Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Variable geometry turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable-geometry turbochargers (VGTs), (also known as variable nozzle turbines/VNTs), are a family of turbochargers, usually designed to allow the effective aspect ratio (A:R) of the turbo to be altered as conditions change.

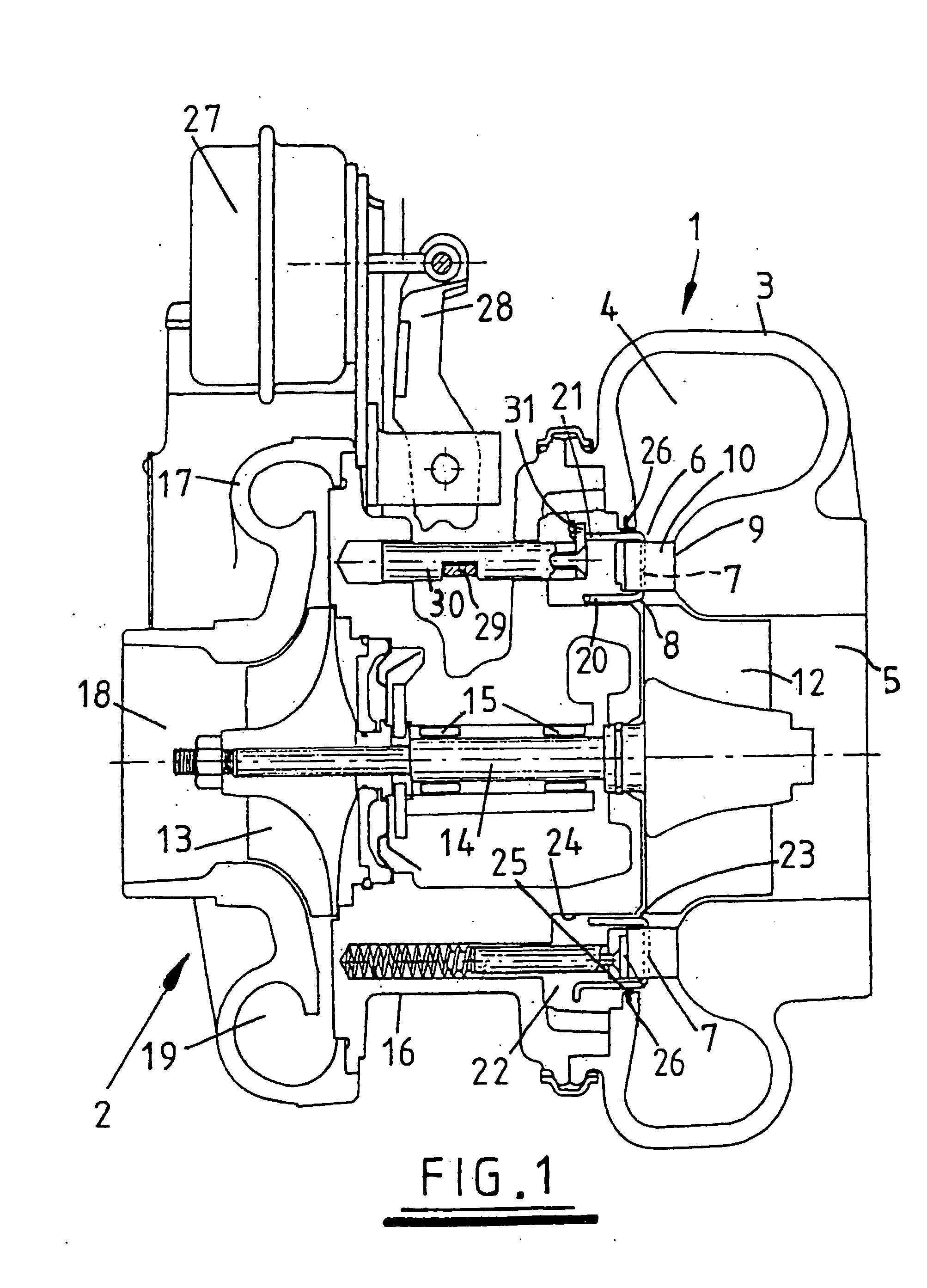

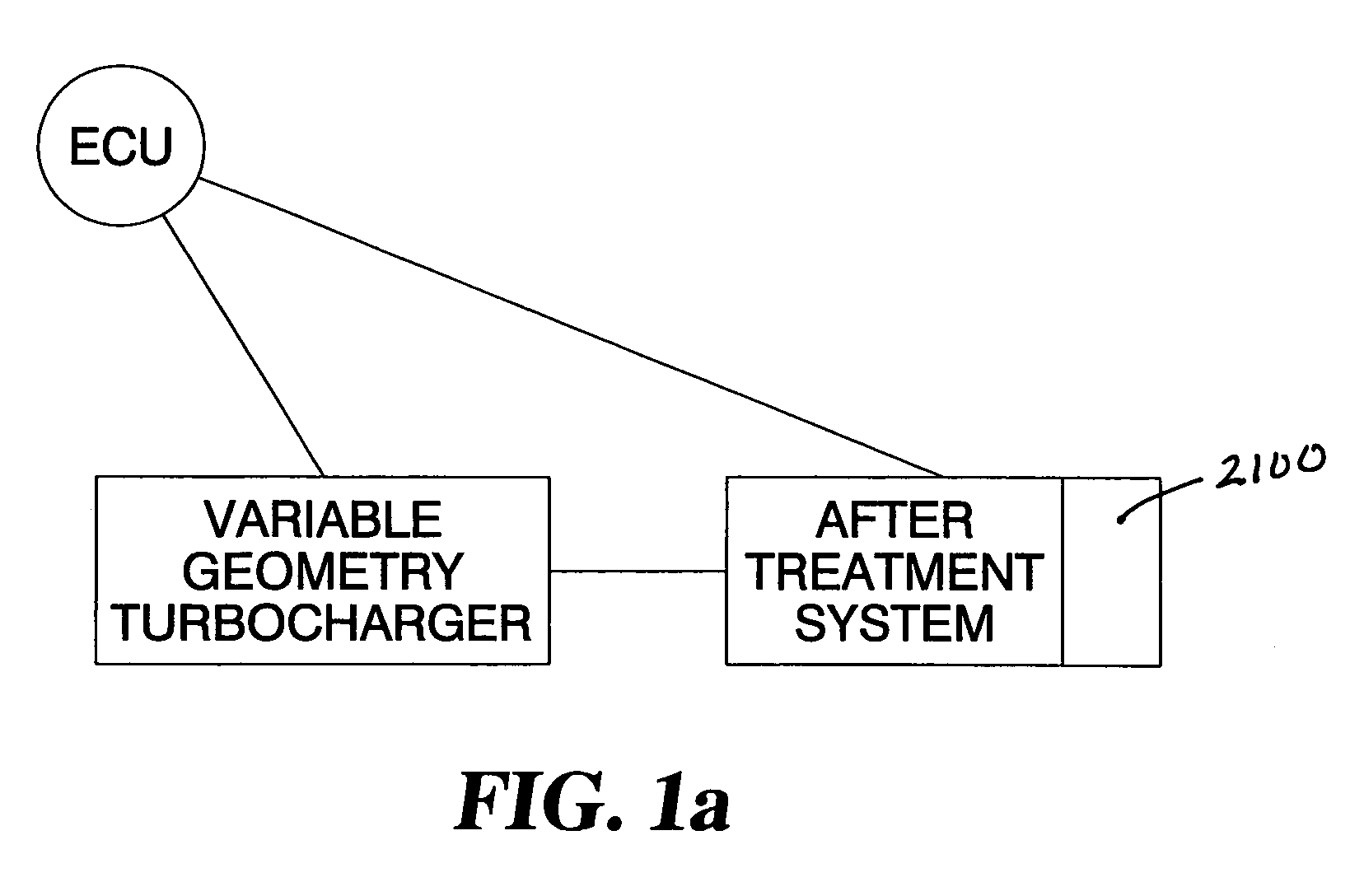

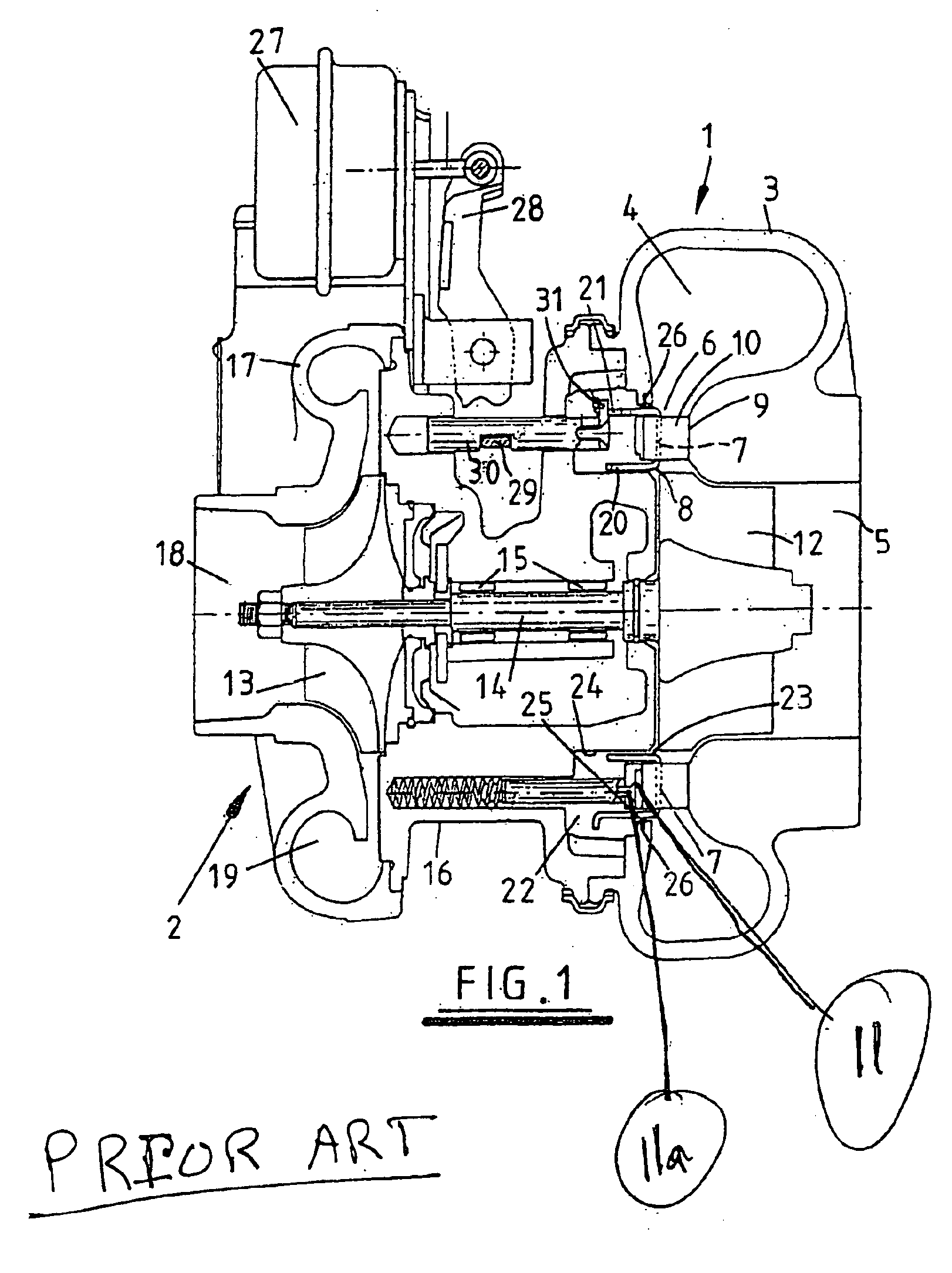

Method of controlling the exhaust gas temperature for after-treatment systems on a diesel engine using a variable geometry turbine

InactiveUS20050060999A1Small sizeElectrical controlInternal combustion piston enginesAfter treatmentVariable geometry turbine

A method for controlling a variable geometry turbine of a turbocharger to increase the temperature of the exhaust gas delivered to an after-treatment system. In one form the method includes reducing a fluid flow area to the turbine below a normal size and bypassing a portion of the exhaust gas around a plurality of guide vanes.

Owner:CUMMINS INC

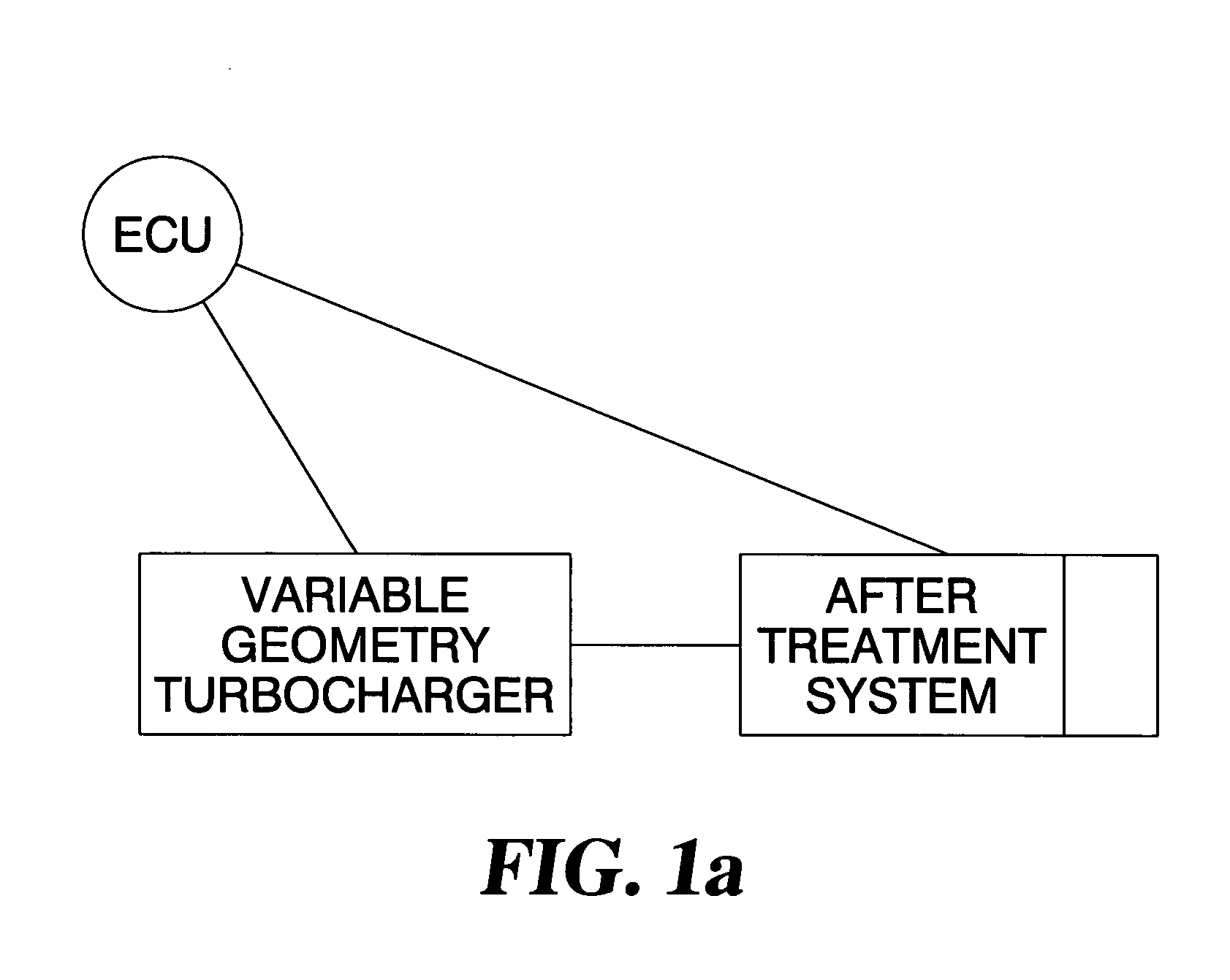

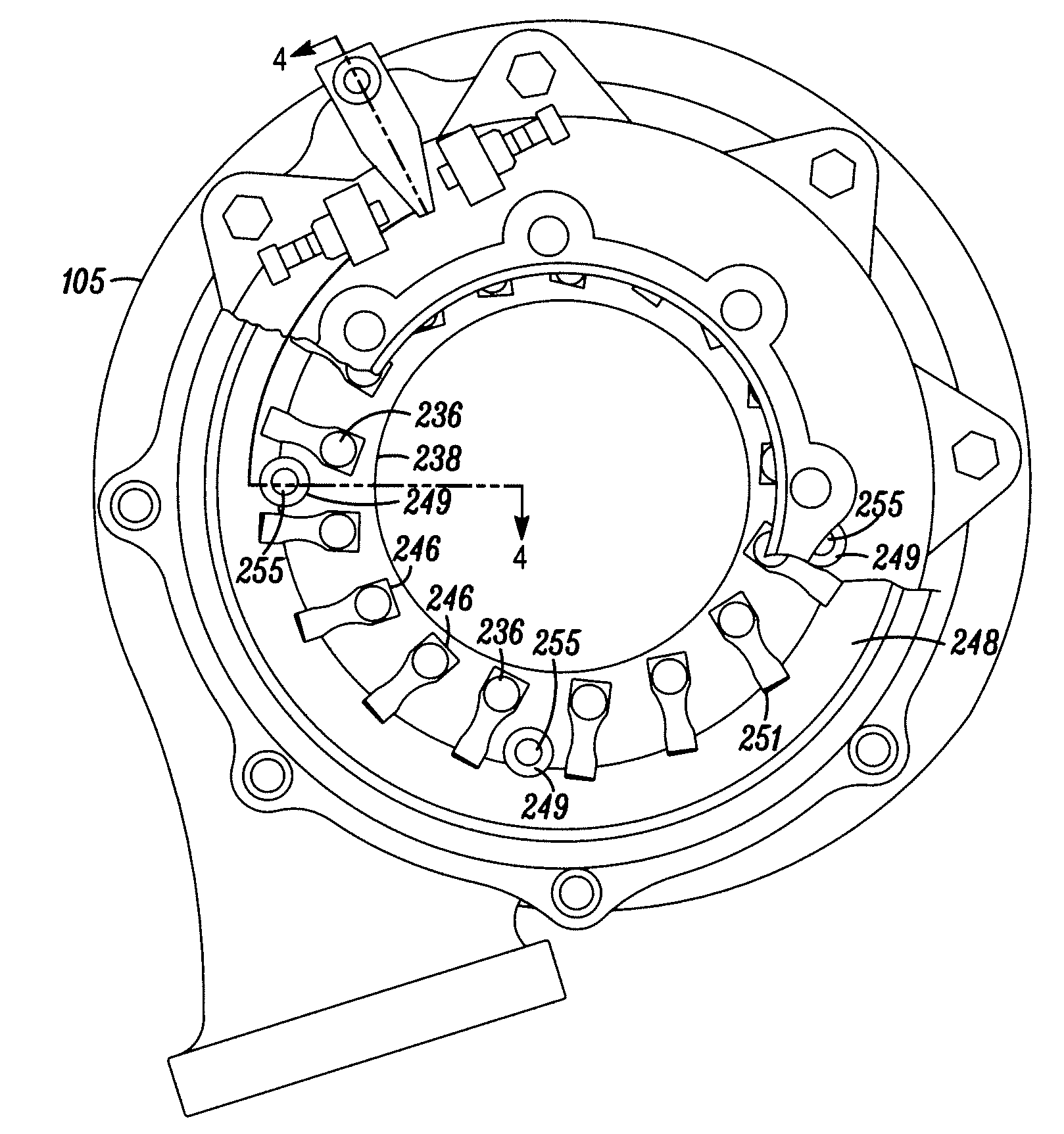

Adaptive variable geometry turbocharger strategy

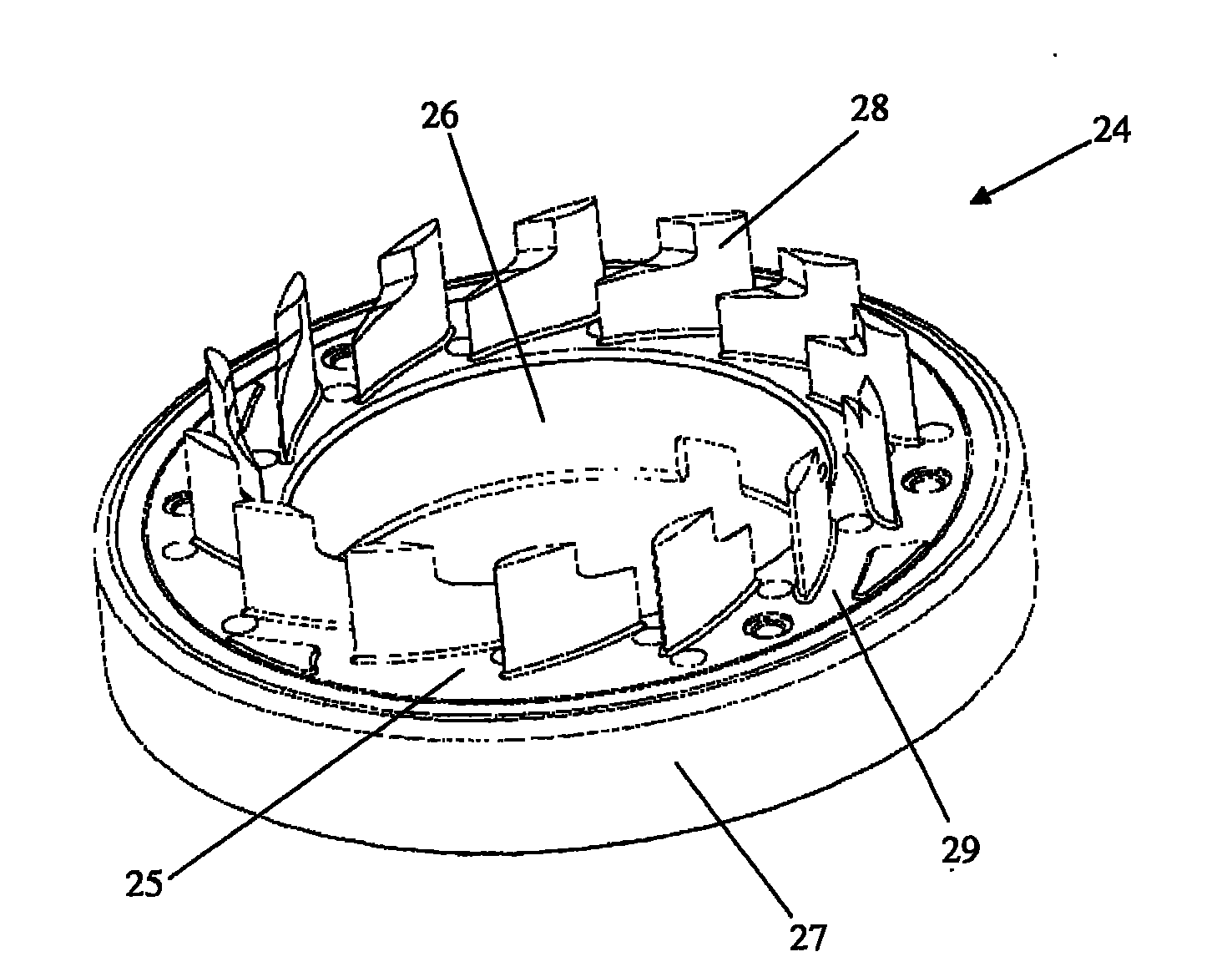

ActiveUS20090123272A1Provide goodEfficient and reliableElectrical controlInternal combustion piston enginesVariable geometry turbineActuator

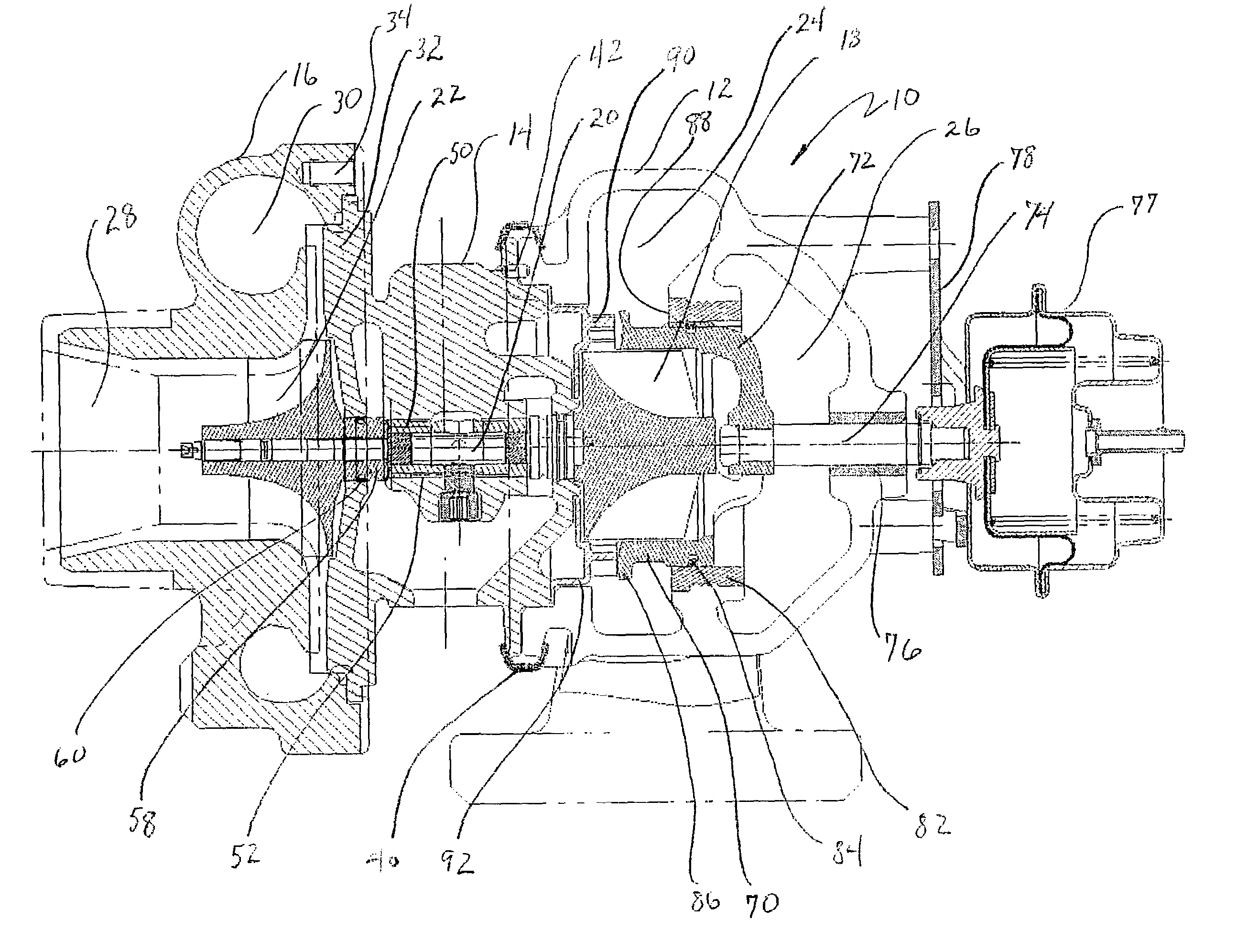

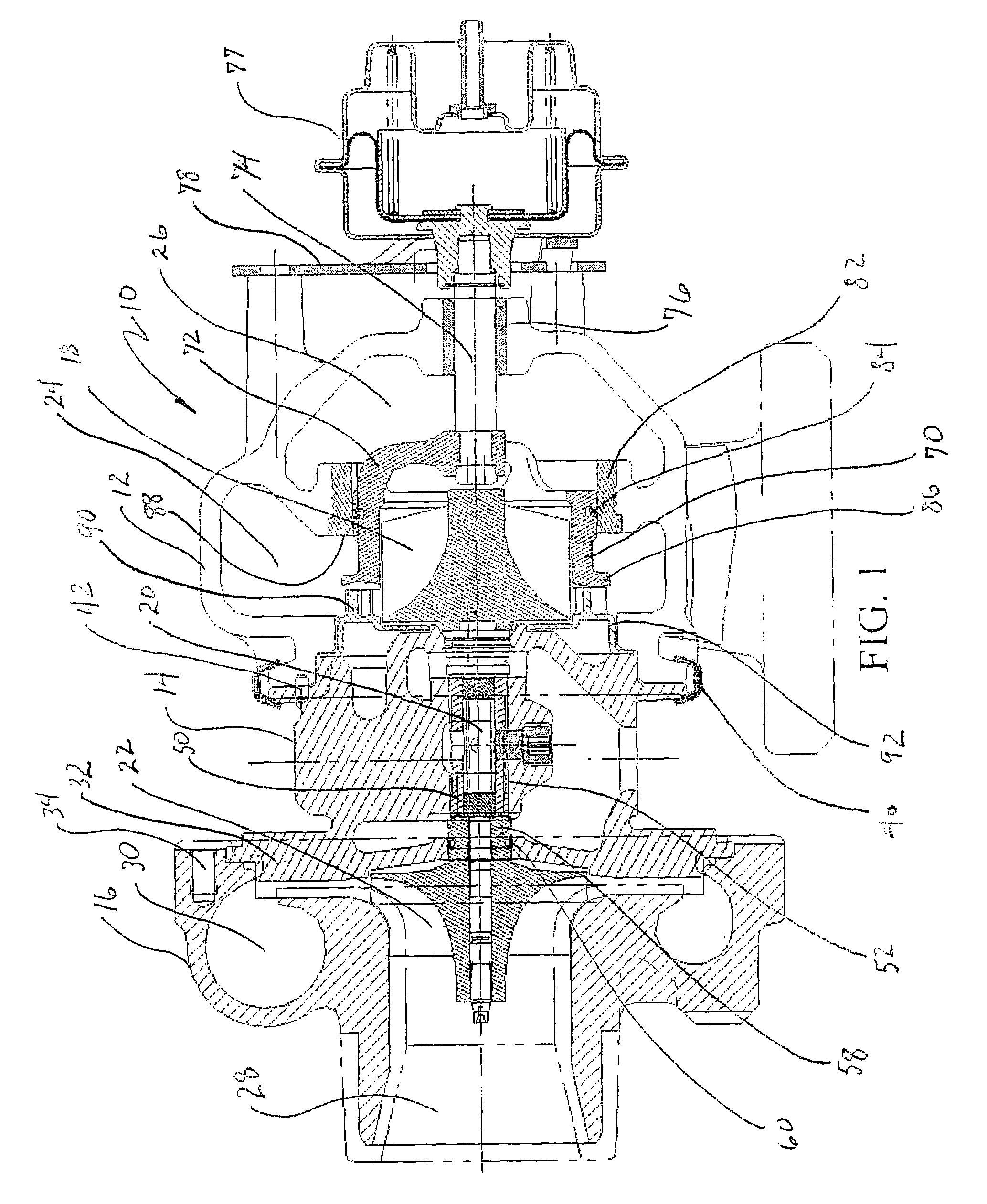

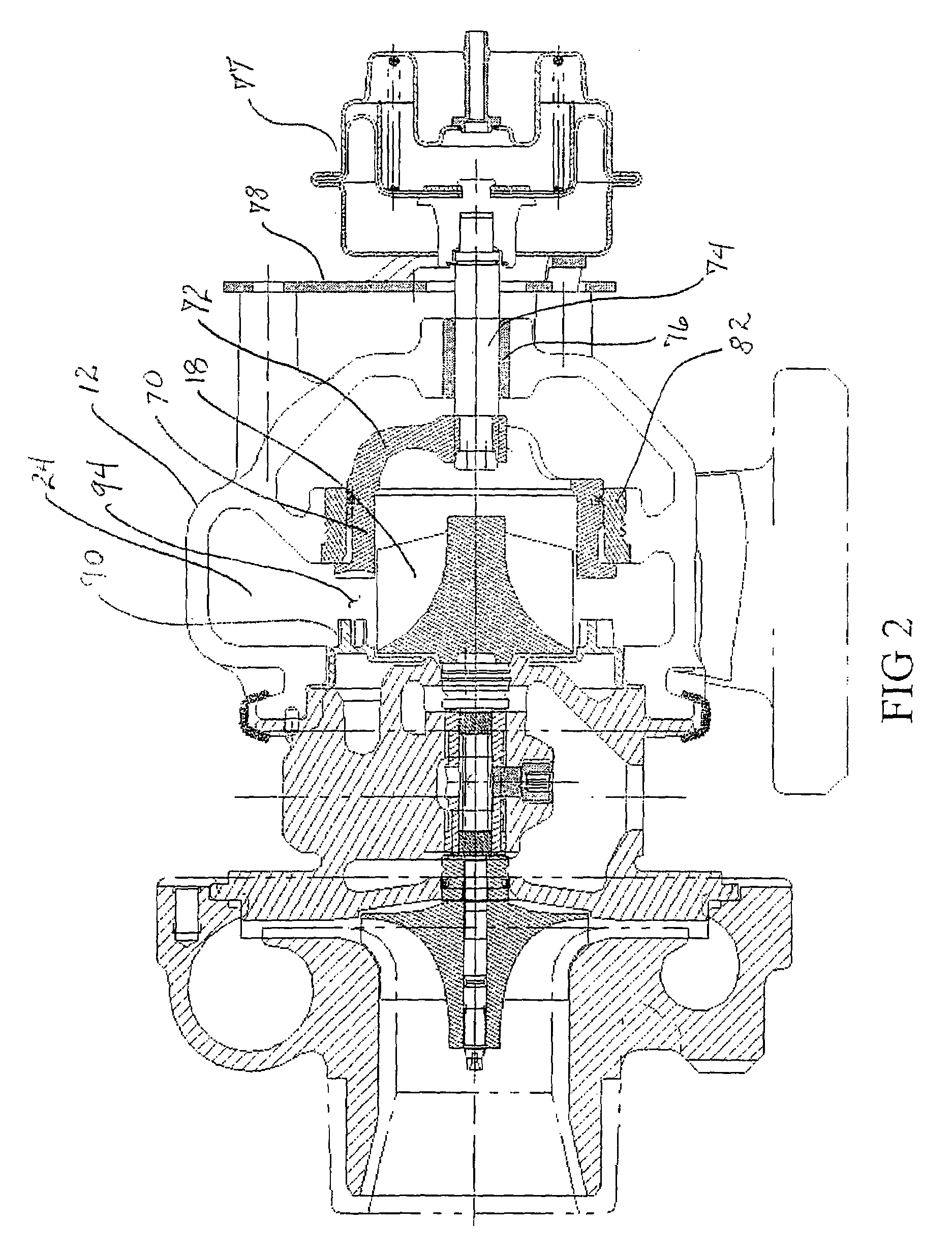

A variable geometry turbocharger employs multiple vanes in the turbine inlet with a unison ring and integral cast wall in the turbine housing forming the nozzle walls. An actuator rotates the unison ring through a rack and pinion driven crank shaft to move the vanes through a range of vane positions that extends between a hard-stop closed position and a hard-stop open position, and that includes a reference position corresponding to a desired flow condition. A variable geometry turbine controller uses a sensor indicating the actuation position of the actuator to guide the operation of the vanes to the reference position. The controller intermittently directs the actuator to force the vanes to the hard-stop closed and hard-stop open positions, and uses sensor information from those positions to reestablish the reference-position information that the actuator uses to guide the actuation of the vanes.

