Electroconductive slurry and preparation method thereof, and printed circuit material

A technology of conductive paste and resin, applied in conductive materials, printed circuit components, circuits, etc. dispersed in non-conductive inorganic materials, can solve the problems that the cost and conductivity cannot be optimized at the same time, and the percolation threshold is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

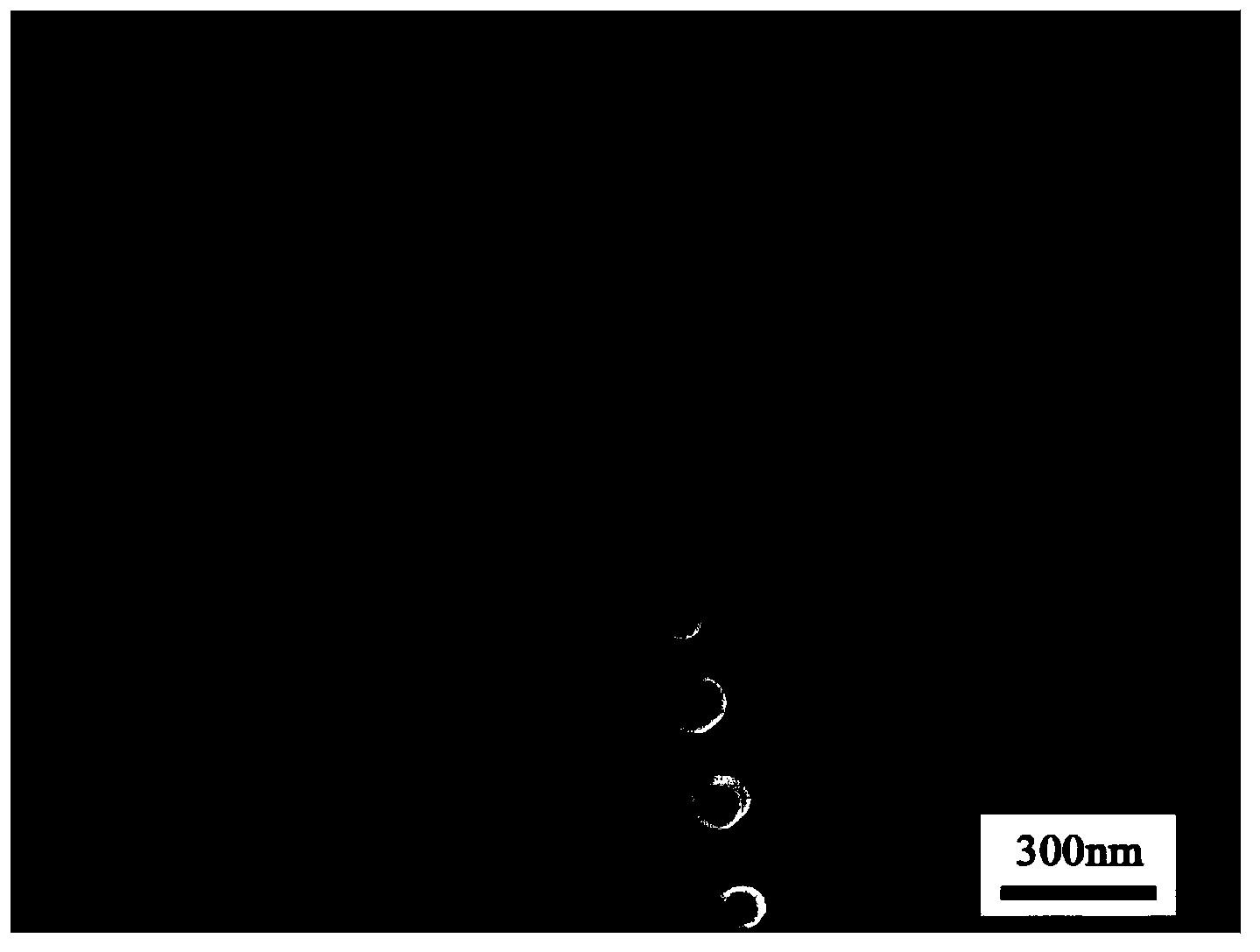

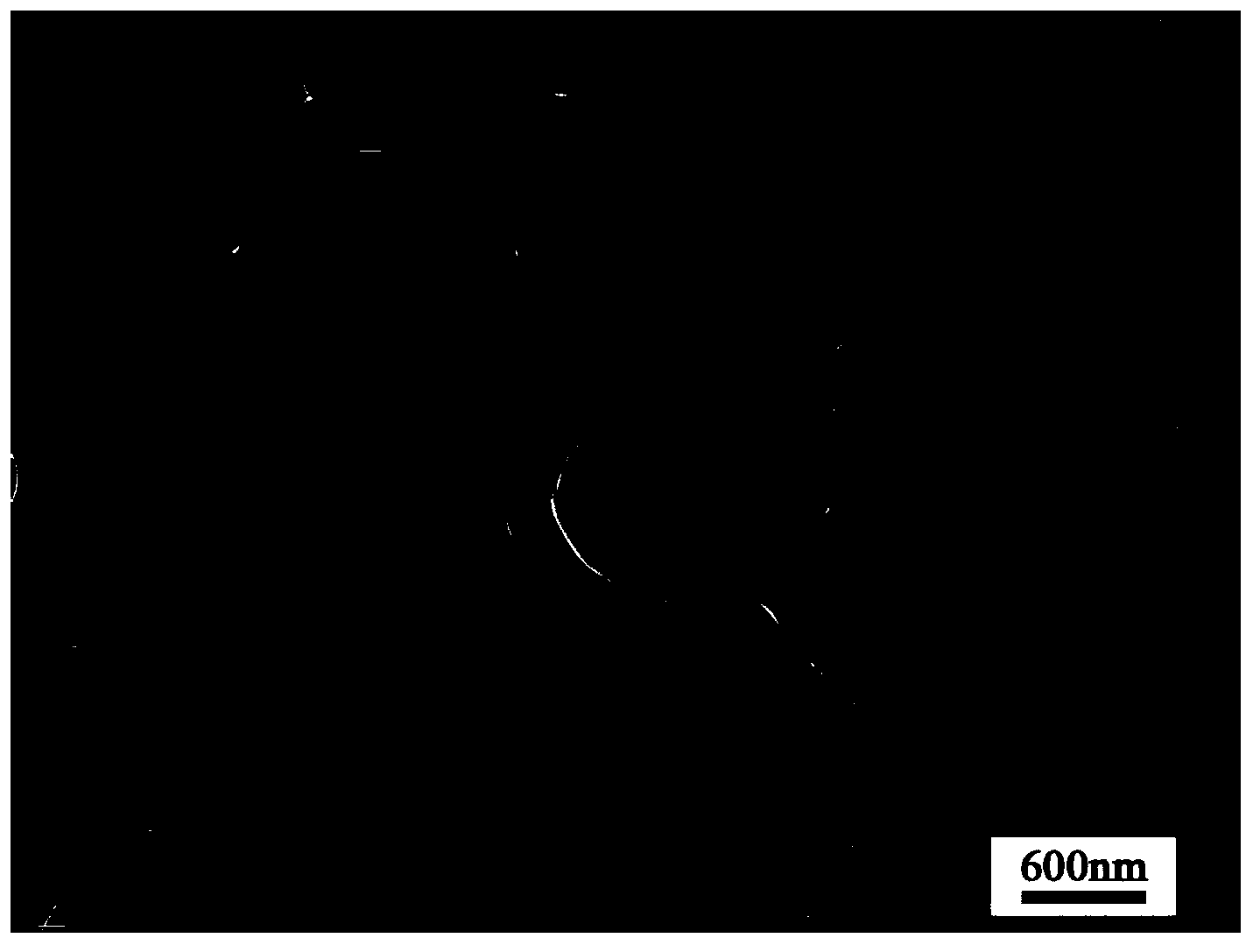

[0030] In this specific embodiment, a method for preparing conductive paste is also provided, which includes the following steps: 1) preparing a polymer resin matrix and a metal powder whose microstructure is a three-dimensional dendritic metal crystal structure; the diameter of the metal crystal structure is 0.5 microns to 50 microns, the length of the secondary dendritic structure is 5 nanometers to 5 microns; 2) Mix the polymer resin matrix and the metal powder to obtain a mixture; 3) Prepare the conductive paste after curing the mixture material.

[0031] Preferably, when mixing in step 2), auxiliary materials such as curing agent and / or catalyst are added and mixed together. In this way, auxiliary materials can be added according to application requirements to improve the performance of the conductive paste. When mixing, a high-speed shear mixer can be used to fully mix the materials.

[0032] Further preferably, before step 3) is solidified, step 2') may be included to...

Embodiment 1

