Photoelectric compound catalysis fluid purification method

A fluid purification, photoelectric composite technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as low photocatalytic quantum efficiency, achieve improved catalytic conversion efficiency, broad-spectrum oxidation and conversion capacity, increase The effect of contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

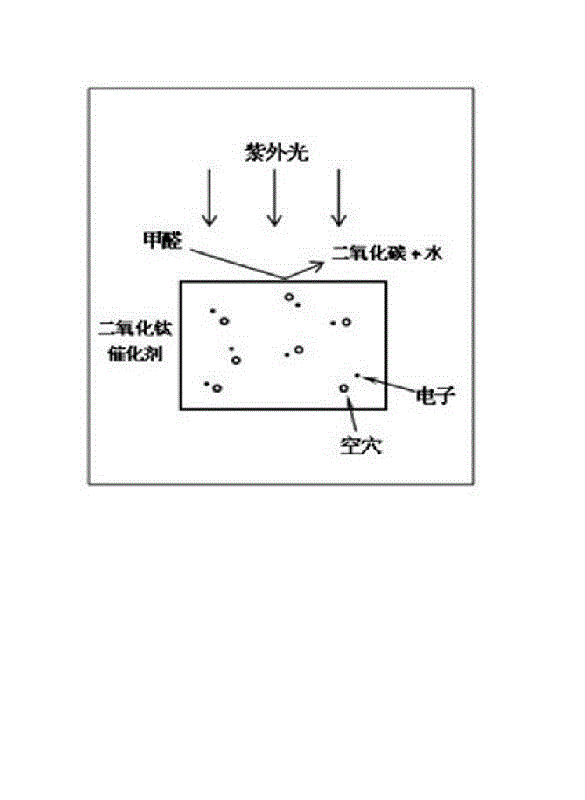

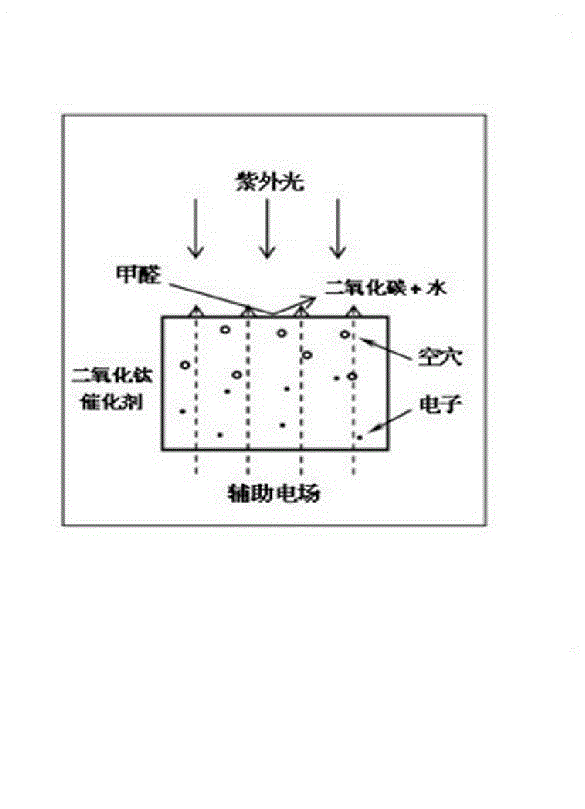

[0027] Embodiment one: Purify the mixed gas of 1% formaldehyde and air

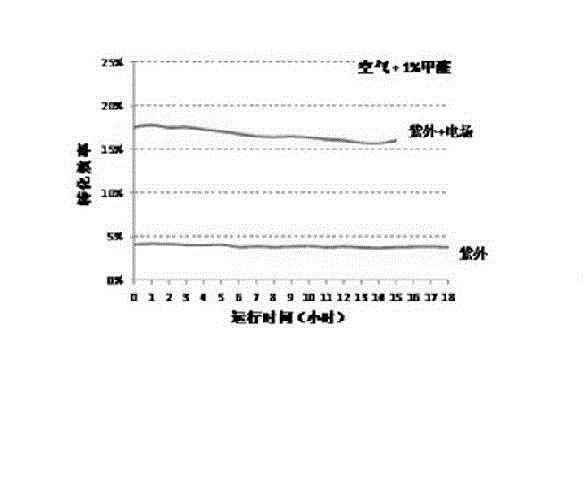

[0028] The simulated pollution gas is a mixture of 1.0%±0.01% formaldehyde and air. The catalyst is titanium dioxide catalyst (TiO 2 ). The ultraviolet light source is an 83W low-pressure mercury lamp. The auxiliary electric field is a static DC voltage of 90 volts. The direction of the electric field is perpendicular to the movement direction of the fluid medium formed by the air in the purification container. The reactant gas composition was analyzed online using a Fuji ZRJ-3 infrared gas analyzer. Test time: 18 hours for conventional photocatalysis; 15 hours for photoelectric composite catalysis. The simulated gas is injected once per hour, and the conversion rate is measured at the same time.

[0029] The experimental results show that after applying the coupled electric field, the oxidation efficiency of formaldehyde is greatly improved, from image 3 As shown, the conversion rate of formaldehy...

Embodiment 2

[0030] Embodiment two: purify the mixed gas of 3% methane and air

[0031] The simulated pollution gas is a mixture of 3.0%±0.01% formaldehyde and air. The catalyst is titanium dioxide catalyst (TiO 2 ). The ultraviolet light source is an 83W high-pressure mercury lamp. The auxiliary electric field is a static DC voltage of 75 volts. The direction of the electric field is perpendicular to the movement direction of the fluid medium formed by the air in the purification container. The reactant gas composition was analyzed online using a Fuji ZRJ-3 infrared gas analyzer. Test time: 14 hours for conventional photocatalysis and photoelectric composite catalysis.

[0032] Experimental results show that after applying a coupled electric field, the oxidation efficiency of methane is also greatly improved, from 10%. like Figure 4 Shown is the change curve of methane conversion rate (ordinate, unit: %) with reaction time (abscissa, unit: hour). It can be seen that the auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com