Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Calcium pyrophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium pyrophosphate (Ca₂P₂O₇) is a chemical compound, an insoluble calcium salt containing the pyrophosphate anion. There are a number of forms reported: an anhydrous form, a dihydrate, Ca₂P₂O₇·2H₂O and a tetrahydrate, Ca₂P₂O₇·4H₂O. Deposition of dihydrate crystals in cartilage are responsible for the severe joint pain in cases of calcium pyrophosphate deposition disease (pseudo gout) whose symptoms are similar to those of gout. Ca₂P₂O₇ is commonly used as a mild abrasive agent in toothpastes, because of its insolubility and nonreactivity toward fluoride.

Porous nano titanium oxide base heterogeneous bioactive surface and its preparing process

InactiveCN1381615AImprove biological activityHigh bonding strengthSurface reaction electrolytic coatingProsthesisPlasma electrolytic oxidationApatite

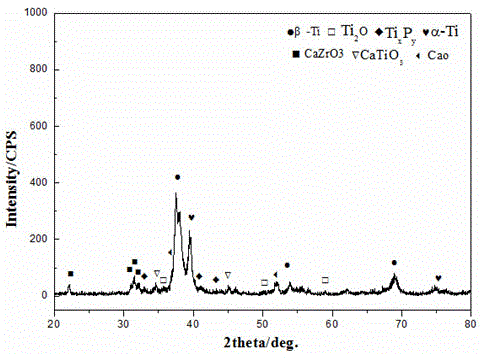

A prorous nanometre titanium oxide based heterogeneous bioactive surface layer is prepared by micro-arc oxidizing process, that is, the aqueous solution containing Ca and P is used as electrolyte andthe Ti or Ti-alloy is oxidized by micro-arc generated by high-voltage pulse power supply. The said bioactive surface layer is composed of TiO2, calcium titanate, alpha-calcium phosphate and beta-calcium pyrophosphate and has a thickness of over 30 microns, no interface with the matrix, multi-porous nm-crystalline structure on morphology, high bonding strength, good plastic toughness, capability of inducing the formation of apatite and good bioactivity. Its advantages are more than 30 micros for thickness, no interface with matrix, high adhesion, good plastic, toughness and bioactivity, and the elastic modulus close to that of bone.

Owner:XI AN JIAOTONG UNIV

Artificial bone graft substitute using calcium phosphate compounds and method of manufacturing the same

A bone graft substitute using magnesium substituted calcium phosphate compounds and a method of manufacturing the same is provided in which the bone graft substitute is used for recovering bones damaged due to a bone fracture. The method of manufacturing a bone graft substitute includes the steps of mixing powdered calcium pyrophosphate and a magnesium included compound to thereby obtain a composition, pressure-forming the compositions to obtain a plastic body; and sintering the plastic body.

Owner:KUG SUN HONG +1

Bone repair material

The bone repair material comprises the following components:A) a first granular component with a diameter larger than 20 μm chosen from the group of: calcium phosphate, calcium pyrophosphate, or calcium sulfate dihydrate;B) a second component chosen from the group of apatite powder with a particle diameter smaller than 1 μm, (preferably smaller than 100 nm); andB) a third component comprising water or an aqueous solution, wherebyC) the volume fraction of the second and third component represents at least 35 volume-% of the total bone repair material.

Owner:DR H C ROBERT MATHYS STIFTUNG +1

Process for preparing modified ardealite by water-free calcining

The invention relates to a method for preparing modified phosphogypsum through calcination without water scrubbing. The method is as follows: firstly, composite excitant and modifier are added into phosphogypsum and uniformly mixed, wherein, the weight percent of the phosphogypsum is between 85 and 95 percent; the weight percent of the composite excitant is between 2 and 5 percent; the weight percent of the modifier is between 3 and 10 percent; the composite excitant is green vitriol and aluminum sulphate, and the modifier is calcium oxide and cement; secondly, after uniform mixing, the mixture is dried at a drying temperature of between 100 and 110 DEG C, and the moisture of the phosphogypsum is lower than 8 percent; thirdly, the mixture enters into a calciner, is calcined for 0.5 to 1 hour at a temperature of between 150 and 300 DEG C, and is naturally cooled to prepare the modified phosphogypsum. The method decomposes and volatilizes harmful substances such as phosphor, fluorine, organic substances and so on contained in the phosphogypsum or converts the harmful substances into inert substance calcium pyrophosphate which is harmless to products, thereby not only avoiding secondary pollution but also reducing or avoiding influence of harmful chemical microconstituents contained in the phosphogypsum on the quality and the performance of the products. Moreover, the method shortens the processing time by 15 to 20 percent, saves the investment by 3 to 8 percent and reduces the energy consumption by 10 to 20 percent.