Owner:GARRETT TRANSPORATION I INC

Method of controlling the exhaust gas temperature for after-treatment systems on a diesel engine using a variable geometry turbine

InactiveUS7207176B2Small sizeElectrical controlInternal combustion piston enginesAfter treatmentVariable geometry turbine

A method for controlling a variable geometry turbine of a turbocharger to increase the temperature of the exhaust gas delivered to an after-treatment system. In one form the method includes reducing a fluid flow area to the turbine below a normal size and bypassing a portion of the exhaust gas around a plurality of guide vanes.

Owner:CUMMINS INC

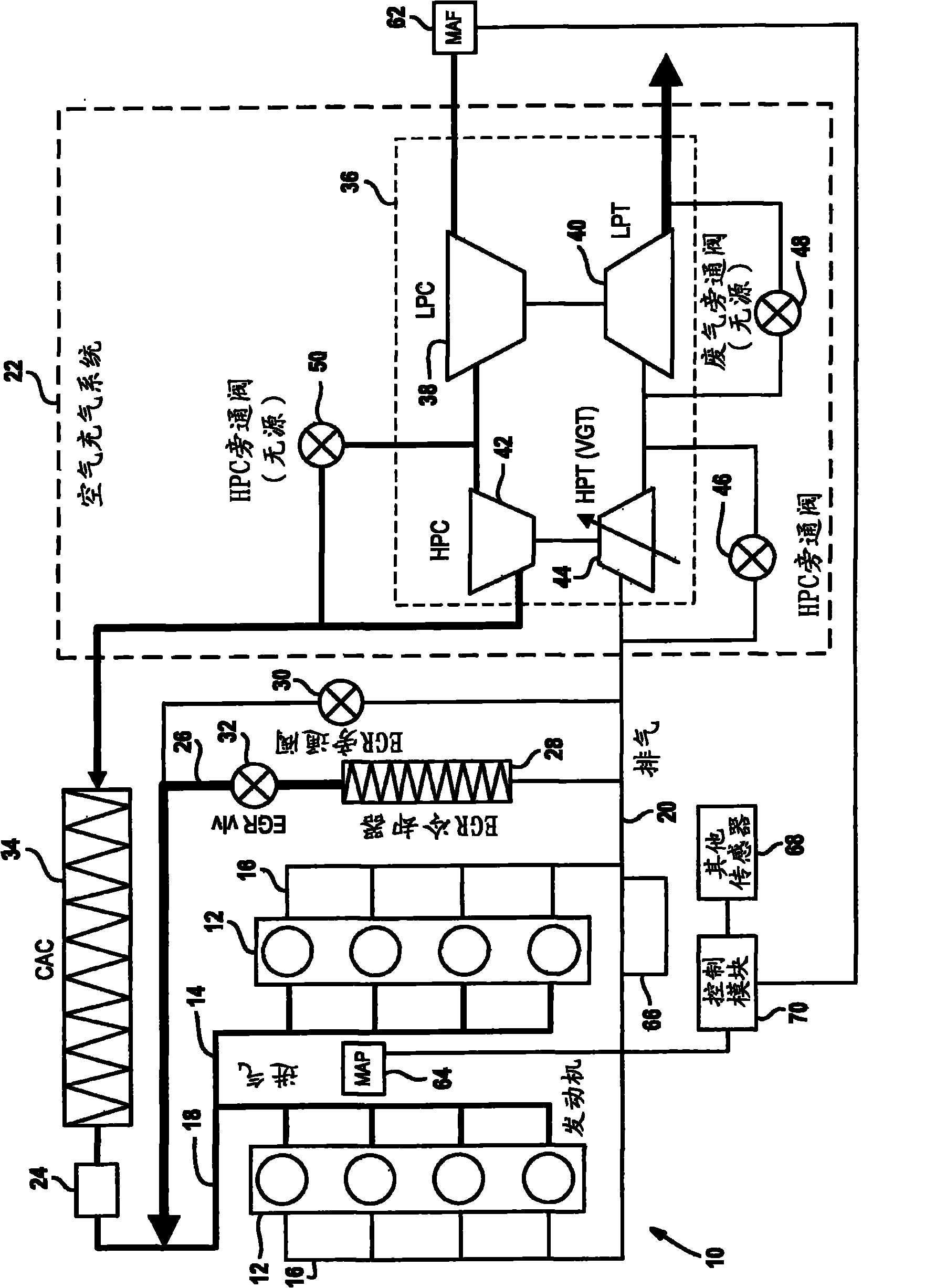

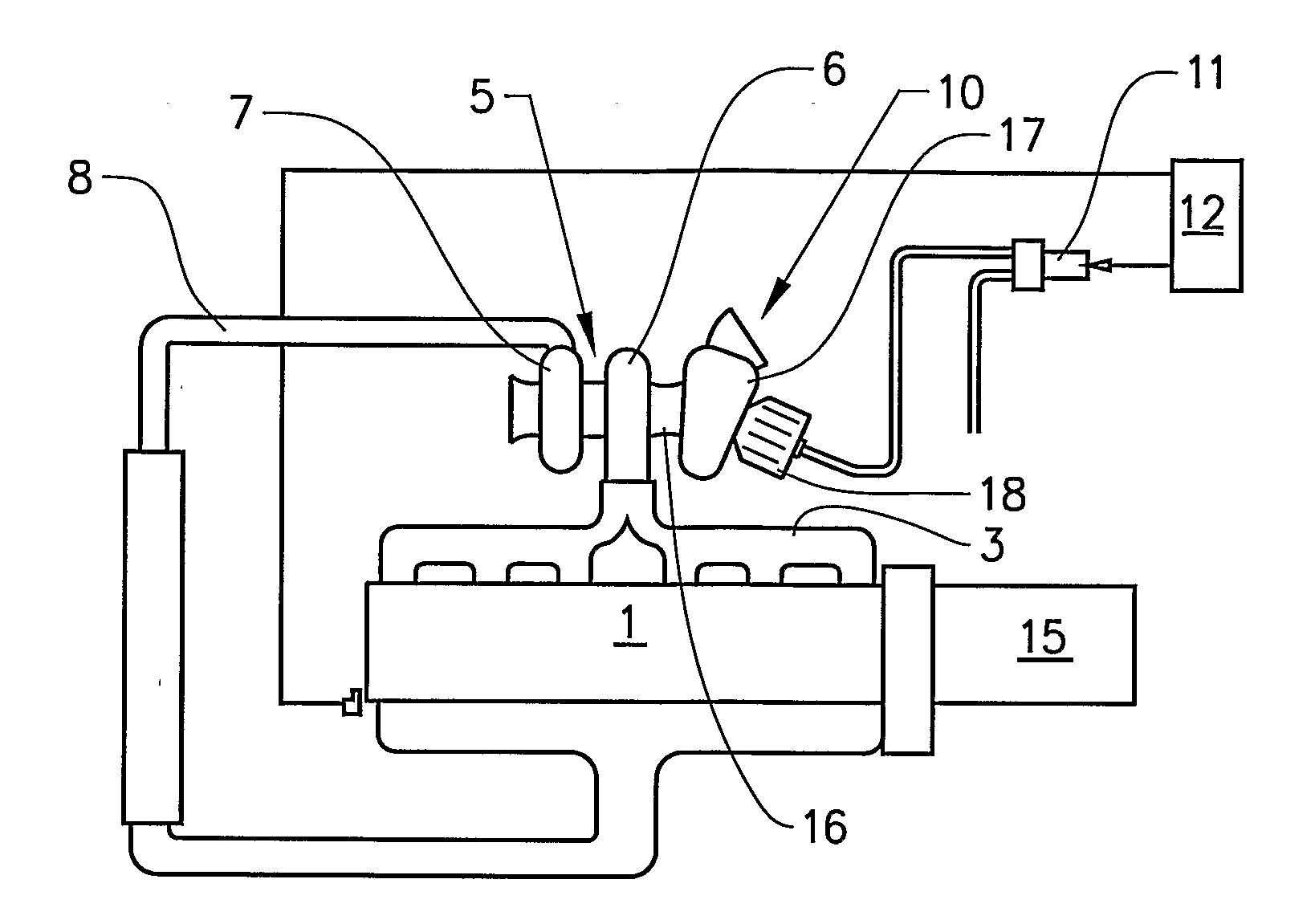

Turbocharged internal combustion engine with egr system having reverse flow

InactiveUS20080216476A1Electrical controlNon-fuel substance addition to fuelVariable geometry turbineExternal combustion engine

An internal combustion engine includes a block defining at least one combustion cylinder. An intake manifold is fluidly coupled with at least one combustion cylinder, and an exhaust manifold is also fluidly coupled with at least one combustion cylinder. An exhaust gas recirculation system is fluidly coupled between the exhaust manifold and the intake manifold. A turbocharger includes a variable geometry turbine fluidly coupled with the exhaust manifold. The variable geometry turbine is movable to a first position effecting fluid flow of exhaust gas from the exhaust manifold to the intake manifold, and movable to a second position effecting fluid flow of charge air to the variable geometry turbine.

Owner:DEERE & CO

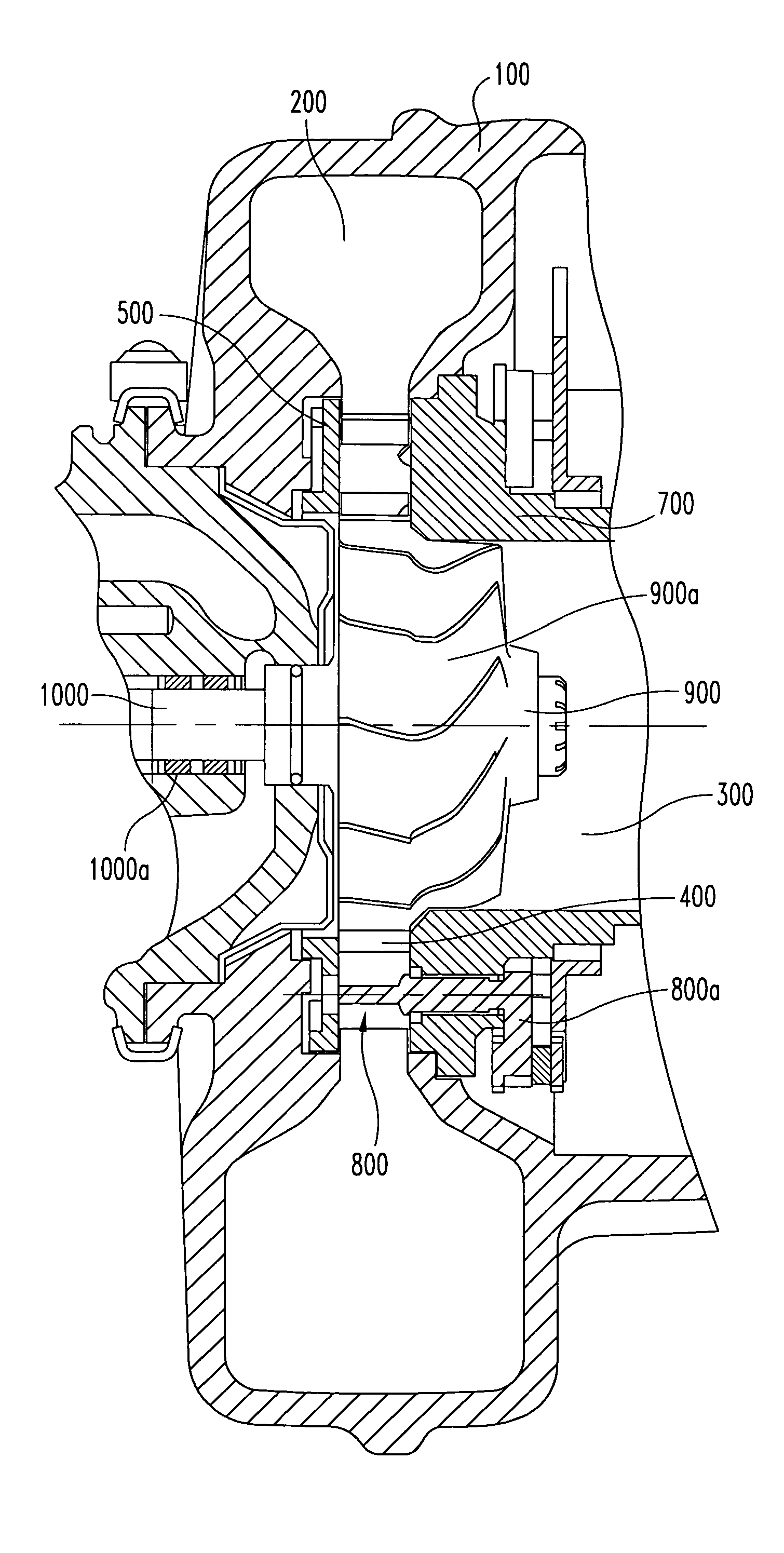

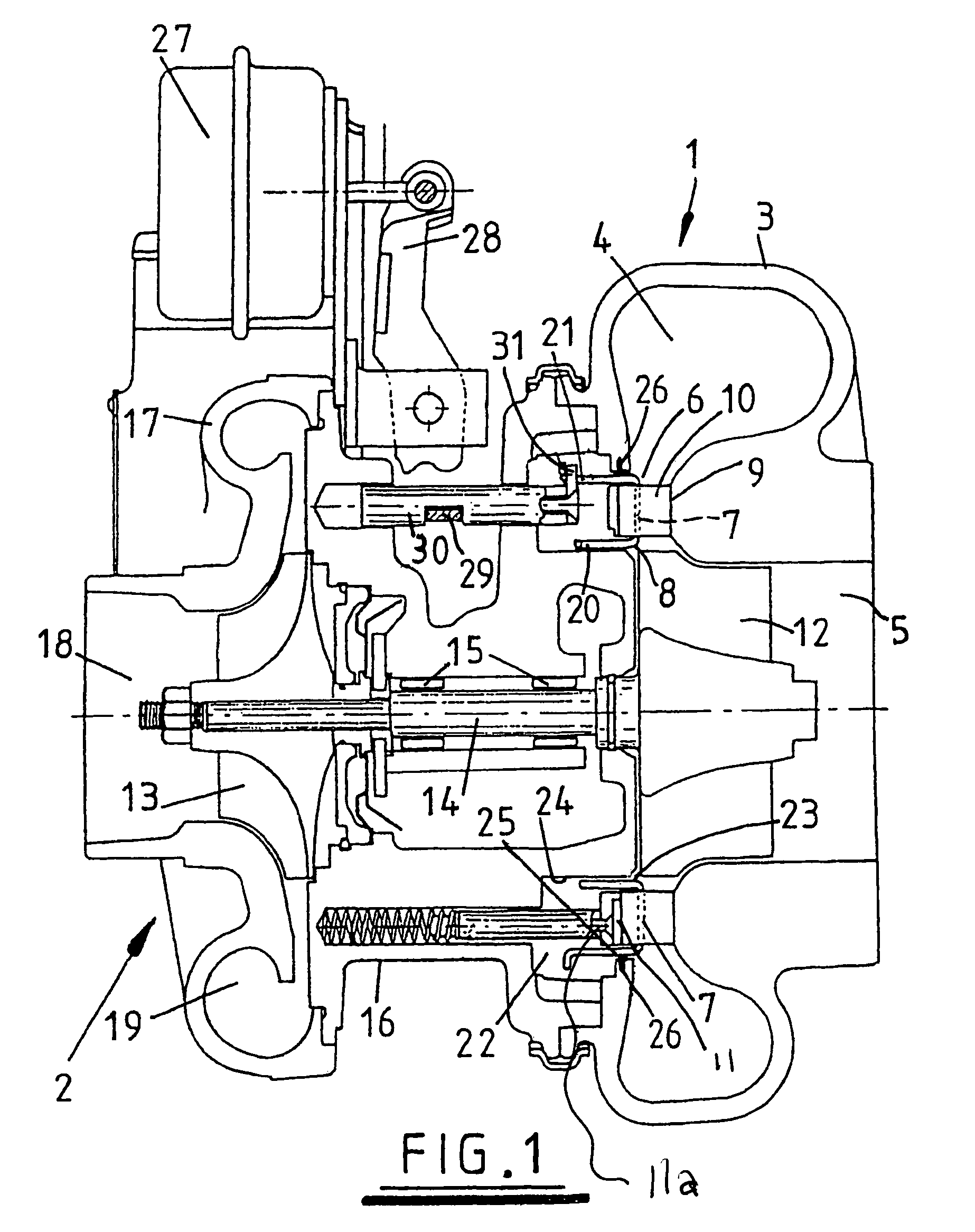

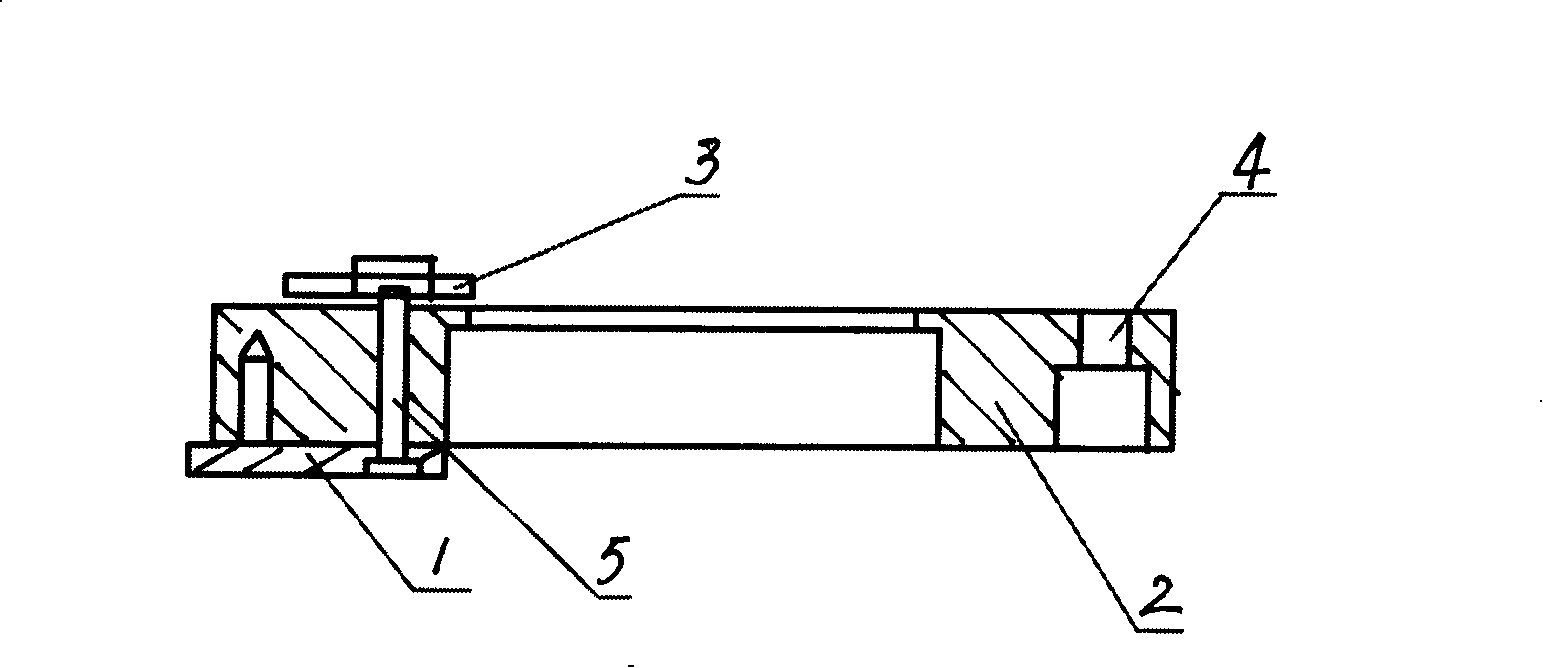

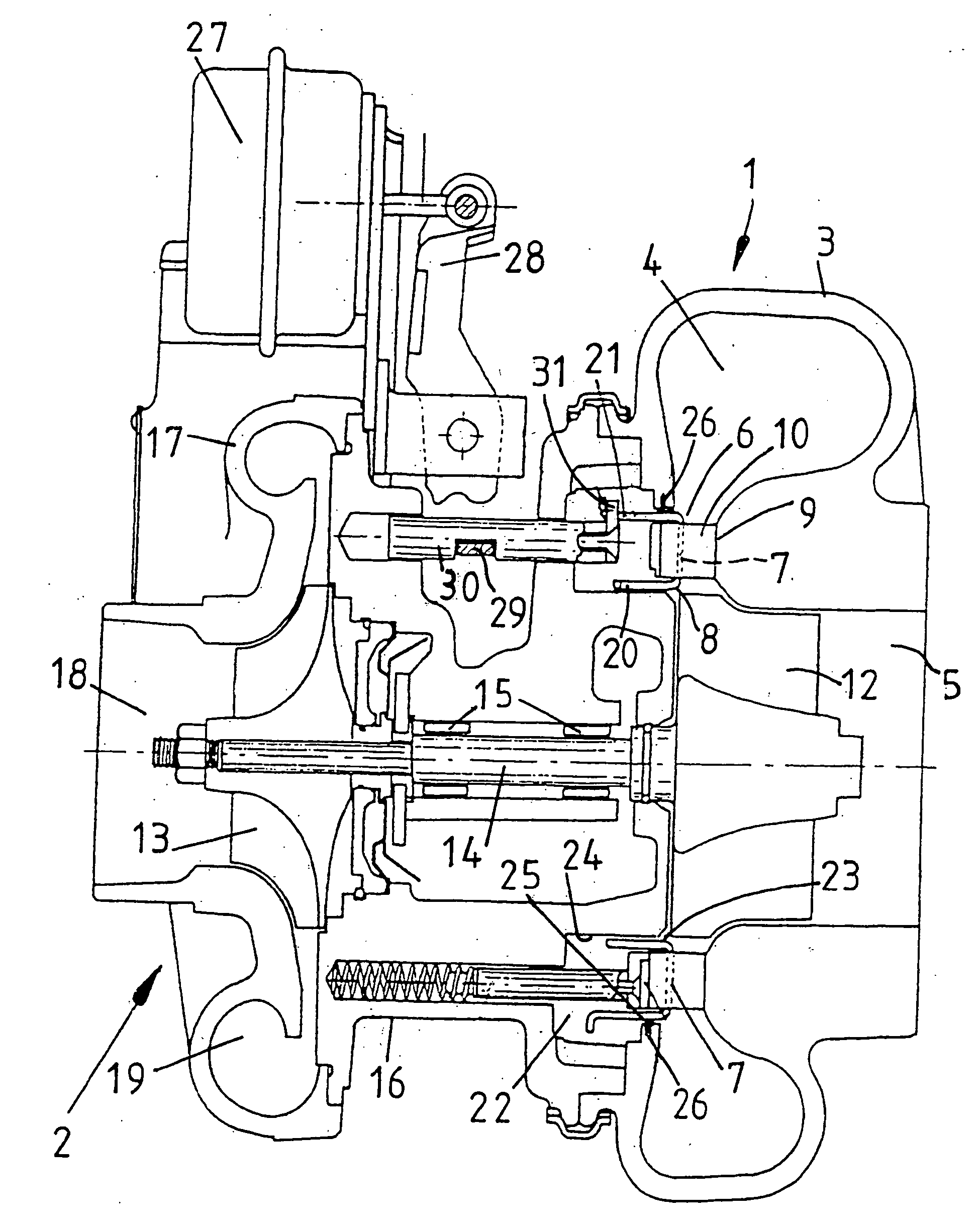

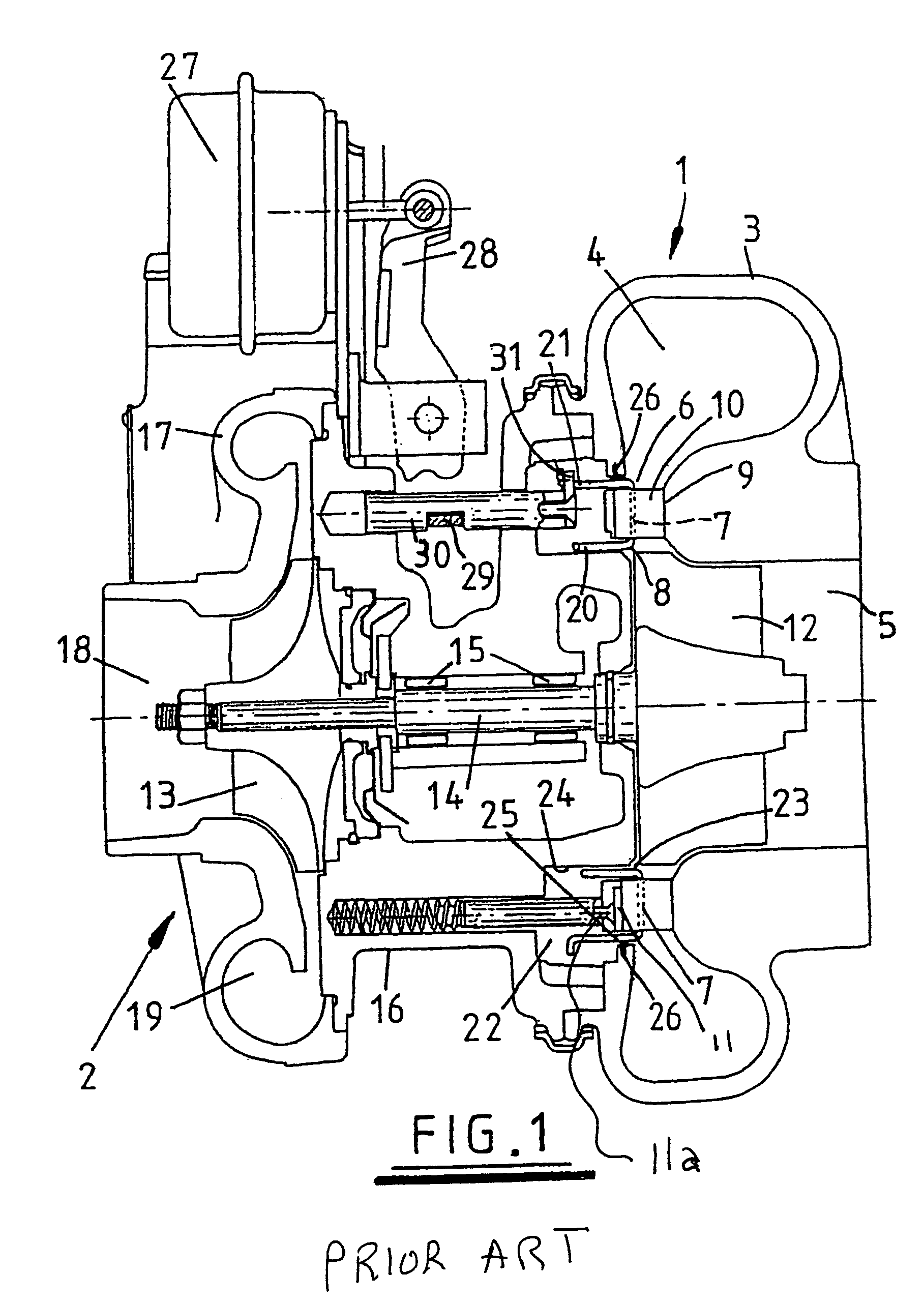

Variable geometry turbocharger with sliding piston

A turbocharger having a variable geometry turbine inlet incorporates a piston movable to vary the area of the inlet nozzle into the turbine. Vanes extending from the heat shield for flow control in the nozzle are engaged by the piston in a first closed position. In a second open position, the piston is spaced from the vanes increasing the inlet nozzle area.

