High-electrodeformation dielectric elastomer composite and preparation method thereof

A dielectric elastomer and electro-induced deformation technology, applied in the field of dielectric elastomers, can solve the problems of reduced breakdown field strength of composite materials, the maximum electro-induced deformation is only 5.68%, and achieve the effect of suppressing the depletion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

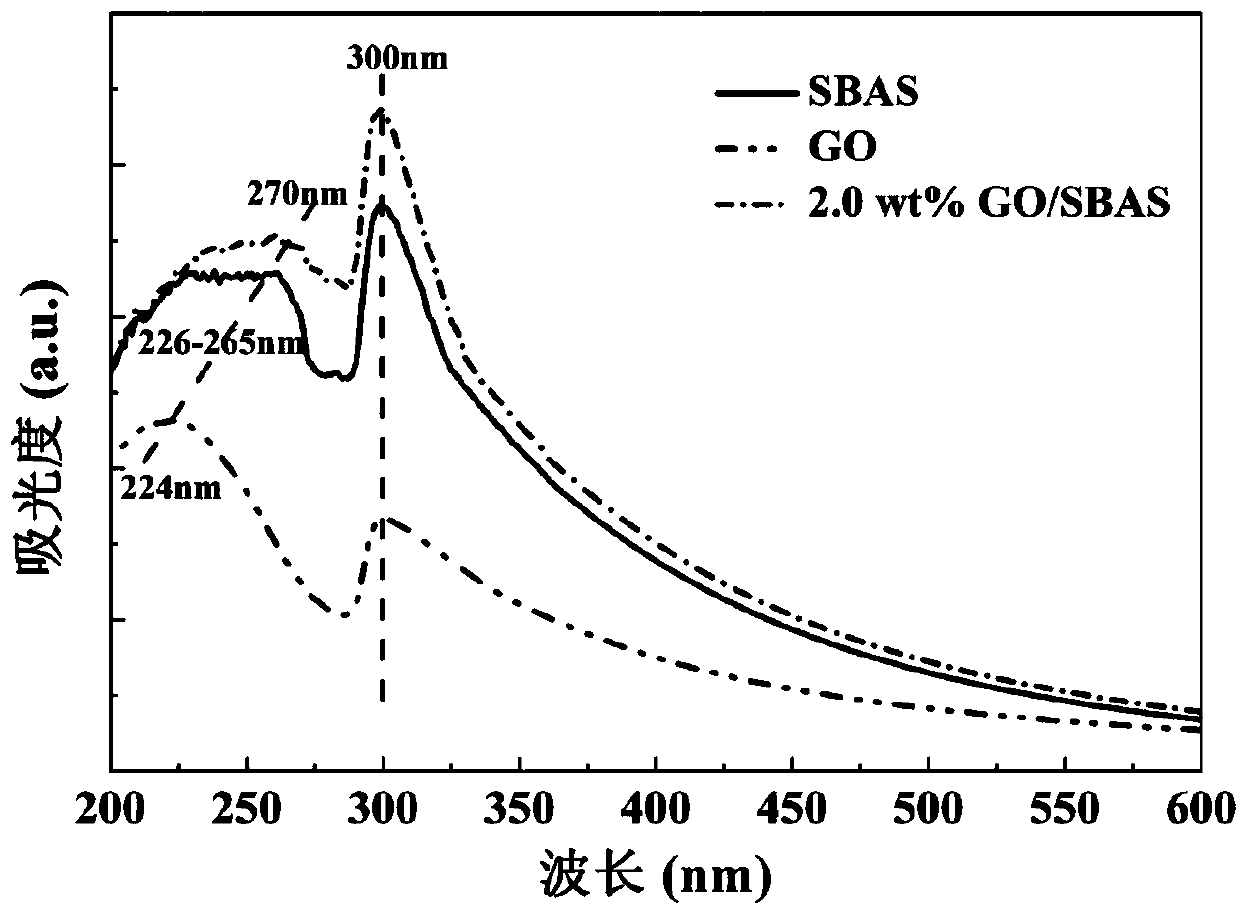

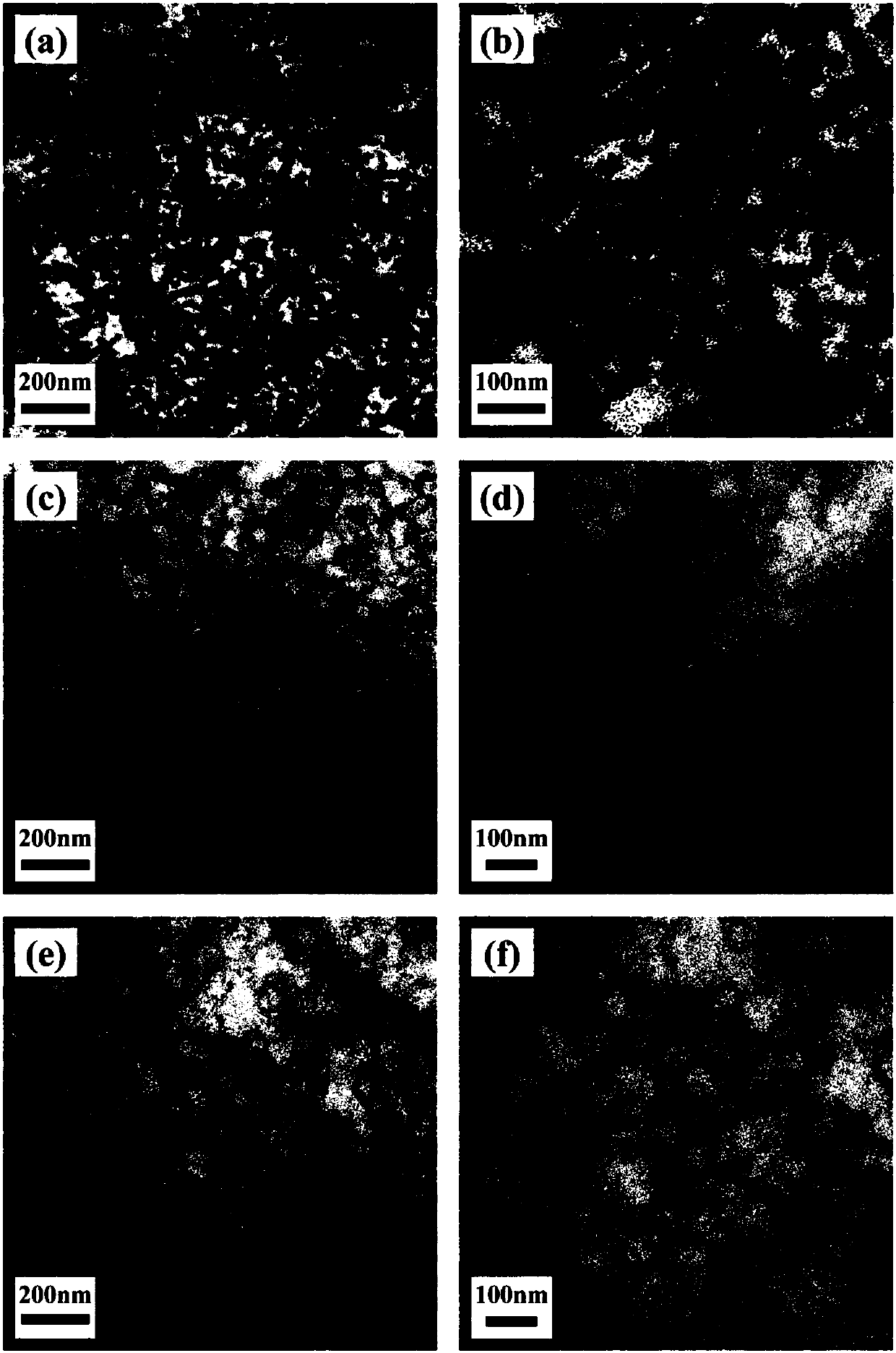

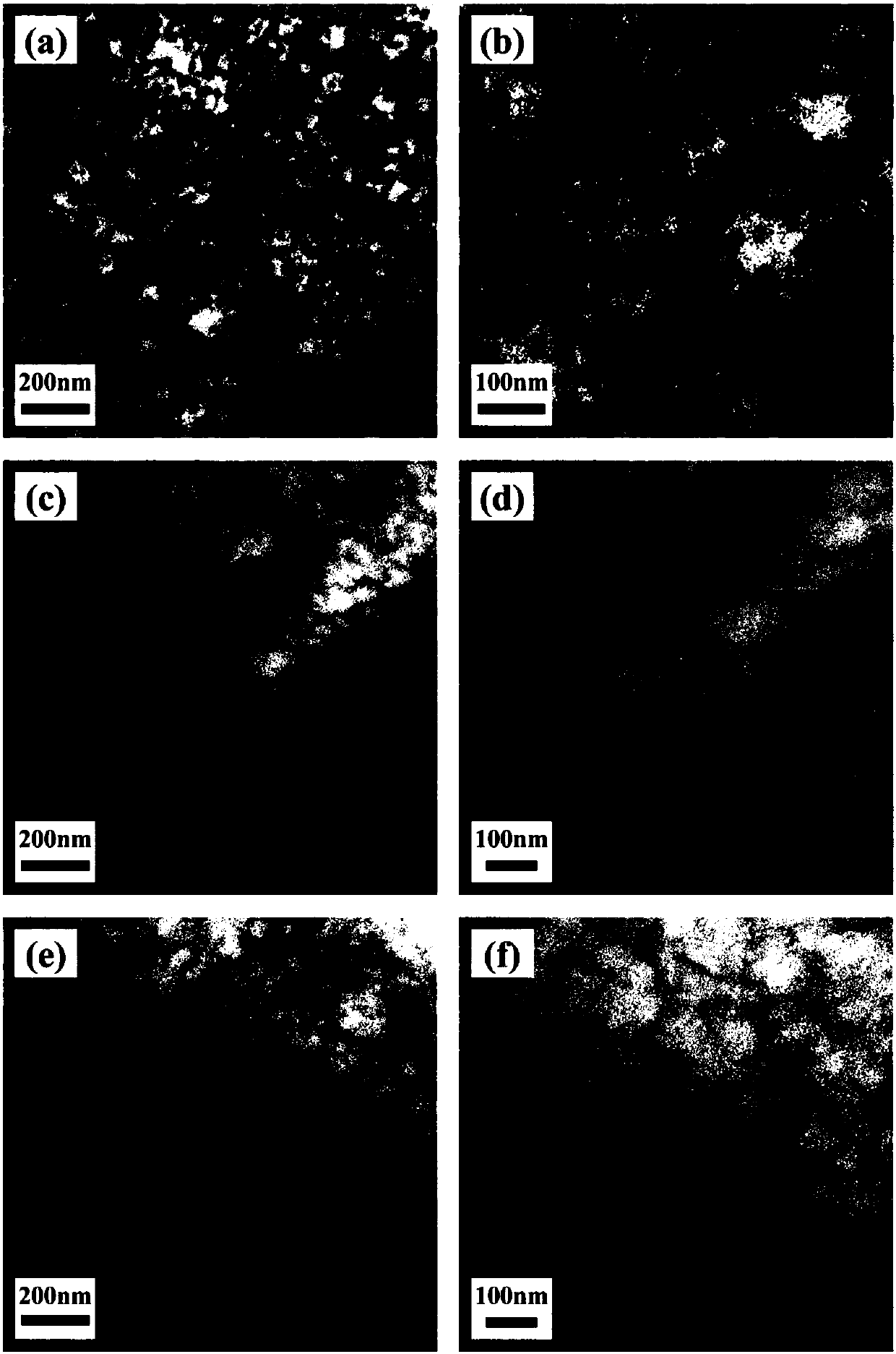

[0032] The first step: adding 2.0 parts by mass of GO to 600 parts by mass of water, sonicating at 600W for 2 hours to obtain a uniformly dispersed GO aqueous dispersion;

[0033] Step 2: Mix 300 parts by mass of SBAS triblock copolymer latex with a molecular chain structure of 15k-170k-15k and a latex solid content of 33.6wt% with 600 parts by mass of the GO aqueous dispersion obtained in step (1) , Shake and stir for 12 hours to obtain the composite latex of the two;