Owner:KUNMING UNIV OF SCI & TECH

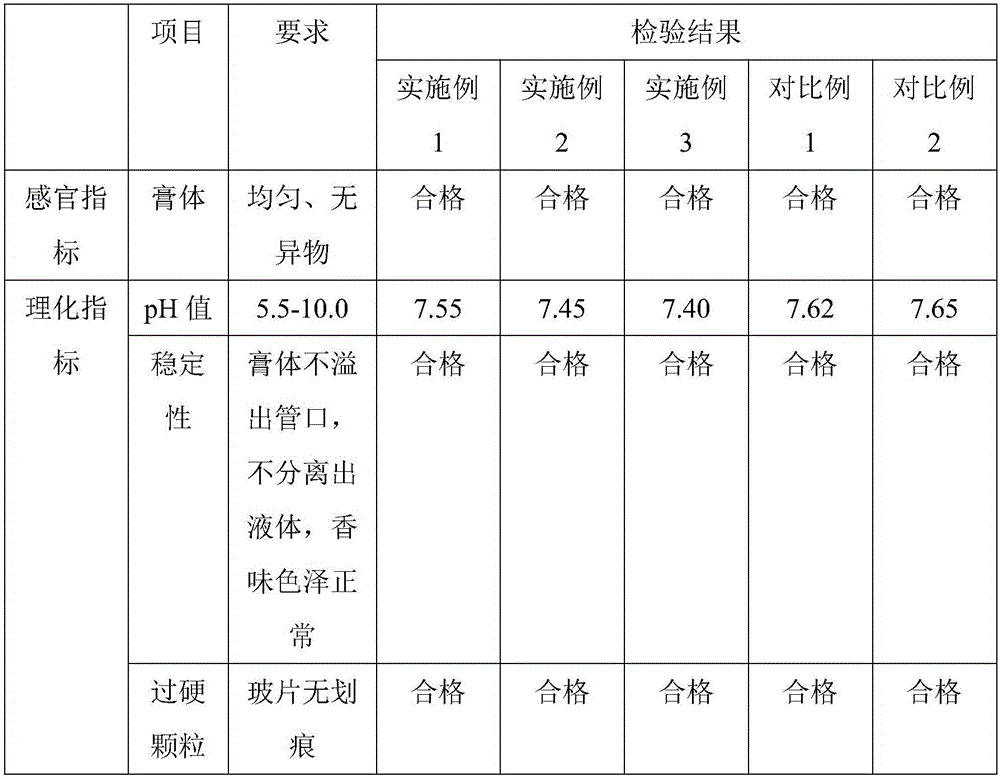

Hydrogen Peroxide Toothpaste With Improved Stability

InactiveUS20130108559A1Improve stabilityCosmetic preparationsToilet preparationsPhosphatePhosphoric acid

Aqueous oral care compositions containing hydrogen peroxide and having improved stability, such compositions containing at least 35%, by weight of the composition, of water and further including a peroxide compatible abrasive such as fused silica, calcium pyrophosphate and / or dicalcium phosphate, a gel network, and a protection system containing sodium acid pyrophosphate, disodium phosphate, and / or phosphoric acid.

Owner:THE PROCTER & GAMBLE COMPANY

High-quality water-based paint for wicker products

ActiveCN105969015AImprove temperature resistanceImprove wear resistanceAnti-corrosive paintsWater basedPolyethylene glycol

The invention discloses a high-quality water-based paint for wicker products. The high-quality water-based paint is prepared from the following materials: acrylic emulsion, ethylene glycol monobutyl ether, polyethylene glycol monomethyl ether, urea-formaldehyde resin, polyethylene glycol, potassium stearate, epoxidized soybean oil, calcium pyrophosphate, modified kaolin, modified alkyd resin, hexakis (methoxymethyl) melamine, carbomer, sodium coconut oil acyl methyl taurine and deionized water. The high-quality water-based paint is good in bonding property with the wicker products and rapid in self-dryness; the strength is improved by 30% or more, the characteristics of corrosion prevention and dampness prevention are obviously improved, and the scratch resistance and the high-temperature after-tack resistance are improved; and furthermore, the high-quality water-based paint is environment-friendly and free from environmental pollution.

Owner:安徽亮发家居有限公司

Preparation process of degradable foam-like strontium-doped calcium phosphate ceramic bone holder material

The present invention discloses the preparation process of bone tissue engineering rack material of degradable foamed Sr-doped calcium phosphate ceramic. It is prepared through bone cement copying foam structure process, and the Sr-doped apatite bone cement slurry as material includes solid phase particles of Ca4(PO4)2, CaPO4 and SrPO4 in certain molar ratio and liquid phase of 0.5-1.0 mol / L H3PO4 aqua in the solid / liquid ratio of 1.5-3.0. Polyurethane foam template is adopted. The final product is mixture of Sr-doped apatite and tricalcium strontium phosphate or the mixture of tricalcium strontium phosphate and calcium strontium pyrophosphate, and its component phase contents may be controlled through regulating the molar ratio of materials, solid / liquid ratio and phosphoric acid concentration so as to control the material degrading rate.

Owner:XI AN JIAOTONG UNIV

Environment-friendly microbial fertilizer for farmland income increase

The invention discloses an environment-friendly microbial fertilizer for farmland income increase. The environment-friendly microbial fertilizer comprises the following substances in parts by weight: 35-45 parts of chicken manure, 10-15 parts of sweet potato powder, 20-35 parts of peat, 9-16 parts of calcium superphosphate, 7-10 parts of potassium sulphate, 0.1-0.2 part of spherical bacillus powder, 35-45 parts of rice straw, 30-40 parts of rice bran, 1-2 parts of amino acid, 0.5-1.0 part of chitin, 0.1-0.2 part of atrialNatriuretie polypeptide, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 3-4 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrophosphate, 2-6 parts of calcium phosphate, 3-4 parts of calcium pyrophosphate, 5-9 parts of humic acid and 0.1-0.3 part of verticicladiella powder. The environment-friendly microbial fertilizer disclosed by the invention does not contain a large number of nutrient elements, and can provide multiple kinds of nutritional ingredients for crops after being used through the key function of contained microorganisms.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Method for preparing fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Single Phase Whitening Dentifrice with High Purity Metaphosphate Abrasive

Provided is a single phase oral care composition having a whitening agent; a first abrasive selected from calcium pyrophosphate, calcium carbonate, and dicalcium phosphate; a second abrasive that may include sodium metaphosphate; an anticalculus agent; and a substantially anhydrous carrier that may include an ethylene oxide / propylene oxide copolymer. In the composition, a wt % of the second abrasive is equal to or greater than a wt % of the first abrasive.

