Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

324 results about "Samarium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Samarium(III) oxide is used in optical and infrared absorbing glass to absorb infrared radiation. Also, it is used as a neutron absorber in control rods for nuclear power reactors. The oxide catalyzes dehydration of acyclic primary alcohols to aldehydes and ketones. Another use involves preparation of other samarium salts.

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

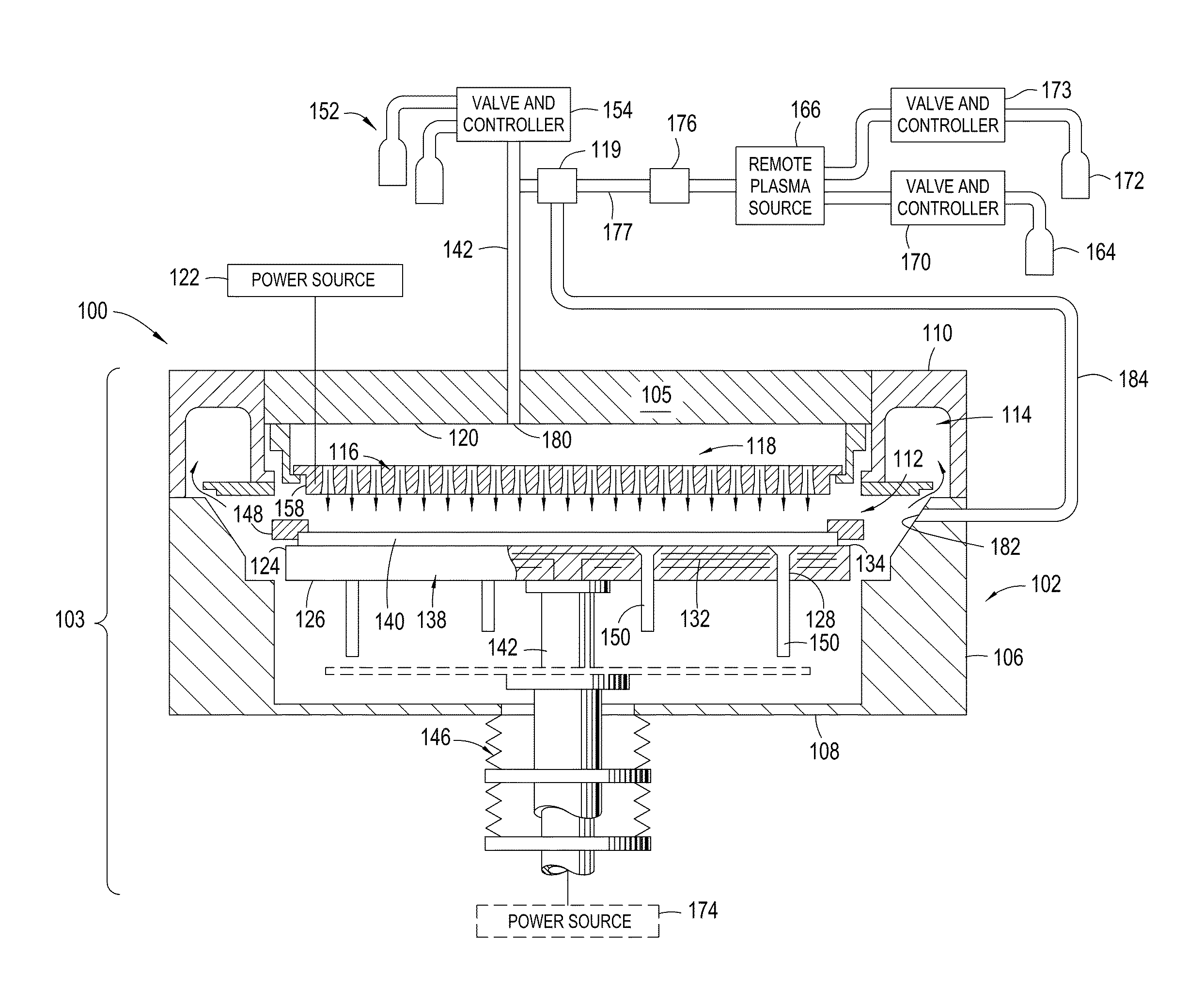

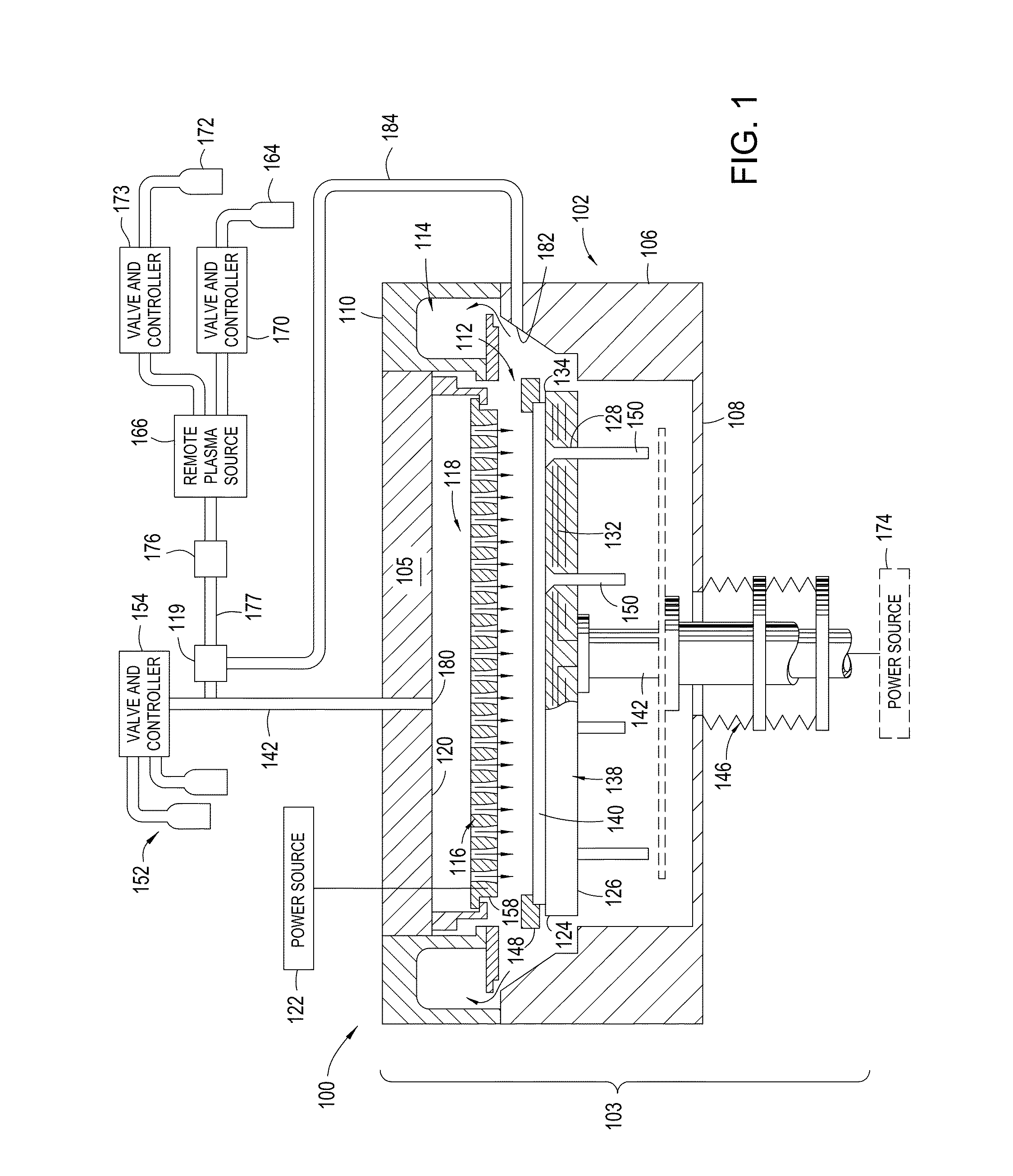

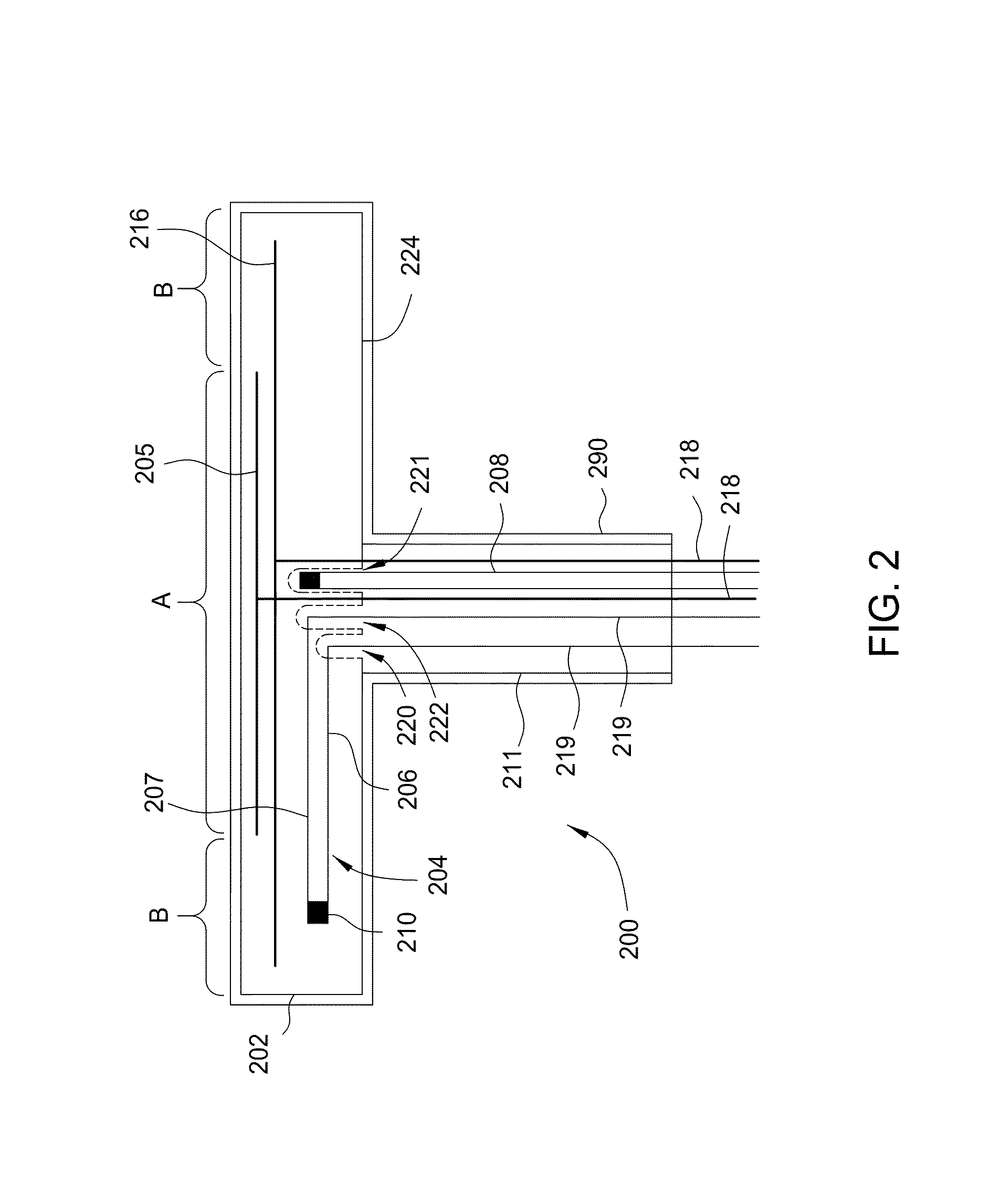

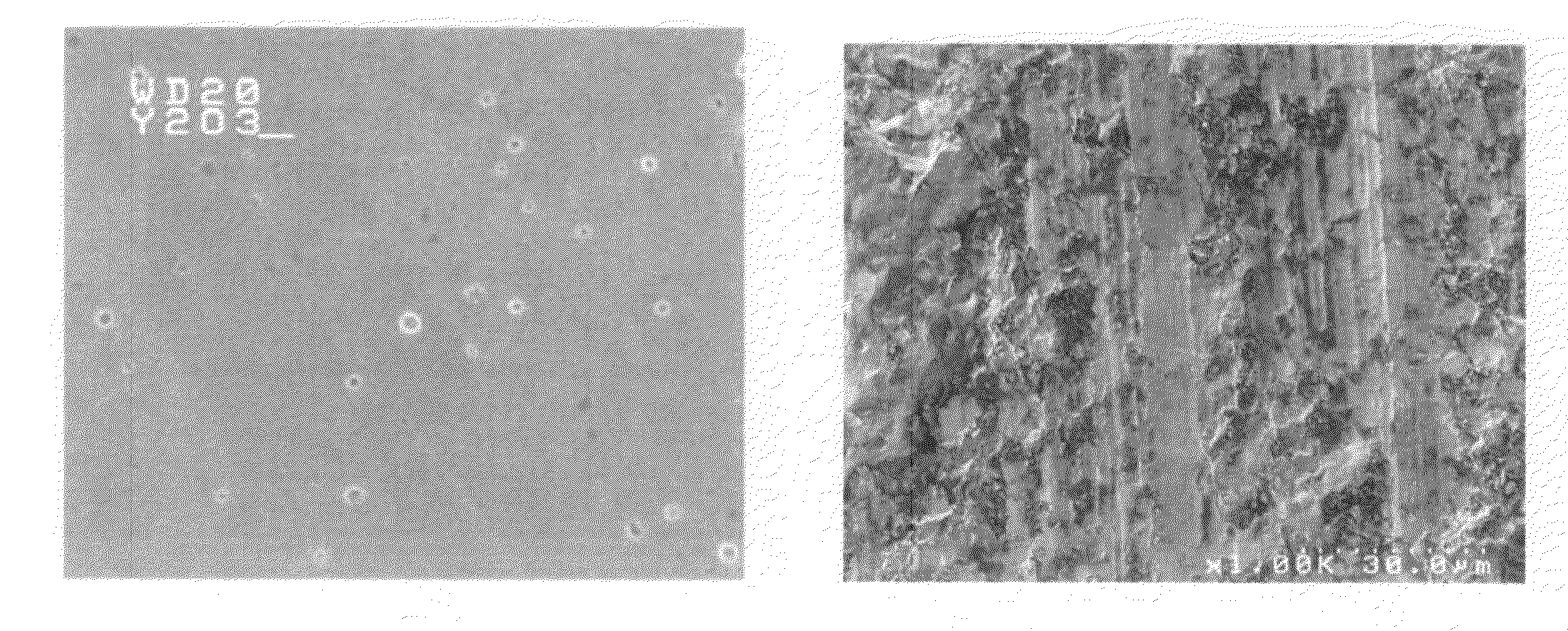

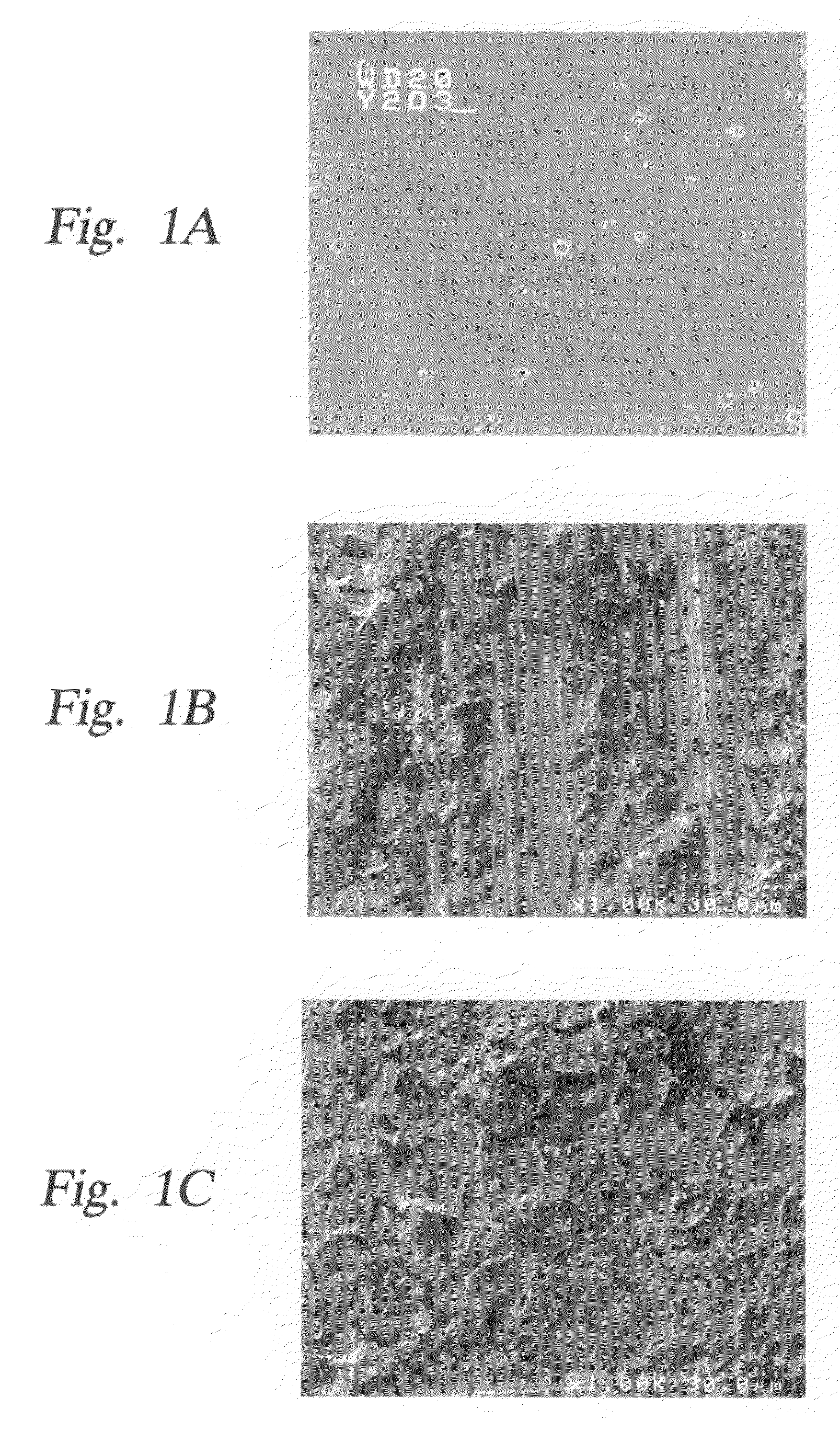

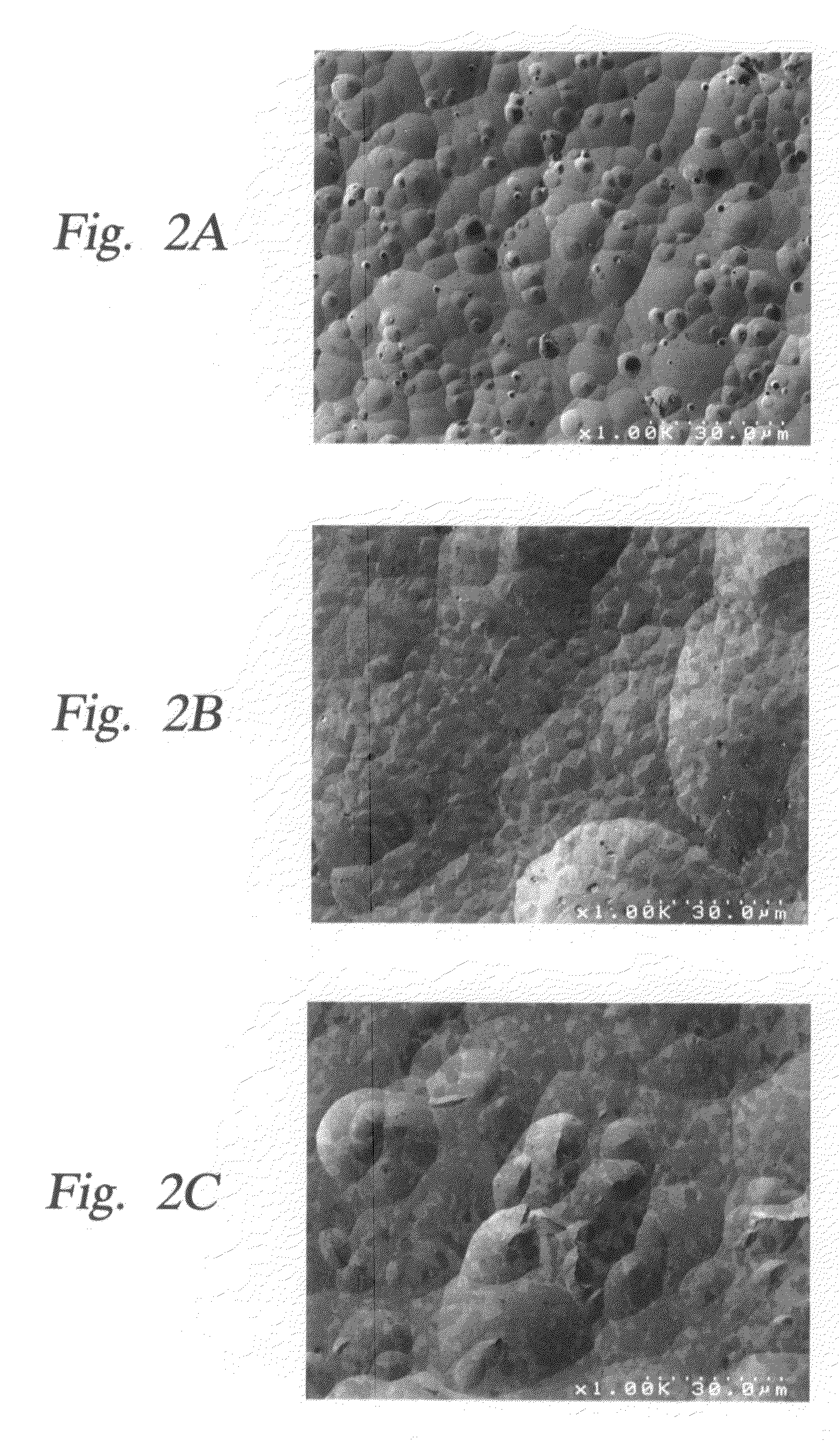

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

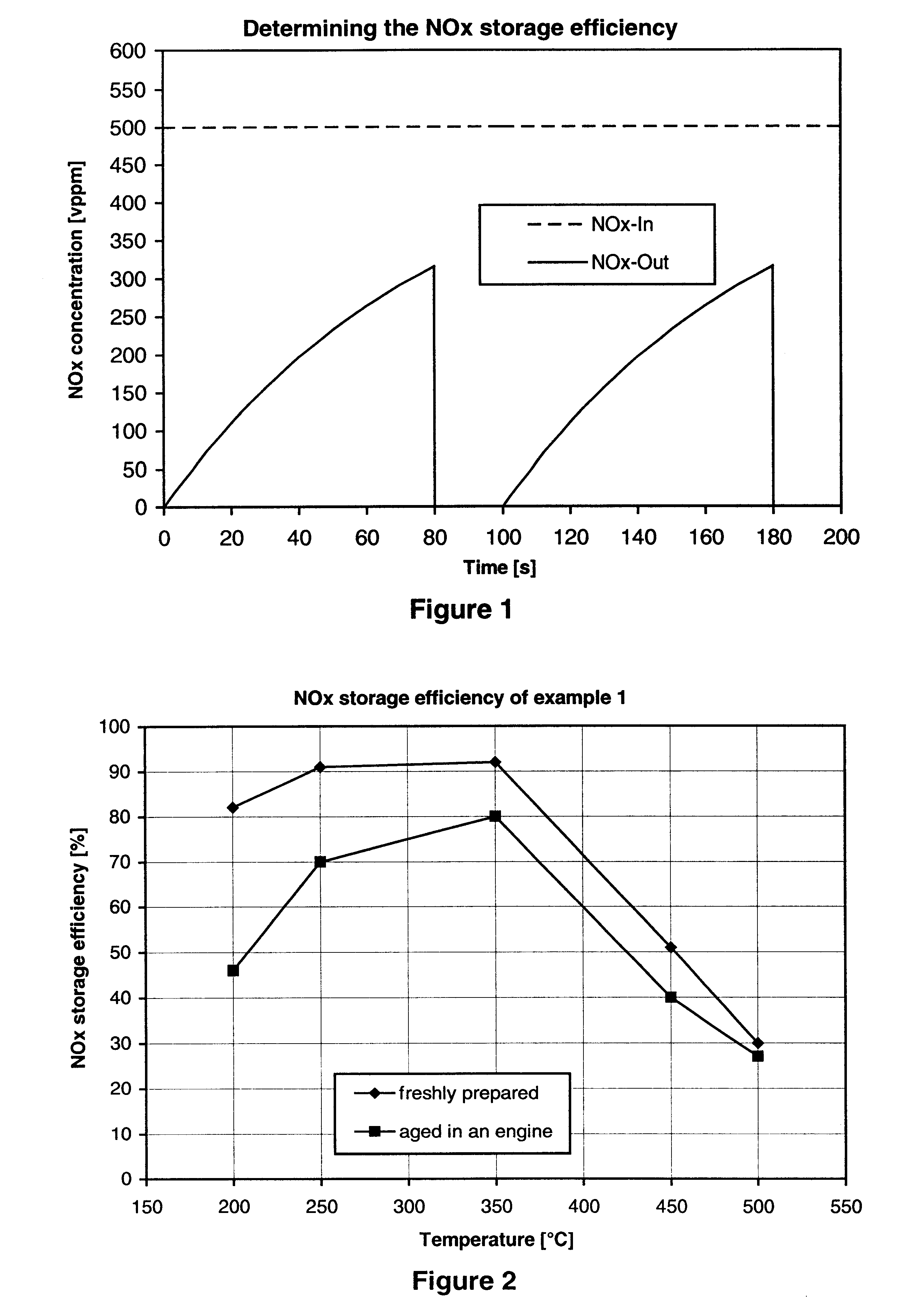

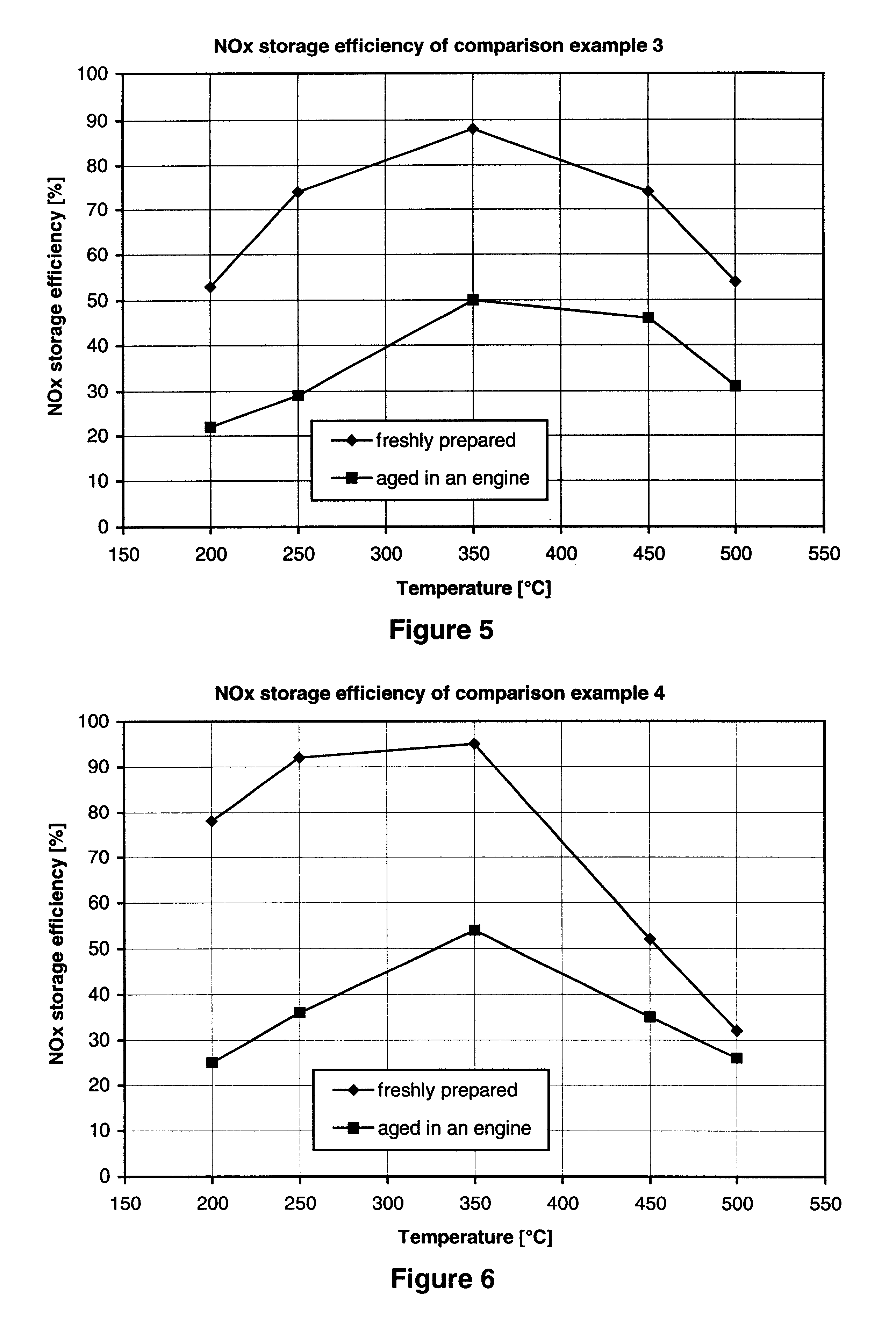

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

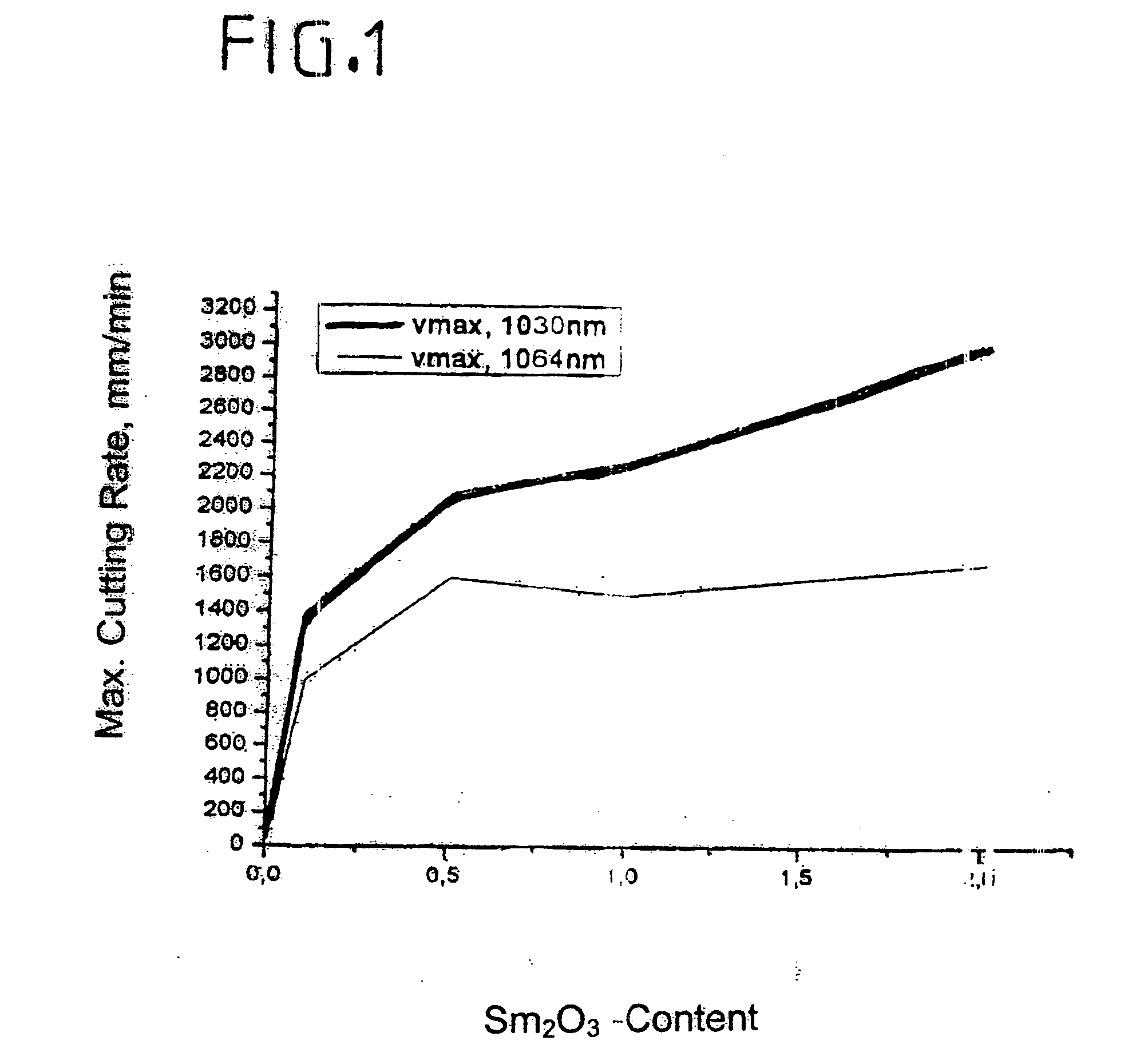

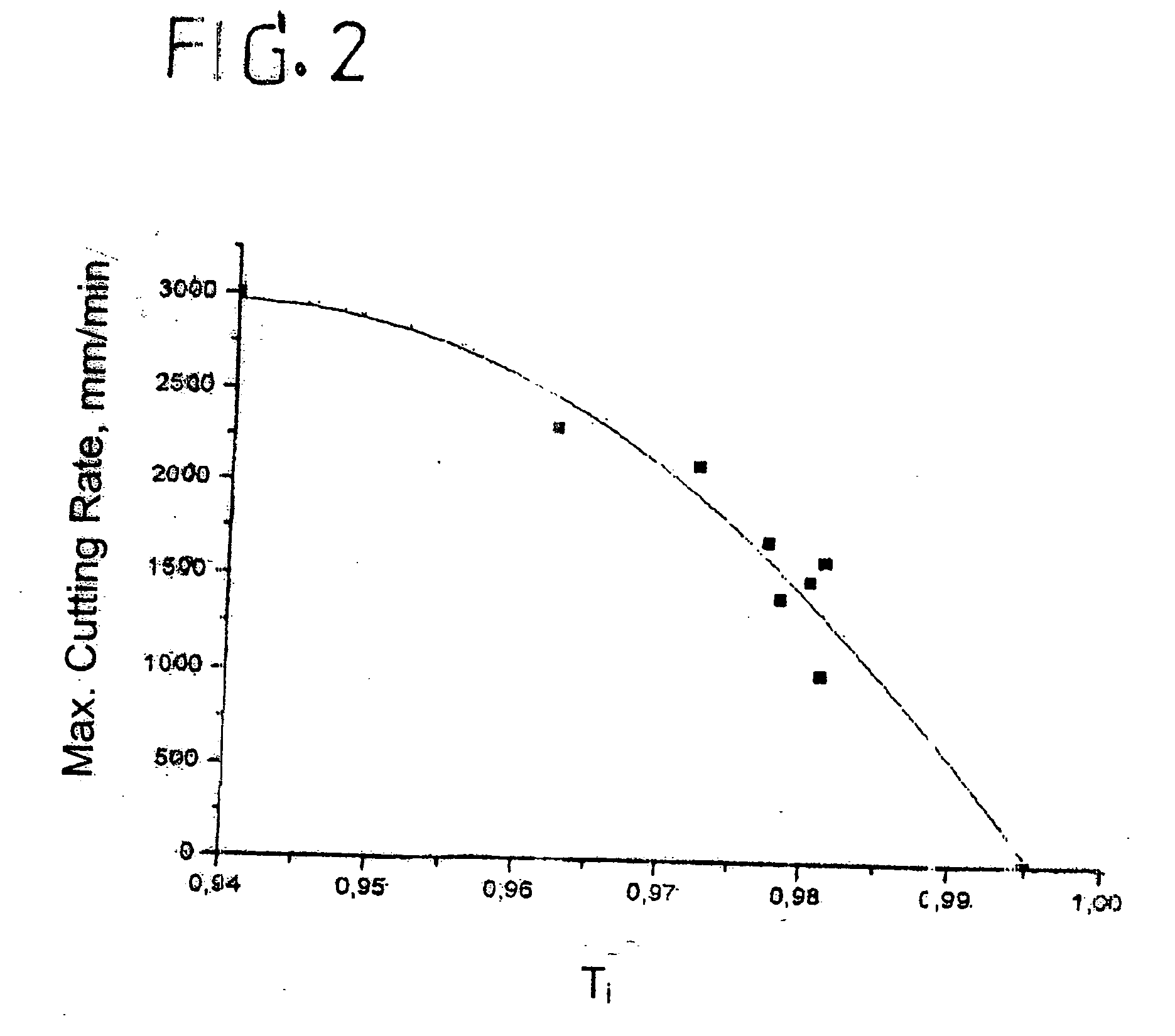

Thin flat glass for display purposes and method of cutting the thin flat glass into display sheets