[0034] The third step: Put the GO / SBAS composite latex in a polytetrafluoroethylene watch glass, evaporate the water at 25℃, and then place it in a 75℃ vacuum oven to dry and cool for 12 hours to obtain GO / SBAS Composite membrane

[0035] The fourth step: the GO / SBAS composite membrane is thermally reduced at 180°C for 4 hours to prepare the RGO / SBAS composite membrane.

Embodiment 2

[0037] The first step: adding 1.5 parts by mass of GO to 450 parts by mass of water, sonicating at 600W for 2 hours to obtain a uniformly dispersed aqueous GO dispersion;

[0038] Step 2: Mix 300 parts by mass of SBAS triblock copolymer latex with a molecular chain structure of 15k-170k-15k and a latex solid content of 33.6wt% with 450 parts by mass of the GO aqueous dispersion obtained in step (1) , Shake and stir for 12 hours to obtain the composite latex of the two;

[0039] The third step: Put the GO / SBAS composite latex in a polytetrafluoroethylene watch glass, evaporate the water at 25℃, and then place it in a 75℃ vacuum oven to dry and cool for 12 hours to obtain GO / SBAS Composite membrane

[0040] The fourth step: the GO / SBAS composite membrane is thermally reduced at 180°C for 4 hours to prepare the RGO / SBAS composite membrane.

Embodiment 3

[0042] Step 1: Add 1.0 parts by mass of GO to 300 parts by mass of water, and ultrasonically treat at 600W for 2 hours to obtain a uniformly dispersed GO aqueous dispersion;

[0043] Step 2: Mix 300 parts by mass of SBAS triblock copolymer latex with a molecular chain structure of 15k-170k-15k and a latex solid content of 33.6wt% with 300 parts by mass of the GO aqueous dispersion obtained in step (1) , Shake and stir for 12 hours to obtain the composite latex of the two;

[0044] The third step: Put the GO / SBAS composite latex in a polytetrafluoroethylene watch glass, evaporate the water at 25℃, and then place it in a 75℃ vacuum oven to dry and cool for 12 hours to obtain GO / SBAS Composite membrane

[0045] The fourth step: the GO / SBAS composite membrane is thermally reduced at 180°C for 4 hours to prepare the RGO / SBAS composite membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com