Owner:COLGATE PALMOLIVE CO

Low Water Dentifrice Compositions

ActiveUS20180147125A1Stable rheologyHigh viscosityCosmetic preparationsToilet preparationsPolyphosphateNuclear chemistry

The present disclosure provides low water dentifrice compositions comprising an effective amount of a zinc ion source, a stannous ion source, a polyphosphate and an acid in a calcium pyrophosphate base. The acid lowers the pH of the composition to enable stabilization of the metal ions and extend shelf-life of the composition.

Owner:COLGATE PALMOLIVE CO

Paste of remover for removing printing ink

InactiveCN1727412AEasy to useEasy to carryChemical paints/ink removersHydrogen phosphateWater insoluble

An ink erasing paste is prepared from rubbing agent (2-65 Wt%), shaping agent (3-40) and solvent (10-90). Said rubbing agent is the adhesive-type rubbing agent chosen from inorganic adhesive, organic adhesive and their mixture and / or the water-insoluble rubbing agent chosen from aluminium hydroxide, SiO2,calcium pyrophosphate, calcium hydrogen phosphate, calcium carbonate, etc.

Owner:兰仰光

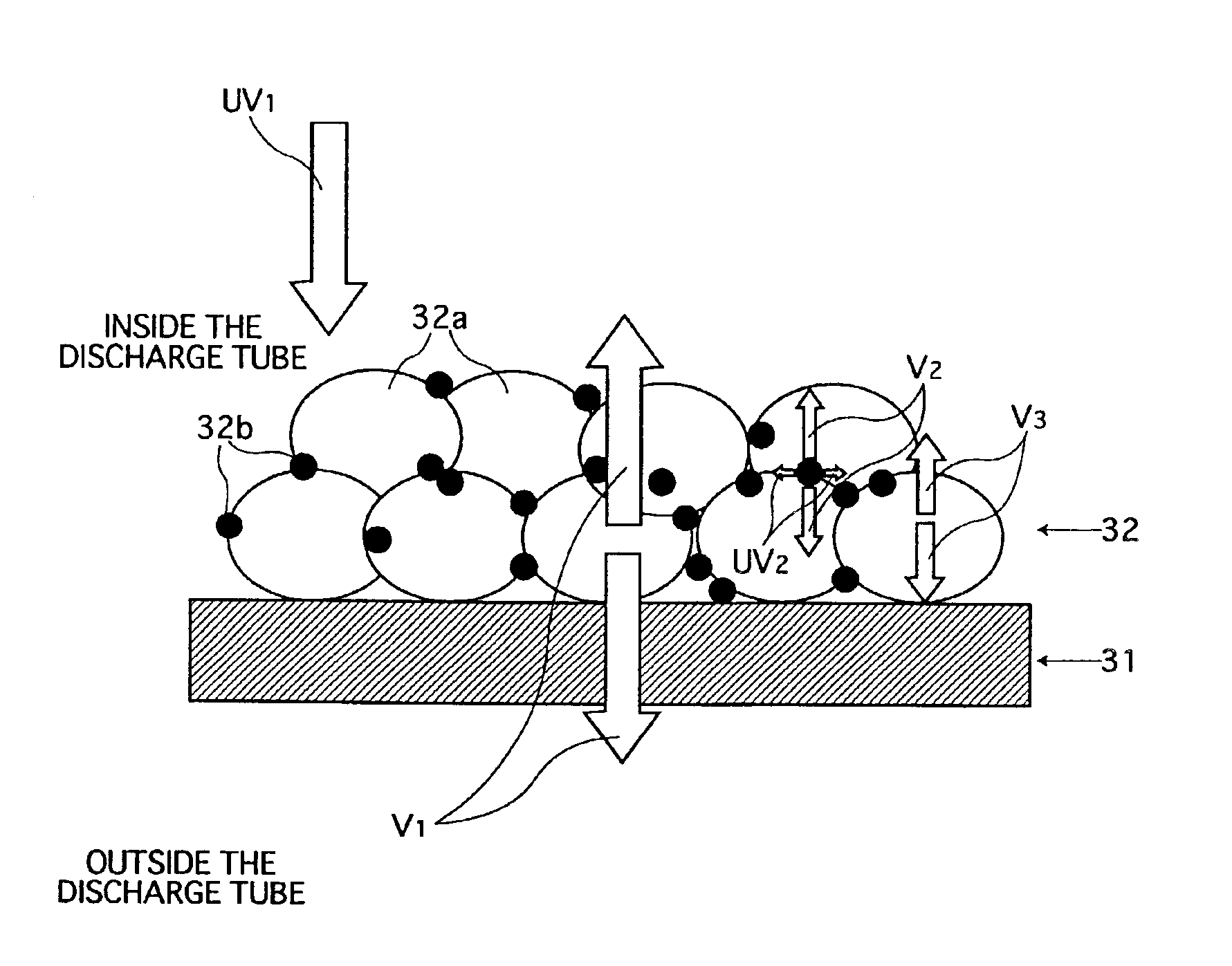

Glass composition, protective-layer composition, binder composition, and lamp

InactiveUS6921730B2Improve luminous efficiencyDischarge tube luminescnet screensLamp detailsLanthanumEuropium

A phosphor layer is composed of tri-band phosphor particles bound together by a binder. A material as the main component of the binder is a mixture of (1) a compound formed by calcium oxide, barium oxide, and boron oxide, and (2) calcium pyrophosphate. Dissolved in the main component material of the binder is a luminescent component that converts ultraviolet radiation of 254 nm to ultraviolet radiation of longer wavelengths or to visible light. Examples of such a luminescent component include an oxide of gadolinium (Gd), terbium (Tb), europium (Eu), neodymium (Nd), or dysprosium (Dy), each of which belongs to lanthanum series, and an oxide of thallium (Tl), tin (Sn), lead (Pb), or bismuth (Bi).