Owner:HONEYWELL GARRETT

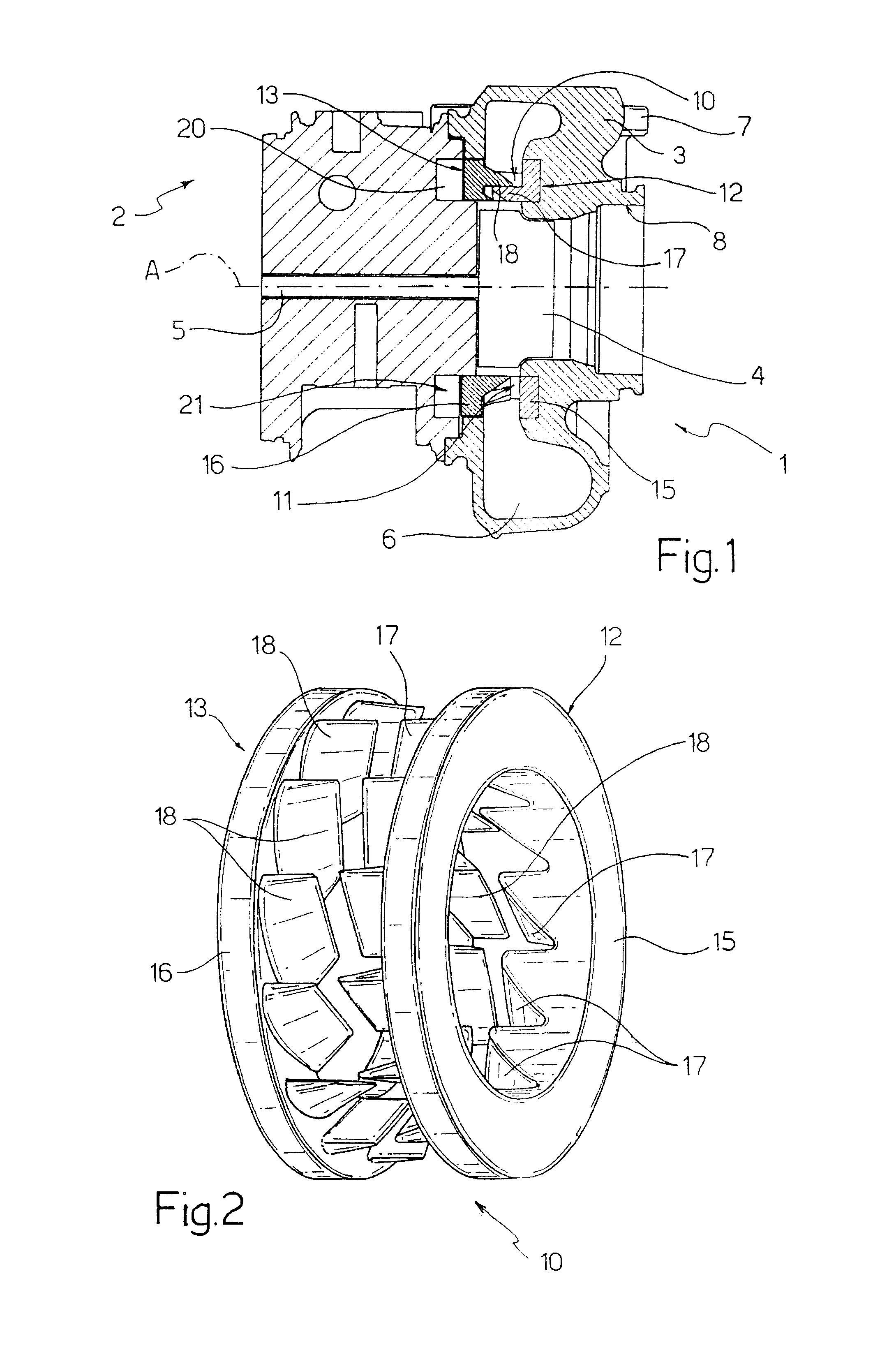

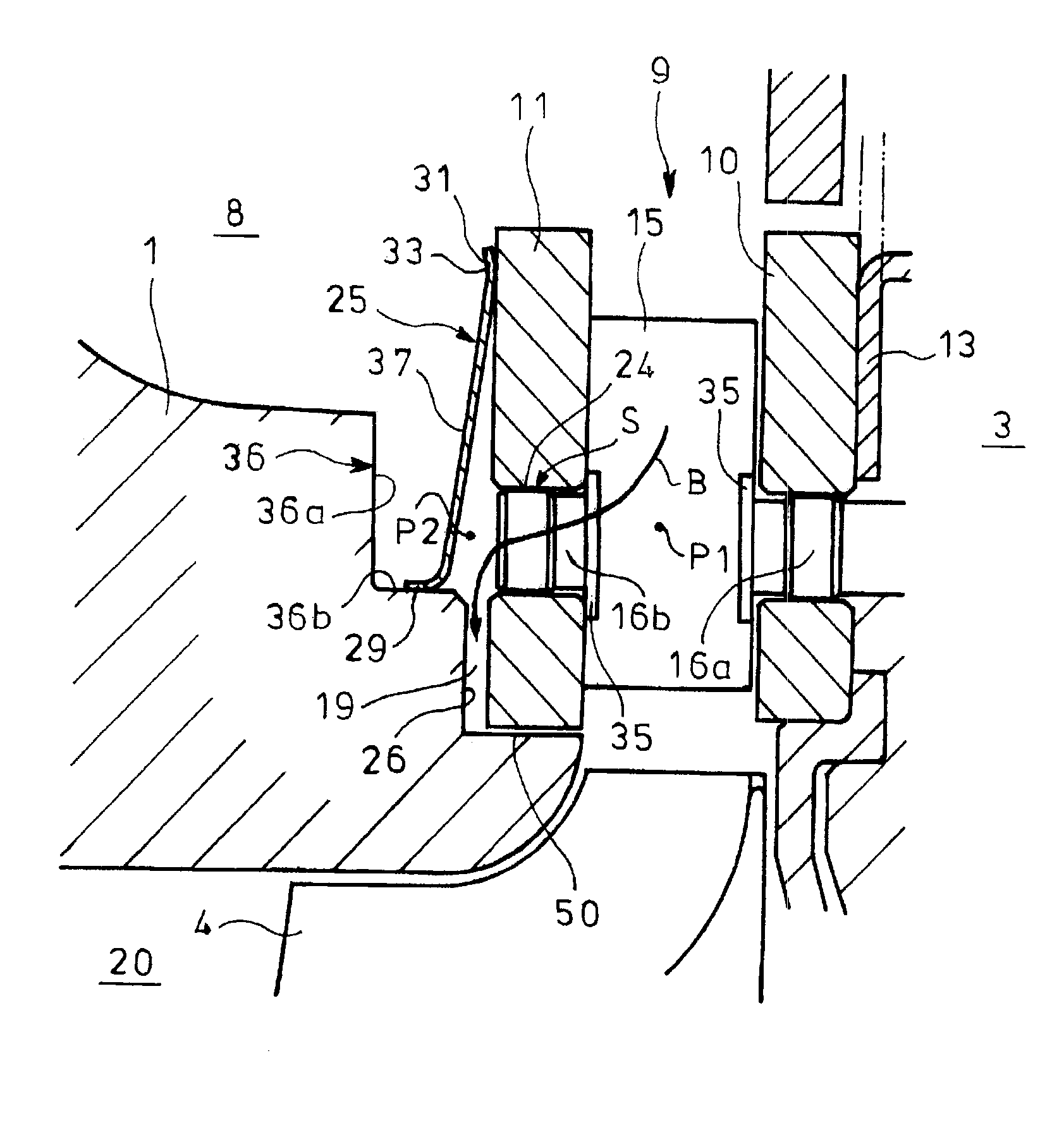

Variable geometry turbine

A variable geometry turbine, particularly for a supercharger turbocompressor of an internal combustion engine, comprising an outer housing forming a spiral inlet channel for an operating fluid, a rotor supported in a rotary manner in the housing, and an annular vaned nozzle of variable geometry interposed radially between the channel and the rotor; the nozzle comprises a pair of vaned rings facing one another and provided with respective pluralities of vanes tapered substantially as wedges and adapted to penetrate one another, one of which can move axially with respect to the other in order to define a variable throat section between these vaned rings.

Owner:FPT MOTORENFORSCHUNG

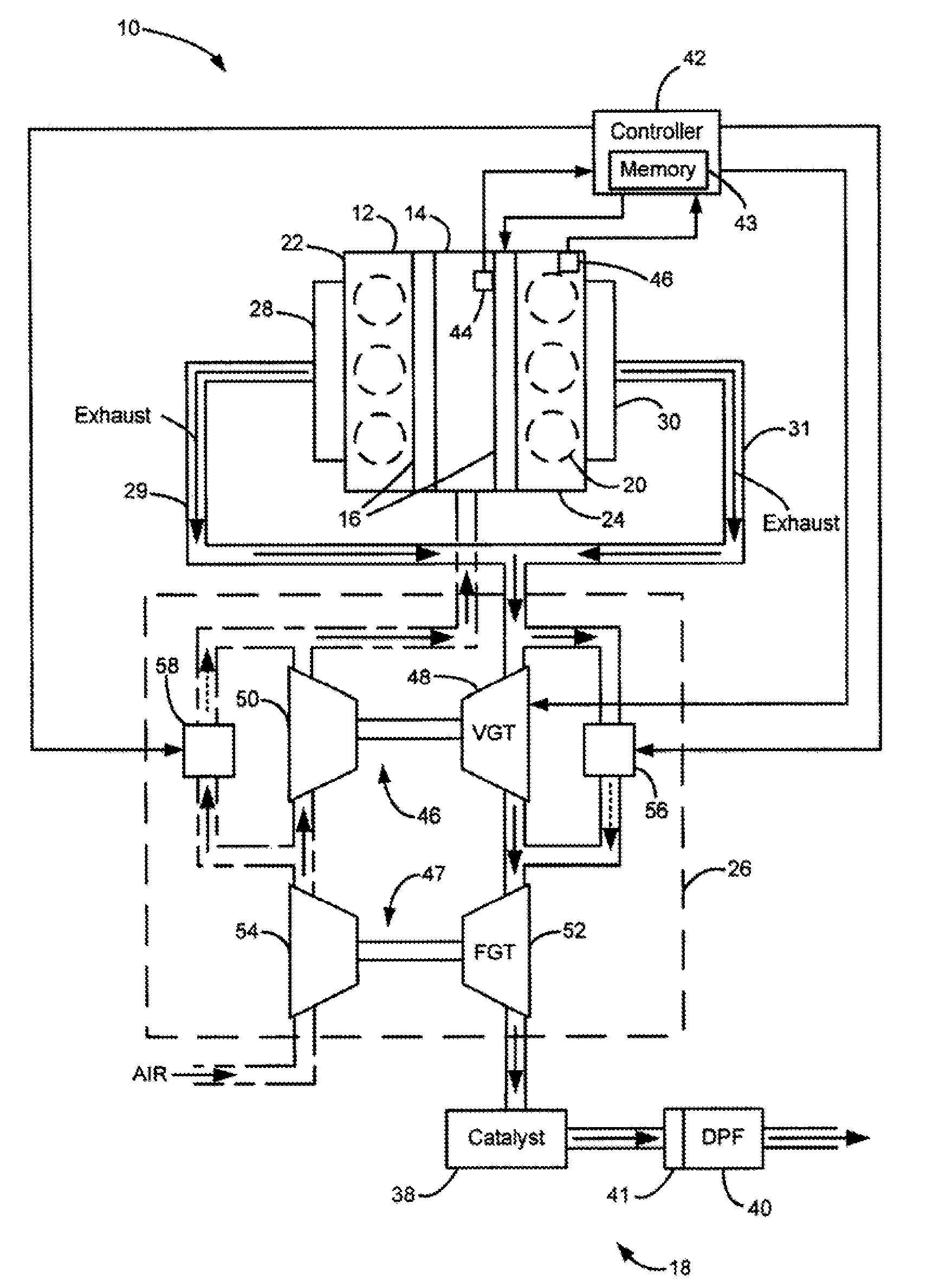

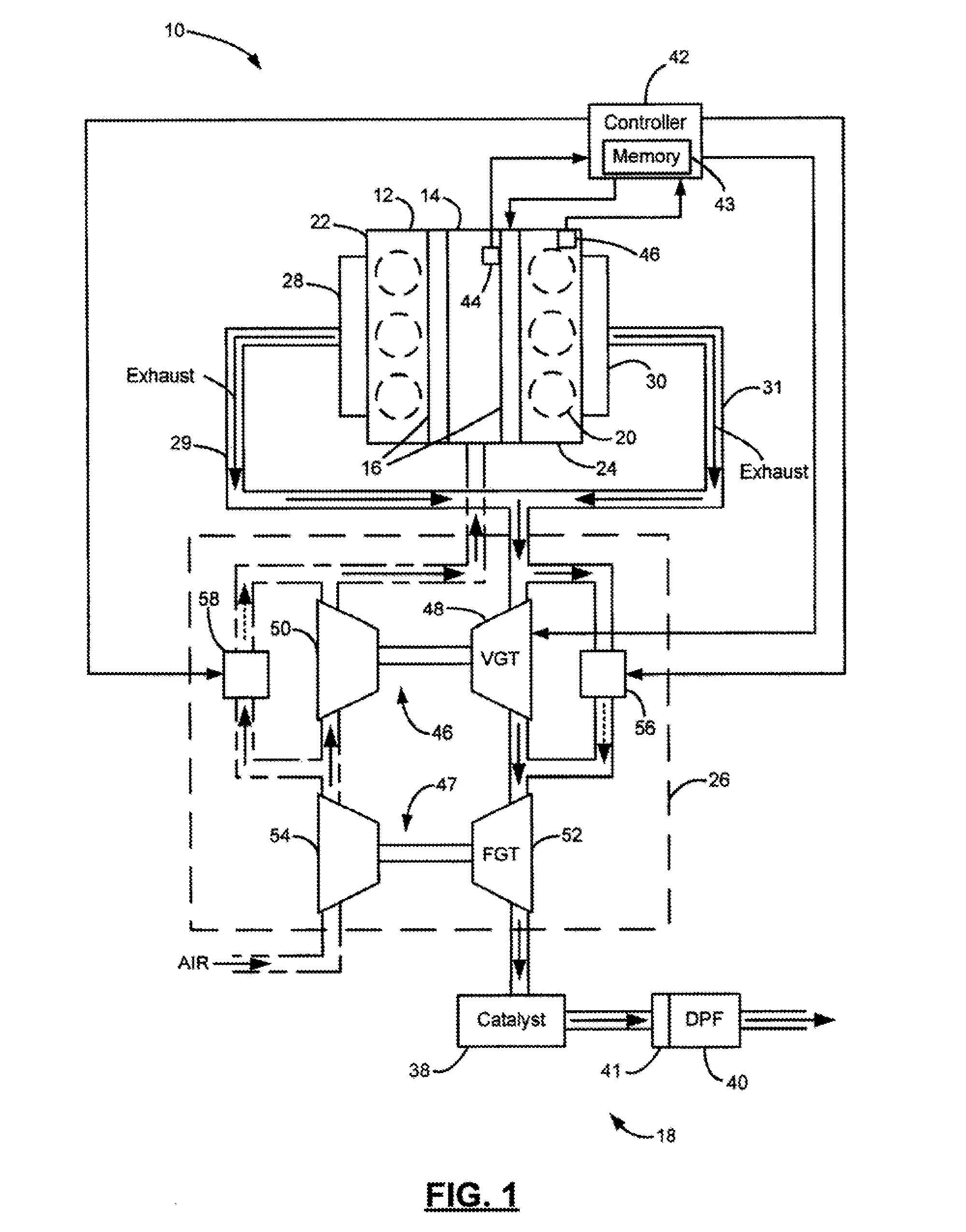

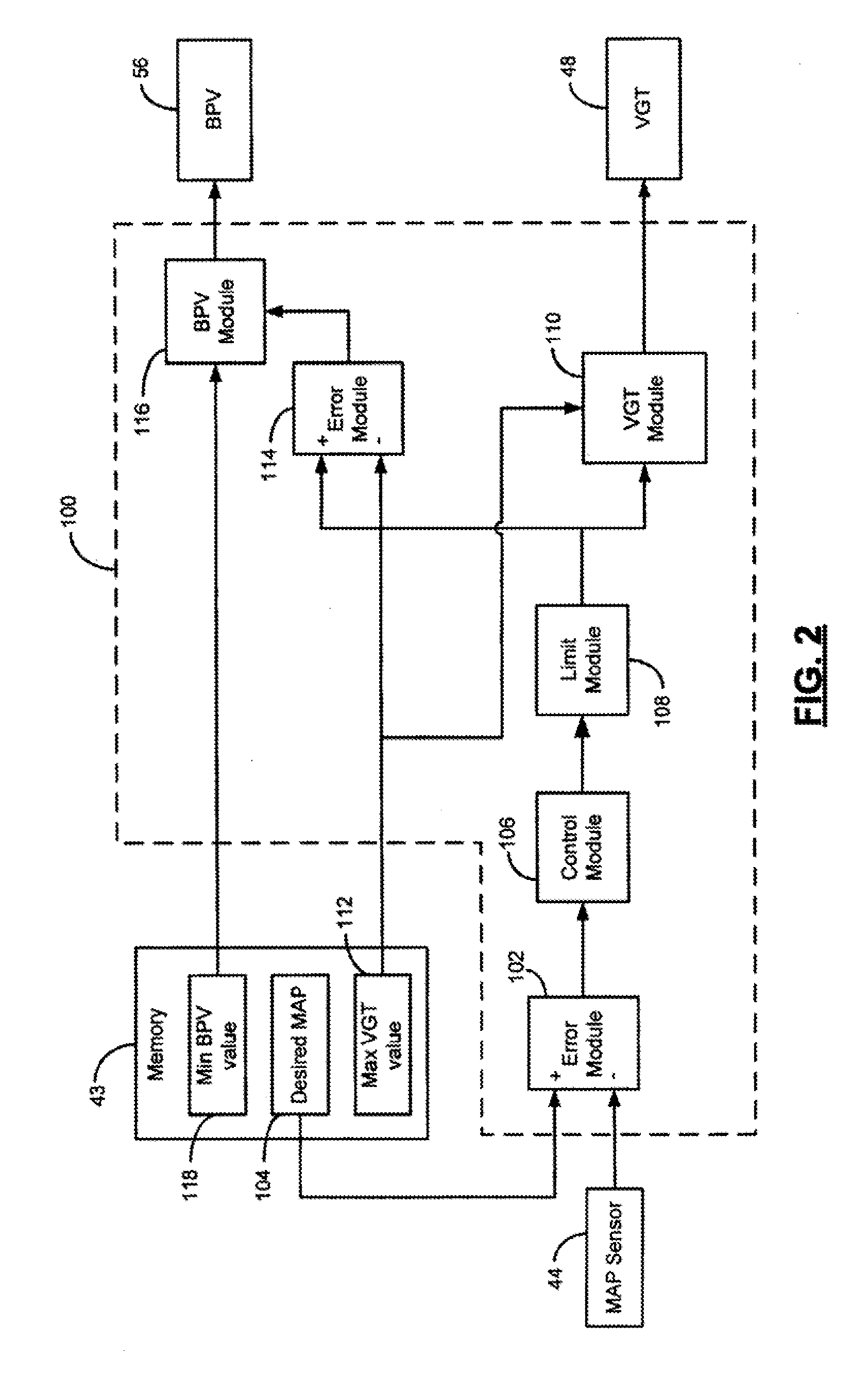

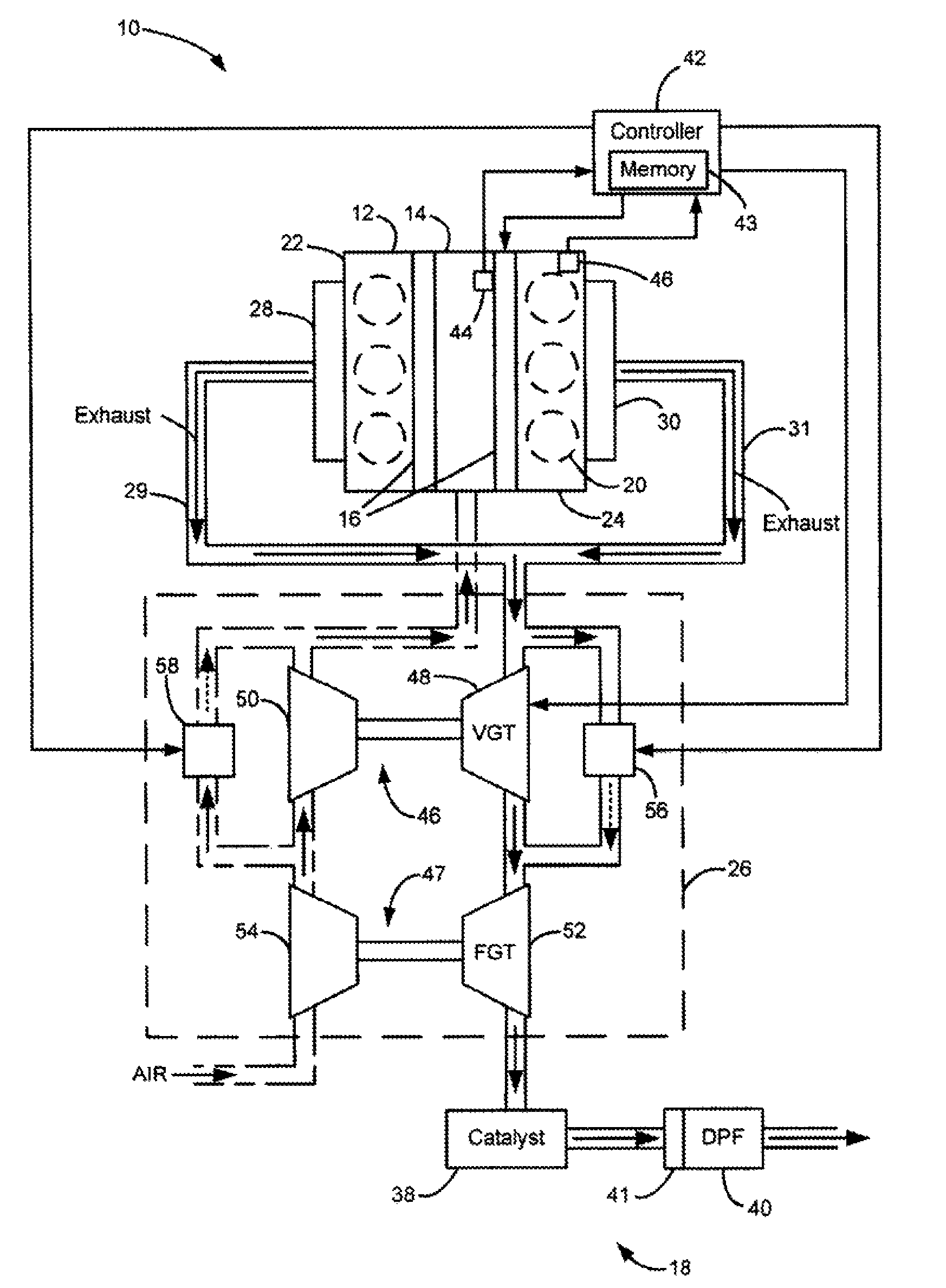

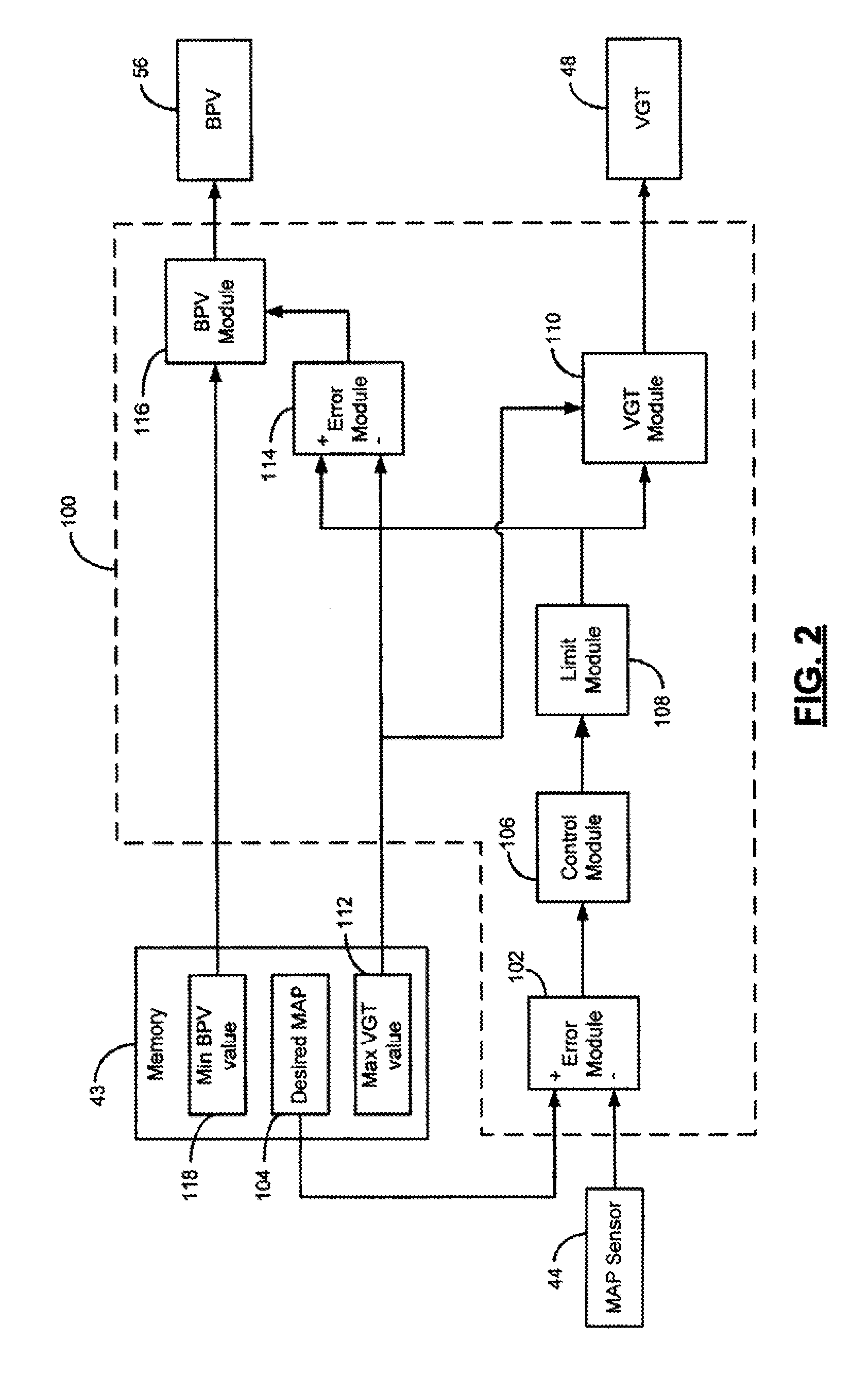

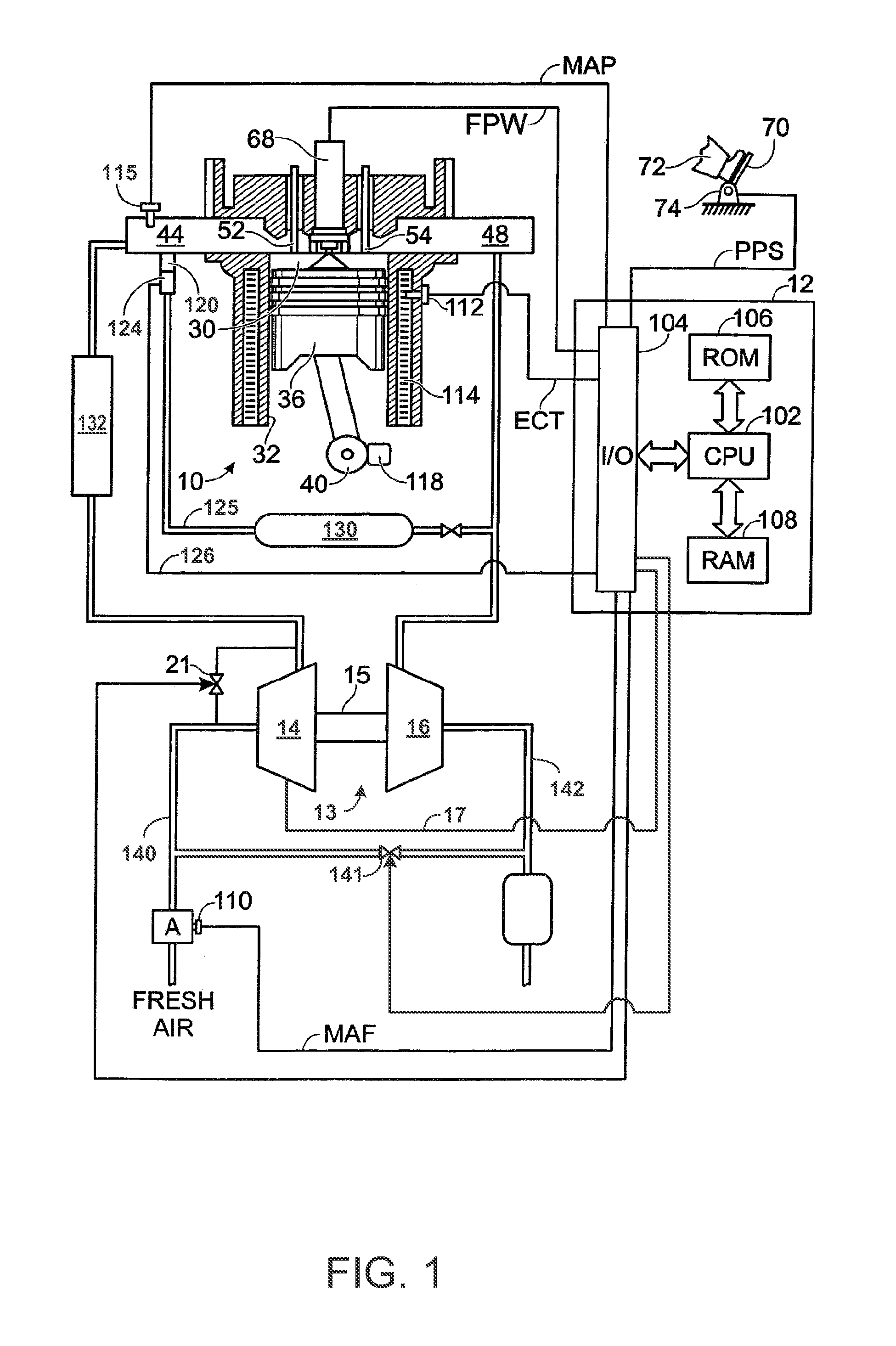

Dual stage turbocharger control system

ActiveUS20080053088A1Internal combustion piston enginesExhaust apparatusDual stageVariable geometry turbine

A control system for a dual stage turbo includes a control module, a variable geometry turbine (VGT) module, and a bypass valve module. The control module generates a turbo control signal based on an manifold absolute pressure (MAP) and a desired MAP. The VGT module generates a VGT control signal to actuate vanes in a VGT based on the turbo control signal. The bypass valve module generates a bypass control signal based on the turbo control signal and the VGT control signal. The bypass control signal actuates a valve to bypass the VGT.

