Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Lower percolation threshold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive materials

InactiveCN101308710AImprove conductivityLower percolation thresholdNon-conductive material with dispersed conductive materialMetal/alloy conductorsPolymer scienceLiquid medium

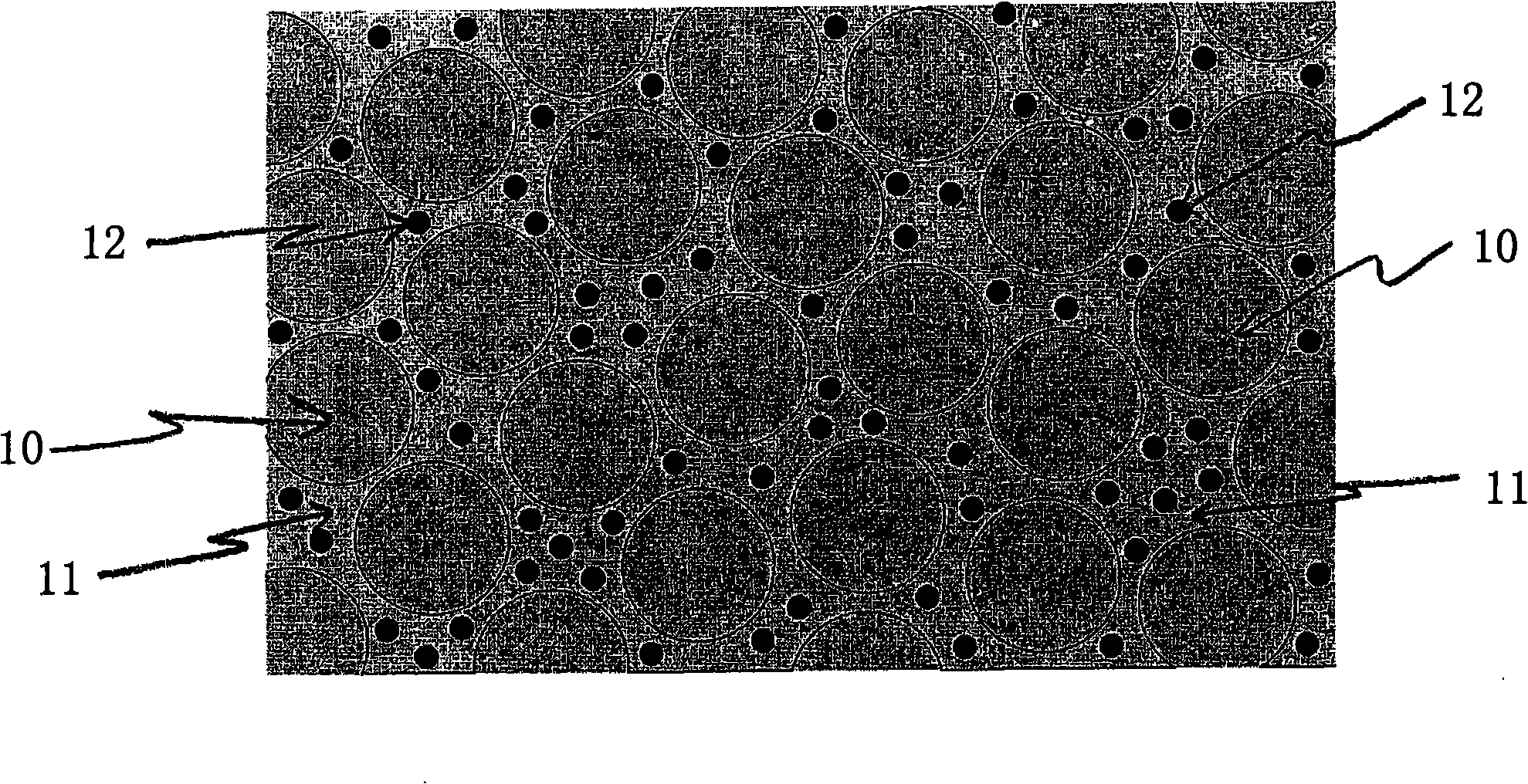

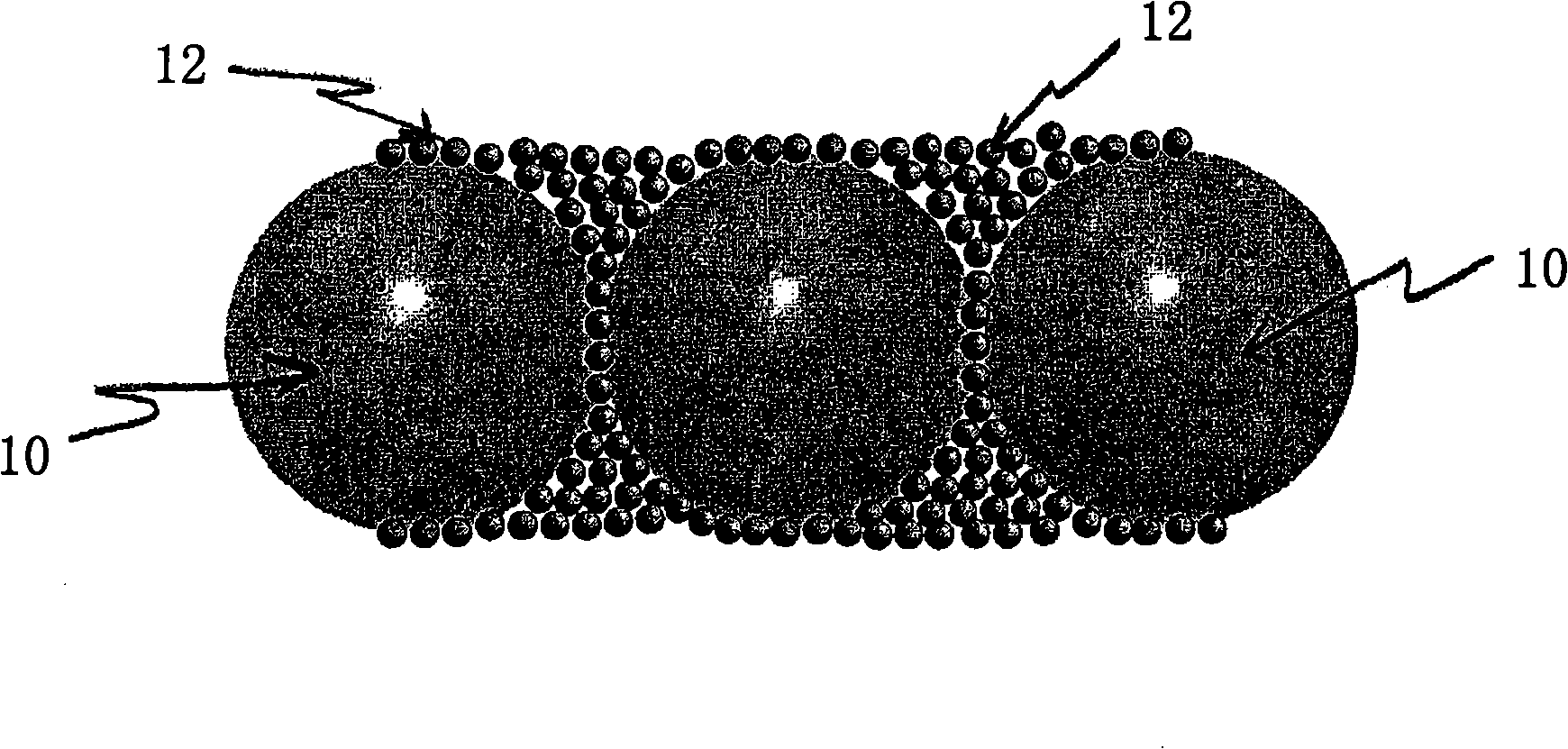

A material for producing a conductive composition comprising polymer particles, conductive particles, and a liquid medium. The material is in a liquid / dispersion form until it is cured at which time it forms an electrically conductive composition. The composition contains larger sized polymer particles along with smaller metal conductive filler particles such as nanoparticle-sized filler particles. The larger polymer particles create excluded volume in the material matrix and reduce the percolation threshold of the conductive filler particles to provide a conductive material with a reduced volume fraction of electrically conductive filler. The electrical conductivity of the material is further increased after heat treatment which causes the conductive filler particles to sinter together to form a highly conductive network.

Owner:HENKEL KGAA

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

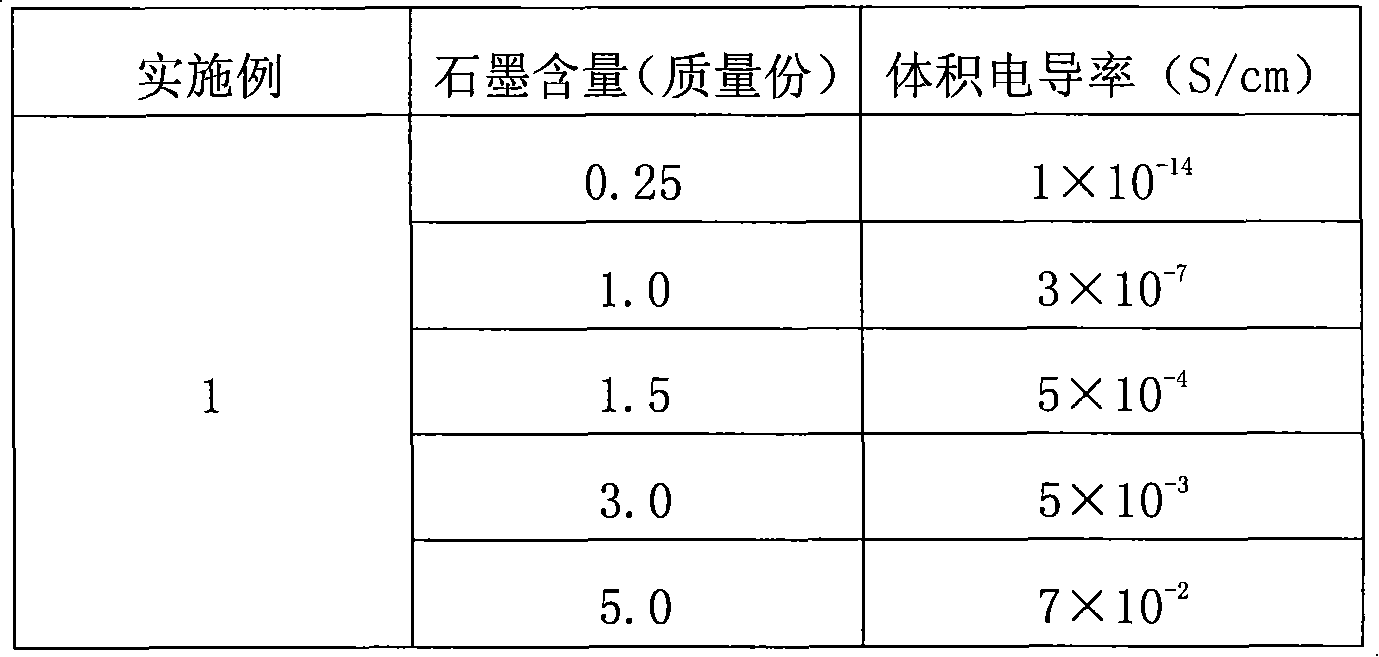

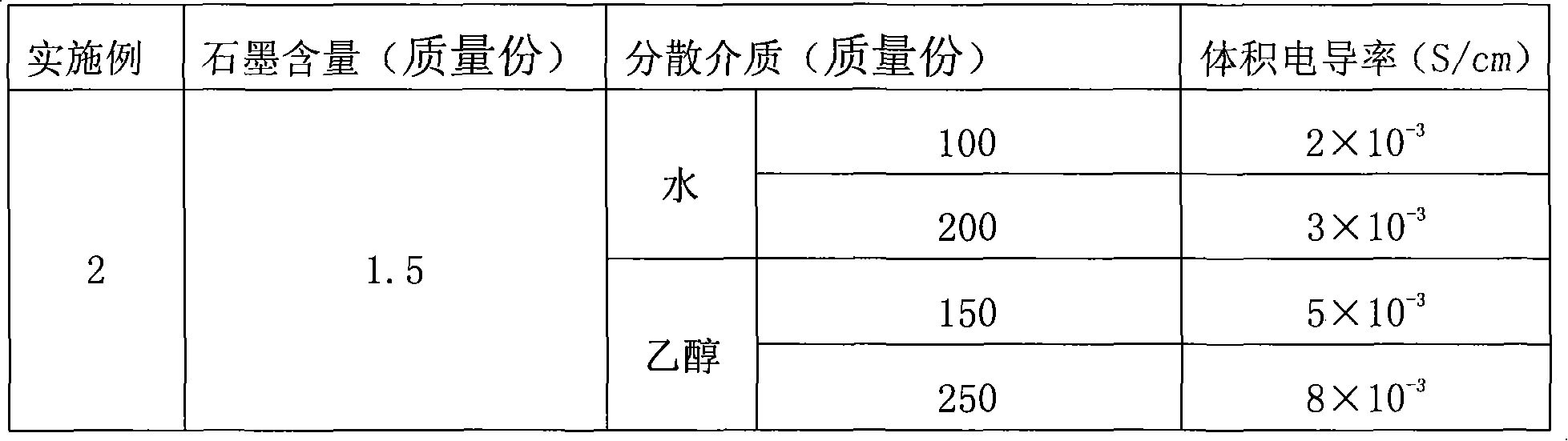

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

Method for producing carbon nano-tube/composite conducting polymer material

InactiveCN101173051AEvenly dispersedDisadvantages of customer service reunionNon-conductive material with dispersed conductive materialPolymer scienceCarbon nanotube

The invention discloses a preparation method of a carbon nanotube / polymer conductive composite material. 0.3 to 0.8 parts of polymer are added into 18.9 to 57.8 parts of solvent and continuously stirred under the temperature ranging from 110 to 150 DEG C till the polymer is sufficiently dissolved, and then the polymer is cooled to the room temperature; 0.054 to 0.008 parts of carbon nanotube and 80.746 to 41.392 parts of solvent are mixed and put into an ultrasonic mill as ultrasound evenly disperses the carbon nanotube into the solvent; subsequently, the two solutions are mixed and put into the ultrasonic mill as the ultrasound evenly mixes the solution; the slow qualitative filter paper extracts and filters the mixed solution, and the obtained solid mixture is vacuumized and dried under the temperature ranging from 80 to 100 DEG C till the weight is constant; finally, the dried solid material is hot molded, and the carbon nanotube / polymer conductive composite material can be obtained. The invention ensures that the polymer evenly disperses in the carbon nanotube.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of electrically conductive composite material with positive temperature coefficient effect

The invention discloses a making method of conductive composite material with positive-temperature coefficient effect, which comprises the following steps: (1) putting two blending polymers and conductive filler in the double-screw squeezing machine or sealed fusing machine to fuse 5-20 min with fusing temperature higher than fusing point of polymer by 10-50 deg.c; (2) moulding the blending material into film in the flat sulfurized machine.

