3D/2D ni-co double metal oxide/g-c 3 no 4 Nanocomposite materials and their preparation methods and applications

A g-c3n4, nanosheet technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of limiting the photocatalytic performance of pure catalysts, narrow visible light response range, low specific surface area, etc., to achieve effective The effect of photocatalytic degradation, promotion of photocatalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] 2D g-C 3 N 4 Preparation of nanosheets

[0027] First, add a certain amount of urea into the aluminum crucible with lid, put it in a muffle furnace, cover the lid, and carry out the first calcination; then collect the product, adjust the calcination temperature and heating rate for the second calcination, and obtain a light yellow product for g-C 3 N 4 Nanosheets.

[0028] 3D / 2D Ni-Co Bimetal Oxide / g-C 3 N 4 Preparation of nanocomposites

[0029] First, nickel nitrate hexahydrate (Ni(NO 3 ) 3 ·6H 2 O), sodium citrate (Na 3 C 6 H 5 O 7 ·2H 2 O) and g-C 3 N 4 The nanosheets were evenly mixed in water to obtain solution A, and the cobalt potassium cyanide (K 3 [Co(CN) 6 ]) Dissolved in water to obtain a colorless and transparent solution B, mixed solution A and solution B, centrifuged and washed after aging to obtain light blue Ni-Co Prussian blue / g-C 3 N 4 precursor, which was then transferred to a muffle furnace for calcination to obtain Ni-Co bimetal...

Embodiment 1

[0038] 2D g-C 3 N 4 Preparation of nanosheets: First, add 10 g of urea to an aluminum crucible with a lid, put it in a muffle furnace, cover with the lid, and calcine at 550 °C for 4 h at a heating rate of 2.5 °C·min -1 (room temperature to 550 °C), after the muffle furnace was cooled to room temperature, a yellow solid was obtained; then the obtained yellow solid was spread in a rectangular crucible, and then calcined at 500 °C for 2 h at a heating rate of 5 °C min -1 (room temperature to 500°C), the light yellow product, namely two-dimensional g-C, was collected. 3 N 4 Nanosheets.

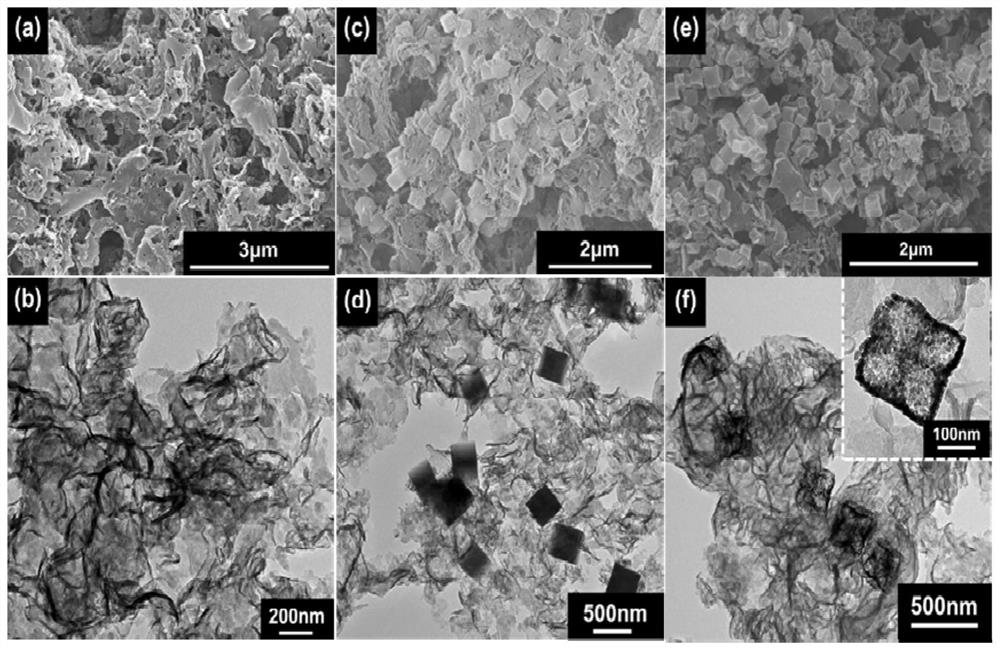

[0039] In order to observe the morphology of the material, the products prepared in this example were characterized by scanning electron microscopy and transmission electron microscopy. figure 1 is the two-dimensional g-C prepared in this example 3 N 4 SEM images and TEM images of nanosheets, (a) and (b) are g-C prepared in this example, respectively 3 N 4 nanosheets, called CNs.