[0036] The silver metal powder used as conductive filler is prepared, wherein the microscopic structure of the silver metal powder is a three-dimensional dendritic silver dendrite structure, the diameter of the structure is 0.5 microns to 50 microns, and the length of the secondary dendritic structure is 5 nanometers to 5 microns. Mix 2 g of dry three-dimensional dendritic silver dendrite powder with 1.10 g of bisphenol A epoxy resin (EPON828) and 0.89 g of curing agent methyltetrahydrophthalic anhydride (MTHPA) for 15 minutes under high-speed stirring (Stirring rate is 1500 rpm). Then 0.01 gram of hexamethylenetetramine used as a catalyst on cure was added and mixing was continued for 5 minutes. The mixture was then degassed for 5 minutes, screen printed, and the samples were cured at 160 °C for 15 minutes. After curing, the conductive paste 1 was prepared, wherein the mass fraction of the silver filler was 2 / (2+1.10+0.89+0.01)=50%. Observing the surface of the conductive p...

Embodiment 2

[0039] The silver metal powder used as conductive filler is prepared, wherein the microscopic structure of the silver metal powder is a three-dimensional dendritic silver dendrite structure, the diameter of the structure is 0.5 microns to 50 microns, and the length of the secondary dendritic structure is 5 nanometers to 5 microns. Mix 2 g of dry three-dimensional dendritic silver dendrite powder with 1.65 g of bisphenol A epoxy resin (EPON828) and 1.32 g of curing agent methyltetrahydrophthalic anhydride (MTHPA) for 15 minutes under high-speed stirring (Stirring rate is 1500 rpm). Then 0.03 grams of hexamethylenetetramine was added as a catalyst on cure and mixing was continued for 5 minutes. The mixture was then degassed for 5 minutes, screen printed, and the samples were cured at 160 °C for 15 minutes. After curing, the conductive paste 2 was prepared, wherein the mass fraction of the silver filler was 2 / (2+1.65+1.32+0.03)=40%. Observing the surface of the conductive paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com