InactiveUS20070158317A1Heating up fastCut more rapidlyGlass severing apparatusLaser beam welding apparatusFlat glassAdditive ingredient

To improve the cutting properties, especially the cutting rate, of thin flat glass by means of a laser cutting beam from a Nd:YAG solid-state laser, the flat glass is provided during its manufacture with at least one additive ingredient that effectively absorbs radiation at a wavelength of 1.064 μm. Preferably the additive ingredient is preferably samarium oxide (Sm2O3). A method of cutting through a flat glass sheet whose composition contains at least one additive ingredient that absorbs a significant amount of radiation at a wavelength of 1.064 μm, which includes cutting the flat glass sheet with the focused radiation of a Nd:YAG laser, is also part of the present invention.

Owner:SCHOTT AG

High-performance cerium zirconium oxide and production method of high-performance cerium zirconium oxide

ActiveCN104190438AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumCopper oxide

The invention relates to a solid liquid supported catalyst and in particular relates to high-performance cerium zirconium oxide. The high-performance cerium zirconium oxide is prepared from the following chemical ingredients in parts by weight: cerium oxide, zirconium oxide, aluminum oxide, praseodymium oxide, lanthanum oxide, neodymium oxide, yttrium oxide, samarium oxide, vanadium oxide, chromic oxide, manganese oxide, iron oxide, cobalt oxide, copper oxide, manganese oxide, nickel oxide and the like. The invention also provides a preparation method of the high-performance cerium zirconium oxide. The preparation method comprises the steps of mixing all raw materials, adding surface active agents, regulating pH value to be 8-10 to obtain gelatinous precipitates, and calcinating to obtain the cerium zirconium oxide. The solid liquid supported catalyst can overcome the doping defect caused by doping in the cerium zirconium carrier and can improve the thermal stability, the aged specific surface area and the oxygen storage capacity of the supported catalyst; and the preparation method is simple, the technological process is simple and the method facilitates large-scale industrial production.

