Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Improve catalytic conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

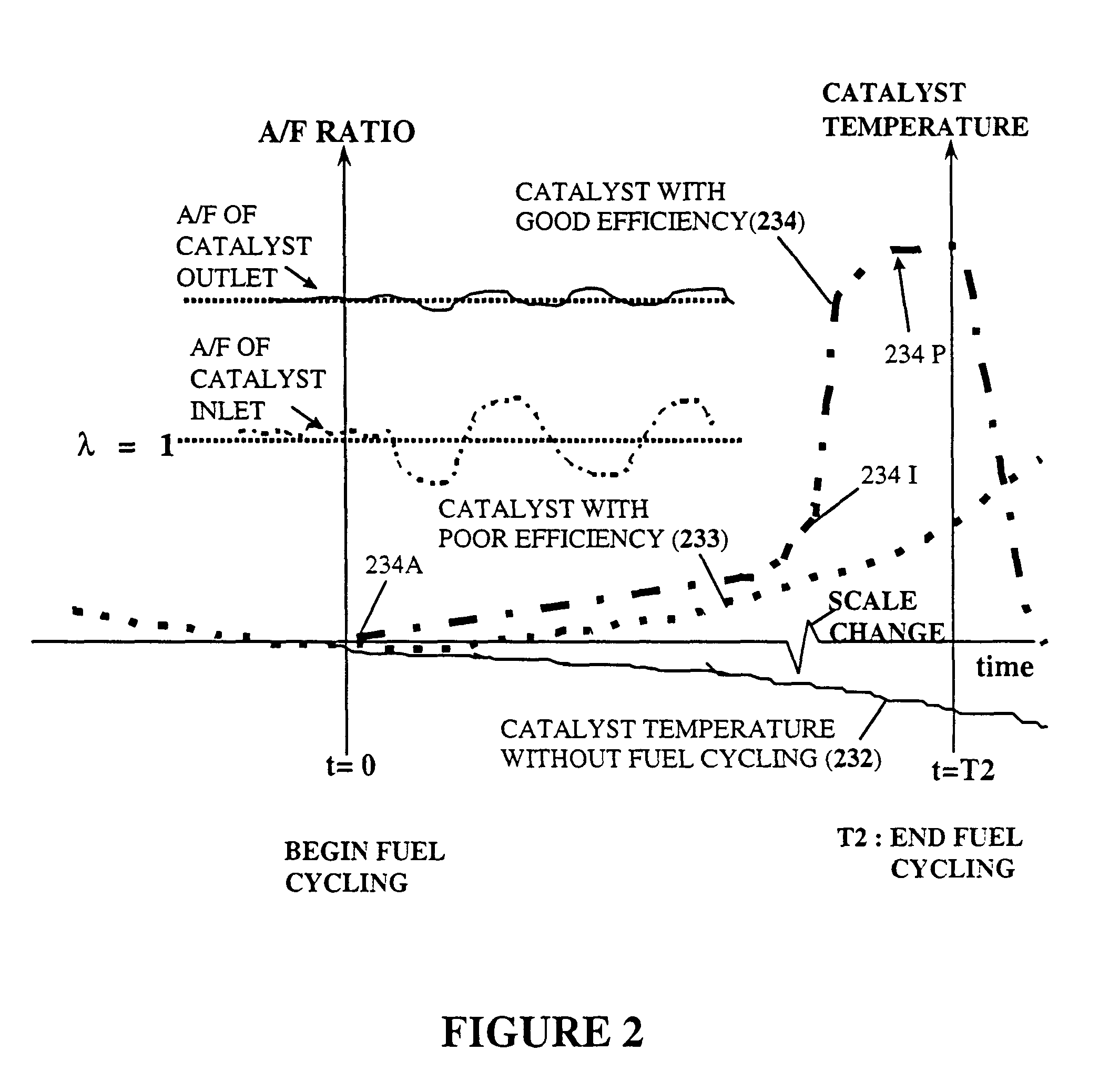

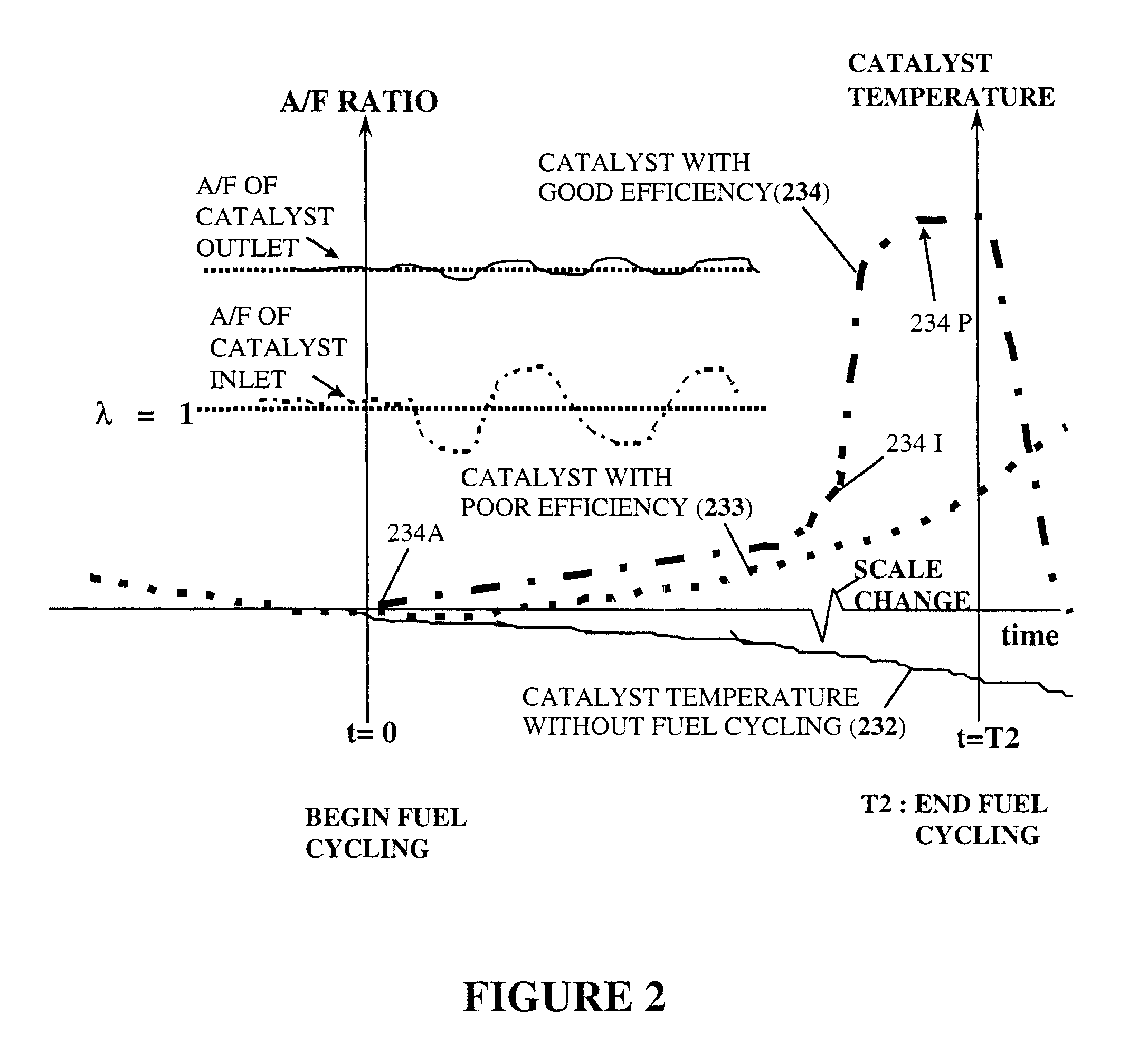

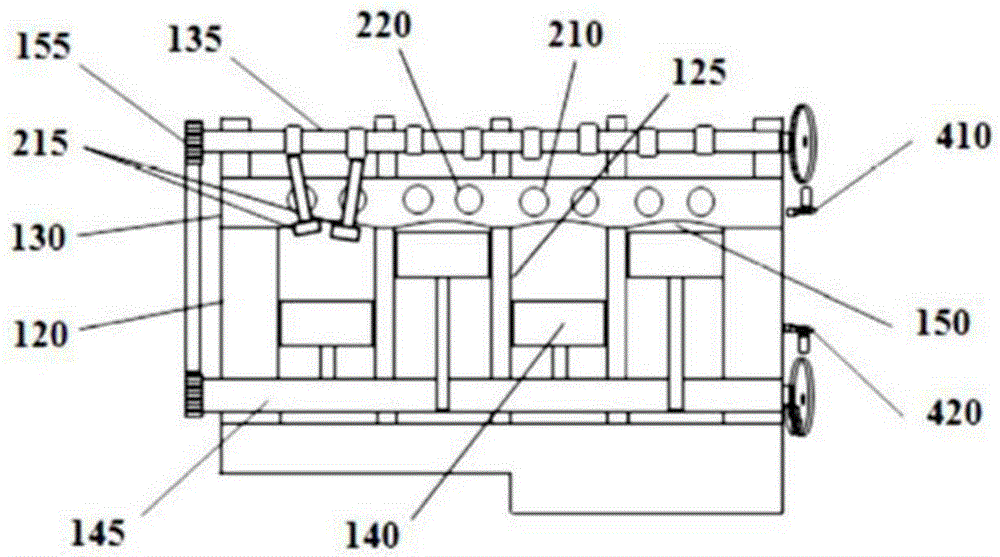

Control methods for improved catalytic converter efficiency and diagnosis

InactiveUS7707821B1Improve efficiencyImprove performanceElectrical controlInternal combustion piston enginesClosed loopProcess engineering

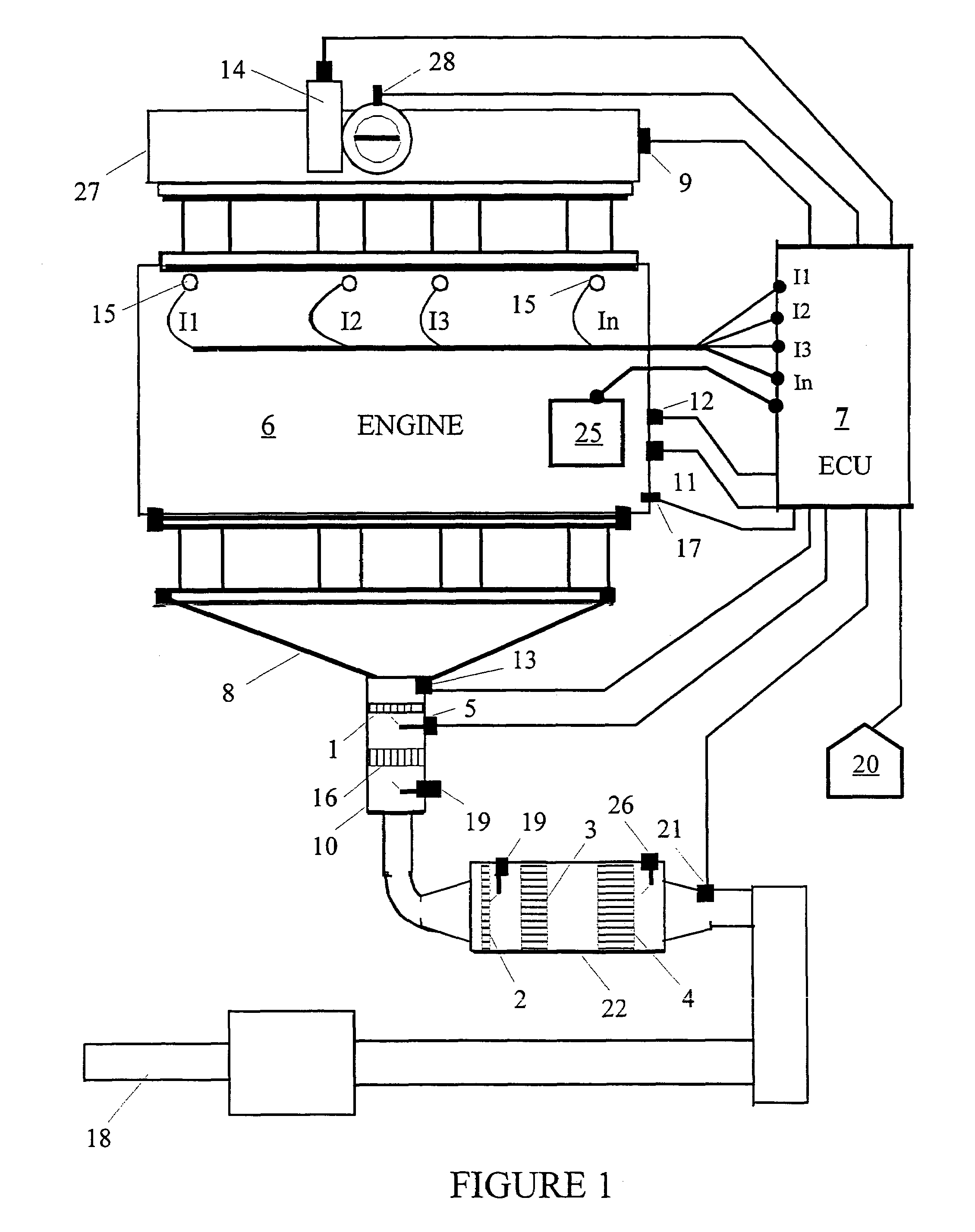

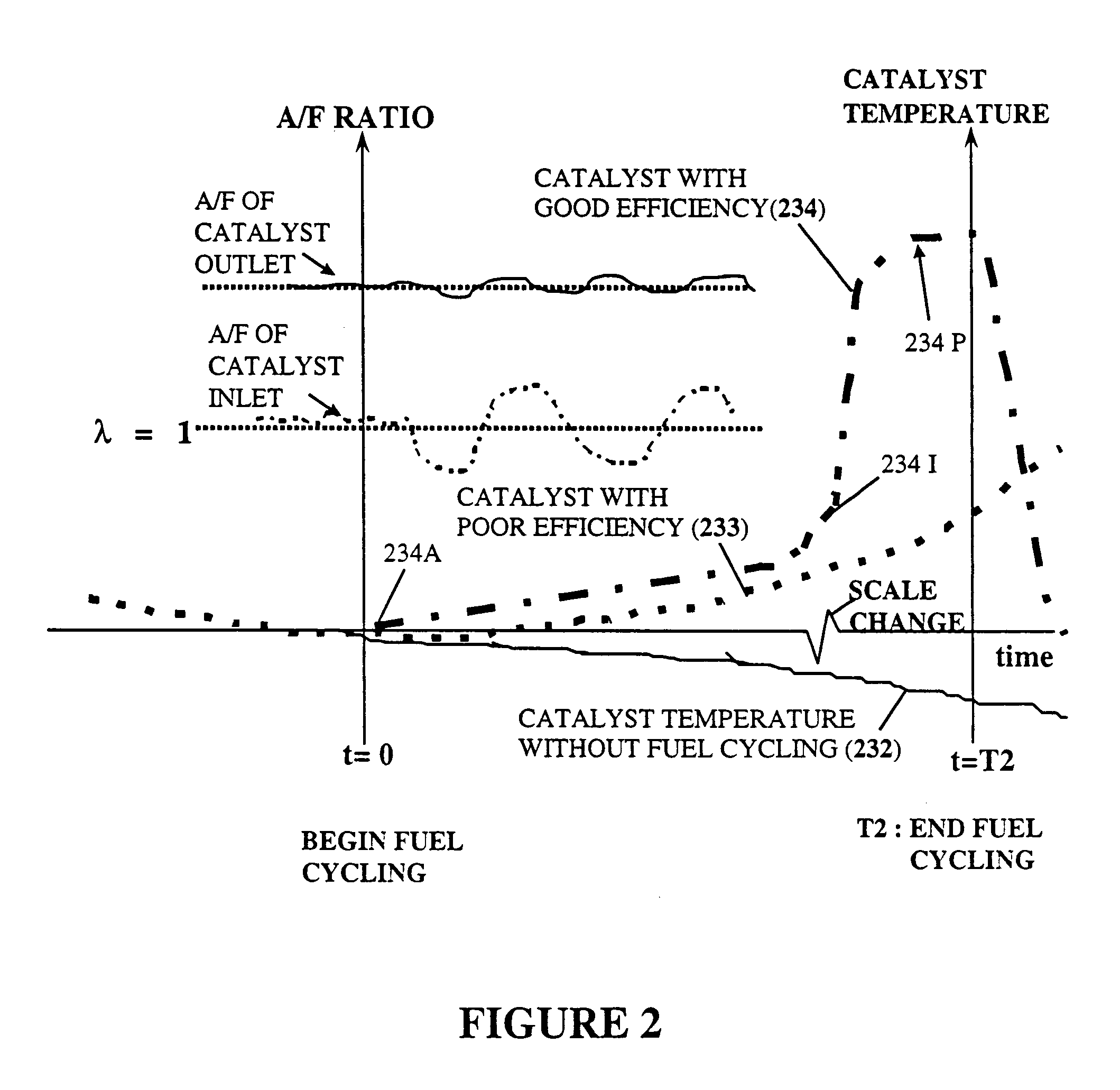

A controlling method for adjusting concentrations of, for example, individual cylinder's exhaust gas constituents to provide engine functions such as catalytic converter diagnosis, increased overall catalytic converter efficiency and rapid catalyst heating, before and / or after initiating closed loop fuel injection control, using a selected temperature sensor location within a low thermal mass catalytic converter design.

