Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

498 results about "Calcium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium titanate is an inorganic compound with the chemical formula CaTiO₃. As a mineral, it is called perovskite, named after Russian mineralogist, L. A. Perovski (1792-1856). It is a colourless, diamagnetic solid, although the mineral is often coloured owing to impurities.

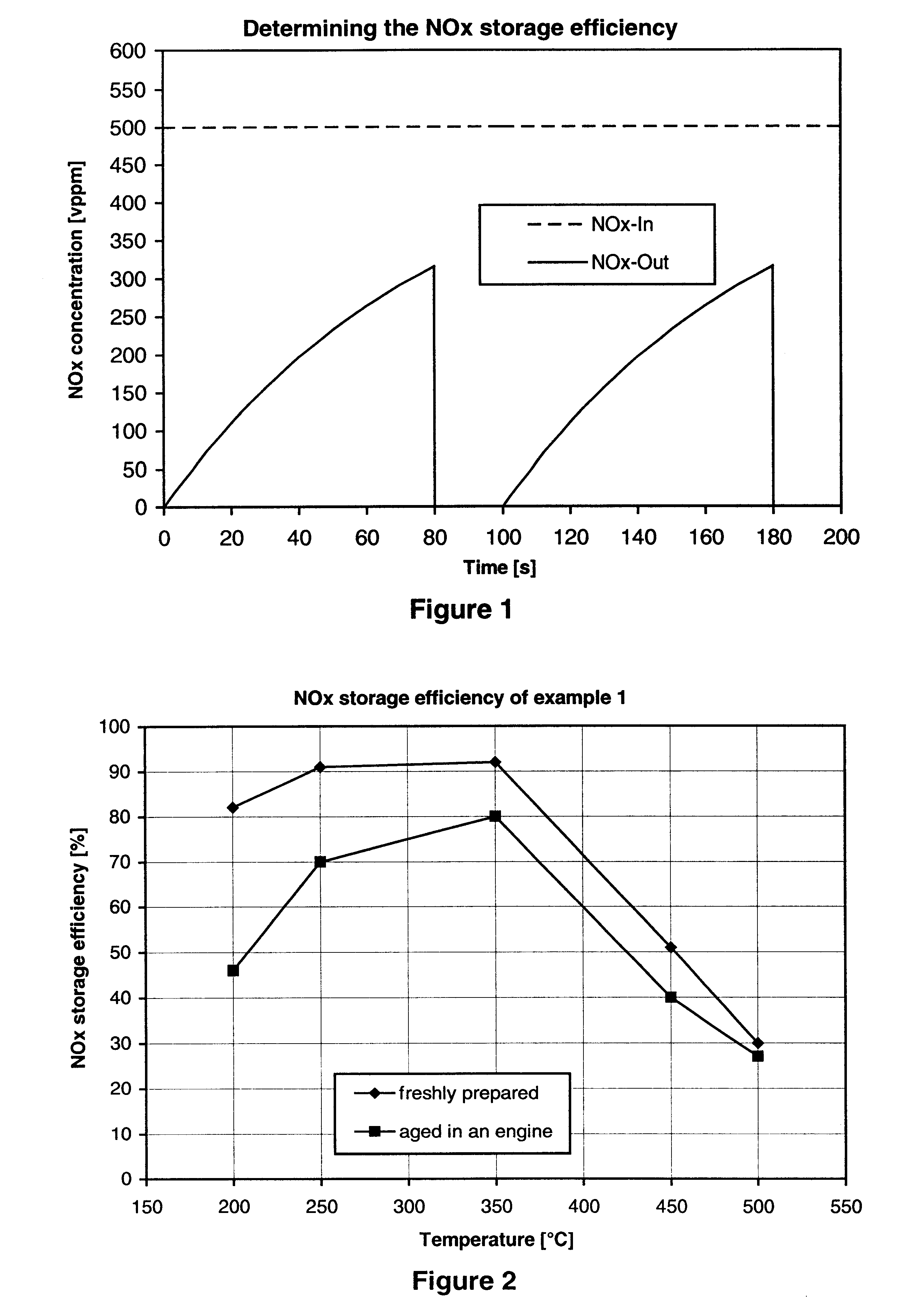

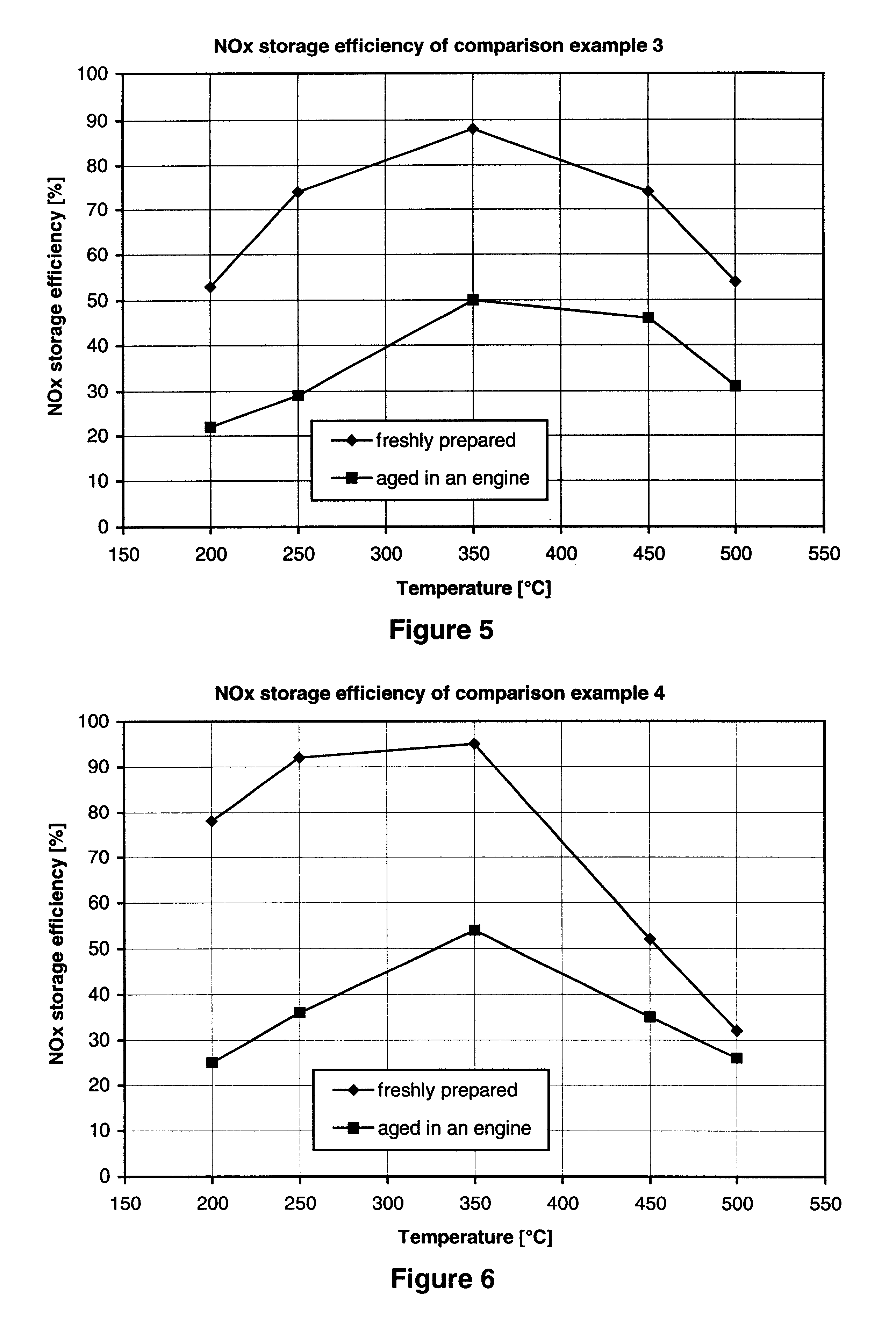

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

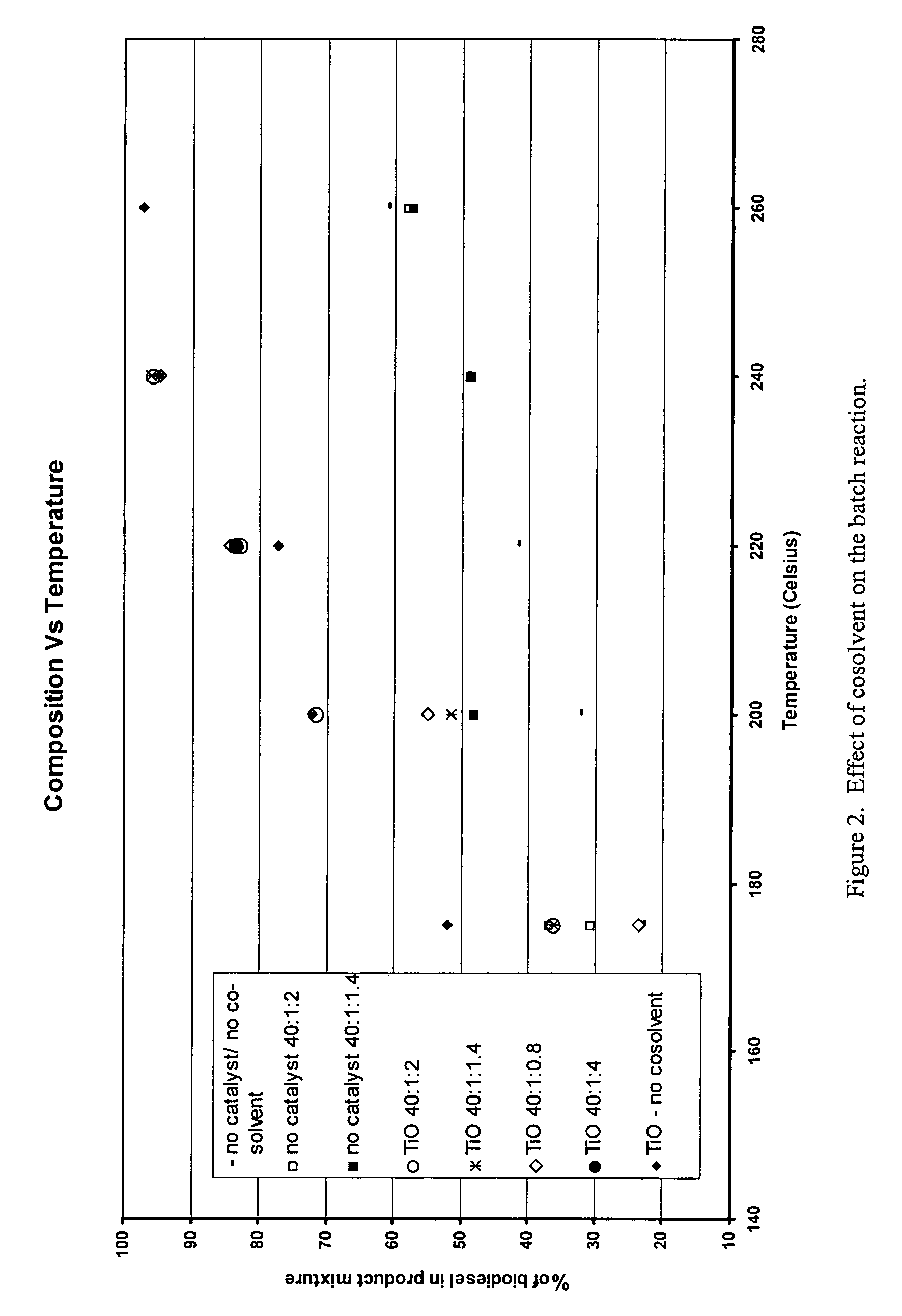

Green biodiesel

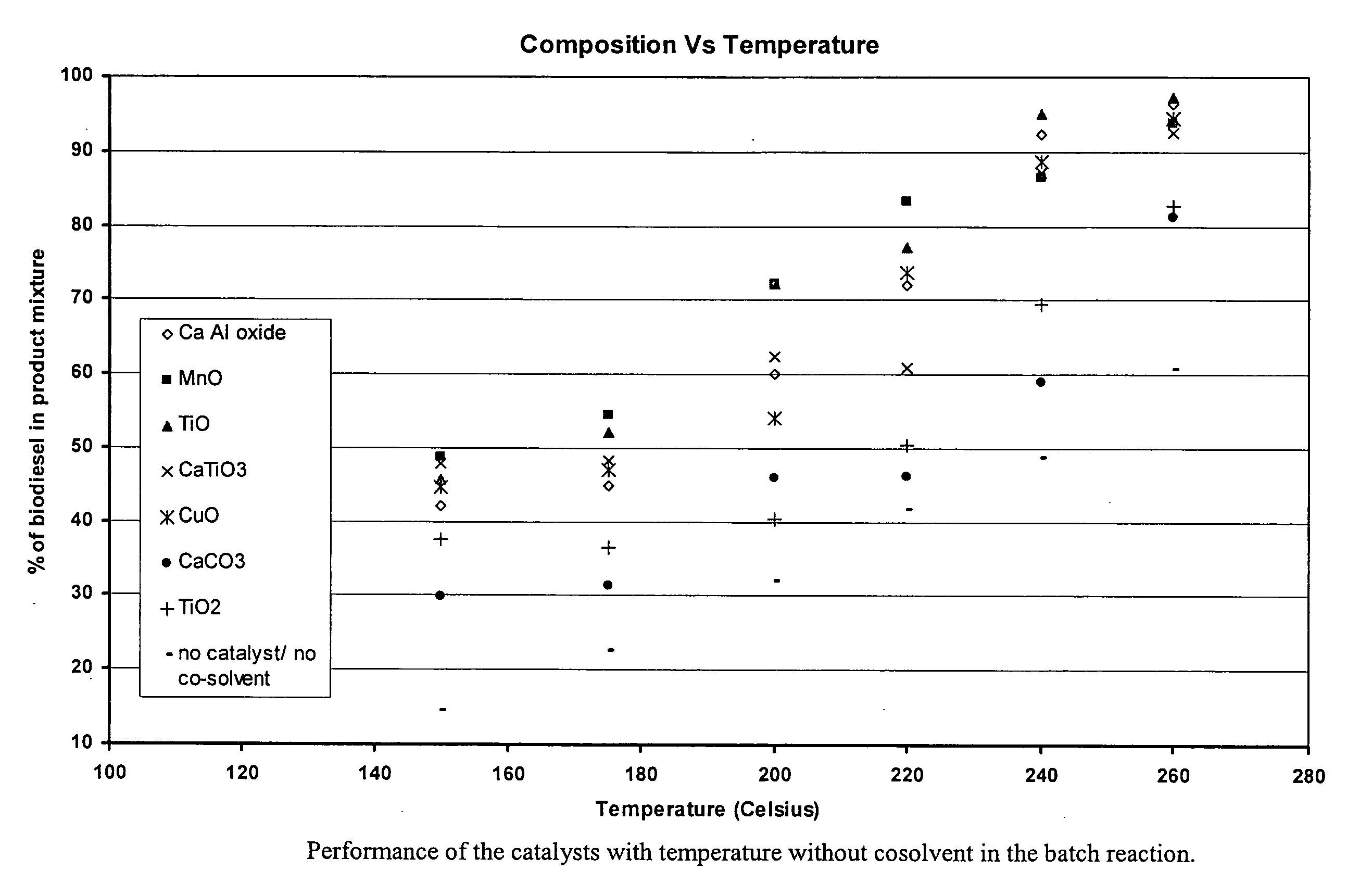

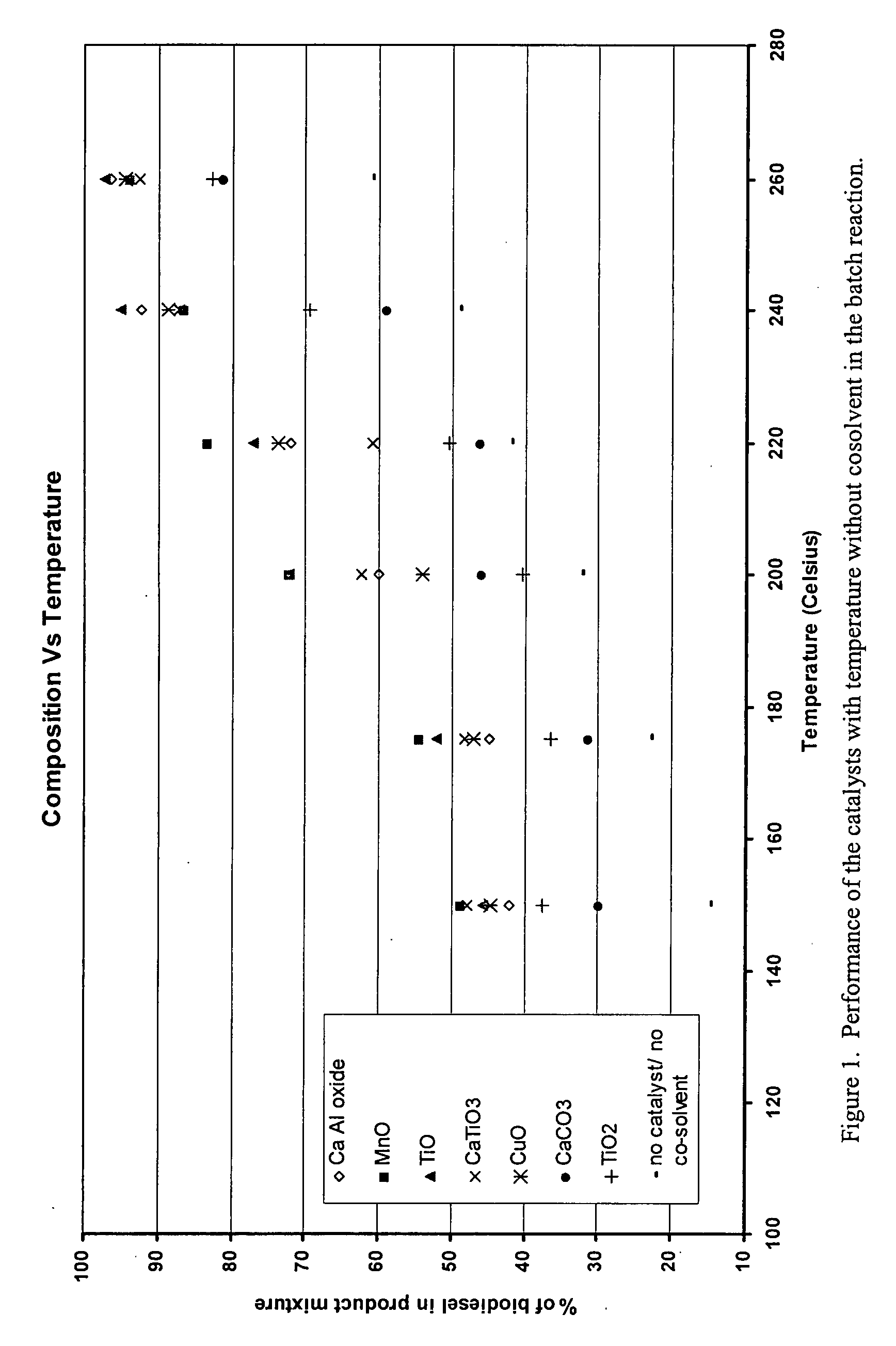

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

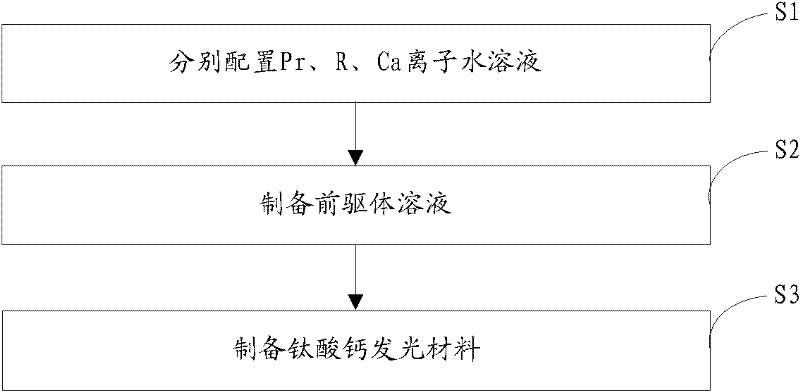

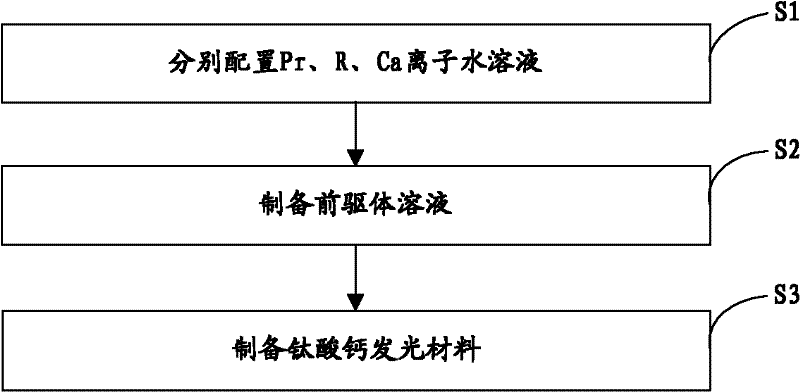

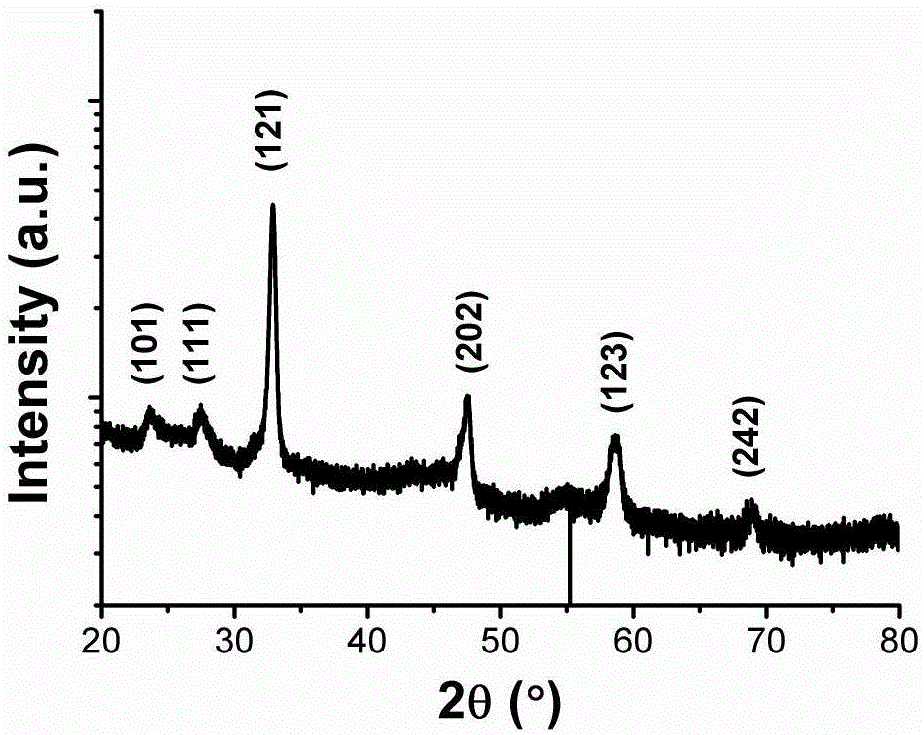

Praseodymium-doped calcium titanate luminescent powder and preparation method thereof

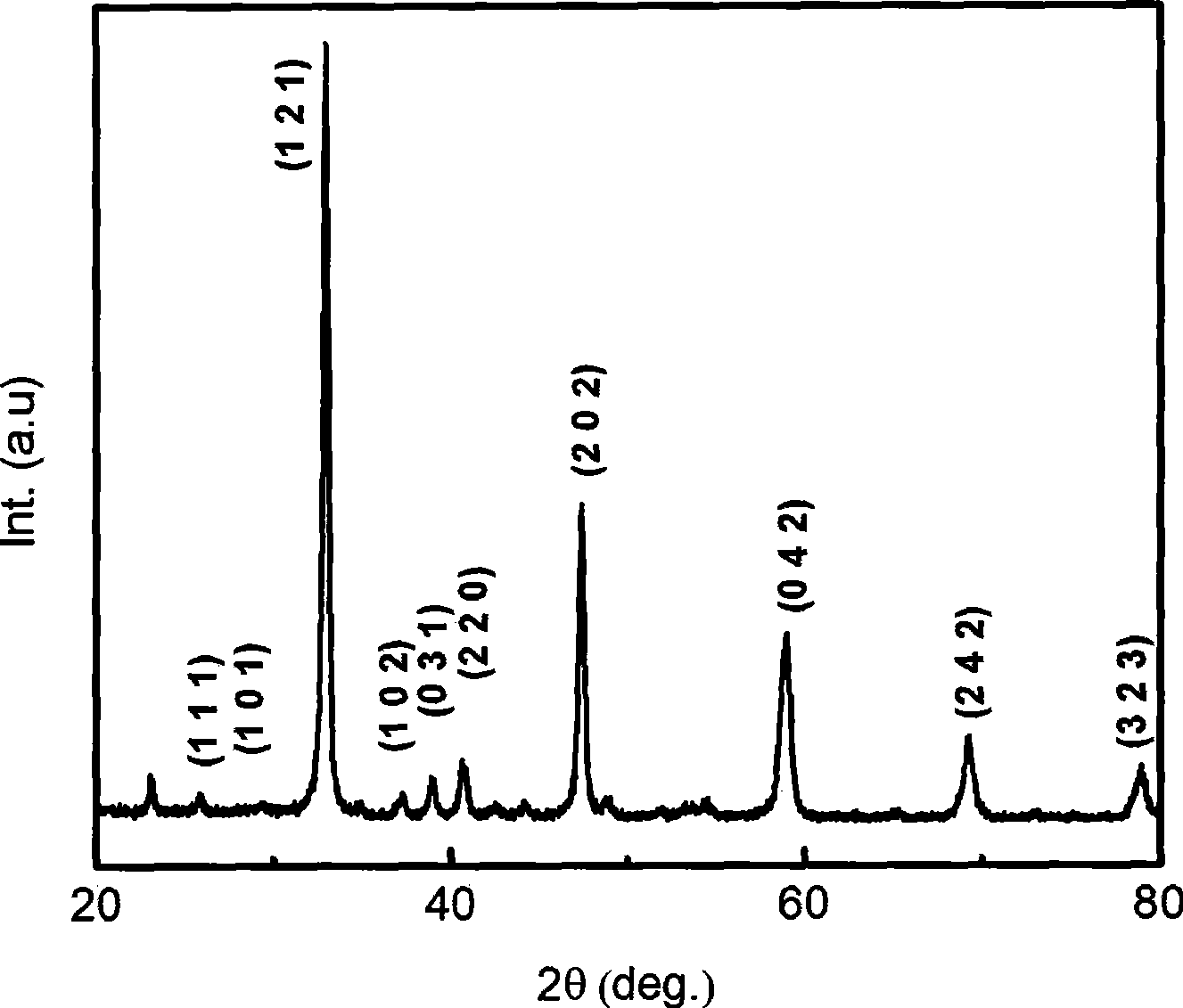

The invention provides praseodymium-doped calcium titanate luminescent powder and a preparation method thereof. The preparation method comprises the following steps: at room temperature, weighing a certain amount of CaCO3 and Pr6O11 solid according to a molar ratio of Pr<3+> / Ca<2+> of 0.005 / 1, dissolving the solid in dilute nitric acid, heating and stirring the solution to remove excessive acid, and heating the solution to a melting state after the pH value of the solution reaches 2 to 3; after the solution is cooled to room temperature, adding 20 milliliters of tetrabutyl titanate and 20 milliliters of water-ethanol solution into the solution according to a stoichiometric proportion, then adding a certain amount of citric acid as complexing agent into the solution, adding polyethylene glycol into the solution, and stirring the solution for 2 hours to obtain an even transparent sol precursor; spraying and drying the obtained precursor solution to obtain precursor powder; and putting the precursor powder into a programmed temperature rising furnace, heating the precursor powder to between 600 and 1,000 DEG C, and then keeping the precursor powder for 3 hours at a constant temperature to obtain CaTiO3:Pr<3+> luminescent powder. The praseodymium-doped calcium titanate luminescent powder prepared by the method has good crystallization degree and high purity, and is a CaTiO3 pure phase of a perovskite structure.

Owner:HARBIN ENG UNIV

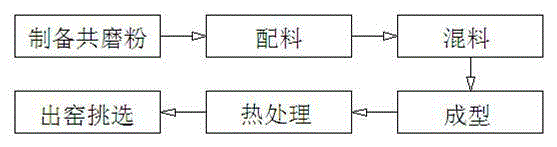

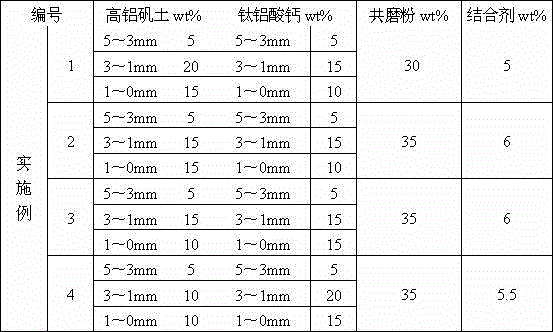

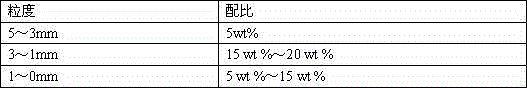

Titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as preparation method and application thereof

ActiveCN104609872AHigh melting pointSmall coefficient of thermal expansionMelt-holding vesselsSteelmakingAluminate

The invention discloses a titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as a preparation method and application thereof, belongs to the field of refractory materials, and adopts the technical scheme that the modified refractory material comprises 25 to 40 wt% of high alumina bauxite, 25 to 40 wt% of titanium-containing calcium aluminate, and 30 to 35 wt% of co-ground powder, and a phenolic resin binding agent which accounts for 3 to 6 wt% of the total mass of the raw materials is additionally added, wherein the co-ground powder is formed by uniformly mixing titanium-containing calcium aluminate fine powder, alpha-Al2O3 micro-powder, graphite powder, silicon carbide fine powder, graphite powder, silicon carbide fine powder, metal aluminum powder and