Owner:PANASONIC CORP

Artificial bone graft substitute using calcium phosphate compounds and method of manufacturing the same

ActiveUS7037867B2Good bone conductionAccurate ratingBone implantWood working apparatusSynthetic bone graftCalcium biphosphate

A bone graft substitute using magnesium substituted calcium phosphate compounds and a method of manufacturing the same is provided in which the bone graft substitute is used for recovering bones damaged due to a bone fracture. The method of manufacturing a bone graft substitute includes the steps of mixing powdered calcium pyrophosphate and a magnesium included compound to thereby obtain a composition, pressure-forming the compositions to obtain a plastic body; and sintering the plastic body.

Owner:KUG SUN HONG +1

Method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide

ActiveCN106045495AGood chemical stabilityReduce solubilityRadioactive decontaminationCeramicwareEcological environmentPolyethylene glycol

A method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide is characterized by including: using the materials in percent by weight: 50-80% of calcium pyrophosphate, 4-26% of calcium fluoride and 16-45% of calcium carbonate, and mixing, ball-milling, drying, press-forming, calcining, grinding, and screening to obtain fluorapatite powder; mixing the fluorapatite powder with polyethylene glycol solution, methyl cellulose solution and hydrogen peroxide solution, and performing microwave assisted pore-forming, drying and the like to obtain a porous fluorapatite ceramic blank; preparing porous fluorapatite ceramic adsorbing material via normal pressure sintering. The porous fluorapatite ceramic adsorbing material prepared herein has the advantages of high radiation stability, good thermal stability, high mechanical and chemical stability and the like, also has high specific surface energy and nuclide adsorbing capacity and may be used as an efficient adsorbing material for radioactive nuclide in high-radioactive waste liquid, thus effectively protecting human health and ecological environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Titanium-niobium-zirconium-based calcium pyrophosphate biological composite material preparation method

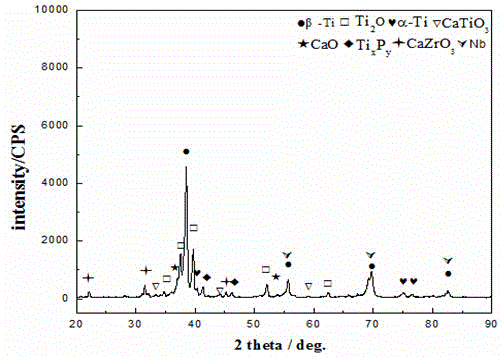

ActiveCN104894420AImprove biological activityHigh strengthSurgeryProsthesisThermal insulationNiobium

The present invention discloses a titanium-niobium-zirconium-based calcium pyrophosphate biological composite material preparation method, and belongs to the technical field of biomedical material preparation, wherein the biological composite material comprises a titanium-niobium-zirconium alloy matrix phase and a calcium pyrophosphate bioactive additive phase. The preparation method comprises: weighing Ti powder, Nb powder and Zr powder according to a component ratio, carrying out ball milling mechanical alloying, and then adding calcium pyrophosphate to carry out ball milling powder mixing; placing into a discharge plasma sintering furnace, applying 50-60 MPa axial pressure, and sintering under a vacuum degree of 15-20 Pa; and carrying out thermal insulation for 10-15 min at a temperature of 950-1050 DEG C, and cooling along with the furnace to a room temperature so as to obtain the titanium-niobium-zirconium-based calcium pyrophosphate biological composite material. According to the present invention, the prepared titanium-niobium-zirconium-based calcium pyrophosphate biological composite material has characteristics of low elastic modulus (38-65 GPa) and high compactness (more than or equal to 95%); the structure contains a large amount of the bioactive ceramic phase so as to easily induce cell growth and be used for human hard tissue replacement and repair, and the preparation method has characteristics of clean manufacturing process, simple process, low cost, and easy industrial production achieving.

Owner:KUNMING UNIV OF SCI & TECH

Whitening and stain removing toothpaste and preparation method thereof

InactiveCN106726773AReasonable formulaEasy to useCosmetic preparationsToilet preparationsToothpasteChemical products

The invention belongs to the technical field of daily chemical products, and particularly relates to whitening and stain removing toothpaste and a preparation method thereof. The whitening and stain removing toothpaste comprises, by weight, 6-9 parts of propylene glycol, 8-10 parts of sorbitol, 18-24 parts of silicon dioxide, 26-30 parts of calcium pyrophosphate, 0.4-0.8 part of mint oil, 0.02-0.06 part of saccharin sodium salt, 0.1-0.3 part of propylparaben, 0.5-1.6 parts of cocamidopropyl betaine, 0.3-1.2 parts of xanthan gum, 0.03-0.08 part of xylitol, 0.05-0.12 part of methyl p-hydroxybenzoate, 0.2-0.5 part of tea tree essential oil, 3-5 parts of perlite, 0.8-1.6 parts of papaya enzyme, 1-2 parts of stannous pyrophosphate, 0.5-1 part of sodium alginate and 14-25 parts of deionized water. The whitening and stain removing toothpaste can effectively remove color spots and dental plaque, and teeth are whitened.

Owner:安徽檀鑫科技有限公司

High-hardness pressure-resistant terrace material

The invention relates to a high-hardness pressure-resistant terrace material which is composed of the following components in parts by weight: 26-28 parts of polypropylene, 9-13 parts of furan resin, 11-12 parts of magnesium bicarbonate, 7-9 parts of calcium pyrophosphate, 11-13 parts of acrylonitrile, 5-6 parts of diphenyl ether and 3-5 parts of methylethylketone. The prepared terrace material has the characteristics of high hardness and pressure resistance.