Owner:GM GLOBAL TECH OPERATIONS LLC

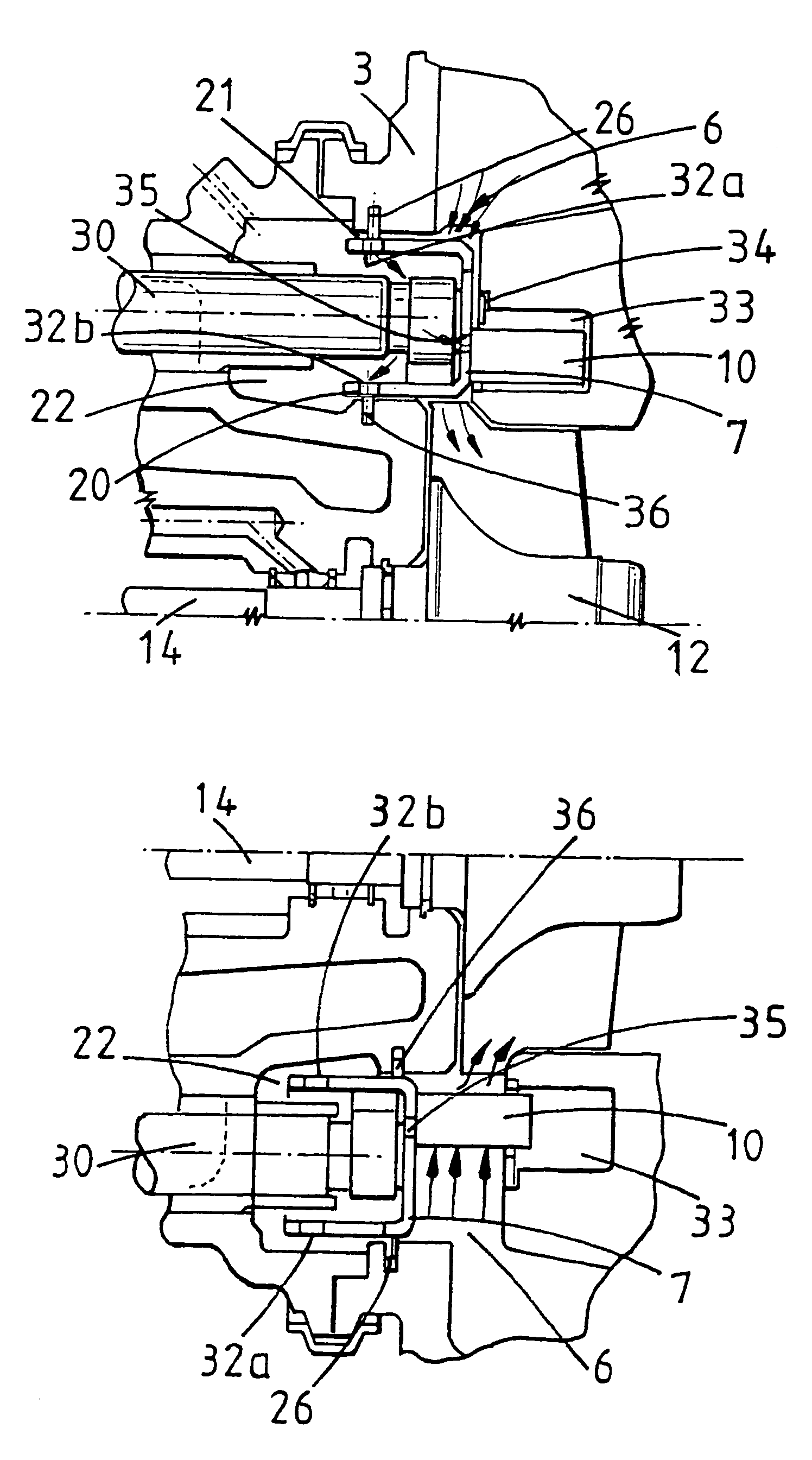

Variable geometry turbine

A variable geometry turbine having a inlet passageway defined between a moveable wall member and a radial wall. The moveable wall member is moveable to vary the width of the inlet passageway. At least one bypass passage is formed in one of the moveable wall member and an adjacent annular cavity surface. Upon the moveable wall member and a seal being moved axially relative to one another the bypass passage permits the flow of exhaust gas around the inlet passageway.