high-temperature asphalt powder; titanium-containing calcium aluminate comprises the following ingredients by ratio: 76.21% of Al2O3, 10.6% of TiO2, 10.16% of CaO, 0.6% of Fe2O3, 1.82% of MgO, and 0.62% of SiO2. According to the invention, titanium-containing calcium aluminate being industrial slag of steelmaking is effectively recycled, so as to greatly reduce the production and manufacture cost; as titanium-containing calcium aluminate is a solid solution of calcium hexaluminate, calcium dialuminate, aluminum titanate, calcium titanate and rutile, the modified refractory material is favorable in thermal shock resistance and heat-insulating property.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Method for preparing porous calcium titanate heavy metal adsorbent

InactiveCN102430382AStrong acid and alkali resistanceStrong heat resistanceOther chemical processesSolid waste disposalSorbentFurfural

The invention discloses a method for preparing a porous calcium titanate heavy metal adsorbent. In the method, the porous flaky calcium titanate heavy metal adsorbent is prepared by taking solid wastes in furfural industry, namely furfural residues as a template agent by a sol-gel method. The method comprises the following steps of: crushing the dried furfural residues, adding calcium titanate sol, stirring uniformly, and drying to obtain a furfural residue-calcium titanate gel composite; and calcining at high temperature, and oxidizing and decomposing organic matters in the furfural residues and the calcium titanate gel to obtain the porous calcium titanate adsorbent. The porous calcium titanate heavy metal adsorbent is used for adsorbing and removing multiple kinds of heavy metals such as lead, cadmium, nickel, copper, zinc, silver and the like simultaneously. The furfural residues are used as the template agent, so the solid wastes are utilized, and the high adsorbability and high stability of the calcium titanate are utilized simultaneously; and the adsorbent synthesized by the method has the advantages of low cost, simple process, large adsorption capacity, wide application range, high hydrothermal stability, high acid and alkali resistance, and the like, and is convenient to regenerate and recover.

Owner:SHENYANG LIGONG UNIV

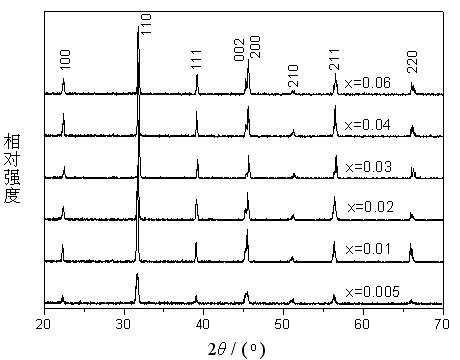

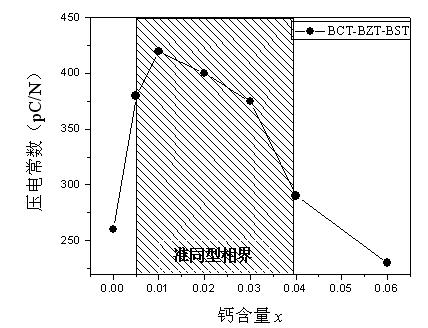

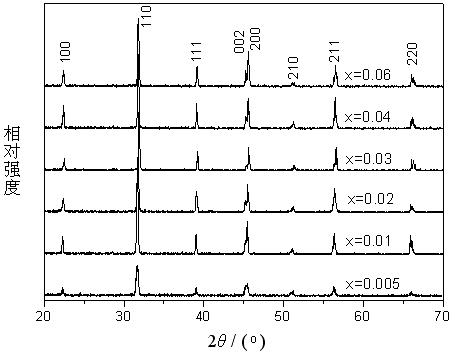

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

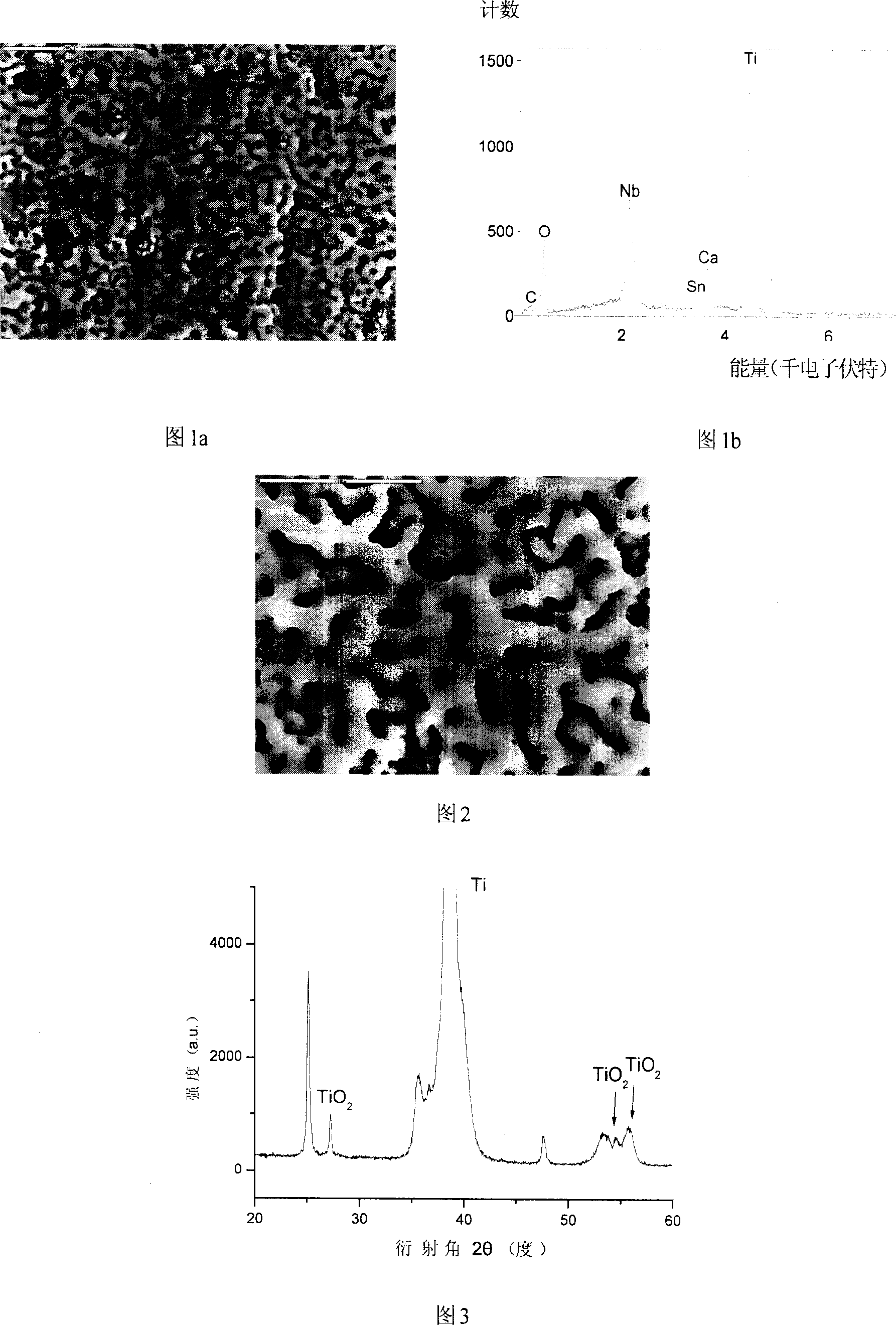

Porous nano titanium oxide base heterogeneous bioactive surface and its preparing process

InactiveCN1381615AImprove biological activityHigh bonding strengthSurface reaction electrolytic coatingProsthesisPlasma electrolytic oxidationApatite

A prorous nanometre titanium oxide based heterogeneous bioactive surface layer is prepared by micro-arc oxidizing process, that is, the aqueous solution containing Ca and P is used as electrolyte andthe Ti or Ti-alloy is oxidized by micro-arc generated by high-voltage pulse power supply. The said bioactive surface layer is composed of TiO2, calcium titanate, alpha-calcium phosphate and beta-calcium pyrophosphate and has a thickness of over 30 microns, no interface with the matrix, multi-porous nm-crystalline structure on morphology, high bonding strength, good plastic toughness, capability of inducing the formation of apatite and good bioactivity. Its advantages are more than 30 micros for thickness, no interface with matrix, high adhesion, good plastic, toughness and bioactivity, and the elastic modulus close to that of bone.