Owner:DONGHUA UNIV

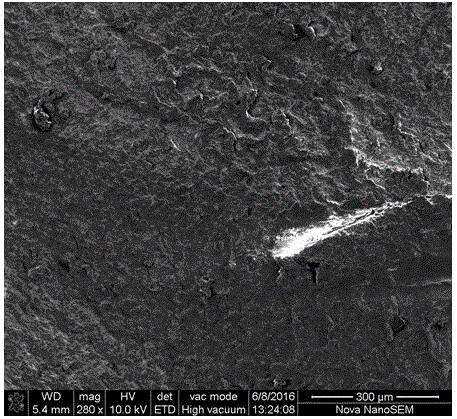

Electroconductive slurry and preparation method thereof, and printed circuit material

ActiveCN103400637AHigh surface curvatureLower percolation thresholdNon-conductive material with dispersed conductive materialCable/conductor manufactureMicrostructurePercolation threshold

The invention discloses electroconductive slurry and a preparation method thereof, and a printed circuit material. The electroconductive slurry comprises a polymer resin matrix and metal powder which is dispersed in the polymer resin matrix and serves as an electroconductive filler, wherein the microstructure of the metal powder is a three-dimensional dendritic metal crystal structure; the diameter of the metal crystal structure is 0.5-50 microns; a second-stage dendritic structure is 5 nanometers- 5 microns long. According to the electroconductive slurry and the preparation method thereof which are disclosed by the invention, the metal powder with the three-dimensional dendritic metal crystal structure serving as the microstructure is used as the electroconductive filler, so that the percolation threshold value of the electroconductive slurry can be greatly reduced, and the higher electroconductivity can be realized with less metal filler; furthermore, the metal powder with the three-dimensional dendritic metal crystal structure serving as the microstructure is used as the electroconductive filler, so that the electroconductive slurry can keep a high isotropous electroconduction effect and uniform dispersion; due to a nano-end structure, the resistivity of the electroconductive slurry can be greatly reduced, and the electroconductivity can be improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

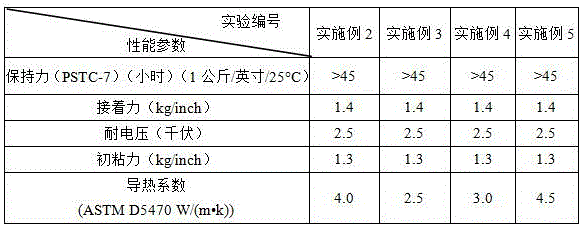

Preparation method of graphene heat conduction double-sided adhesive tape

ActiveCN106433508AReduce thermal resistanceLower percolation thresholdNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceColloid

The invention discloses a preparation method of graphene heat conduction double-sided adhesive tape. The method comprises the following steps: (1) stirring and mixing heat conduction filler and graphene powder so as to enable the heat conduction filler to be coated with graphene, then adding dispersion liquid formed by a silane coupling agent and alcohol and stirring and mixing to obtain composite heat conduction filler; (2) evenly mixing glue with the composite heat conduction filler, and then coating two pieces of single-sided heat conduction adhesive by using release paper or release film as a carrier; after that, sticking the two pieces of single-sided heat conduction adhesive on a enhanced base material, removing the release paper or release film of one side, and winding to obtain a finished product. After the preparation method is adopted, the heat conduction performance of the double-sided adhesive tape is improved to the utmost extent under the condition of very low graphene adding amount, so that the insulating property and the heat conduction performance of the double-sided adhesive tape are improved.

Owner:DEYANG CARBONENE TECH

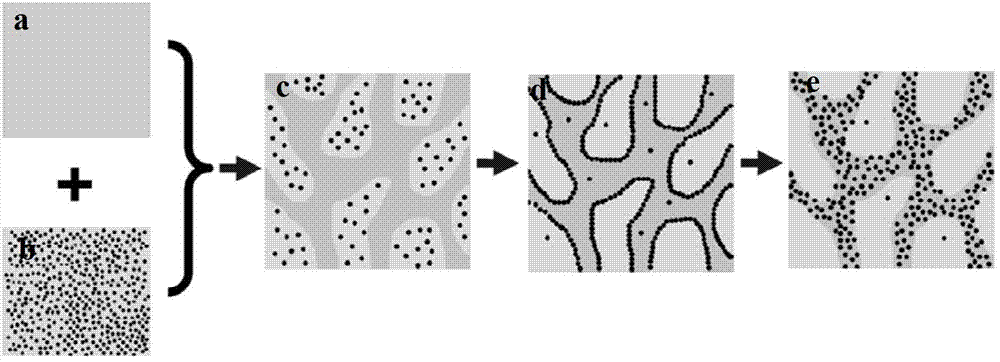

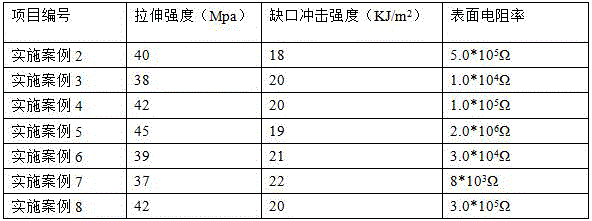

Conductive polymer composite and preparation method thereof

ActiveCN103113732ALower Conductive Percolation ThresholdEasy to prepareNon-conductive material with dispersed conductive materialConductive polymer compositePolyethylene terephthalate glycol

The invention provides a conductive polymer composite and a preparation method thereof. The conductive polymer composite comprises 100 parts by weight of matrix and 0.01-1.5 parts by weight of conductive nanofiller, wherein the matrix is an incompatible polymer blend system with dual-continuous structure, and the length-diameter ratio of the conductive nanofiller is greater than or equal to 100. Compared with a conductive fibering polymer composite prepared from carbon black, polyethylene and polyethylene terephthalate in the prior art, the conductive polymer composite has the advantages that firstly, the length-diameter ratio of the conductive nanofiller adopted in the conductive polymer composite is larger, so that the insulated polymer can conduct electricity by few addition of the conductive nanofiller, thus the conductive percolation threshold of the conductive polymer composite is reduced; secondly, the matrix of the dual-continuous structure and the conductive polymer nanofiller are distributed on a two-phase interface of the incompatible polymer blend system with the dual-continuous structure, so that the conductive percolation threshold of the conductive polymer composite is reduced; and finally, the preparation method provided by the invention is simple, safe and environment-friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

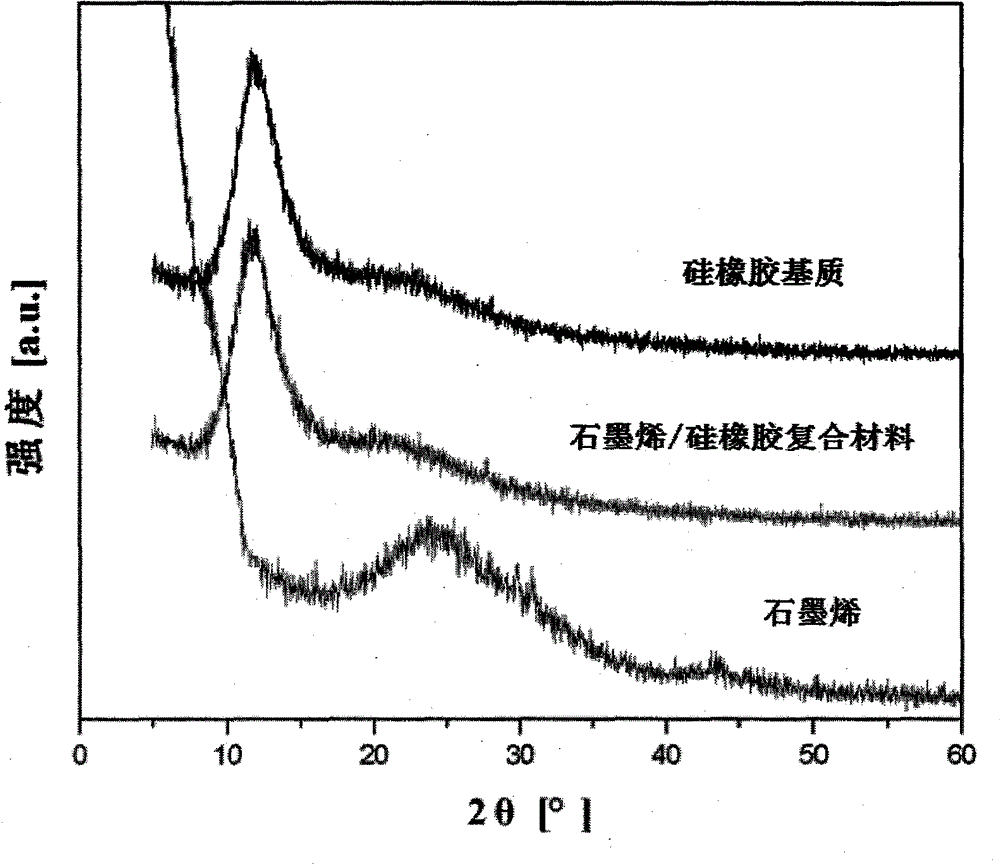

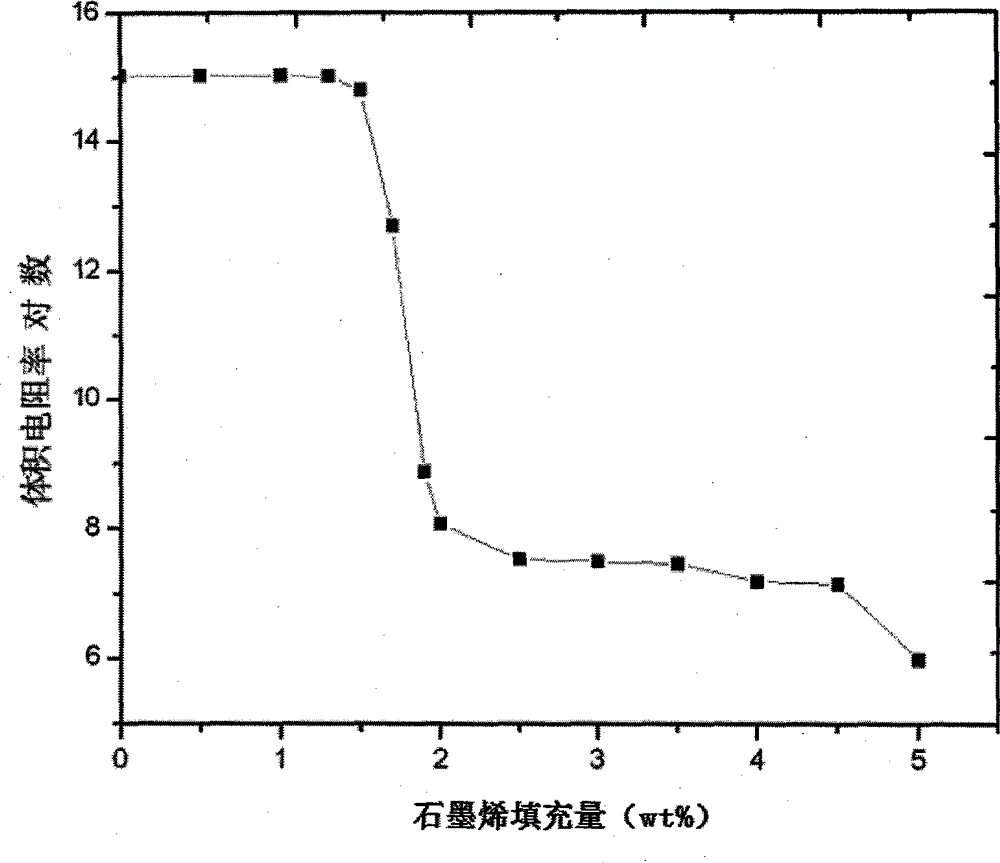

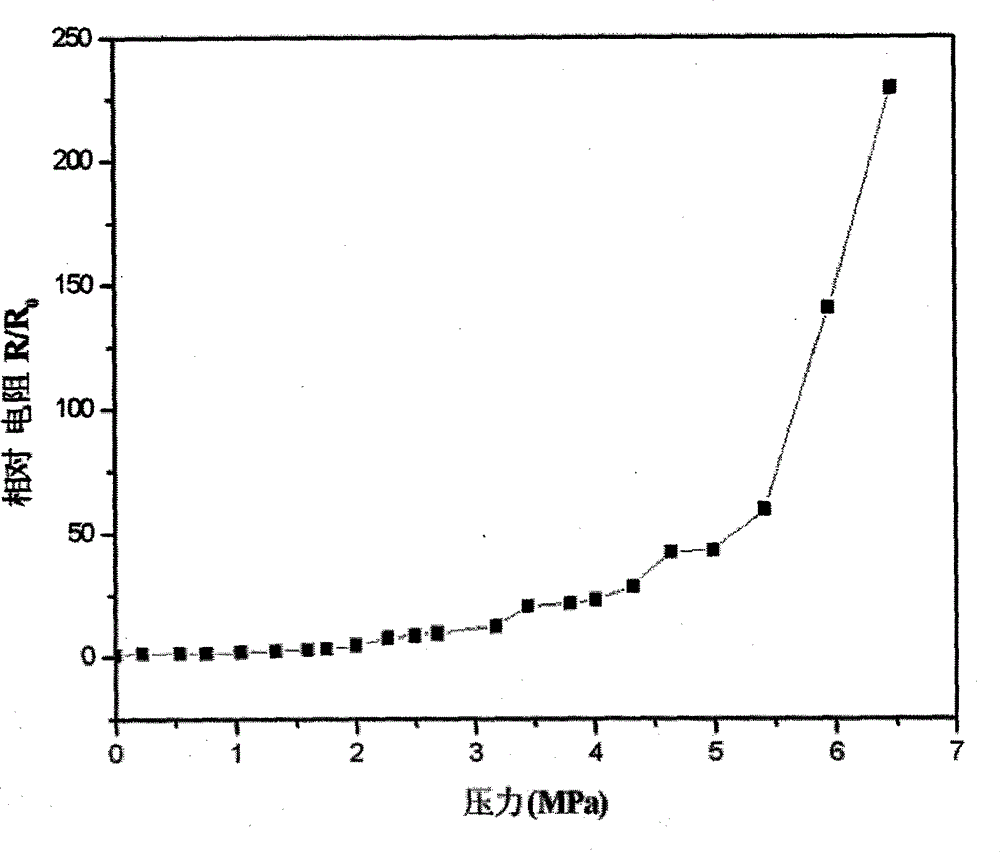

Preparation method of graphene/silicon rubber pressure-sensitive conductive composite

The invention relates to a preparation method of a graphene / silicon rubber pressure-sensitive conductive composite and belongs to the technical field of composite preparation. The preparation method comprises the following steps: dispersing the graphene used as a packing into a silicon rubber matrix by using an ultrasonic-assisted solution mixing method, and furthermore, preparing the graphene / silicon rubber pressure-sensitive conductive composite by using a high-temperature sulphidization method. The graphene has a high diameter-thickness ratio, and a conductive network can be formed in silicon rubber by using a relatively small quantity of graphene through the ultrasonic-assisted solution mixing and high-temperature sulphidization methods, so that the percolation threshold of the graphene / silicon rubber composite is relatively low; in addition, the system is sensitive to pressure so as to achieve a remarkable positive piezoresistive effect. The composite provided by the invention is widely applied to the fields of antistatic rubber, electromagnetic shielding products and pressure sensors.

Owner:TAISHAN MEDICAL UNIV

Method for preparing nanocomposite hybrid multi-dimension material

The invention discloses a method for preparing a nanocomposite hybrid multi-dimension material, which belongs to the technical field of the low-cost manufacturing of resin-based composite materials. The method comprises the following steps of: adding a nanometer material into resin to prepare a nanocomposite resin substrate; and preparing the hybrid multi-dimension composite material by adopting a liquid molding process, wherein the dispersion of the nanometer material in the resin and the subsequent molding process are both performed in an ultrasonic field. As the nanometer material has an extremely large specific surface area and an extremely high length-diameter ratio, the threshold of the percolation of the nanometer material in the composite material is relatively lower, and the addition of 0.1 to 1.5 percent of the nanometer material is insufficient to influence the liquid molding process of the composite material, which does not influence the tensile property mainly determined by reinforcing fibers at the same time of greatly improving the mechanical property, conductivity and glass-transition temperature, mainly determined by the substrate, in the composite material.