Owner:淄博加华新材料有限公司

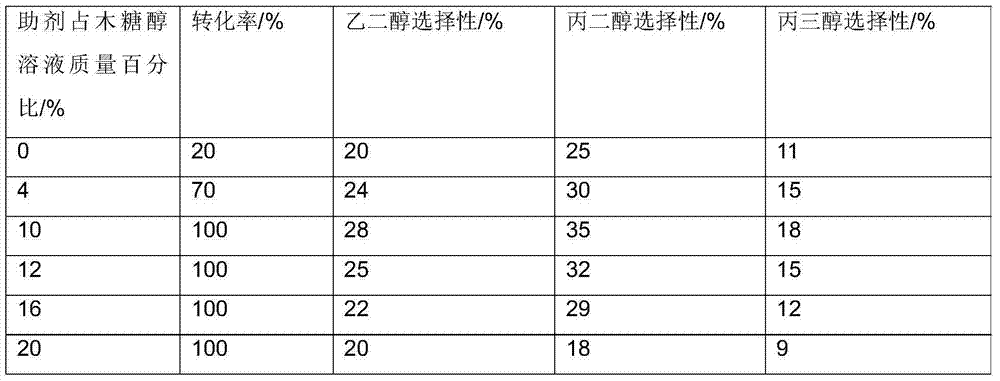

Method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol

InactiveCN104710277AEasy to achieve separationOrganic compound preparationPreparation by OH group eliminationGadolinium oxideGlycerol

The invention relates to a method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol. The method adopts sugar and sugar alcohol as the raw materials, takes one or more than two of iron, cobalt, nickel, copper, zinc, tin, platinum, ruthenium, palladium, iridium and other transition metals as the catalyst active component, and employs a rare earth oxide like promethium oxide, gadolinium oxide, terbium oxide, holmium oxide, erbium oxide, thulium oxide, cerium oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, scandium oxide, yttrium oxide, dysprosium oxide, europium oxide, samarium oxide, ytterbium oxide, lutecium oxide and the like as the assistant. Under a temperature of 150-320DEG C and an H2 pressure of 1-20MPa, catalytic hydrocracking is carried out in a water solution to obtain ethylene glycol, propylene glycol, glycerol and other low carbon alcohols. The method provided by the invention has the advantages that: the rare earth oxide is added as the assistant to realize hydrocracking of sugar and sugar alcohol, rare earth oxides are insoluble in water and easy to separate, and at the end of reaction, the reaction system has no need for additional acid to neutralize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

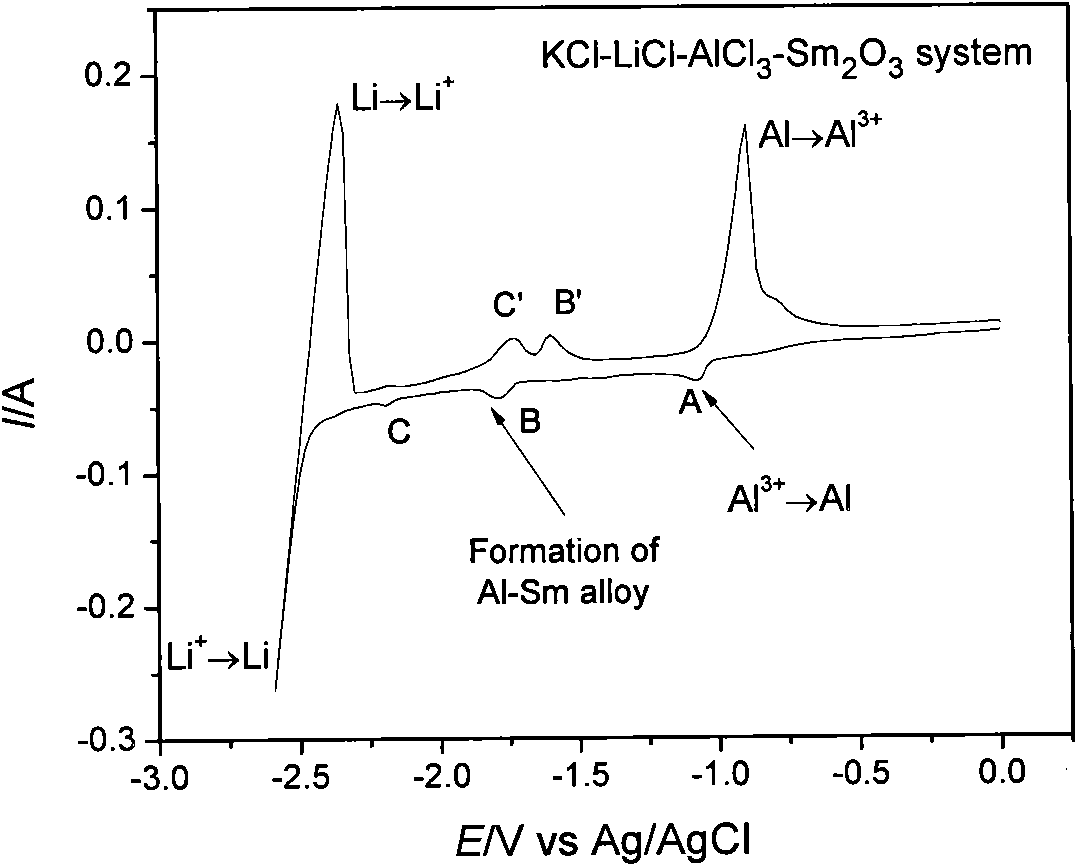

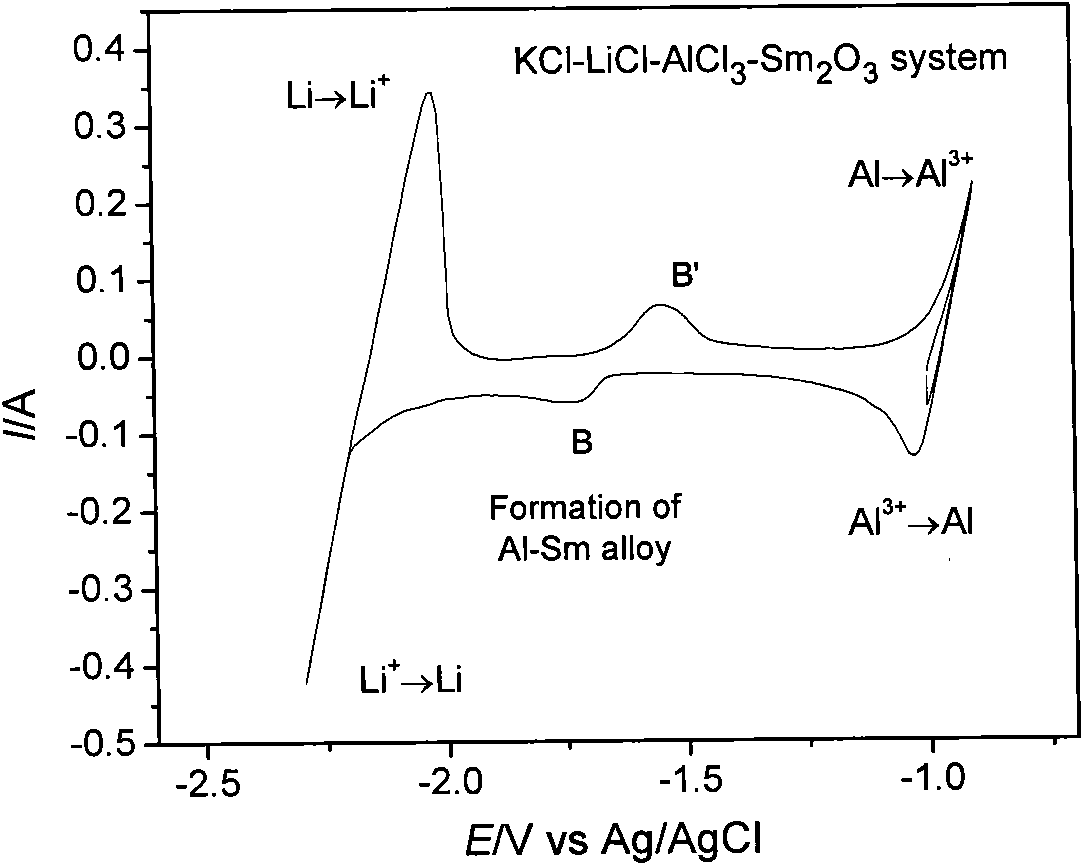

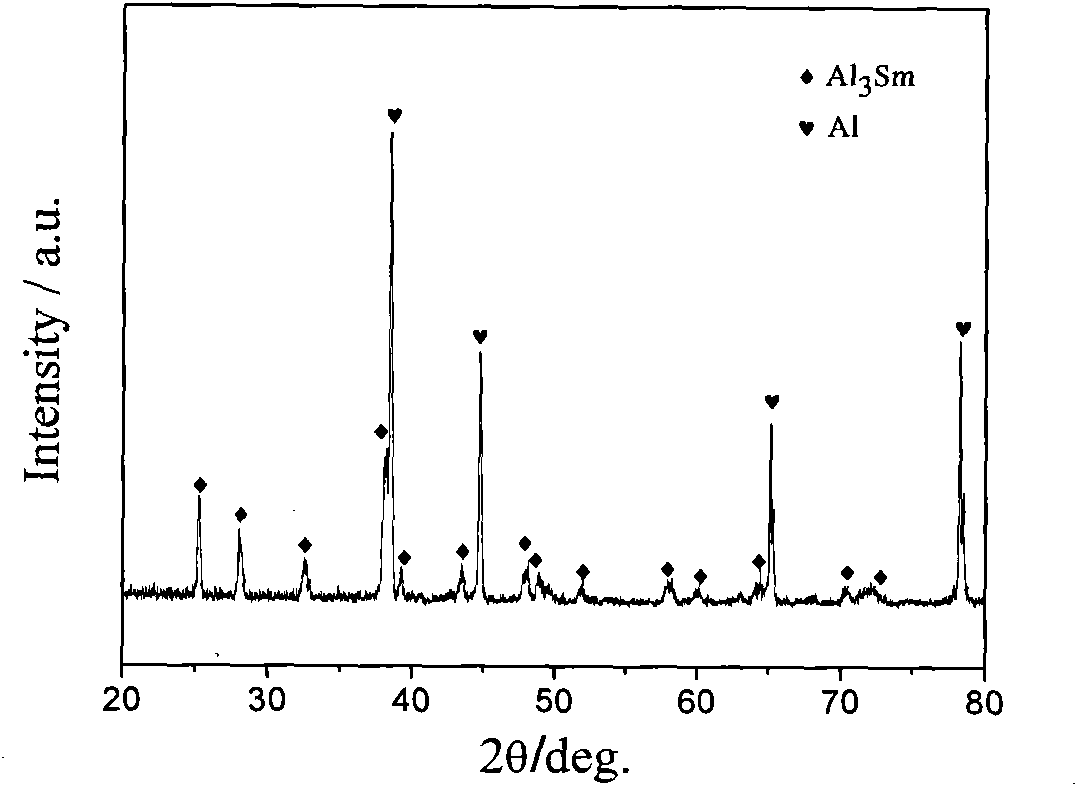

Aluminum-lithium-samarium alloy and fused salt electrolysis preparation method thereof

The invention provides an aluminum-lithium-samarium alloy and a fused salt electrolysis preparation method thereof. The aluminum-lithium-samarium alloy is prepared by the following steps of: heating LiCl and KCl serving as an electrolyte system to 630 DEG C for fusion in an electrolytic furnace; uniformly mixing Sm2O3 powder and AlCl3 and tabletting the mixture, adding the mixture into fused salt in the form of grains to ensure that the mass ratio of the AlCl3, LiCl to KCl is 6.2-11.0 percent to 44.5-46.9 percent to 44.5-46.9 percent, wherein the amount of the added Sm2O3 is 1 percent of the weight of the electrolytic fused salt; and taking metal molybdenum as a cathode and graphite as an anode and performing electrolysis for 2 to 6 hours to deposit the Al-Li-Sm alloy close to the cathode of the fused salt electrolysis cell, wherein the electrolysis temperature is between 630 and 720 DEG C, the cathode current density is 6.4A / cm<2> and the anode current density is 0.5A / cm<2>. By completely using metal compounds as raw materials and adding aluminum chloride, the chlorination of samarium oxide is realized and the aluminum-lithium-samarium alloys of different components are obtained by controlling the conditions such as the proportion of the electrolytes, the electrolysis time, the temperature, the current density and the like. The alloy and the method have the advantages of simple whole process, low requirements on equipment, low energy consumption and low pollution.

Owner:HARBIN ENG UNIV

Catalyst for synthesizing isobutanol by utilizing synthesis gas as well as preparation method and application of catalyst

ActiveCN103272609AEmission reductionReduce energy consumptionOrganic compound preparationHydroxy compound preparationIsobutanolThorium oxide

The invention relates to a catalyst for synthesizing isobutanol by utilizing synthesis gas. The catalyst comprises the following components in percentage by weight: 5.0-15.0% of copper oxide, 45.0-60.0% of zirconium oxide, 10.0-20.0% of zinc oxide, 1.0-5.0% of lanthanum oxide, 5.0-20.0% of cerium oxide, 0-5.0% of nickel oxide, 0-5.0% of samarium oxide, 0-5.0% of thorium oxide, 0-5.0% of vanadium pentoxide and 1.2-5.2% of potassium oxide. The catalyst has the advantages of high isobutanol selectivity and warm operation process condition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method of manufacturing aluminium nitride/boron nitride multiple phase ceramic

The invention discloses a making method of aluminium nitride / boron nitride multiple phase ceramic in the functional ceramic domain, which comprises the following steps: sintering boron nitride pioneer C3N6H12B2O6 and aluminium nitride particle in the non-oxygen environment; adopting nitrogen or hydrogen as environmental gas; generating pure composite powder of aluminium nitride / boron nitride; dispersing boron nitride in the aluminium nitride base without block; blending the composite powder and one rare earth oxide additive completely; selecting additive from one of yttrium oxide, samarium oxide and dysprosium oxide with yttrium oxide at best; placing in the discharge plasma sintering furnace; extracting into vacuum; heating at 100-200 deg.c / min to 1600-1800 to sinter 5-20 min; insulating at 800-1000 deg.c for 10-30min; closing power; cooling.