Owner:XI AN JIAOTONG UNIV

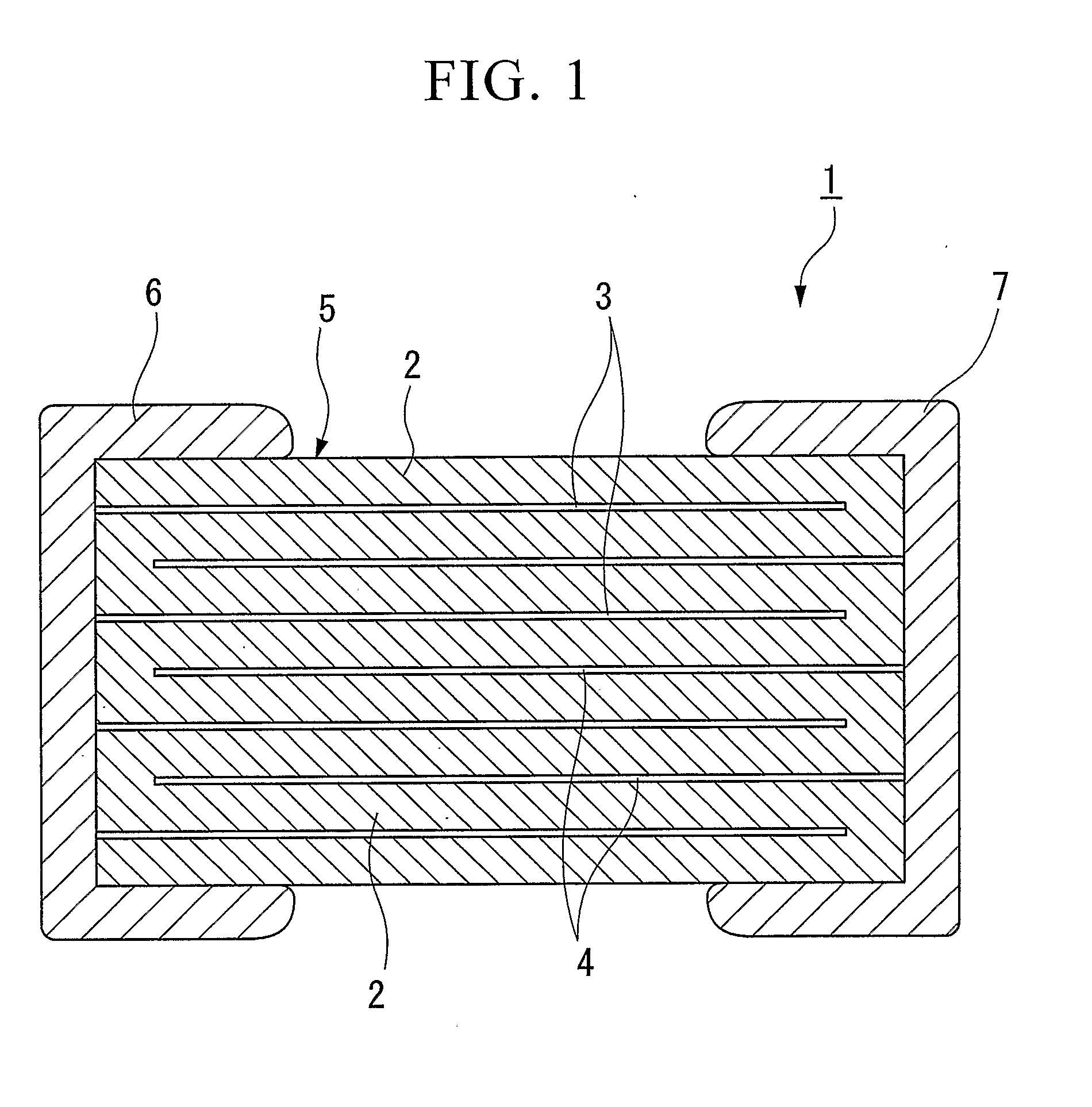

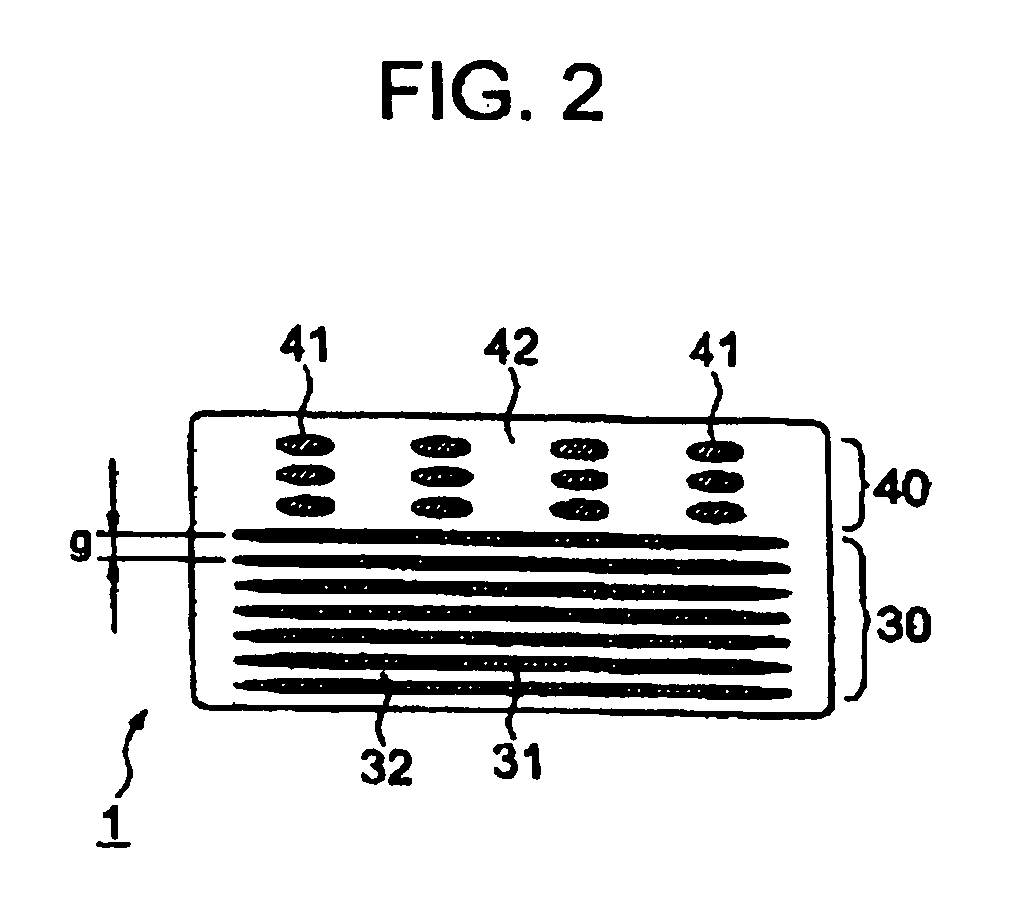

Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

InactiveUS20060287184A1Improve electrical insulation reliabilityReduced insulation performanceCeramic layered productsPrinted circuit manufactureStrontium titanateLithium oxide

A glass-ceramic composition contains first ceramic particles principally containing forsterite; second ceramic particles principally containing at least one selected from the group consisting of calcium titanate, strontium titanate, and titanium oxide; and borosilicate glass particles containing about 3% to 15% lithium oxide, about 20% to 50% magnesium oxide, about 15% to 30% boron oxide, about 10% to 45% silicon oxide, about 6% to 20% zinc oxide, 0% to about 15% aluminum oxide, and at least one additive selected from the group consisting of calcium oxide, barium oxide, and strontium oxide on a weight basis. The content of the borosilicate glass particles is about 3% or more; the lower limit of the content of the additive is about 2%; and the upper limit of the additive content is about 15%, about 25%, or about 25% when the additive is calcium oxide, barium oxide, or strontium oxide, respectively, on a weight basis.

Owner:MURATA MFG CO LTD

CO2-Sorptive Pellets and Uses Thereof

CO2 sorptive pellets and / or granules and their use for removing CO2 from CO2-containing gases and for producing hydrogen. CO2 sorptive pellets are suitable for use in fixed bed reactors and the like due to sufficient crush strength. CO2 sorptive granules are suitable for moving, ebullated, expanded and fluidized beds. The CO2 sorptive pellets and / or granules comprise calcium oxide and / or magnesium oxide and at least one binding agent such as calcium titanate, calcium aluminate, calcium zirconate, magnesium titanate, magnesium aluminate, and magnesium zirconate. A method for making the CO2-sorptive pellets is described. The CO2 sorptive pellets optionally comprise at Ni, Pd, Pt, and / or Rh.

Owner:AIR PROD & CHEM INC

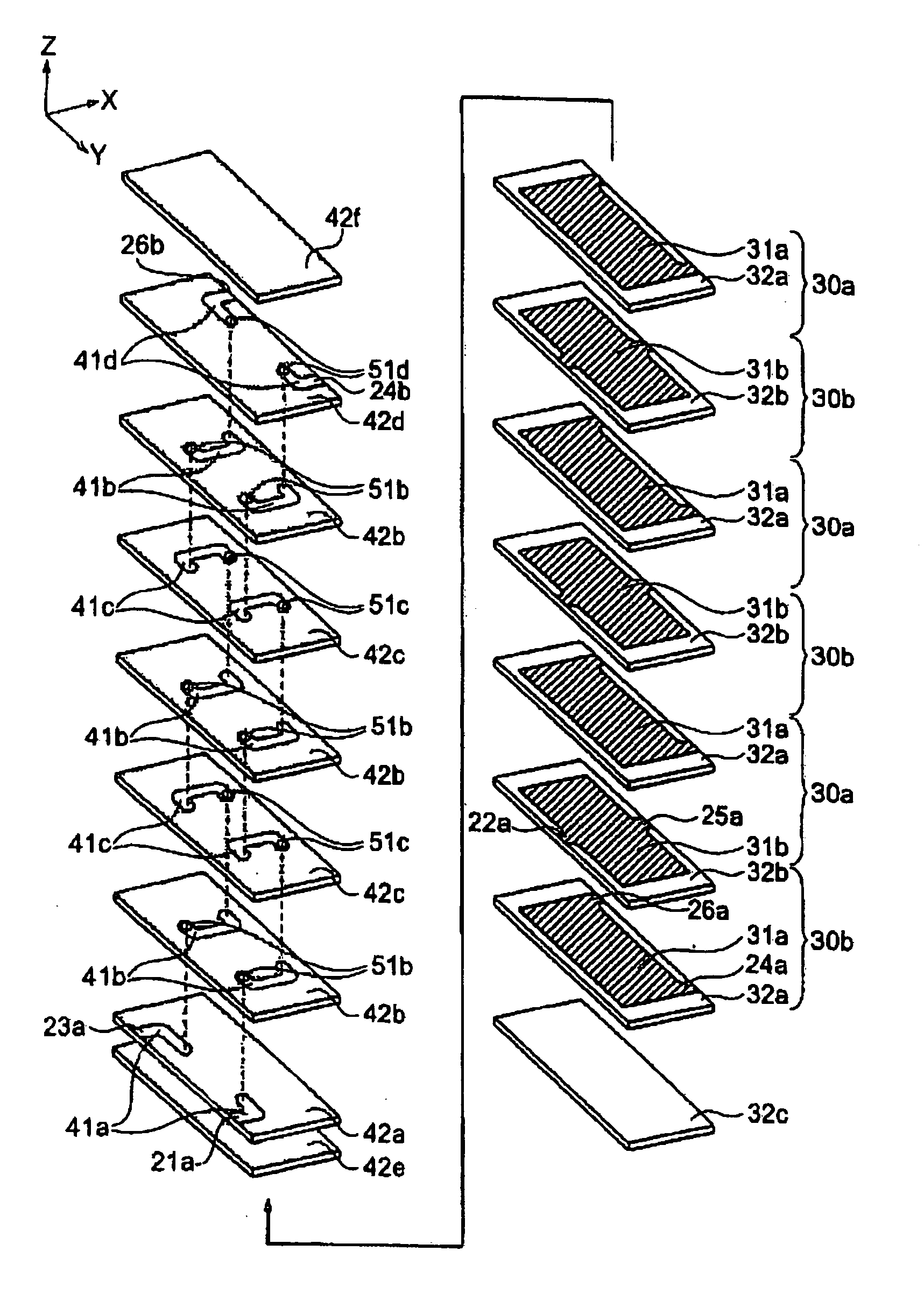

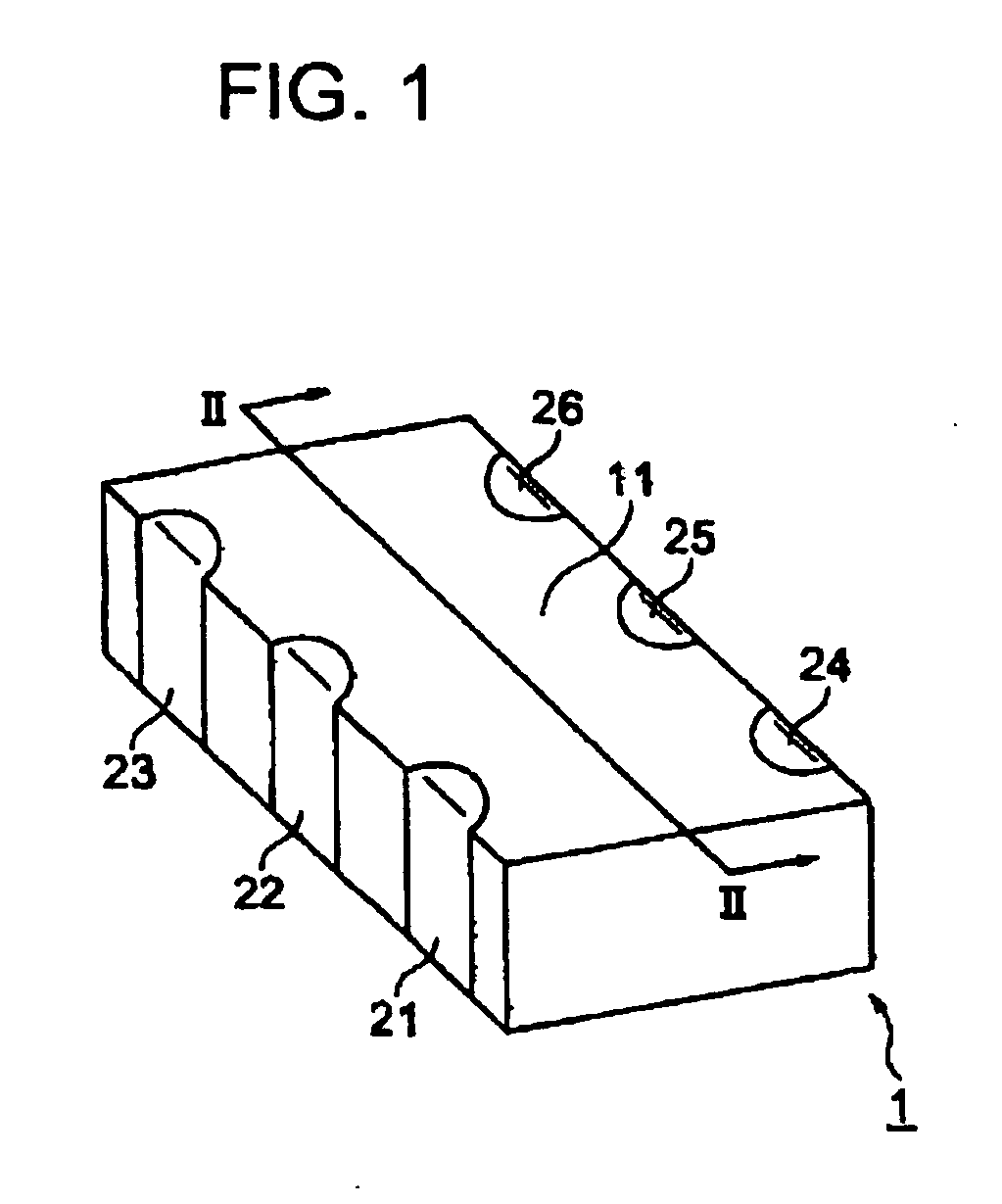

Barium Calcium Titanate, Production Process Thereof and Capacitor

InactiveUS20070253145A1Good dispersionReduce the presence of impuritiesAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyBarium titanatePhysical chemistry

A barium calcium titanate of the present invention has a remarkable effect that a fine barium calcium titanate powder having excellent dispersibility, reduced impurities and high crystallinity and being solid-dissolved at an arbitrary ratio, and a production process thereof are provided. The barium calcium titanate represented by the compositional formula: (Ba(1-X)CaX)YTiO3 (wherein 0<X<0.2 and 0.98≦Y≦1.02), which contains 3 mol % or less (including 0 mol %) of an orthorhombic perovskite compound and in which the specific surface area D is from 1 to 100 m2 / g.