Owner:SHENYANG AEROSPACE UNIVERSITY +1

Conductive and antistatic nylon

The invention discloses a conductive and antistatic nylon which adopts polyamide resin as basic material and adds nano inorganic filling material, conductive carbon black, a lubricating agent, a surface processing agent and an antioxidant and the like; the part by weight ratio of all the components is as follows: 60 parts to 98 parts of polyamide resin, 1 part to 15 parts of nano inorganic filling material, 5 parts to 30 parts of conductive carbon black, 0.1 part to 1.0 part of lubricating agent, 0.1 part to 1.0 part of surface processing agent and 0.1 part to 0.5 part of antioxidant; the invention adds the conductive carbon black in the polyamide resin to improve the conductive effect of the material, reduces the using amount of the carbon black under the premise of guaranteeing the same conductivity and antistatic electricity and effectively improves the cost performance of the material, effectively improves the dispersion of the carbon black, and reduces the 'percolation threshold' of plastic; and the nano material is added into the nylon and has the effect of a nucleating agent, which has obvious strengthening and toughening effects to matrix resin and improves the comprehensive performance of the product.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS

Resource-renewable and biodegradable conductive fiber and preparation method thereof

ActiveCN102936761ARealize conductive functionLower percolation thresholdElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiber3-Hydroxypentanoic acid

The invention discloses resource-renewable and biodegradable conductive fiber and a preparation method thereof. The fiber consists of the following raw materials in parts by weight: 30-70 parts of polylactic acid (PLA), 30-70 parts of poly(3-hydroxybutyric acid-co-3-hydroxyvalerate (PHBV) and 0.05-8 parts of conductive filler. The preparation method of the conductive fiber comprises the following steps of: (1) proportionally pre-mixing PHBV (if PLA is not less than 50 parts) or PLA (if PLA is less than 50 parts) and the conductive filler, and performing melt blending and granulation to obtain the conductive master batch of the PHBV or PLA; (2) proportionally pre-mixing the PLA or PHBV and the conductive master batch of the PHBV or PLA, and performing melt blending and granulation to obtain composite conductive mater batches; and (3) spinning and drafting the composite conductive master batches one by one to obtain the conductive fiber. The conductive fiber disclosed by the invention can be used as the material for electrodes, static resistance, low-temperature heating, electromagnetic shielding, thermal sensitivity, gas sensitivity and the like.

Owner:JIANGNAN UNIV

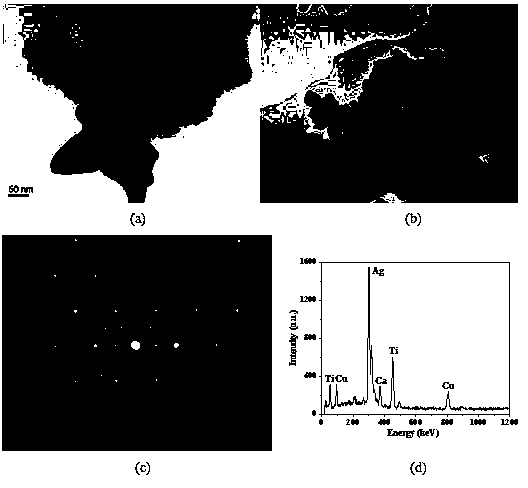

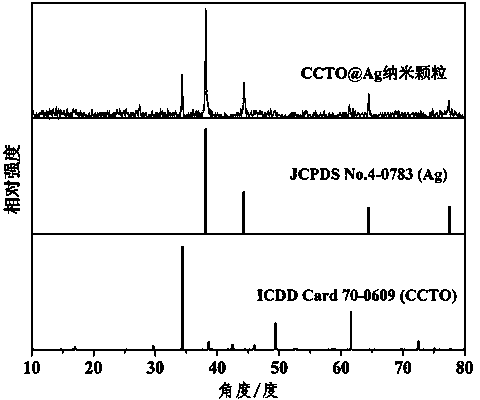

Preparation method of polyimide/copper calcium titanate coated silver nanoparticle composite material

InactiveCN103755958APromote recombinationImprove electric field distributionIn situ polymerizationHigh energy

The invention discloses a preparation method of polyimide / CCTO@Ag nanoparticle composite material with high dielectric and low loss. According to the method, polyimide is used as matrix, the prepared CCTO@Ag nanoparticles are ultrasonically dispersed in absolute ethyl alcohol, then is blended with polyimide monomer in solvent, then in situ polymerization reaction is carried out on the monomer at room temperature to simultaneously realize copolymerization of polyimide and intercalation recombination with the CCTO@Ag nanoparticles, obtained stock solution is subjected to gradient annealing according to a coating method to finally obtain the polyimide / CCTO@Ag nanoparticle composite film. Compared with pure polyimide, the polyimide / CCTO@Ag nanoparticle composite material prepared according to the preparation method has the dielectric constant (103) increased by 30 times, also has low dielectric loss (0.006) and can be widely applied in fields of high energy storage capacitors, artificial organs, high speed integrated circuits, and the like.