Owner:江苏悠谷未来科技有限公司

Active nano grade organic fine humic fertilizer and its production

InactiveCN1472176AEliminate orange resistanceGrowth coordinationOrganic fertilisersFertilizer mixturesChemical reactionNanostructure

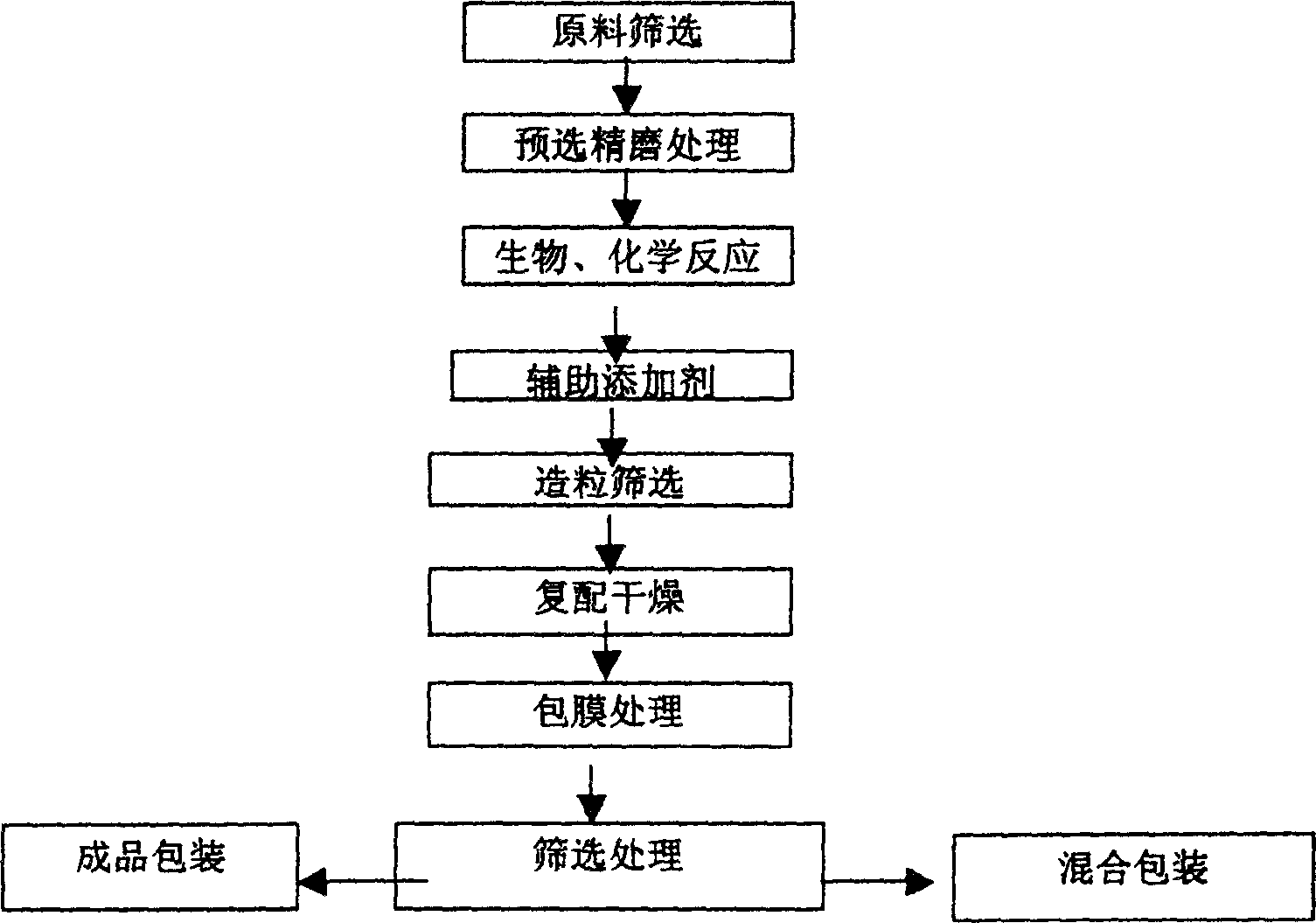

A nano-class fermented active organic fertilizer is prepared from ammonium humate organonitrogen, ammonium polyphosphate, ammonium phosphate, calcium potassium pyrophosphate, organopotassium, additive and water through screening raw materials, grinding, biochemical reacting, adding additive, granulating, compounding, drying, cooling and coating. Its advantages are no poison and environmental pollution, and multiple functions including improving soil and crops, regulating growth of plant, increasing yield of crops, resisting diseases and bacteria, etc.

Owner:武兴战

Hetian jade nano-powder, ultra-fine powder, powder toothpaste and production process of powder toothpaste

InactiveCN102772332AHigh activityStrong adsorption functionCosmetic preparationsToilet preparationsCalcium bicarbonateToothpaste

The invention discloses a toothpaste containing an abrasive made by grinding the hetian jade to nanometer powder, ultrafine powder or powder and mixing the powder with calcium carbonate, calcium bicarbonate, calcium pyrophosphate, silica, aluminum hydroxide, and a production process of the toothpaste. The toothpaste mainly comprises a powdered abrasive, a wetting agent, a surface active agent, a binder, a flavoring agent and a sweetener; the hetian jade nano-powder, ultra-fine powder or powder has strong functions of activation and adsorption, which can fast remove the residual lead, arsenic, mercury, other harmful heavy metals and a variety of toxins cells residue in the oral cavity to restore the clean sterile state of oral cavity; the powder also has the effects of nourishing heart and lung, benefiting qi and improving eyesight, clearing dirty and expelling toxin, boosting qi and nourishing yin, purging fire and engendering liquid, promoting blood circulation and other physical therapy functions; by using the hetian jade nano-powder, ultra-fine powder or powder with physical and chemical characteristics as well as special health care functions instead of conventional fungicides and preservatives, the invention creates a brand new mineral oral hygiene product.

