Preparation method of polyimide/copper calcium titanate coated silver nanoparticle composite material

A nanoparticle and polyimide technology, applied in the field of electronic materials, can solve the problems of low dielectric constant, lower percolation threshold, high conductivity, etc., and achieve the goal of increasing dielectric constant, improving electric field distribution and reducing dielectric loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

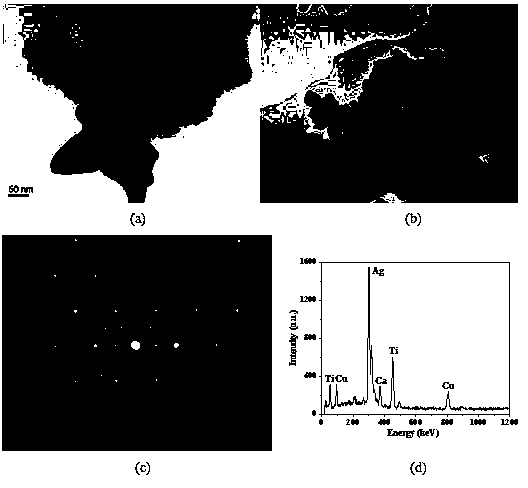

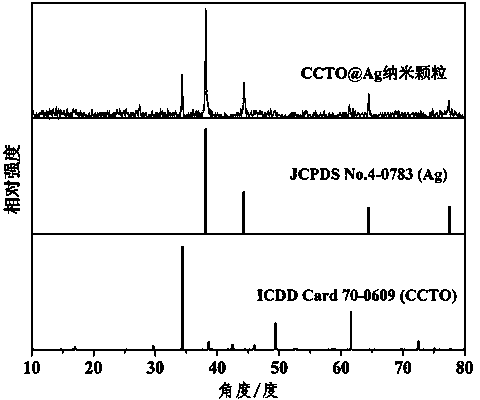

[0040] Embodiment 0, preparation of CCTOAg nanoparticles with good dispersibility

[0041] First, the oxalic acid precursor reaction method is used to prepare nano-CCTO particles with good dispersion. The method specifically includes the following steps:

[0042] (1) Titanium tetrachloride (TiCl 4 ) (18.2093 g) was added to ice water (distilled water at 0°C) (1920 ml) for hydrolysis, and ammonia water (NH 4 OH) to adjust the pH to a certain value, that is, when the white flocculent precipitation in the solution is the most produced (when the pH is adjusted to about 8), it will generate titanium dioxychloride (TiOCl 2 ).

[0043] (2) Put the above mixture in a Buchner funnel for several times of washing and suction filtration to obtain a white floc precipitate.

[0044] (3) Transfer the white floc precipitate to a beaker, add an appropriate amount of oxalic acid dihydrate (C 2 h 2 o 4 .2H 2 O) (24.2054 g) mixed, fully stirred and reacted at 25°C to 45°C for several hou...

Embodiment 1

[0055] a) press figure 1 According to the procedure in , weigh 2.554 g of diaminodiphenyl ether (ODA) into a three-necked bottle containing 7.4 ml of N,N-dimethylacetamide (DMAC) solution.

[0056] b) Weigh 0.1955 g of CCTOAg nanoparticle powder (volume fraction 1.5 vol%) and add it into the above mixture, and perform magnetic stirring while adding.

[0057] c) Put the solution obtained in b) into an ultrasonic disperser for 2 hours to mix the solution evenly.

[0058] d) Weigh 2.835 grams of pyromellitic dianhydride (PMDA) and add it to the mixture, stir it magnetically while adding it, and then react at 30°C for 8 hours in a nitrogen-protected environment to obtain polyimide Stock solution of CCTOAg nanoparticle composites.

[0059] e) Pour the original solution of the composite material on the glass substrate, spread it flat, put it in a muffle furnace, anneal it in a vacuum environment, and keep it at 60°C, 100°C, 200°C and 300°C for 1 hour , and then cool down naturall...

Embodiment 2

[0068] a) press figure 1 According to the procedure in , weigh 2.554 g of diaminodiphenyl ether (ODA) into a three-necked bottle containing 74 ml of N,N-dimethylacetamide (DMAC) solution.

[0069] b) Weigh 0.393 g of the prepared CCTOAg nanoparticle powder (volume fraction 3 vol%) and add it into the above mixed solution, and perform magnetic stirring while adding.

[0070] c) Put the solution obtained in b) into an ultrasonic disperser for 2 hours to mix the solution evenly.

[0071] d) Weigh 2.835 grams of pyromellitic dianhydride (PMDA) and add it to the mixed solution, stir magnetically while adding, and then react at room temperature for 4 hours in a nitrogen-protected environment to obtain polyimide / Stock solution of CCTOAg nanoparticle composites.

[0072] e) Pour the original solution of the composite material on the glass substrate, spread it flat, put it in a muffle furnace, anneal it in a vacuum environment, and keep it at 60°C, 100°C, 200°C and 300°C for 1 hour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com