Owner:CUMMINS LTD WEST YORKSHIRE

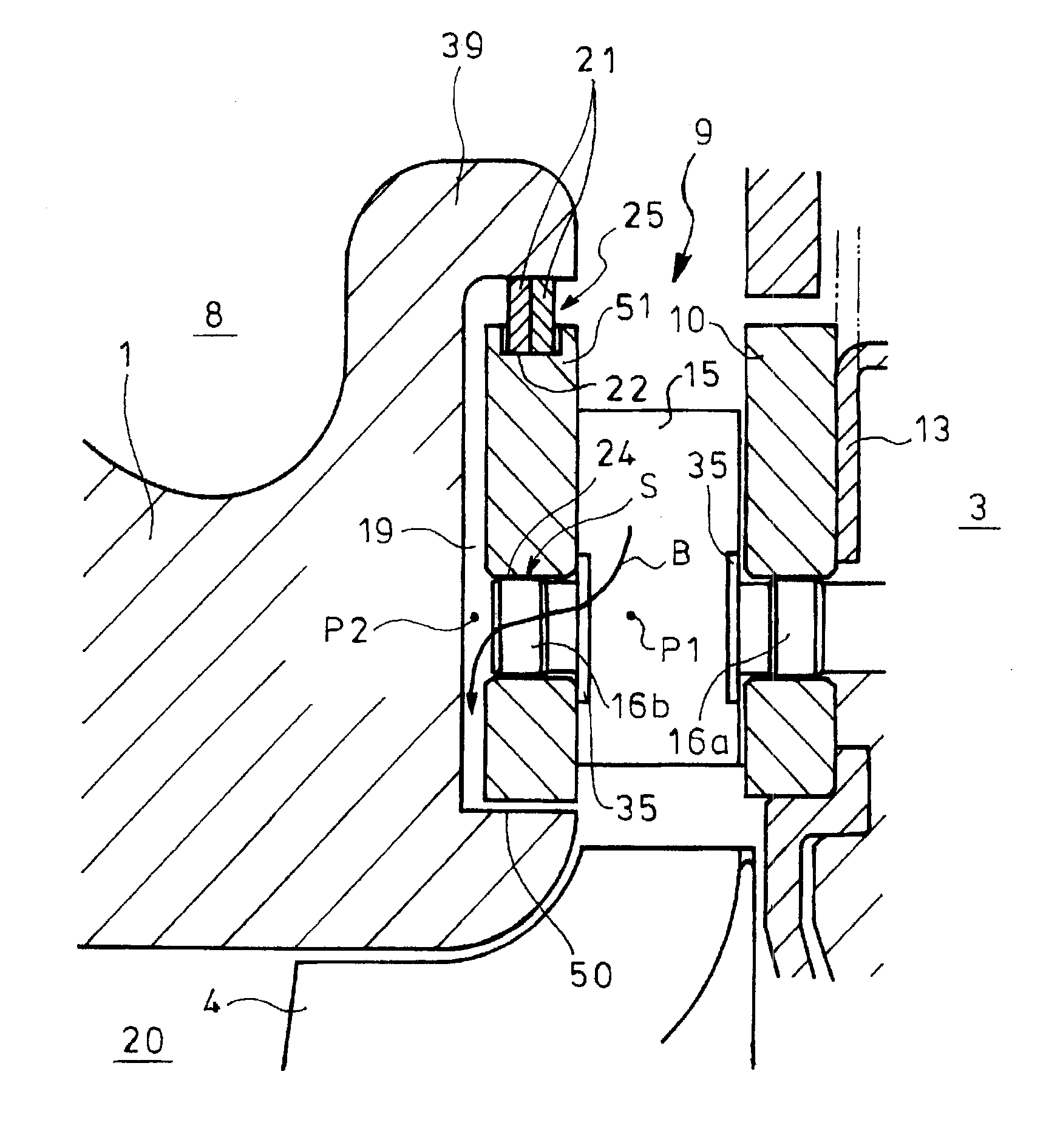

Variable geometry turbine

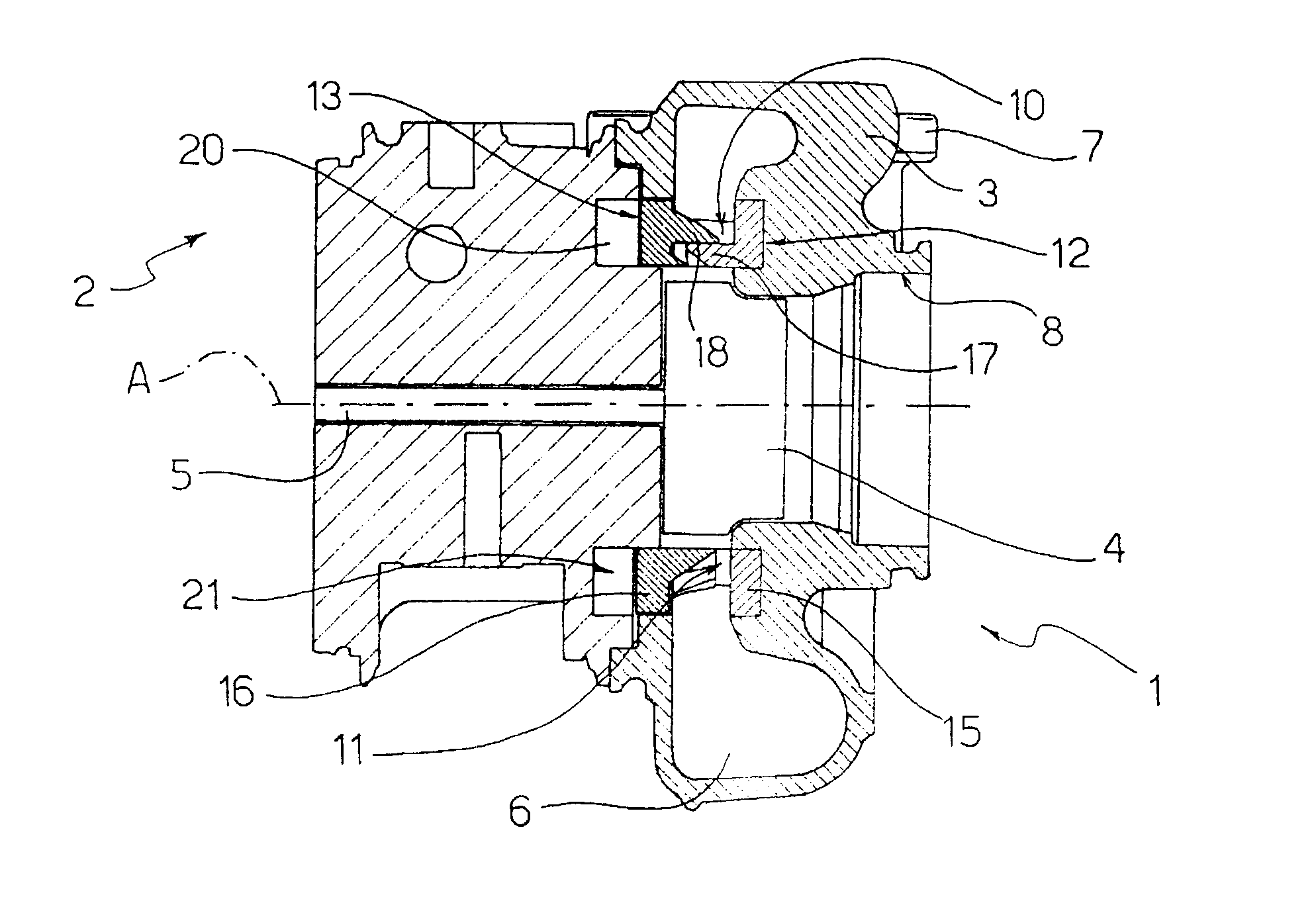

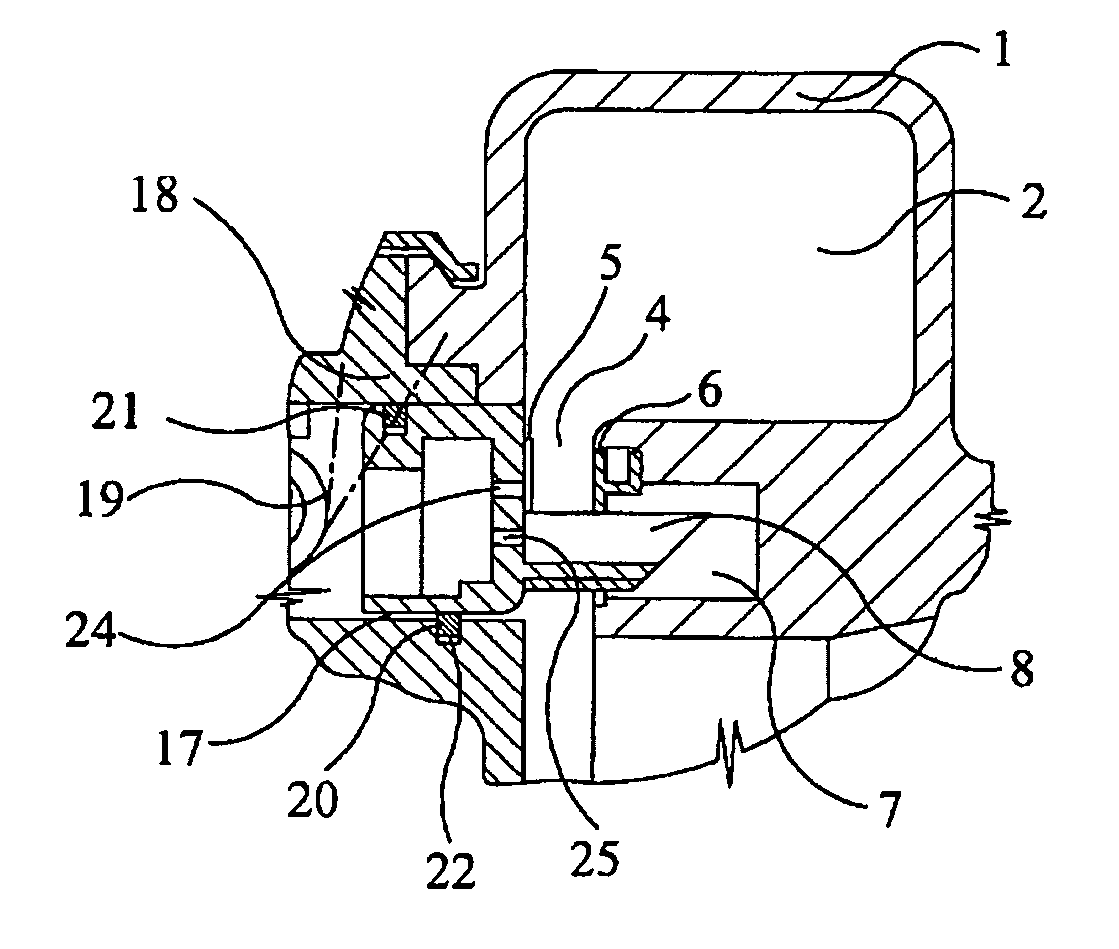

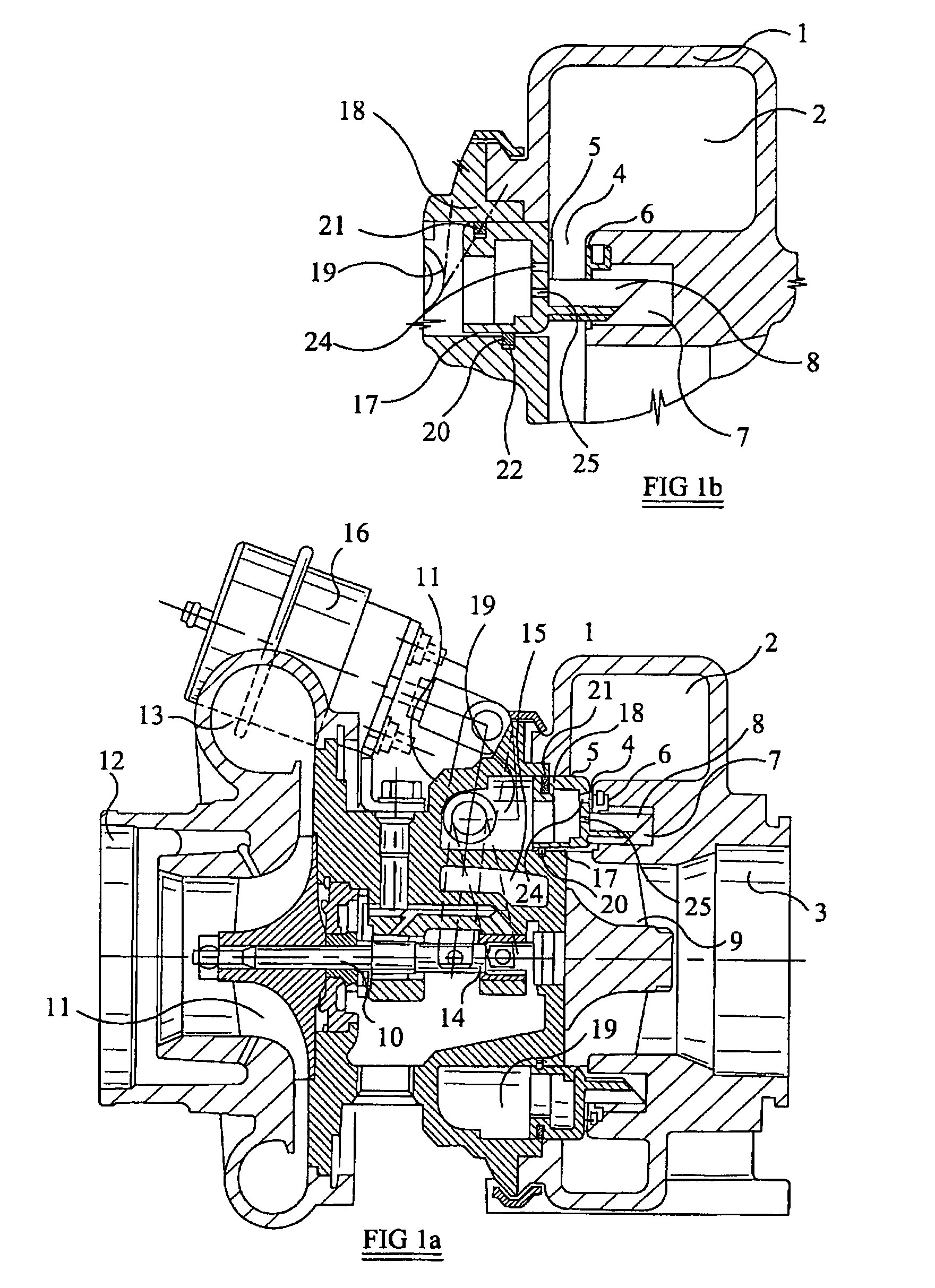

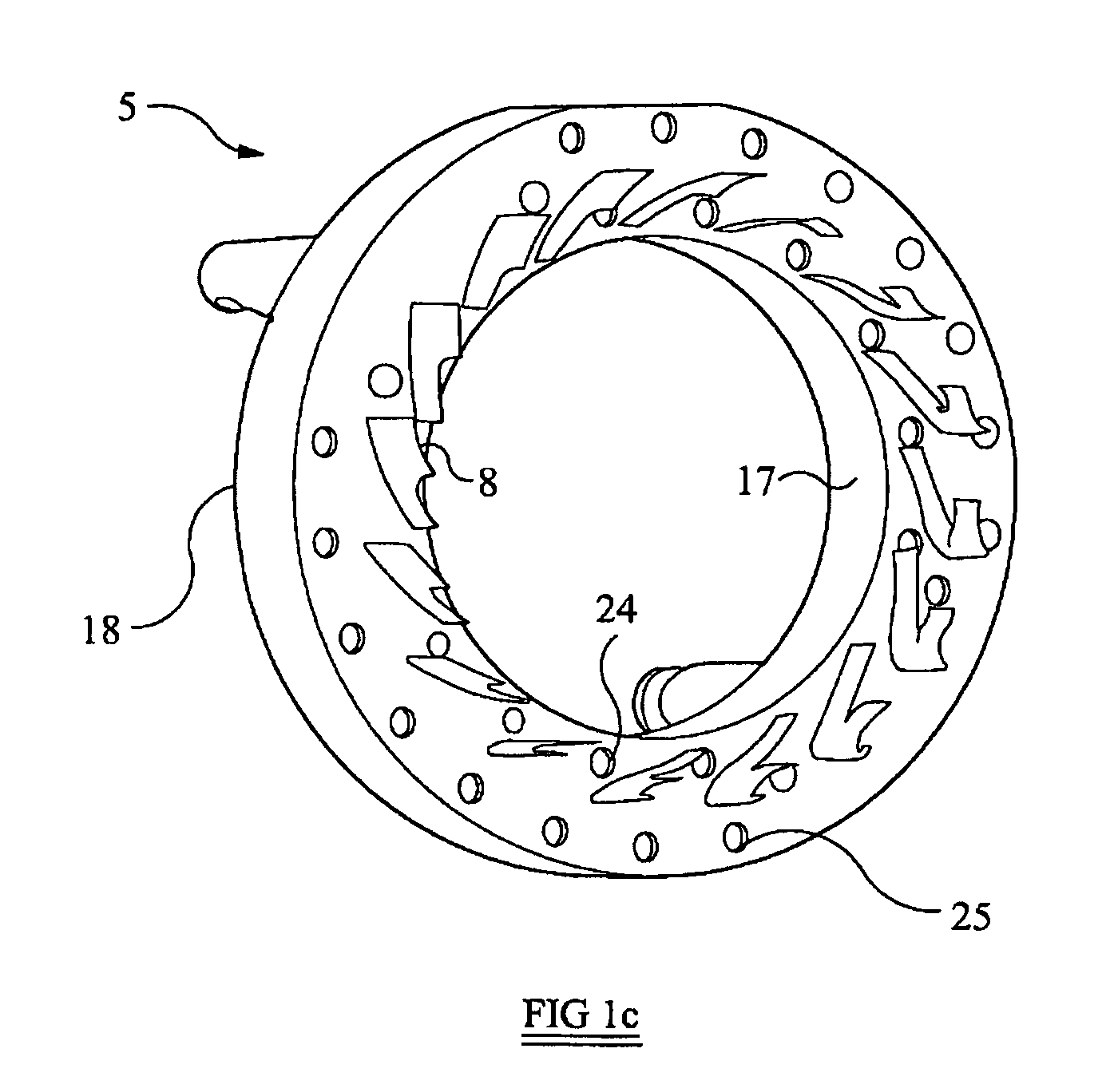

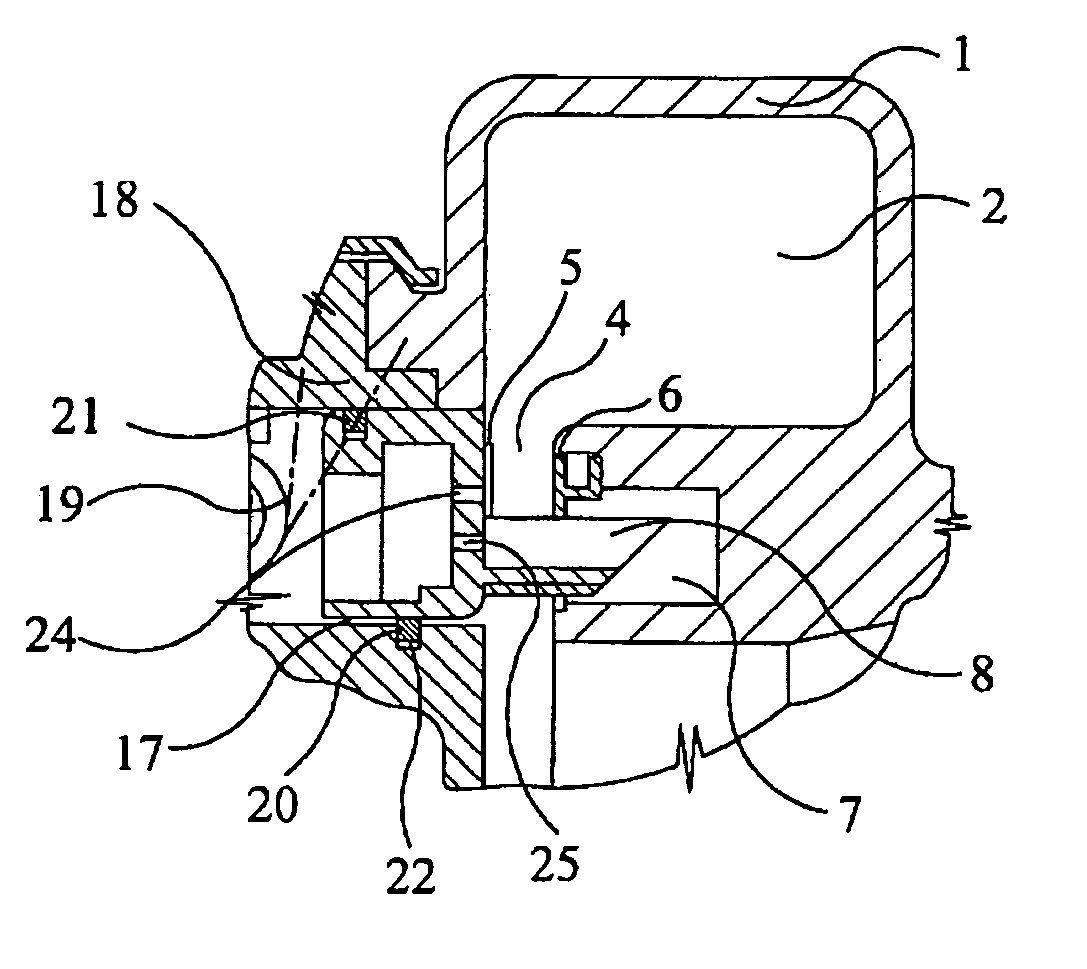

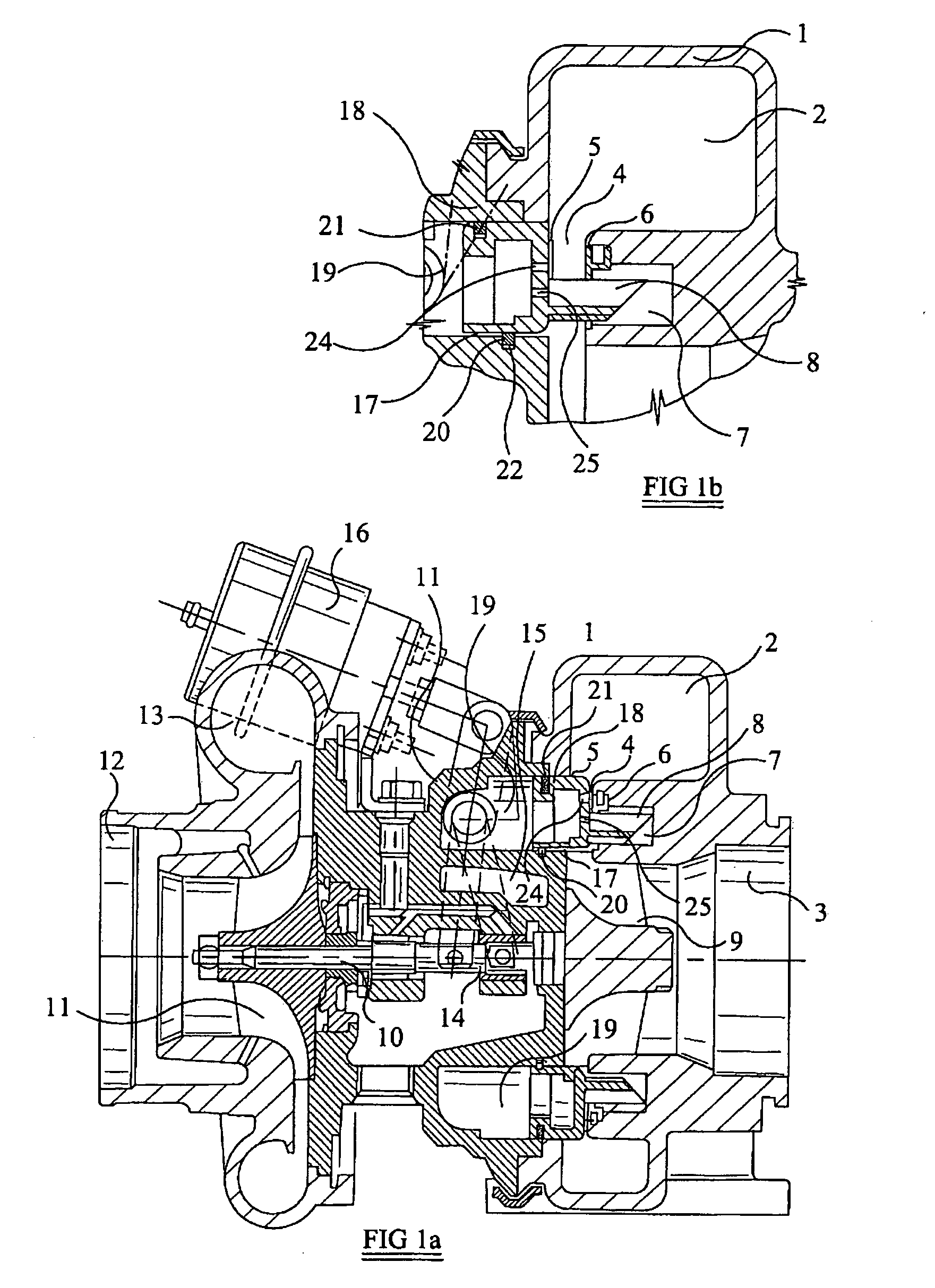

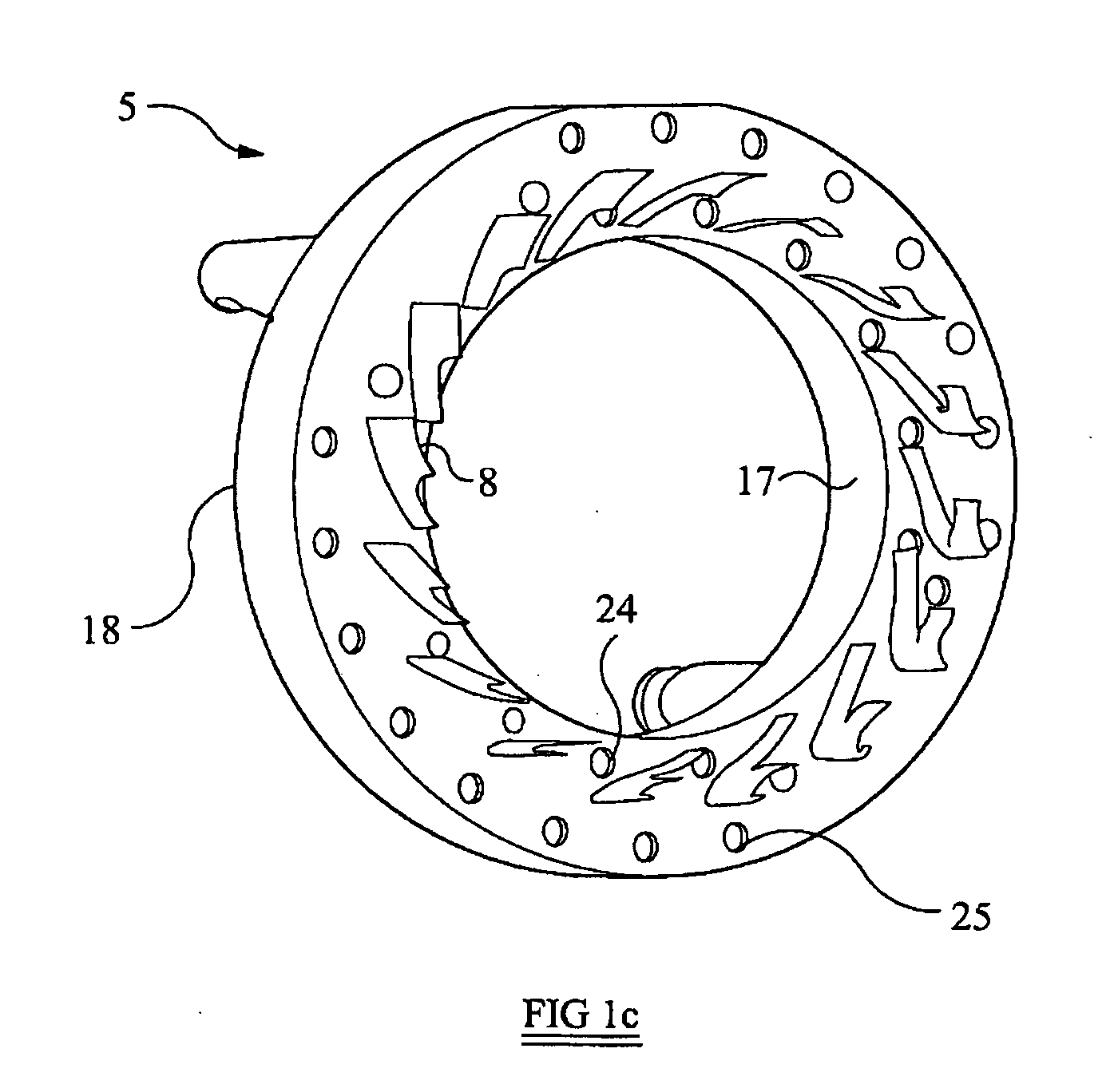

A variable geometry turbine comprises a turbine wheel (9) supported in a housing (1) for rotation about an axis. A nozzle ring (5) is moveably mounted within a cavity (19) provided within the housing for adjustment of the width of an annular inlet passageway (4) extending radially inwards towards the turbine wheel (9). An array of inlet guide vanes (8) extends between a radial face of the nozzle ring (5) and an opposing wall of the inlet (4) defining a radial vane passage. A first circumferential array of apertures (25) is provided through the radial face, each of which lies substantially within the vane passage. A second circumferential array of apertures (24) is also provided in said radial face, each of lies substantially upstream or downstream of the first array (25) of apertures. The inlet (4) and cavity (19) are in fluid communication via both the first and second sets of apertures (25,24).

Owner:CUMMINS LTD

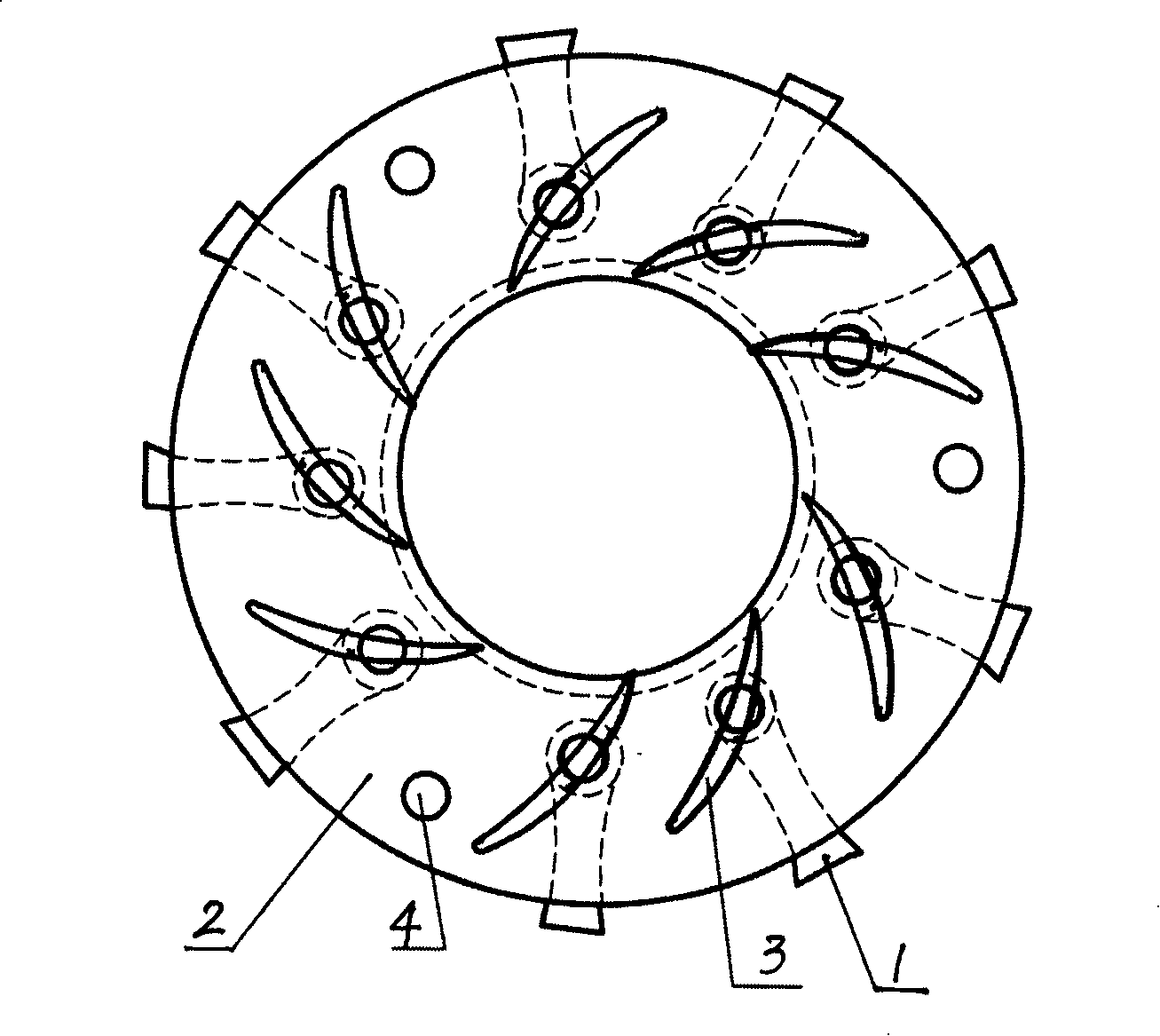

Internal combustion engine variable geometry turbine supercharger nozzle ring components

ActiveCN101191425AExtended service lifeIncrease output powerInternal combustion piston enginesEngine componentsVariable geometry turbineEmission standard

The invention discloses an internal-combustion engine variable geometry turbocharger nozzle ring component, comprising forks(1), a mounting plate(2) and a blade(3), wherein the side surface of the mounting plate(2) is provided with a plurality of groups of blades(3) which are evenly spaced and arranged on the same circumference and are in the same direction, each group of blades which consists of at least three blades(3) and can be mutually opened and folded simultaneously; the other side of the mounting plate is provided with forks(1) which are connected with corresponding blades; because the blades are the three dimensional curved surface, air inlet passages for blades are continuously changed, the air input of the turbocharger is also continuously changed according to the working condition of the engine, thereby the engine can get proper amount of pressurized air under all conditions, which makes that the engine always runs under a reasonable condition, thereby realizing that the turbocharger increases the output power of the engine by 30 to 100 percent, reducing the emission of harmful gas by more than 10 percent, realizing that the fume emission reaches the emission standard of the European IV, lowering oil consumption by 5 to 10 percent and improving the economical efficiency of the automobile.

Owner:PINGXIANG DEBO TECH CO LTD

Dual stage turbocharger control system

A control system for a dual stage turbo includes a control module, a variable geometry turbine (VGT) module, and a bypass valve module. The control module generates a turbo control signal based on an manifold absolute pressure (MAP) and a desired MAP. The VGT module generates a VGT control signal to actuate vanes in a VGT based on the turbo control signal. The bypass valve module generates a bypass control signal based on the turbo control signal and the VGT control signal. The bypass control signal actuates a valve to bypass the VGT.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of controlling the exhaust gas temperature for after-treatment systems on a diesel engine using a variable geometry turbine

ActiveUS20060010864A1Small sizeInternal combustion piston enginesWind motor controlAfter treatmentVariable geometry turbine

A method for controlling a variable geometry turbine of a turbocharger to increase the temperature of the exhaust gas delivered to an after-treatment system. In one form the method includes reducing a fluid flow area to the turbine below a normal size and bypassing a portion of the exhaust gas around a plurality of guide vanes.

Owner:CUMMINS INC

Method of controlling the exhaust gas temperature for after-treatment systems on a diesel engine using a variable geometry turbine

InactiveUS7150151B2Small sizeInternal combustion piston enginesWind motor controlAfter treatmentVariable geometry turbine

Owner:CUMMINS INC

Variable geometry turbine

ActiveUS20080089782A1Reduce the amplitudeReduce forcePump componentsWind motor controlImpellerTurbine wheel

A variable geometry turbine comprises a turbine wheel (9) supported in a housing (1) for rotation about an axis. A nozzle ring (5) is moveably mounted within a cavity (19) provided within the housing for adjustment of the width of an annular inlet passageway (4) extending radially inwards towards the turbine wheel (9). An array of inlet guide vanes (8) extends between a radial face of the nozzle ring (5) and an opposing wall of the inlet (4) defining a radial vane passage. A first circumferential array of apertures (25) is provided through the radial face, each of which lies substantially within the vane passage. A second circumferential array of apertures (24) is also provided in said radial face, each of lies substantially upstream or downstream of the first array (25) of apertures. The inlet (4) and cavity (19) are in fluid communication via both the first and second sets of apertures (25,24).

Owner:CUMMINS LTD WEST YORKSHIRE

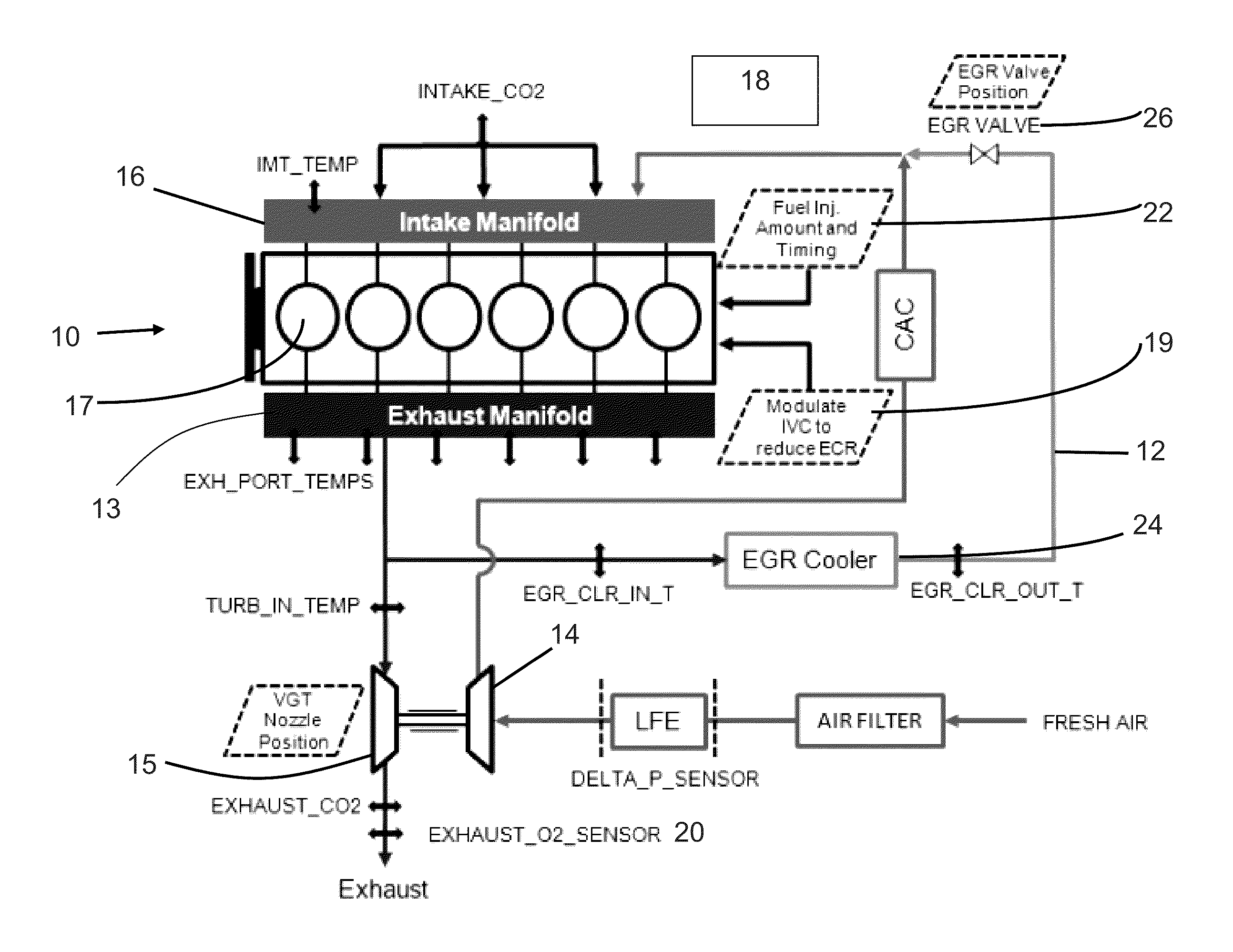

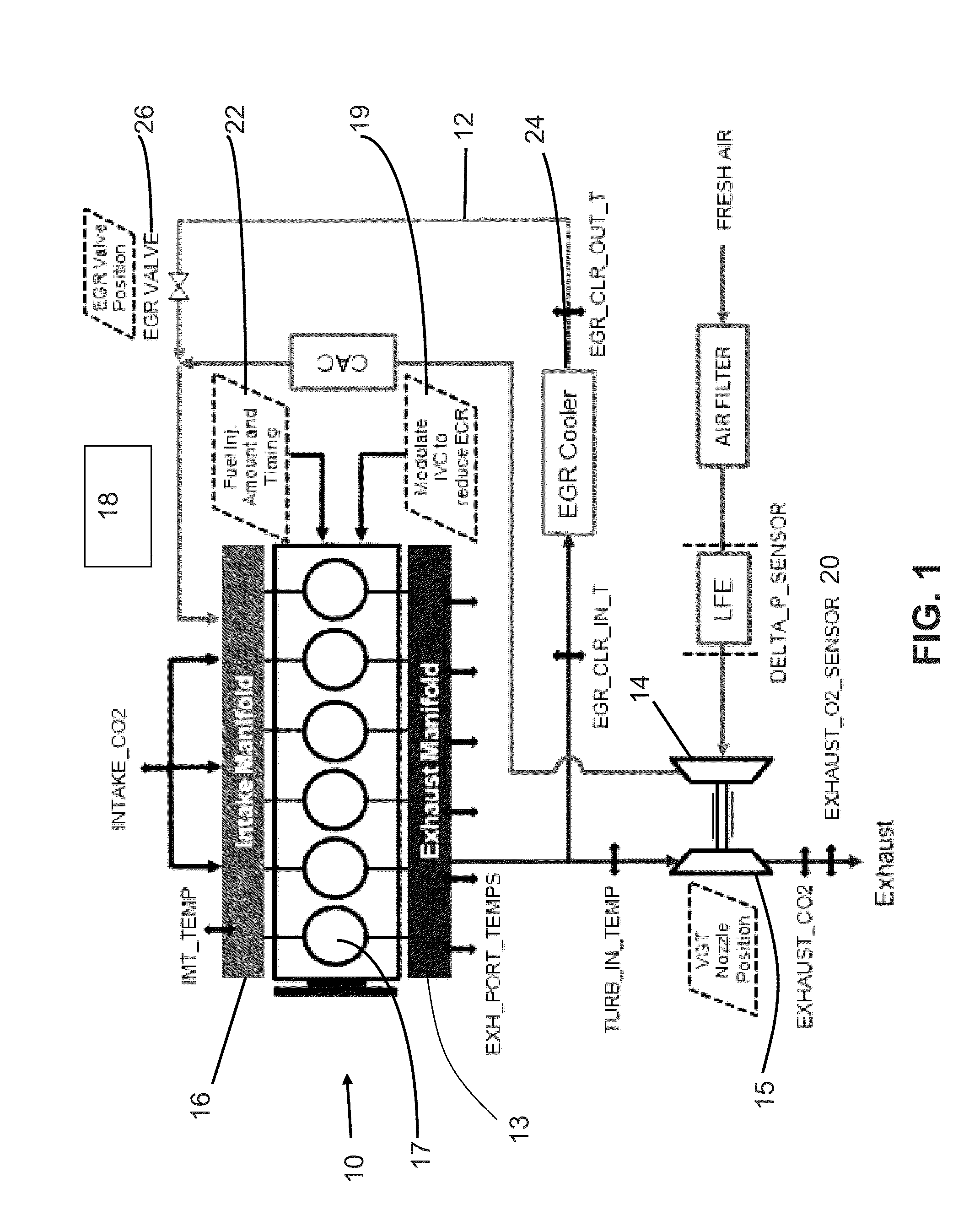

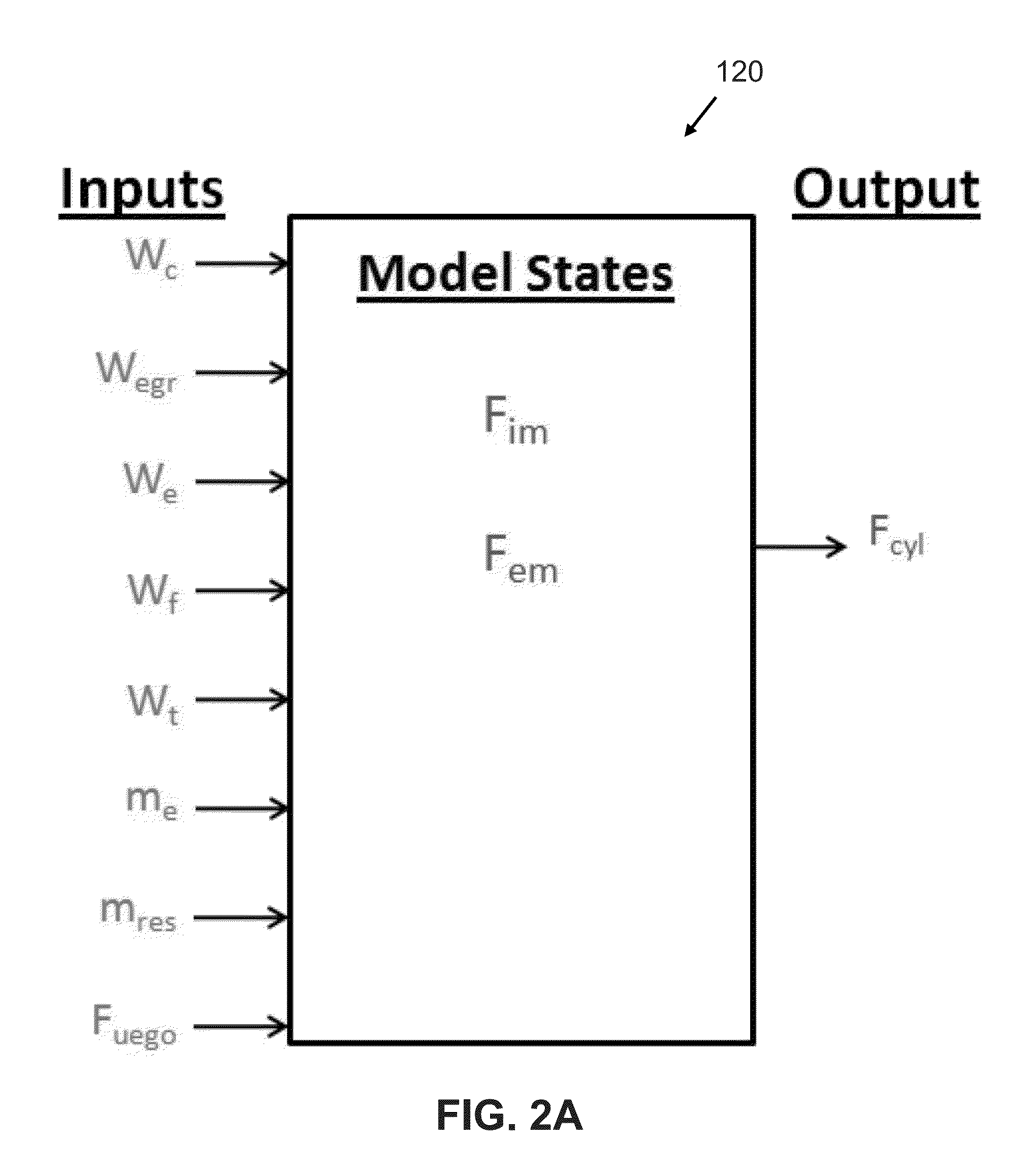

Oxygen fraction estimation for diesel engines utilizing variable intake valve actuation

InactiveUS20140060506A1Improve EGR flow estimateAccurate EGR flow estimateElectrical controlInternal combustion piston enginesVariable geometry turbineInlet valve

A physically-based, generalizable method to estimate the in-cylinder oxygen fraction from production viable measurements or estimates of exhaust oxygen fraction, fresh air flow, charge flow, fuel flow, turbine flow and EGR flow. The oxygen fraction estimates can be sensitive to errors in the EGR and turbine flow, and in other embodiments, a high-gain observer is implemented to improve the estimate of EGR flow. The observer is applicable to engines utilizing high pressure cooled exhaust gas recirculation, variable geometry turbocharging and flexible intake valve actuation as well as other engines.

Owner:PURDUE RES FOUND INC

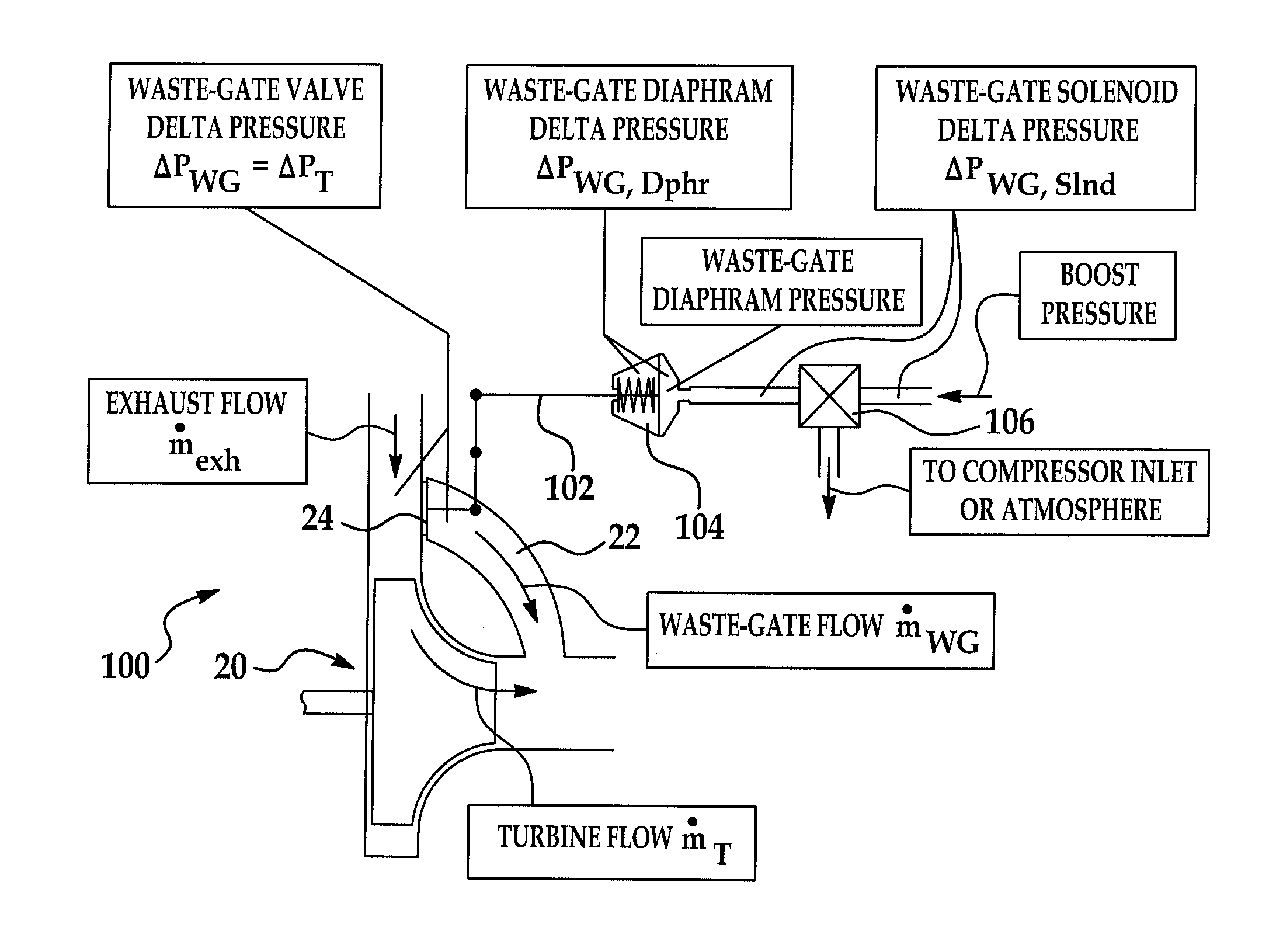

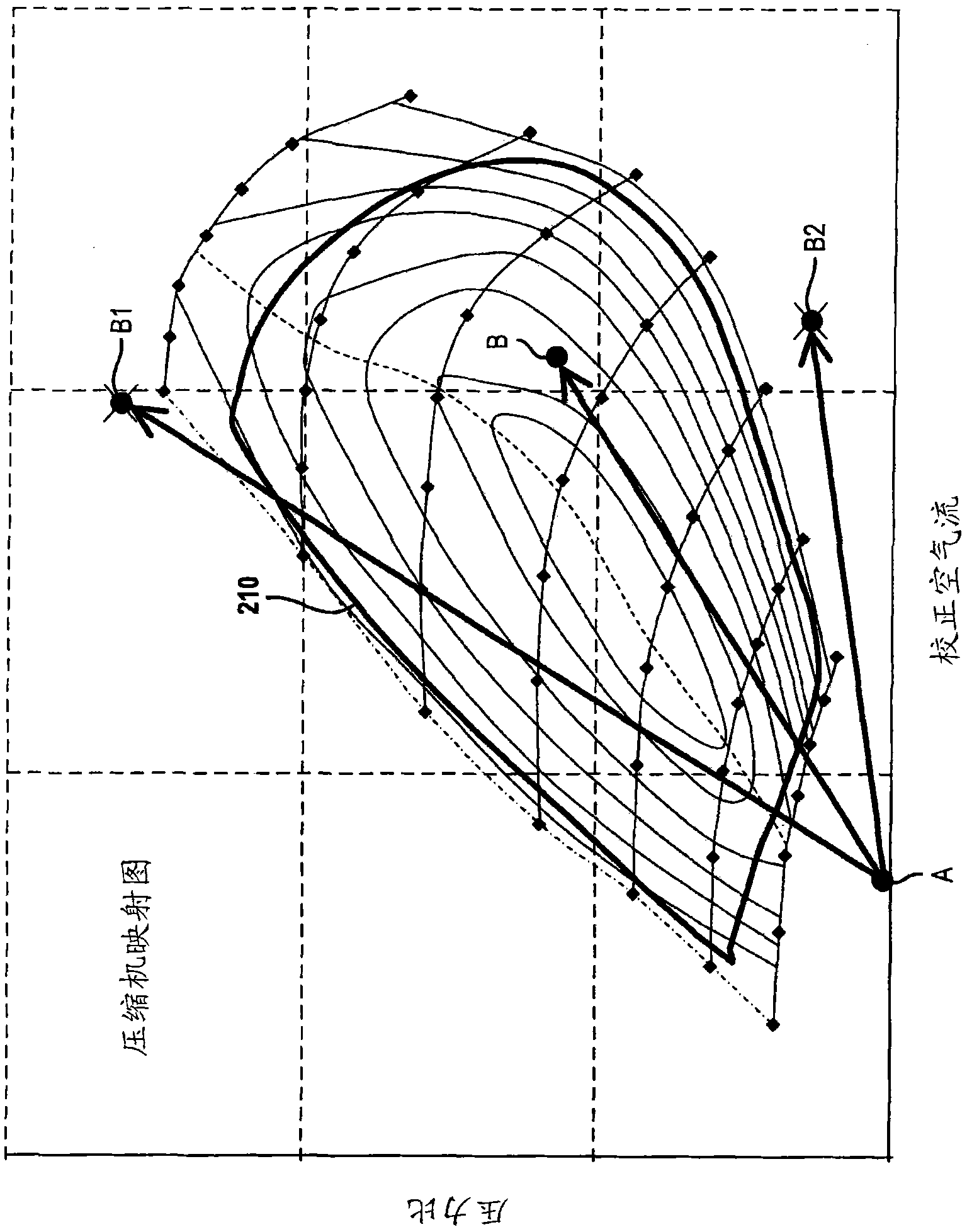

System and method for model based boost control of turbo-charged engines

ActiveUS7788922B2Improve engine efficiencyEasy to controlInternal combustion piston enginesNon-fuel substance addition to fuelWastegateControl signal

A system and method for controlling boost pressure in various turbo-charged engine configurations as well as variable geometry turbine (VGT) arrangements includes an electronic controller programmed to receive a predetermined desired boost pressure PBoostdes. A desired pressure delta ΔPWGdes across a waste-gate valve is determined using the desired boost pressure PBoostdes. A control signal is generated for controlling the waste-gate valve so as to achieve the desired pressure delta ΔPWGdes. In boost pressure and vacuum pneumatically-actuated waste-gate valve arrangements, the respective solenoid duty cycles are obtained through use of various data structures. Where a waste-gate valve position is controlled by an electrical motor, the valve position is determined using a data structure as a function of desired waste-gate valve flow at sonic standard conditions.