Owner:BEIJING UNIV OF TECH

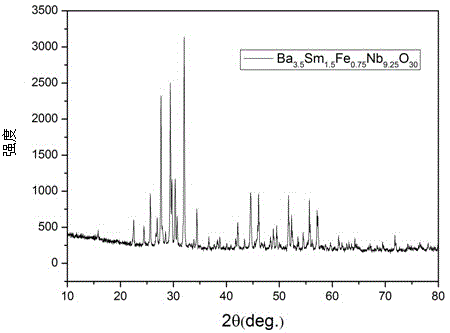

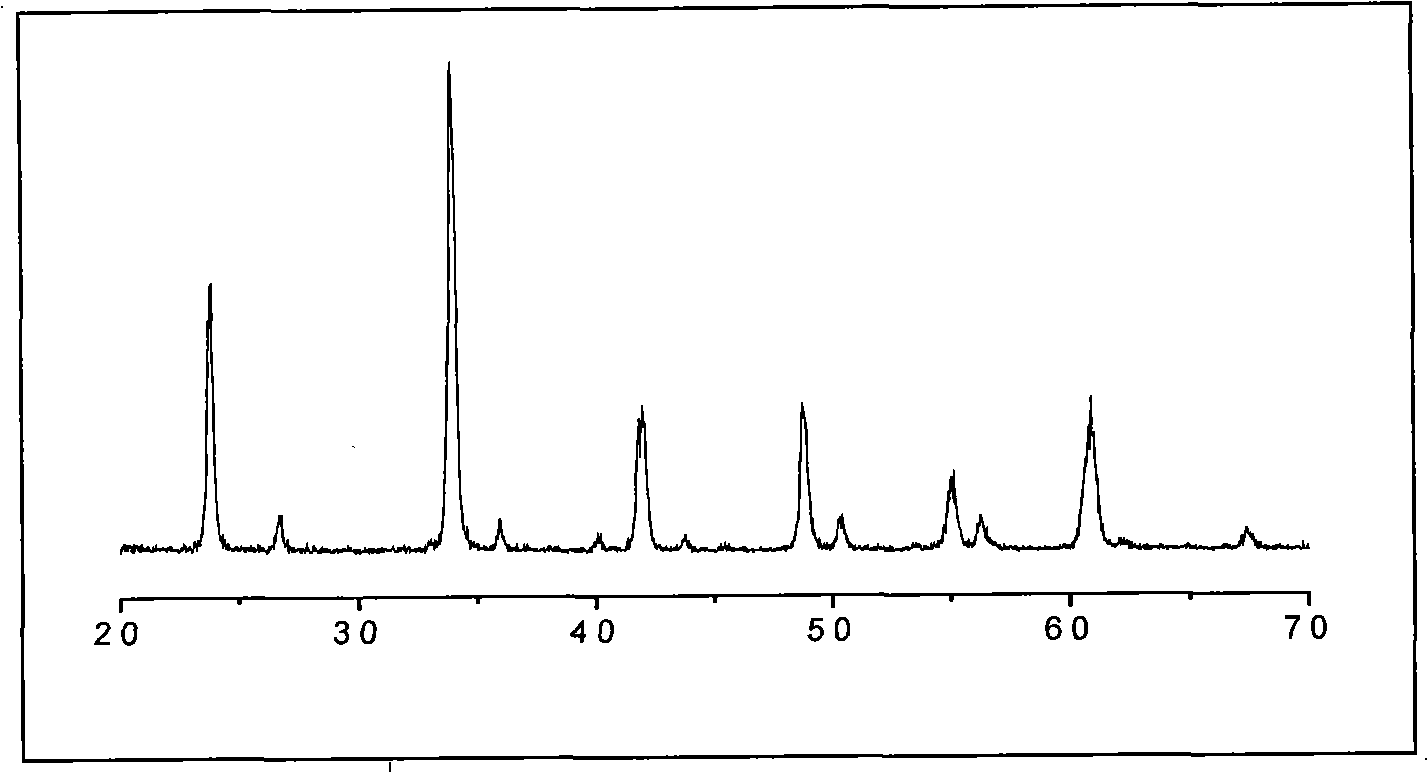

X9R ceramic capacitor dielectric material and preparation method thereof

The invention discloses an X9R ceramic capacitor dielectric material and a preparation method thereof. The preparation method comprises the following steps: niobium pentoxide, barium carbonate, ferric oxide and samarium oxide are subjected to ball milling firstly, raw materials are refined, burdening is performed at stoichiometric ratio according to the nominal chemical formula Ba3.5Sm1.5Fe0.75Nb9.25O30, procedures including presintering, second ball milling and the like are performed, and the X9R ceramic capacitor dielectric material Ba3.5Sm1.5Fe0.75Nb9.25O30 is finally prepared through a solid-phase reaction and a decarbonation process. The ceramic capacitor dielectric material with good temperature stability can be obtained with the method, the EIA (Electronic Industries Association) X9R standard can be met; and the method is simple and suitable for batch production, the cost is moderate, and energy conservation and emission reduction are realized.

Owner:苏州弘吴科技中介服务有限公司

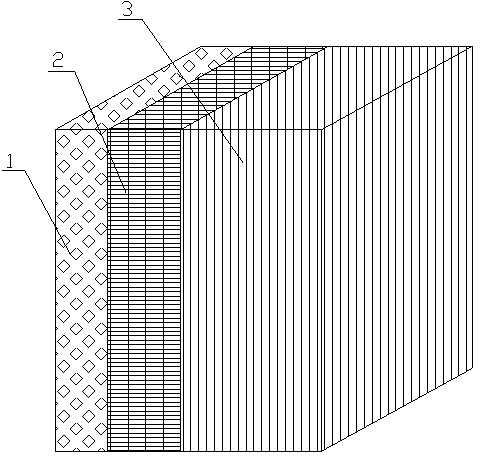

Gradient type macromolecule-based neutron absorption grid tray material and preparation method thereof

ActiveCN104228268AEffective absorptionEnsure safetySynthetic resin layered productsLaminationHigh absorptionGadolinium oxide

The invention discloses a gradient type macromolecule-based neutron absorption grid tray material which comprises a fast neutron slow absorption layer, an intermediate energy neutron absorption layer and a heat neutron absorption layer, wherein the three absorption layers are formed by gradient lamination; a neutron absorption body material doped in the fast neutron slow absorption layer is a lithium fluoride, lithium hydride or boron carbide absorption body material; a neutron absorption body material doped in the intermediate energy neutron absorption layer is a samarium oxide neutron absorption body material; a neutron absorption body material doped in the heat neutron absorption layer is a gadolinium oxide or cadmium oxide neutron absorption body material. The invention also discloses a preparation method of the gradient type macromolecule-based neutron absorption grid tray material. The gradient type macromolecule-based neutron absorption grid tray material has the characteristics of high absorption efficiency, long service life, high mechanical property, simple technology and the like, has a certain absorption effect on gamma photons, can be used for spent fuel storage and neutron sources of other types and has a wide application prospect.

Owner:ZHONGXING ENERGY EQUIP

MC nylon engineering plastics and production process thereof

The invention relates to MC nylon engineering plastics and production process thereof. The MC nylon engineering plastics include 100 parts of masterbatch caprolactam, 1-2 parts of nanometer samarium oxide, 0.15-0.25 part of an accelerant sodium hydroxide, 0.5-1 liter of a curing agent TDI, 3-4 parts of a solid lubricant MoS2, 0.8-1.5 parts of graphite and 0.5-0.8 part of boron nitride. The production process comprises the specific steps of mould heating, feeding, curing molding, stress treatment and machining. The product of the invention can effectively transfer the external stress, and can lead to matrix yielding and consume a large amount of impact energy, so as to enhance the toughness and strength of the product. The production process of the invention employs a centrifugal casting technology, eliminates the inner pores of the product, overcomes the product quality problems of steel slider caused by internal pores and inclusion.

Owner:徐崇娣

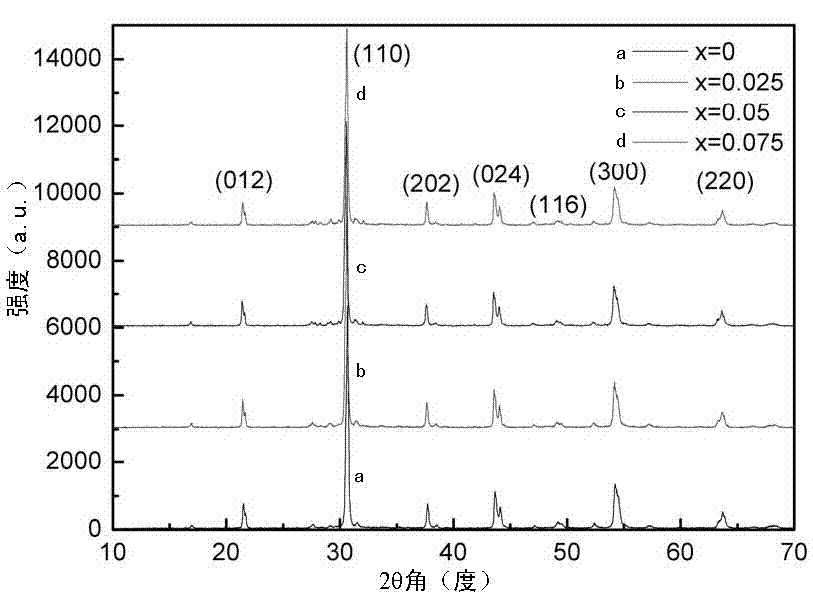

Samarium-oxide-doped modified lead zirconate titanate ferroelectric ceramic and preparation method thereof

The invention relates to samarium-oxide-doped modified lead zirconate titanate ferroelectric ceramic and a preparation method thereof. The ferroelectric ceramic has a composition general formula as follows: Pb1-xSmx(ZryTi1-y)0.98Nb0.02O3, wherein x is more than 0 and not more than 0.1, and y is not smaller than 0.9 and not more than 0.97. The residual polarization strength Pr of the ferroelectric ceramic ranges from 4 mu C / cm<2> to 36 mu C / cm<2>, so that the energy storage density of the ferroelectric ceramic is regulated in a wider range, and the performance requirement of the output power design of a pulse power supply is met. According to the process, formula design, weighing, mixing, powder synthesizing and sintering are carried out according to design requirements; and the addition amount of Sm2O3 is low, and no extra process program is needed. Compared with the traditional process in which a pore-forming agent is added, the preparation method has the advantage that the use of the pore-forming agent and processes such as uniform dispersion are reduced. Accordingly, the invention is simple in process and suitable for scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Stealthy coating compatible with laser and infrared and preparation method thereof

InactiveCN106867382ALow emissivityGood stealthPolyurea/polyurethane coatingsEnvironmental resistanceLow emissivity

Belonging to the technical field of functional materials, the invention relates to a stealthy coating compatible with laser and infrared and a preparation method thereof. The stealthy coating compatible with laser and infrared is composed of filler and a resin matrix, wherein the filler is a composite filler composed of samarium oxide, lanthanum oxide, flake aluminum powder and indium tin oxide, and the resin matrix is polyurethane resin. The invention adopts the composite filler composed of samarium oxide, lanthanum oxide, flake aluminum powder and indium tin oxide to cooperate with the resin matrix and an assistant, the combined action endows the coating with low emissivity at the infrared band and low reflectivity at the laser waveband. By using polyurethane resin as the resin matrix and cooperating with specific spray coating process, the coating provided by the invention has good stealth performance, and also has good mechanical properties and environmental resistance at the same time. Also the preparation method is simple and is easy for operation.

Owner:NANJING UNIV

Recycling method of samarium cobalt magnetic waste material

InactiveCN103555950AEasy extractionSimple processRare earth metal compoundsProcess efficiency improvementOXALIC ACID DIHYDRATERare-earth element

The invention relates to a recycling method of a samarium cobalt magnetic waste material. The method is characterized by comprising the steps of: a, leaching a samarium cobalt waste material with dilute hydrochloric acid, and after the complete reaction, filtering to remove substances insoluble in acid; b, regulating pH of a leaching solution, precipitating rare earth elements in the solution with oxalic acid to generate a grey and white oxalate precipitate, filtering, drying and calcining the precipitate to obtain solid samarium oxide; c, precipitating samarium, oxidizing Fe<2+> into Fe<3+> in a filtrate by an oxidant, regulating the pH value to precipitate iron in the solution before cobalt, and filtering; and d, removing iron, adjusting the pH value of filtrate, adding oxalic acid to obtain a cobalt oxalate precipitate, and conducting filtration, drying and calcination to obtain cobalt oxide. The method has the following advantages: hydrochloric acid optimal solution, oxalic acid precipitation, iron removal by oxidation and calcination method are employed according to the chemical properties of the elements contained in the waste material, so as to successfully extract valuable elements in the samarium cobalt in waste material; the recycling process is simple in process and low in production cost and the does not produce secondary pollution of the environment; and the prepared samarium oxide and cobalt oxide products have high extraction rate.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