Owner:SHOWA DENKO KK

Dielectric ceramic composition, complex electronic device and multilayer ceramic capacitor

ActiveUS20080254968A1Maintain good propertiesSolve the blockageImpedence networksFixed capacitor dielectricStrontium titanateElectrical resistance and conductance

The present invention relates to a dielectric ceramic composition comprising a main component including at least one selected from barium titanate, strontium titanate and calcium titanate, and as a subcomponent, a glass component including an oxide of B, wherein a content of said glass component is 2 to 7 wt % with respect to 100 wt % of said main component. According to the present invention, there are provided a dielectric ceramic composition wherein a layer can be made thinner by relatively decreasing a content of the glass component, etc., as well as having good properties (specific permittivity, loss Q value and insulation resistance), and a complex electronic device such as a multilayer filter or a multilayer ceramic capacitor, which has a dielectric layer composed of the dielectric ceramic composition.

Owner:TDK CORPARATION

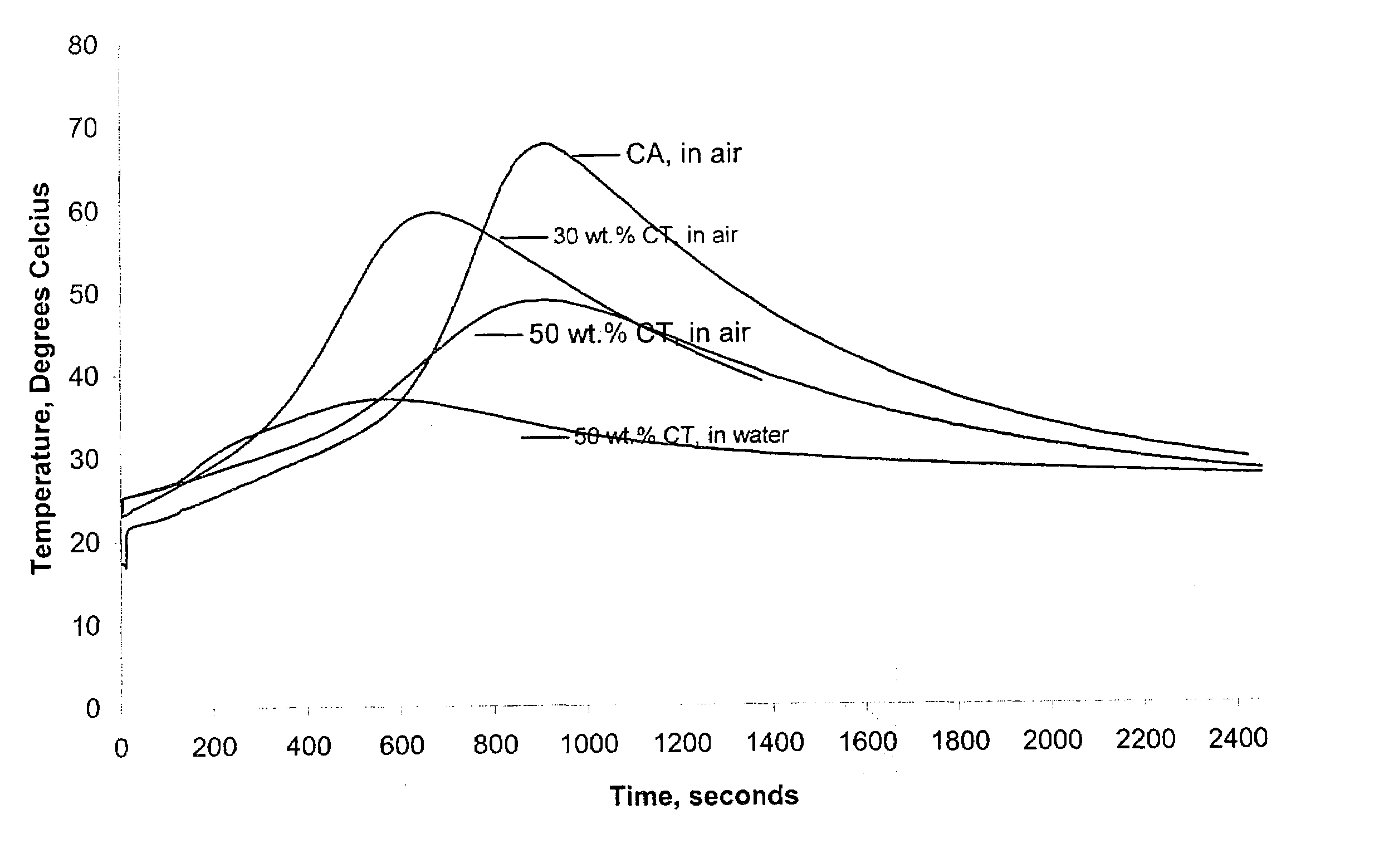

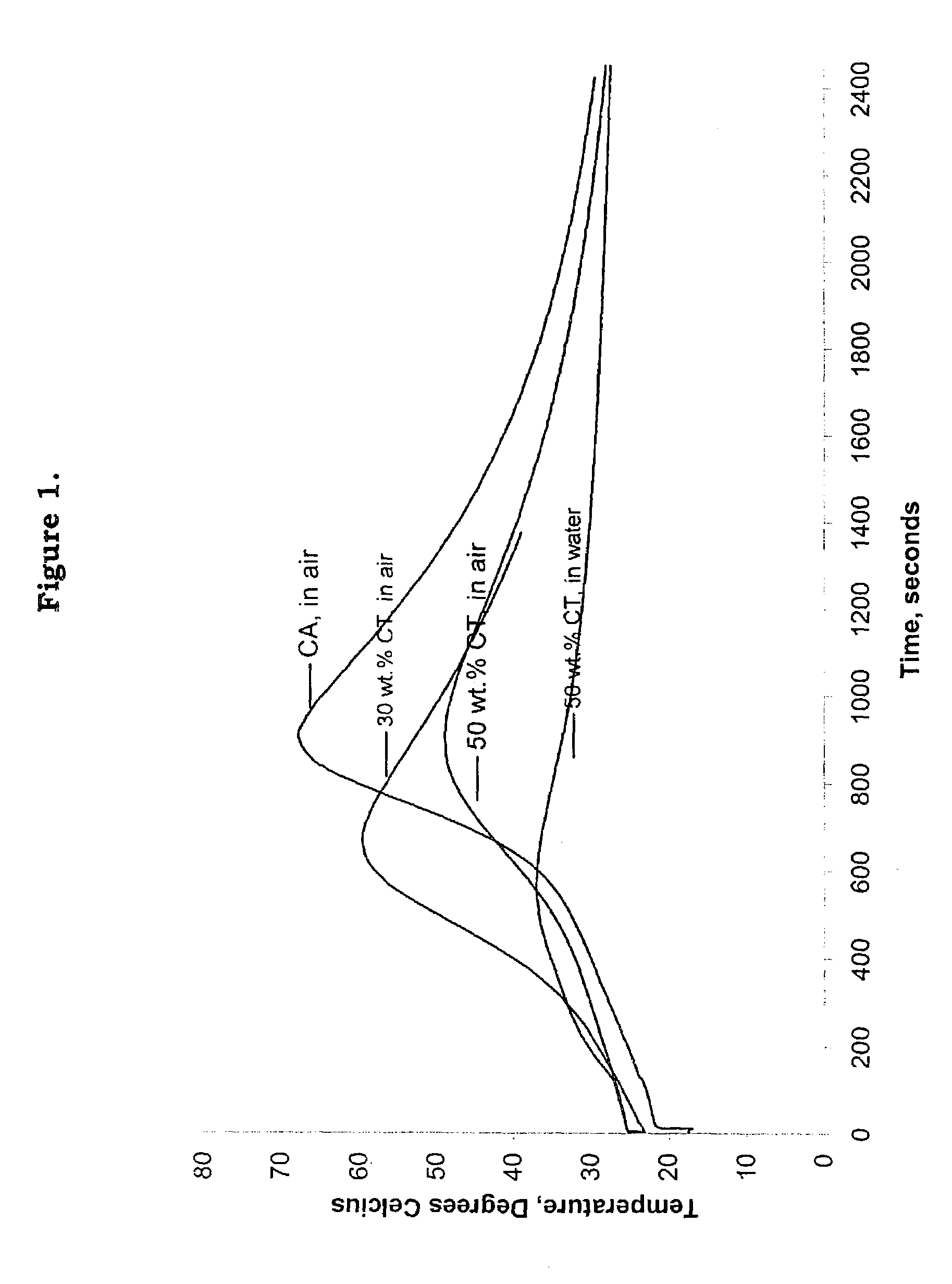

Ceramic material and process for manufacturing

InactiveUS7025824B2Reduce riskReduce the amount requiredImpression capsSurgical adhesivesAluminatePlastic surgery

A chemically bonded ceramic material based on calcium aluminate hydrate with additives of primarily calcium titanate, but also chemically similar compounds. The material is a biocompatible material for implants, particularly for orthopaedic and dental applications. The material possesses the properties required for an orthopaedic biocement. It cures through reaction with water and develops its strength within a short period of time, has good workability prior to curing, is shape stable, has a low heat generation during curing, and is friendly to adjacent tissues.

Owner:DOXA AB

Calcium titanate luminescent material and preparation method thereof

InactiveCN102477294ASimple preparation processLow equipment requirementsLuminescent compositionsLuminous intensityDysprosium titanate

The invention belongs to the field of luminescent materials, and discloses a calcium titanate luminescent material and a preparation method thereof. The chemical general formula of the calcium titanate luminescent material is Ca1-xTi1-yO3: xPr, yR, M, wherein 0.001<=x<=0.01, 0.005<=y<=0.03, R refers to at least one of Al and Ga, and M refers to at least one of nano particles of Ag, Au, Pt and Pd. The calcium titanate luminescent material is simple in preparation process, low in equipment requirement and short in preparation period. A small quantity of metallic nano particles is added into the luminescent material to enhance luminescence of the luminescent material, and the luminous intensity can be enhanced under excitation of cathode rays.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

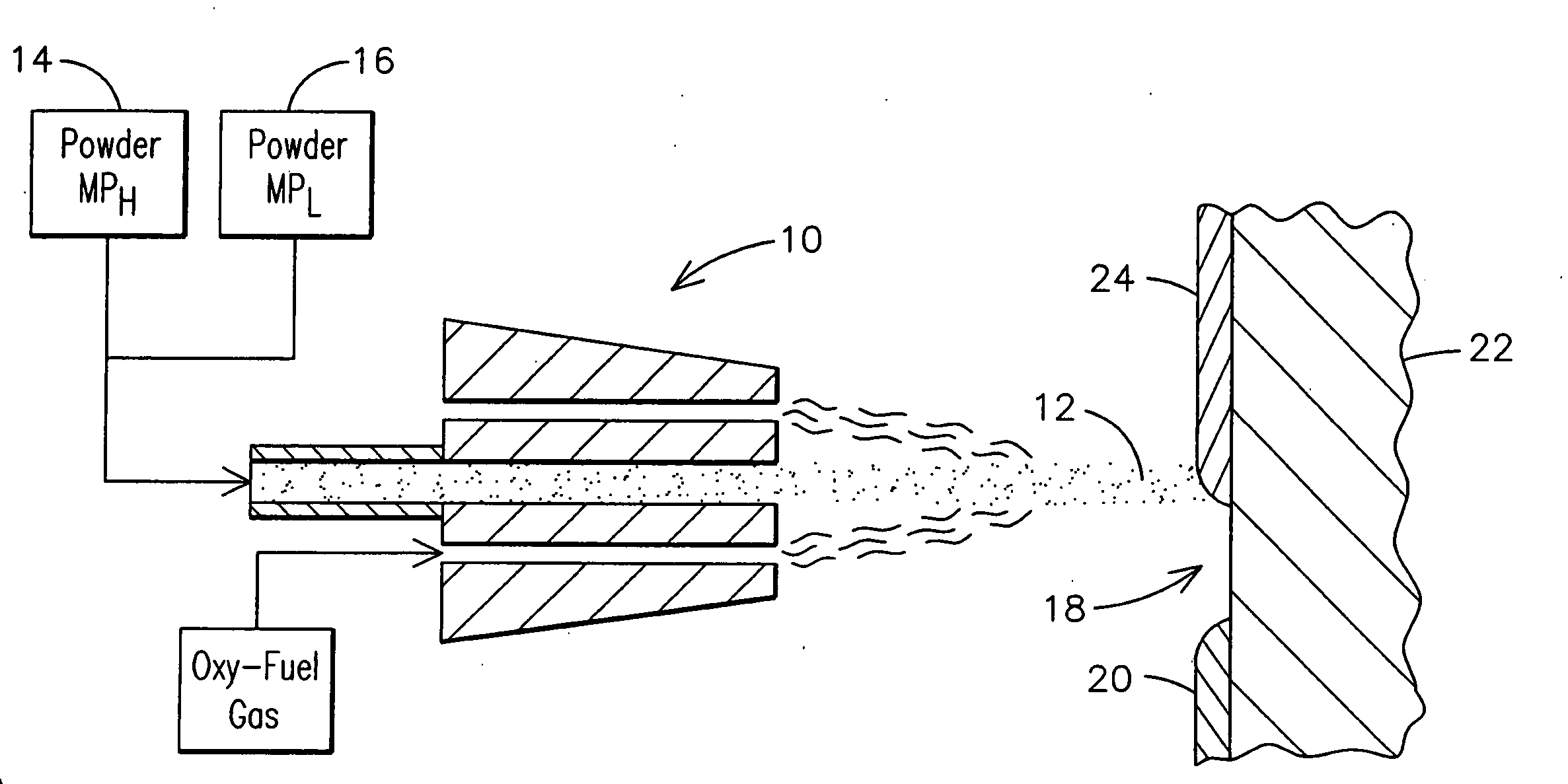

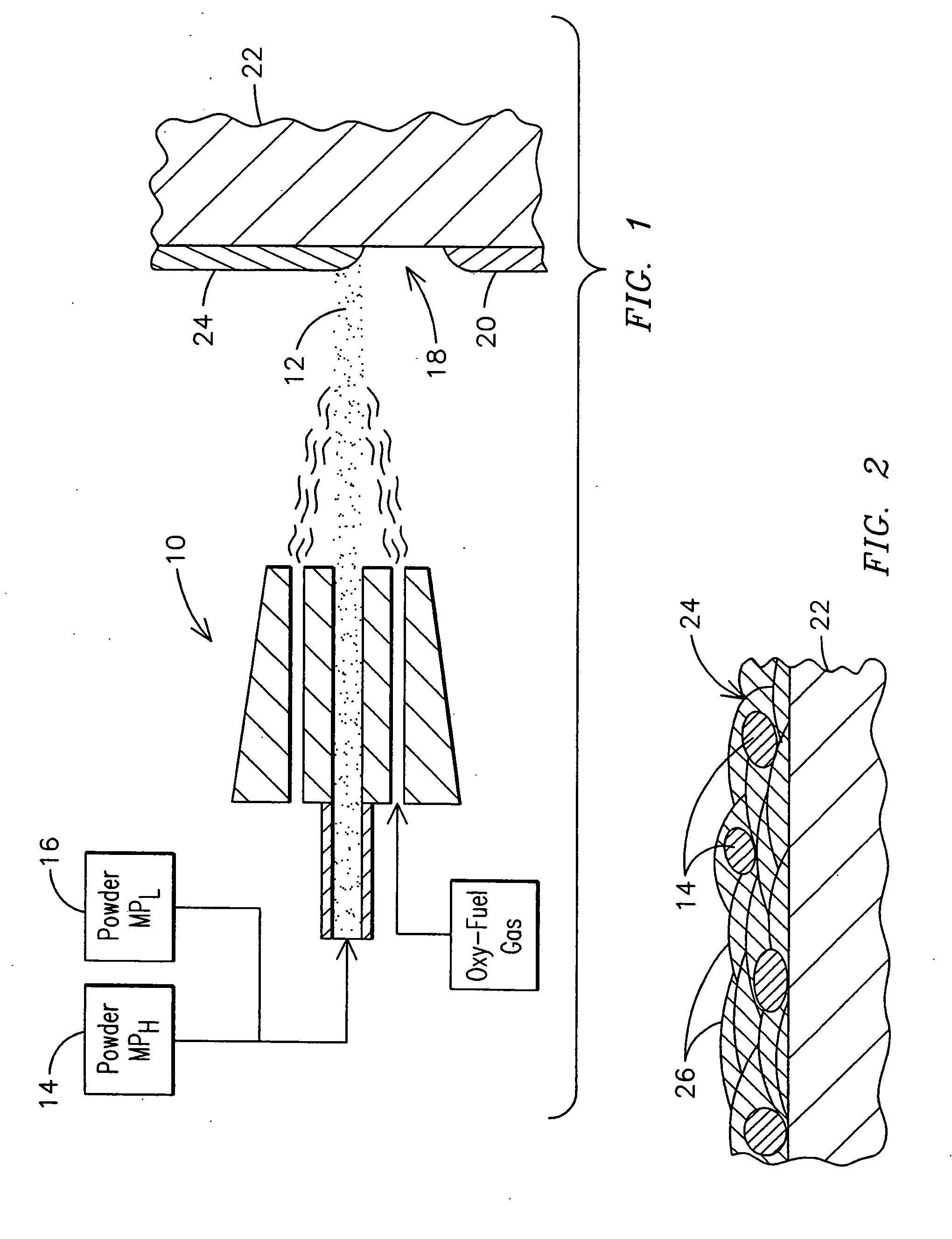

Repair of zirconia-based thermal barrier coatings

A method of depositing a zirconia-based ceramic coating (24) using a low velocity oxy-fuel (LVOF) process. Particles of zirconia (14) are mixed with second constituent particles (16) of a material having a melting temperature sufficiently low to be successfully deposited by an LVOF process. The second constituent particles may have a coefficient of thermal expansion within 30% of that of the zirconia particles, and / or they may have a thermal conductivity less than or no more than 20% higher that that of the zirconia particles. The second constituent particles may include calcium titanate, strontium titanate or sodium-zirconium-phosphate-silicate (NZPS). The capability to deposit the zirconia-containing particle mix with an LVOF process facilitates the in-situ repair of a component having a damaged zirconia-based thermal barrier coating.

