Device and method for treating molten steel in tundish by utilizing rare earth

A technology of tundish and molten steel, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the physical and chemical properties of covering agents, incomplete deterioration of inclusions, low recovery rate of rare earth elements, etc., and achieve good Diffusion and melting properties, avoiding burning loss, and increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

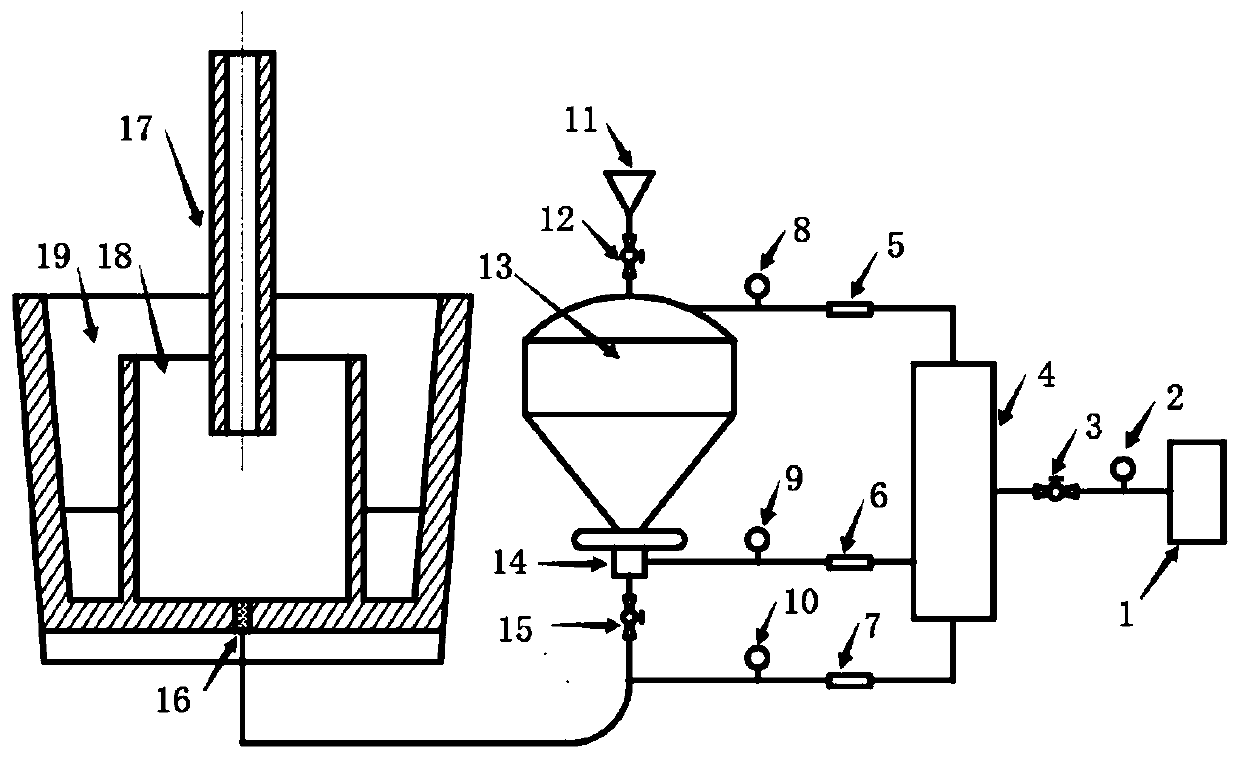

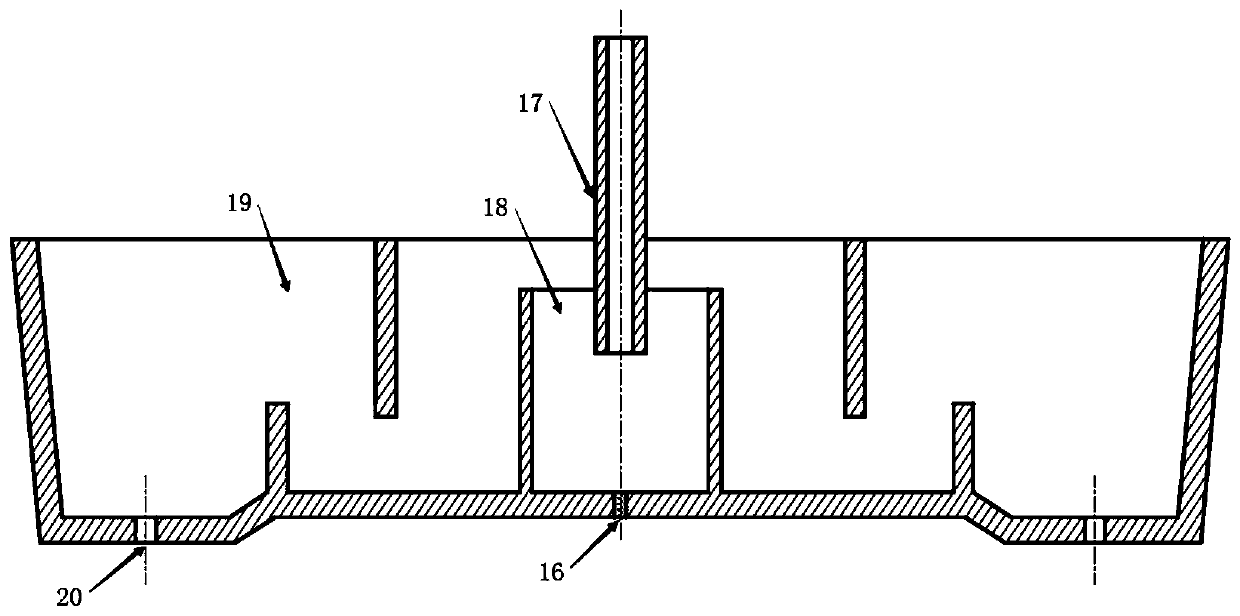

[0036] like Figure 2-5As shown, a device for treating molten steel with rare earth in a tundish includes a tundish body 19, a cylindrical reactor 18 and a powder spraying device. The cylindrical reactor 18 is located at the center of the tundish body 19, and its bottom center Ventilation holes are left, and ventilation elements 16 are provided; the ventilation holes and ventilation elements 16 are located at the center of the bottom of the cylindrical reactor 18; molten steel flows into the cylindrical reactor 18 through the long nozzle 17 of the ladle and is fully mixed with the rare earth powder And after the reaction, it flows into the tundish body 19 from the upper edge of the cylindrical reactor 18, and the air-permeable element 16 adopts slit-type air-permeable bricks. The amount of rare earth powder added needs to be determined according to the number of continuous casting furnaces, the total amount of molten steel, and the purpose of adding rare earth elements. The ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height range | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com