Owner:肖晖

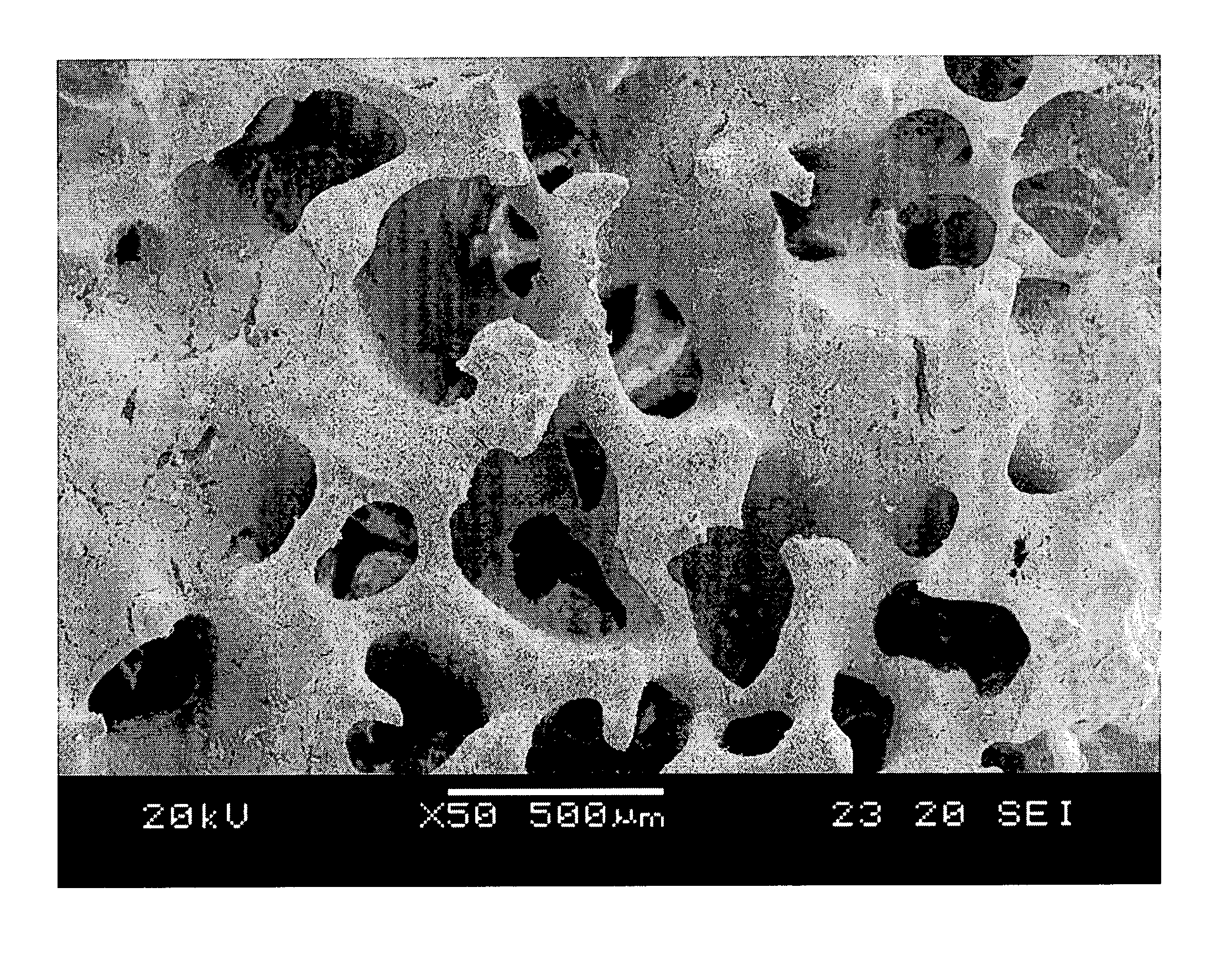

Method for preparing porous hydroxyapatite/calcium pyrophosphate compound bone repair material

ActiveCN105561386AGood biocompatibilityLower sintering temperatureTissue regenerationProsthesisPorosityHard tissue

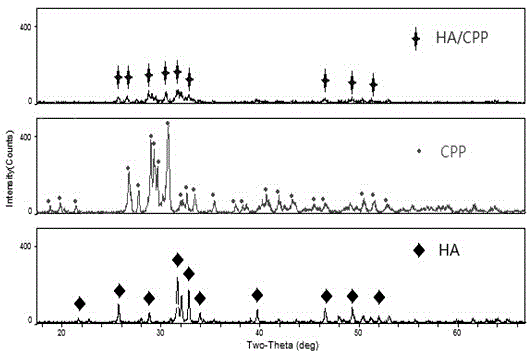

The invention relates to a method for preparing a porous hydroxyapatite / calcium pyrophosphate compound bone repair material, and belongs to the technical field of biomedical material preparation. The method includes the steps that 85%-95% by mass of hydroxyapatite and 5%-15% by mass of calcium pyrophosphate ceramic powder are weighed and are subjected to ball milling to obtain mixed powder; then 45%-55% by mass of mixed powder and 45%-55% by mass of ammonium-bicarbonate pore forming agent powder are mixed to be even, and are pressed into a block pressed blank through a machine; the pressed blank is put into a graphite mold to be placed into a spark plasma sintering furnace to be sintered, the temperature is naturally cooled to the room temperature along with the spark plasma sintering furnace, demolding is carried out, and the porous hydroxyapatite / calcium pyrophosphate compound bone repair material is obtained. According to the method for preparing the porous hydroxyapatite / calcium pyrophosphate compound bone repair material, binding agents and template agents are avoided, ingredients are pure and free of detrimental impurities, the porosity is controllable between 10% and 30%, and the degradation rate is better matched with bone tissue growth; the good ossifying inducing capability is achieved, the technology is simple and easy to operate, and the porous hydroxyapatite / calcium pyrophosphate compound bone repair material can be used as a bone defect repair material for body hard tissue regeneration or reconstruction.