Owner:SIEMENS POWER GENERATION

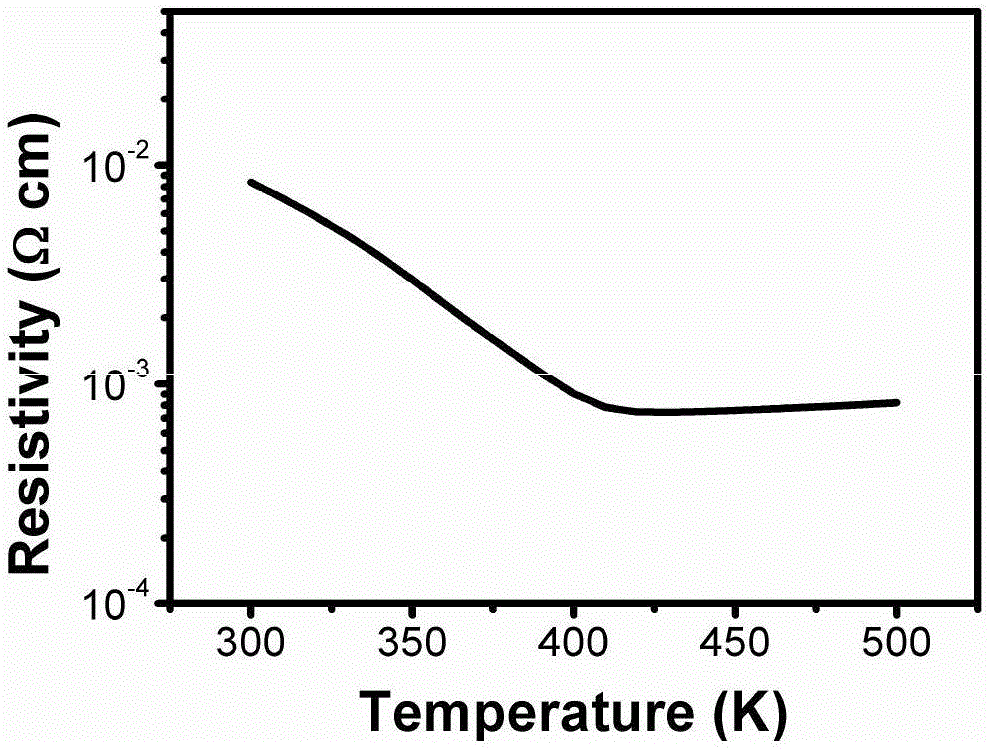

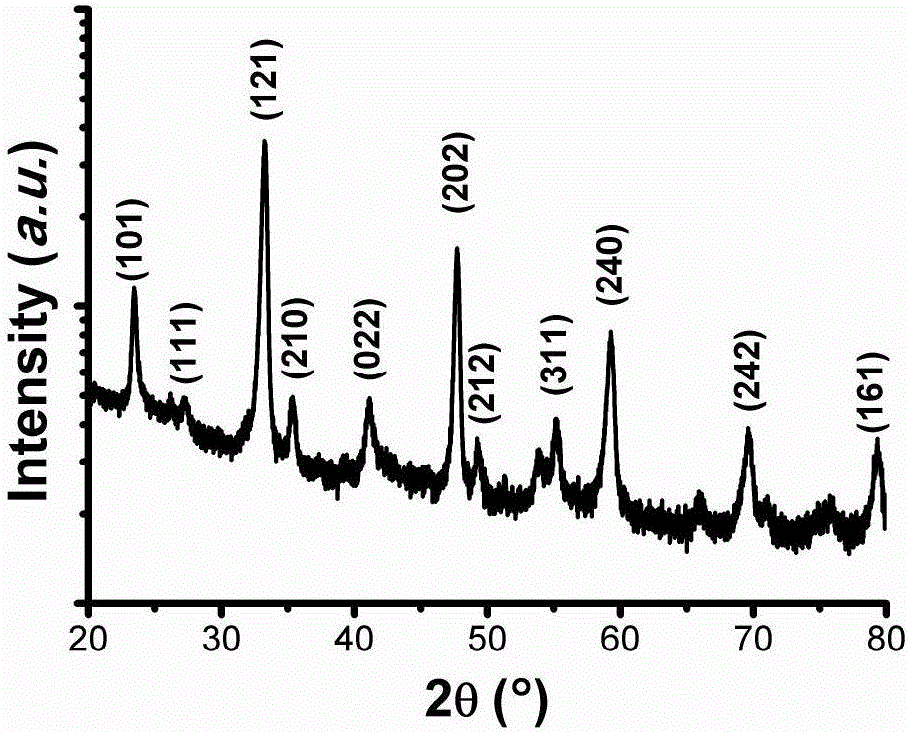

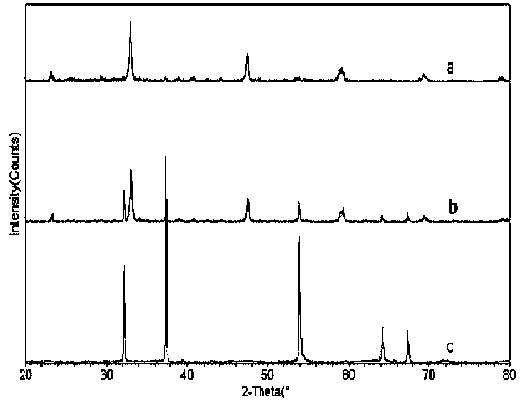

Preparation method of rare earth nickel-based oxide polycrystalline film material

InactiveCN106480413AAchieve non-epitaxial growthAchieve growthVacuum evaporation coatingSputtering coatingRare-earth elementStrontium titanate

The invention discloses a preparation method of a rare earth nickel-based oxide polycrystalline film material, and belongs to the field of inorganic nonmetal film materials. The preparation method comprises the steps that an oxide material buffer layer with lattice parameters similar with that of a rare earth nickel-based perovskite oxide material grows on the surface of a substrate material; and a rare earth nickel-based perovskite oxide film is further deposited on the surface of the buffer layer through a vacuum deposition method. The crystal structure of the rare earth nickel-based perovskite oxide material is the perovskite structure ReNiO3 of ABO3, and the Re position is one rare earth element or the combination of various rare earth elements. The materials of the buffer layer preferentially comprise strontium rubidium oxygen, strontium titanate, lanthanum doped strontium titanate, neodymium doped strontium titanate, barium titanate and calcium titanate. The preparation method of the rare earth nickel-based oxide polycrystalline film material is easy, convenient and efficient. The prepared film material has excellent temperature dependent and hydrogen-induced performance and can be further applied in the fields of functional electronic devices, fuel cells, infrared detectors and the like.

Owner:UNIV OF SCI & TECH BEIJING

Calcium titanate/calcium oxide composite photocatalyst as well as preparation method and application thereof

InactiveCN103736476AOvercoming the disadvantage of low photocatalytic activityLow equipment requirementsWater/sewage treatment by irradiationWater contaminantsBarium titanateMuffle furnace

The invention provides a calcium titanate / calcium oxide composite photocatalyst as well as a preparation method and an application thereof. The preparation method comprises the following steps: dissolving a titanium source in absolute ethyl alcohol, performing ultrasonic treatment, adding a soluble calcium salt solution, continuously stirring for an hour, ageing the gel at room temperature for several hours, and drying the gel in a drying oven; and finally, putting the gel in a muffle furnace for roasting for 2-8 hours at the temperature of 500-900 DEG C, wherein the obtained white powder is the calcium titanate / calcium oxide composite photocatalyst. The composite photocatalyst prepared by the method is used for degrading organic pollutants in water. Compared with a commercial catalyst TiO2 (P25), the composite photocatalyst has higher photocatalytic activity.

Owner:YUNNAN UNIV

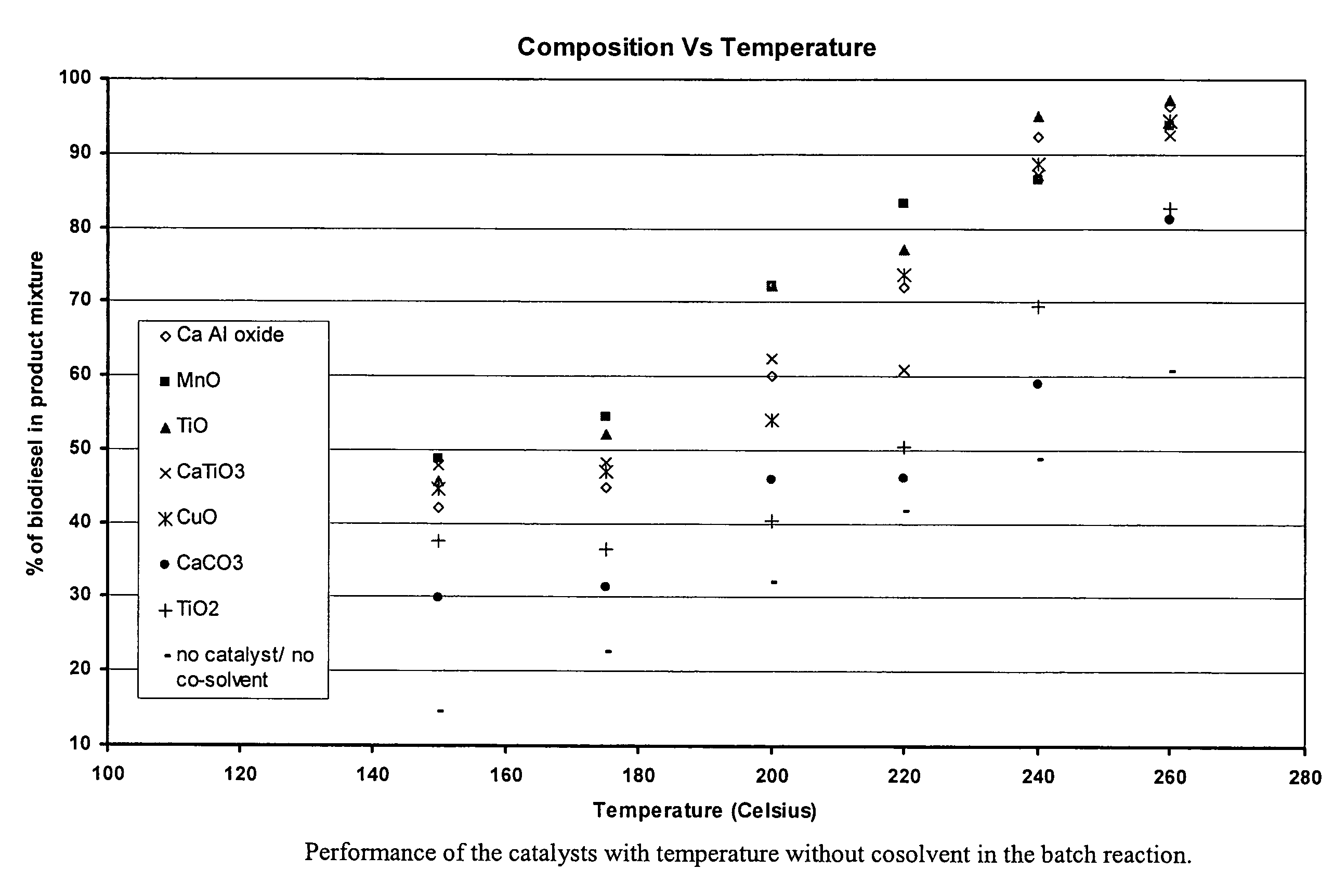

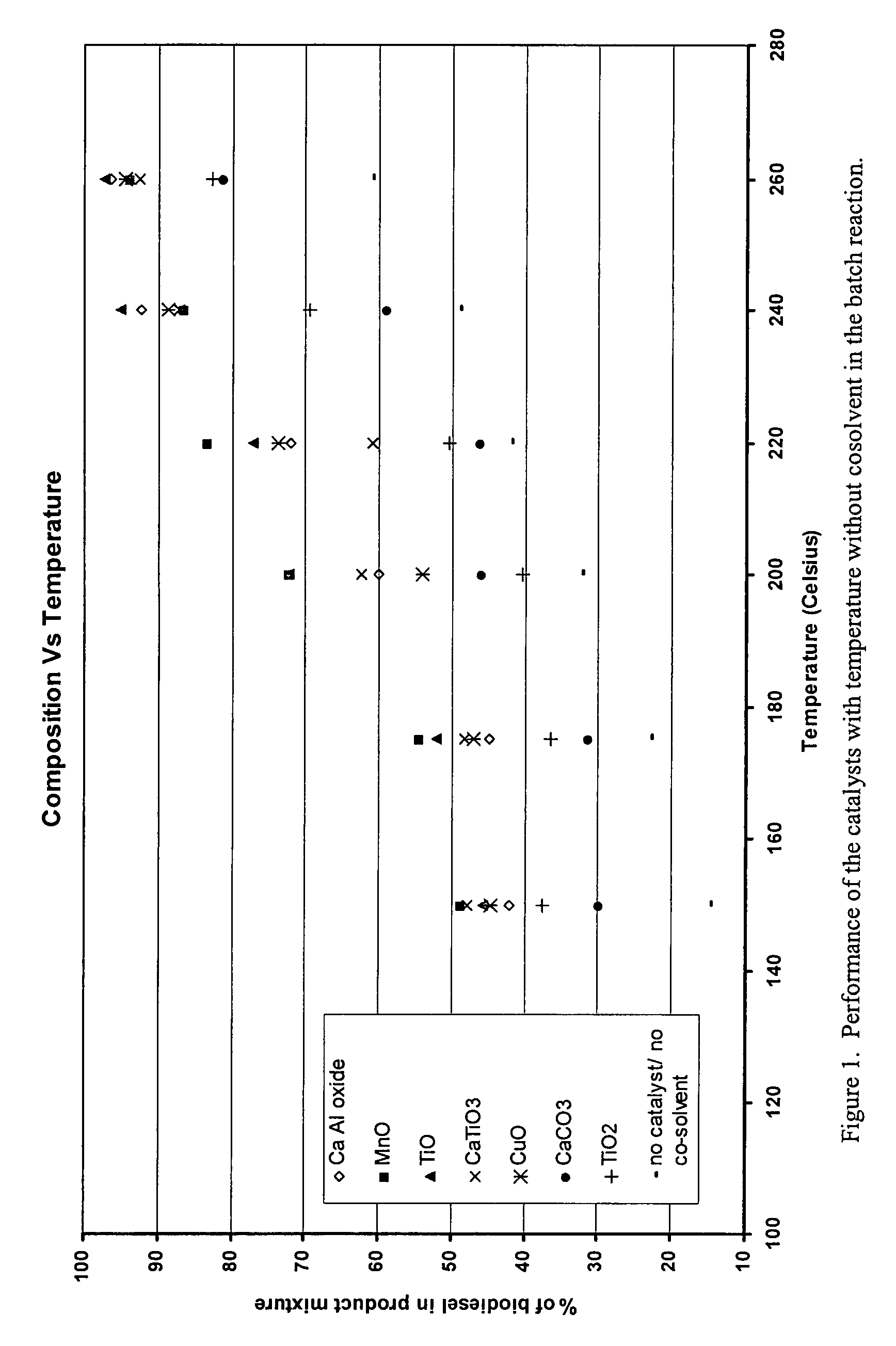

Green Biodiesel

InactiveUS20070282119A1Significant energySignificant processing timeFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