Owner:WUHAN UNIV

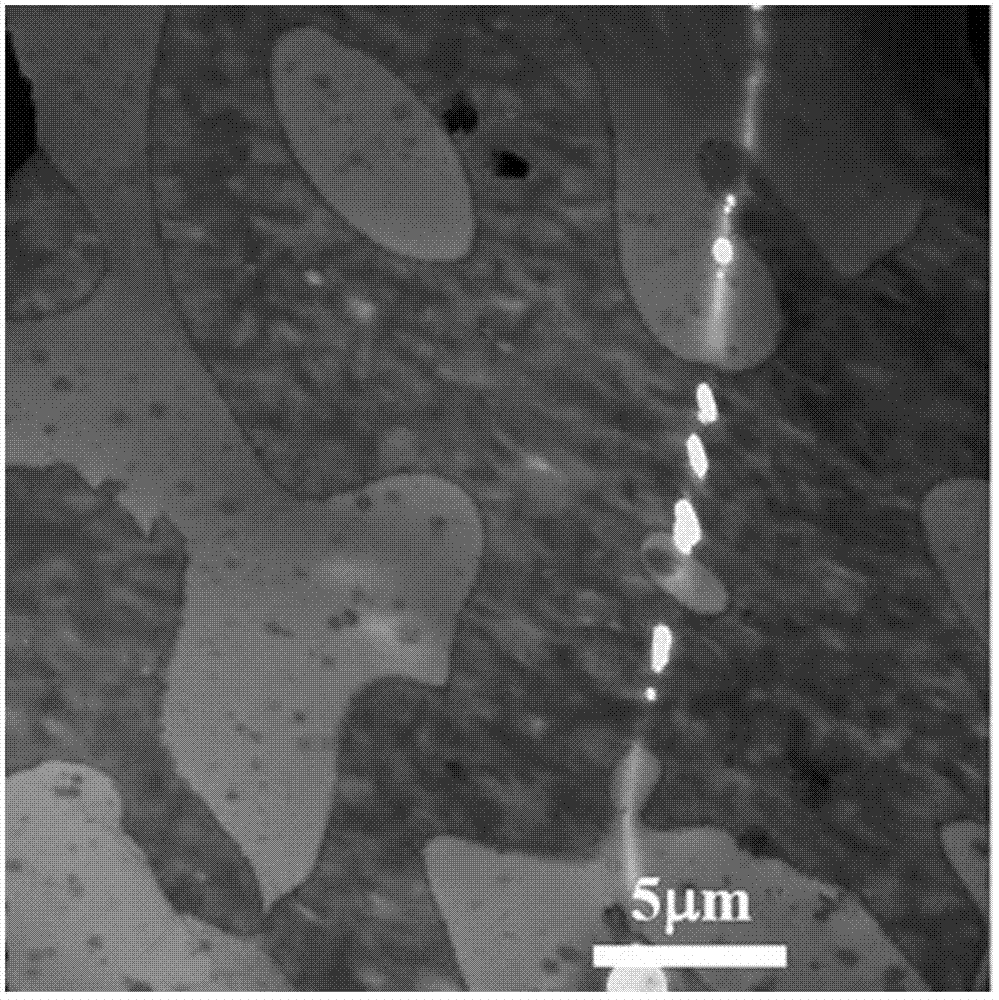

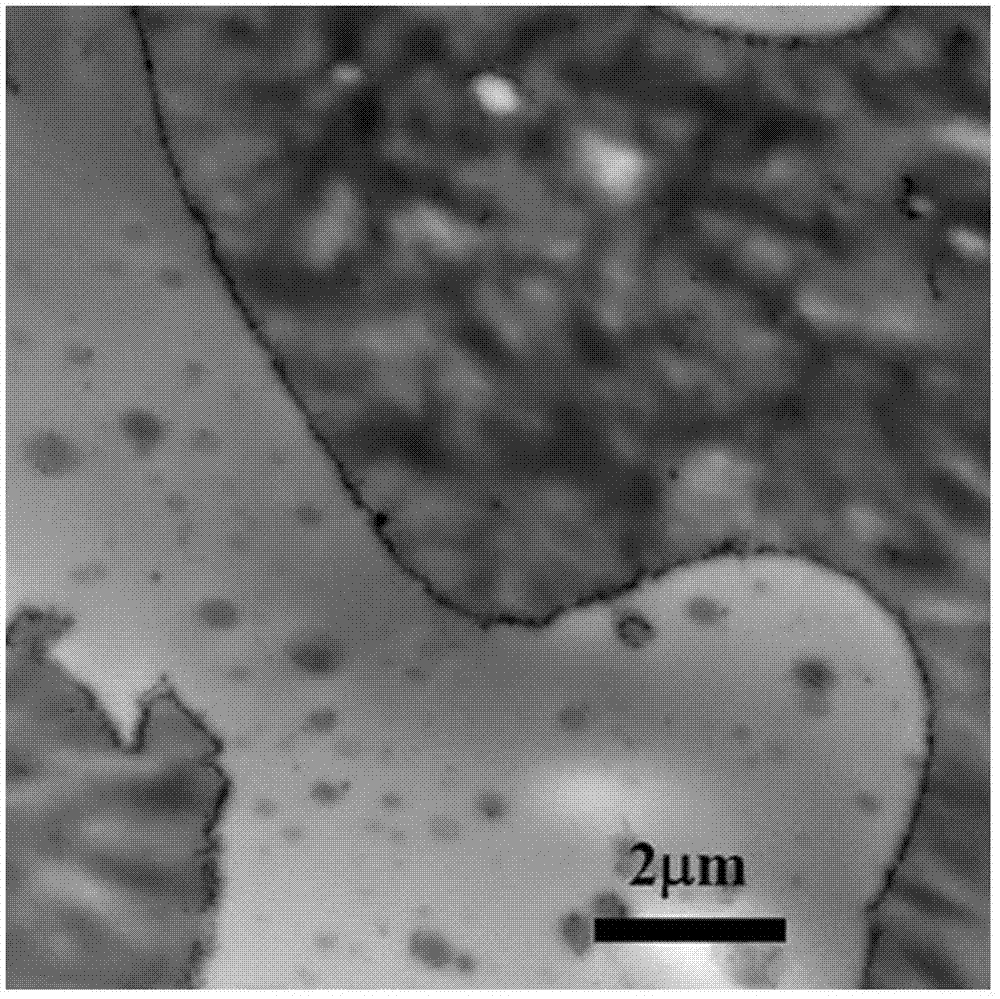

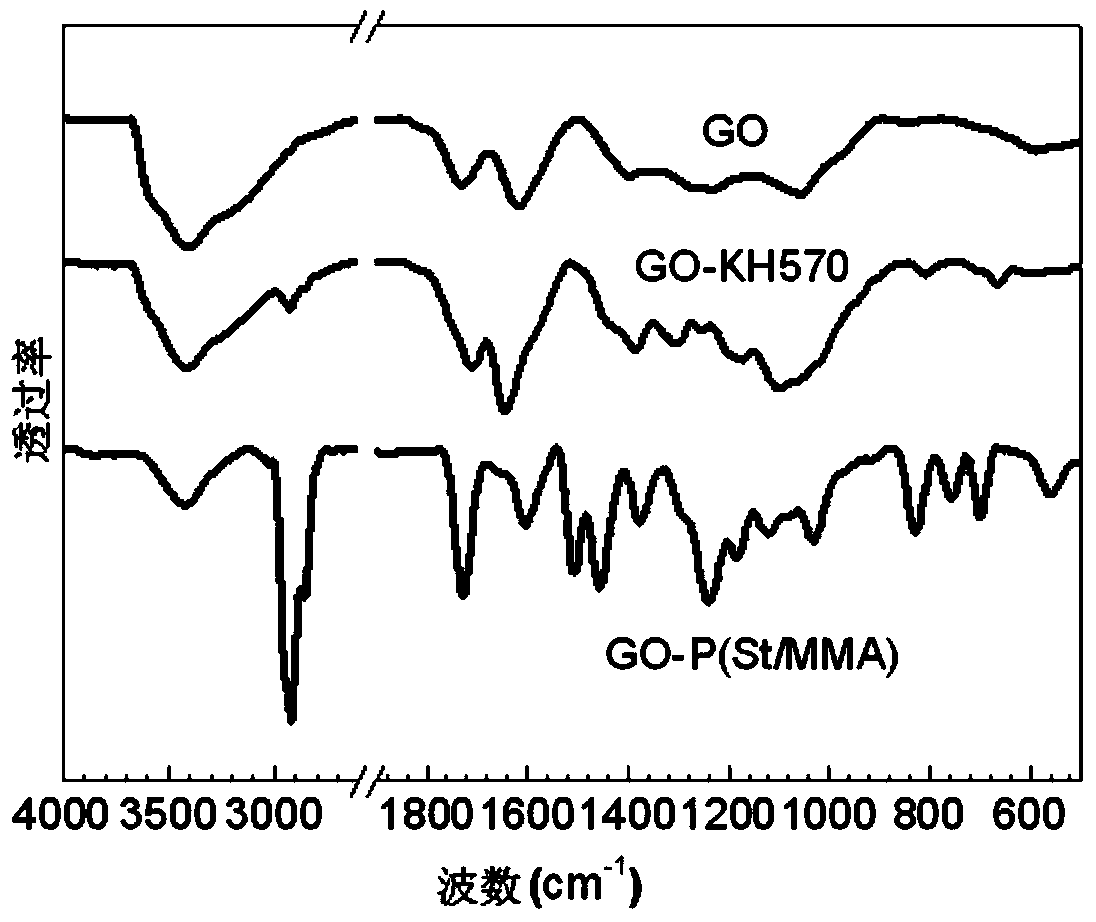

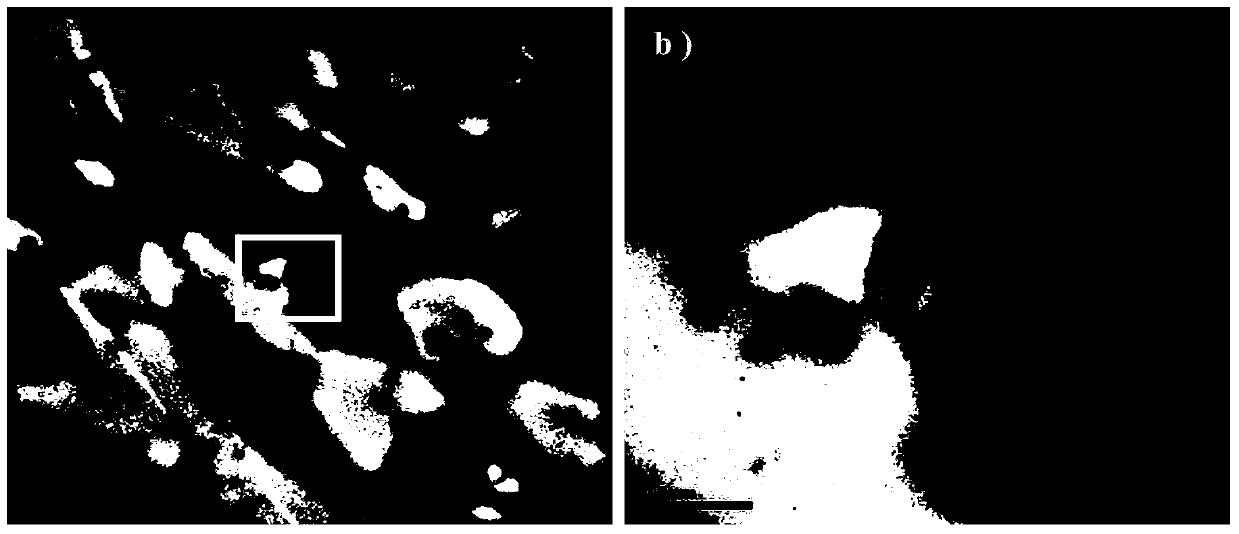

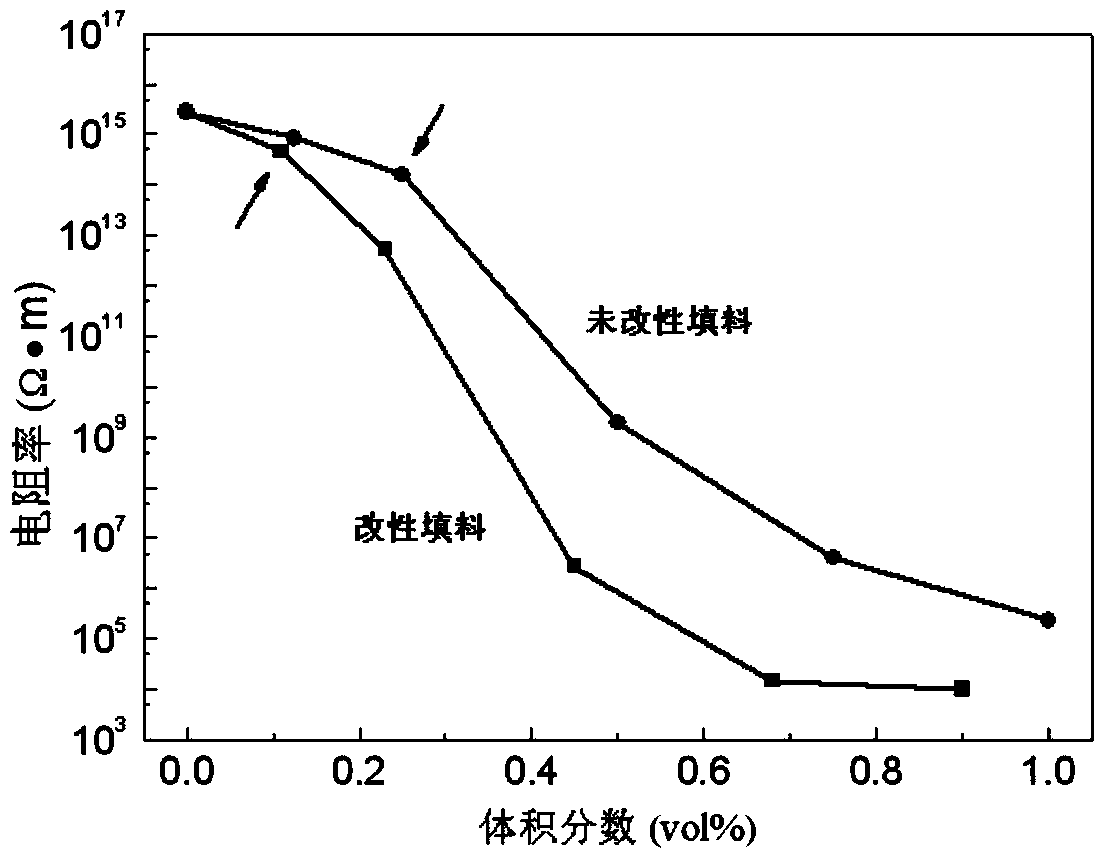

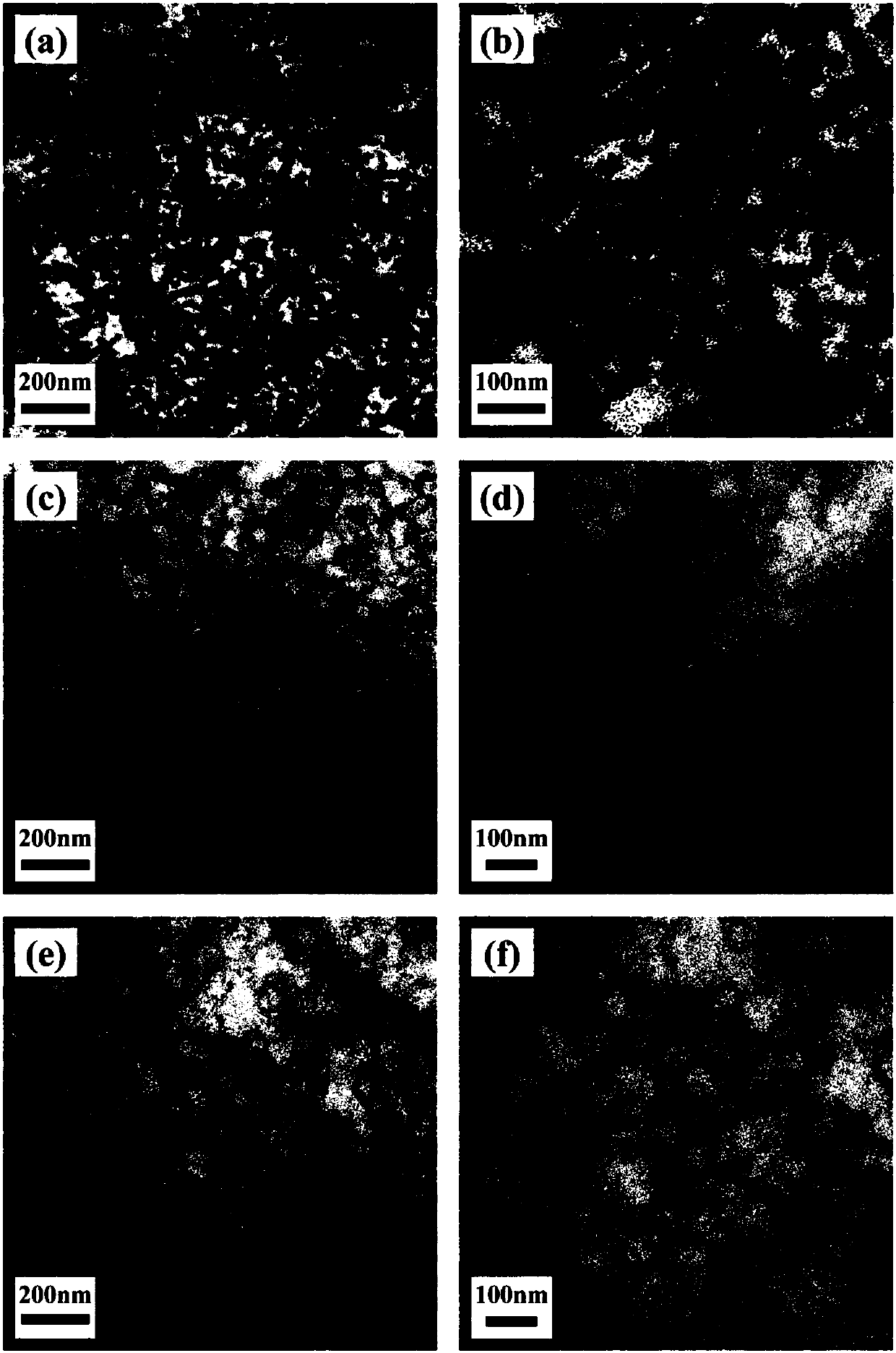

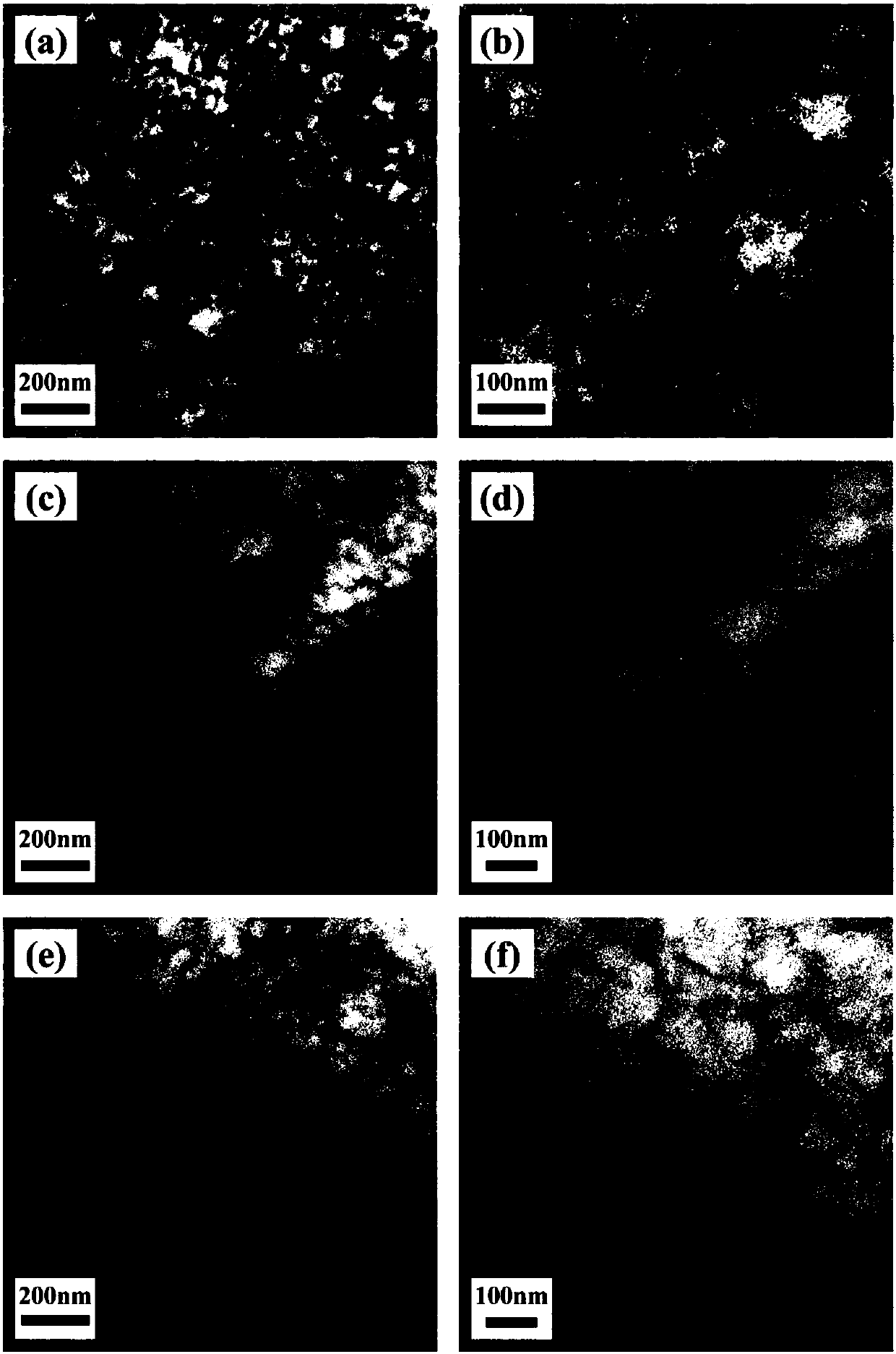

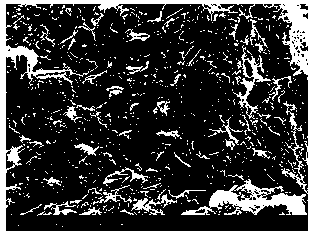

Method for preparing graphene composite with low percolation threshold value and high heat stability

The invention relates to a method for preparing a graphene composite with a low percolation threshold value and high heat stability. The method comprises the following steps: introducing double bonds by the grafting of graphene oxide with a silane coupling agent; polymerizing preliminarily-modified fillers with styrene and methyl methacrylate fine emulsion, and preparing modified fillers of grafting random copolymers; mixing the modified fillers with polystyrene and a poly methyl methacrylate solution, and using hydrazine hydrate for synchronous reduction; precipitating polymers, drying and performing. TEM tests for the graphene composite provided by the utility model show that part of fillers are distributed at two phases of interfaces and generates good compatibilization to a system, and the percolation threshold value is only 0.11 vol%. Meanwhile, SEM tests show that phase coarsening is inhibited before and after heat treatment, the heat stability of the system is obviously increased, and the graphene composite can be widely used in the field of conductive polymer composites.