Owner:KUNMING UNIV OF SCI & TECH +1

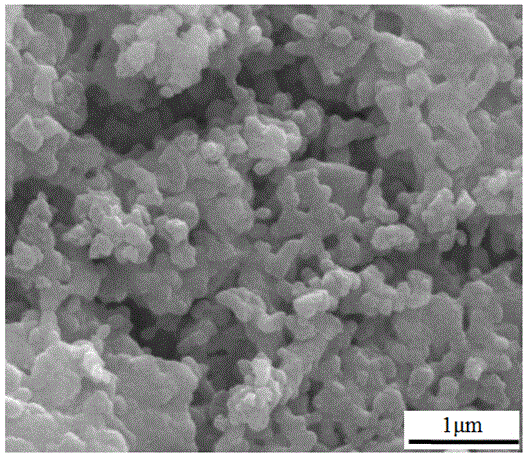

Osteoid structure biological ceramic composite material with adjustable coating thickness

The invention discloses an osteoid structure biological ceramic composite material with adjustable coating thickness, which is prepared from the following raw materials in weight percentage: 1-3% of rare earth, 70-74% of Ca.HPO4.2H2O, and 23-29% of CaCO3. The thickness of a coating prepared by adopting the osteoid structure biological ceramic composite material can achieve 3mm. The invention has the advantages as follows: the rare earth is added into the composite biological material, so that the stability of a HAP phase structure is improved. The coating prepared by adopting the composite material mainly contains hydroxyapatite with stable property, tertiary calcium phosphate, degradable calcium pyrophosphate and calcium titanate, so that the biocompatibility is excellent; the coating and a matrix are combined in a chemical metallurgic manner, so that the combination strength is high and the problem that the biological ceramic coating drops off during clinic application can be solved. Meanwhile, the raw materials are low in price, convenient to buy and easy to store, so that the osteoid structure biological ceramic composite material has favorable market application prospect and commercial value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

High-efficiency organic biofertilizer

InactiveCN103351232AHigh organic contentNutritional diversityFertilizer mixturesSodium aluminum phosphatePoultry manure

The invention discloses a high-efficiency organic biofertilizer which is characterized by comprising the following components in parts by weight: 50-90 parts of livestock and poultry manure, 4-9 parts of sodium dihydrogen phosphate, 5-6 parts of disodium hydrogen phosphate, 6-15 parts of sodium polyphosphate, 0.5-1.0 part of chitosan, 0.1-0.2 part of atrial natriuretic peptide, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 3-4 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrogen phosphate, 2-6 parts of calcium phosphate, 3-4 parts of calcium pyrophosphate, 5-9 parts of humic acid and 0.1-0.3 part of verticicladiella powder. The biofertilizer contains rich beneficial microbes, has the advantages of comprehensive and balanced nutrients and persistent effect, and can enhance the organic matter content in soil.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Biological active nano titanium oxide ceramic for hard tissue repairing and its preparing method

The bioactive nano titania ceramic block is prepared with nano titania powder meeting biological and medical requirement, such as rutile powder and / or anatase powder, as main material, and through mixing with magnesium oxide powder, alumina powder, calcium pyrophosphate or other crystal growth inhibitor, cold isostatic pressing formation, and sintering. Under intracorporal physiological environment condition, the ceramic block can adsorb calcium and phosphorus ion to form surface bone apatite layer for bioactive chemical combination with bone tissue. The bioactive nano titania ceramic may be implanted into tooth or other bone fault cavity to form bioactive combination safely and reliably in relatively low cost.

Owner:SICHUAN UNIV

Ultrasonic bright cleaning agent for aluminum case workpiece of mobile phase battery as well as preparation method thereof

InactiveCN103103548AEfficient removalReduce manufacturing costCleaning using liquidsElectrical batteryPotassium hydroxide

The invention discloses an ultrasonic bright cleaning agent for an aluminum case workpiece of a mobile phase battery. The ultrasonic bright cleaning agent comprises the components in percentage by weight as follows: 0.1-0.4% of potassium hydroxide, 1-7% of sodium tripolyphosphate, 1-4% of sodium pyrophosphate, 1-6% of sodium silicate pentahydrate, 0.1-2% of ethylene glycol monobutyl ether, 1-5% of activator (Y-71), 1-6% of activator (Y-90), 0.1-1.0% of activator (QYL-252C), 0.5-2% of JFC, 1-3% of NP-6, 1-2% of defoamer and the balance of deionized water. The preparation method comprises the following steps of: firstly, adding calculated and weighed deionized water into a stainless steel reaction kettle, starting a stirrer and controlling the rotating speed at 60rpm; then, sequentially adding the calculated and weighed solid raw materials into the reaction kettle; at least stirring each raw material for 10 minutes; then sequentially adding liquid raw materials calculated and weighed into the reaction kettle slowly; stirring while adding; and continuously stirring till the liquor is the uniform maize-yellow liquor.

Owner:DALIAN SANDAAOKE CHEM

Solid oral tooth whitening confectionary composition

The present invention provides a solid, oral tooth whitening confectionary composition comprising a tooth whitening agent comprising an alkaline or alkaline earth metal pyrophosphate, preferably calcium pyrophosphate. In one embodiment, the composition of the invention comprises an additional tooth whitening agent.