Owner:LEGARE JOSEPH E

Control methods for improved catalytic converter efficiency and diagnosis

ActiveUS7886523B1Improve performance and efficiencyIncrease speedElectrical controlInternal combustion piston enginesClosed loopProcess engineering

A controlling method for adjusting concentrations of, for example, individual cylinder's exhaust gas constituents to provide engine functions such as catalytic converter diagnosis, increased overall catalytic converter efficiency and rapid catalyst heating, before and / or after initiating closed loop fuel injection control, using a selected temperature sensor location within a low thermal mass catalytic converter design.

Owner:LEGARE JOSEPH E

Control methods for improved catalytic converter efficiency and diagnosis

InactiveUS8863497B1Improve performance and efficiencyIncrease speedElectrical controlInternal combustion piston enginesClosed loopProcess engineering

A controlling method for adjusting concentrations of, for example, individual cylinder's exhaust gas constituents to provide engine functions such as catalytic converter diagnosis, increased overall catalytic converter efficiency and rapid catalyst heating, before and / or after initiating closed loop fuel injection control, using a selected temperature sensor location within a low thermal mass catalytic converter design.

Owner:LEGARE JOSEPH E

Preparation method of composite metal oxide catalyst for catalytic decomposition for VOCs (Volatile Organic Compounds)

InactiveCN107442106ASimple methodLow costGas treatmentDispersed particle separationCatalytic decompositionCatalytic oxidation

The invention discloses a preparation method of a composite metal oxide catalyst for the catalytic decomposition of VOCs (Volatile Organic Compounds). Nano powder TiO2 is used as a carrier; after a composite metal oxide layer is formed, transition metal salt is added; the composite metal oxide catalyst with multiple active components is formed after heat treatment. The composite metal oxide catalyst has higher catalytic oxidation capacity (more than 98 percent) for ester and benzene organic matters at a low ignition temperature (300 DEG C). The catalyst is prepared by adopting a normal-temperature precipitation method; the method is simple and convenient. The composite metal oxide catalyst does not contain a noble metal element, and is low in cost. The composite metal oxide catalyst is prepared by adopting a two-step precipitation method to ensure that Ce is closely in contact with the TiO2; a solid solution is conveniently formed during roasting; the composite metal oxide catalyst has favorable oxygen supply capacity. Finally, loaded transition metal elements are uniformly distributed on the surface of the catalyst; the adsorption on molecules of the VOCs is facilitated; an active site is provided; the catalytic capacity is increased. The obtained catalyst is used for oxidizing the VOCs into CO2 and H2O, has advantages of high catalytic conversion rate, low ignition temperature, high stability, low price and the like, and has favorable application value and prospect.

Owner:南通斐腾新材料科技有限公司

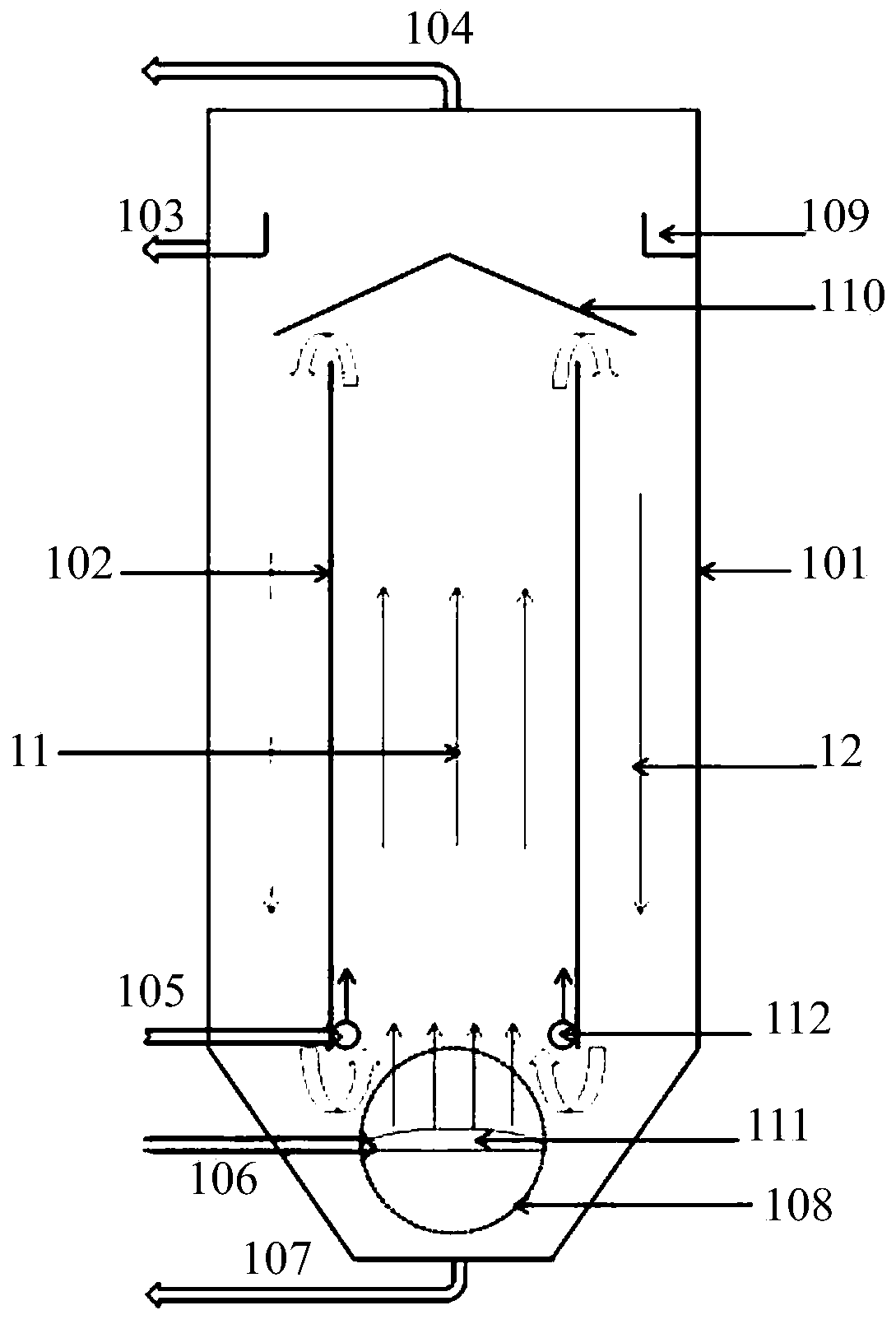

Method and device for treating oil refining salt-containing sewage by using oil refining waste catalyst and ozone

ActiveCN104370358AHigh value-added utilizationIncrease production capacityWater treatment compoundsWater/sewage treatment apparatusChemical oxygen demandPrimary standard

The invention provides a method and device for treating oil refining salt-containing sewage by using an oil refining waste catalyst and ozone. According to the method, the oil refining salt-containing sewage is subjected to catalytic oxidation treatment of internal circulation in a fluidized bed reactor by using ozone-containing gas and an activated oil refining waste catalyst, and the treated sewage flows through a vertical sedimentation basin and then is discharged outwards, wherein the CODcr (chemical oxygen demand) value of the effluent satisfies the primary standard A of Chinese Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002). The device is used for implementing the method, and at least comprises a fluidized bed reactor and a vertical sedimentation basin. According to the method and the device disclosed by the invention, the oil refining waste catalyst is used as a sewage ozone treatment cooperating catalyst, so that a utilization direction of 'waste control by waste' is provided for solid wastes of oil refining plants, and the problem of relatively high cost of a catalyst is solved; and the mass transfer effect among ozone, a catalyst and organic pollutants is strengthened by using a fluidization technology, and the problems that the utilization rate of ozone is relatively low and the catalyst is easy to scale are solved.

Owner:北京中实奥杰石油科技有限公司

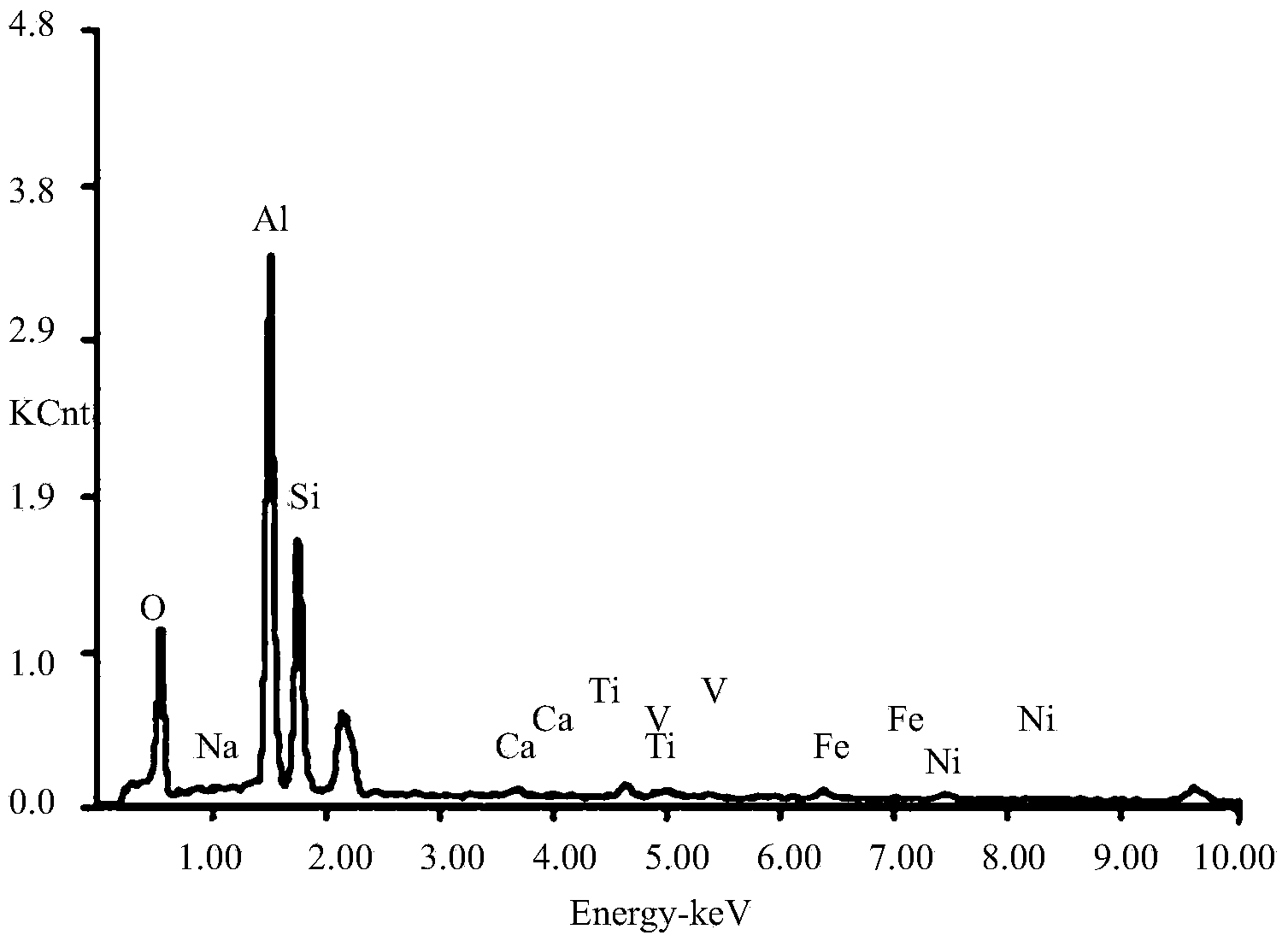

Denitrification copper radical molecular sieve catalyst as well as preparation method and application thereof

InactiveCN104014364AHigh hydrothermal stabilityPrevent dealuminationMolecular sieve catalystsDispersed particle separationIon exchangeNitric oxide

The invention discloses a denitrification copper radical molecular sieve catalyst as well as a preparation method and an application thereof and relates to the technical field of NOx reduction catalysts. The catalyst is a molecular catalyst which has high hydrothermal stability and is used for selective copper radical reduction of diesel engine car exhaust NOx. The preparation method comprises the following steps: with a commercial molecular sieve as a carrier, preparing a copper radical molecular sieve catalyst through an ion exchange method; coating a layer of inert silicon dioxide thin film on the surface of the catalyst through a chemical liquid phase deposition method, and finally drying and calcining the obtained sample to obtain the copper radical sieve catalyst with high hydrothermal stability. Compared with a copper radical sieve catalyst before treatment, through the prepared reduction catalyst, a relatively high NOx catalytic conversion efficiency and a relatively wide active temperature window can still be obtained after the prepared reduction catalyst is hydrothermally aged at the temperature of 750 DEG for 13 hours, the problem that the copper radical sieve catalyst is poor in hydrothermal stability is solved, the purpose of controlling emission of nitric oxide in diesel engine car exhaust is realized and good environment effect is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