Owner:SHANGHAI JIAO TONG UNIV

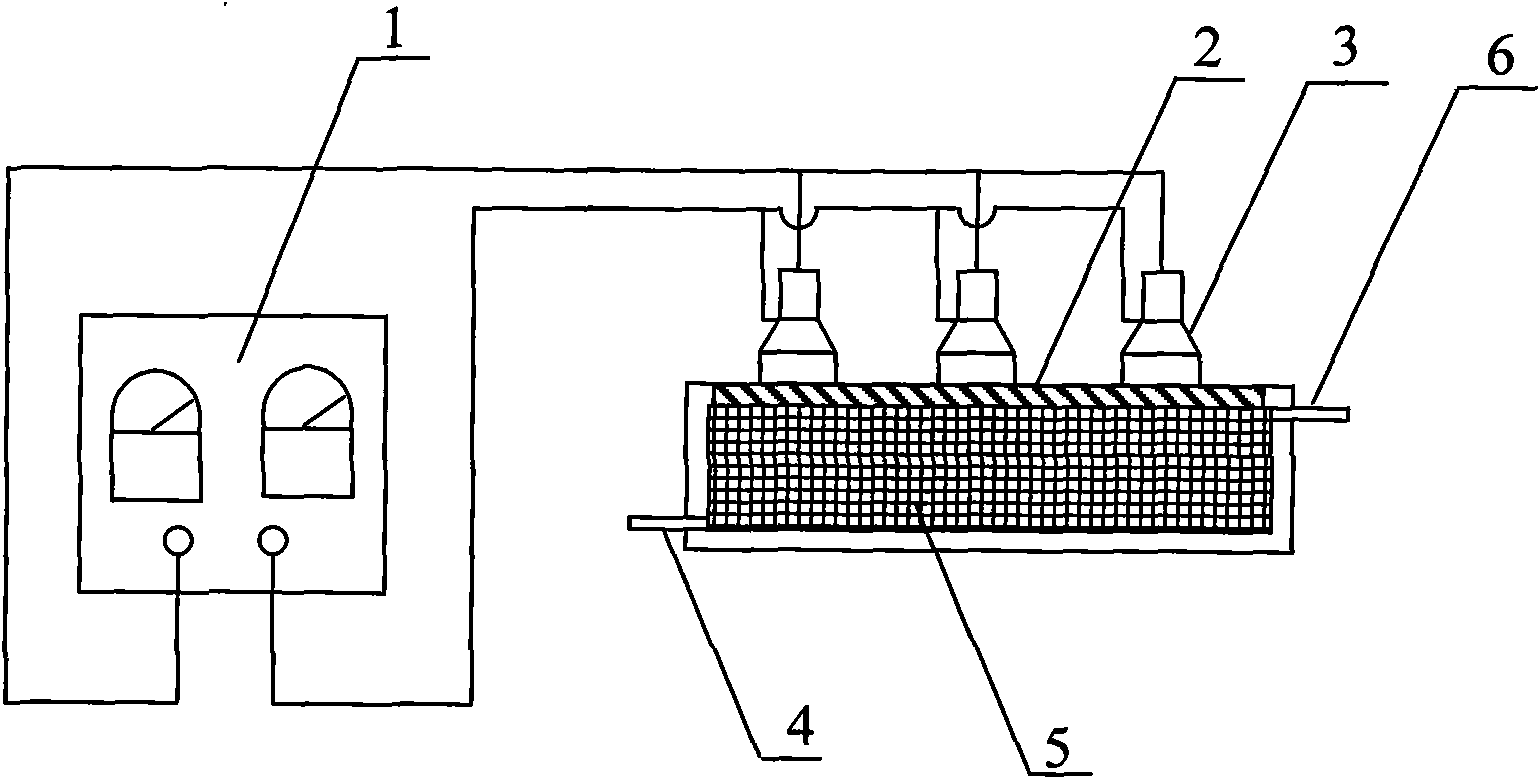

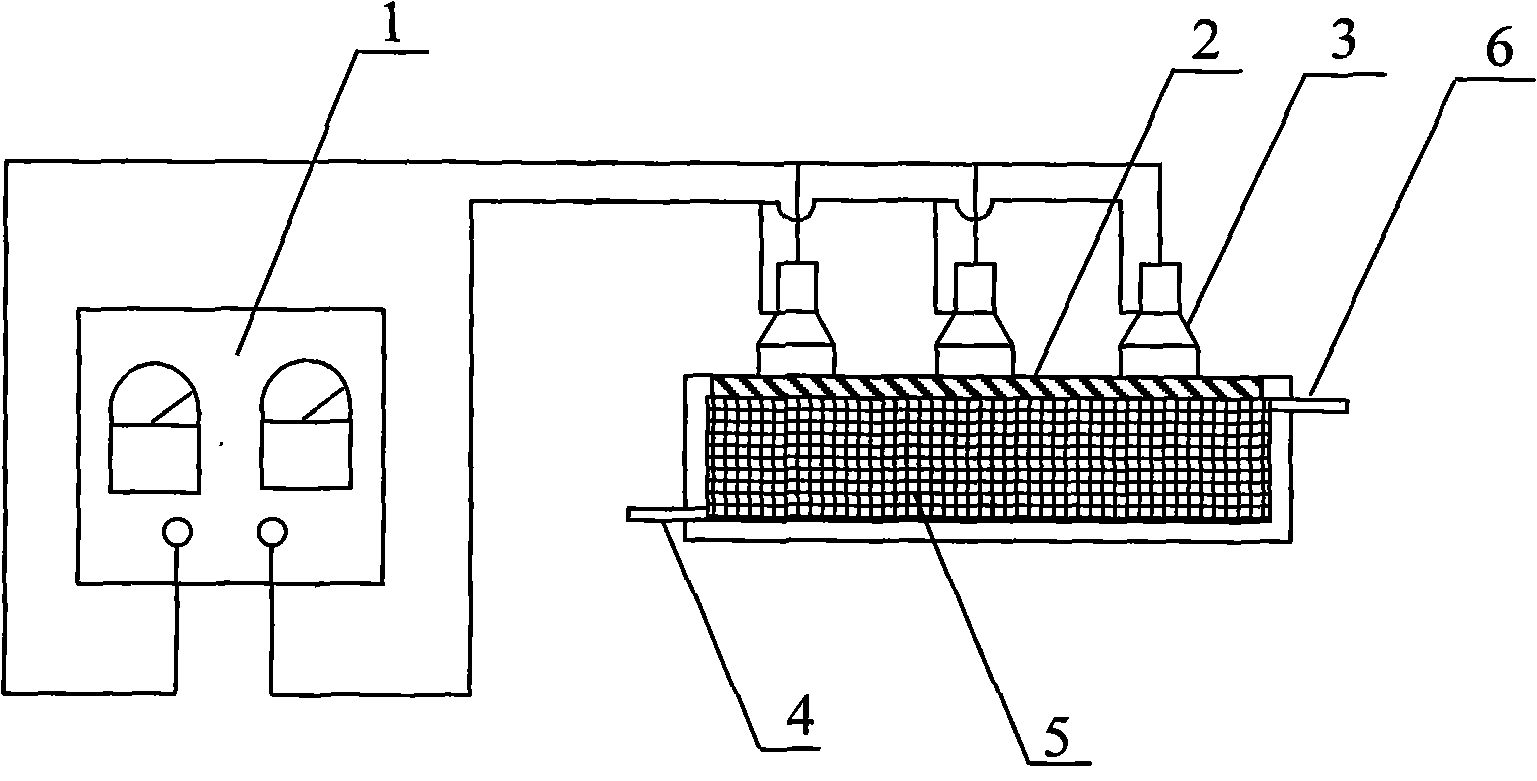

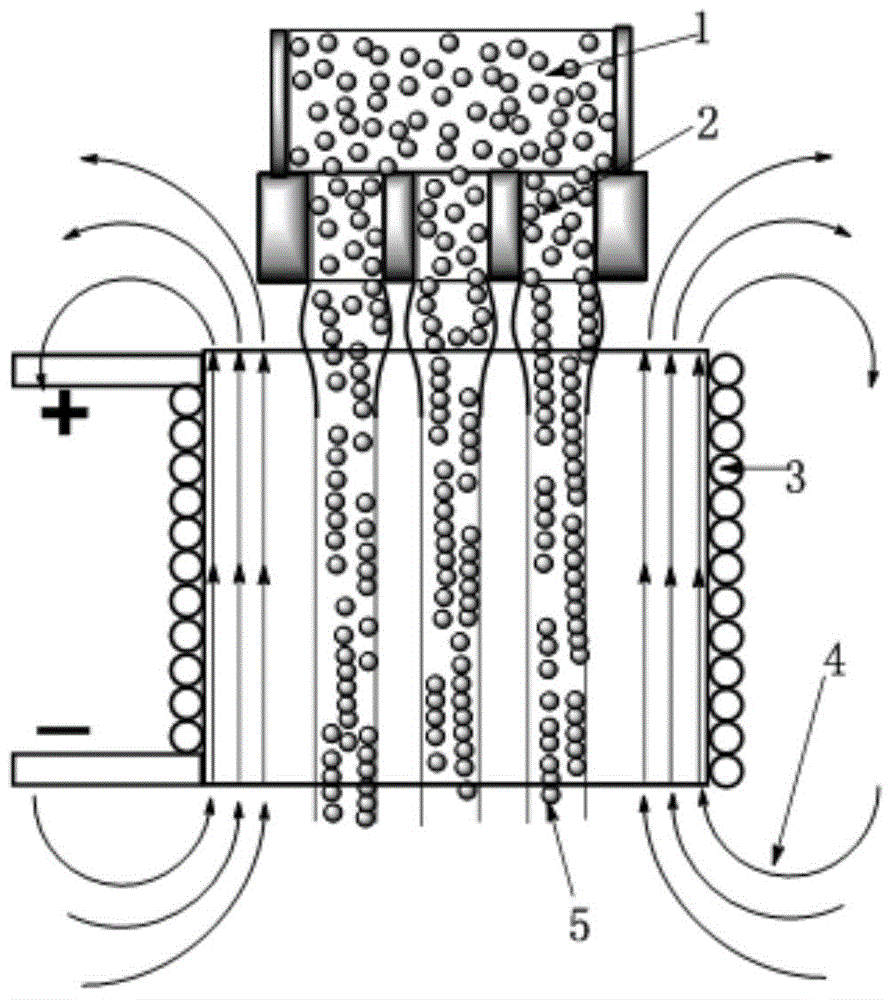

Electric conductive/ magnetic conductive chemical fiber magnetic field induction spinning assisting forming device and production method thereof

InactiveCN104963018AImprove conductivityLower percolation thresholdElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesMetering pumpPolymer

The invention discloses an electric conductive / magnetic conductive chemical fiber magnetic field induction spinning assisting forming device and a production method thereof. The electric conductive / magnetic conductive chemical fiber magnetic field induction spinning assisting forming device and the production method thereof are characterized in that an electromagnetic coil (3) is vertically connected with a spinneret plate (2), the spinneret plate (2) is connected with a melt runner (1), the hollow portion of the electromagnetic coil (3) is in alignment with the center of the spinneret plate to enable fiber stripes (5) to successfully pass through the hollow portion of the electromagnetic coil, the electromagnetic coil is connected with a direct current power source in spinning, and then magnetic lines of force (4) are generated; then melt blending is conducted on magnetic powder, a dispersing agent, an antioxidant and polymer, the blended melting body is extruded out by a spinneret orifice through a metering pump, under the action of the magnetic field of the electromagnetic coil, magnetic particles are arrayed in the directions of the magnetic lines of force to form microfibers or string bead structures, the fiber stripes are cooled and solidified, and then oil applying, concentration of beams, drafting and heat shaping are conducted on the fiber stripes, and then the finished electric conductive / magnetic conductive complex fibers are obtained.

Owner:ZHONGSHAN KECHENG CHEM FIBER +1

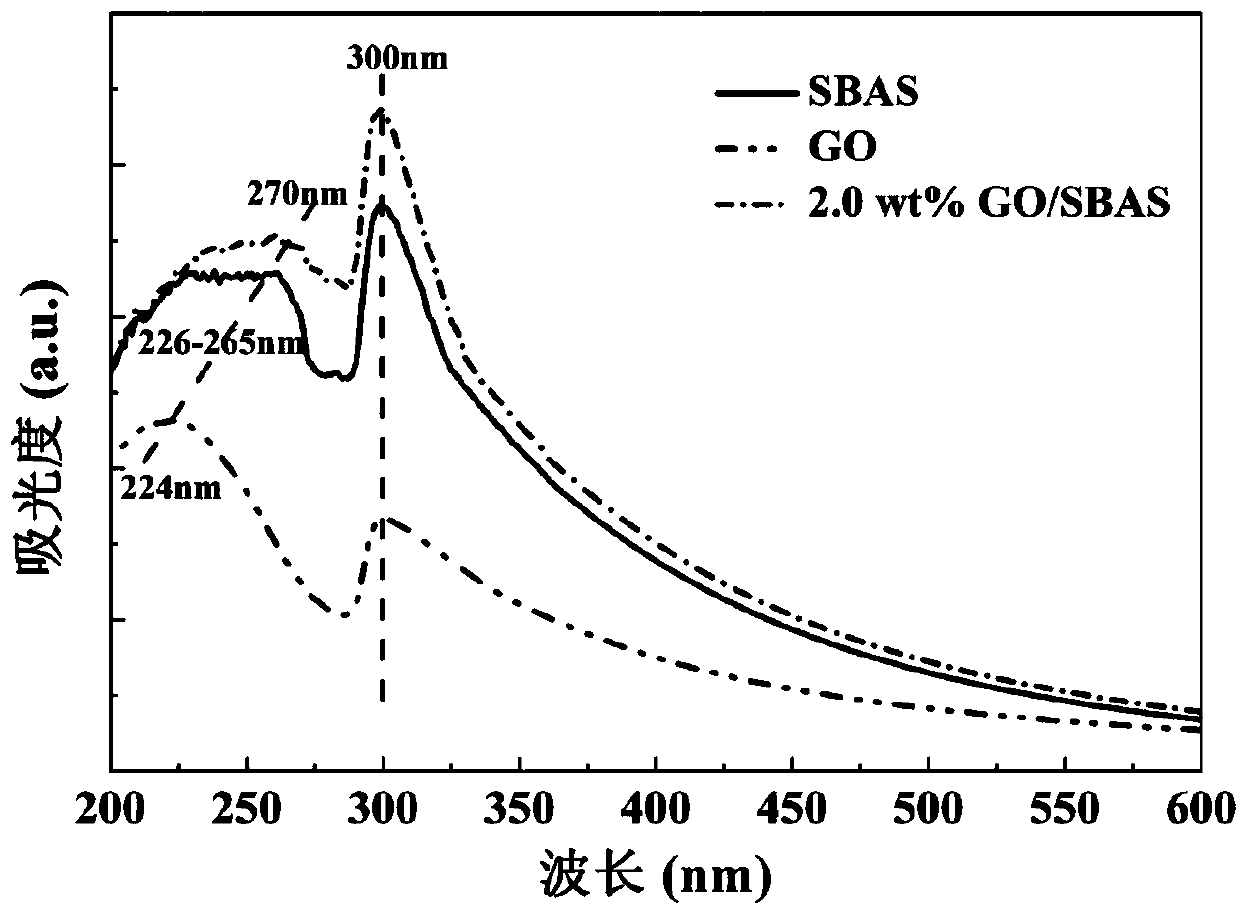

High-electrodeformation dielectric elastomer composite and preparation method thereof

The invention discloses a high-electrodeformation dielectric elastomer composite and a preparation method thereof. A polystyrene-b-poly(n-butyl acrylate)-polystyrene triblock copolymer is taken as a dielectric elastomer matrix, a method of direct emulsion blending of a graphene oxide water dispersion liquid and polystyrene-b-poly(n-butyl acrylate)-b-polystyrene emulsion is implemented, drying is performed at the room temperature, a dielectric elastomer composite film of graphene oxide / polystyrene-b-poly(n-butyl acrylate)-b-polystyrene is prepared, and a partially reduced graphene oxide / polystyrene-b-poly(n-butyl acrylate)-b-polystyrene dielectric elastomer composite is obtained through heat reduction. The adding amount of graphene and the elasticity modulus of the composite are effectivelyreduced, the dielectric property of the dielectric elastomer composite is improved, and the maximum electrodeformation of the partially reduced graphene oxide / polystyrene-b-poly(n-butyl acrylate)-b-polystyrene high-performance dielectric elastomer composite under the condition of no prestretching can be up to 21.3%.

Owner:ZHEJIANG UNIV

Special material for permanent antistatic flexible PE (polyethylene) pipes

The invention discloses a special material for permanent antistatic flexible PE (polyethylene) pipes. 100 parts of PE-RT resin by weight, 20-35 parts of a conductive master-batch by weight, 2-8 parts of a thermoplastic elastomer by weight, 1-5 parts of a dispersing agent by weight, 0-0.5 part of an antioxidant by weight, 0-0.5 part of a release agent by weight and 0-0.5 part of a liquid lubricant by weight are evenly mixed in a high-speed stirrer, then extruded by twin screws, cooled with water and granulated, and the machining temperature is in a range of 180-195 DEG C. The special material for the pipes is dried, then extruded to form the pipes, cooled and drawn to be prepared into finished products. Compared with the prior art, the special material has the advantages that the antistatic property is good, the permanent antistatic effect is realized, the tensile strength, the flexural strength and the impact strength are equivalent to those of pure PE-RT, the flexural modulus is lower, the advantage of the flexibility of the PE pipes is kept, the special material is convenient to transport, construct and install, good in environment resistance and low in cost, and the volume resistivity of the special material for the permanent antistatic flexible PE pipes can be stabilized at 106 ohm / cm.

Owner:YANGZHOU UNIV

Preparation method for 3D printed wire rod with functionalized skin-core structure

ActiveCN109111706AEasy to prepareLower percolation thresholdAdditive manufacturing apparatusSkin coreEngineering

The invention discloses a 3D printed wire rod with a functionalized skin-core structure and a preparation method thereof. The preparation method comprises the following steps: (1) coating a functionalauxiliary agent with a coupling agent; (2) subjecting the functional auxiliary agent coated with the coupling agent and a flexible polymer to twin-screw melt blending to obtain functional masterbatch; and (3) subjecting the functional masterbatch and PLA to single-screw blending extrusion. The 3D printed wire rod obtained in the invention has a skin-core structure; the flexible polymer is used asa skin layer, the PLA is used as a core layer, and the functional auxiliary agent is mainly dispersed in the skin layer and is immobilized on the surface of the device by fusion deposition melting (FDM); and the preparation method is simple and efficient, reduces the percolation threshold of the functional auxiliary agent and realizes multi-functionality of 3D printed devices.

Owner:FUJIAN NORMAL UNIV

Preparation method of isolated thermoplastic elastomer composite microporous electromagnetic shielding material

ActiveCN111592684AIncrease elasticityImprove conductivityMagnetic/electric field screeningBulk chemical productionElastomerThermoplastic elastomer

The invention discloses a preparation method of an isolated thermoplastic elastomer composite microporous electromagnetic shielding material. The preparation method specifically comprises the following steps: 1, adding MAX-phase ceramic powder into a hydrochloric acid / lithium fluoride mixed solution to obtain a dark green aqueous dispersion; 2, placing the thermoplastic elastomer beads in an autoclave for saturated absorption, then carrying out microcellular foaming on the completely saturated thermoplastic elastomer beads in a high-temperature foaming device to obtain thermoplastic elastomermicrocellular foamed beads with different foaming ratios; 3, immersing the thermoplastic elastomer microcellular foamed beads into the aqueous dispersion to obtain wrapped thermoplastic elastomer composite microcellular beads; and 4, putting the wrapped thermoplastic elastomer composite microporous beads into a mold, and pouring formic acid to dissolve the surfaces of the composite microporous beads, thereby obtaining the isolated thermoplastic elastomer composite microporous electromagnetic shielding material. The prepared electromagnetic shielding material has the advantages of light weight,low filling, high electromagnetic shielding efficiency and the like.