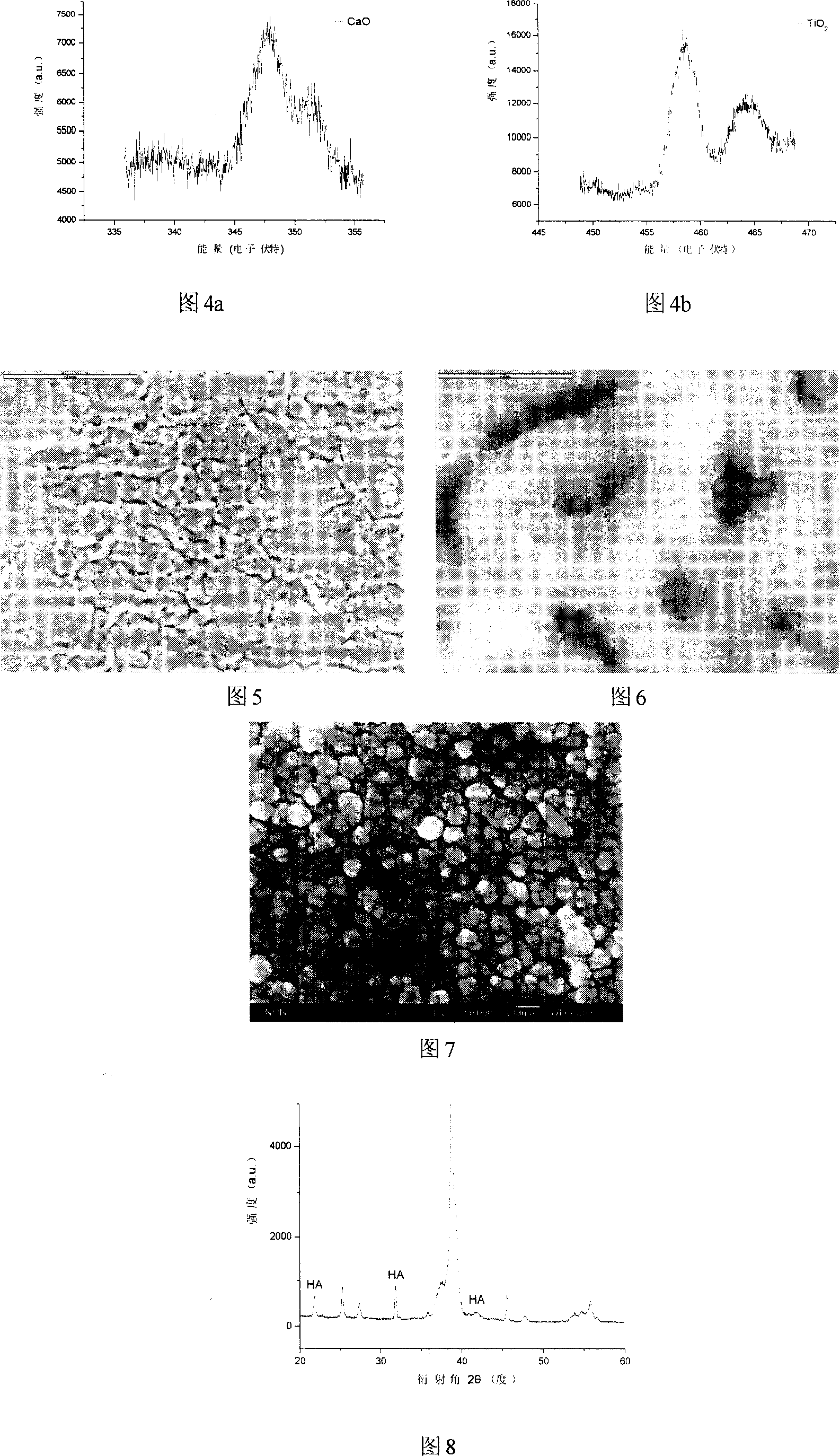

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation of doped calcium titanate (CaTiO3: Eu3+) fluorescent powder

InactiveCN101376523AGood chemical stabilitySmall grain sizeTitanium compoundsLuminescent compositionsAlcoholDissolution

The invention relates to a preparation method of Eu-doping calcium titanate CaTiO3:Eu<3+> fluorescent powders, which comprises the steps as follows: a soluble europium salt, a calcium salt and Ti(OC4H9)4 are weighed according to the mole ratio that is 1:49:50 to 1:4:5 among Eu<3plus>, Ca<2plus> and Ti<4plus>, and are respectively dissolved in absolute ethyl alcohol, and the confected solution is stirred for ample dissolution; (2) a mixed ethanol solution of the europium salt and the calcium salt is added in an ethanol solution of Ti(OC4H9)4, and a sol is obtained through stirring; (3) the sol is placed at the temperature ranging from 0 to 50 DEG C to obtain a wet gel which is put in a baking box for drying; (4) the dried gel is milled into powders, the obtained powders are calcined for 2 to 8 hours to obtain the CaTiO3:Eu<3plus> fluorescent powders. In the preparation method, the prepared CaTiO3:Eu<3plus> fluorescent powders have high chemical durability, small grain size, pure crystalling phase and low calcination temperature; the preparation method has simple technology, and is easy for industrialized production.

Owner:DONGHUA UNIV

Method for preparing high-radioactivity effluent glass-ceramic solidified body in microwave process

ActiveCN102584018AFast heatingReduce energy consumptionRadioactive decontaminationSilicic acidSilicon oxide

The invention discloses a method for preparing a high-radioactivity effluent glass-ceramic solidified body in a microwave process, which belongs to the field of new materials and includes steps of: using one or several of calcium titanate, zirconium silicate, calcium carbonate, titanium oxide, zirconium oxide and silicon oxide as the raw materials, using microwave as a heating source, and using graphite powder or silicon carbide powder as a combustion-assisting agent to perform low-temperature microwave volume-reduction treatment on high-radioactivity effluent, then roasting at high temperature to prepare a combined mineral solidified body, and performing vitrification treatment so as to further reduce volume of the solidified body. The method for preparing the high-radioactivity effluent glass-ceramic solidified body in the microwave process is little in energy consumption, simple in process and low in production cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

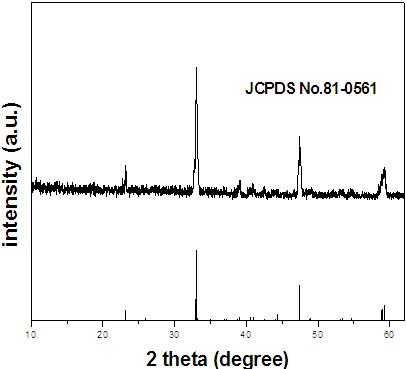

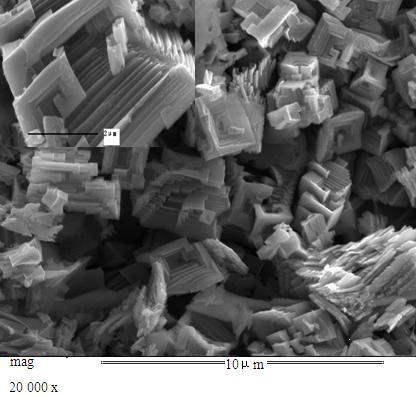

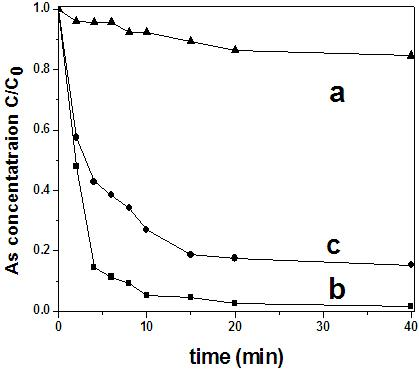

Calcium titanate photocatalyst for removing arsenic by photocatalysis

InactiveCN101829556AGood photocatalytic oxidation activityImprove adsorption capacityWater/sewage treatment by irradiationWater contaminantsArsenic pollutionPhysical chemistry

The invention provides a method for preparing a novel photocatalyst CaTiO3 for processing an arsenic polluted water body, which belongs to a photocatalysis technology in environmental management. The calcium titanate with a lamellar microstructure is obtained for the first time by adopting a product obtained by fully hydrolyzing tetra-n-butyl titanate as a titanium source. In addition, the photocatalyst can effectively optically catalyze and oxidize As (III) and greatly adsorb and remove As (V) generated by oxidization and prevents secondary pollution of the water body caused by a flocculant added after the photocatalyst adopting TiO2 as a main component oxidizes the As (III) in the prior art. Finally, the method for preparing the photocatalyst is simple and easy and is beneficial to popularization at a large scale.

Owner:FUZHOU UNIV

Barium titanate-based lead-free high-voltage ceramic capacitor material

The invention provides a barium titanate-based lead-free high-voltage ceramic capacitor material, which takes barium titanate, bismuth titanate, strontium titanate and calcium titanate as raw materials. After the materials are mixed, polyvinyl alcohol is added, the obtained mixture is pressed and formed, and the obtained product is sintered under about 1220 DEG C to obtain the high-pressure lead-free ceramic capacitor material. The voltage resistance of the capacitor material sintered by using the ceramic material formula is improved to 16.9kv / mm, the dielectric constant (Xir) is equal to 2089, and the dielectric loss (tan Delta) is equal to 0.0006 under 1MHz AC working current.