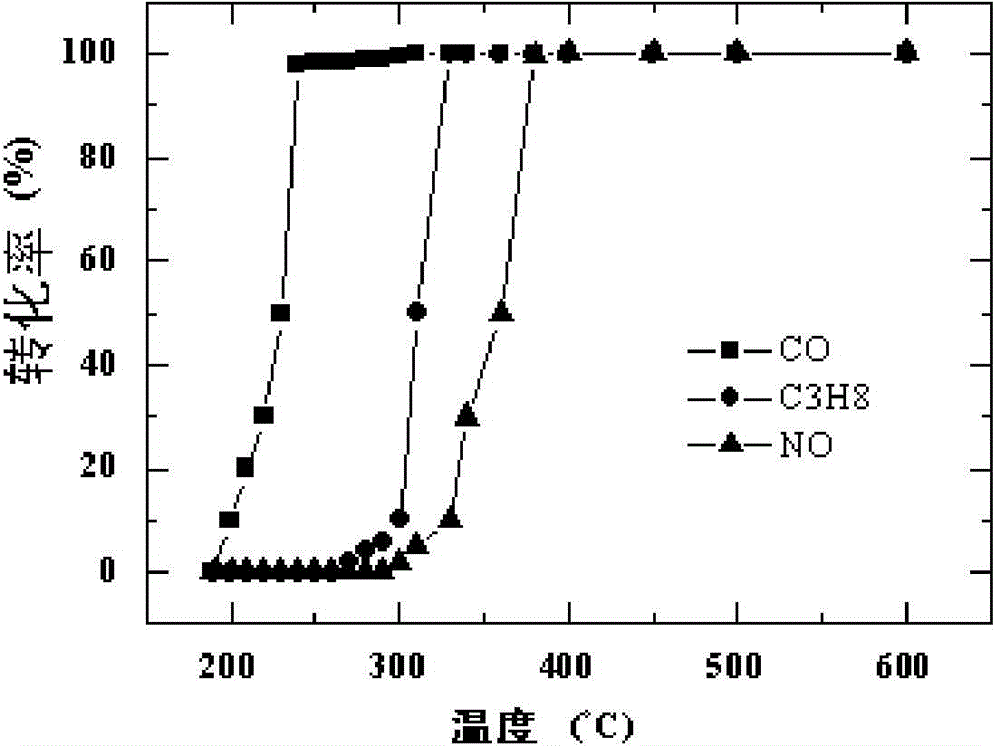

Rare-earth perovskite type catalyst for treating industrial waste gas as well as preparation method and application thereof

ActiveCN102513123ASuitable for handlingGood dispersionMolecular sieve catalystsDispersed particle separationRare earthCordierite

The invention relates to a rare-earth perovskite type catalyst for treating industrial waste gas as well as a preparation method and application thereof, which belong to the fields of a treating technology of atmospheric pollution and an environment-friendly catalyzing material. According to the catalyst, rare-earth perovskite type oxide ABO3 is used as an active component, an adopted vector is ahome-made cordierite vector or a vector of a natural inorganic material, the mass of the vector is used as a reference, and the mass percent content of the loading quantity of the active component is5 to 20 percent. In the active component of the rare-earth perovskite type oxide ABO3, A bit elements are La and M, B bit elements are Co and N, and the general formula is LaxM1-xCoyN1-yO3 (M=Ba and Ca; N=Mn, Fe and Ni), wherein x is not smaller than 0.1 and not greater than 1, and y is not smaller than 0.1 and not greater than 1; and moreover, the mol ratio of the A bit elements of the La and the M is x:1-x, and the mol ratio of the B bit elements of the Co and the N is y:1-y. The catalyst is used for the processing of chemical engineering, electronics, medicine, paint and new materials and the catalytic treating of industrial waste gas discharged in the production process of the automobile industry.

Owner:南京盈博环保科技有限公司

Preparation process of selective reduction catalyst for lean-burn gasoline motor car exhausted gas nitrogen oxide

InactiveCN1762585AEmission controlHigh selectivityInternal combustion piston enginesDispersed particle separationDiasporeCordierite

The preparation method for catalyst to selective reduce nitrogen oxide in tail gas from gasoline vehicle comprises: with quasi-thin diaspore dry powder as material, nitric acid as peptizer and urea as dispersant, grinding to obtain aluminum solution; dipping the 200-800 pores / inch2 cordierite honeycomb ceramic carrier into said solution, taking out to dry and form Al2O3 coat; excessive immersing into silver nitrate solution, taking out to calcine and obtain the product. This catalyst has high catalytic conversion rate to NOx special at low temperature, solves the difficulty that it is hard to remove NOx on oxygen-enriched condition, and has well environmental benefit.

Owner:TSINGHUA UNIV

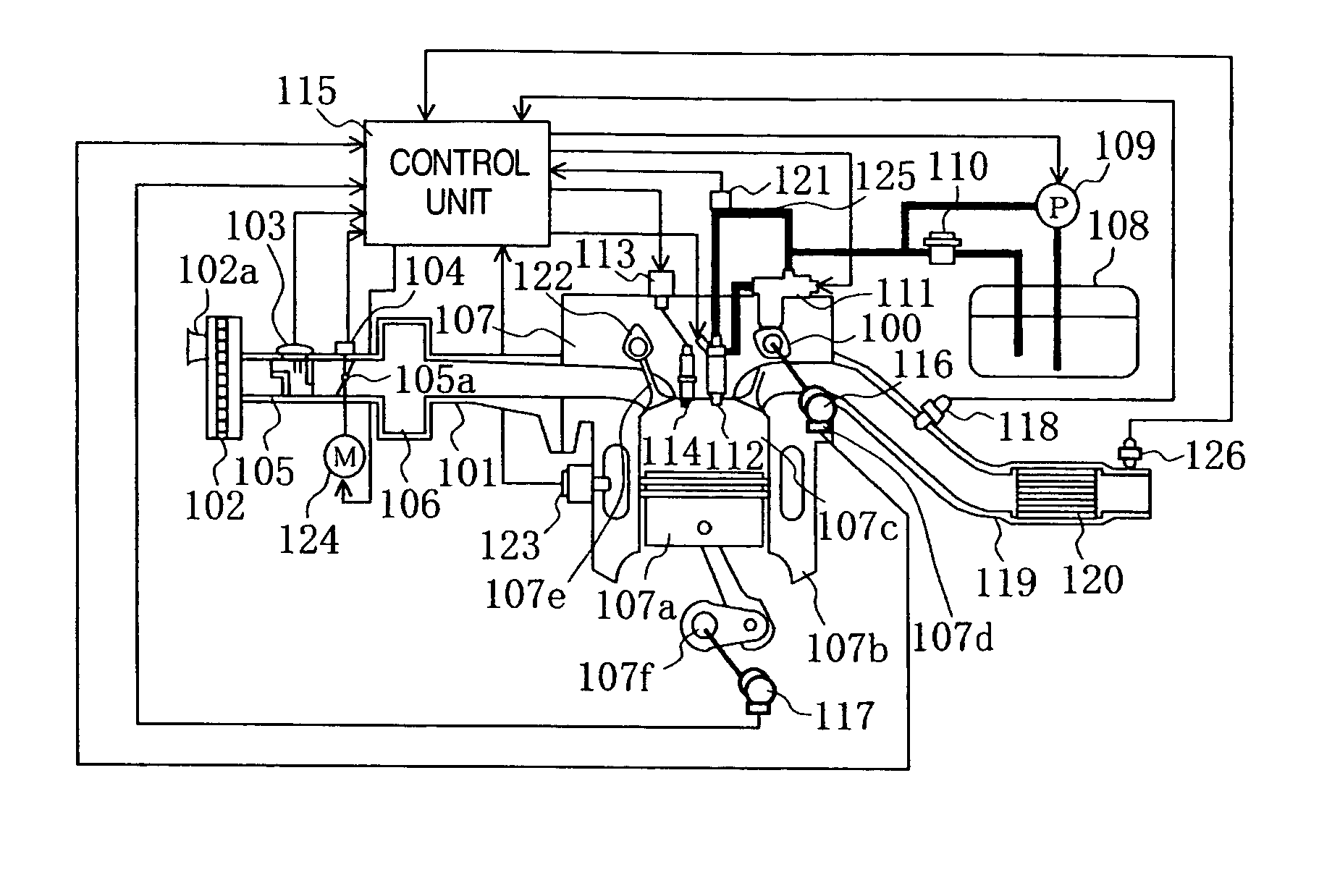

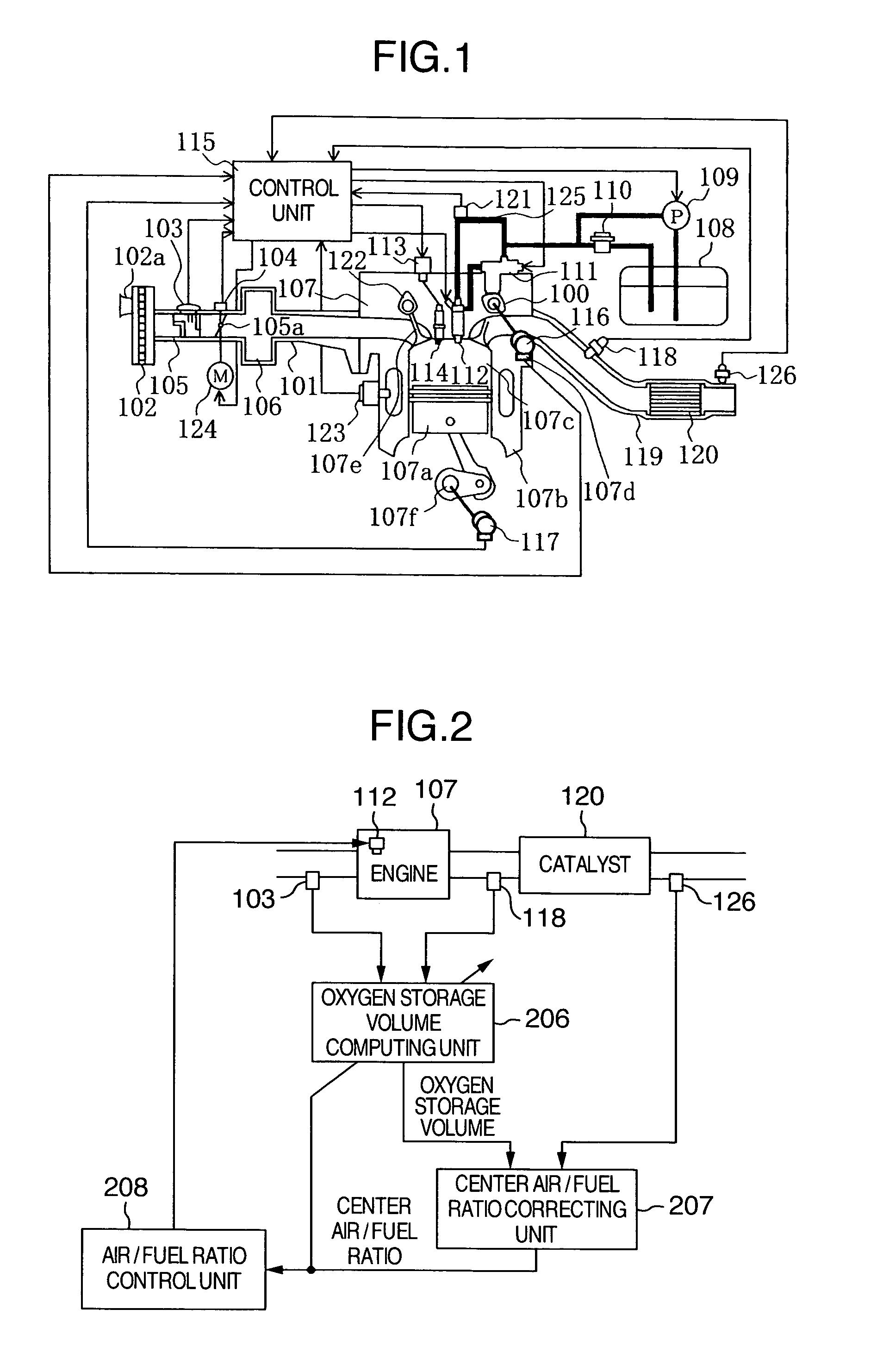

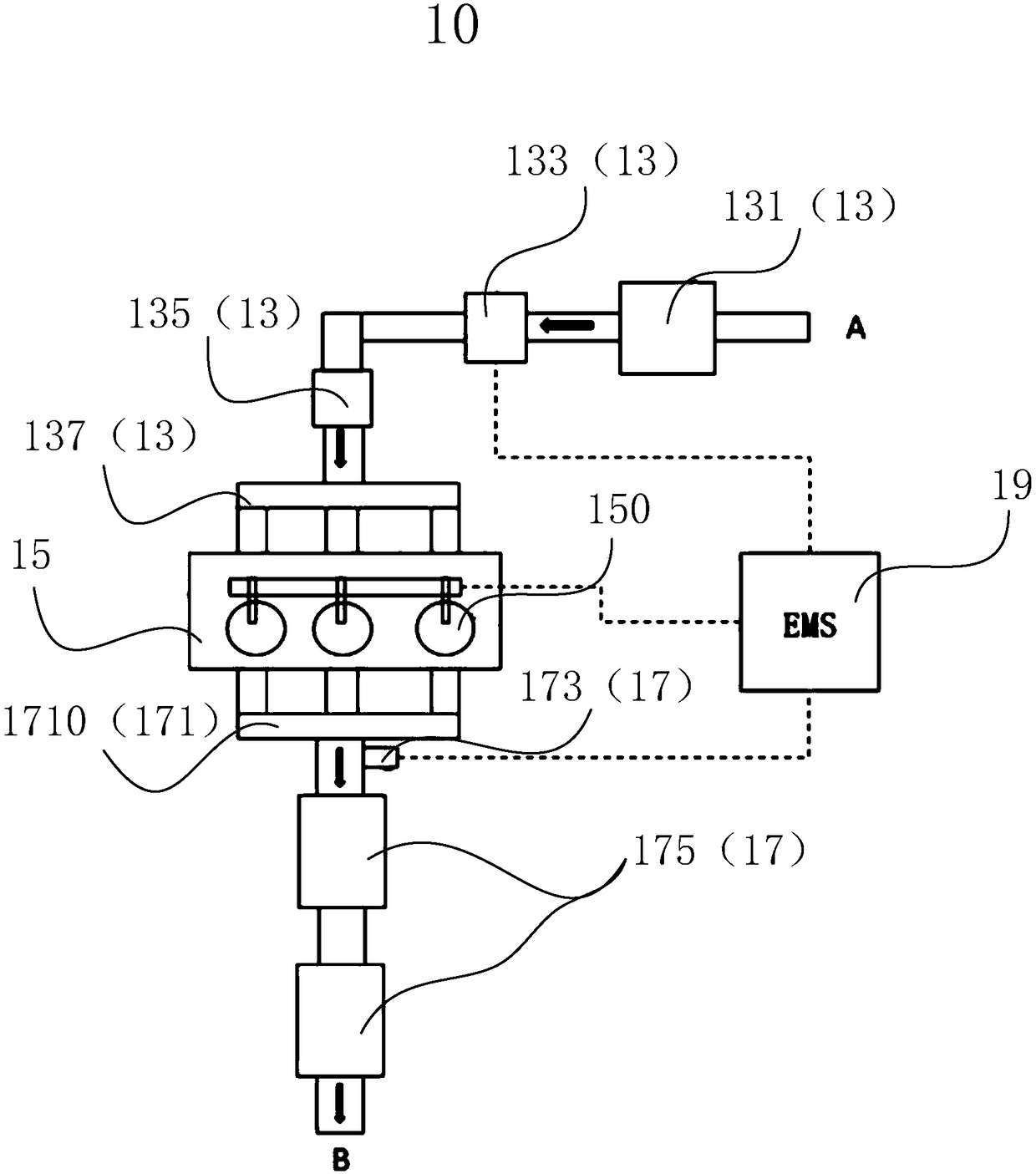

Control apparatus and method for internal combustion engine

InactiveUS7559193B2Improve estimation accuracyImprove catalytic conversion efficiencyElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

A control apparatus for an internal combustion engine has an oxygen storage volume computing unit for computing an oxygen storage volume of a catalyst by using a real air / fuel ratio detected by an air / fuel ratio sensor installed on the upstream side of a catalyst, a center air / fuel ratio representing a stoichiometric air / fuel ratio and an estimated air flow volume or detecting a flow rate of air flowing into the catalyst. A center air / fuel ratio correcting unit for correcting a center air / fuel ratio based on output of a rear air / fuel ratio sensor provided on the downstream side of the catalyst, and an oxygen storage volume computed by an oxygen storage volume computing unit, and the oxygen storage volume computing unit computes an oxygen storage volume by using a center air / fuel ratio corrected by the center air / fuel ratio correcting unit.

