Preparation method of kularite ceramic solidifying body

A technology of ceramic solidification and monazite, applied in radioactive purification, nuclear engineering, etc., to achieve the effects of being beneficial to engineering applications, increasing density, and shortening sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

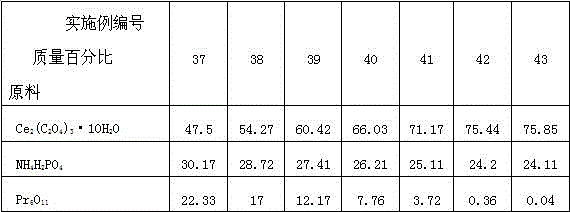

[0031] A kind of preparation method of cerium monazite ceramic solidified body, is based on Ce 2 (C 2 o 4 ) 3 10H 2 O, NH 4 h 2 PO 4 、Gd 2 (C 2 o 4 ) 3 10H 2 O is the raw material, and the formula is: Ce 2 (C 2 o 4 ) 3 10H 2 O 68.06wt.% (weight percent), NH 4 h 2 PO 4 24.02wt.%, Gd 2 (C 2 o 4 ) 3 10H 2 O 7.92wt.%; Weigh various raw materials, select materials: ball: absolute ethanol or / and water at 1:3.0:1.5 (mass ratio), use planetary mill for 4 hours, dry, add 6% polyethylene Alcohol (PVA) sol (the concentration of PVA is 12%), mixing, sieving, granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 10MPa, and then use a pressure of 200MPa to cold isostatically press it; the molded green body is heat-treated at 700°C for 300 minutes; the heat-treated green body is Sintering in a vacuum hot-pressing sintering furnace at 1100° C. and 30 MPa for 120 minutes to obtain a solid-dissolved gadolinium cerium...

Embodiment 2

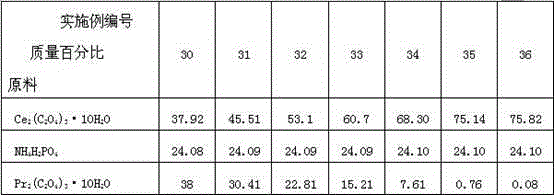

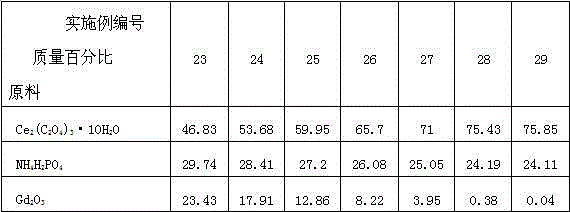

[0033] A kind of preparation method of cerium monazite ceramic solidified body, is based on Ce 2 (C 2 o 4 ) 3 10H 2 O, NH 4 h 2 PO 4 、Pr 2 (C 2 o 4 ) 3 10H 2 O is the raw material, and the formula is: Ce 2 (C 2 o 4 ) 3 10H 2 O 68.30wt.% (weight percent), NH 4 h 2 PO 4 24.10wt.%, Pr 2 (C 2 o 4 ) 3 10H 2 O 7.61wt.%; Weigh various raw materials, select materials: ball: absolute ethanol or / and water at 1:3.0:1.5 (mass ratio), use planetary mill for 4 hours, dry, add 6% polyethylene Alcohol (PVA) sol (the concentration of PVA is 12%), mixing, sieving, granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 10MPa, and then use a pressure of 200MPa to cold isostatically press it; the molded green body is heat-treated at 700°C for 300 minutes; the heat-treated green body is Sintering at 1100° C. and 30 MPa for 120 minutes in a vacuum hot-pressing sintering furnace to obtain a solid-dissolved praseodymium ceri...

Embodiment 3

[0035] A kind of preparation method of cerium monazite ceramic solidified body, is based on Ce 2 (C 2 o 4 ) 3 10H 2 O, NH 4 h 2 PO 4 、Eu 2 (C 2 o 4 ) 3 10H 2 O is the raw material, and the formula is: Ce 2 (C 2 o 4 ) 3 10H 2 O 68.14wt.% (weight percent), NH 4 h 2 PO 4 24.04wt.%, Eu 2 (C 2 o 4 ) 3 10H 2 O 7.82wt.%; Weigh various raw materials, select materials: ball: absolute ethanol or / and water at 1:3.0:1.5 (mass ratio), use planetary mill for 4 hours, dry, add 6% polyethylene Alcohol (PVA) sol (the concentration of PVA is 12%), mixing, sieving, granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 10MPa, and then use a pressure of 200MPa to cold isostatically press it; the molded green body is heat-treated at 700°C for 300 minutes; the heat-treated green body is Sintering in a vacuum hot-pressing sintering furnace at 1100° C. and 30 MPa for 120 minutes to obtain a solid-dissolved europium cerium m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com