Owner:钱云春

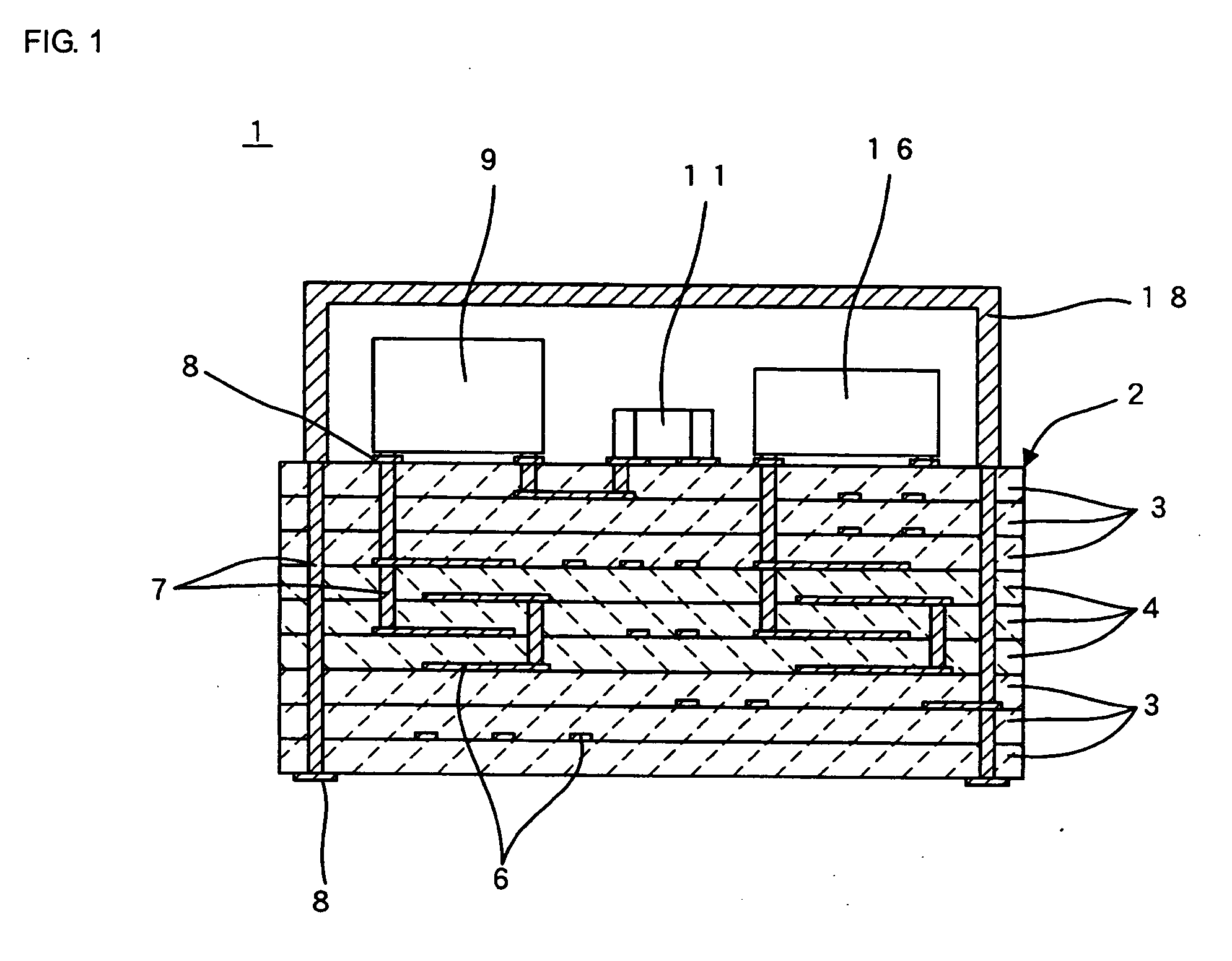

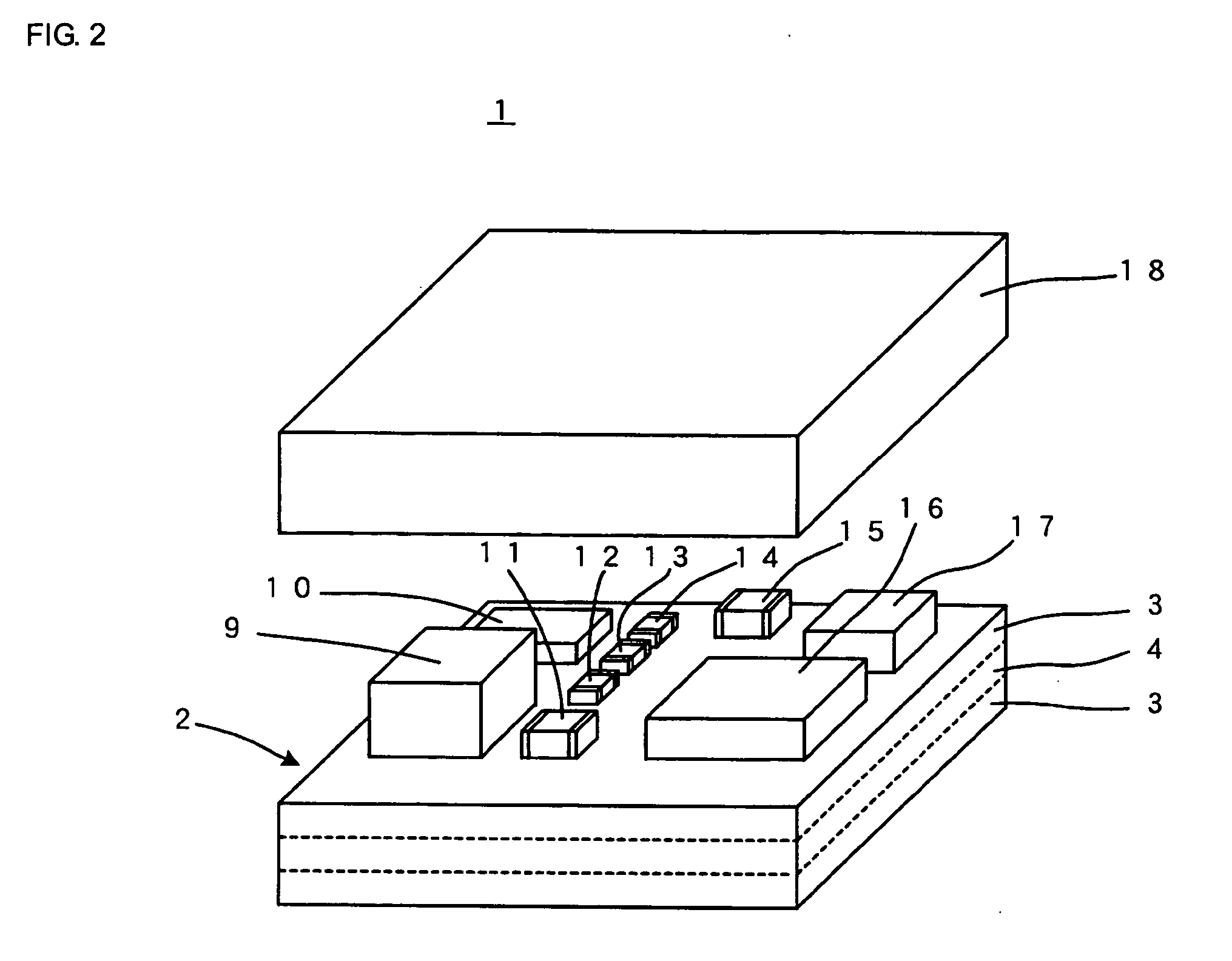

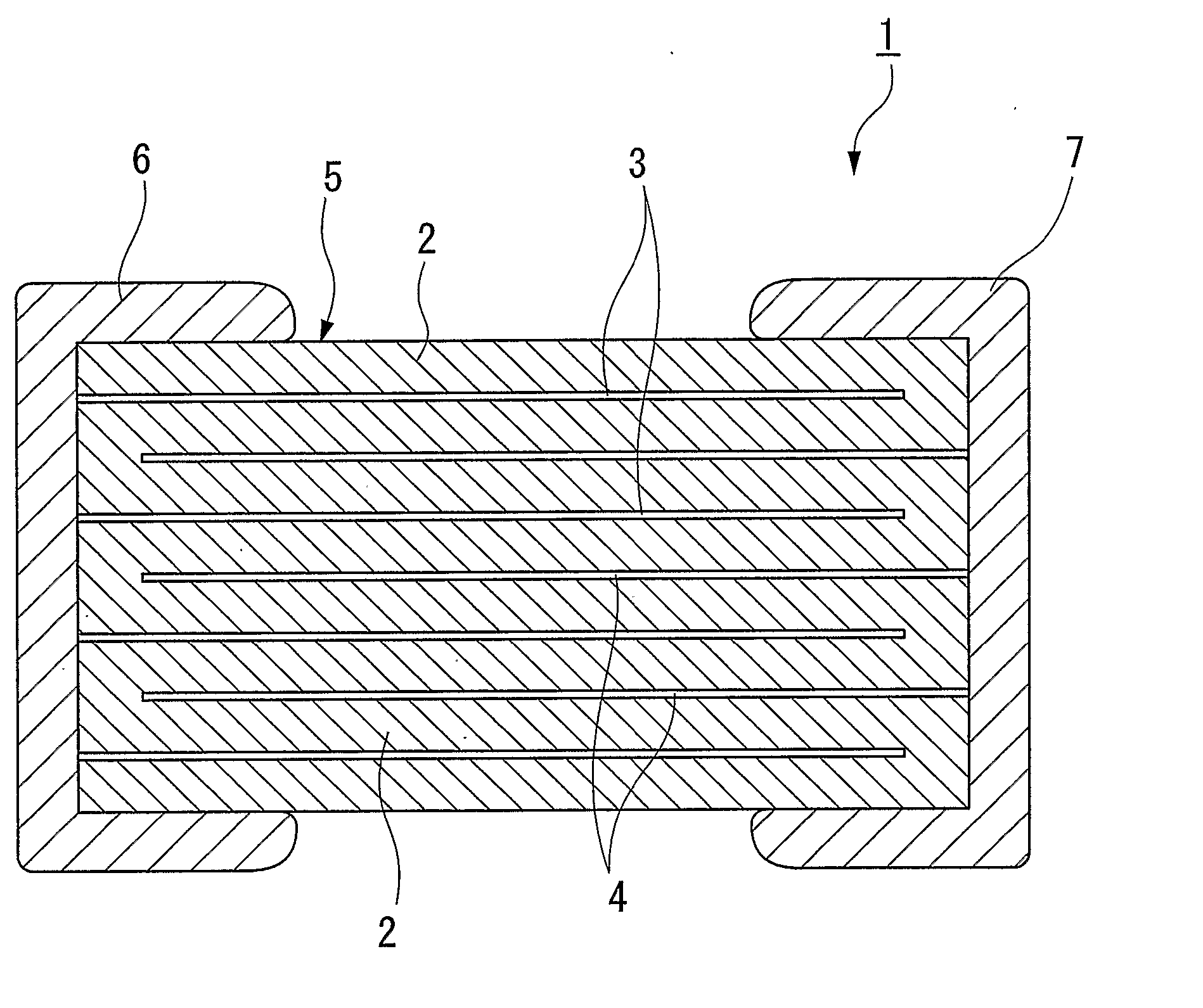

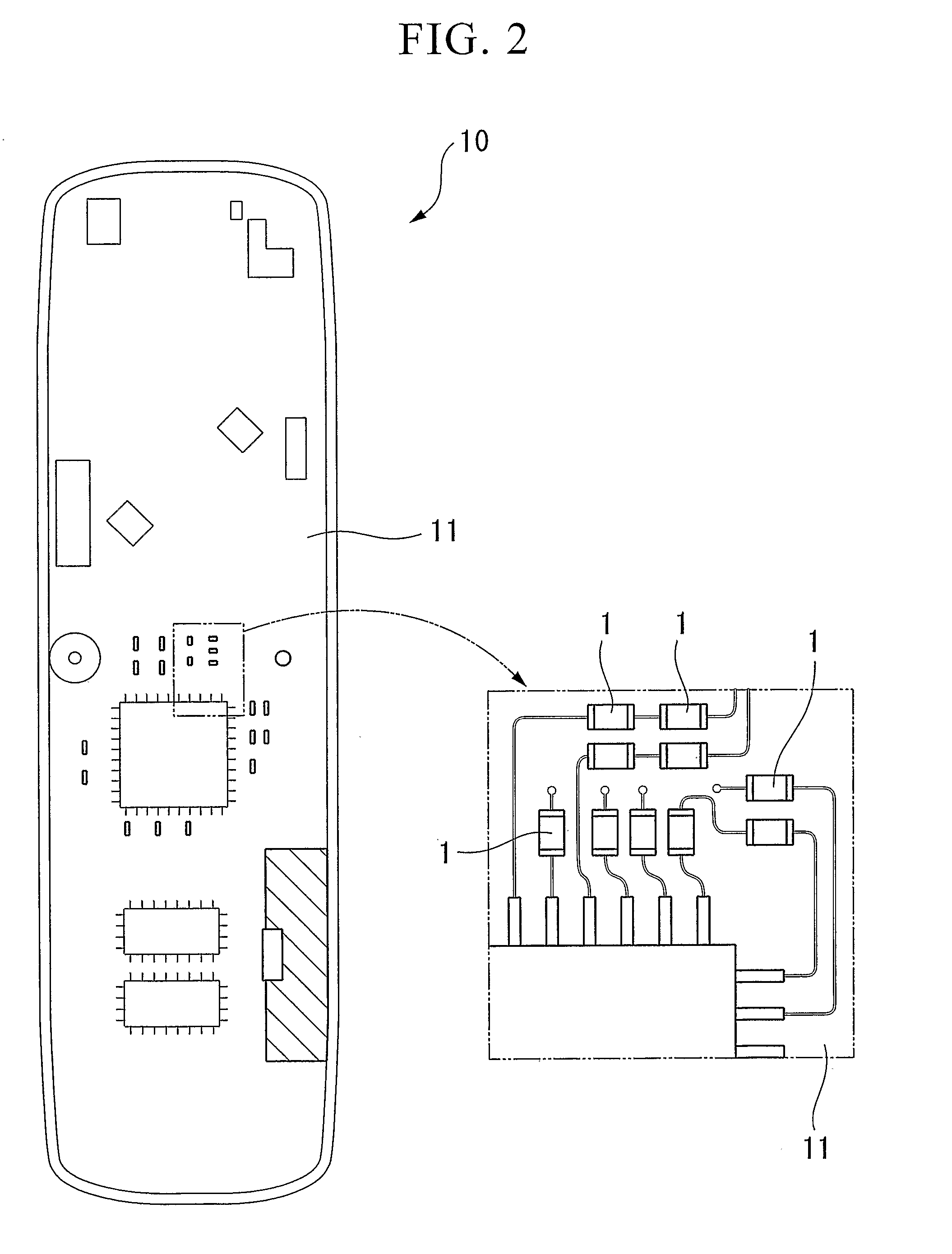

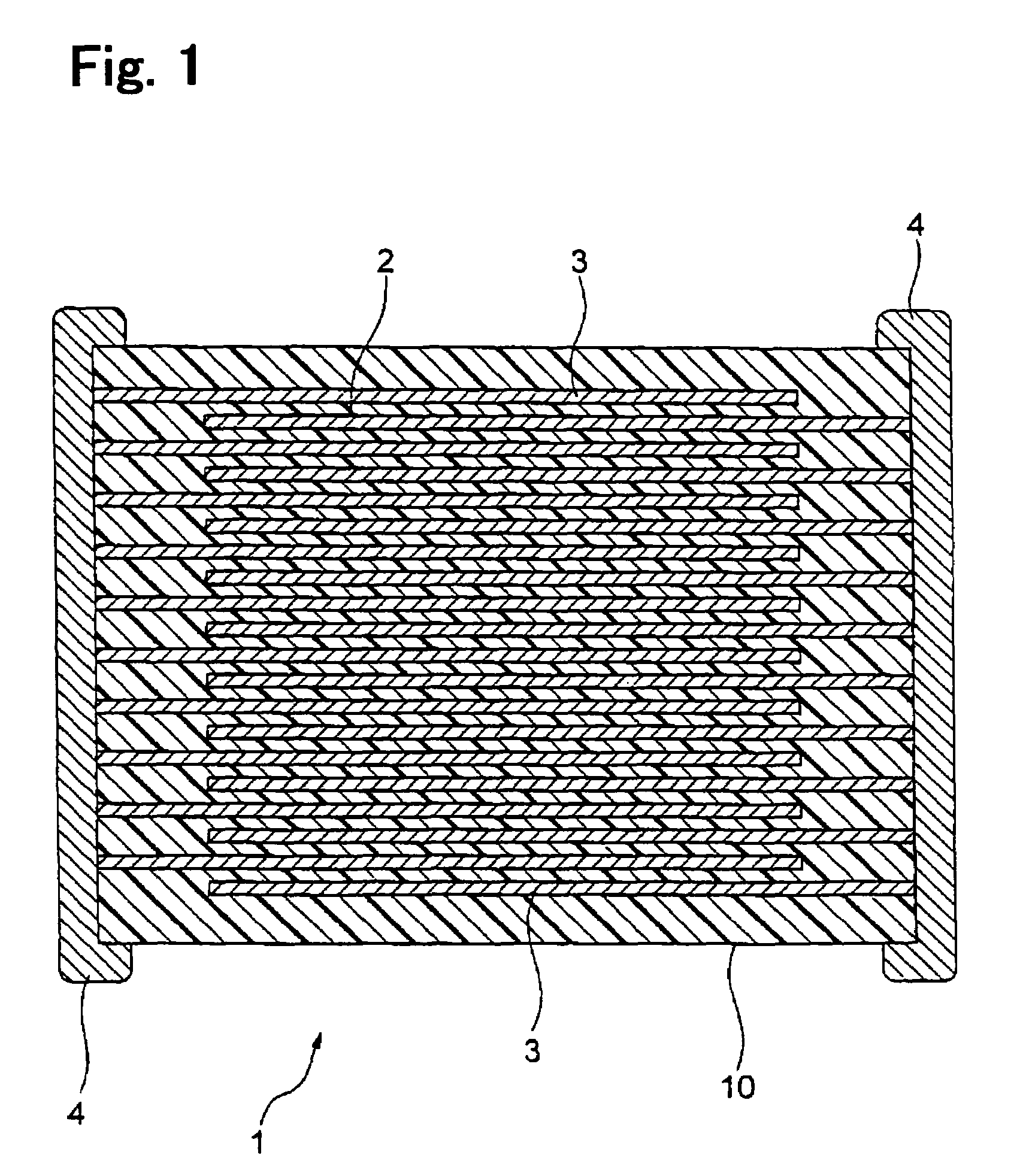

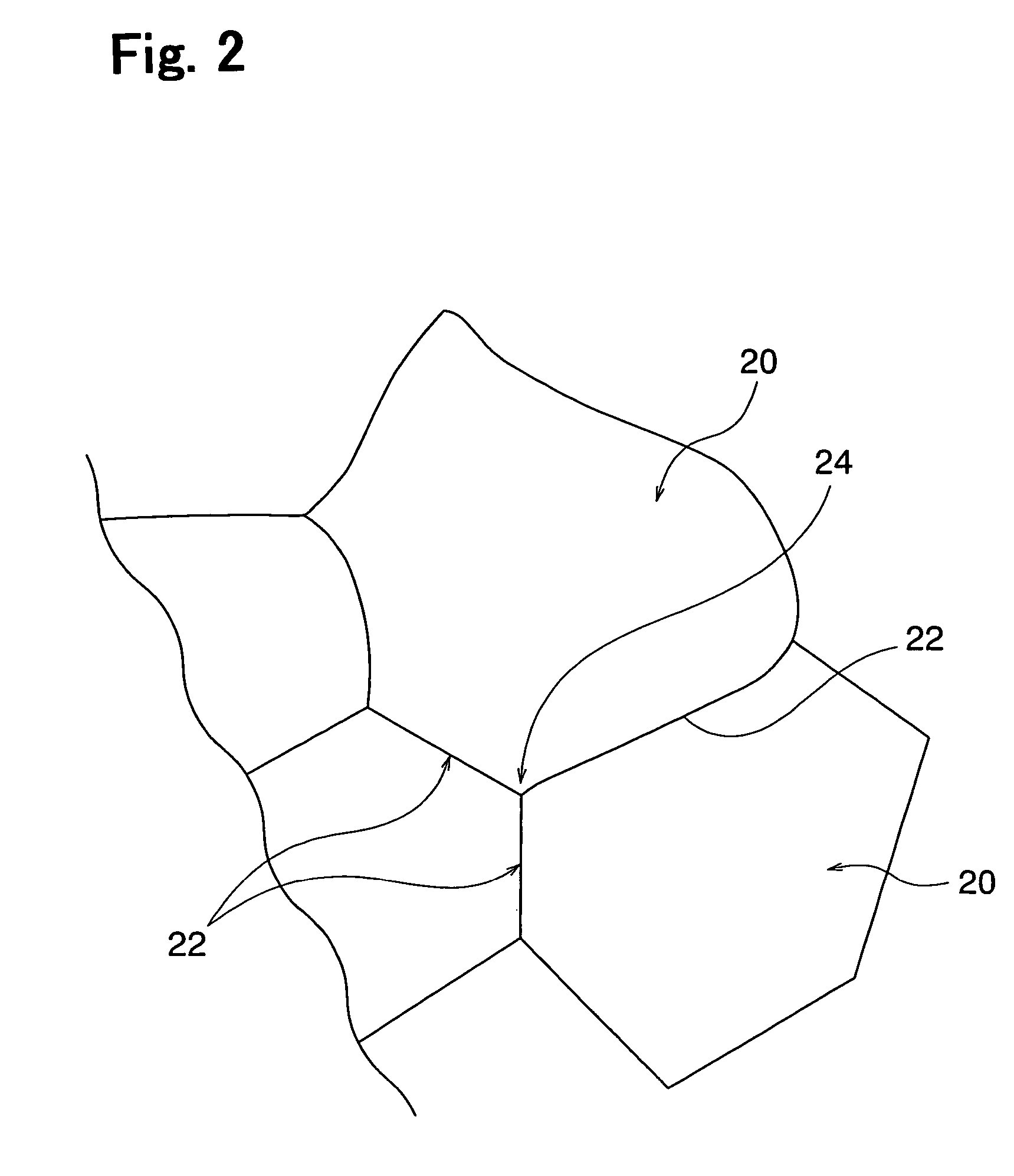

Electronic device

ActiveUS7528088B2Excellent characteristicsSuperior in constantMaterial nanotechnologyFixed capacitor dielectricBarium titanateCeramic capacitor

A multilayer ceramic capacitor 1 having dielectric layers 2 having barium titanate or barium calcium titanate as a main ingredient. When the dielectric layers are barium titanate, the ratio of the grains having a thickness of the crystal grain boundaries 22 present between adjoining dielectric grains 20 is 30% to 95% of the plurality of dielectric grains 20 forming the dielectric layers 2. When the dielectric layers 2 are barium calcium titanate, the ratio of the grains having a thickness of the crystal grain boundaries 22 present between adjoining dielectric grains 20 is 20% to 70% of the plurality of dielectric grains 20 forming the dielectric layers 2.

Owner:TDK CORPARATION

Method for preparing calcium titanate nanoparticles

InactiveCN102139914ASimple processEasy to controlNanotechnologyTitanium compoundsPotassium hydroxideCalcium nitrate

The invention discloses a method for preparing calcium titanate nanoparticles. The method comprises the following steps of: adding a mineralizing agent, namely potassium hydroxide, with proper concentration, into hydrothermal reaction materials, namely titanium hydroxide coprecipitate and deionized water solution of calcium nitrate; introducing solution obtained by hydrothermally decomposing glucose into a hydrothermal system to influence nucleation and control the particle size of products; and synthesizing the calcium titanate nanoparticles of which the diameter is 30 to 60nm by hydrothermal reaction. The process is simple and is easy to control; the method is environment-friendly and low in cost; and the products are easy to produce.