Embodiment 2

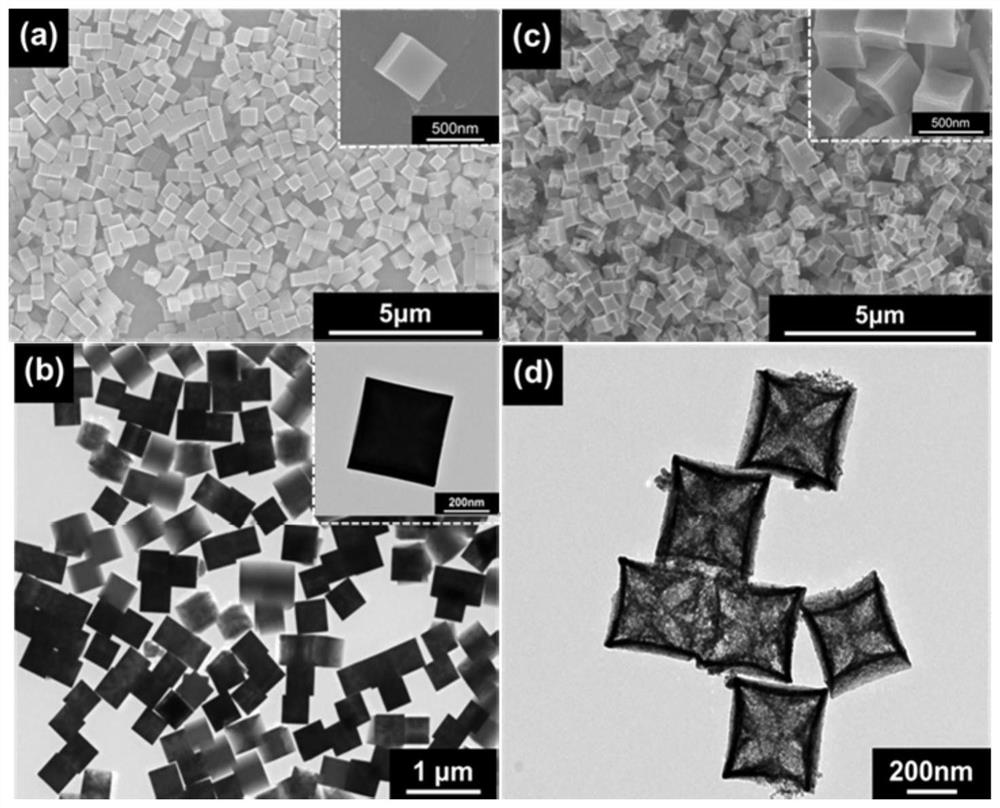

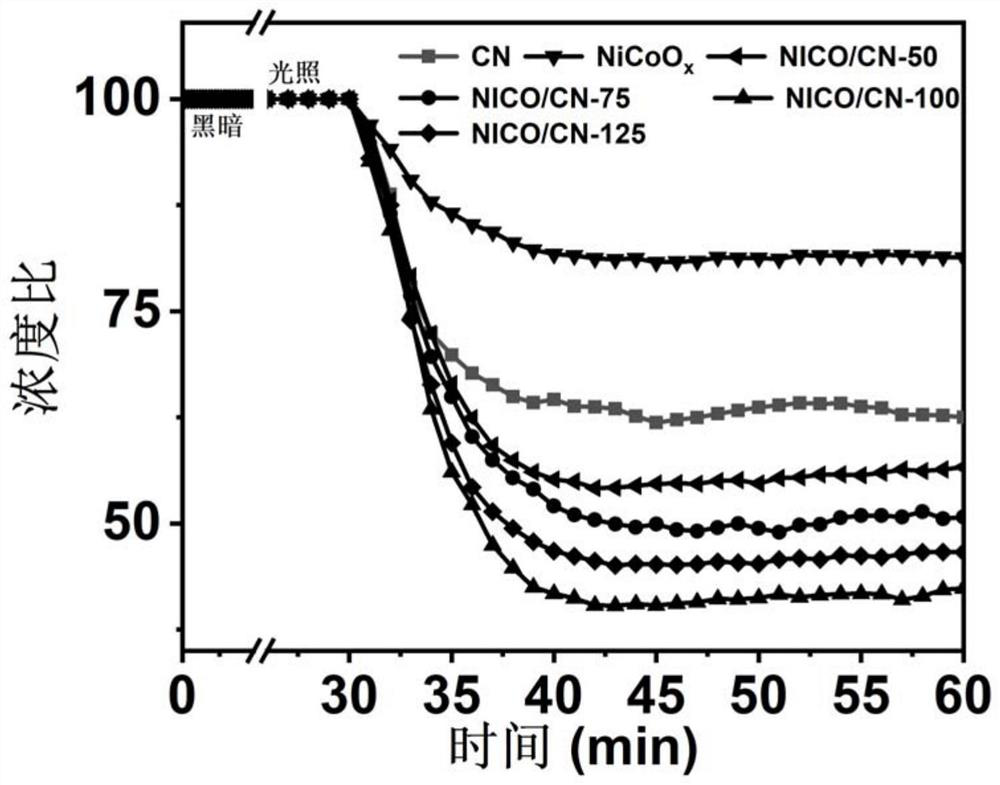

[0041] Ni-Co bimetal oxide / g-C 3 N 4 Preparation of nanocomposites: First, 100 mg of nickel nitrate hexahydrate (Ni(NO 3 ) 3 ·6H 2 O), 162.5 mg sodium citrate (Na 3 C 6 H 5 O 7 ·2H 2 O) and 150 mg g-C 3 N 4 The nanosheets were dispersed in 20 ml of deionized water, and the solution A was formed by conventional stirring; 200 mg of potassium cobalt cyanide (K 3 [Co(CN) 6 ]) in 20 ml of deionized water to form solution B; the solution A and B were mixed and then left to stand for aging at room temperature for 24 h. The obtained product was washed by conventional centrifugation with water and ethanol, and the precipitate was dried in an oven at 60 °C for 24 h. , the obtained light blue sample is Ni 3 [Co(CN) 6 ] / g-C 3 N 4 nanocomposite; then the resulting Ni 3 [Co(CN) 6 ] / g-C 3 N 4 The nanocomposites were calcined at 350 °C for 2 h in a muffle furnace with a heating rate of 2 °C min -1 (room temperature to 350°C), after the muffle furnace was naturally cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com