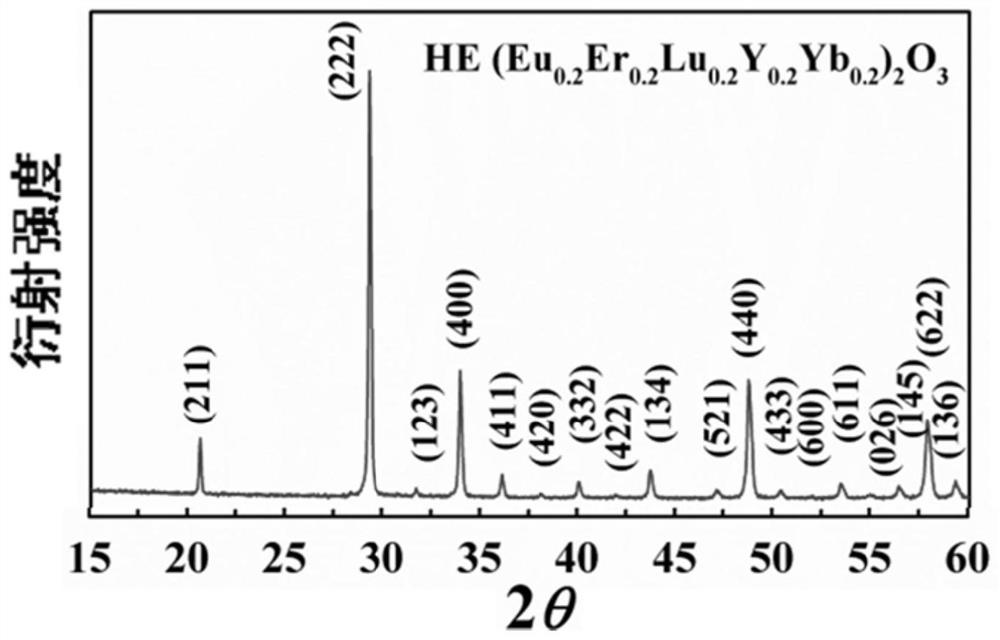

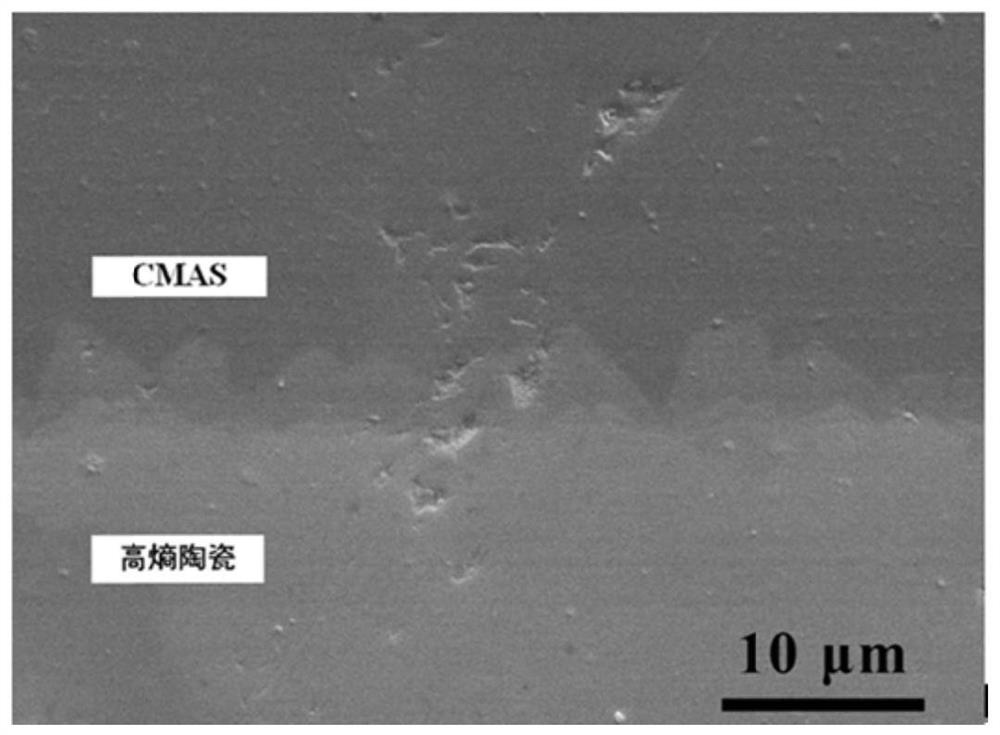

High-entropy ceramic material resistant to CMAS corrosion and preparation method and application thereof

The invention provides a high-entropy ceramic material resistant to CMAS corrosion, a preparation method and an application thereof, the high-entropy ceramic material comprises the following raw materials: at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, yttrium oxide and ytterbium oxide, and the amounts of substances of the raw materials are the same. The preparation method comprises the following steps: optionally selecting at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, and conducting mixing with yttrium oxide and ytterbium oxide to obtain uniformly mixed slurry; and drying the slurry to obtain mixture powder, and carrying out pressureless calcination on the dried powder to obtain the high-entropy ceramic powder material. Analysis shows that the high-entropy ceramic powder material has the characteristics of high purity and strong CMAS corrosion resistance, the preparation method is simple and suitable for industrial production, and the high-entropy ceramic powder material has excellent application prospect in the field of thermal barrier coating materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

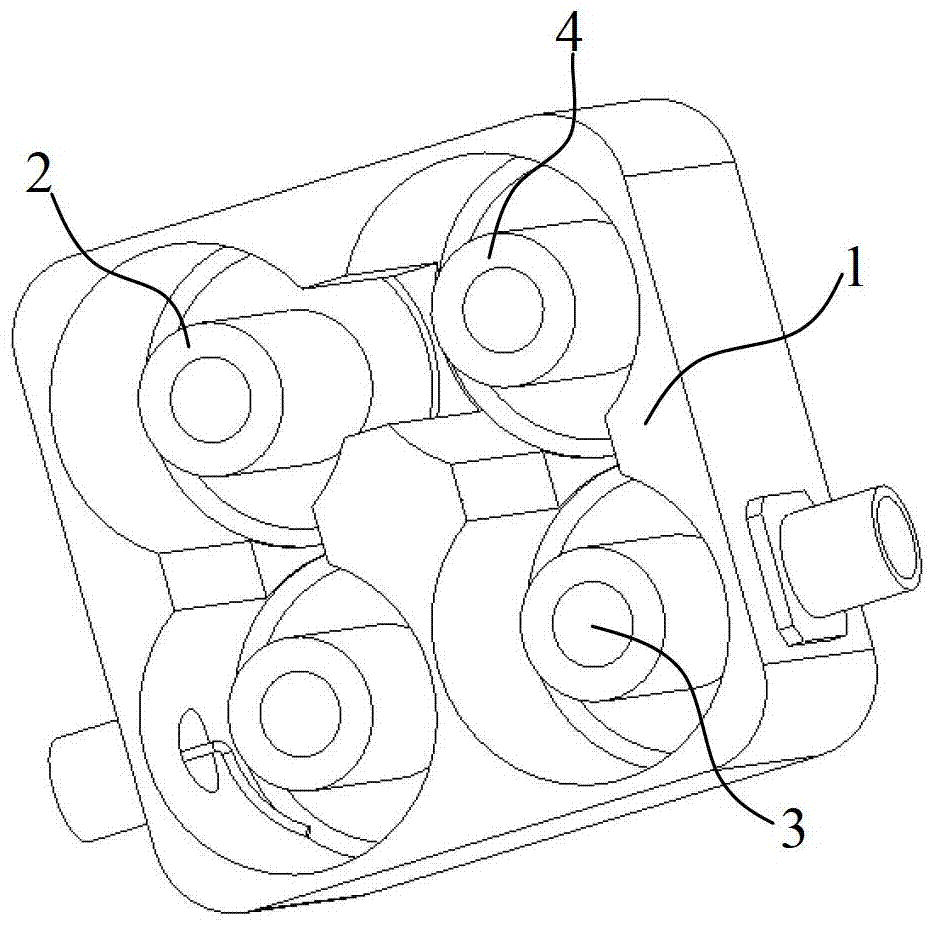

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

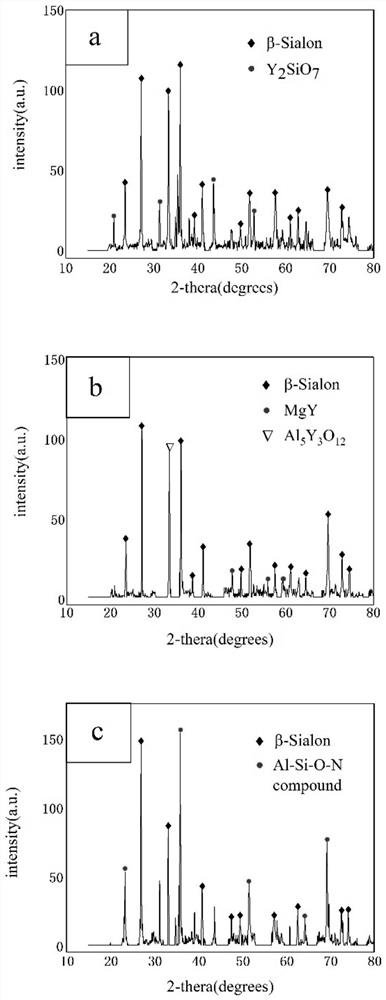

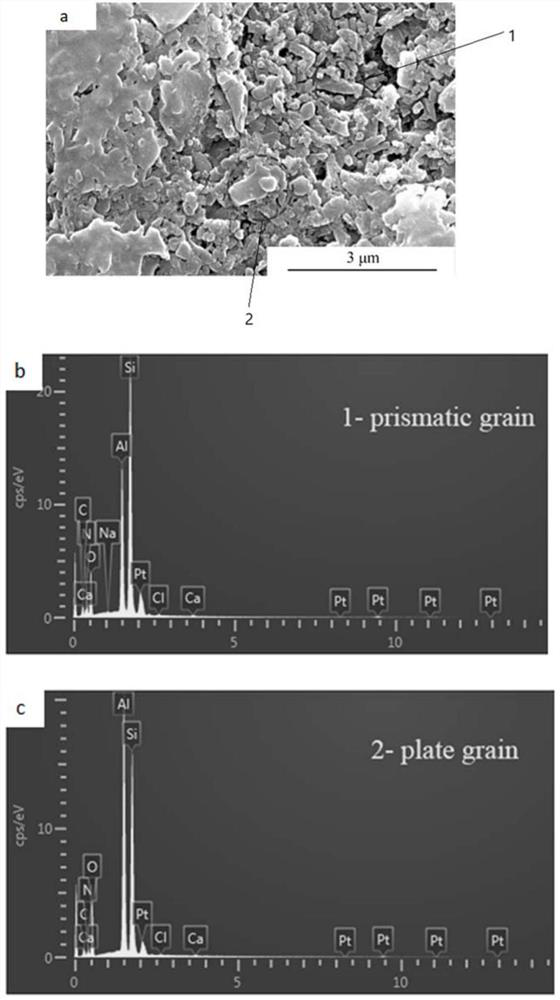

Method for microwave sintering of sialon ceramic material

ActiveCN111635236ARealize integrationHomogeneous material microstructureChemical industryYTTERBIUM OXIDEMicro nano

The invention belongs to the field of material preparation, and particularly relates to a method for microwave sintering of a sialon ceramic material. Micro-nanoscale silicon nitride powder, aluminumnitride powder and aluminum oxide powder are adopted as the raw materials, several of yttrium oxide, ytterbium oxide, magnesium oxide, magnesium silicon nitride and samarium oxide are arbitrarily selected as the sintering aid, and microwave sintering is conducted to obtain the sialon ceramic material. According to the method, micro-nanoscale silicon nitride powder, aluminum nitride powder and aluminum oxide powder are subjected to atom replacement in the microwave sintering process, and the sintering aid is added to synthesize a required phase, so that the sintering densification temperature can be effectively reduced, the production efficiency can be improved while the microstructure of the material is more uniform, and the integration of the phase synthesis and densification process is realized. The prepared ceramic material has high hardness and good fracture toughness on the basis of guaranteeing basic complete compactness, the actual density is 3.233g / cm<3>, the Vickers hardness is 14.3GPa, and the fracture toughness is 7.28MPa.m<1 / 2>.

Owner:NANJING UNIV OF SCI & TECH

Binary cerium-zirconium doped supported catalyst and preparation method thereof

ActiveCN104128174AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsHeat stabilityCerium

The invention relates to a solid solution, namely a supported catalyst and in particular relates to a binary cerium-zirconium doped supported catalyst. The supported catalyst comprises the following chemical components in parts by weight: 30-50 parts of cerium oxide, 30-50 parts of zirconium oxide and 1-20 parts of other rare earth oxides, wherein other rare earth oxides are at least two of lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide or samarium oxide. The invention also provides a preparation method of the supported catalyst. The preparation method comprises the steps of mixing all the raw materials, adding surfactants, then adjusting the pH value to 8-10 to obtain a colloidal precipitate, and roasting to obtain the product. The supported catalyst and the preparation method have the advantages that doping defects caused by doping in cerium-zirconium supports are overcome; meanwhile, the performance indexes of the supported catalyst, such as heat stability, aging specific surface area, oxygen storage capacity and the like are greatly improved; the preparation method is low in raw material price and simple in process and is beneficial to large-scale industrial production.

Owner:淄博加华新材料有限公司

Copper/rare-earth oxide/carbon contact and method for producing same

ActiveCN1595569AImprove welding resistanceReduce burning lossContact materialsRare earthOxidation resistant

A copper / rare earth oxide / carbon aontact, whose material composite ratio(mass percentage) is: carbon 0.1-2.0, ytterbium trioxide or samarium trioxide 0.1-15, alloy 0.05-2.0 and copper the other, uses method of powder metallurgy and electroplating sediment to produce and the contact produced has excellent resistance to oxidation and electric arc burnt.

Owner:浙江帕特尼触头有限公司

Deep red infrared transmission quartz glass plate and preparation method thereof

The invention discloses a deep red infrared transmission quartz glass plate which comprises the following raw materials in percentage by weight: high-purity quartz sand as a basic raw material and trace element additives accounting for 6%-9.5% of the high-purity quartz sand, wherein the trace element additives comprise copper oxide CuO, manganese dioxide MnO2, samarium oxide SmO, aluminum oxide AL2O3, cobalt oxide CoCL2.6H2O and erbium oxide Er2O3. The deep red infrared transmission quartz glass plate formed by drawing through an integral plate body coloring preparation process has the characteristics of low doping expansion, good uniformity, high temperature resistance, acid resistance, alkali resistance, quick heating and cooling performances, ultraviolet transmission, infrared transmission and the like, absorbs visible light, passes through near-infrared rays of 800-2500 nm, and has the spectral features that (the sample thickness is 2.0 mm) the transmittance T is not more than 14%, 800 nm T is not less than 5.0%, and 1100 nm T is not less than 75.0%.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