Owner:HITACHI AUTOMOTIVE SYST LTD

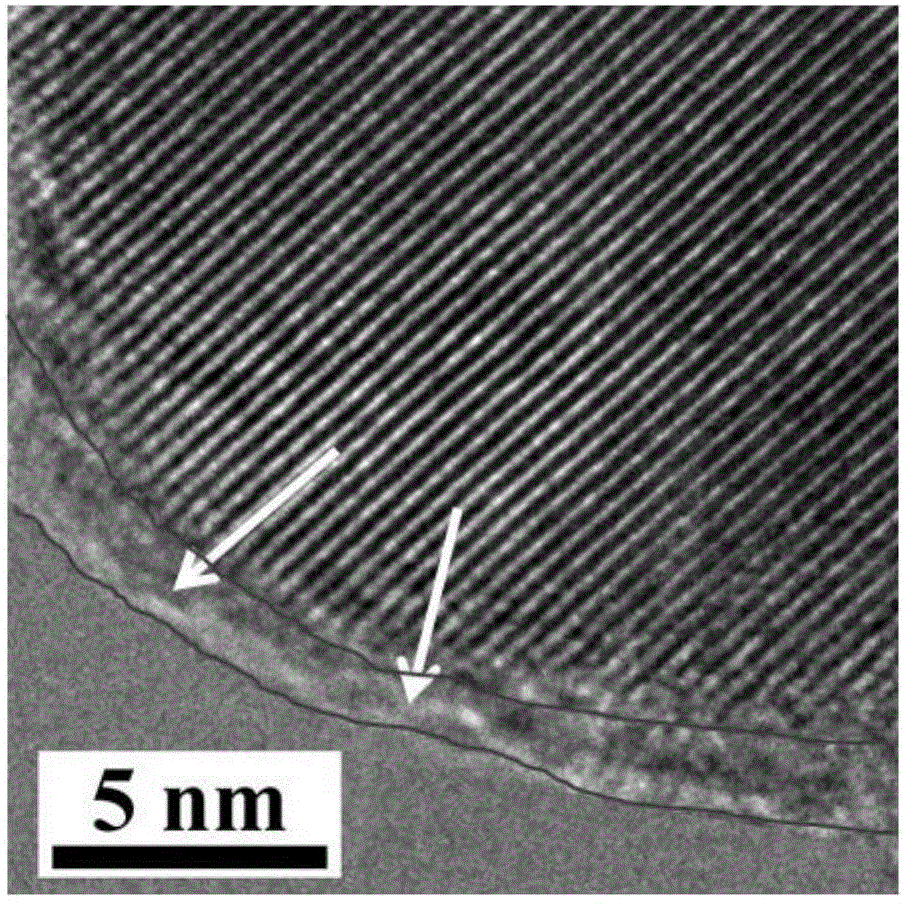

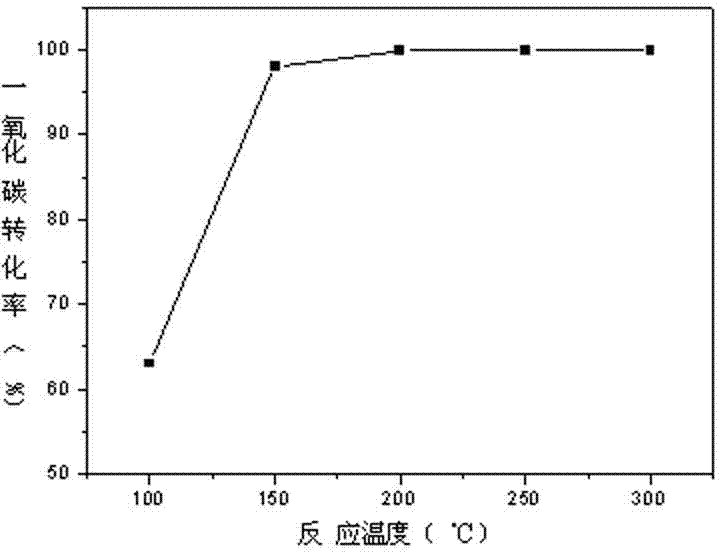

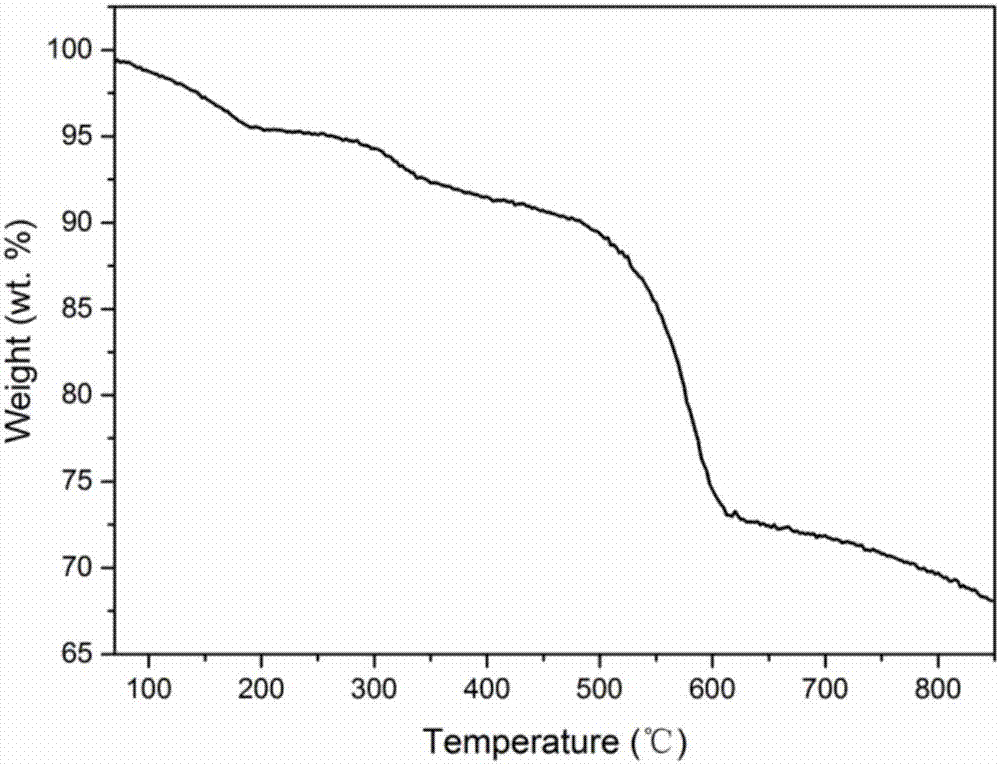

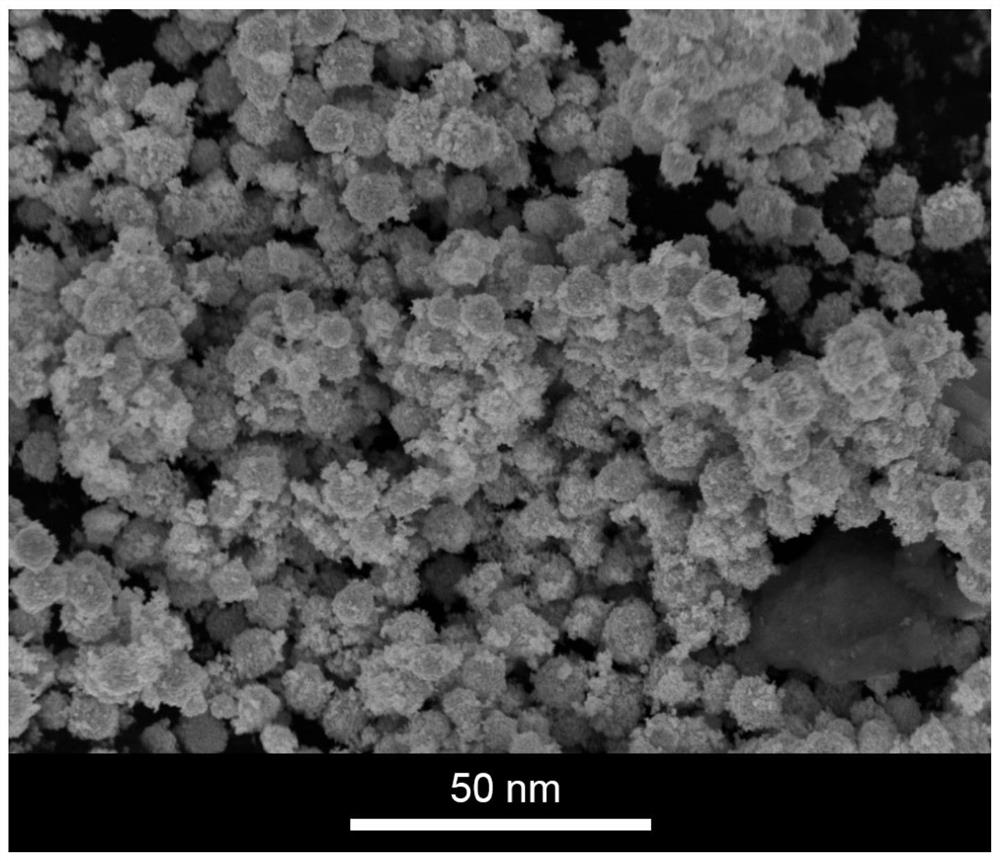

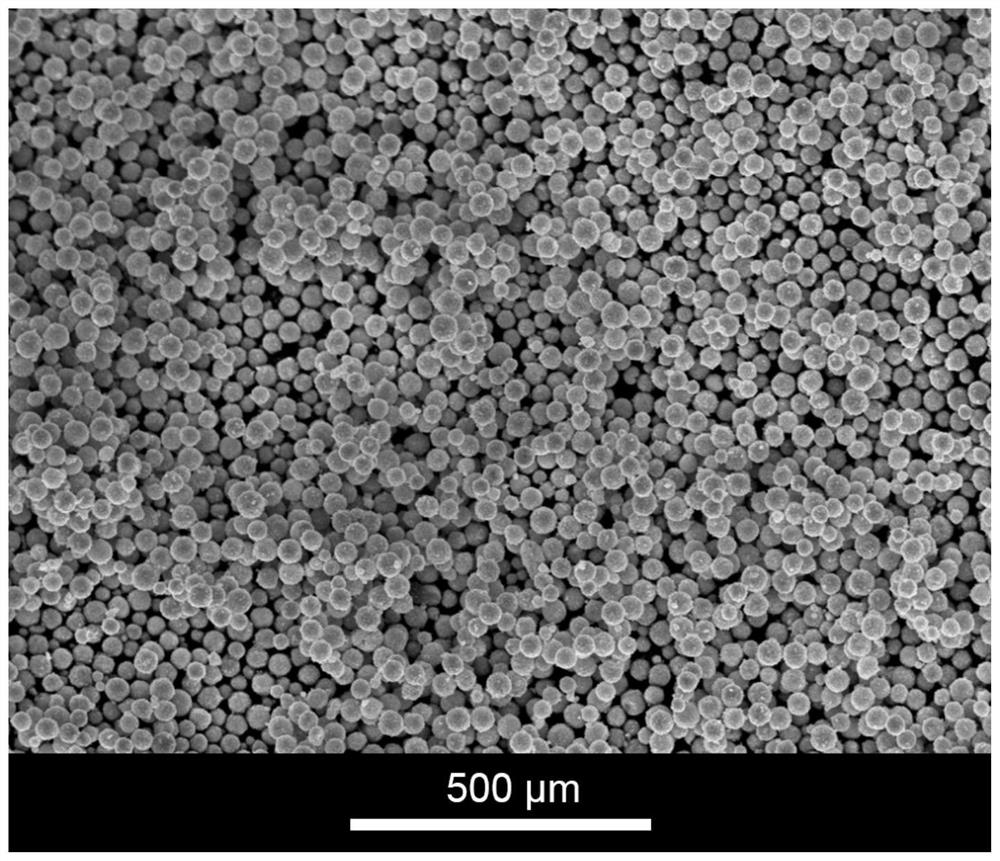

Composite catalyst for catalytic combustion and preparation method of composite catalyst

ActiveCN103055849AAvoid inactivationImprove catalytic conversion efficiencyMetal/metal-oxides/metal-hydroxide catalystsNanoparticleTemperature resistance

The invention provides composite catalyst for catalytic combustion and a preparation method of the composite catalyst. The composite catalyst comprises noble metal as core, and aluminum oxide as shell for wrapping the noble metal or growing on the noble metal; and the mol ratio of the noble metal to the aluminum oxide is 1: (10-50). The aluminum oxide carrier (namely the composite catalyst) wrapping the noble metal nanoparticles has excellent high-temperature resistance, so that the catalytic conversion performance of the noble metal catalyst is improved; and the catalytic conversion efficiency of the composite catalyst can reach high up to 100%.

Owner:ENN SCI & TECH DEV

Biomass carbon-based solid acid catalyst and preparation method and application thereof

ActiveCN108940313AHigh catalytic activityImprove stabilityPhysical/chemical process catalystsOrganic chemistryPtru catalystPorous carbon

The invention provides a preparation method and an application of a biomass carbon-based solid acid catalyst. The preparation method comprises the following steps: A) impregnating biomass of a nitrogen-containing compound in an acid solution, and filtering to obtain a solid product; B) carbonizing the solid product to obtain a porous carbon carrier; and C) reacting the porous carbon carrier with p-aminobenzenesulfonic acid and isoamyl nitrite, and sulfonating to obtain a catalyst. In the preparation method provided by the invention, the biomass of the nitrogen-containing compound is impregnated and carbonized to obtain the porous carbon carrier; and after carbonization, diversified surface chemical compositions have better sulfonic acid group loading property compared with a highly carbonized surface, so that the Bronsted acid loading amount is increased, and the conversion efficiency of various types of sugar is improved. The adjustable and controllable carbon-based carrier porous structure formed in the preparation method provided by the invention enables sulfonic acid groups to be firmly loaded inside pore passages, and the pore passages are mesopores and macropores after loading, thereby being beneficial to contact of a substrate with acid sites, and maintaining better recycling property. The biomass carbon-based solid acid catalyst prepared by the invention has high catalytic activity, good stability and high catalytic conversion efficiency.

