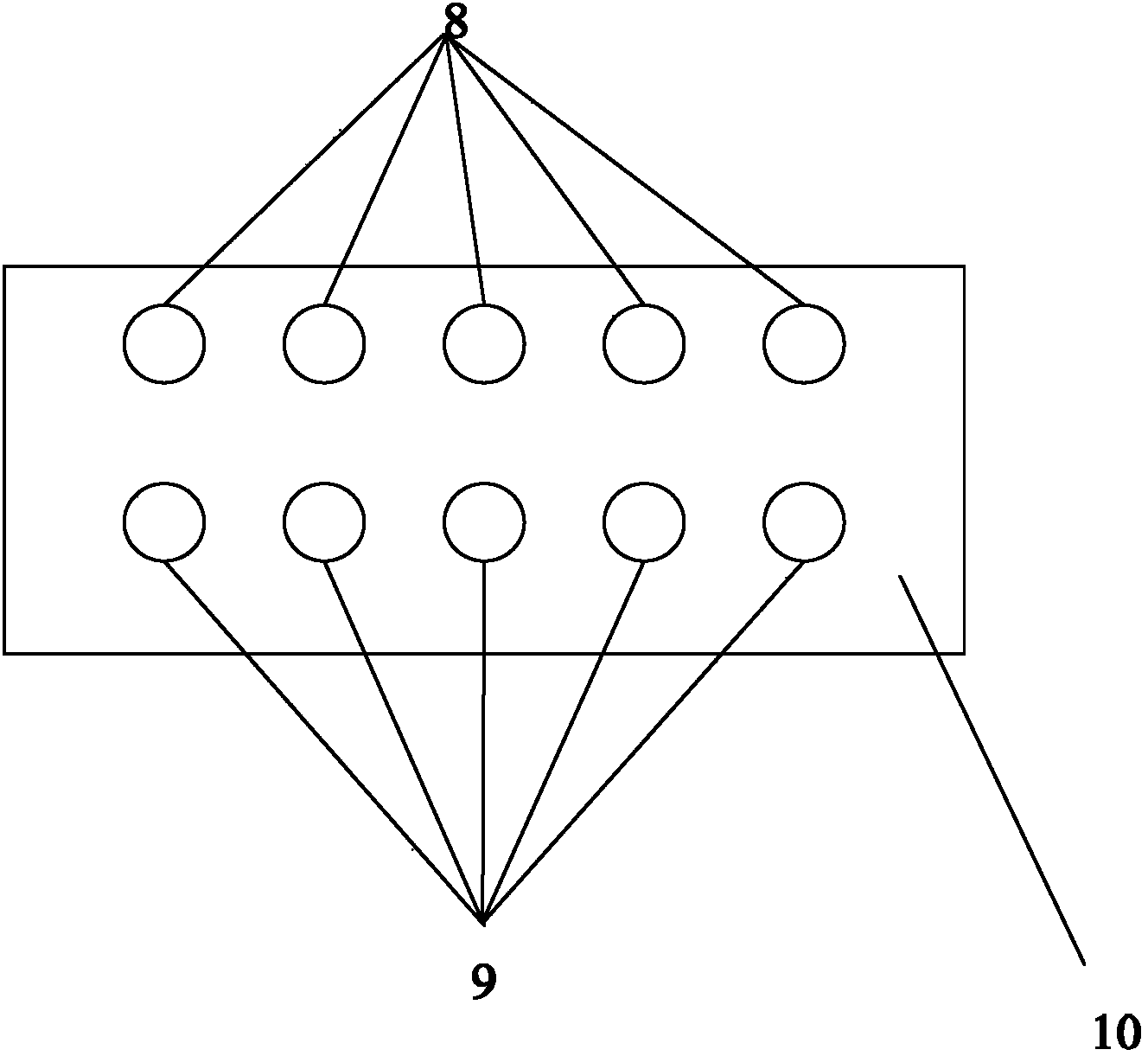

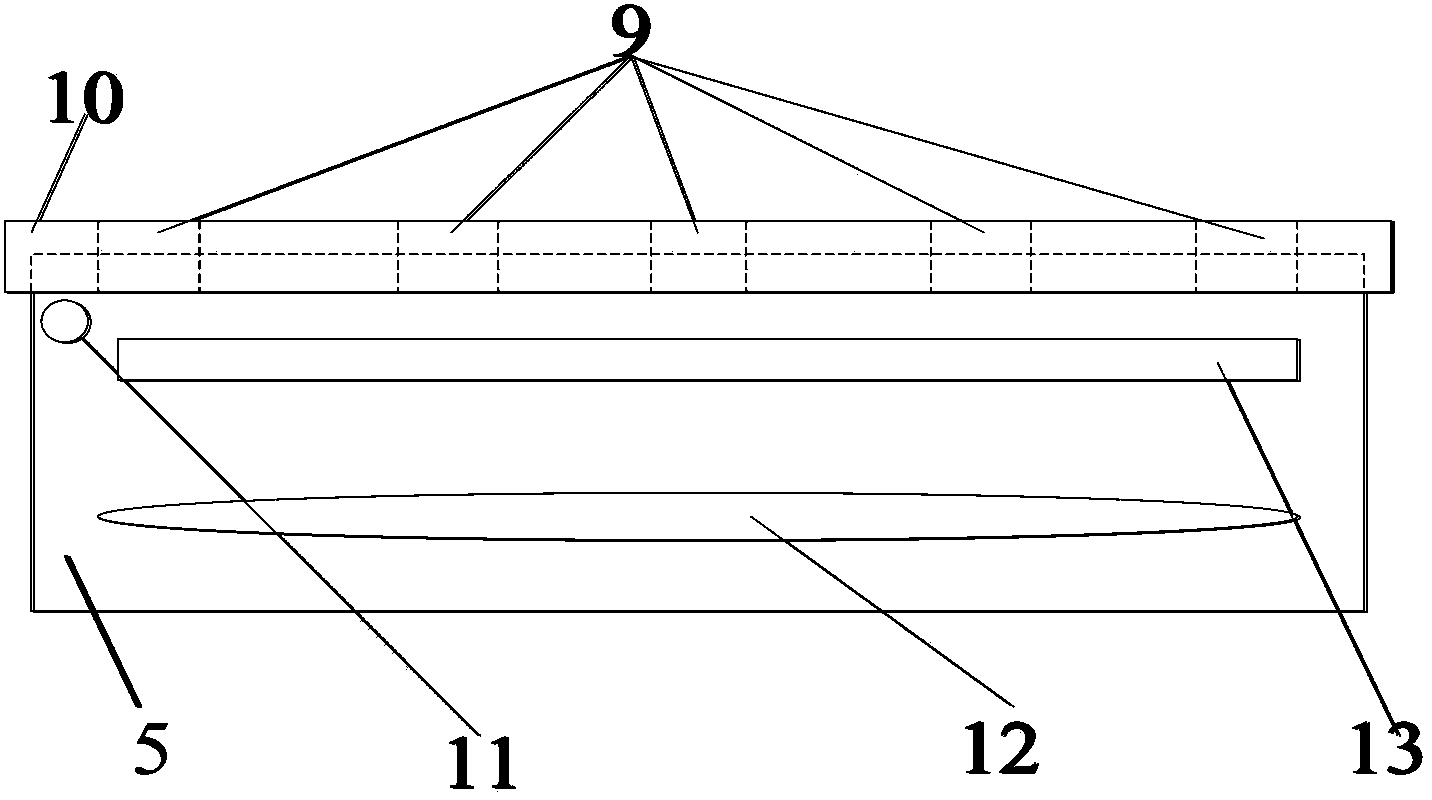

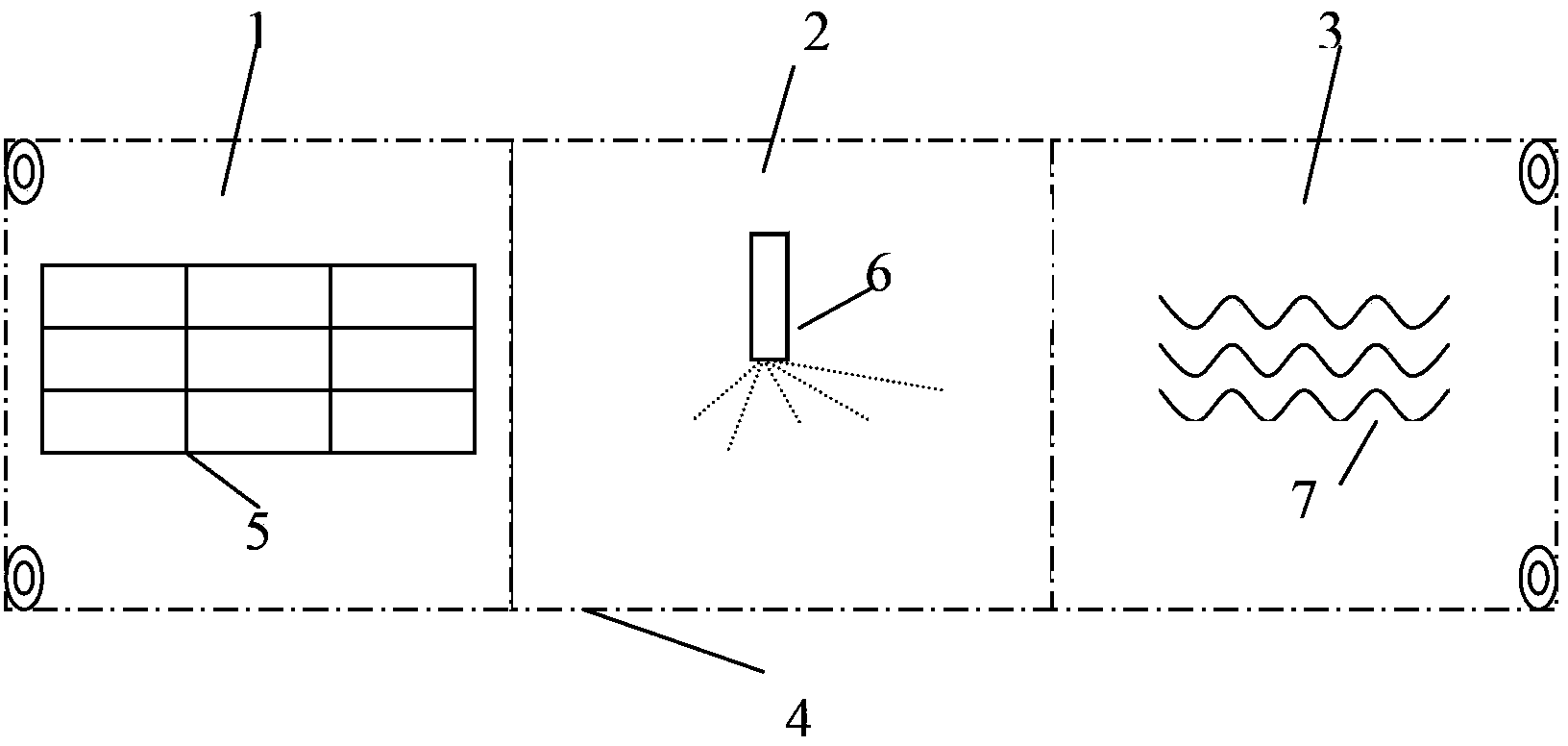

[0037] Uranium dioxide core aging tank, the aging tank is a cylindrical body with an opening on the upper surface, and the opening is sealed with a sealing cover. The aging tank sealed with the sealing cover and the sealing cover form a complete aging tank. The upper surface of the groove is the sealing cover. The sealing cover has an air outlet, a spray interface, a heating device interface, and a vibrating device on the side surface of the aging tank. At the same time, a stirring device may be provided inside the aging tank.

[0038] The vibrating device may be any one of mechanical vibrating device, ultrasonic vibrating device or a combination of both. A mechanical stirring device can be installed inside the aging tank as required.

[0039] The aging tank belt can have its own heating device, and the heating device can be laid inside or outside the aging tank. The external heating device of the aging tank can be any combination of heating rods, heating sheets, and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com