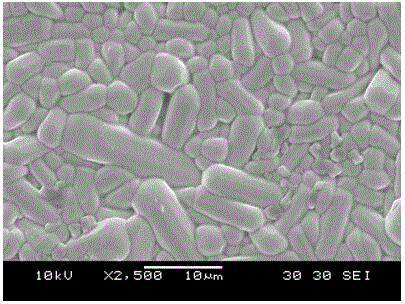

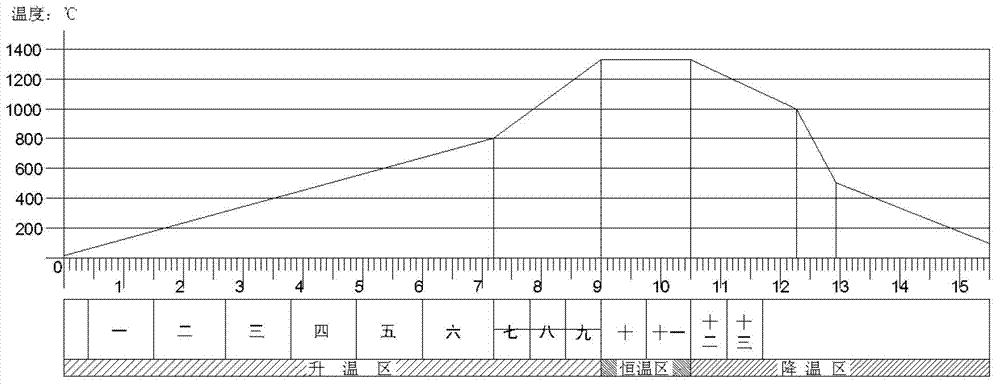

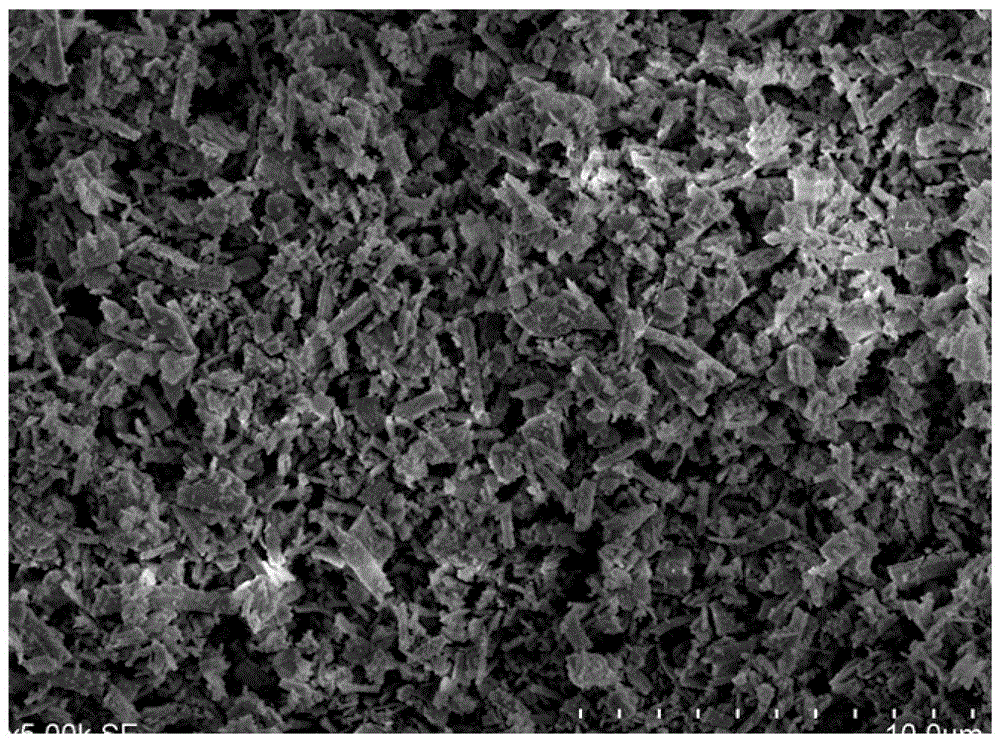

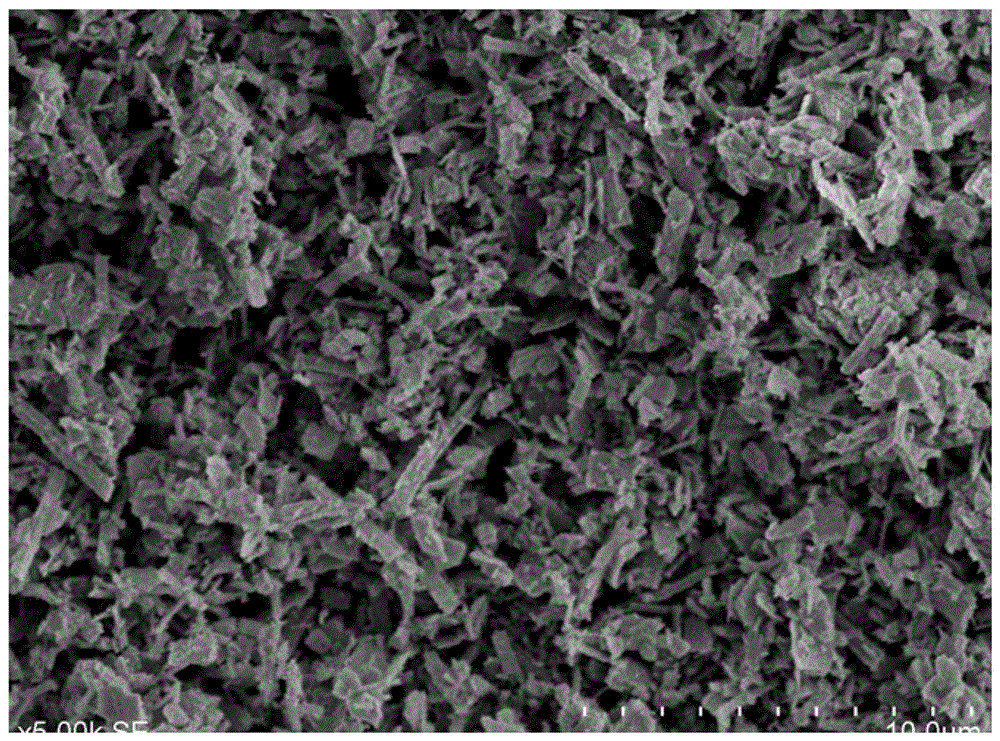

Preparation method of 1-2-micron samarium oxide

ActiveCN106044834AUniform particlesEasy to operateRare earth metal oxides/hydroxidesOxalatePolyethylene glycol

The invention discloses a preparation method of 1-2-micron samarium oxide. The preparation method comprises the following steps: step 1, the concentration of oxalic acid is 0.8-1.5 mol / L, pH is regulated to 3-5 with an ammonia water solution with the mass fraction of 28%, and a dispersing agent polyethylene glycol accounting for 5%-10% by mass of samarium oxide is added; the concentration of a samarium chloride solution is 0.8-2.0 mol / L, and pH is regulated to 2 with the ammonia water solution with the mass fraction of 28%; step 2, oxalic acid and the samarium chloride solution are proportioned in the mole ratio being 1.8:1, under the condition of constant temperature of 40-60 DEG C, the samarium chloride solution after pH value regulation in the step 1 is added to the oxalic acid solution after pH value regulation in the step 1, and precipitation is performed for 3-20 min; step 3, after a reaction, filtering and washing are performed; burning is performed at 900-1,000 DEG C and heat preservation is performed for 2 h; an ultrafine samarium oxide product with the particle size of 1-2 microns, uniform particle and rod-shaped morphology is obtained.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

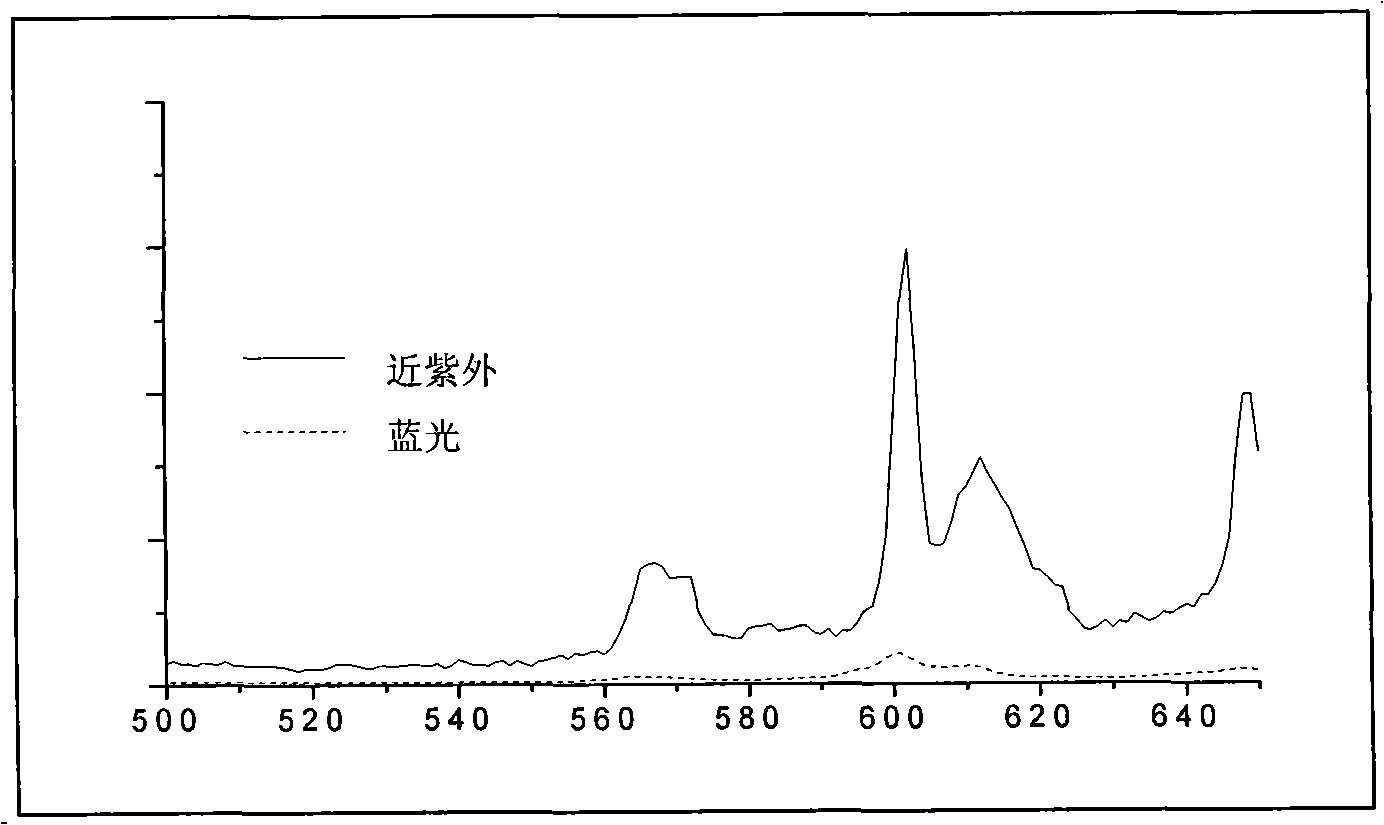

Samarium doping gadolinium aluminate base fluorescent powder body and preparation method thereof

InactiveCN101265408AHigh luminous intensityUniform particle size distributionLuminescent compositionsRare-earth elementAir atmosphere

The invention relates to a samarium doped gadolinium aluminate phosphor powder body and a preparation method thereof. The chemical constituent formula of the phosphor powder body is Gd1-x1-x2A1yOz:Smx1, Rex2, wherein the y value range is 0 to 5 / 3, the RE is the rare earth element ion and / or one or more of transition metal ions, the X1 is Sm doped gram molecular weight and is larger than 0.01 and smaller than 0.1, the X2 is RE doped gram molecular weight, and the content is 1 to 0.1 time of the content of Sm. The invention adopts the preparation process that gadolinium oxide, samarium oxide and RE iron in the stoichiometric ratio are dissolved in acetic acid at 60 to 70 DEG C, then aluminium nitrate is added and is uniformly stirred; ethylene glycol is mixed into the reacting solution according to the mole number of the ethylene glycol / the mole number of metallic ion being over than or equal to 3 and less than or equal to 1.5, and is uniformly stirred; the solution is stirred and vaporized at 60 to 70 DEG C, then is dried and ground, pre-burning is performed for 2 to 3 h at 600 to 800 DEG C in air atmosphere, and the temperature increasing speed is less than and equal to 5 DEG C / min; after the pre-burnt powder is ground, agglomeration is performed for 3 to 4 h over 1000 DEG C in air atmosphere. The processing is simple, the materials are cheap and available, and the powder has large luminescent intensity and even grain size distribution under the stimulation of the blue light and the near ultraviolet.

Owner:NANCHANG UNIV

Fullerene reinforced ceramic tile

InactiveCN104150871AVisible and adjustable colorImprove mechanical propertiesClaywaresFiberSodium phosphates

The invention discloses a fullerene reinforced ceramic tile. The fullerene reinforced ceramic tile with good mechanical properties is obtained by applying a glaze on the surface of a green body in a glaze spraying or sprinkling manner, wherein potassium feldspar, albite, clay, attapulgite, alumina, water, fullerene, sodium tripolyphosphate and tempered fiber serve as raw materials of the green body, feldspar, kaoline, quartz, burnt talcum, limestone, iron oxide, diboron pentoxide, alumina, kieselguhr, magnesite, zirconium silicate, titanium oxide, zinc oxide, terbium oxide, samarium oxide, lutecia and metal nano particles serve as raw materials of the glaze, and a glazed surface of the ceramic tile is attractive and elegant.