Owner:DELPHI TECH IP LTD

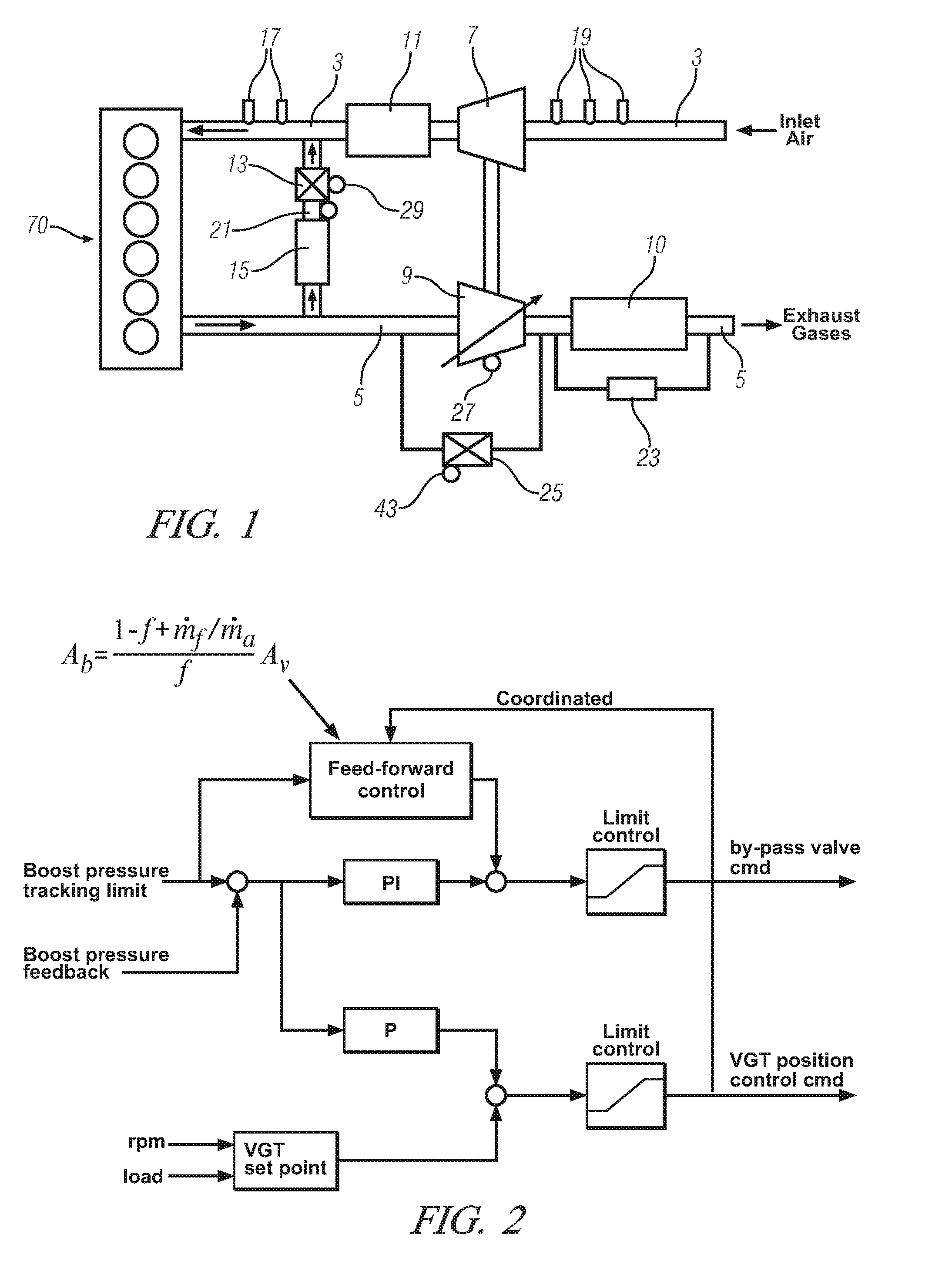

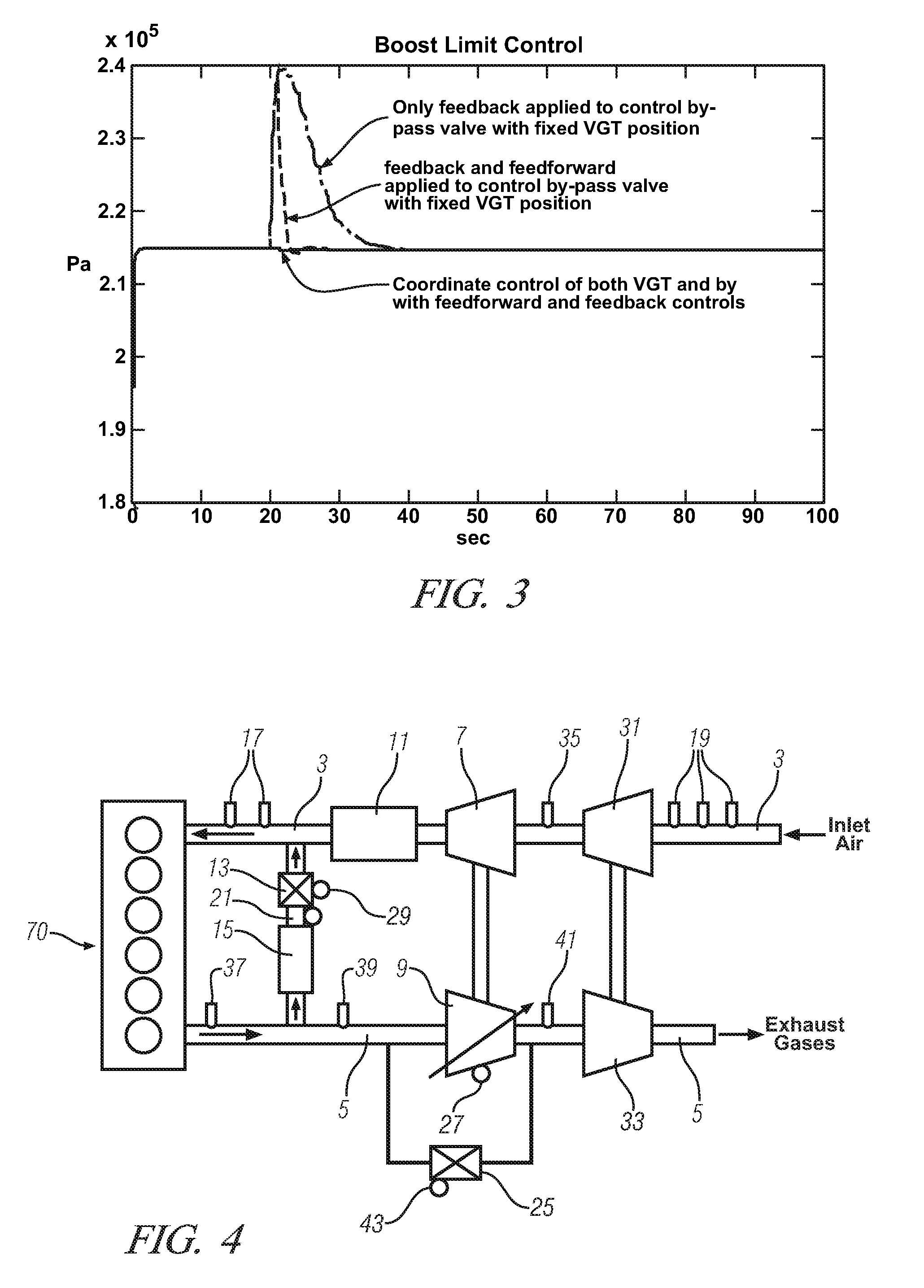

Model-based control of airpath pressure limits by modulating a turbo charger by-pass valve and a variable-geometry turbine

ActiveUS8209979B2Analogue computers for vehiclesElectrical controlVariable geometry turbineInternal combustion engine

Simultaneous or independent control of a by-pass valve and a variable-geometry forced induction component on a combustion engine is based on operational parameters measured by various sensors provided as inputs to a control module. Sudden loss of power due to low turbine efficiencies is prevented during transitions between operating conditions of engine speed and load. Excessive peak cylinder pressures are also prevented by controlling engine boost pressure to a permitted limit at high engine speed and load.

Owner:GM GLOBAL TECH OPERATIONS LLC

Variable geometric turbine nozzle ring

ActiveCN101915129AInternal combustion piston enginesEngine componentsVariable geometry turbineEngineering

The invention discloses a nozzle ring used in variable geometric turbine and the variable geometric turbine having the nozzle ring, such as a variable geometric turbocharger; also discloses a method for producing the nozzle ring. The nozzle ring comprises a radial wall which limits a first radial surface; a blade group is extended from the first radial surface; and the first radial surface is extended backwards to form a flange which is located inside or outside while extended along the axial direction; the nozzle ring is an assembly composed of a first part and a second part; the first part comprises a support member for supporting at least one of the blades; the second part is used for limiting the flange located inside or outside while extended along the axial direction, and limiting one or more axially extended apertures which construct the axial flow path of the second part for gases to flow through in use.

Owner:CUMMINS TURBO TECH

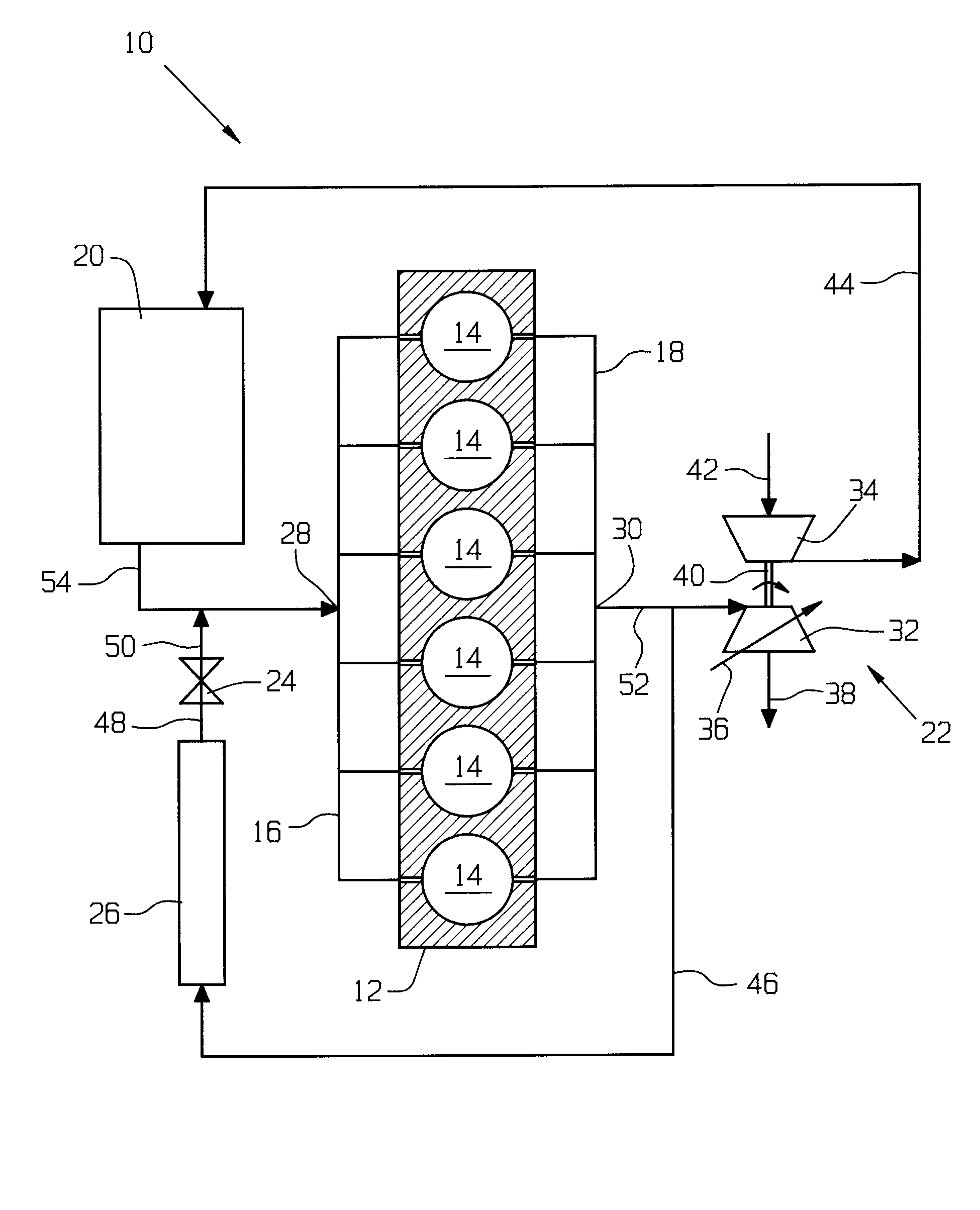

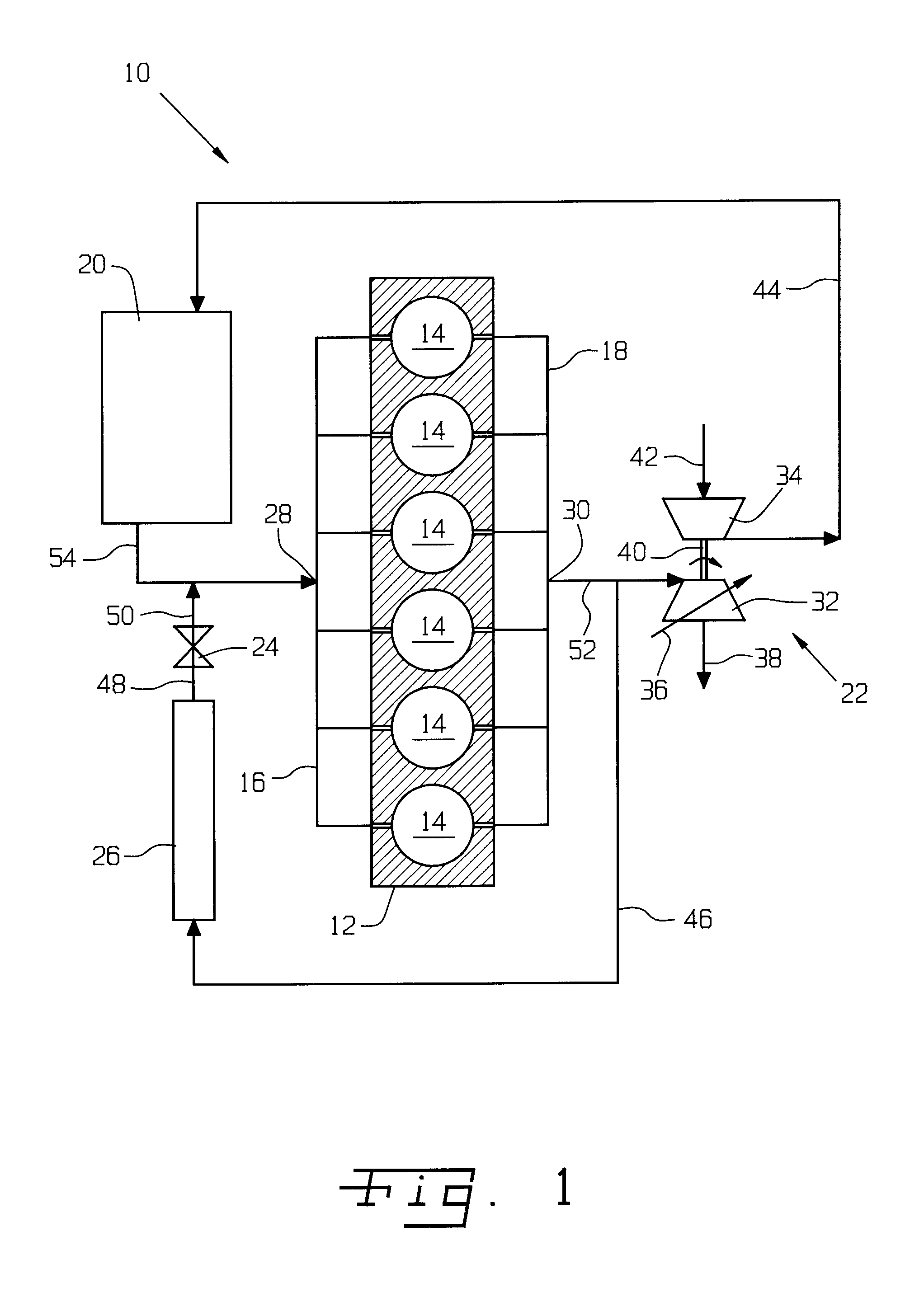

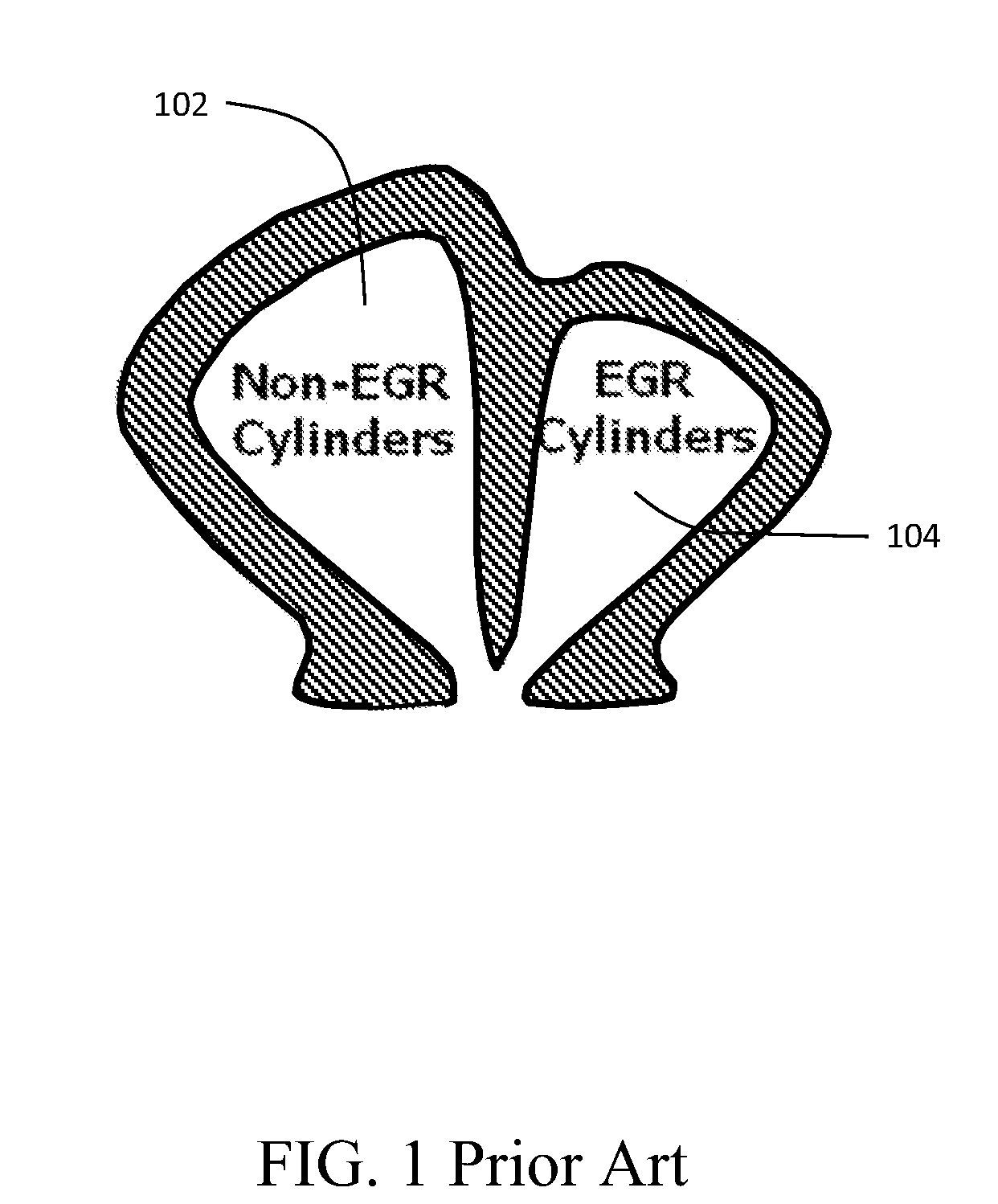

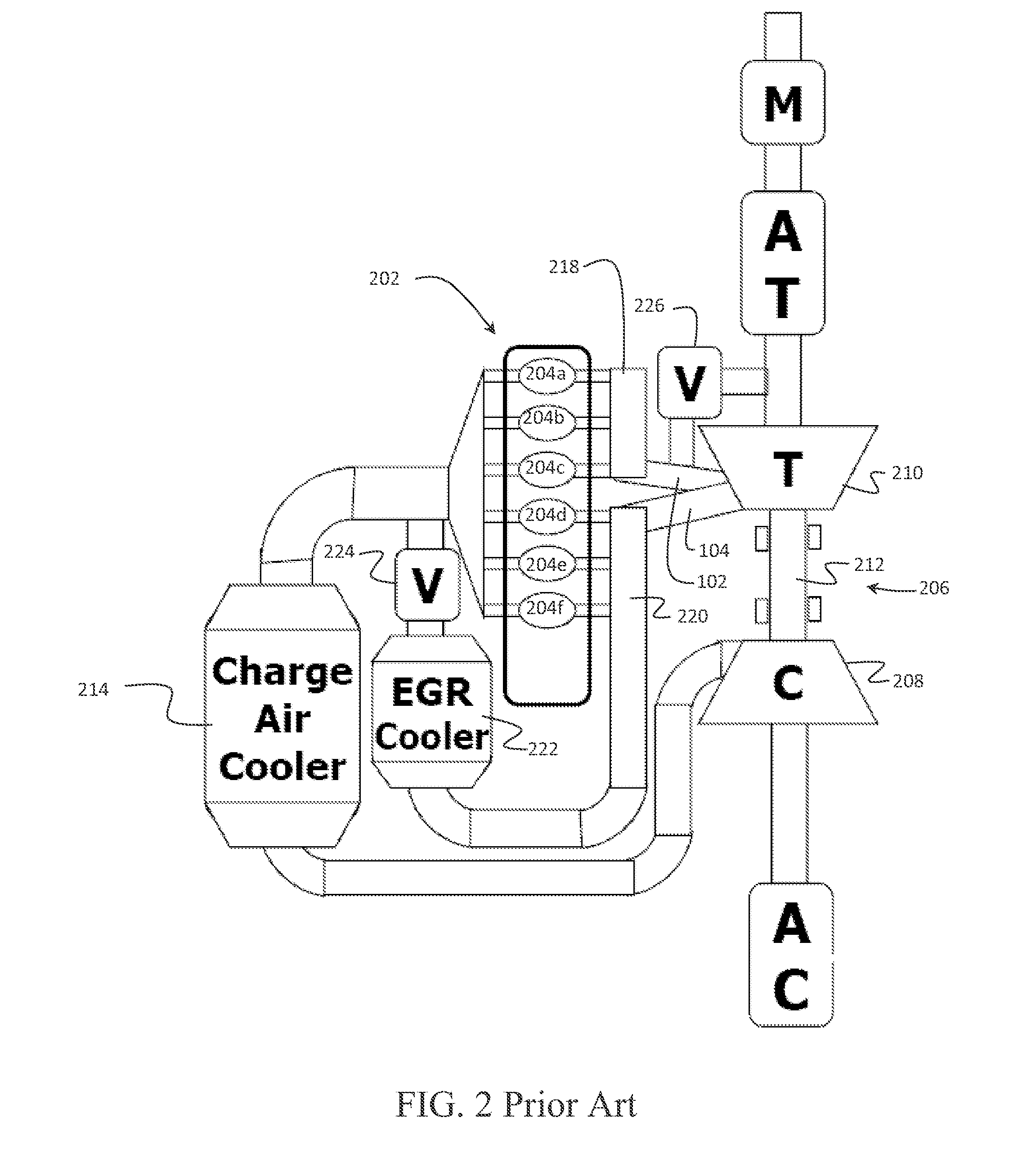

Quad layer passage variable geometry turbine for turbochargers in exhaust gas recirculation engines

InactiveUS20160003196A1Electrical controlNon-fuel substance addition to fuelVariable geometry turbineEngineering

A variable geometry turbine for turbochargers in exhaust gas recirculation engines incorporates a turbine housing having an exhaust inlet with a first side receiving exhaust from cylinders having exhaust gas recirculation (EGR) and a second side receiving exhaust from non-EGR cylinders. The first side has a first EGR-driving passage and a second EGR-driving passage and the second side having a first non-EGR-driving passage and a second non-EGR-driving passage. A first control valve is associated with the second EGR-driving passage and a second control valve is associated with the second non-EGR-driving passage. A controller is adapted to control the first and second control valves.

Owner:KANGYUE TECH

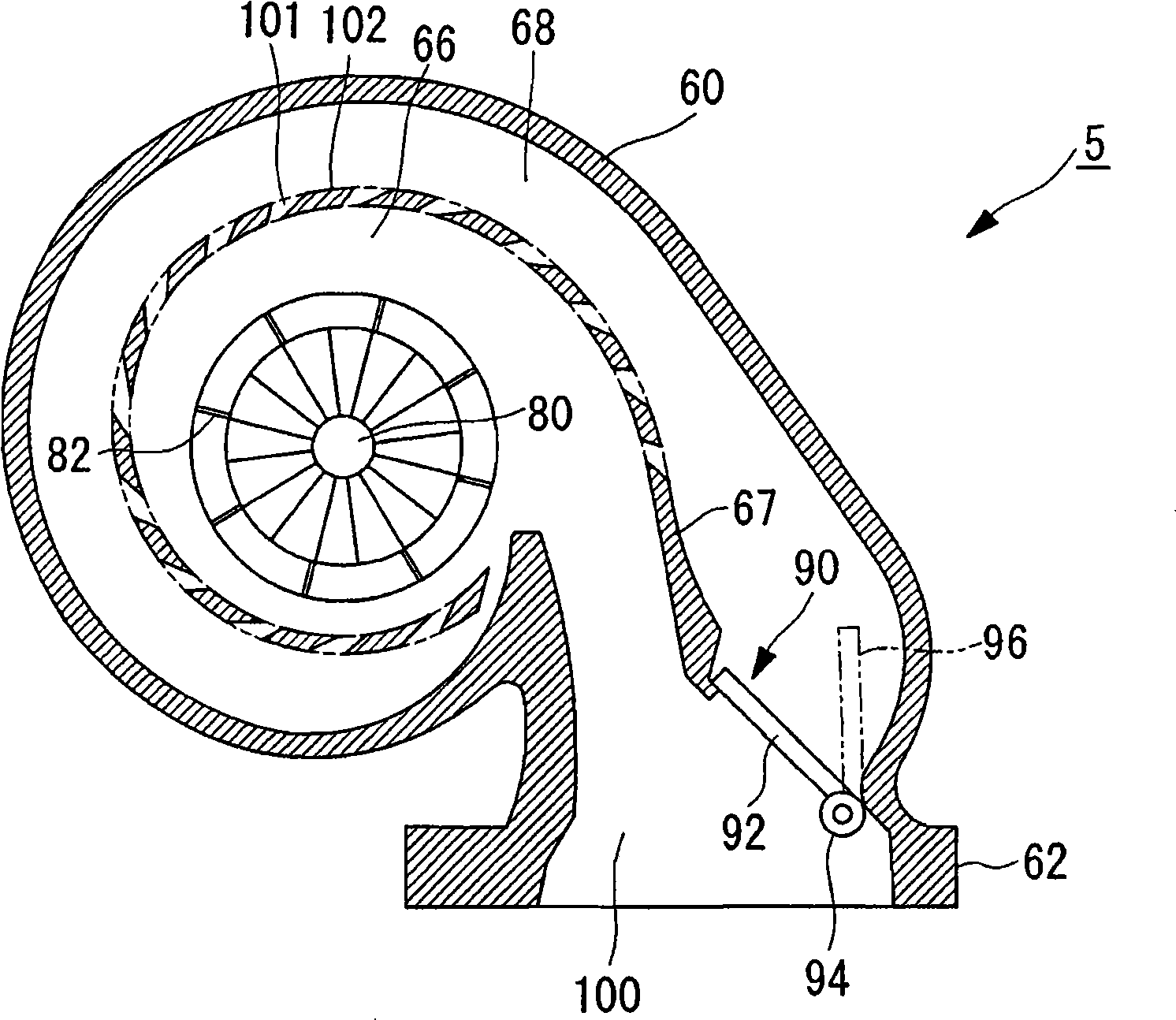

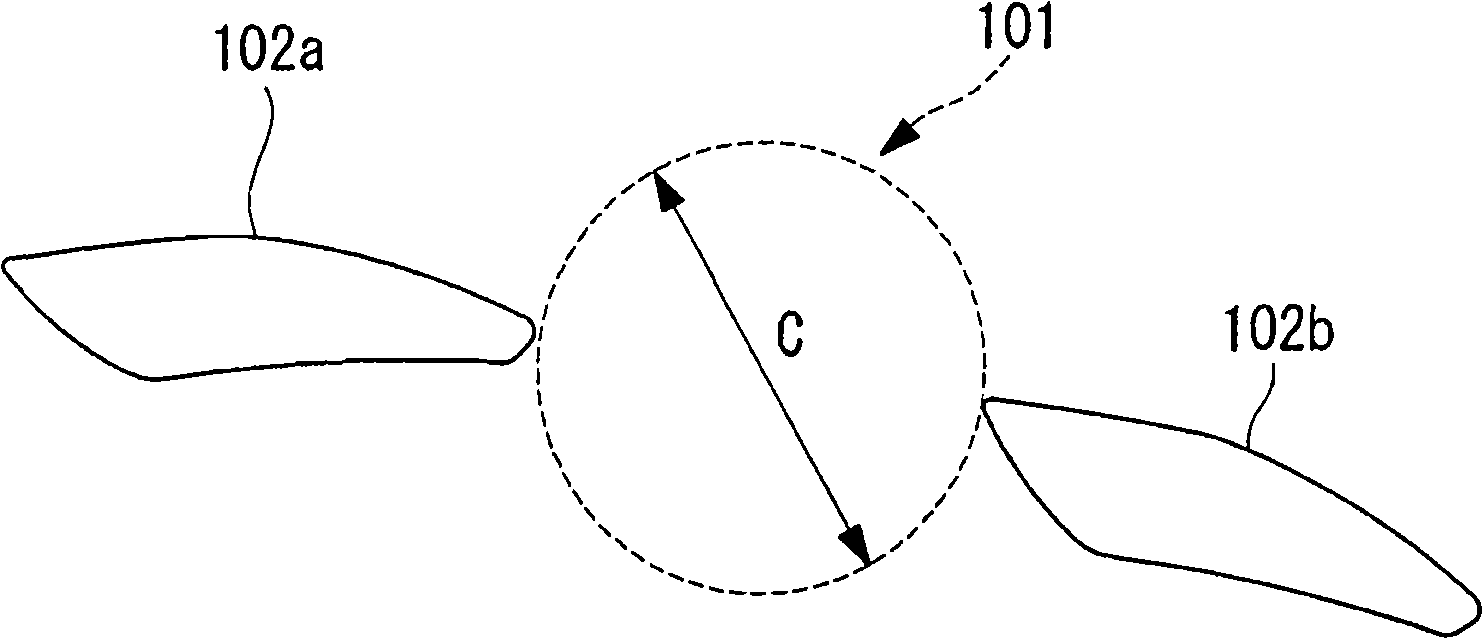

Variable geometry turbine and turbocharger

ActiveCN101519997AEffective rotationUniform flowInternal combustion piston enginesGas turbine plantsVariable geometry turbineTurbine blade

A turbine (5) is provided which can reduce variations in mass flow at throats even when the flow rate of fluid is low or high, to prevent a decrease in performance. A turbine (5) includes a turbine rotor (80) which has turbine blades (82); a turbine housing (60) which accommodates the turbine rotor (80) and whose cross-sectional area of a scroll portion (100) formed between the turbine housing (60) and the turbine rotor (80) gradually decreases; a plurality of fixed vanes (102) which are fixed along a curved line dividing the scroll portion (100) into an inner scroll part (66) and an outer scroll part (68); throats (101) which are formed between the adjacent fixed vanes (102) and communicate between the inner scroll part (66) and the outer scroll part (68); and a switch valve (90) which switches a flow path in the turbine housing (60) either to the inner scroll part (66) or to both the inner scroll part (66) and the outer scroll part (68), wherein flow path areas of the throats (101) are reduced in a downstream direction of the scroll portion (100).