Owner:CADBURY HLDG

Combined pretreatment method of ardealite

InactiveCN107244690AHigh mechanical strengthHigh purityCalcium/strontium/barium sulfatesPretreatment methodHazardous substance

The invention relates to a combined pretreatment method of ardealite, belonging to the technical field of renewable resources and environment. The method comprises the following steps of removing harmful substances in the ardealite by grinding and screening firstly, then smashing and fermenting lemon to obtain fermented filtrate rich in citric acid and microorganisms, mixing and piling by using the fermented filtrate and the ardealite, converting phosphorus and fluorine into water-soluble citrate, ferrite and chlorate by utilizing the citric acid in the fermented filtrate, degrading and removing organic pollutants in the ardealite by utilizing the microorganisms, then using water as a stream-pressure medium, improving the removal rate of water-soluble impurities, then frying and heating continuously under a high-temperature condition to enable co-crystallized phosphorus in the ardealite to be separated out and then converted into insoluble and inert calcium pyrophosphate so as to be decomposed and removed at high temperature, and finally, further removing residual soluble impurities and organic matters by flotation. By the method disclosed by the invention, the content of the soluble impurities and co-crystallized phosphorus in the ardealite is greatly reduced, and the purity of the ardealite is improved.

Owner:嘉兴市南湖区翊轩塑料五金厂(普通合伙)

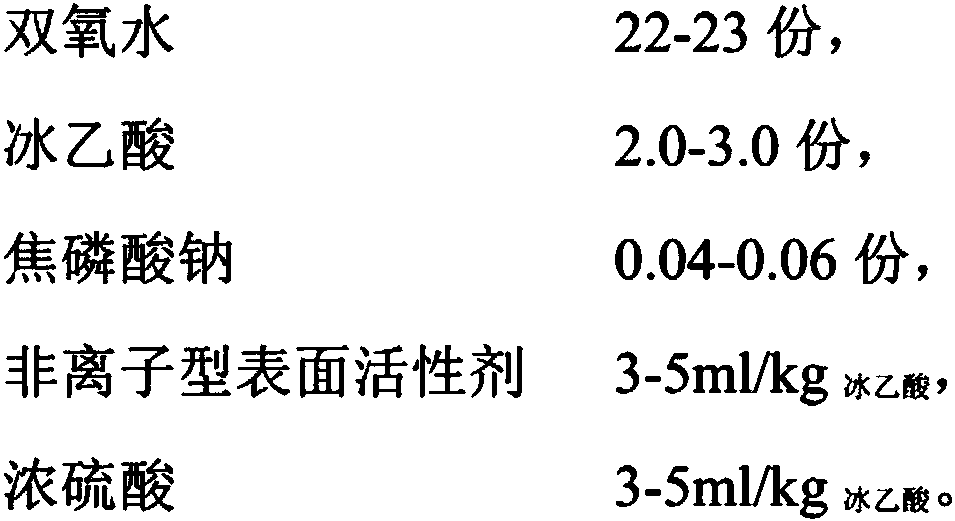

Peroxyacetic acid compound disinfectant and preparation method thereof

InactiveCN109077054AEfficient killingGood sterilization effectBiocideDisinfectantsAcetic acidDisinfectant

The invention provides a peroxyacetic acid compound disinfectant and a preparation method thereof. The peroxyacetic acid compound disinfectant is prepared from hydrogen peroxide solution, glacial acetic acid, sodium pyrophosphate, concentrated sulfuric acid and nonionic surfactants, wherein the mass ratio of hydrogen peroxide, namely the active component of hydrogen peroxide to glacial acetic acidis greater than 1. Under co-action of excessive hydrogen peroxide, the stabilizer, namely sodium pyrophosphate, and the nonionic surfactants, namely Tween 80, the purpose of improving stability whiledisinfecting is achieved. The disinfectant can kill germs fully within 5 minutes, and has the advantage of rapid disinfection.

Owner:SICHUAN ANIMAL SCI ACAD

Flat bread dough composition and method for making flat breads

InactiveUS20120263854A1Dough composition to relaxDough treatmentPre-baking dough treatmentSodium aluminum phosphateSodium phosphates

The present invention relates to a flat bread dough composition, comprising: A) flour; B) shortening; C) water; and D) a leavening system having a leavening base and a leavening acid having a combination selected from the group consisting of a) sodium aluminum phosphate and dicalcium phosphate dihydrate; b) sodium aluminum phosphate and sodium acid pyrophosphate; c) sodium acid pyrophosphate and dicalcium phosphate dihydrate; d) sodium acid pyrophosphate, monocalcium phosphate, and calcium acid pyrophosphate; e) dicalcium phosphate dehydrate, monocalcium phosphate, and calcium acid pyrophosphate; f) sodium aluminum phosphate, sodium acid pyrophosphate, and dicalcium phosphate dihydrate; g) sodium aluminum sulfate and dicalcium phosphate dihydrate; and h) sodium aluminum sulfate and sodium acid pyrophosphate, the sodium acid pyrophosphate exhibiting an evolved percentage of carbon dioxide of about 30 or less at room temperature prior to baking, and the slower reacting of the leavening acids in the combination being at least 10 wt % of the total weight of the acid combination.

Owner:INNOPHOS INC

Porous nano titanium oxide base heterogeneous bioactive surface and its preparing process

InactiveCN1147625CImprove biological activityHigh bonding strengthSurface reaction electrolytic coatingProsthesisPlasma electrolytic oxidationApatite

A prorous nanometre titanium oxide based heterogeneous bioactive surface layer is prepared by micro-arc oxidizing process, that is, the aqueous solution containing Ca and P is used as electrolyte andthe Ti or Ti-alloy is oxidized by micro-arc generated by high-voltage pulse power supply. The said bioactive surface layer is composed of TiO2, calcium titanate, alpha-calcium phosphate and beta-calcium pyrophosphate and has a thickness of over 30 microns, no interface with the matrix, multi-porous nm-crystalline structure on morphology, high bonding strength, good plastic toughness, capability of inducing the formation of apatite and good bioactivity. Its advantages are more than 30 micros for thickness, no interface with matrix, high adhesion, good plastic, toughness and bioactivity, and the elastic modulus close to that of bone.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com