Revolving furnace tail gas filter device for manufacturing uranium dioxide from uranium hexafluoride

A technology of uranium dioxide and converter exhaust gas, which is applied in the direction of uranium dioxide, uranium oxide/hydroxide, chemical/physical/physicochemical processes, etc., can solve problems such as filter tube blockage, improve service life and avoid root Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

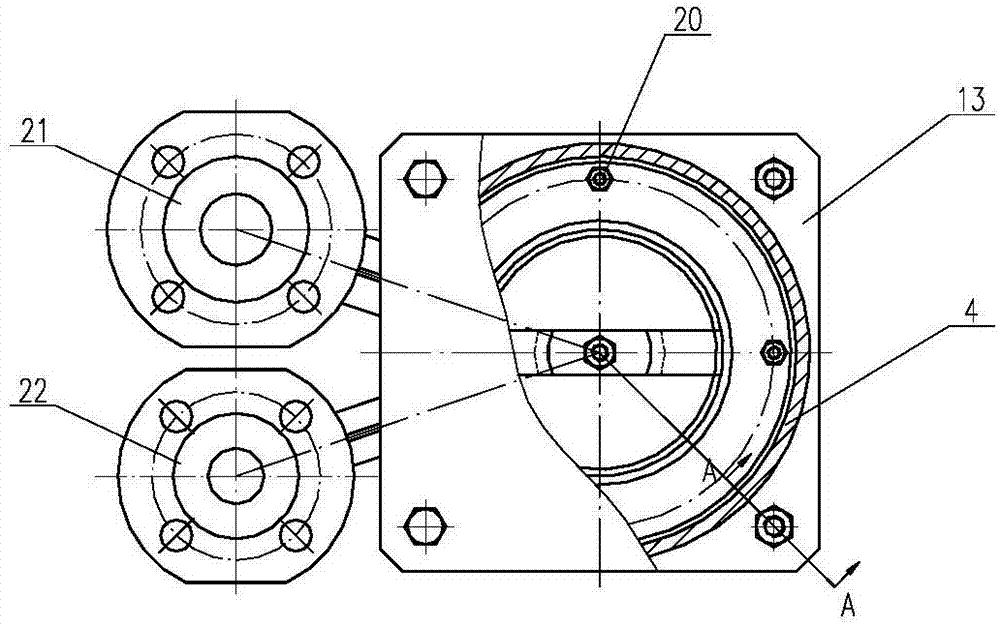

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

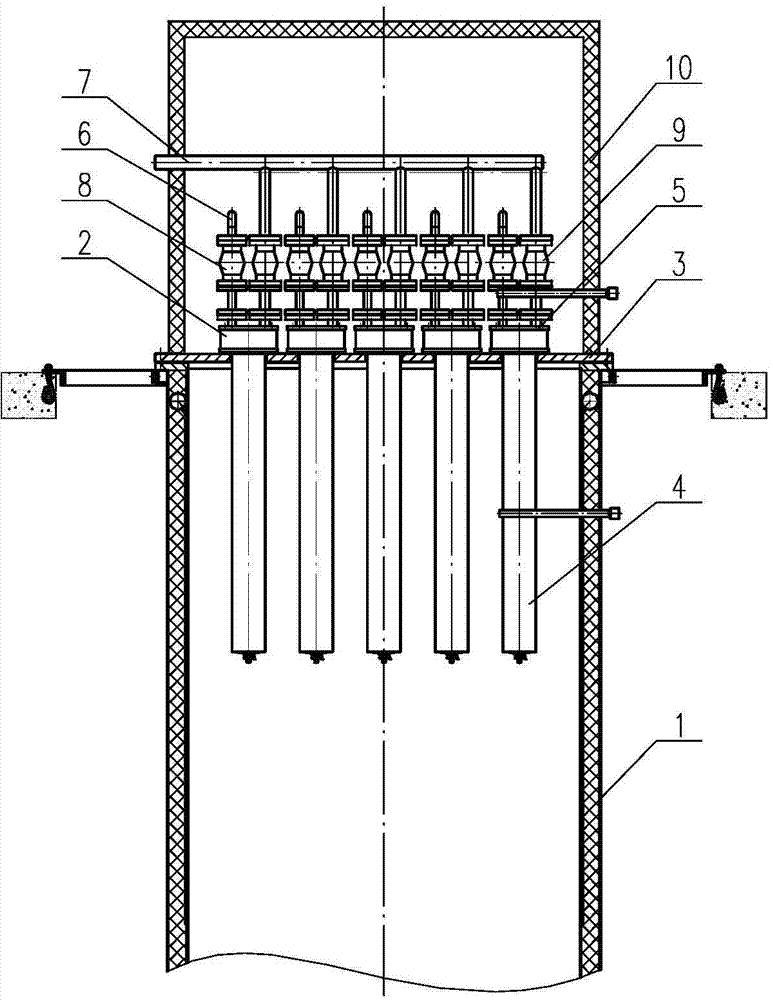

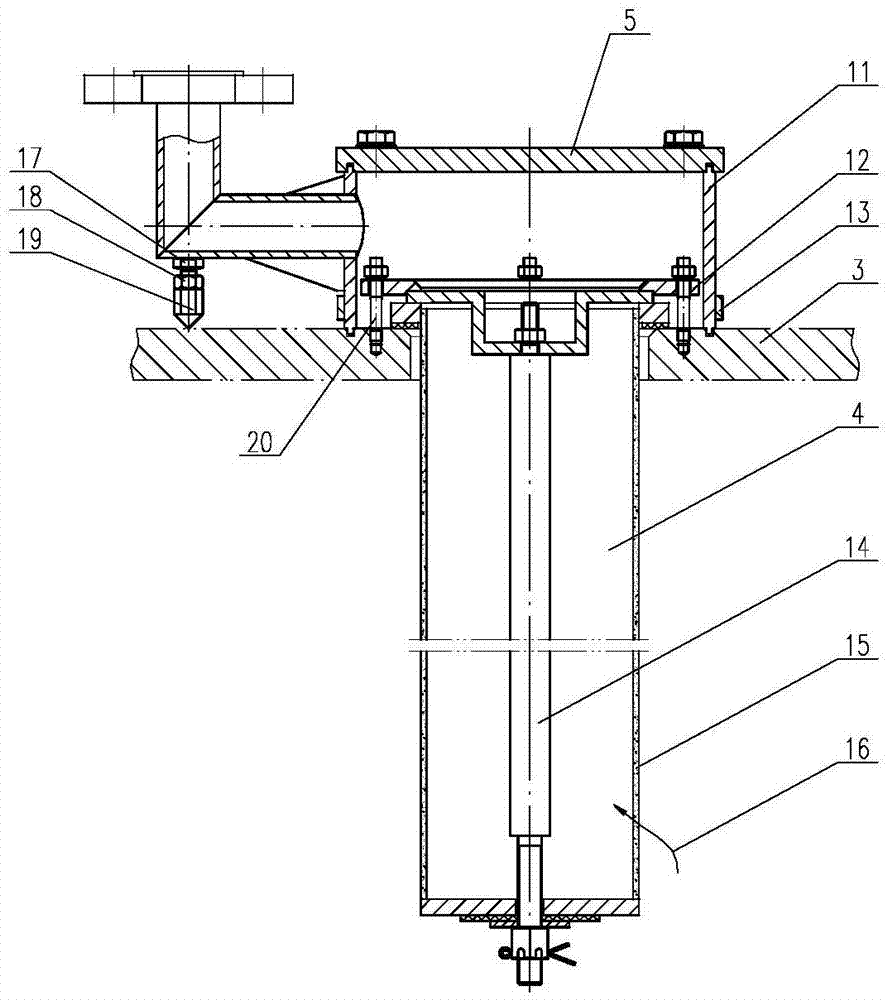

[0026] Such as figure 1 As shown, the reaction chamber 1 of the converter is composed of a shell in a vertical position as a whole, and the gaseous uranium hexafluoride UF is fed through the feed nozzle 6 And water vapor is injected into the shell of reaction chamber 1. Uranium hexafluoride UF 6 The hydrolysis reaction with water vapor in reaction chamber 1 produces powdered uranyl fluoride. The uranyl fluoride powder falls to the bottom of reaction chamber 1 and is collected by a feeding screw, which puts it in the reaction chamber 1. The uranyl fluoride formed in solid powder form in the process is conveyed to the inlet of a furnace tube where it is converted to uranium dioxide.

[0027] The hydrolysis reaction of uranium hexafluoride produces gaseous HF in the reaction chamber 1 , and the gaseous HF is discharged out of the reaction chamber 1 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com