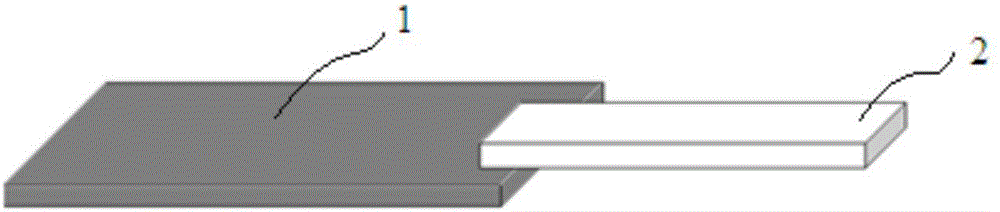

Surface-treated metal, surface treatment method of metal and metal and resin composite body

A surface treatment and metal technology, which is applied in the field of metal and resin composites, can solve the problems of large product size, reduce the bonding strength of aluminum alloy and resin, and fall off, so as to increase the contact probability, improve the connection strength, and enhance the bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

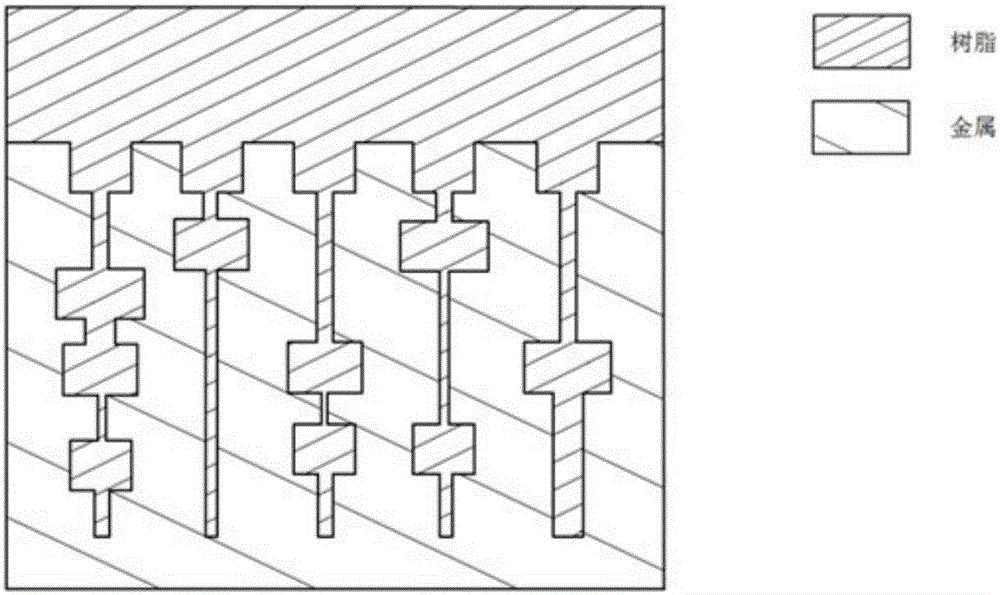

[0047] Pretreatment: Cut a commercially available 1mm thick 5052 aluminum alloy plate into 450mm*150mm rectangular pieces, put it into acetone solution, clean it ultrasonically for 15 minutes, and then rinse it with deionized water to obtain the pretreated aluminum alloy plate. alloy sheet.

[0048] Multi-stage anodizing treatment:

[0049] 1. Put the aluminum sheet that has undergone conventional surface pretreatment as the anode into the electrolytic cell for polishing. The electrolyte is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:3, and electrolyze at a constant voltage of 40V for 3 minutes;

[0050] 2. Put the metal substrate as the anode in the 0.8M oxalic acid solution, the voltage is 40V, the temperature is 50°C, and the treatment is 0.6h;

[0051] 3. In composition of 2% H 2 CrO 4 +10%H 3 PO 4 Soak in the chromium-phosphorus mixed acid solution for 25 minutes, the temperature during soaking is maintained at 50°C, and then rinse with d...