Owner:朱玉华

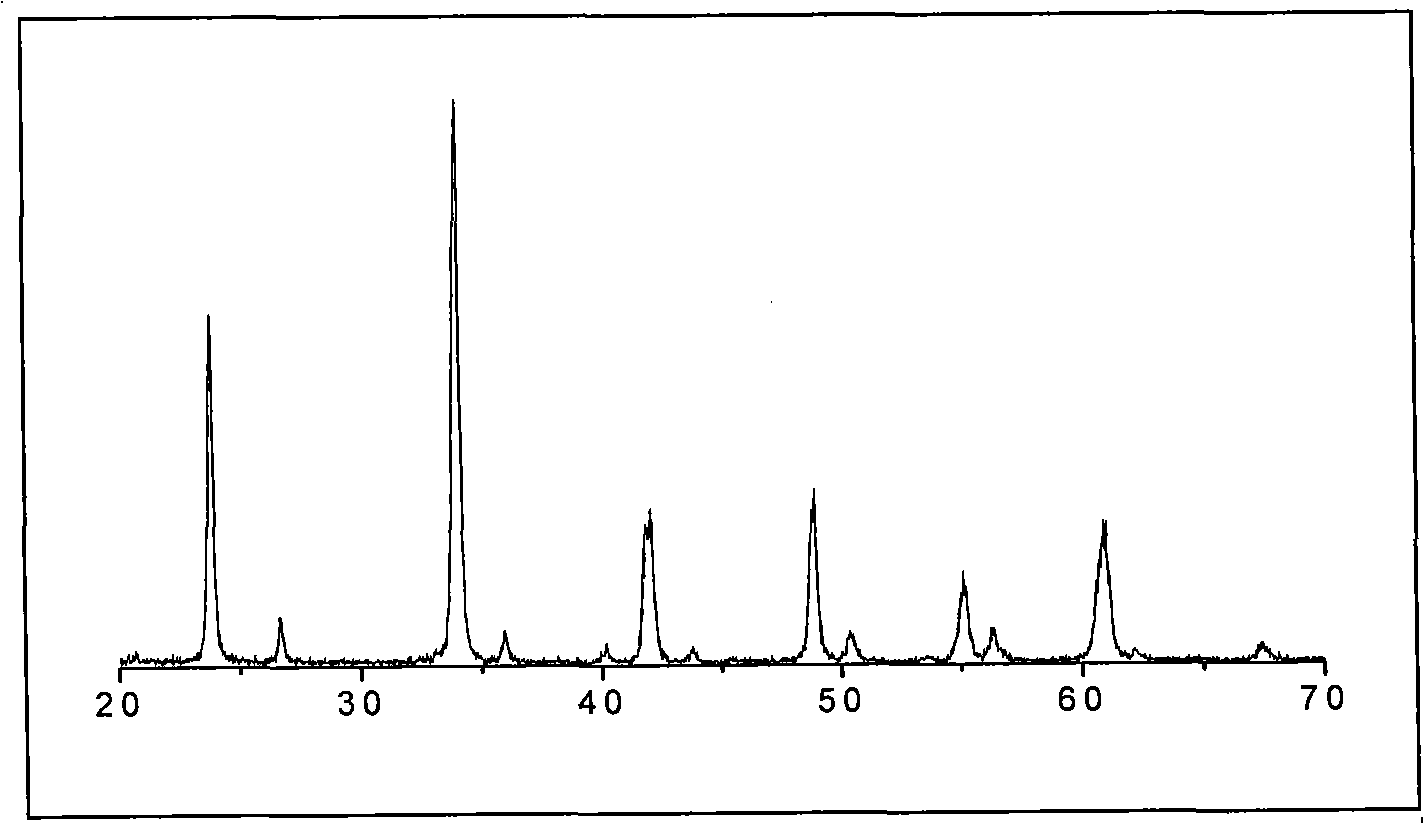

High-temperature-resistant near-infrared absorption high-entropy ceramic and preparation method thereof

The invention relates to high-temperature-resistant near-infrared absorption high-entropy ceramic and a preparation method thereof. The high-entropy ceramic is prepared from the following raw materials in equal molar ratio: 1 part of yttrium oxide, 1 part of neodymium oxide, 1 part of samarium oxide, 1 part of europium oxide, 1 part of ytterbium oxide, 1 part of erbium oxide, 1 part of niobium oxide and 1 part of tantalum oxide. The purity of the high-temperature-resistant near-infrared absorption high-entropy ceramic is not lower than 99wt%, the relative density is not lower than 98%, and theabsorptivity of the high-temperature-resistant near-infrared absorption high-entropy ceramic in a near-infrared band of 0.25-2.5 microns is not lower than 0.9. The high-temperature-resistant near-infrared absorption high-entropy ceramic is obtained by utilizing a high-entropy technology, introducing not less than 6 rare earth metal elements into niobium tantalate at the same time and adjusting the absorption energy level of the forbidden band width to enable the forbidden band width to be matched with the near-infrared wavelength, and the technological process is simple, rapid, flexible and controllable.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

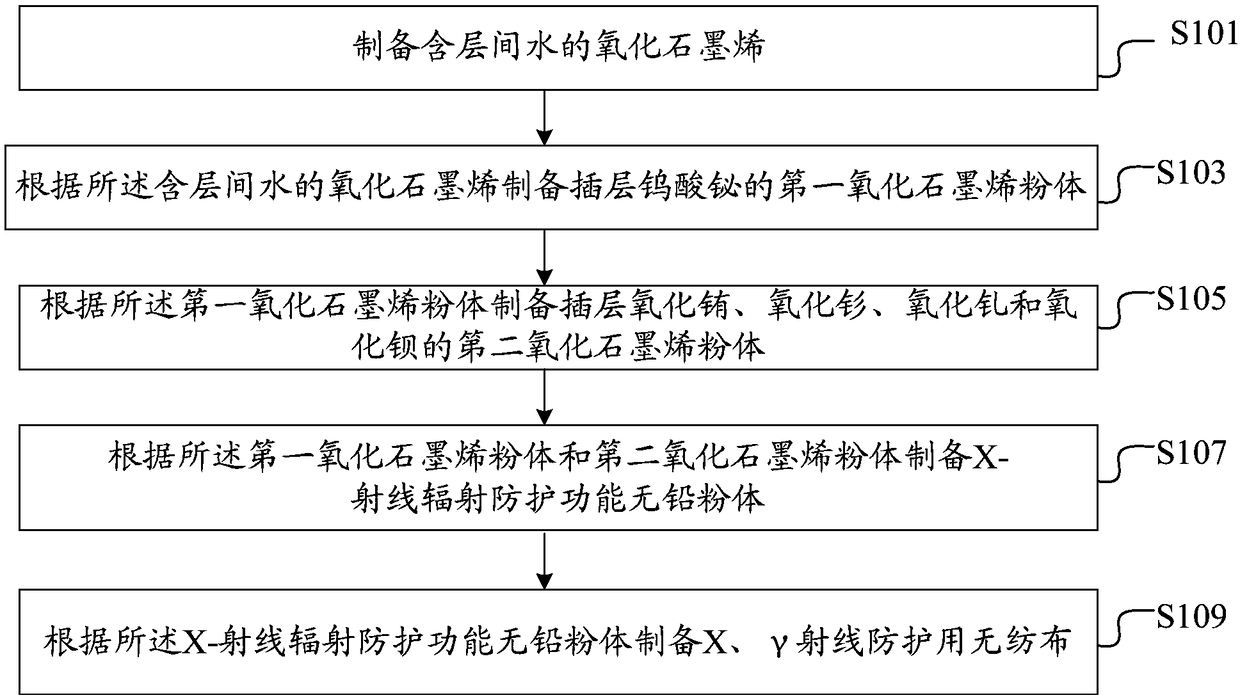

Preparation method of non-woven fabric for X and gamma ray protection

ActiveCN108411492AGood compatibilityIncrease the amount addedShieldingMelt spinning methodsFiberTungstate

The invention provides a preparation method of a non-woven fabric for X and gamma ray protection. The method comprises the steps of preparing interlayer water-containing graphene oxide; preparing first graphene oxide powder intercalated with bismuth tungstate according to the interlayer water-containing graphene oxide; preparing second graphene oxide powder intercalated with europium oxide, samarium oxide, gadolinium oxide and barium oxide according to the first graphene oxide powder; preparing X-ray radiation protection function lead-free powder according to the first graphene oxide powder and the second graphene oxide powder; preparing the non-woven fabric for the X and gamma ray protection according to the X-ray radiation protection function lead-free powder. The addition amount of functional powder in the prepared PE / PP sheath-core composite fiber is improved, the fiber has good physical and mechanical properties, textile processing properties and wearability and also has high X and gamma ray shielding rate, good durability, no lead and light weight, and the application prospects in X and gamma ray radiation protection are good.

Owner:江苏锦欣达纤维新材料科技集团有限公司

Easy-to-clean industrial ceramic and preparation method thereof

ActiveCN105218159AImprove stain resistanceImprove cleanlinessCeramic materials productionClaywaresBarium titanateYttrium

Belonging to the technical field of industrial ceramics, the invention relates to an easy-to-clean industrial ceramic and a preparation method thereof. The easy-to-clean industrial ceramic comprises a green body and a glaze surface covering the green body. The easy-to-clean industrial ceramic is characterized in that the glaze surface is fritted glaze made from the following raw materials by weight part: 20-40 of feldspar, 10-20 of flint clay, 10-20 of cooked talc, 5-10 of Datong soil, 1-2 of stalactite, 1-3 of quartz, 1-2 of barium titanate, 1-2 of bismuth oxide, and 0.1-0.5 of an improver; the improver is a mixture of yttrium oxide, cerium oxide and samarium oxide in a weight ratio of 1:1:1; or the improver is a mixture of cerium oxide, samarium oxide and gadolinium in a weight ratio of 1:1:1. The green body is prepared from the following raw materials: 30-35 parts of coal gangue, 17-22 parts of feldspar, 8-12 parts of quartz, 8-13 parts of calcined Datong soil, 10 parts of calcined high alumina bauxite, 5-10 parts of Jiexiu soil, 5-10 parts of zimujie clay, 1-3 parts of Suzhou clay, 5-8 parts of Fangzi clay, and 1-3 parts of cooked talc. According to the invention, a layer of ceramic glaze is attached to the industrial ceramic surface, and the preparation process is optimized so as to obtain industrial ceramic with a super smooth surface, and the industrial ceramic has excellent antifouling and easy-to-clean performance.

Owner:山东隆嘉新材料科技有限公司

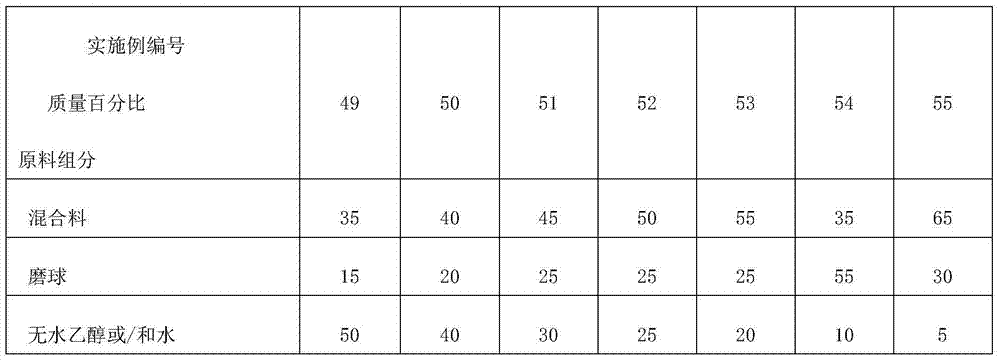

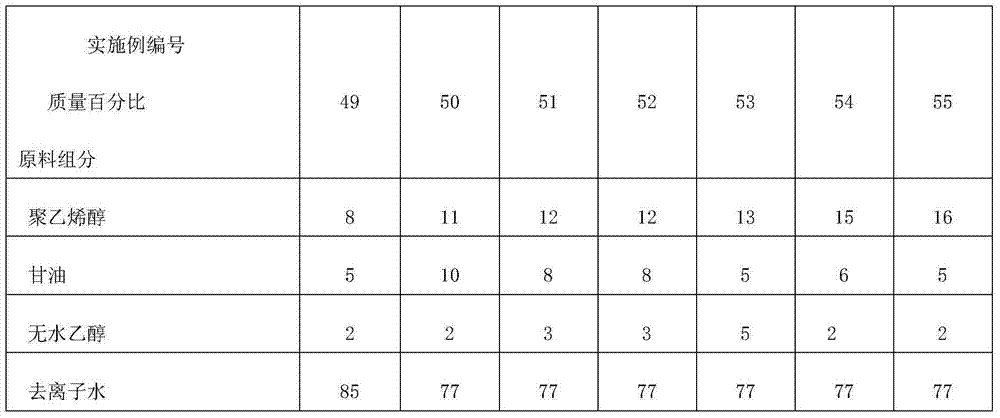

Cerium oxide-base solid electrolyte ceramic material and its production process

InactiveCN1421416AImprove electrolyte strengthImprove mechanical propertiesFinal product manufactureSolid electrolyte fuel cellsOxide ceramicGadolinium oxide

The present invention relates to one kind of cerium oxide-base soild electrolyte ceramic material and its production process. The material includes in mol% cerium oxide 75-95, samarium oxide and / or gadolinium oxide 4.9-20 and characterized specific oxide ceramic alumina and / or zirconia 0.1-5. The production process includes wet milling traditional components, adding the specific oxide ceramic andwet milling in particle ball mill for 4-8 hr to prepare CeO2 base electrolyte powder; preparing blank sheet; and sintering at 1400-1500 deg.c and 6-10 deg.c / min temperature raising rate to produce the ceramic material. The ceramic material of the present invention has high mechanical strength, low sintering temperature and simple production process suitable for industrial production.

Owner:HEBEI UNIV OF TECH

Chromium carbide copper-based contact material for low-voltage electric appliance, and processing method for chromium carbide copper-based contact material

The invention discloses a chromium carbide copper-based contact material for low-voltage electrical appliances, which is characterized in that the composition of the contact material is: 0.1%-10% chromium carbide, 0.1%-5% alloy metal, 0.1% ~10% rare earth oxides, and the balance is copper; the alloy metal is one or two or a combination of two or more of aluminum, lanthanum, cerium, yttrium, nickel, chromium, zirconium, niobium, vanadium, and tungsten , the rare earth oxide is one or a combination of two or more of rhenium oxide, lanthanum oxide, cerium oxide, yttrium oxide, yttrium oxysulfide, samarium oxide, and zirconia. The low-voltage electrical contact made of the above materials not only has excellent welding resistance, wear resistance and oxidation resistance, but also can be used safely for a long time. In addition, the present invention also provides a chromium carbide copper-based contact for low-voltage electrical appliances The processing method of the material.

Owner:仙居县南大合金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com