Dual-carrier modified ternary alloy nano-cavity catalyst as well as preparation method and application thereof

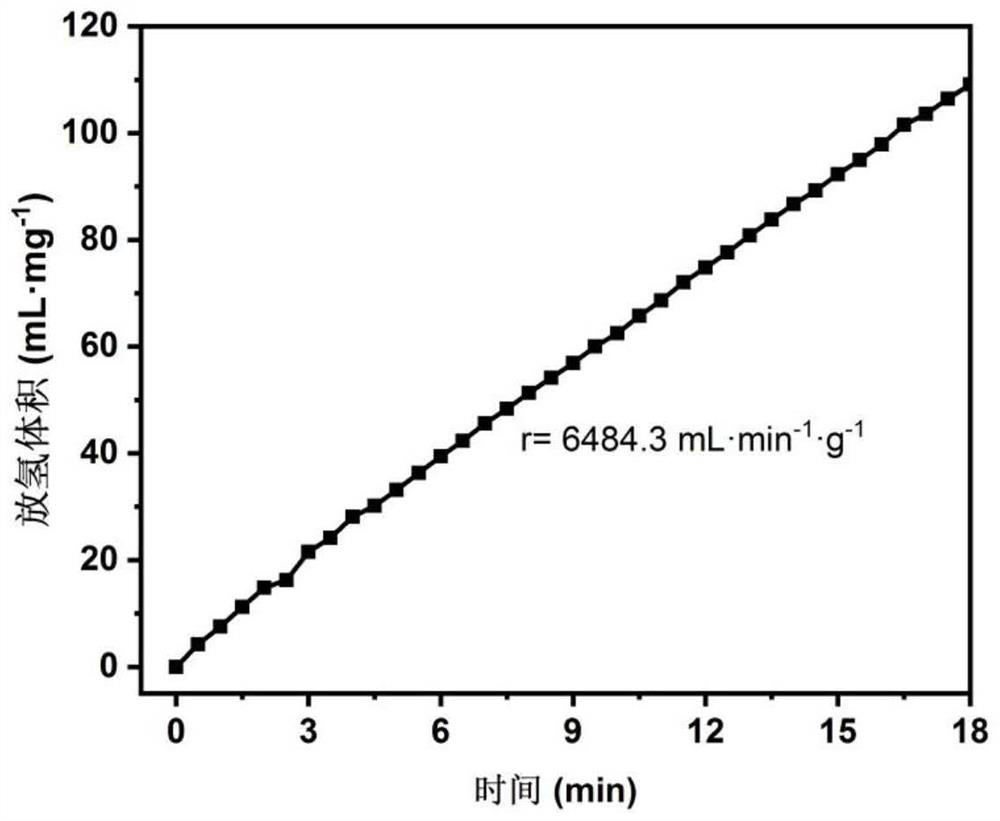

A ternary alloy and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of slow development of hydrogen production, achieve low preparation cost, and be easy to use and produce , the effect of increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Take 0.1g g-C 3 N 4 Ultrasonic dispersion into 80 mL of deionized water to prepare a coarse dispersion system A;

[0048] 2) get 1.1896g cobalt chloride hexahydrate, 1.6487g sodium tungstate dihydrate, 4.5042g glycine and join in above-mentioned coarse dispersion system A, magnetic stirring makes it dissolve, forms dispersion system B;

[0049] 3) Ultrasound for dispersion system B for 1 h, adjust the pH to 11, and prepare dispersion system C;

[0050]4) Take 1.5132g of sodium borohydride and slowly add it into the dispersion system C of step 3), and carry out magnetic stirring for 0.5h;

[0051] 5) put the pretreated nickel foam carrier into the dispersion system formed in the above step 4), and the reaction time is 5min;