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Variable geometry turbocharger

ActiveCN102762838ASmooth movementGood effectInternal combustion piston enginesEngine componentsImpellerVariable geometry turbine

Owner:IHI CORP

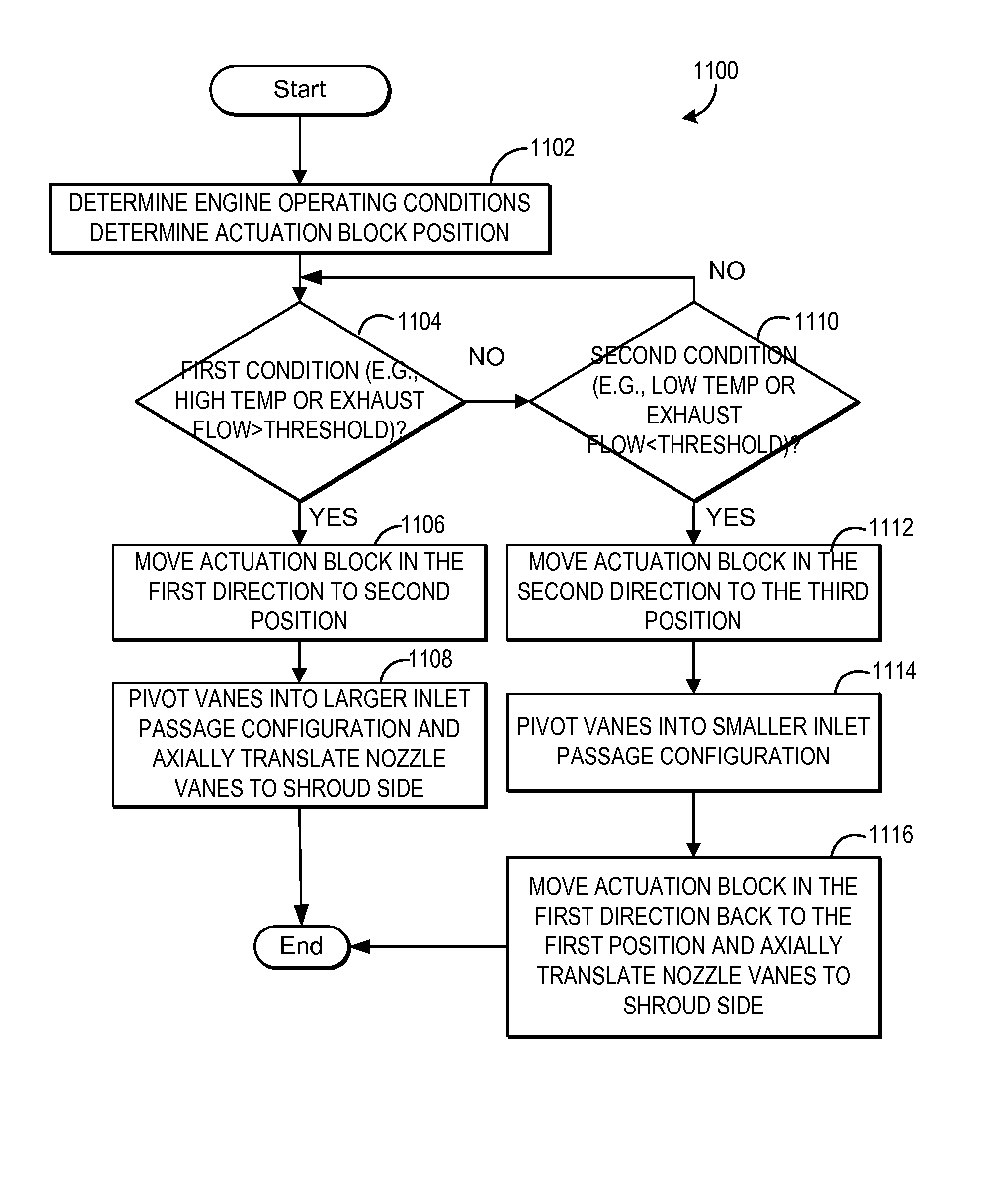

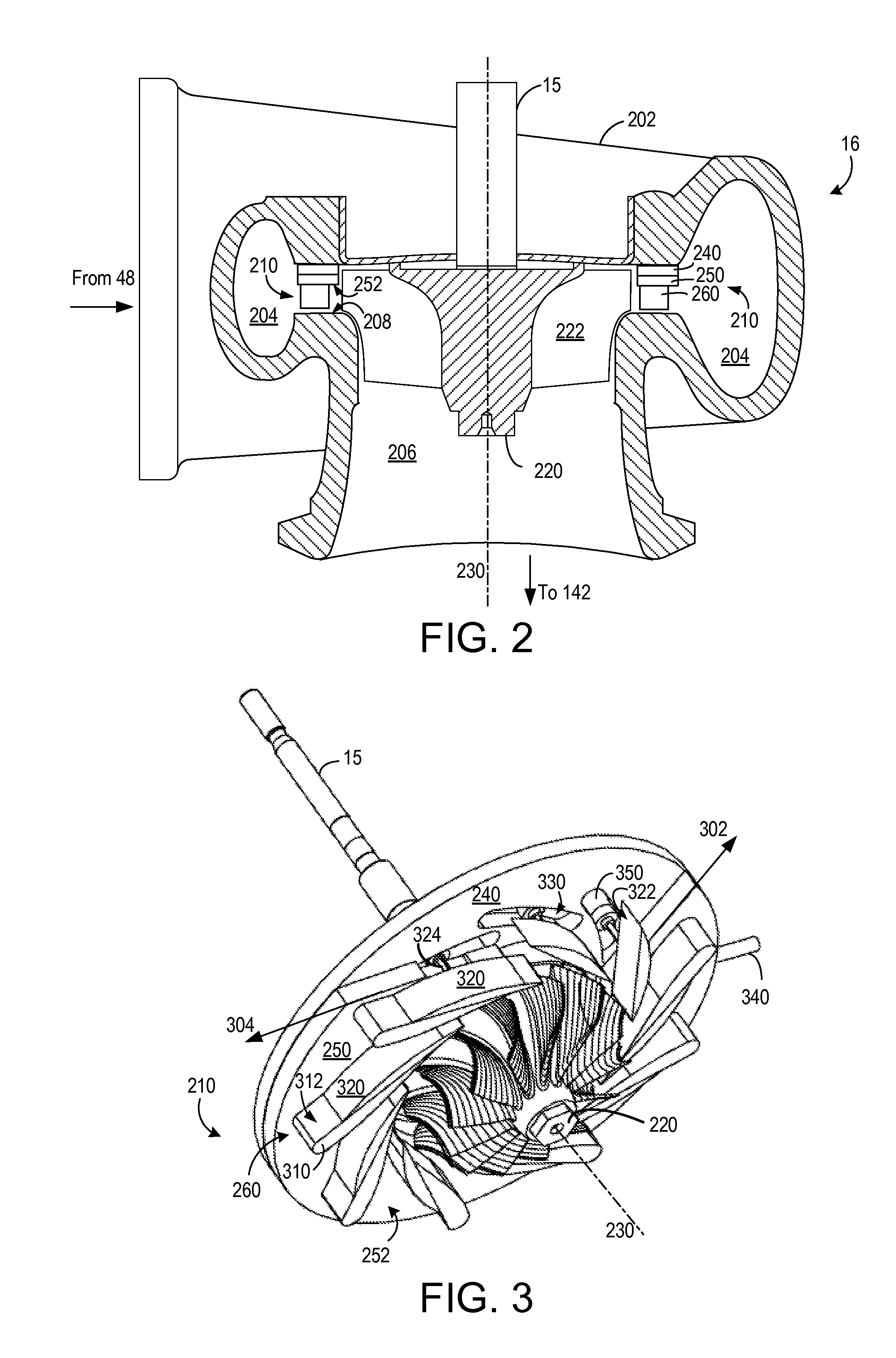

Sliding vane geometry turbines

ActiveUS20130042608A1Reduce the overall heightLoss of expansionInternal combustion piston enginesPump componentsVariable geometry turbineTurbine

Various systems and methods are described for a variable geometry turbine. In one example, a turbine nozzle comprises a central axis and a nozzle vane. The nozzle vane includes a stationary vane and a sliding vane. The sliding vane is positioned to slide in a direction substantially tangent to an inner circumference of the turbine nozzle and in contact with the stationary vane.

Owner:FORD GLOBAL TECH LLC

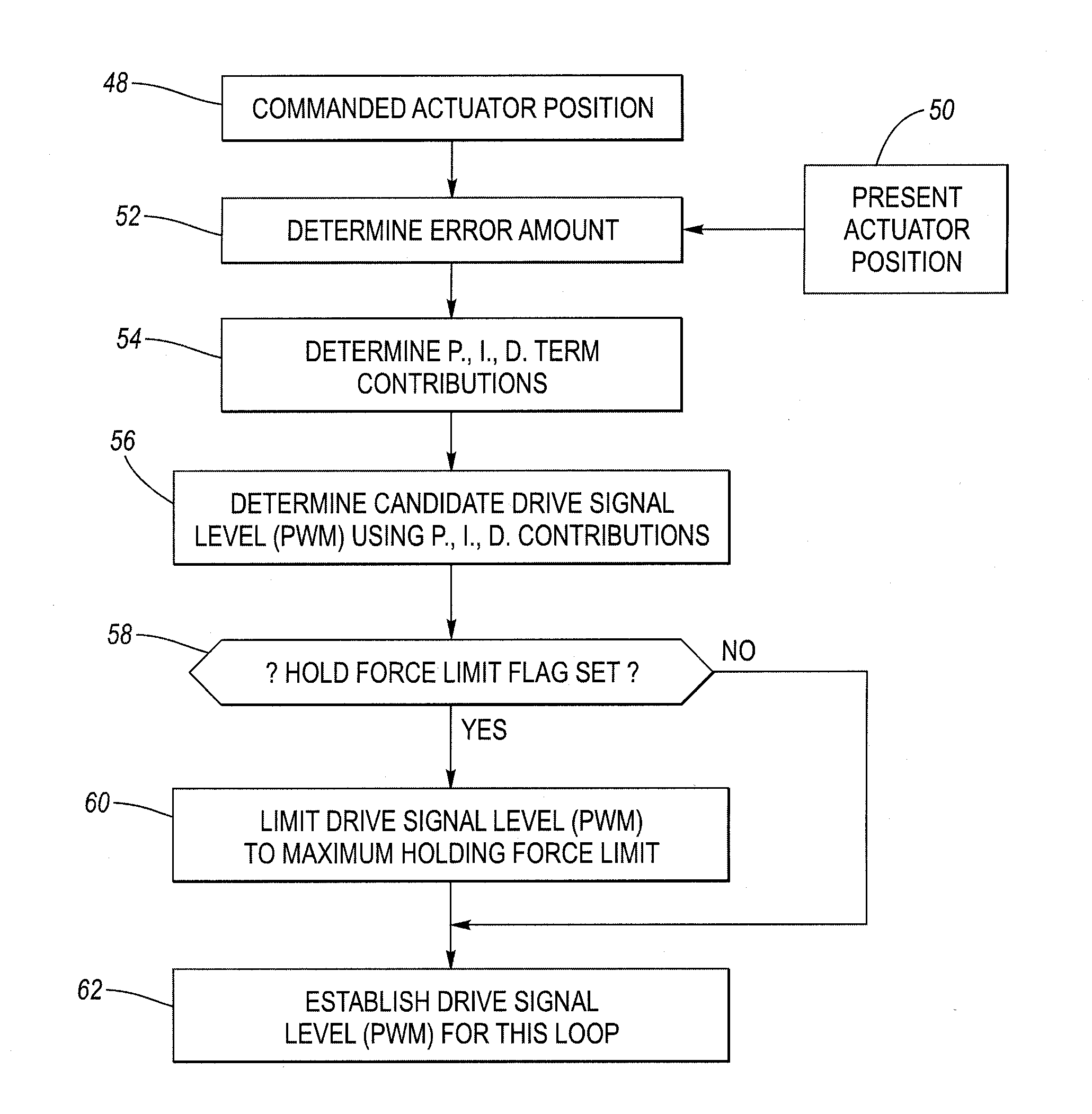

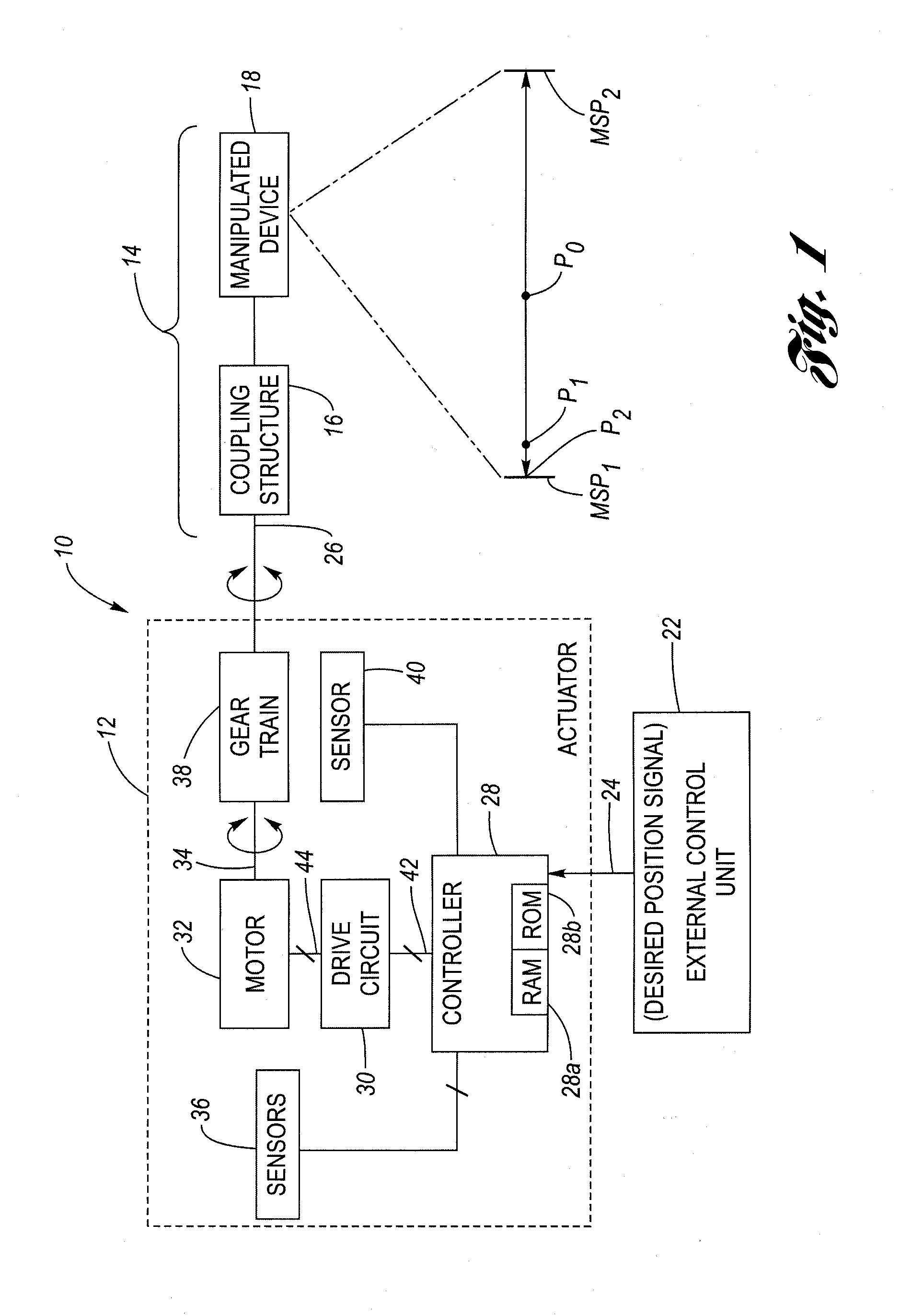

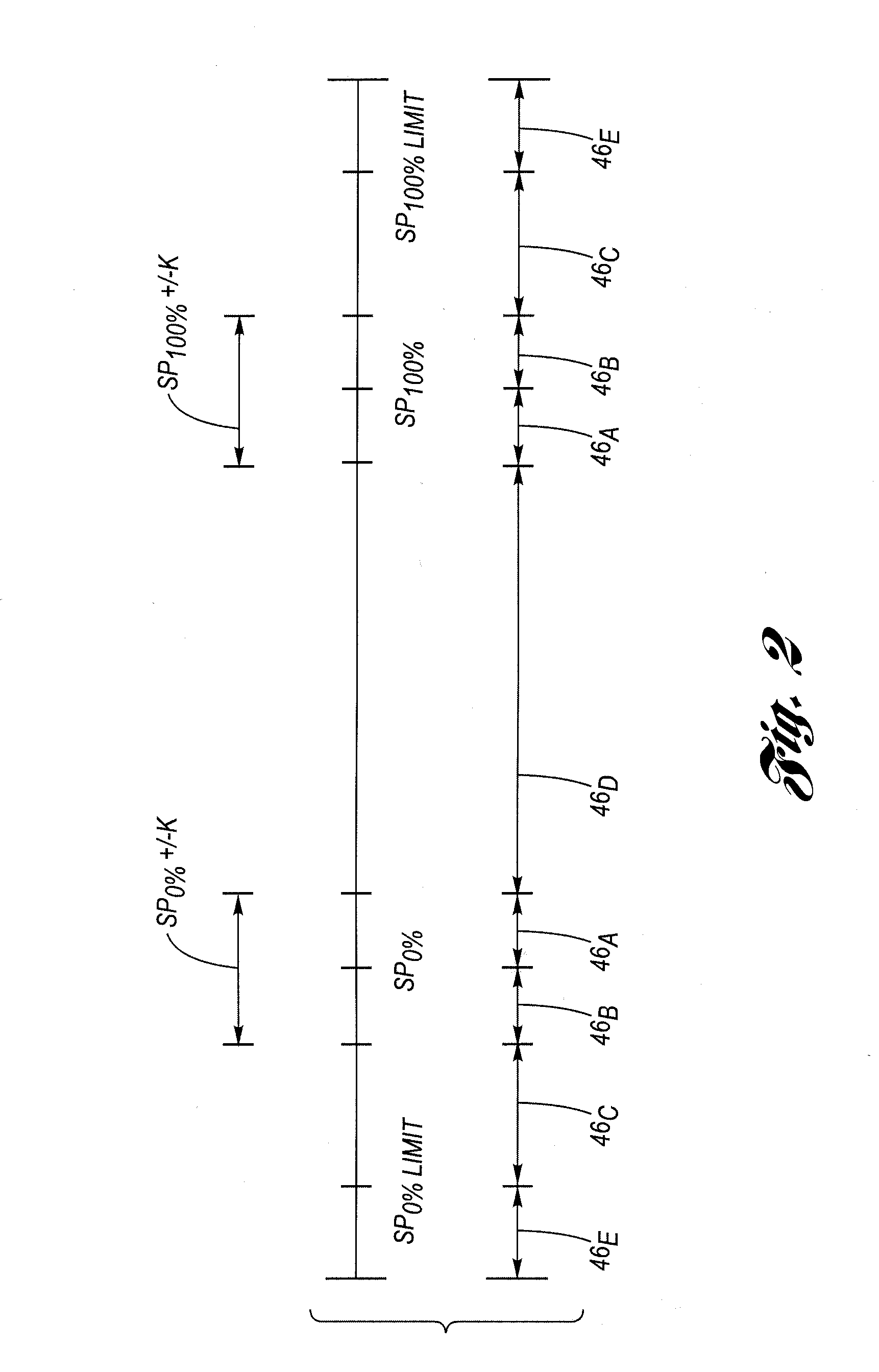

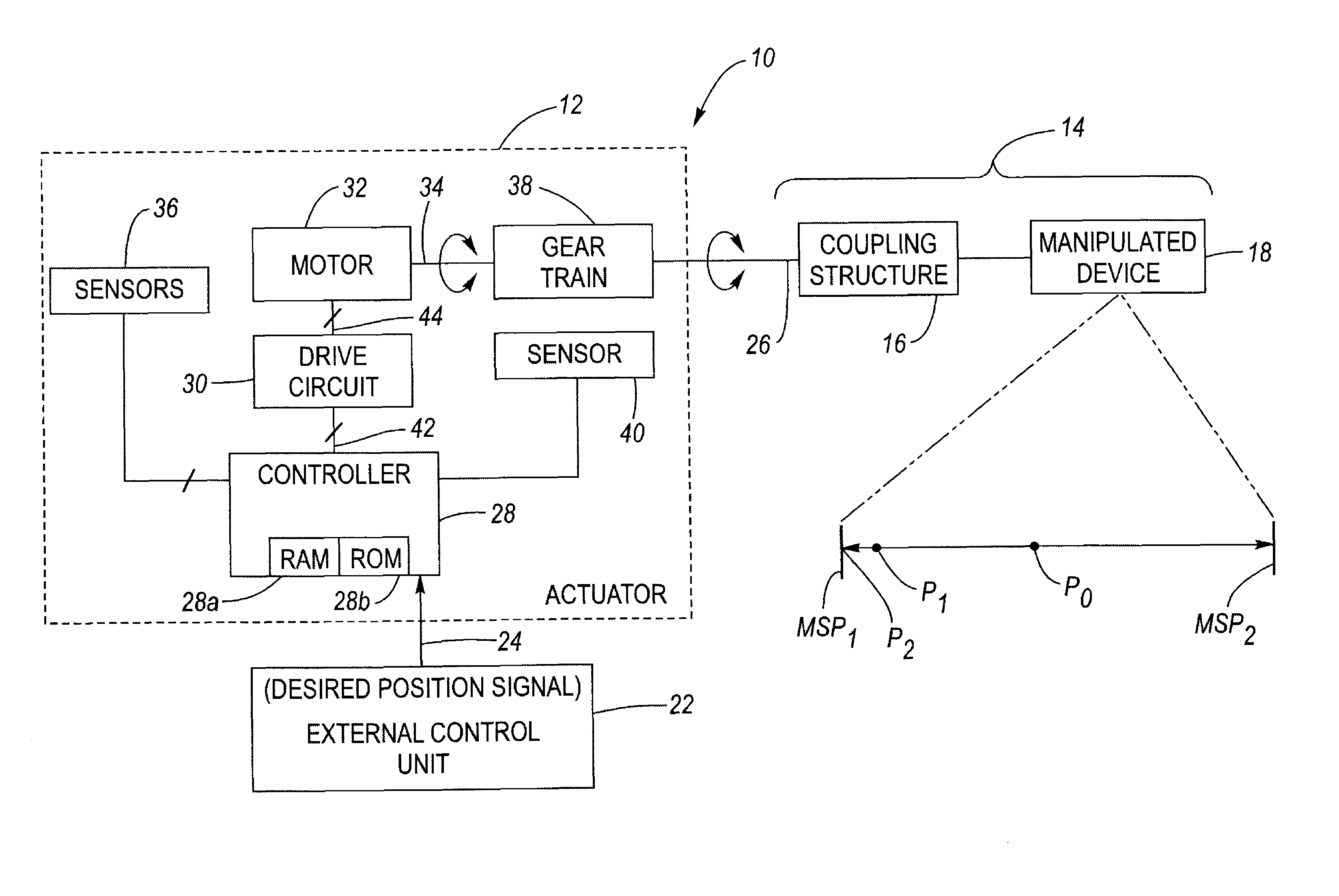

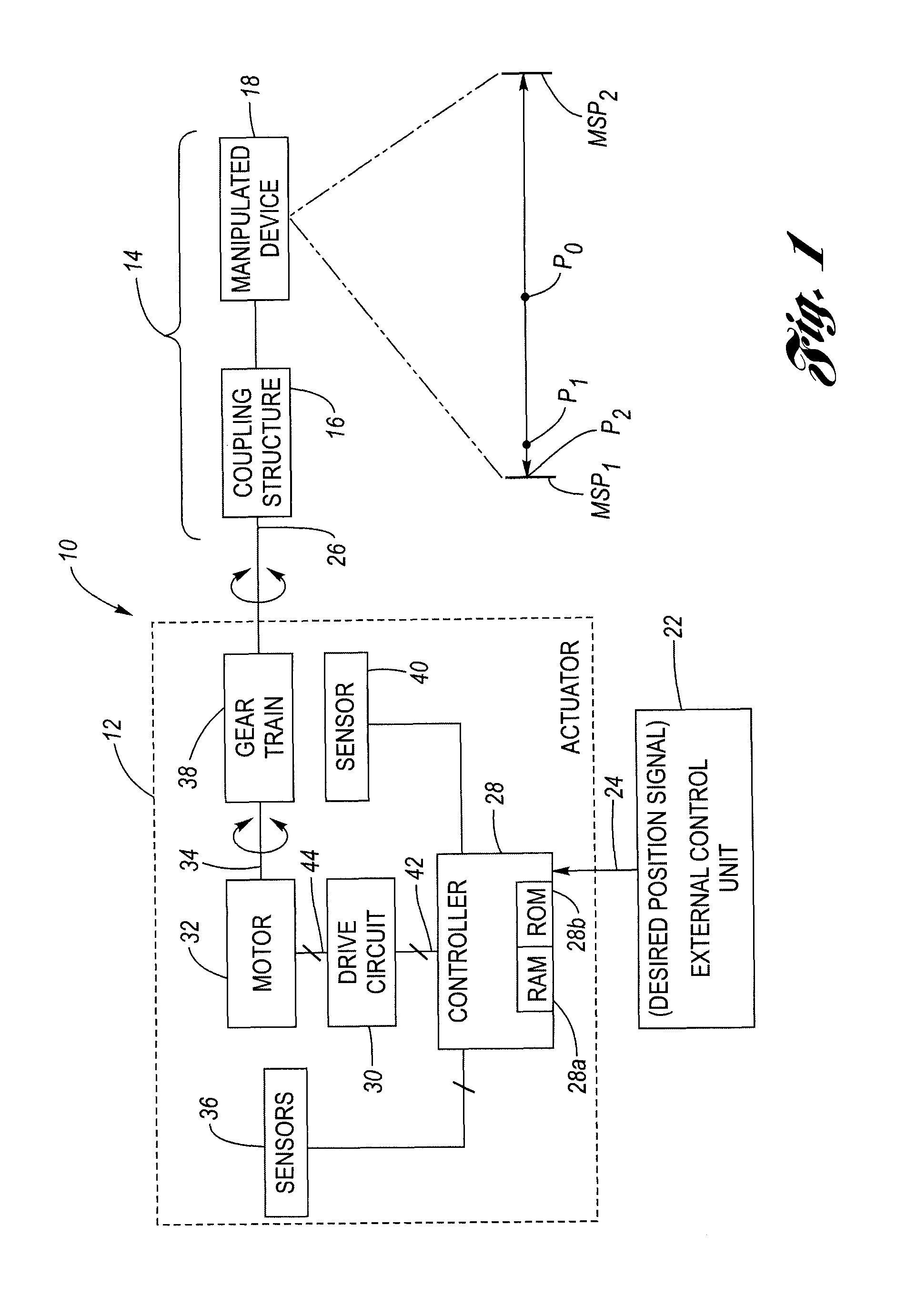

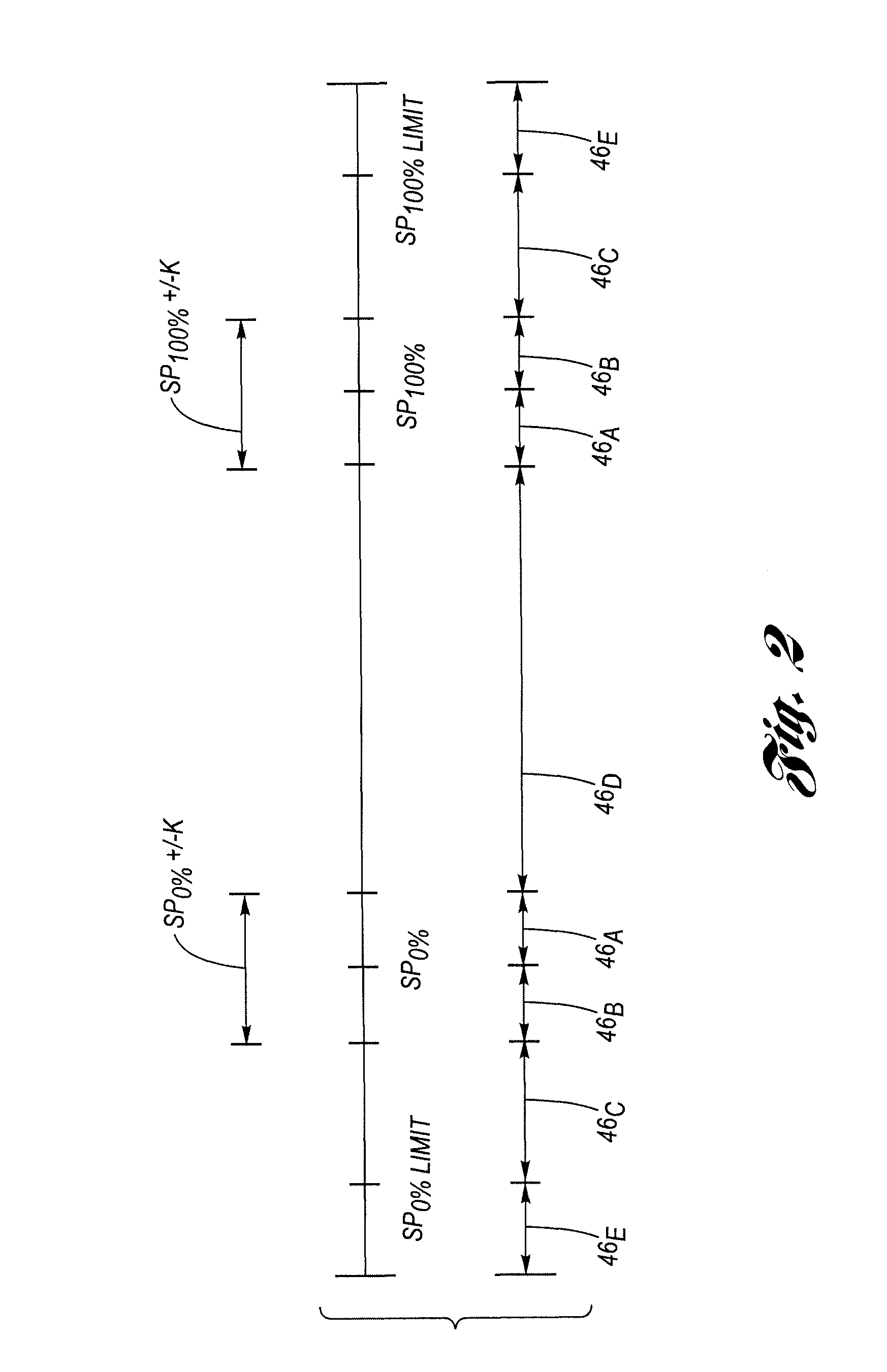

Method for controlling a holding force against, and limiting impact with travel limit positions

ActiveUS20090108793A1More impactDC motor speed/torque controlEmergency protective circuit arrangementsDriver circuitVariable geometry turbine

An actuator includes a motor operated by a controller through a pulse width modulation drive signal applied to a drive circuit that drives the motor. The actuator has an output shaft connected to a coupling structure for manipulating a device such as a variable geometry turbine (VGT) or an exhaust gas recirculation (EGR) valve. The device has a range of motion limited by first and second mechanical stops located at opposing low and high ends of the range. The controller learns the location of the mechanical stops during calibration. An external control unit transmits a desired position to the actuator. A protocol allows the external control unit to implicitly request a positioning mode by virtue of what value range the desired position falls into. The controller is configured to limit the drive signal to a non-harmful level when one of the positioning modes calls for pushing the device against one of the stops.