Owner:SHAANXI UNIV OF SCI & TECH

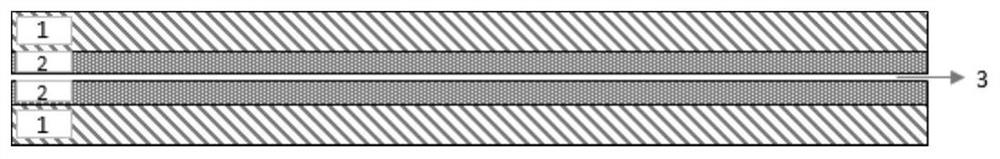

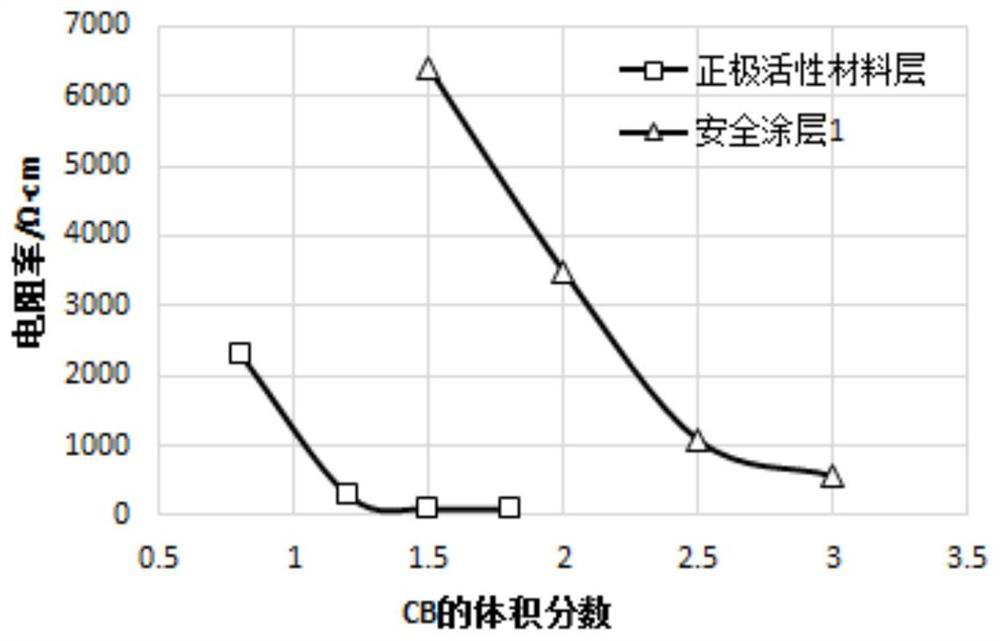

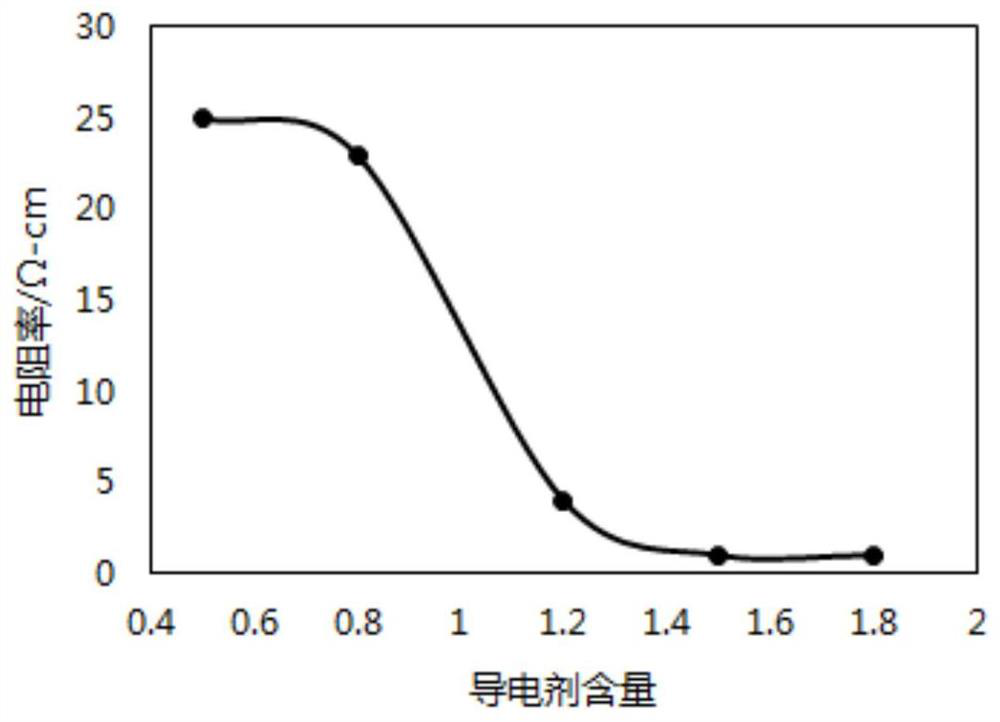

Positive plate and lithium ion battery containing positive plate

ActiveCN111900392AIncrease energy densityIncreased seepage thresholdPositive electrodesSecondary cells servicing/maintenanceHigh energyPhysical chemistry

The invention provides a positive plate and a lithium ion battery containing the positive plate. The safety of the battery cell is improved by controlling the seepage thresholds of the safety coatingcoating the surface of the positive current collector and the positive active material layer, and meanwhile, relatively high energy density and excellent electrical properties are ensured. Particularly, the seepage threshold value of the positive active material layer is small, and the addition amount of the conductive agent is small, so that a good electron path can be ensured, and the energy density of the positive plate can be increased.

Owner:ZHUHAI COSMX BATTERY CO LTD

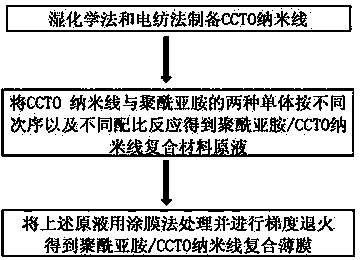

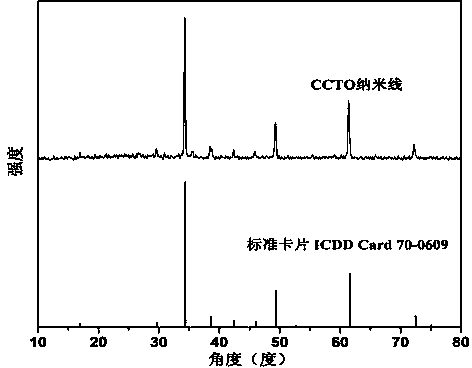

Preparation method of high-dielectric polyimide/calcium copper titanate nanowire composite material

InactiveCN103396548ALower percolation thresholdHigh dielectric constantCalcium copper titanateIn situ polymerization

The invention discloses a preparation method of a high-dielectric polyimide / calcium copper titanate nanowire composite material. The composite material is prepared by using polymer as a substrate. The method comprises the following steps: carrying out ultrasonic dispersion on calcium copper titanate nanowires in anhydrous ethanol, blending with a polyimide monomer in a solvent, and carrying out in-situ polymerization reaction on the monomer at room temperature while implementing copolymerization of polyimide and intercalation compounding with calcium copper titanate nanowires; and carrying out gradient annealing on the stock solution by a coating process to obtain the polyimide / CCTO nanowire composite film. Compared with pure polyimide, the dielectric constant of the polyimide / calcium copper titanate nanowire composite material is enhanced by 25 times, the dielectric loss is lower (0.015), and thus, the polyimide / calcium copper titanate nanowire composite material has wide application prospects in the fields of high energy storage capacitors, artificial organs, high speed integrated circuits and the like.

Owner:武汉一海数字医疗科技股份有限公司

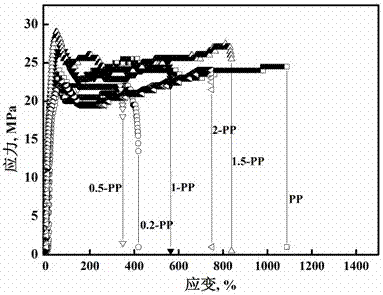

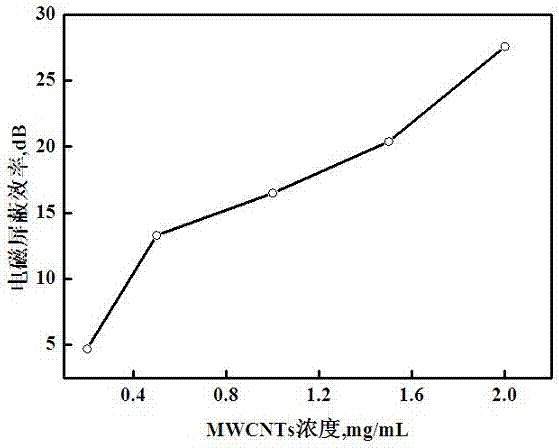

Preparation method for electromagnetic shielding PP thin film

ActiveCN107877893AEvenly dispersedImprove electromagnetic shielding performanceFlat articlesComposite filmCarbon nanotube

The invention discloses a preparation method for an electromagnetic shielding PP thin film. The preparation method for the electromagnetic shielding PP thin film comprises the following steps in sequence that 1, PP raw materials are made to a PP melt-blown nonwoven fabric by a melt-blown spinning technology; 2, a PP composite conductive fiber net modified by carboxylic multi-walled carbon nanotubes (c-MWCNTs) is prepared; and 3, the electromagnetic shielding PP thin film is prepared. The preparation method for the electromagnetic shielding PP thin film uses the carboxylic multi-walled carbon nanotubes (c-MWCNTs) to modify the PP melt-blown nonwoven fabric so as to prepare and obtain the PP composite conductive fiber net, and the PP composite conductive fiber net and a PP film are subjectedto hot pressing combination to prepare the high-performance PP electromagnetic shielding thin film; and the PP composite film is high in shielding effectiveness, and is suitable for being applied tothe field of thin films.

Owner:YANGZHOUSRKLE INDAL

Graphene filled silicone rubber composite material piezoresistive sensor and preparation method thereof

InactiveCN106495085AImprove mechanical propertiesLower percolation thresholdDecorative surface effectsForce measurement using piezo-resistive materialsPolymer scienceElectron

The invention discloses a graphene filled silicone rubber composite material piezoresistive sensor and a preparation method thereof, and belongs to the technical field of measurement. The method comprises the steps of taking grapheme whose bulk density is 0.20g / cm<3>, diameter is 5 microns, thickness is less than 15nm and carbon content is greater than 98wt% as a conductive filler and silicone rubber whose dielectric constant is 3.0 and dielectric strength is 15kV / mm as a matrix phase, preparing a piezoresistive film based on a graphene filled silicone rubber composite material by employing a solution mixing method and a spin-coating method, and then preparing the piezoresistive film and a polyimide copper cladded film into the graphene filled silicone rubber composite material piezoresistive sensor by employing a hot-pressing encapsulation method. The piezoresistive sensor prepared with the method disclosed by the invention has monotonous piezoresistive characteristic, high sensitivity, large measuring range and good flexibility, and can be applied to fields such as electronic skin preparation, curved surface interlayer pressure measurement, and the like.

Owner:CENT SOUTH UNIV

Preparation method for conductive ink with low percolation threshold

The invention discloses a preparation method for conductive ink with a low percolation threshold. The preparation method particularly comprises the following steps that silver nanowire dispersion liquid is mixed with non-conductive nano particle dispersion liquid, and silver nanowires and non-conductive nano particles are hybridized and assembled to form hybrids of the silver nanowires and the non-conductive nano particles; the hybrids are centrifuged, and supernatant liquid is discarded to obtain gelatinous hybrids of the silver nanowires and the non-conductive nano particles; the obtained hybrids are evenly mixed with macromolecular matrixes, and after the viscosity is regulated with solvent, the conductive ink with the low percolation threshold is obtained. The preparation method is simple and effective, solves the problem that at present, the silver nanowires are prone to agglomeration in the resin matrixes after the conductive ink is solidified and dried, and has a wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

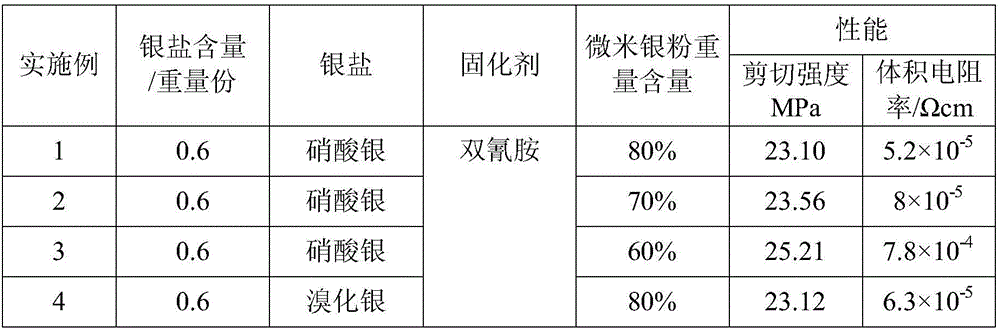

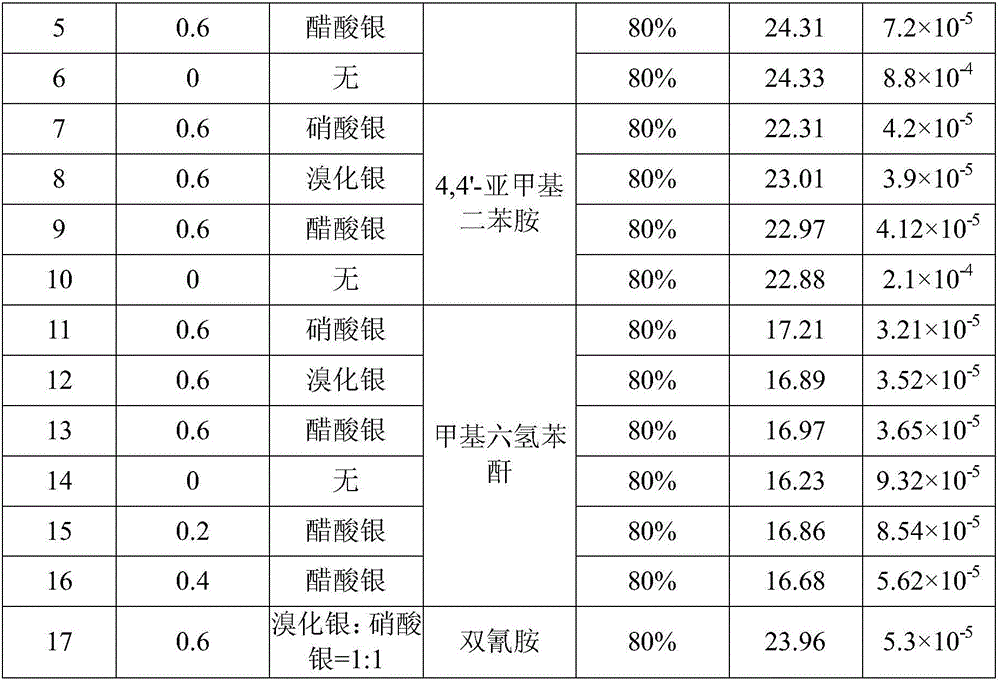

Silver salt doped silver conductive adhesive, as well as preparation method and application thereof

ActiveCN106085276AImprove conductivityIncreased shear strengthEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyAdhesive

The invention provides a silver salt doped silver conductive adhesive, as well as a preparation method and application thereof. The silver salt doped silver conductive adhesive is prepared from the following raw materials in parts by weight: 0.01 to 5 parts of silver salt, 50 to 85 parts of micron silver powder, 10 to 50 parts of epoxy resin, 0.5 to 60 parts of a curing agent, 0.05 to 5 parts of an accelerator, 0.05 to 5 parts of a coupling agent, 1 to 10 parts of a diluent and 0.05 to 2 parts of an anti-precipitant. According to the preparation method, the silver salt is introduced into the formula of the silver conductive adhesive in a doping manner, so that the using amount of the silver powder can be reduced by 15 to 20 percent on the premise of ensuring the conductivity of the silver conductive adhesive; under the same addition of the silver powder, the electrical conductivity of the silver conductive adhesive is greatly improved, and moreover, the silver conductive adhesive has strong shear strength and high aging resistance; the prepared silver salt doped silver conductive adhesive can be widely applied to the fields of solar cell, IC (integrated circuit) and LED (light-emitting diode) packaging and the like.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of static-conductive PVC (polyvinyl chloride) mining pipe

The invention discloses a preparation method of a static-conductive PVC (polyvinyl chloride) mining pipe. The method comprises the following steps: (1) adding a PVC resin and a two-dimensional-plane-structure nano carbon material into a kneader, and kneading to obtain a PVC / nano carbon master batch; and (2) proportionally adding the PVC resin, conductive carbon black, a compatibilizer, a heat stabilizer, lubricant and processing aids into the PVC / nano carbon master batch, stirring and mixing, and carrying out melting and extrusion forming to obtain the mining pipe finished product. The method can enhance the static conductivity of the PVC mining pipe, and can also enhance the impact resistance, corrosion resistance, heat stability and other properties of the PVC mining pipe.