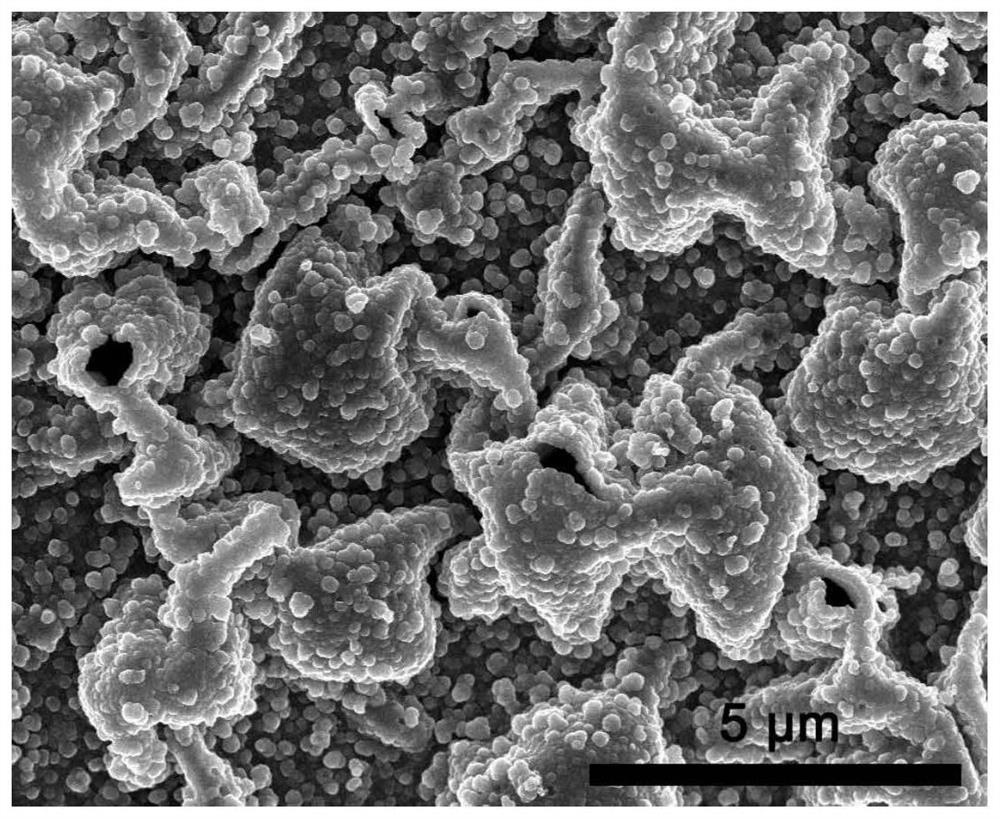

[0052] 6) after the reaction finishes, take out the nickel foam, and obtain g-C through washing and vacuum drying 3 N 4 Co-W-B nanocavity catalyst modified with foamed Ni double carrier, the scanning electron microscope image of the catalyst...

Embodiment 2

[0057] 1) Take 0.01g g-C 3 N 4 Ultrasonic dispersion into 80 mL of deionized water to prepare a coarse dispersion system A;

[0058] 2) get 1.1896g cobalt chloride hexahydrate, 1.6487g sodium tungstate dihydrate, 4.5042g glycine and join in above-mentioned coarse dispersion system A, magnetic stirring makes it dissolve, forms dispersion system B;

[0059] 3) Ultrasound for dispersion system B for 1 h, adjust pH to 10, and make dispersion system C;

[0060] 4) Take 1.5132g of sodium borohydride and slowly add it into the dispersion system C of step 3), and carry out magnetic stirring for 1h;

[0061] 5) put the pretreated nickel foam carrier into the dispersion system formed in the above step 4), and the reaction time is 10min;

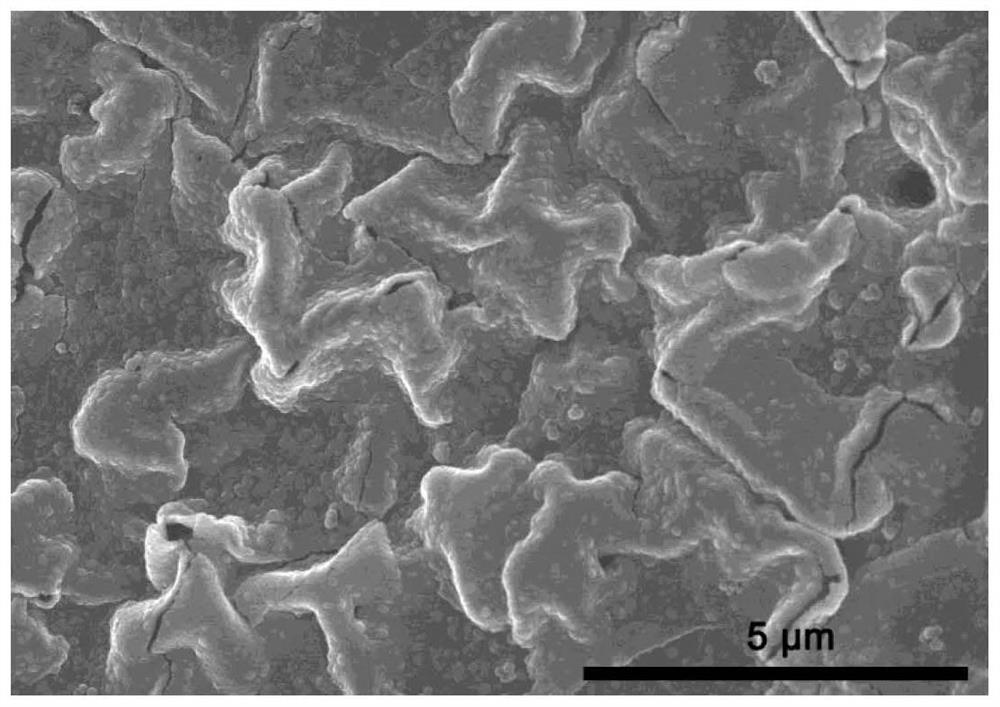

[0062] 6) after the reaction finishes, take out the nickel foam, and obtain g-C through washing and vacuum drying 3 N 4 and Co-W-B nanocavity catalysts modified with foamed Ni double supports. The scanning electron microscope image of the catalys...

Embodiment 3

[0067] 1) Take 2g g-C 3 N 4 Ultrasonic dispersion into 80 mL of deionized water to prepare a coarse dispersion system A;

[0068] 2) get 2.3792g cobalt chloride hexahydrate, 1.6487g sodium tungstate dihydrate, 4.5042g glycine and join in above-mentioned coarse dispersion system A, magnetic stirring makes it dissolve, forms dispersion system B;

[0069] 3) Ultrasound for dispersion system B for 2 hours, adjust pH to 13.5, and prepare dispersion system C;

[0070] 4) Take 1.5132g of sodium borohydride and slowly add it into the dispersion system C of step 3), and carry out magnetic stirring for 1h;

[0071] 5) put the pretreated nickel foam carrier into the dispersion system formed in the above step 4), and the reaction time is 10min;

[0072] 6) after the reaction finishes, take out the nickel foam, and obtain g-C through washing and vacuum drying 3 N 4 Co-W-B nanocavity catalyst modified with foamed Ni double carrier, the scanning electron microscope image of the catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com