Embodiment 2

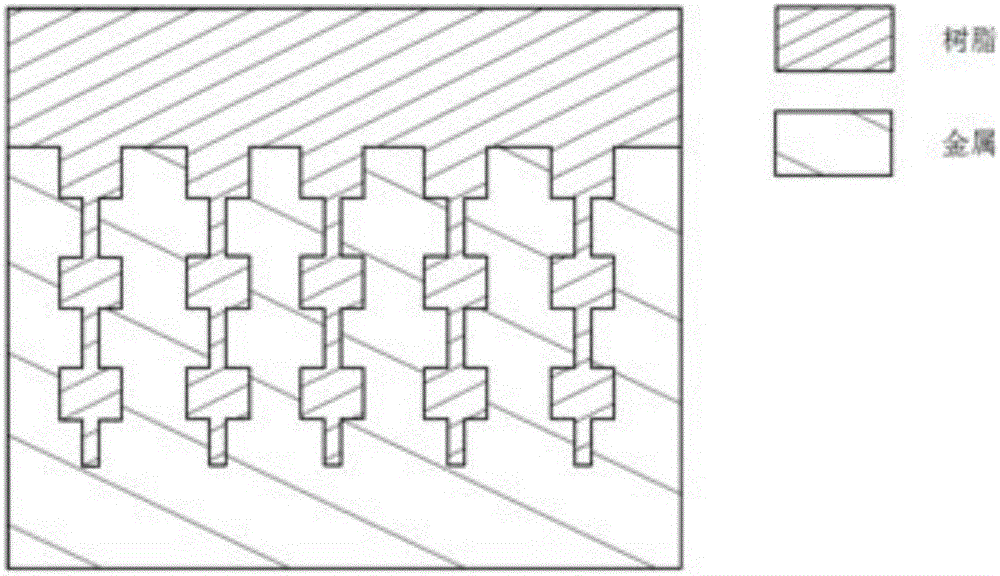

[0059] Pretreatment: Cut a commercially available 1mm thick 5052 aluminum alloy plate into 450mm*150mm rectangular pieces, put it into acetone solution, clean it ultrasonically for 15 minutes, and then rinse it with deionized water to obtain the pretreated aluminum alloy plate. alloy sheet.

[0060] Multi-stage anodizing treatment:

[0061] 1. Put the aluminum sheet that has undergone conventional surface pretreatment as the anode into the electrolytic cell for polishing. The electrolyte is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:3, and electrolyze at a constant voltage of 40V for 3 minutes;

[0062] 2. Put the metal substrate as the anode in the 0.8M oxalic acid solution, the voltage is 40V, the temperature is 50°C, and the treatment is 0.6h;

[0063] 3. In composition of 2% H 2 CrO 4 +10%H 3 PO 4 Soak in the chromium-phosphorus mixed acid solution for 25 minutes, the temperature during soaking is maintained at 50°C, and then rinse with d...

Embodiment 3

[0071] Pretreatment: Cut a commercially available 1mm thick 5052 aluminum alloy plate into 450mm*150mm rectangular pieces, put it into acetone solution, clean it ultrasonically for 15 minutes, and then rinse it with deionized water to obtain the pretreated aluminum alloy plate. alloy sheet.

[0072] Multi-stage anodizing treatment:

[0073] 1. Put the aluminum sheet that has undergone conventional surface pretreatment as the anode into the electrolytic cell for polishing. The electrolyte is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:3, and electrolyze at a constant voltage of 40V for 3 minutes;

[0074] 2. Put the metal substrate as the anode in the 0.8M oxalic acid solution, the voltage is 40V, the temperature is 50°C, and the treatment is 0.6h;

[0075] 3. In composition of 2% H 2 CrO 4 +10%H 3 PO 4 Soak in the chromium-phosphorus mixed acid solution for 25 minutes, the temperature during soaking is maintained at 50°C, and then rinse with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com