Owner:ZHEJIANG UNIV

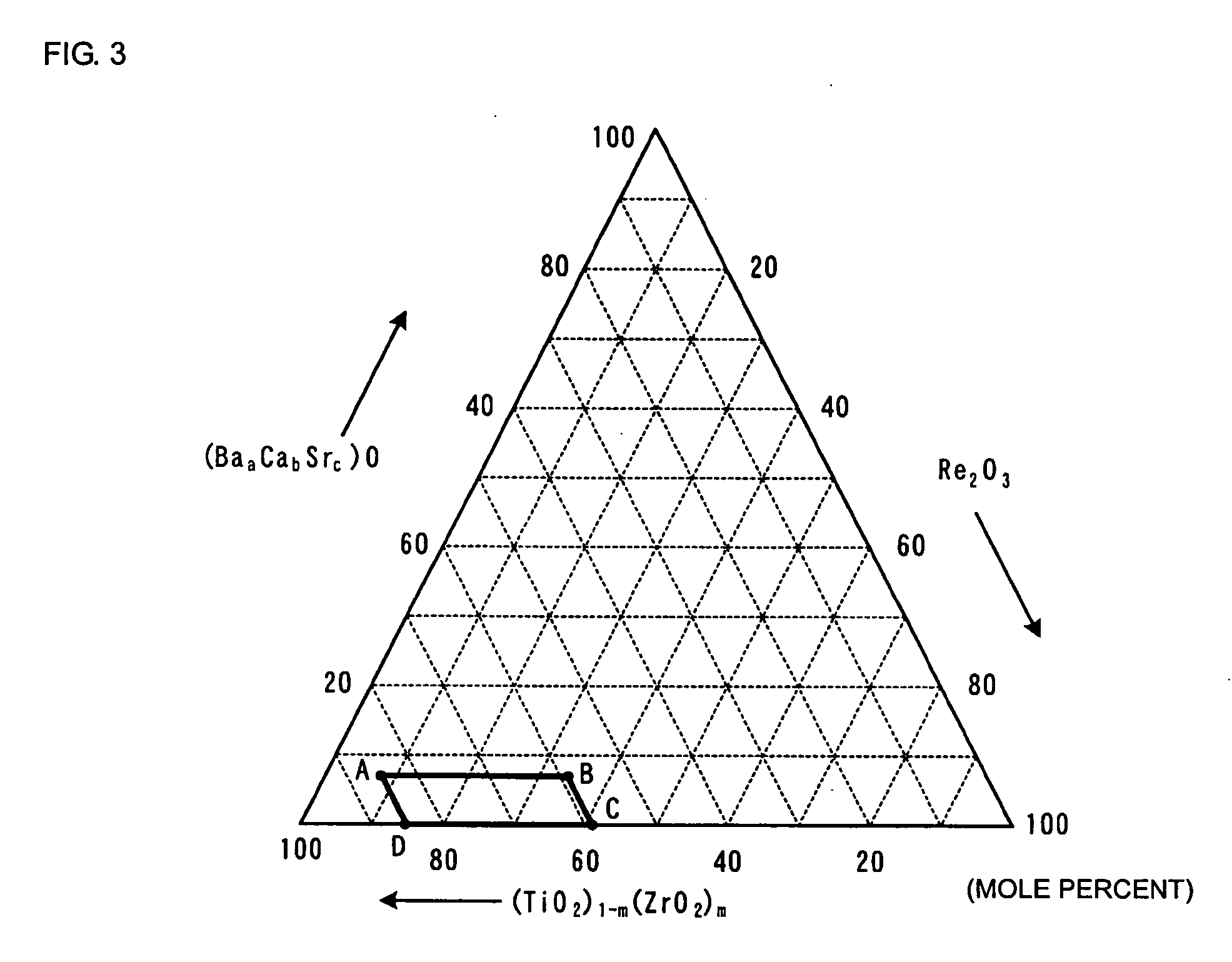

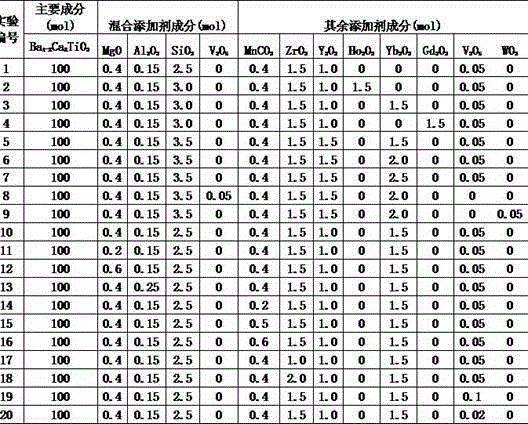

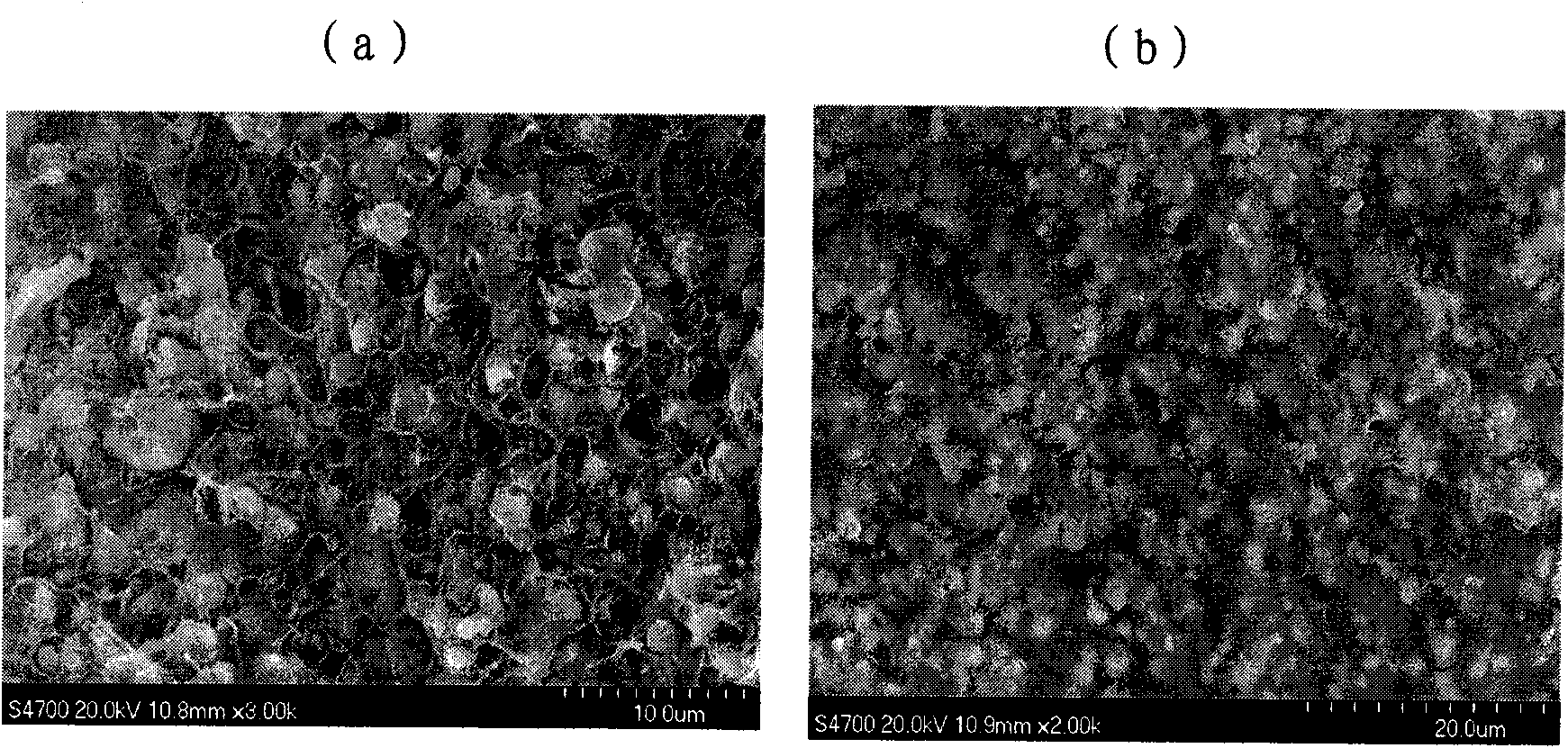

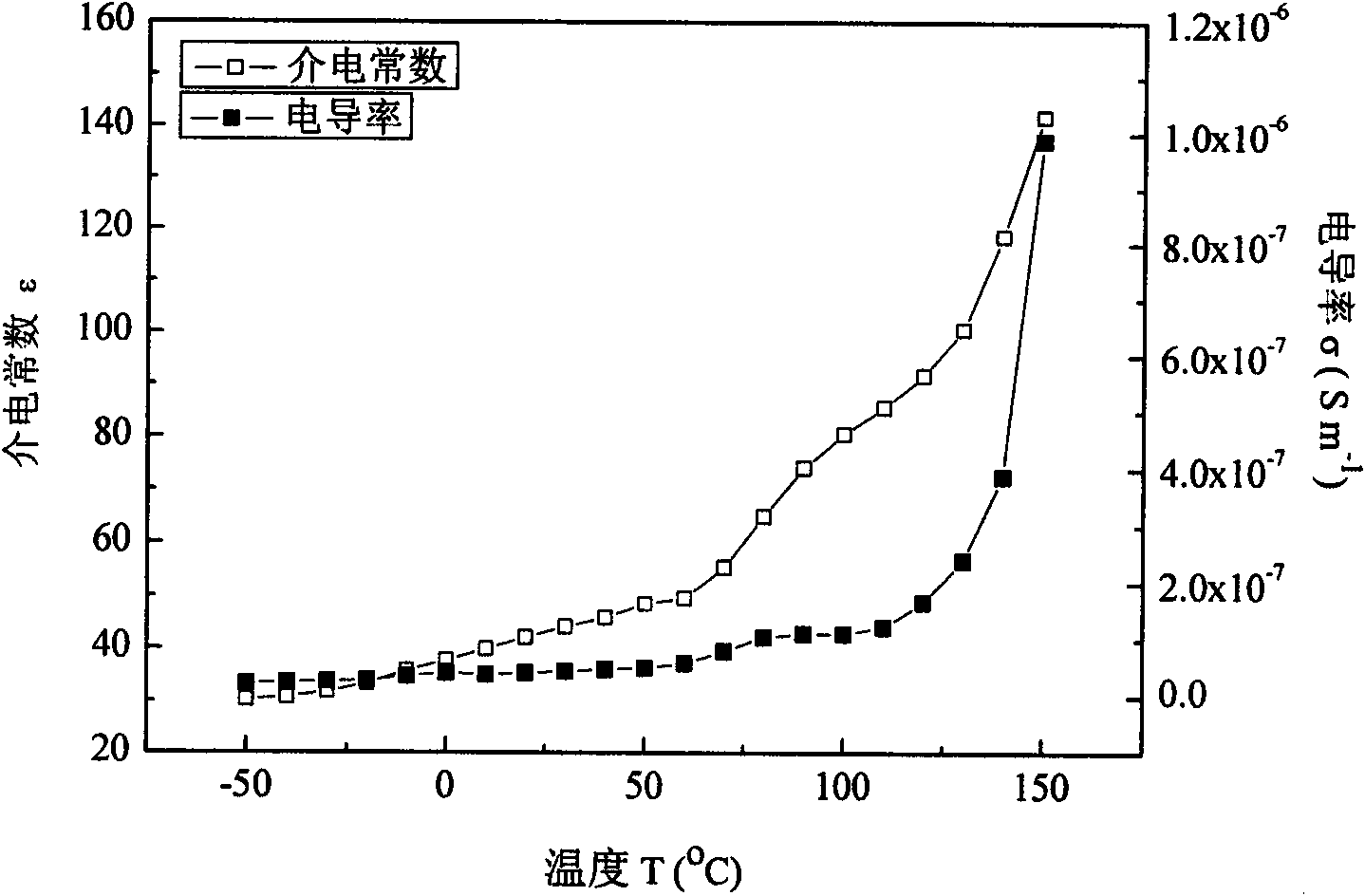

Medium material for high-reliability X8R-type multilayer ceramic capacitor and preparation method thereof

The invention discloses a constitution of a medium material for a high-reliability X8R-type multilayer ceramic capacitor and a preparation method thereof. The medium material comprises the following main components: 100 mol of barium calcium titanate Ba1-XCaXTiO3 (x is more than 0.005 and less than or equal to 0.05), 0.1 to 0.6 mol of MnCO3, 0.2 to 2.0 mol of MgO, 1.5 to 5.5 mol of SiO2, 0.1 to 0.5 mol of Al2O3, 1.0 to 4.0 mol of ZrO2, 0.5 to 3.5 mol of at least one or more of Y2O3, Ho2O3, Er2O3, Yb2O3 and Gd2O3, and 0.01 to 0.5 mol of at least one or more of WO3, MoO3 and V2O5. According to the multilayer ceramic capacitor manufactured by the medium material, an inner electrode adopts nickel or nickel alloy, the multilayer ceramic capacitor satisfies the X8R characteristics of American ELA standard; moreover, the average service life under the high temperature load is 48 hours or more, and the reliability of the multilayer ceramic capacitor is excellent.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

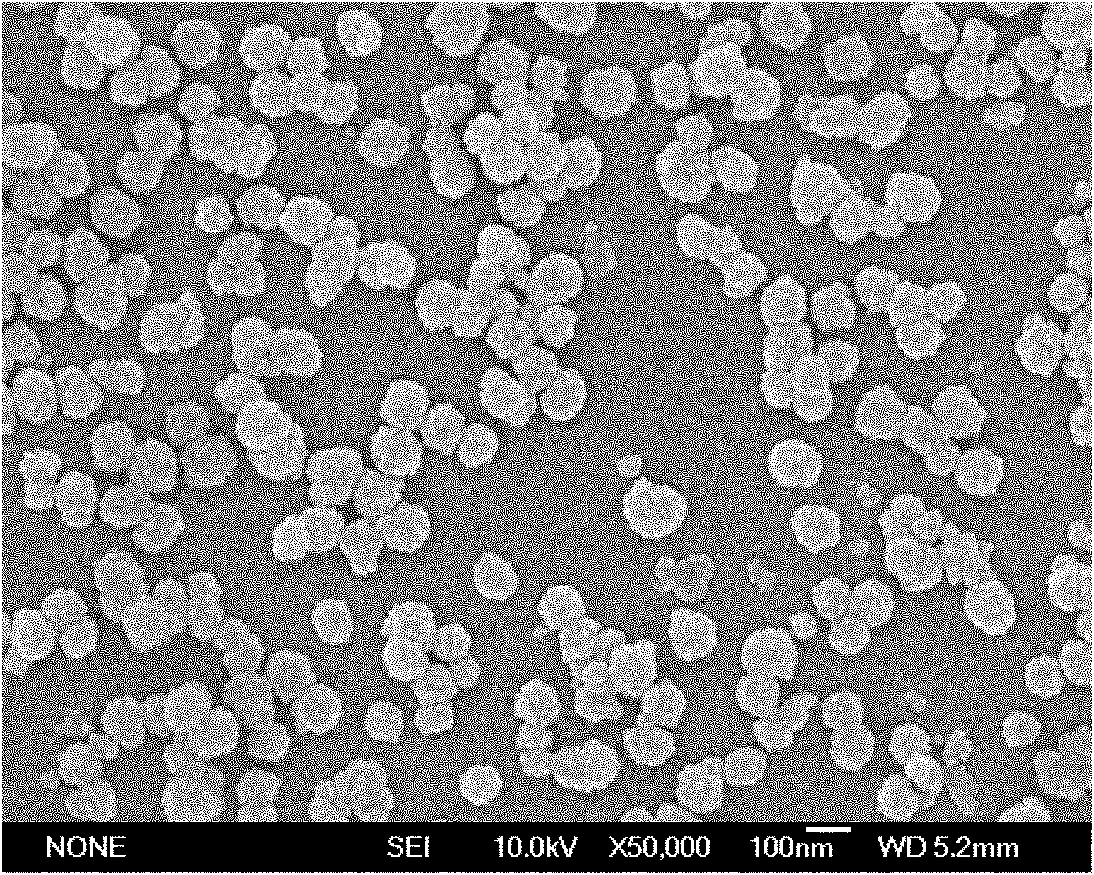

Heat-resisting high-dielectric constant inorganic/polymer composite film

InactiveCN101955667AExcellent dielectric propertiesHigh dielectric constantComposite filmDielectric ceramics

The invention provides a heat-resisting high-dielectric constant inorganic / polymer composite film, which belongs to the field of composite materials. The composite film provided by the invention consists of 60 to 90 volume percent of substrate polyimide and 10 to 40 volume percent of filler copper calcium titanate (CCTO) ceramic powder, has high dielectric properties, and can solve the problems that the dielectric constant of a conventional polymer-based composite material filled with dielectric ceramics is increased slowly with the increasing of filler content, that the dielectric constant of the polymer-based composite material filled with a conductive material greatly changes in the vicinity of a seepage value and that the filler content and the dielectric constant are difficult to control.

Owner:BEIJING UNIV OF CHEM TECH

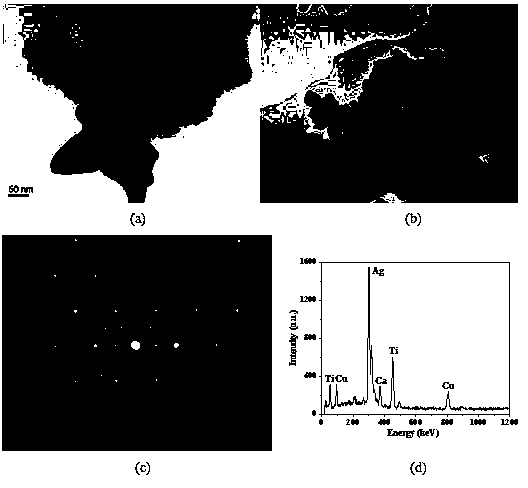

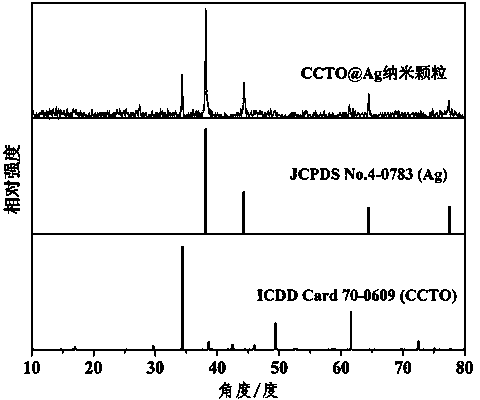

Preparation method of polyimide/copper calcium titanate coated silver nanoparticle composite material

InactiveCN103755958APromote recombinationImprove electric field distributionIn situ polymerizationHigh energy

The invention discloses a preparation method of polyimide / CCTO@Ag nanoparticle composite material with high dielectric and low loss. According to the method, polyimide is used as matrix, the prepared CCTO@Ag nanoparticles are ultrasonically dispersed in absolute ethyl alcohol, then is blended with polyimide monomer in solvent, then in situ polymerization reaction is carried out on the monomer at room temperature to simultaneously realize copolymerization of polyimide and intercalation recombination with the CCTO@Ag nanoparticles, obtained stock solution is subjected to gradient annealing according to a coating method to finally obtain the polyimide / CCTO@Ag nanoparticle composite film. Compared with pure polyimide, the polyimide / CCTO@Ag nanoparticle composite material prepared according to the preparation method has the dielectric constant (103) increased by 30 times, also has low dielectric loss (0.006) and can be widely applied in fields of high energy storage capacitors, artificial organs, high speed integrated circuits, and the like.

Owner:WUHAN UNIV

Liquid-crystalline polyester blend compositions

ActiveUS8231807B2High dielectric constantLow dielectric loss tangentLiquid crystal compositionsSynthetic resin layered productsPolyesterLiquid crystalline

Owner:UENO PHARMA CO LTD

Antibacterial environment-friendly inorganic mineral interior-wall decorative material

The invention discloses an antibacterial environment-friendly inorganic mineral interior-wall decorative material. The antibacterial environment-friendly inorganic mineral interior-wall decorative material comprises the following materials in percentage by weight: 15%-25% of white cement, 5%-10% of zeolite powder, 5%-10% of roasted diatomite powder, 20%-35% of quartz sand, 5%-10% of ground calcium titanate, 0.5%-3% of nanometer titanium dioxide, 1%-5% of dispersible latex powder, 1.5%-3% of bentonite, 0.5%-5% of pigment and 0.1%-0.4% of cellulose ether. All of the materials are almost inorganic mineral materials without volatile organic compounds, so that the antibacterial environment-friendly inorganic mineral interior-wall decorative material is an ecological environment-friendly material with adsorption and self-humidifying effects, has certain antibacterial and air purifying effects, and is very convenient to store, transport and use.

Owner:QINGDAO LONGMEI ELECTROMECHANICAL TECH

Barium strontium titanate-based superfine powder and preparation method thereof

The invention relates to barium strontium titanate-based superfine powder and a preparation method thereof. The powder is Ba1-xSrxTiO3, wherein x=0.2-0.8; or the powder is Ca2+ doped Ba1-z-ySrxCayTiO3, wherein z=0.2-0.7 and y=0-0.2. The method comprises the following steps of: preparing salt solution, buffer solution of ammonium nitrate, oxalic acid solution, ethanol solution of titanium butoxide and acid solution of titanyl oxalate monohydrate; performing coprecipitation reaction; and ageing, drying and calcining to obtain barium strontium calcium titanate powder. The barium strontium titanate-based superfine powder with the advantages of a little agglomeration, high dispersability, and high chemical activity is prepared by the chemical copercipitation method, accords with a stoichiometric ratio, has the advantages of small grain size, high uniformity, a little agglomeration, large specific surface area, and high chemical activity, and contributes to the compactness and sintering performance of the prepared ceramic capacitor materials.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com