Owner:UNIV OF SCI & TECH OF CHINA

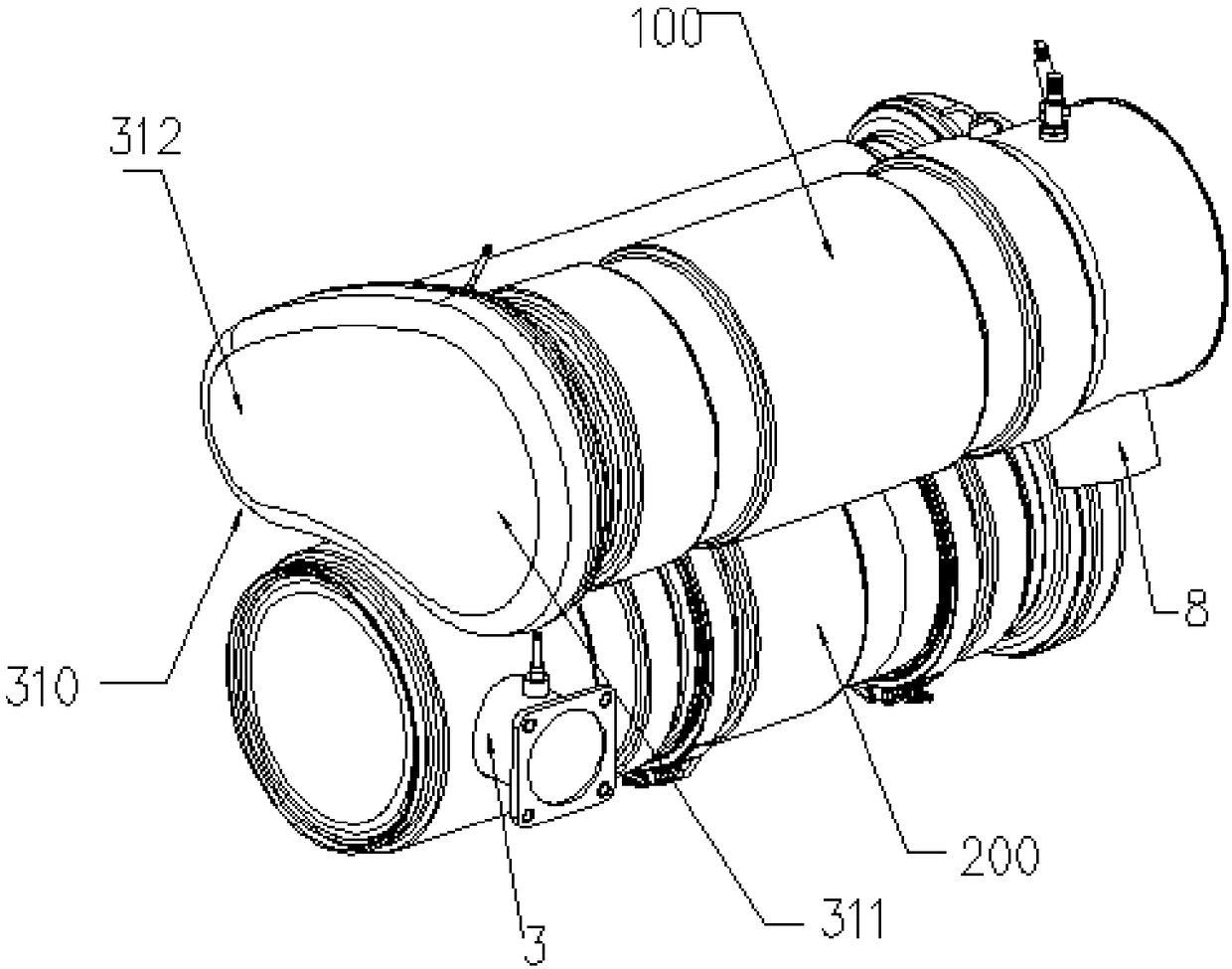

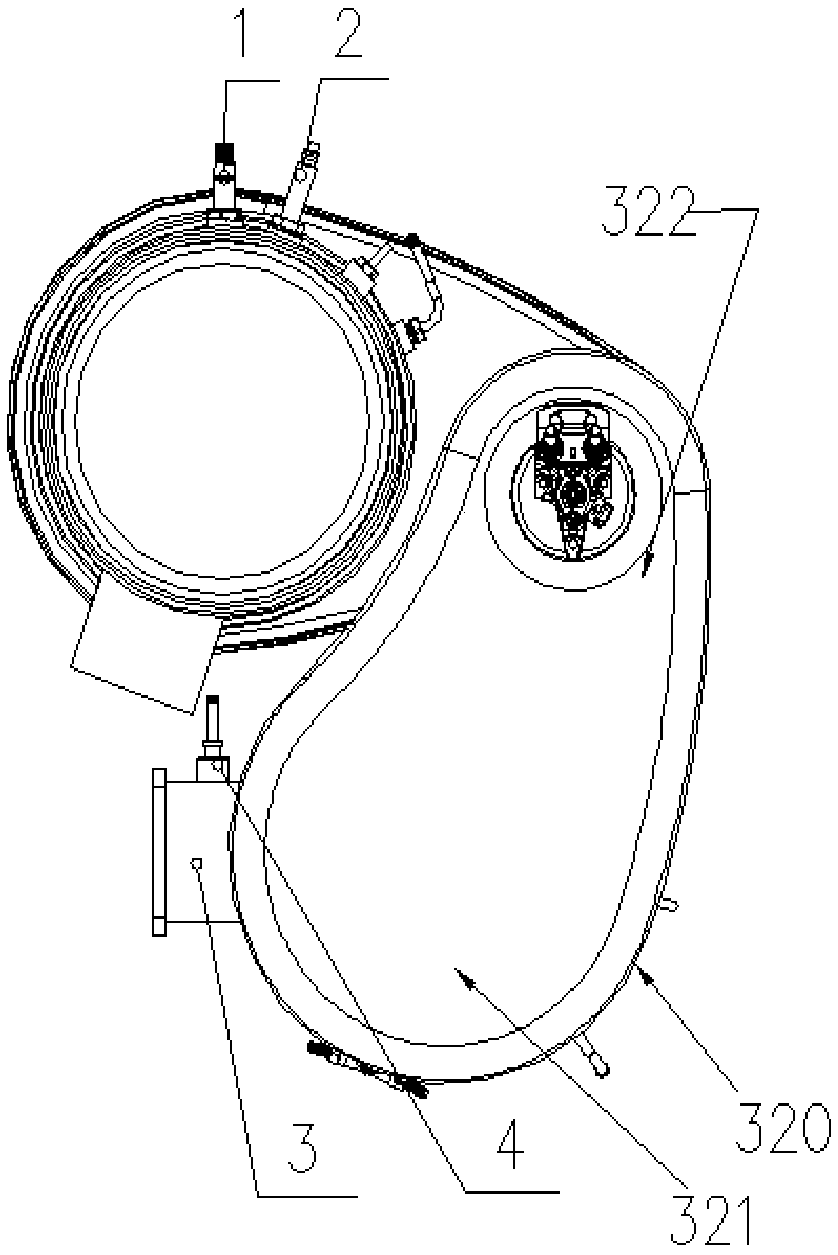

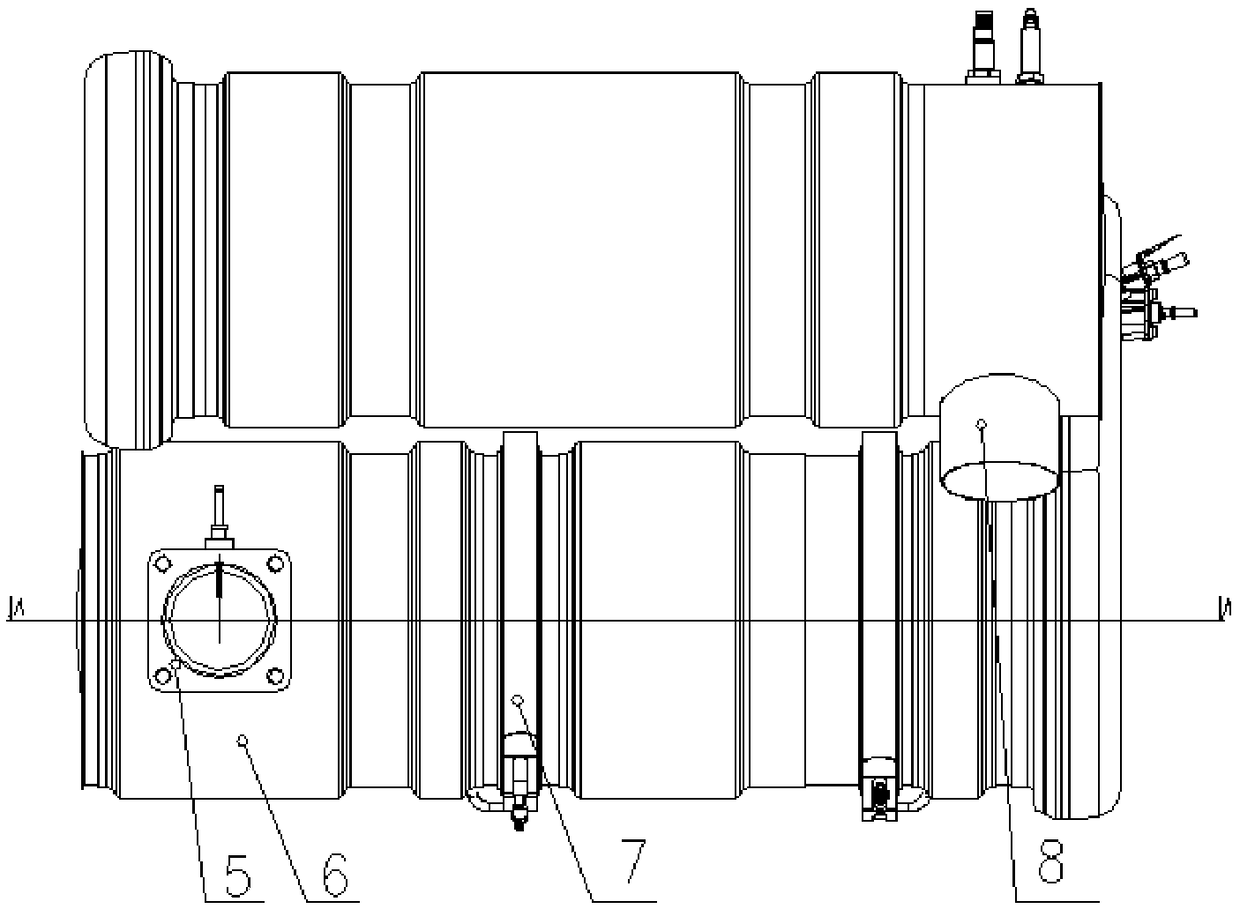

Parallel cylinder type aftertreatment structure assembly

InactiveCN108412593AImprove uniformitySafe Recycling GuaranteeInternal combustion piston enginesExhaust apparatusNitrogenNitrogen oxide

The invention relates to the field of diesel engine tail gas aftertreatment, in particular to a parallel cylinder type aftertreatment structure assembly. The parallel cylinder type aftertreatment structure assembly comprises a first cylinder, a second cylinder, and a connecting pipe for connecting the two cylinders; a first-grade SCR carrier and a second-grade SCR carrier are mounted in the firstcylinder in sequence; a small-head end of a right end cover is welded with the other end of the connecting pipe, and a large-head end is connected with one end of the second cylinder; an intake end cover is arranged at the other end of the second cylinder; the outer wall of the second cylinder is of a segmented structure, and all the sections are connected through hoops; and a DPF carrier and a DOC carrier are arranged between the right end cover and the intake end cover in the second cylinder in sequence. A cyclone mixing pipe is arranged in the connecting pipe. DOC, DPF and SCR are integrated as an aftertreatment circuit; and urea water solution is used as a reducing agent for spraying into an exhaust system to decompose as ammonia in waste gas currents for reaction with nitric oxides under the effect of a catalyst to finally convert to harmless nitrogen and water so as to achieve the effect of purifying vehicle tail gas.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Control apparatus and method for internal combustion engine

InactiveUS20070095051A1Improve accuracyPrevents exhaust deteriorationElectrical controlInternal combustion piston enginesStream flowAir–fuel ratio

A control apparatus for an internal combustion engine has an oxygen storage volume computing unit for computing an oxygen storage volume of a catalyst by using a real air / fuel ratio detected by an air / fuel ratio sensor installed on the upstream side of a catalyst, a center air / fuel ratio representing a stoichiometric air / fuel ratio and an estimated air flow volume or detecting a flow rate of air flowing into the catalyst. A center air / fuel ratio correcting unit for correcting a center air / fuel ratio based on output of a rear air / fuel ratio sensor provided on the downstream side of the catalyst, and an oxygen storage volume computed by an oxygen storage volume computing unit, and the oxygen storage volume computing unit computes an oxygen storage volume by using a center air / fuel ratio corrected by the center air / fuel ratio correcting unit.

Owner:HITACHI AUTOMOTIVE SYST LTD

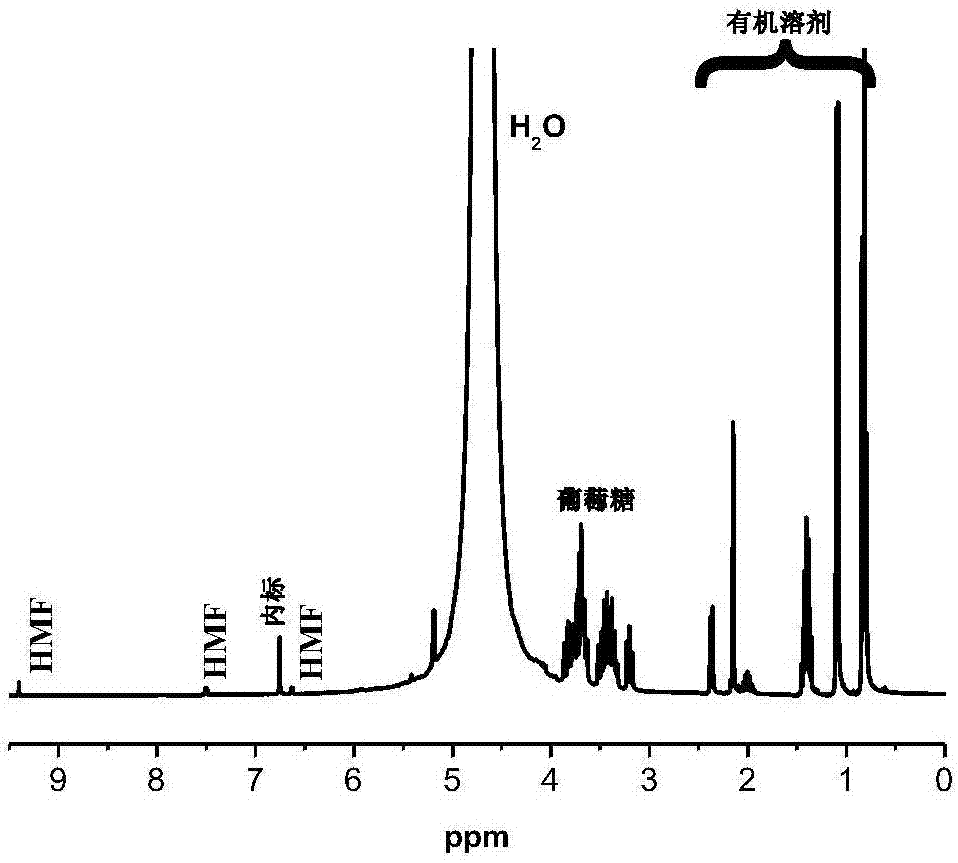

Catalyst for catalyzing saccharides to synthesize 5-hydroxymethyl furfural and method of catalyzing saccharides to synthesize the same

ActiveCN107163006AImprove catalytic conversion efficiencyImprove stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction rateHydroxymethylfurfural