Owner:DEYANG CARBONENE TECH

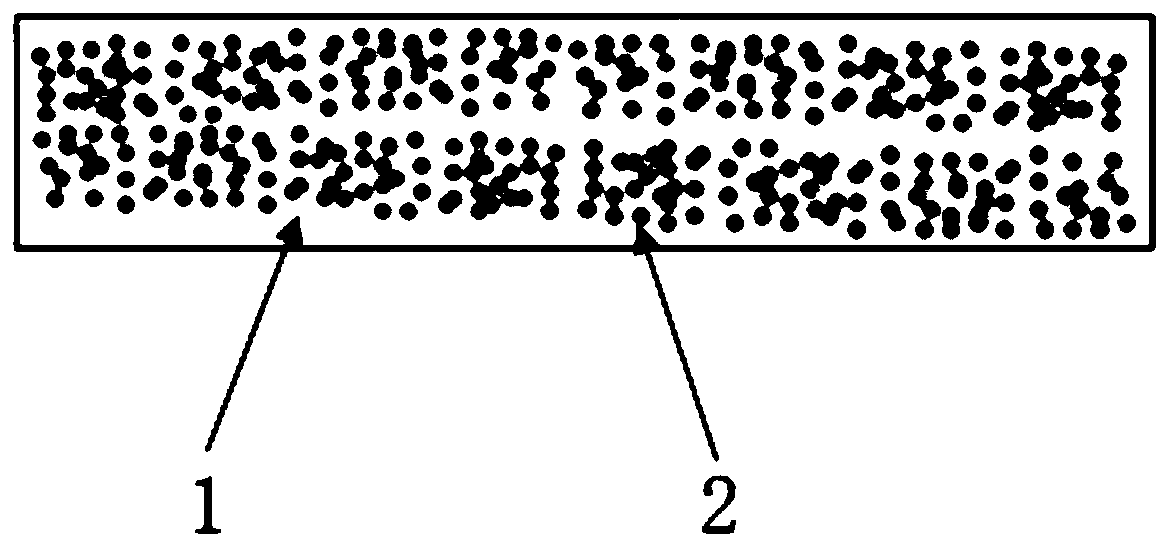

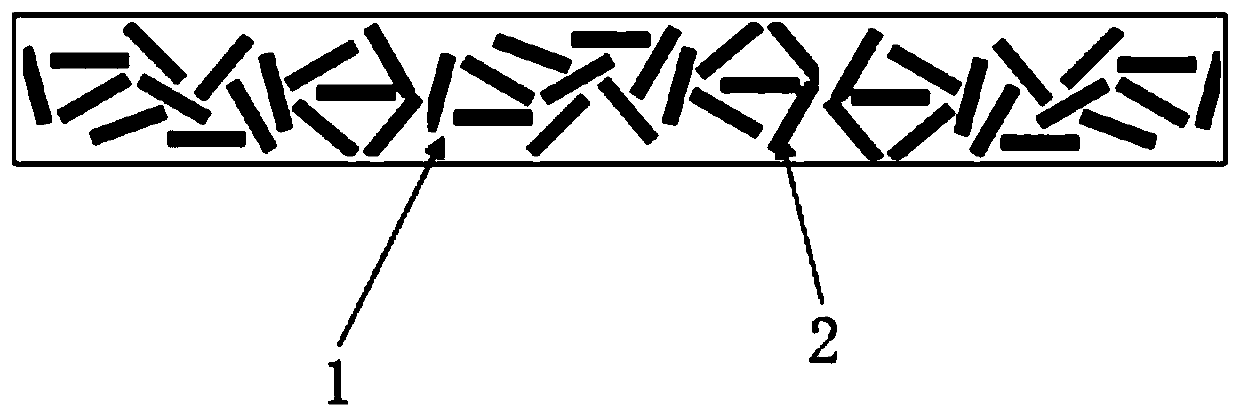

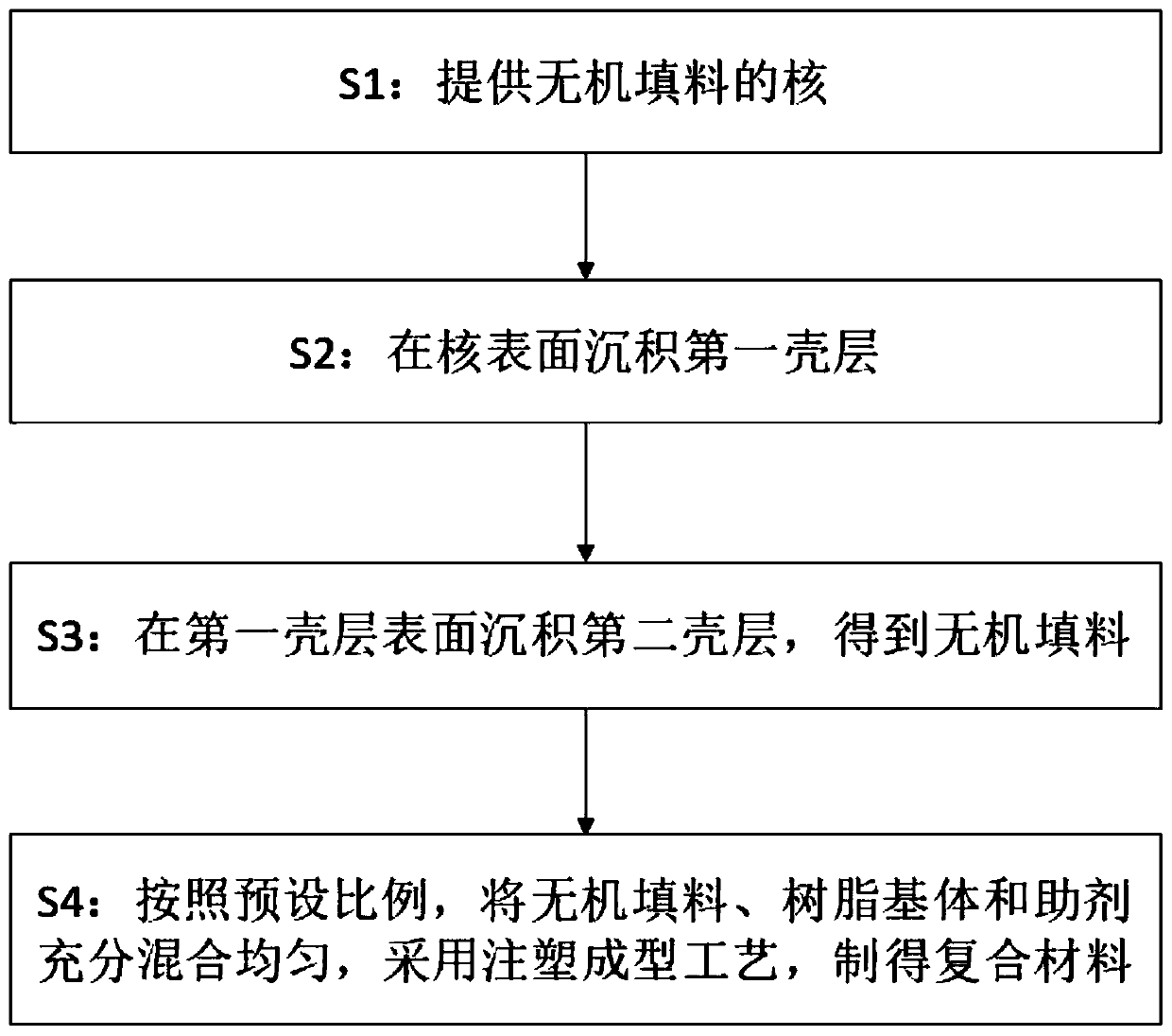

Resin matrix composite and preparing method thereof

The invention discloses a resin matrix composite and a preparing method thereof. The composite is a composite which is mainly composed of a resin matrix and an inorganic filler dispersed in the resinmatrix, wherein the inorganic filler is of a double-layer core-shell structure. The inorganic filler is composed of a core prepared from an insulating material, a first shell layer covering the core and a second shell layer covering the first shell layer, wherein the material of the first shell layer has conductivity, and the material of the second shell layer has insulativity. According to the composite, by optimizing the structure of the inorganic filler, the inorganic filler has different properties of insulativity and conductivity, the volume proportion of the inorganic filler is lowered,the dielectric constant can also be increased, and the dielectric loss can be lowered.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

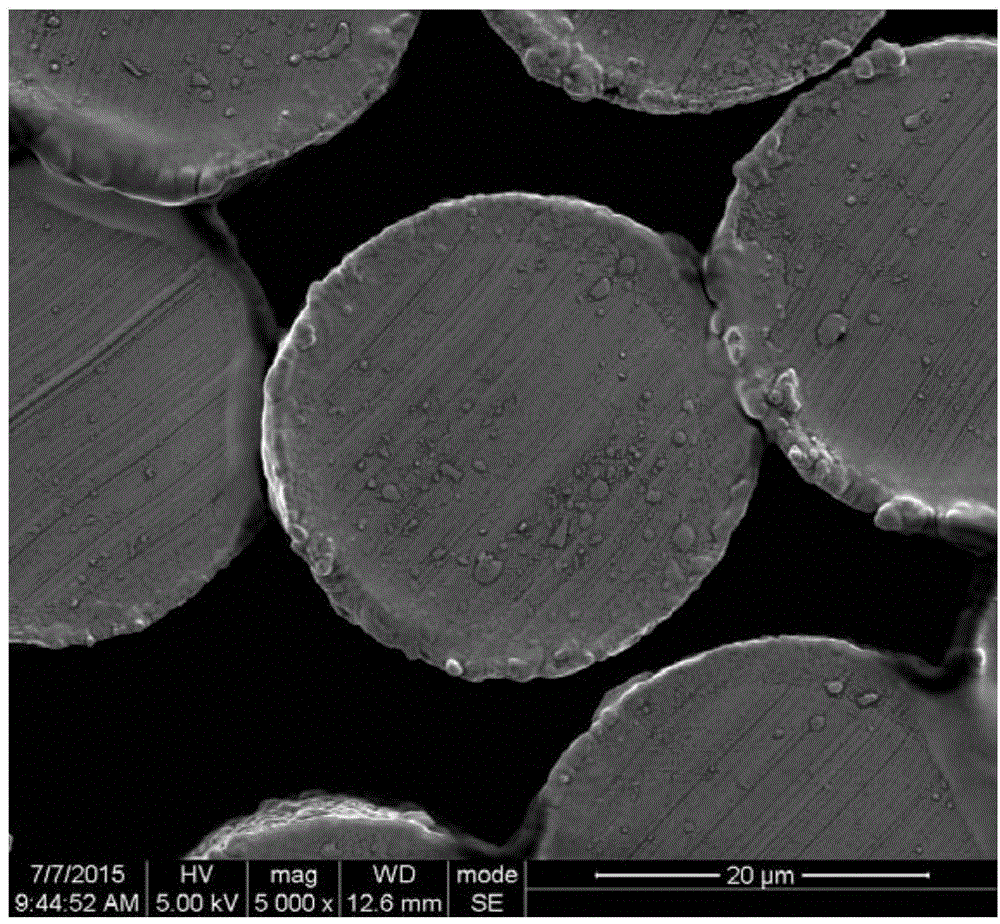

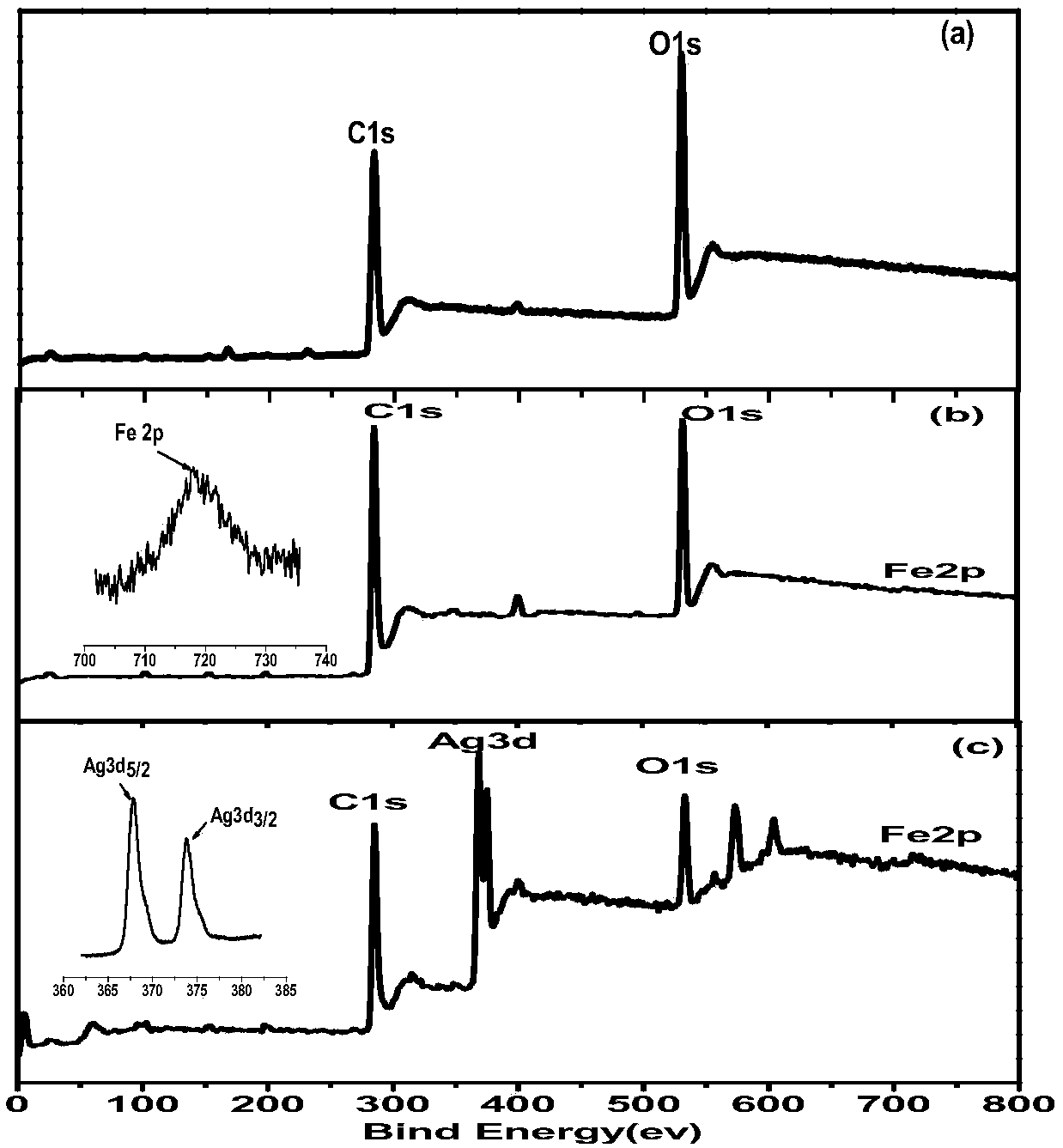

Preparation method for secondarily-silver-plated highly-conductive filling material

ActiveCN109423636AShorten the timeSimple and fast operationLiquid/solution decomposition chemical coatingSilver plateUltrasonic dispersion

The invention discloses a preparation method for a secondarily-silver-plated highly-conductive filling material. The preparation method comprises the following steps: 1) subjecting a substrate to ultrasonic dispersion in deionized water, successively adding tannic acid and a ferric trichloride solution, and carrying out uniform mixing under stirring so as to obtain a substrate surface-deposited with polytannic acid-ferric trichloride; 2) dissolving the obtained substrate in deionized water, adding a silver nitrate solution and ethylene glycol, and carrying out reducing with octylamine so as toobtain a substrate having silver nanoparticle on the surface after primary silver plating; 3) titrating a silver nitrate solution with ammonia until a precipitate just disappears so as to prepare a silver plating solution; 4) placing the substrate having the silver nanoparticle on the surface into the silver plating solution prepared in the step 3), adding a dispersant, and carrying out stirring;and 5) adding a reducing agent solution so as to obtain a substrate with silver layer covered surface. The preparation method provided by the invention is simple and convenient to operate, greatly shortens the time of modification, realizes uniform and compact silver plating, and prepares a composite material with excellent bonding stability and electrical conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of conductive composite material

InactiveCN104650438ALower percolation thresholdLow room temperature resistivityCompression moldingManufactured material

The invention provides a preparation method of a conductive composite material and belongs to the field of material preparation. The preparation method is characterized by comprising the following steps: soaking graphene micro-flakes and an ultrahigh-molecular weight polyethylene powder in ethanol and performing ultrasonic dispersion by use of an ultrasonic cell smasher to form a uniformly distributed suspension; performing suction filtration and vacuum drying to remove the ethanol solvent, so that the graphene micro-flakes are evenly attached on the surface of the ultrahigh-molecular weight polyethylene particles; finally, performing compression molding on the obtained material, and then cooling to a room temperature under a constant pressure, thereby obtaining a raw material. The preparation process is improved, so that a more complete and stable effective conductive network structure can be formed inside the conductive composite material, and therefore, the percolation threshold of the material is greatly reduced, and the material has the maximum peak resistivity and relatively low room temperature resistivity. The preparation method of the conductive composite material is simple to operate, simple and convenient in process, and suitable for popularization and utilization in the related fields.