The invention provides a catalyst for catalyzing saccharides to synthesize 5-hydroxymethyl furfural and a method of catalyzing saccharides to synthesize the same. In the invention, a compound containing metal ions and an organic ligand are used for synthesizing MOF, wherein the ligand supplies a Bronsted acid active center while the metal supplies a Lewis acid active center. The catalyst can greatly improve the catalytic conversion efficiency of glucose; meanwhile, the catalyst has strong catalysis performance on disaccharides and polysaccharides, even crop straws, cotton, hemps and other biomass raw materials; in addition, the method of catalyzing saccharides to synthesize the 5-hydroxymethyl furfural has high reaction rate and gentle reaction conditions. Being different from conventional homogeneous catalysts, the solid-phase catalyst is easy to recycle and reutilize. The MOF catalyst has good stability and can be recycled without regeneration. The catalyst not only reduces environment pollution but also greatly reduces preparation cost. The product, HMF, is easy to separate, so that the method is simple and convenient.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

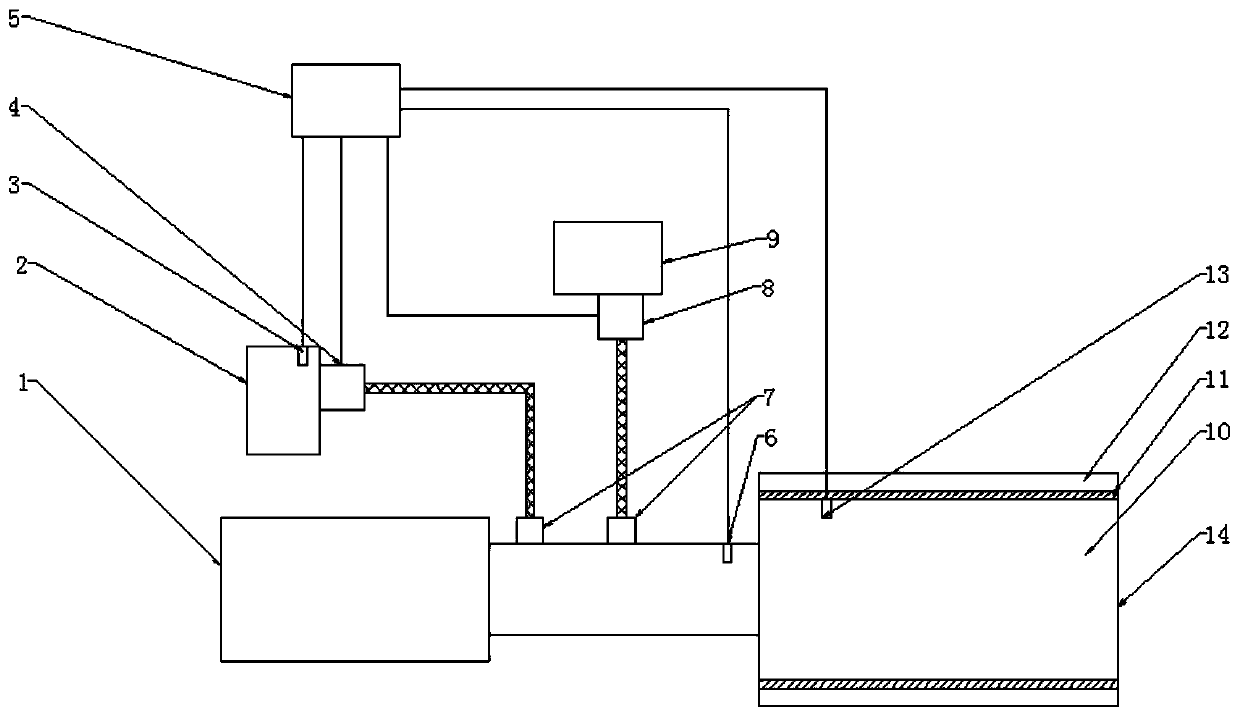

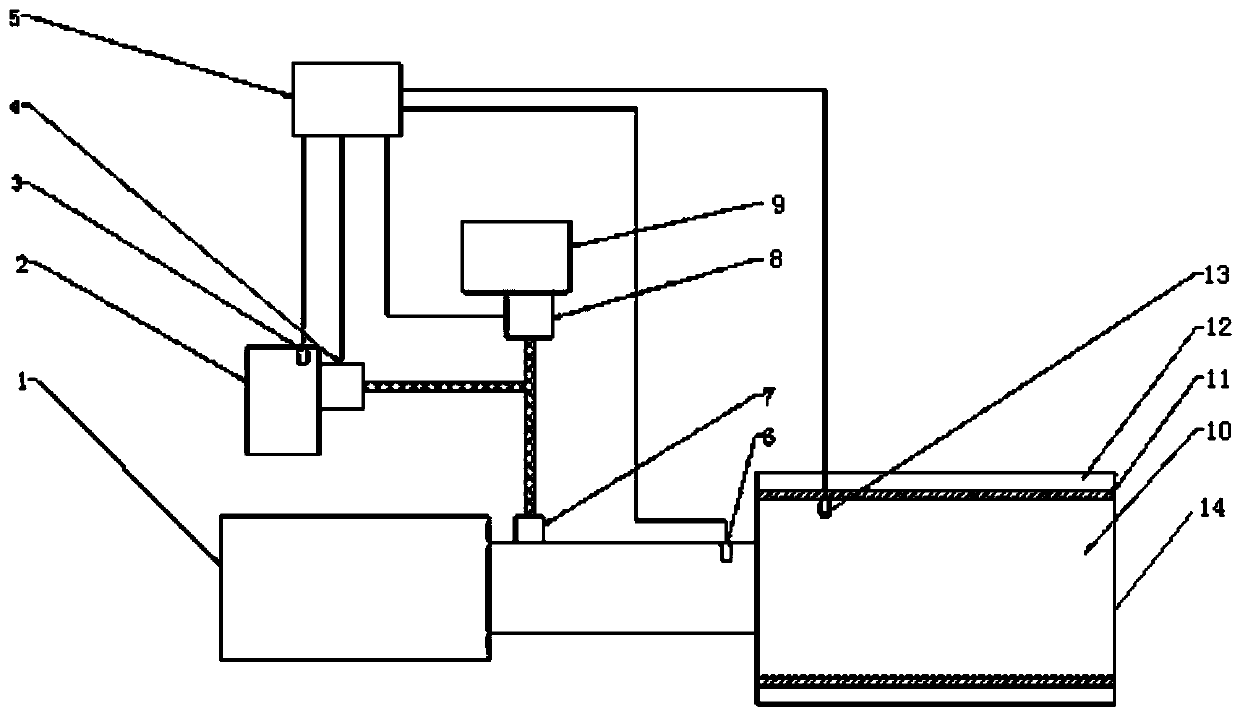

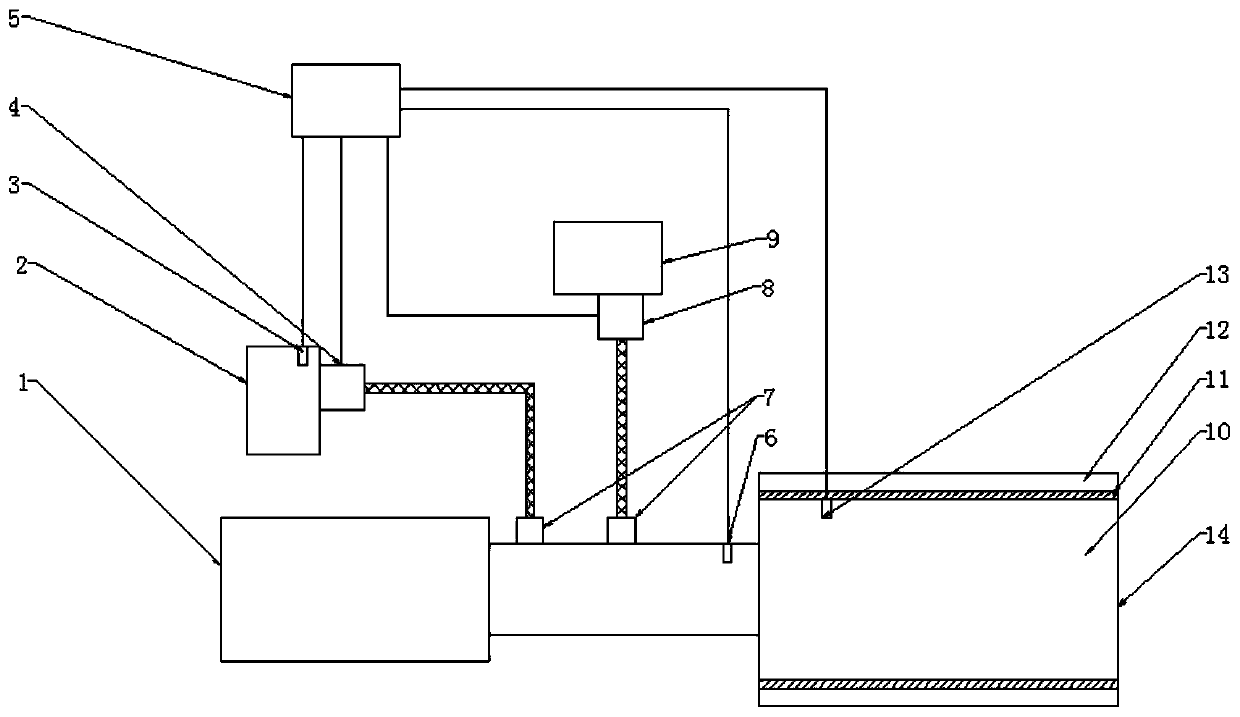

Diesel engine aftertreatment anti-crystallization heating mixing device

InactiveCN106468202AAchieve heatingPromoting pyrolysis and hydrolysisInternal combustion piston enginesExhaust apparatusSpray nozzleEngineering

The invention discloses a diesel engine aftertreatment anti-crystallization heating mixing device. The device comprises a temperature sensor (1), a relay (2), a power supply (4), a resistance wire (7), a switch (3), a resistance heating cylinder (6), a mixer (5) and a urea spraying nozzle (8); the resistance wire (7) is fixedly mounted on the inner wall periphery of the resistance heating cylinder (6); the temperature sensor (1) is connected with the relay (2); the switch (3), the power supply (4), the resistance wire (7) and the relay (2) are serially connected; and the resistance heating cylinder (6) is connected with the mixer (5), and is positioned in a spraying area of the urea spraying nozzle (8). The device is low in exhaust back pressure, simple and compact in structure and convenient for installation, and can be widely applied to a diesel engine exhaust pipeline with a SCR system.

Owner:上海新动力汽车科技股份有限公司

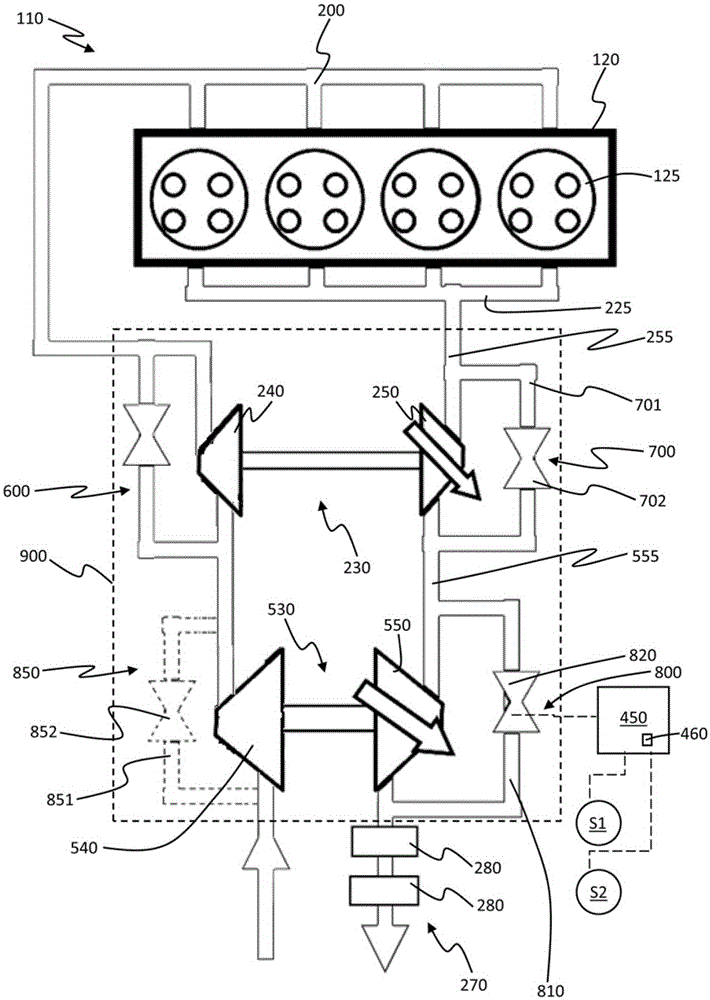

Internal combustion engine having a two stage turbocharger

InactiveCN105715361AGuaranteed normal operationImprove regeneration efficiencyElectrical controlInternal combustion piston enginesLow speedVariable geometry turbine

Disclosed is a two stage turbocharger 900 for an internal combustion engine 110, the two stage turbocharger 900 comprising a high pressure turbine 250 fluidly connected to an exhaust manifold 225 of the engine 110 through a high pressure turbine inlet duct 255 and a low pressure turbine 550 fluidly connected to the high pressure turbine 250 through a low pressure turbine inlet duct 555, wherein the low pressure turbine 550 is a variable geometry turbine, wherein the two stage turbocharger 900 comprise a bypass duct system 800 to bypass the variable geometry low pressure turbine, wherein the bypass duct system comprises a bypass valve 820, (855, figure 4). The variable geometry low pressure turbine 550 comprises a housing (560), and the bypass valve may be a housing-integrated bypass valve (855). A value is monitored of an operating parameter of said engine 110 during operation, wherein the operating parameter is engine speed and / or an engine torque correlated parameter. The bypass valve of the variable geometry low pressure turbine is operated when a monitored value is below, or equal to, a threshold value (e.g. especially at low speed or low loads of the engine).

Owner:GM GLOBAL TECH OPERATIONS LLC

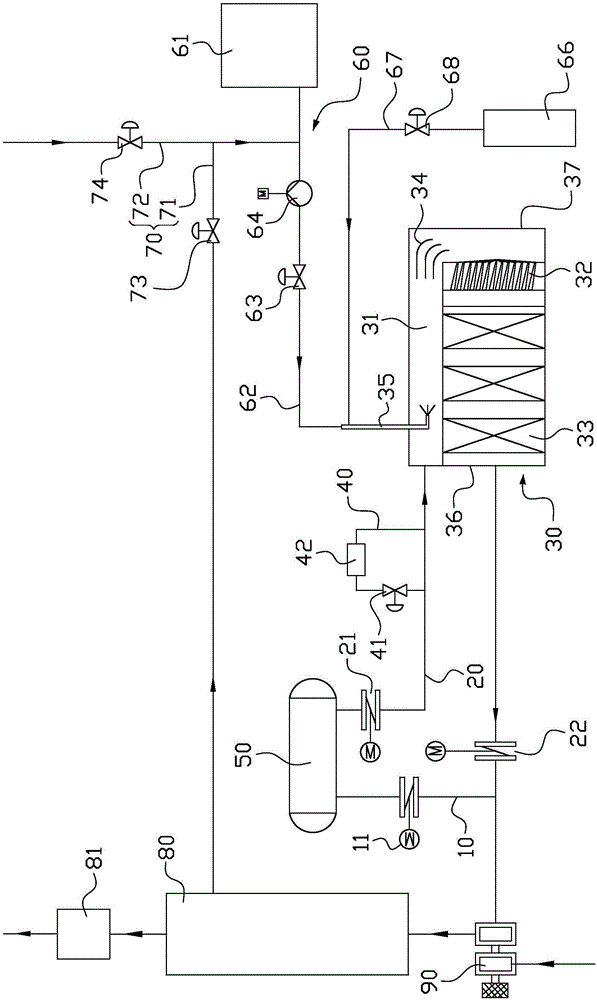

Ship waste gas denitration system

InactiveCN106640291AShorten the lengthReduce the set of connectorsExhaust apparatusDispersed particle separationExhaust fumesEngineering

A ship waste gas denitration system comprises a waste gas direct exhaust pipeline connected with a gas outlet of a waste gas collecting tank through a first valve, a waste gas denitration pipeline connected with the gas outlet of the waste gas collecting tank through a second valve and a denitration reactor connected in the waste gas denitration pipeline, wherein the denitration reactor comprises a urea evaporation chamber, a mixer and a reacting chamber. The urea evaporation chamber is provided with a urea solution spray gun. The mixer is connected with the urea evaporation chamber and the reacting chamber. When the first valve is opened and the second valve is closed, waste gas is exhausted through the waste gas direct exhaust pipeline; and when the first valve is closed and the second valve is opened, the waste gas enters the urea evaporation chamber of the denitration reactor through the waste gas denitration pipeline, then is mixed with urea, enters the reactor through the mixer, and is subjected to denitration and then exhausted. According to the ship waste gas denitration system, the urea evaporation chamber, the mixer and the reacting chamber are combined in the denitration reactor, so that the structure is more compact.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Preparation method of pure natural concentrated type scindapsus aureus nutrient solution

InactiveCN107056346AImprove catalytic conversion efficiencyRealize resource utilizationOrganic fertilisersLiquid fertilisersPretreatment methodResource utilization

The invention discloses a preparation method of a pure natural concentrated type scindapsus aureus nutrient solution. According to the preparation method disclosed by the invention, the pure natural concentrated type scindapsus aureus nutrient solution is prepared by taking a byproduct-kelp leftover materials of a kelp production and processing enterprise as a raw material, establishing a raw material pretreatment method and developing a kelp bio-refinery technology based on coupling of a low-temperature ultrahigh-pressure continuous flow cell disruption technology, a biological enzymolysis technology and a product falling film evaporation technology, so that resource utilization of kelp processing waste is realized, a kelp industrial chain is extended, and the level of a kelp processing technology is increased; a preparation mode of the pure natural concentrated type scindapsus aureus nutrient solution is innovated, and the byproduct of the kelp production and processing enterprise is used as the raw material, so that waste reclamation is realized, the kelp resource utilization efficiency is increased, the environment is protected, the production cost of the nutrient solution is reduced, the practicability is very strong, large-scale production is easy to realize, and the preparation method is a new method which meets industrial requirements and is environment-friendly.

Owner:NANCHANG UNIV

Preparation method of grape special purpose seaweed fertilizer

InactiveCN106915987AAchieve resource utilizationReduce manufacturing costBioloigcal waste fertilisersNitrogenous fertilisersHigh concentrationPretreatment method

The invention discloses a preparation method of grape special purpose seaweed fertilizer. The preparation method utilizes sodium alginate production enterprise by-product kelp slag as a raw material, builds a raw material pretreatment method and develops a bio-refining technology for two-step catalytic conversion of kelp slag based on an enzyme. Through the establishment of substrate and enzyme feeding strategy, substrate inhibition is reduced, high concentration substrate system enzyme efficient catalytic conversion is realized, high concentration seaweed fertilizer is prepared, recycling use of kelp processing wastes and protection of the environment are realized, a kelp industry chain is extended and the kelp processing technology and seaweed fertilizer production level are improved. The preparation method innovates a seaweed fertilizer preparation mode, utilizes kelp production enterprise by-products as raw materials, realizes waste recycling, improves seaweed resource utilization efficiency, protects the environment, reduces a seaweed fertilizer production cost, improves a yield of grapes after application, has strong practicability and can be easily industrialized. The seaweed fertilizer is a pure natural product, does not product pollution, can be degraded, satisfies industrial demands and is environmentally friendly.

Owner:NANCHANG UNIV

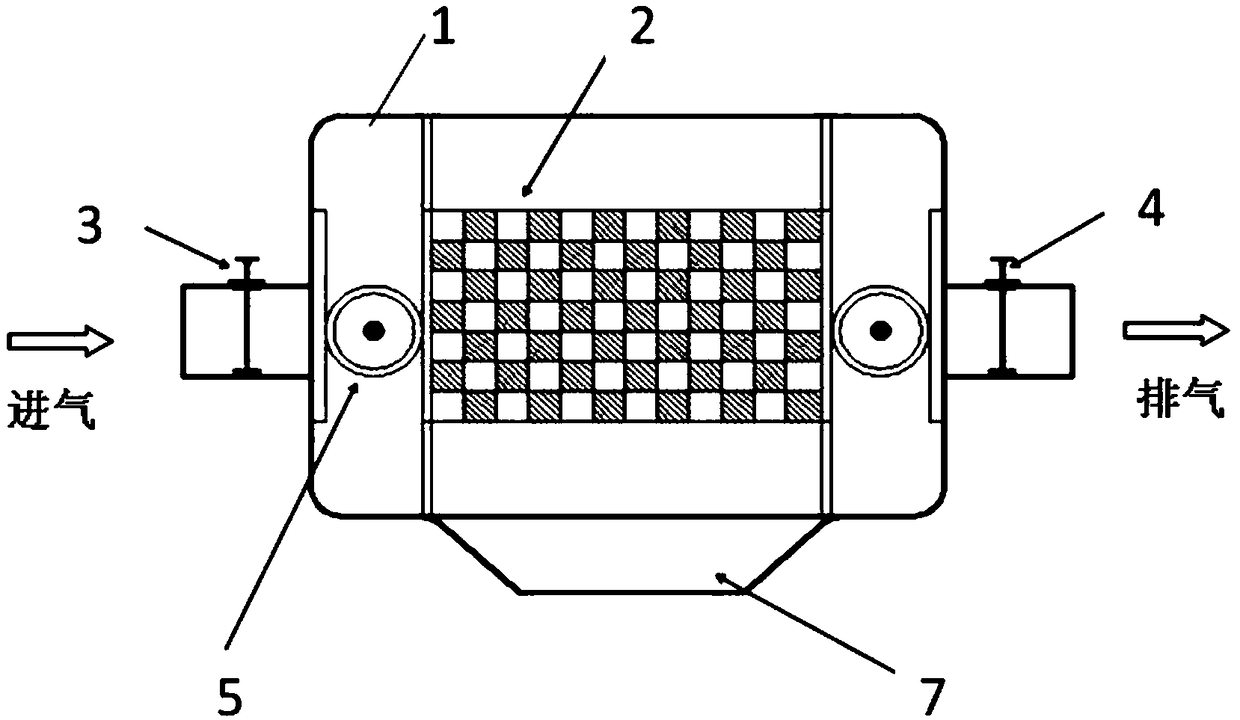

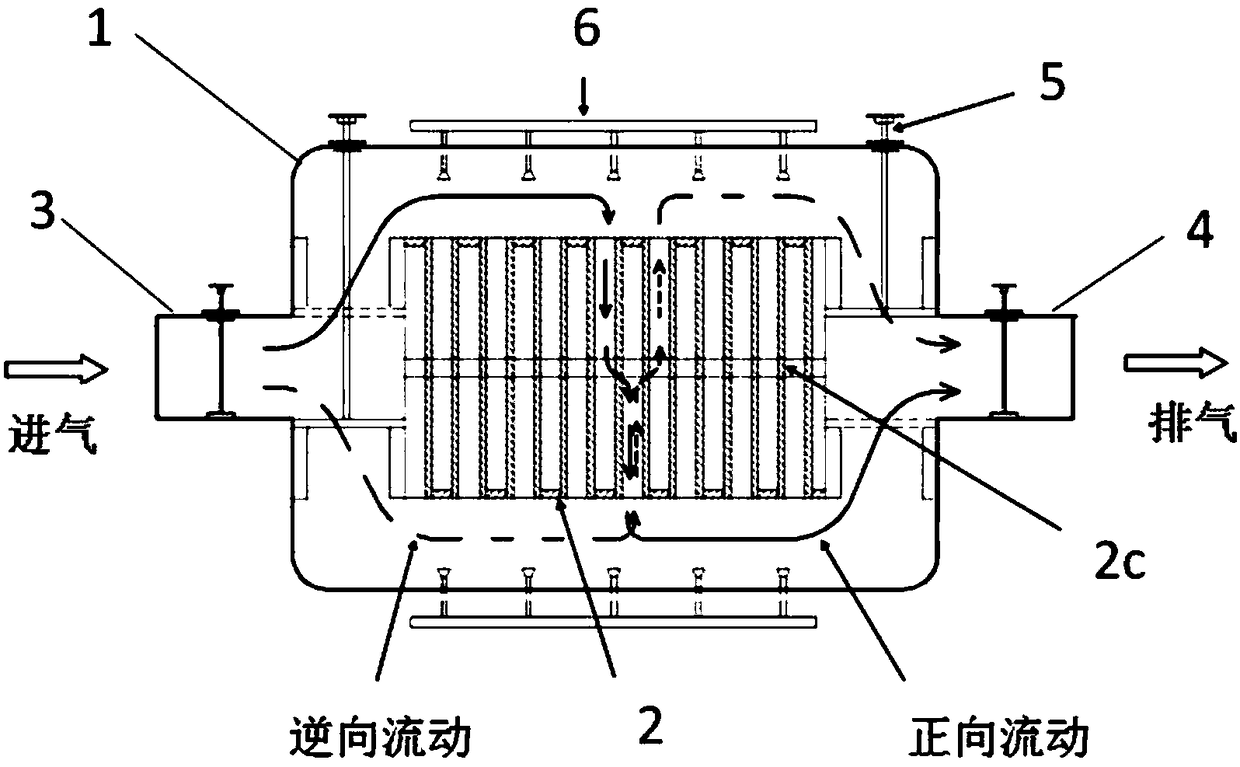

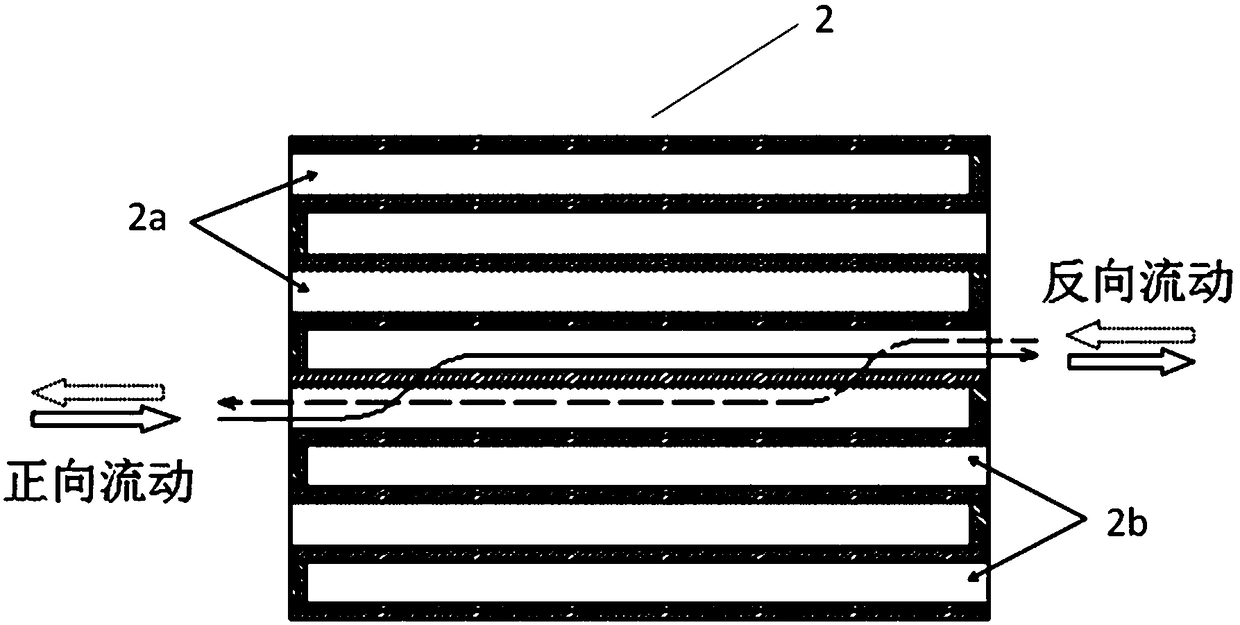

Reciprocated flowing type marine diesel engine continuous catalyzing regenerating diesel oil particle filter

ActiveCN108316993ACaptureAbility to suppress failureInternal combustion piston enginesExhaust apparatusSulfurTherapeutic effect

The invention belongs to the technical field of aftertreatment of marine diesel engine particulate matter emission control, and particularly relates to a reciprocated flowing type marine diesel enginecontinuous catalyzing regenerating diesel oil particle filter. According to the filter, an adverse current oxidation device is used for achieving the principle that ultra-thin organic substance is subject to reciprocated flowing within a self-maintaining period to be subject to oxidation treatment, and the reciprocated flowing type marine diesel engine novel continuous catalyzing regenerating DPFsuitable for a marine diesel engine burning heavy oil. The novel DPF technology is applied into the marine diesel engines burning heavy oil, a marine diesel engine particulate matter control device has the advantages of small flowing resistance, the good particulate matter removing effect, the compact structure, easiness in regeneration, high catalyst sulfur poisoning resistance and the like, integrated matching of the marine diesel engine particulate matter control device and a diesel engine host, an SCR denitration device and a wet-type washing desulfurizer is easily achieved, and the integrated treatment effect of desulfuration, denitration and particulate matter removal of waste gas of the marine diesel engine is achieved.