Owner:王兴

Polyester/graphite nano-conductive composite material and its preparation method

InactiveCN1903935AImprove mechanical propertiesImprove heat resistanceOther chemical processesMagnetic/electric field screeningMaterials preparationPolyester

The present invention relates to a polyester / gypsum nano electrical conductive composite material and its preparation method, belonging to the field of electrical conductive composite material preparation technology. It is formed from main base body polyester, auxiliary base body and gypsum according to the mixing ratio of 100:5-60:2-40. Said invention has lower percolation threshold (3-4%), and when the gypsum content is 4%, its conductivity can be upto 10 to the pwer-6 s / cm.

Owner:YANGZHOU UNIV

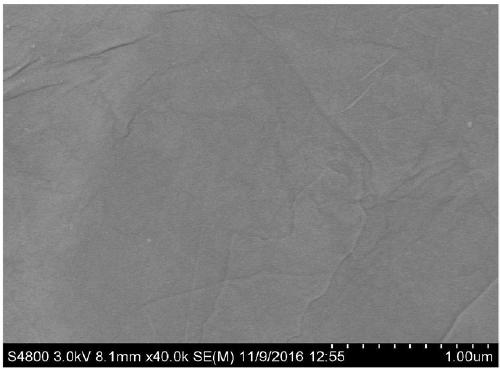

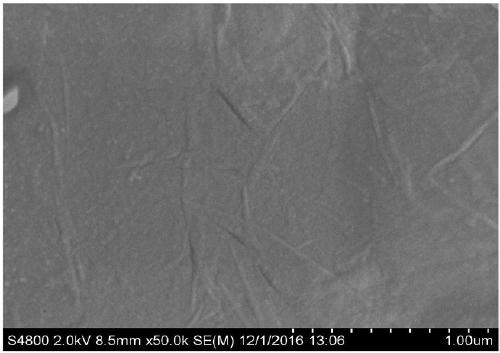

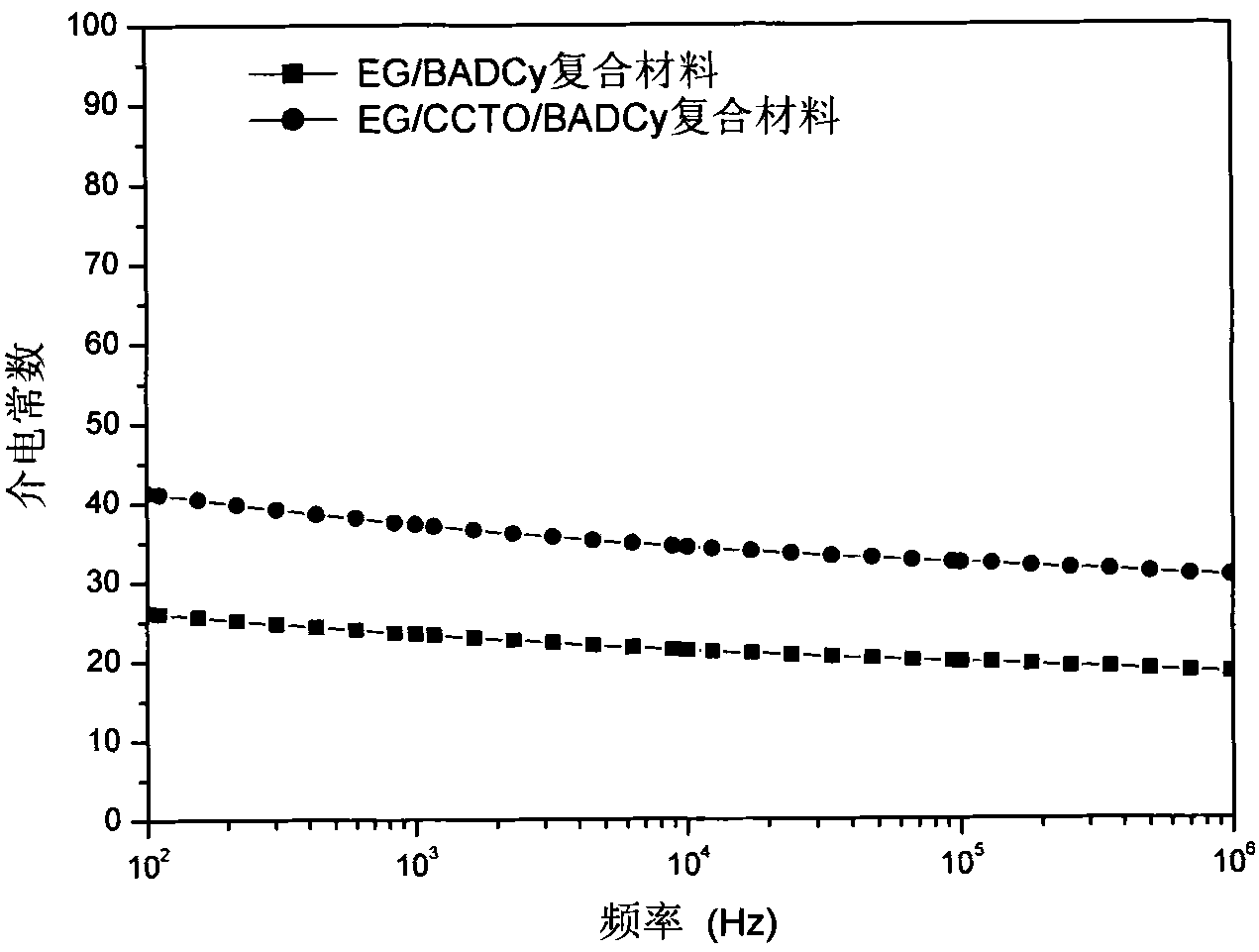

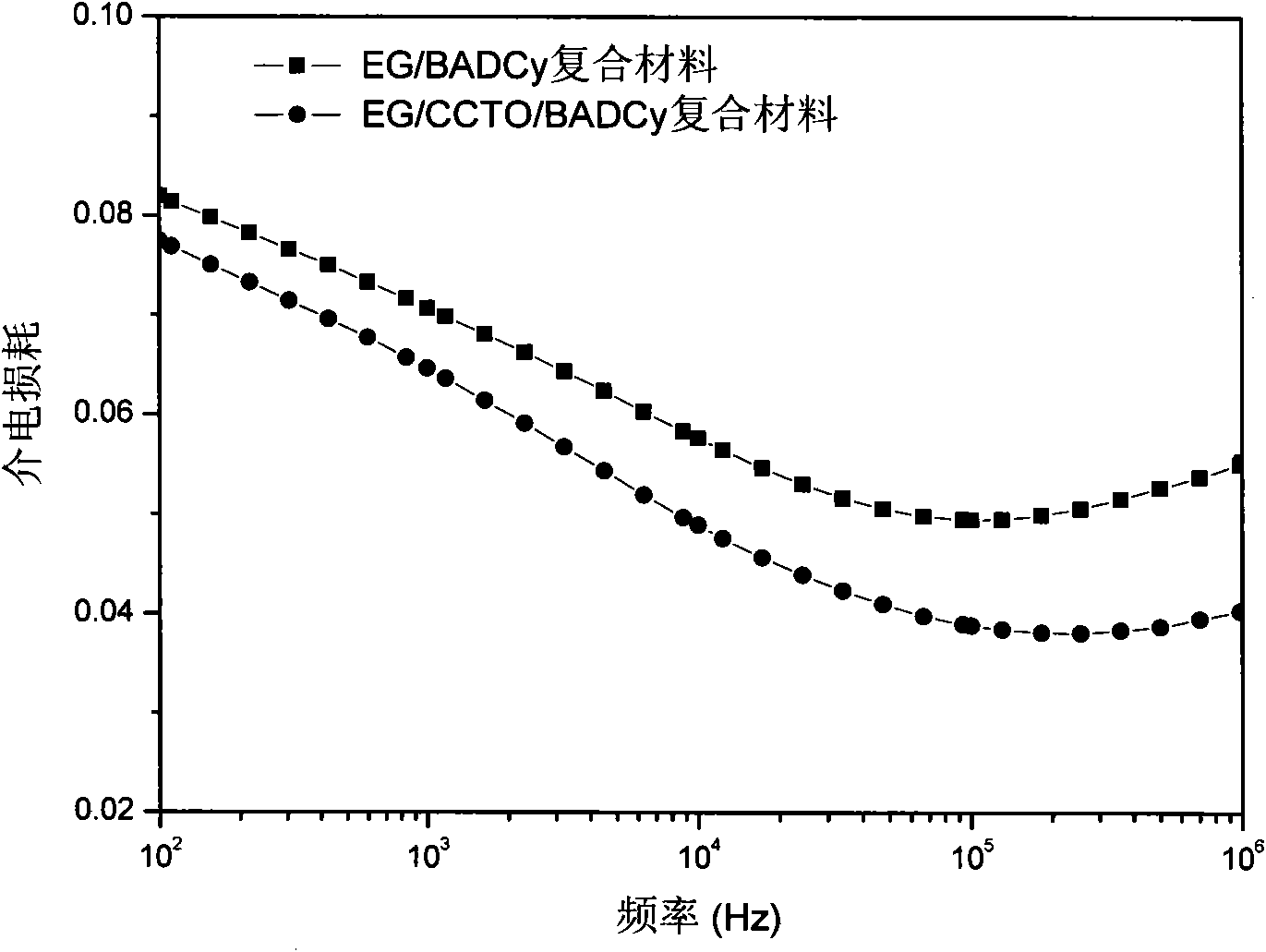

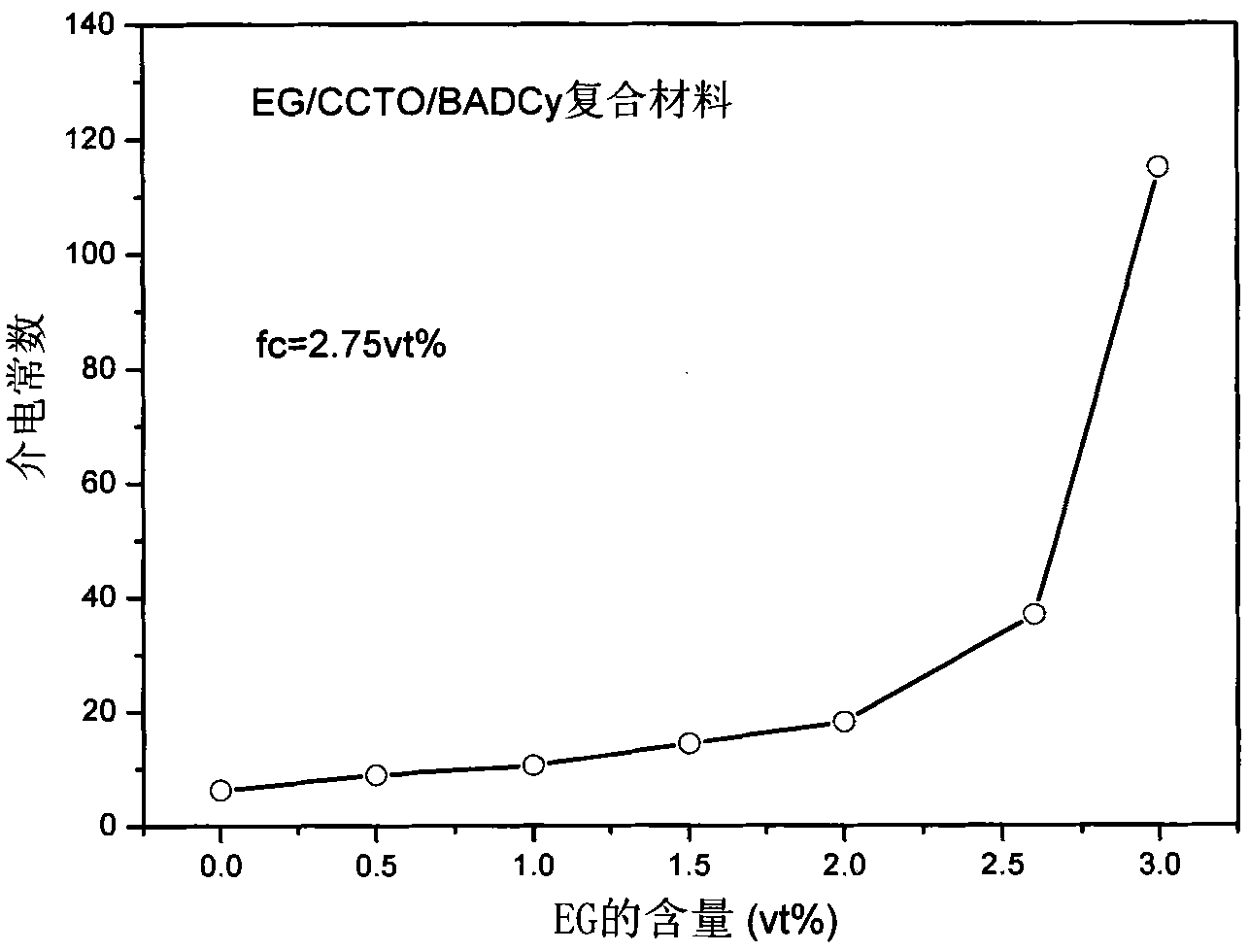

Cyanate resin base composite material and preparation method thereof

The invention discloses a cyanate resin base composite material with a low percolation threshold and a high dielectric constant and a preparation method thereof. The cyanate resin base composite material is characterized by comprising the following components by volume: 10%-15% of calcium copper titanate, 0.5%-3.0% of expanded graphite sheets and 89.5%-82.0% of cyanate, wherein the granularity of the calcium copper titanate ranges from 1 micrometer to 2 micrometers; the diameters of the expanded graphite sheets are 10-50 micrometers, and radius-thickness ratio is between 300 and 500. The preparation method of the cyanate resin base composite material comprises the following steps of: mixing the calcium copper titanate, the expanded graphite sheets and the cyanate; and melting at 80-100 DEG C, then raising temperature to 120-150 DEG C, and pre-polymerizing until obvious sedimentation of the calcium copper titanate and the expanded graphite sheets exists. The invention can obviously enhance the dielectric constant of the cyanate resin base composite material by regulating the relative content of added components in the cyanate resin base composite material and utilizing synergistic effect generated among physically and chemically treated components, has the advantages of great low percolation threshold, low dielectric loss, good heat resistance, low cost, simple preparation method, and the like and has wide application prospect in the fields of electronic engineering, electrical engineering, and the like as a composite material with the high dielectric constant.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com