Owner:DALIAN MARITIME UNIVERSITY

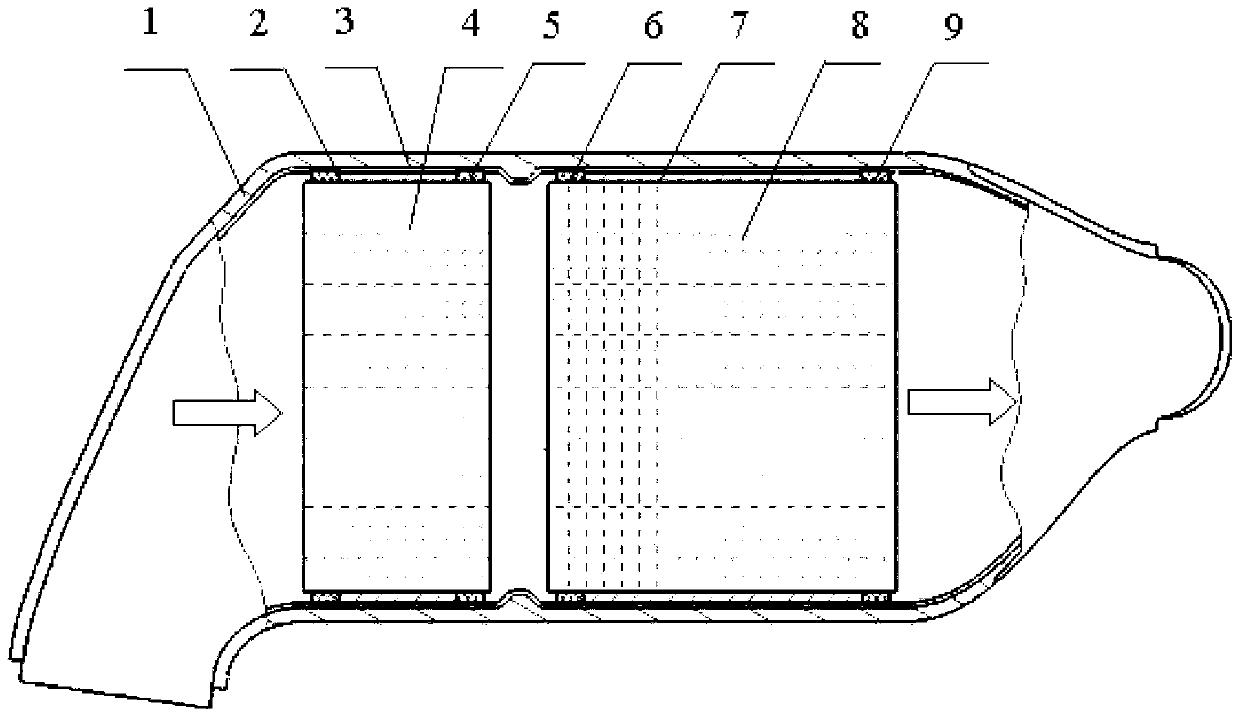

Automobile exhaust catalyst and prepared catalytic converter thereof

ActiveCN103343708ASmall heat capacityReduce contentExhaust apparatusSilencing apparatusEngineeringEngine power

The invention provides an automobile exhaust catalyst which comprises a front end carrier and a rear end carrier. The automobile exhaust catalyst is characterized in that the front end carrier is in an oval runway shape, and the mesh number of the carrier is 3 / 600. A front end coating coats the front end carrier, and a single layer of palladium coats the front end coating. The rear end carrier is in an oval runway shape, the mesh number of the carrier is 4 / 400, a rear end coating coats the rear end carrier, and precious metal coats the rear end coating in a partitioned mode. The invention further provides a catalytic converter which is low in initiation temperature, short in initiation time, high in catalytic conversion efficiency, simple in structure, and low in cost. Meanwhile, backpressure loss of the catalytic converter is further reduced, engine power is guaranteed, and reduction of oil consumption of an automobile is facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Catalyst and coating material for automobile tail gas purification and preparation methods therefor and application therefor

ActiveCN104959144AAchieve conversionReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMineral particlesRare earth

The invention discloses a catalyst coating material for automobile tail gas purification. The catalyst coating material comprises an oxygen storage layer and a catalytic active layer, wherein the oxygen storage layer is located at a lower layer, and the catalytic active layer is located at an upper layer; the oxygen storage layer is formed through uniformly loading oxides of one or more of rare-earth metals or transition metals to porous mineral particles; and the catalytic active layer is formed through uniformly loading oxides of one or more of transition metals to porous mineral particles. The invention further discloses a preparation method for the coating material and a catalyst prepared by employing the coating material. The catalyst coating material disclosed by the invention fully consists of rare-earth and transition metal oxides and is completely free of noble metal elements, so that the preparation cost is low; and the load amount of metal elements is large, the number of catalysis sites is large, and the upper and lower layers have a very good synergistic catalysis action, so that the catalytic conversion efficiency is high, and the application prospect is good.

Owner:苏磊

Method for preparing nitrogen-containing heterocyclic ring compound by use of chitin biomass

ActiveCN103951622AWide variety of sourcesRich reservesOrganic chemistryWater bathsNitrogenous heterocyclic compound

The invention discloses a method for preparing a nitrogen-containing heterocyclic ring compound by use of chitin biomass. The method comprises the following steps: uniformly mixing a chitin biomass raw material, an imidazole type ionic liquid solution and an additive for reaction, sequentially adding acetic oxide and pyridine into a reaction product for acylation, quenching the acylation-finished reaction liquid, adding an extracting agent into the acylation-finished reaction liquid for extraction, rotationally evaporating and concentrating to obtain an acylation product, adding an NaOH solution into the acylation product which is obtained through the extraction, stirring under a water-bath condition, adding hydrochloric acid which has the same molar weight as alkali, adding methanol, filtering to remove inorganic salt, rotationally evaporating and concentrating the filtrate to obtain a deacylation product, and crystallizing the deacylation product. The method disclosed by the invention has the advantages of simple process, high product purity, high yield and short reaction time.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

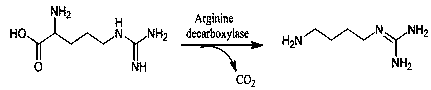

Method using thallus whole cells to catalyze arginine to convert into agmatine

ActiveCN110257448ASolve the high cost of preparationImprove conversion efficiencyMicroorganism based processesFermentationChemistryCarbon source

The method relates to a method using thallus whole cells to catalyze arginine to convert into agmatine and belongs to the technical field of bioengineering. The method includes: preparing whole-cell arginine decarboxylase concentrate, mixing the whole-cell arginine decarboxylase concentrate with initial conversion liquid, converting, crystalizing and recrystallizing. The method has the advantages that by controlling the carbon source, nitrogen source and dissolved oxygen during fermentation induction, the obtained arginine decarboxylase genetically engineered thallus whole-cell concentrate is high in arginine catalytic conversion efficiency; the concentrate does not contain byproducts, so that the agmatine obtained by conversion can be conveniently crystalized and purified; the thallus whole-cell concentrate is short in fermentation period, a large amount of the thallus whole-cell concentrate can be obtained in a short time, and large-scale preparation of the agmatine is benefited; agmatine product concentration on conversion liquid is 200-300g / L, conversion rate is 92-99%, agmatine product purity can reach 97-100%, and product yield can reach 90-100%.

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH +1

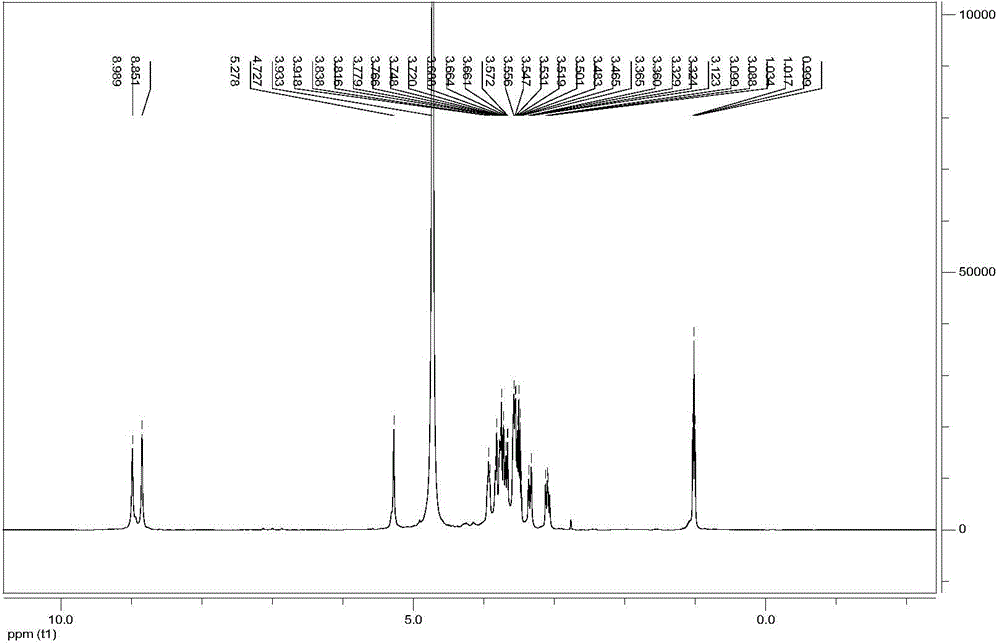

Application of glucosyltransferase in production of ethyl vanillin-alpha-D-glucoside

ActiveCN109762794AImprove catalytic conversion efficiencyHigh product concentrationTransferasesFermentationMicrobial agentEthyl vanillin

The invention discloses application of glucosyltransferase in production of ethyl vanillin-alpha-D-glucoside. The amino acid sequence of the glucosyltransferase is shown as SEQ ID NO.2. According to the application, the fermentation liquor obtained by fermentation culture of engineering bacteria containing a glucosyltransferase coding gene is taken as a microbial agent, maltose and ethyl vanillinare taken as substrates, and the pH value is 6.0-8.5, conversion reaction is executed under the condition of 20-40 DEG C, and after the reaction is completed, the reaction liquid is separated and purified to obtain the ethyl vanillin-alpha-D-glucoside. The microbial agent disclosed by the invention is used for biocatalytic production of the ethyl vanillin-alpha-D-glucoside, the substrate conversion rate is 80% or above, and the product concentration of the ethyl vanillin-alpha-D-glucoside is high, the conversion rate is high, and recovery and purification the ethyl vanillin-alpha-D-glucoside prepared by a biological method are facilitated.

Owner:SHENZHEN SHINESKY BIOLOGICAL TECH CO LTD

Diesel engine post-processing device

InactiveCN109973177AImprove catalytic conversion efficiencyImprove cooling effectInternal combustion piston enginesExhaust apparatusLow loadExternal combustion engine

The invention relates to a diesel engine post-processing device, and belongs to the technical field of internal combustion engine post-processing. The diesel engine post-processing device comprises aDPF chamber and an SCR catalyst chamber; a channel, between the DPF chamber and the SCR catalyst chamber, is provided a nozzle which is used for injecting into the channel; the nozzle is connected toa liquid supply pipeline; and a catalyst carrier is arranged in the SCR catalyst chamber, and an electric heater is arranged on the periphery of the catalyst carrier. When the diesel engine is cold started or runs at a low rotating speed and a low load, the arranged tubular electric heater is used for heating a catalyst, so that the purpose of comprehensively improving the catalytic conversion efficiency of the catalyst is achieved. In addition, when the exhaust temperature is too high, water can be sprayed into the channel through the liquid supply pipeline and the nozzle, so that the coolingeffect is achieved, and the catalyst is prevented from losing effect.

Owner:HENAN UNIV OF SCI & TECH

Photocatalyst and application thereof in photocatalytic environment-friendly treatment of power battery

ActiveCN111804323AImprove permeabilityWill not cause mutual occlusionGas treatmentDispersed particle separationCatalytic transformationPower battery

The invention discloses a photocatalyst and application of the photocatalyst in photocatalytic environment-friendly treatment of a power battery. The photocatalyst is obtained by loading Ag-TaON on hollow glass beads, wherein the mass ratio of the Ag-TaON to the hollow glass beads is 1: (5-10). Ag-TaON and the hollow glass beads are compounded, the hollow glass beads have better light permeability, mutual shielding between catalysts is avoided, the photocatalyst filled in the reactor is fully excited, the light utilization rate can be effectively increased, and thus the catalytic conversion efficiency of the photocatalyst is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

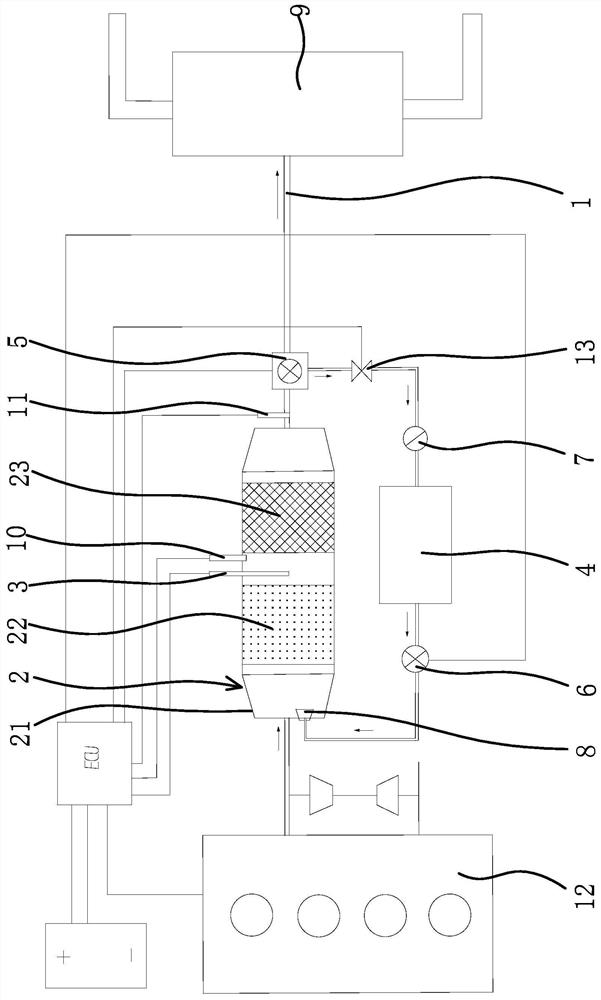

Emission pollutant treatment system and method applied to gasoline engine

InactiveCN108612593APrecise control of air-fuel ratioLower raw emissionsElectrical controlExhaust apparatusOxygen sensorGasoline

The invention discloses an emission pollutant treatment system and method applied to a gasoline engine. The system comprises a gas inlet system, an engine, an exhaust aftertreatment system and an electric control system which are connected in sequence. The gas inlet system is used for precisely measuring the air flow and feeding back signals to the electric control system. The electric control system is used for receiving the signals and cooperating with an oxygen sensor in the exhaust aftertreatment system to precisely control the air-fuel ratio. The engine comprises a fuel injection system mounted in an engine body, and the fuel injection system is used for precise fuel injection atomization. According to the system and method, the arrangement structure is optimized, the technological level is increased, and therefore original emissions are reduced, and the aim of the emission regulation (CHINA 6) is achieved under the condition of not utilizing GPF.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Nanofiber catalyst and preparation method thereof

ActiveCN107115860AImprove catalytic conversion efficiencyThe synthesis method is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberComposite nanofibers

The invention relates to a lanthanide series and yttrium-bismuth composite nanofiber catalyst and a preparation method thereof. The conventional industrial catalyst is mainly synthesized by adopting a hydrothermal synthesis or co-precipitation method, only a powdery structure can be formed, and agglomeration is easy; an electrostatic spinning method is adopted for successfully spinning partial industrial catalyst to be nanofibrous, thereby being simple and convenient; meanwhile, the diameter of the nanofiber maintains to be 60-800nm, and length ranges from 0.3mu m to 30mu m and is even longer; and experimental operation is simplified, and during a NO catalysis experiment, the composite nanofiber catalyst shows higher catalytic performance compared with a sample synthesized by adopting the traditional method.

Owner:栗豹

Exhaust system of vehicle

InactiveCN112922702ASolve pollutionImprove gas storage capacityInternal combustion piston enginesExhaust apparatusPollutant emissionsElectric control

The invention provides an exhaust system of a vehicle, and belongs to the technical field of automobiles. The technical problem that the pollution emission is high when cold starting of an existing engine is conducted is solved by the exhaust system. The exhaust system of the vehicle comprises an exhaust pipe and a catalytic converter, wherein a temperature sensor which is used for detecting the temperature of gas is arranged in the catalytic converter. The exhaust system further comprises a gas storage part and an electric control part, wherein an inlet and an outlet of the gas storage part correspondingly communicate with an outlet and an inlet of the catalytic converter through pipelines. When the temperature sensor detects that the temperature is smaller than a set value, the electric control part can communicate with the outlet of the catalytic converter and the inlet of the gas storage part and disconnect the outlet of the catalytic converter and an outlet of the exhaust pipe at the same time; and when the temperature sensor detects that the temperature is larger than or equal to the set value, the electric control part can disconnect the outlet of the catalytic converter and the inlet of the gas storage part and communicate with the outlet of the catalytic converter and the outlet of the exhaust pipe at the same time. According to the exhaust system of the vehicle, the pollutant emission in the cold starting process of the vehicle is remarkably reduced.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com