Owner:DELPHI TECH IP LTD

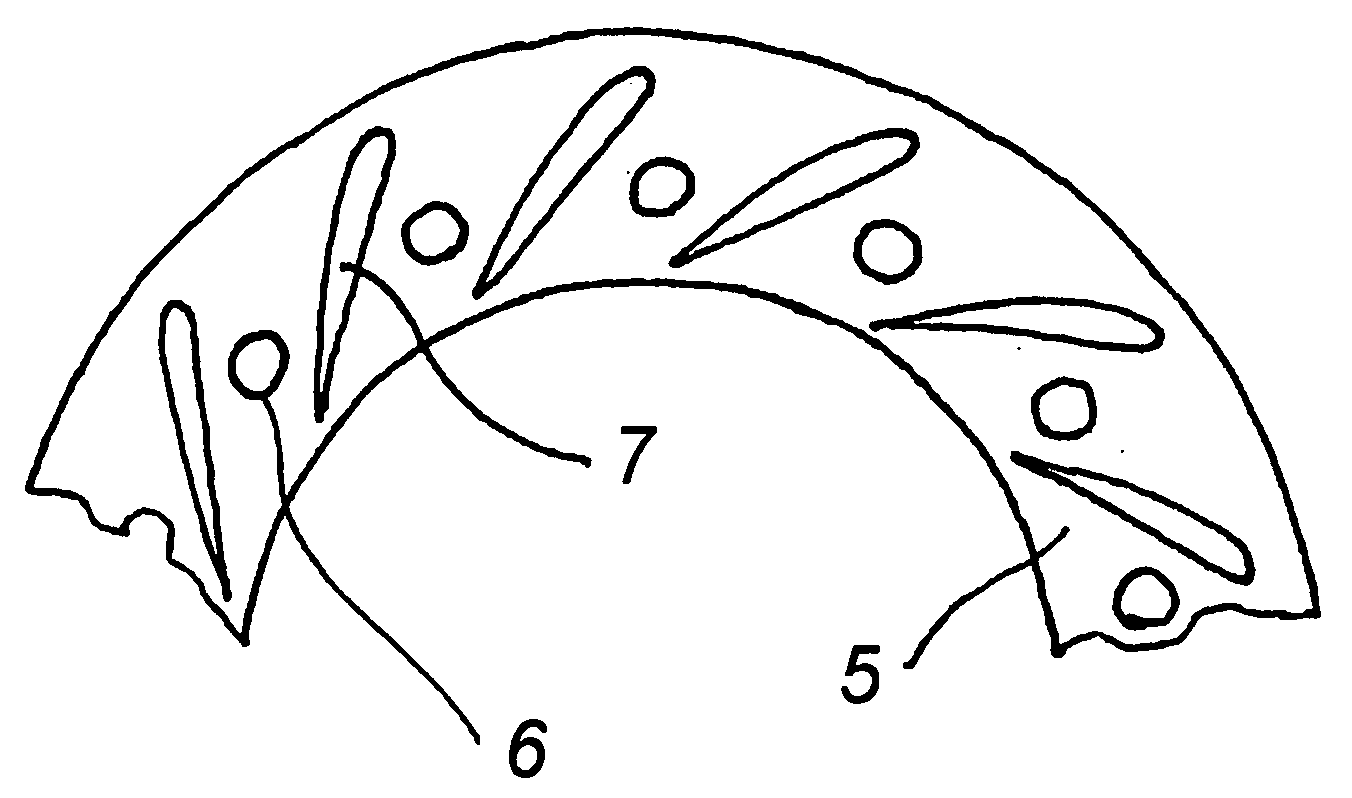

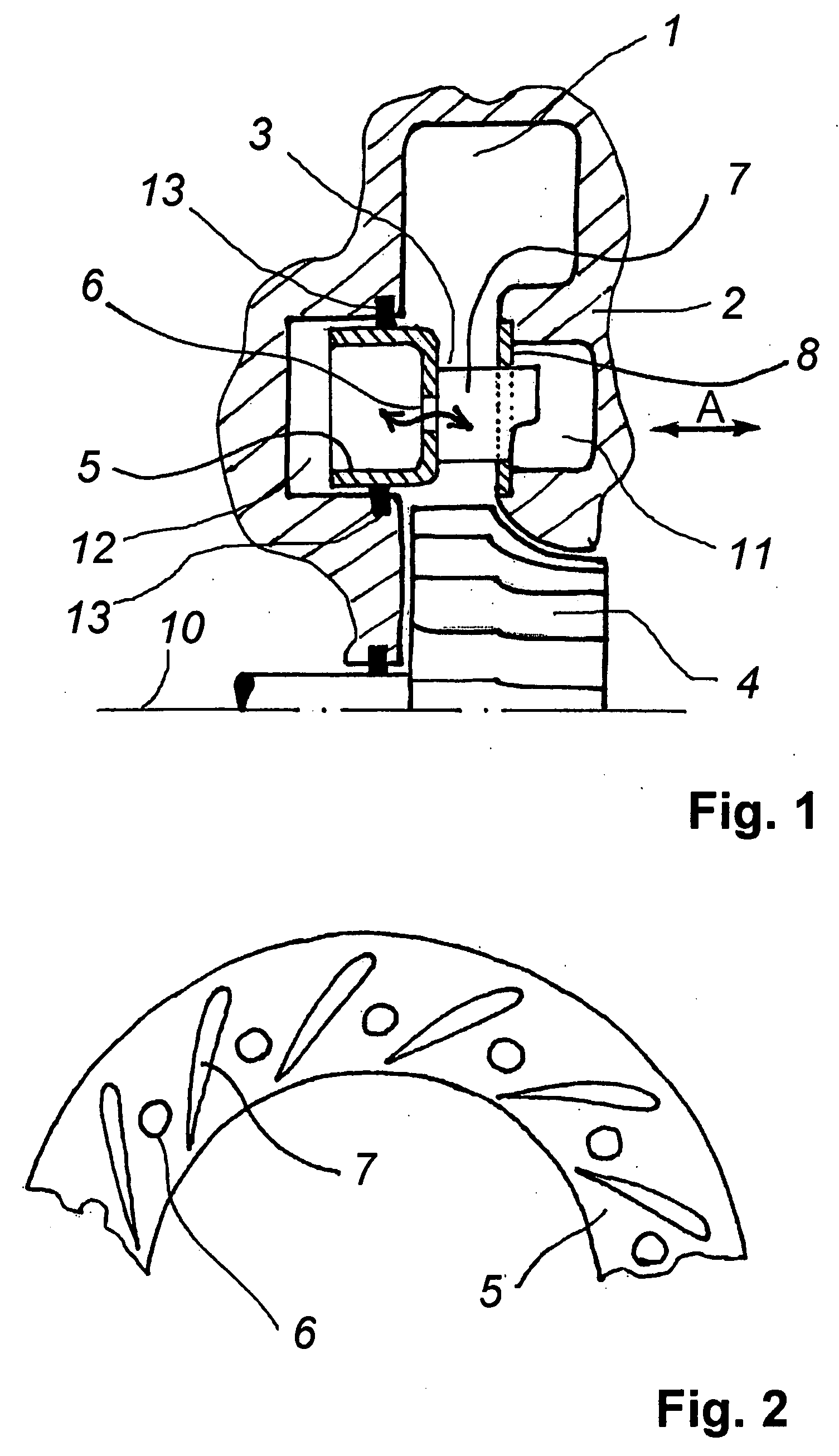

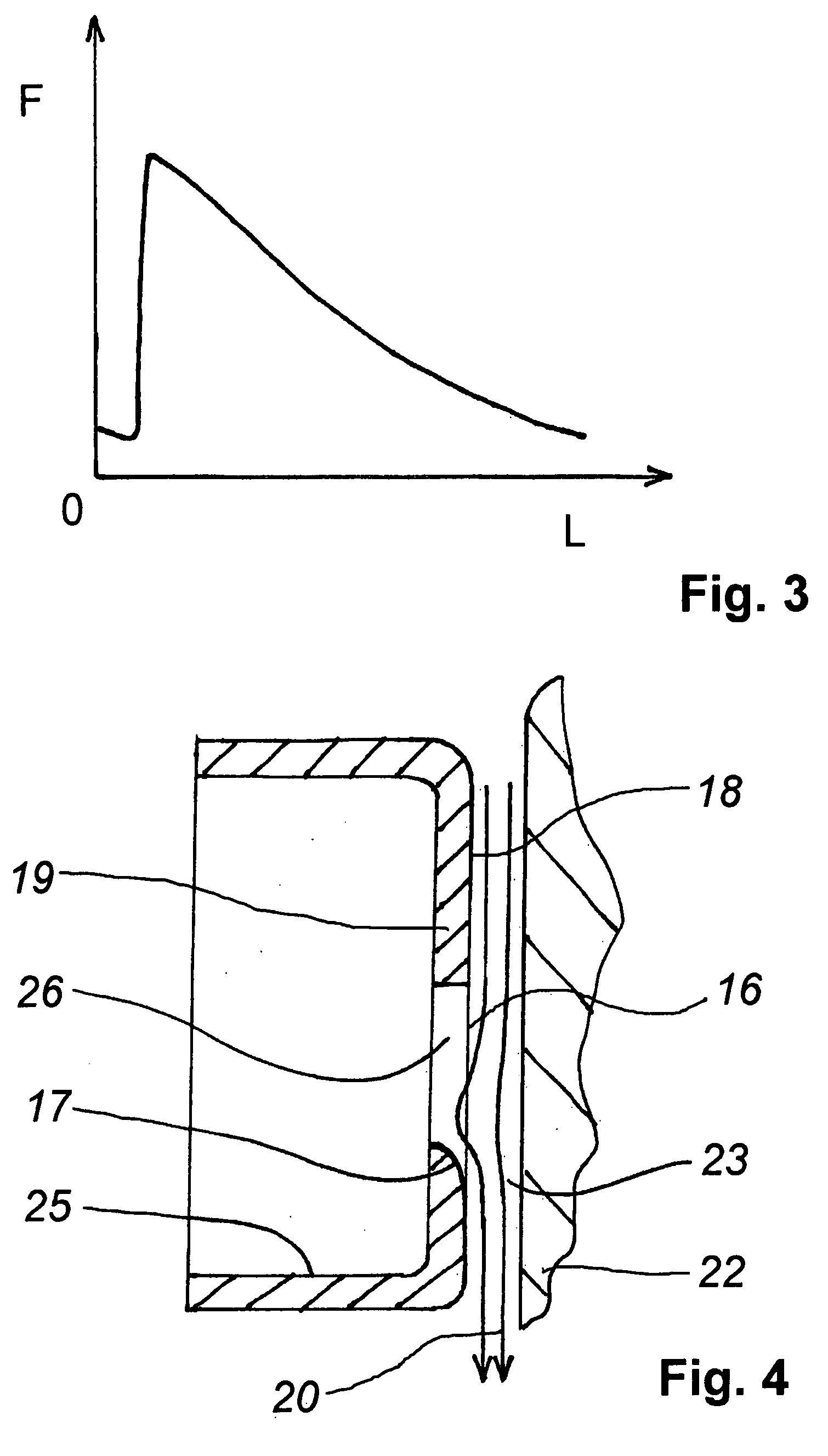

Variable geometry turbine

Variable geometry turbine, in particular a gas turbine, comprising a housing (2, 22), a turbine rotor (4), a fluid inlet scroll (1) that surrounds said turbine rotor, a vaned nozzle interposed between said inlet scroll and said turbine rotor conceived to accelerate the flow of fluid, said nozzle comprising an axially adjustable ring (5, 25) conceived to vary the nozzle gap (3, 23) and having a wall (19) delimiting said nozzle gap, said wall having balance holes (6, 26, 26′) connecting the nozzle gap with a chamber (12) delimited by said housing and said ring, characterised in that the edges (16), formed by said holes with the surface (18) of said wall facing the nozzle gap, are rounded in the portion (17, 17′) located downstream the holes with respect to the fluid flow.Turbocharger and supercharged engine comprising said turbine.

Owner:FPT MOTORENFORSCHUNG

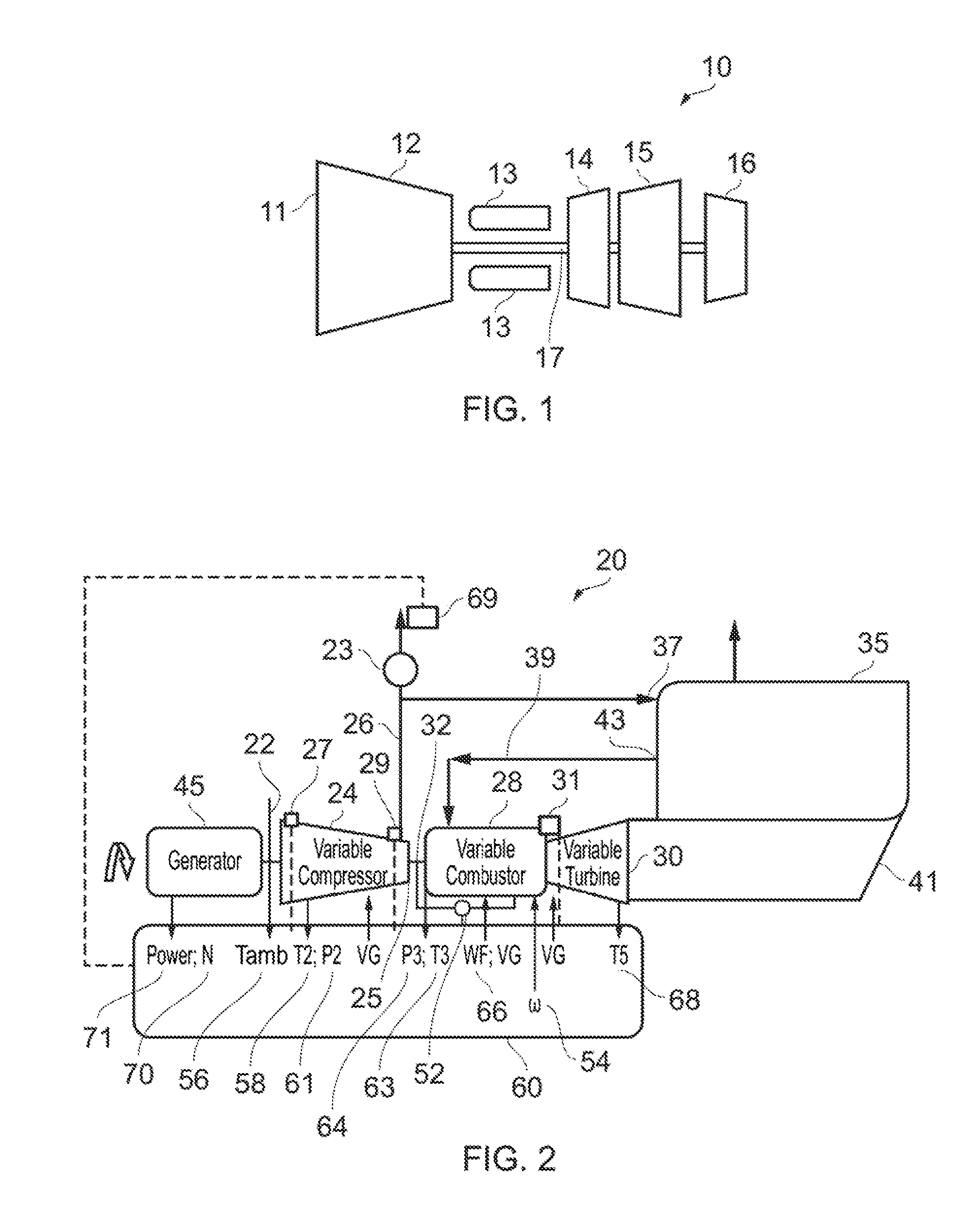

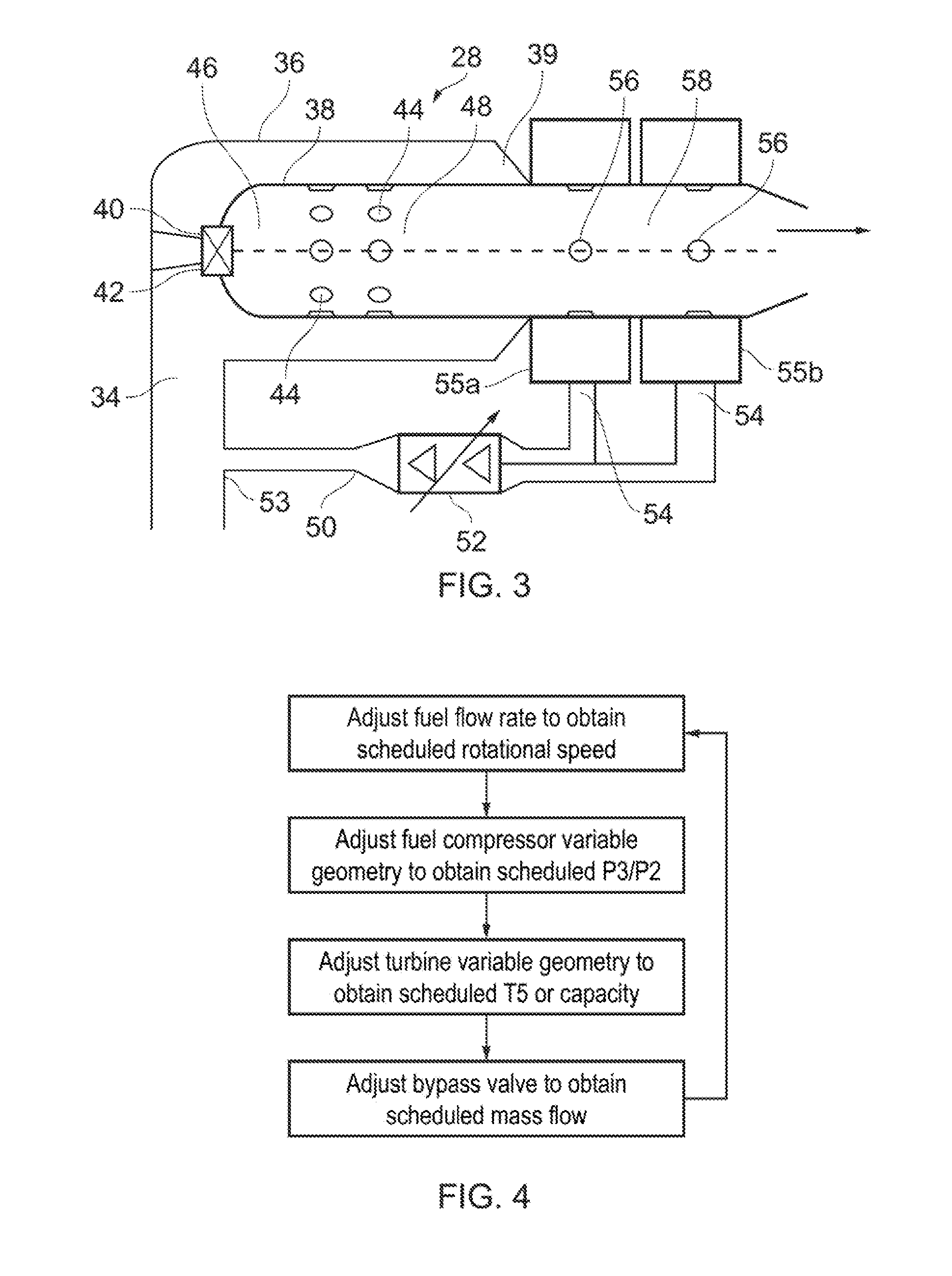

Method of Operation of a Gas Turbine Engine

InactiveUS20160153365A1Increased longevityConstant cycle operationContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorVariable geometry turbine

A method of operating a gas turbine engine (20) comprising a variable geometry compressor (24), a variable geometry combustor (28), and a variable geometry turbine (30). The method comprises operating the variable geometry combustor (28) such that a corrected flow ωc through a combustion zone (46, 48) of the combustor (28) matches a predetermined value.

Owner:ROLLS ROYCE PLC

System and method for mode transition for a two-stage series sequential turbocharger

InactiveCN101900042AElectrical controlInternal combustion piston enginesVariable geometry turbineControl system

The invention relates to a system and method for mode transition for a two-stage series sequential turbocharger. A method of controlling a series turbocharger for an engine and a control system for the same includes a boost determination module determining a first predicted boost pressure for a first position of a variable geometry turbine when a high pressure turbine bypass valve is in an open position. The boost determination module determines a second boost pressure for a second position of the variable geometry when the high pressure turbine bypass valve is in the open position. A desiredboost module determines a desired boost. A comparison module determines when the desired boost signal is between the first predicted boost pressure and the second predicted boost pressure. A bypass valve control module closes the high pressure turbine bypass valve when the desired boost signal is between the first predicted boost pressure and the second predicted boost pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for controlling a holding force against, and limiting impact with travel limit positions

ActiveUS7855525B2More impactProgramme controlDC motor speed/torque controlDriver circuitRange of motion

Owner:DELPHI TECH IP LTD

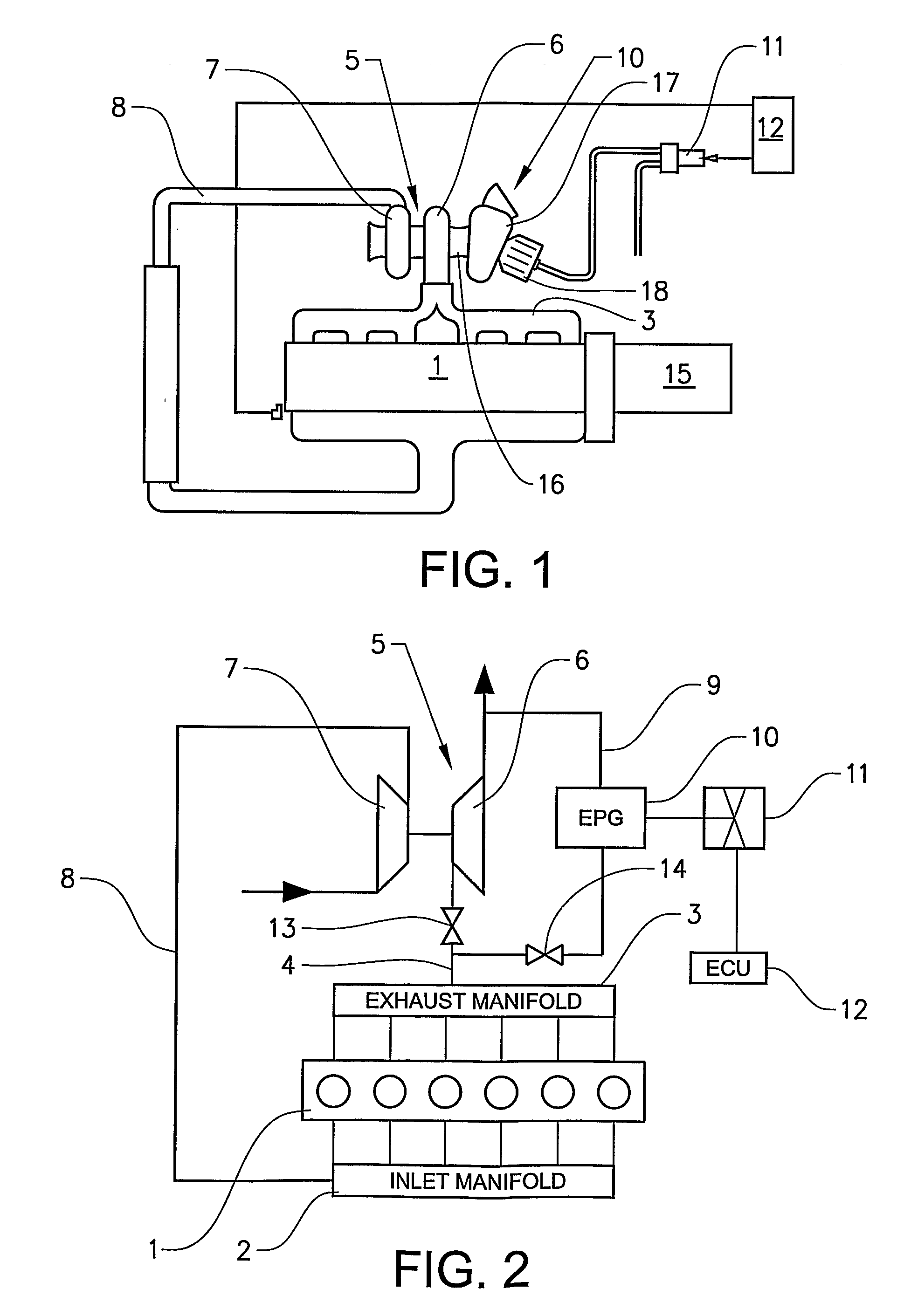

Engine brake for vehicle

ActiveUS20100101531A1Easy to manageHigh leveling accuracyInternal combustion piston enginesNon-fuel substance addition to fuelControl signalVariable geometry turbine

An engine brake system and a method for controlling the exhaust gas pressure of an exhaust system for a vehicle provided with an engine are provided. The system includes a main exhaust gas conduit connected to the turbine of a turbo arrangement and an Exhaust Pressure Governor (EPG) which is used to create a backpressure in the exhaust system so as to function as an engine brake. The turbo arrangement includes a Variable Geometry Turbine (VGT). The Exhaust Pressure Governor is located in a bypass conduit which is connected to the main exhaust conduit upstream the connection to the turbine of the turbo arrangement and the main exhaust conduit includes a valve arrangement downstream the bypass conduit connection for closing the main exhaust conduit. According to the method for controlling the system, the flow passage through the main conduit is open and the flow through the bypass conduit is closed in response to an output control indicating that no engine braking is desired. In case there is an output control indicating that engine braking is desired, the flow passage through the main conduit is closed and the flow through the bypass conduit is open whereby the EPG is controlled to provide a desired backpressure according to the control signals from the control system.

Owner:VOLVO LASTVAGNAR AB

Systems and methods for a variable geometry turbine nozzle

ActiveUS20160146100A1Improve engine torqueIncreased power output densityInternal combustion piston enginesWind motor controlVariable geometry turbineEngineering

Various systems and methods are described for a variable geometry turbine. In one example, a nozzle vane includes a stationary having a first cambered sliding surface and a sliding vane having a second cambered sliding surface where the second cambered sliding surface includes a flow disrupting feature in contact with the first sliding cambered surface. The sliding vane may be positioned to slide in a direction from substantially tangent along a curved path to an inner circumference of the turbine nozzle and selectively uncover the flow disrupting feature.

Owner:FORD GLOBAL TECH LLC

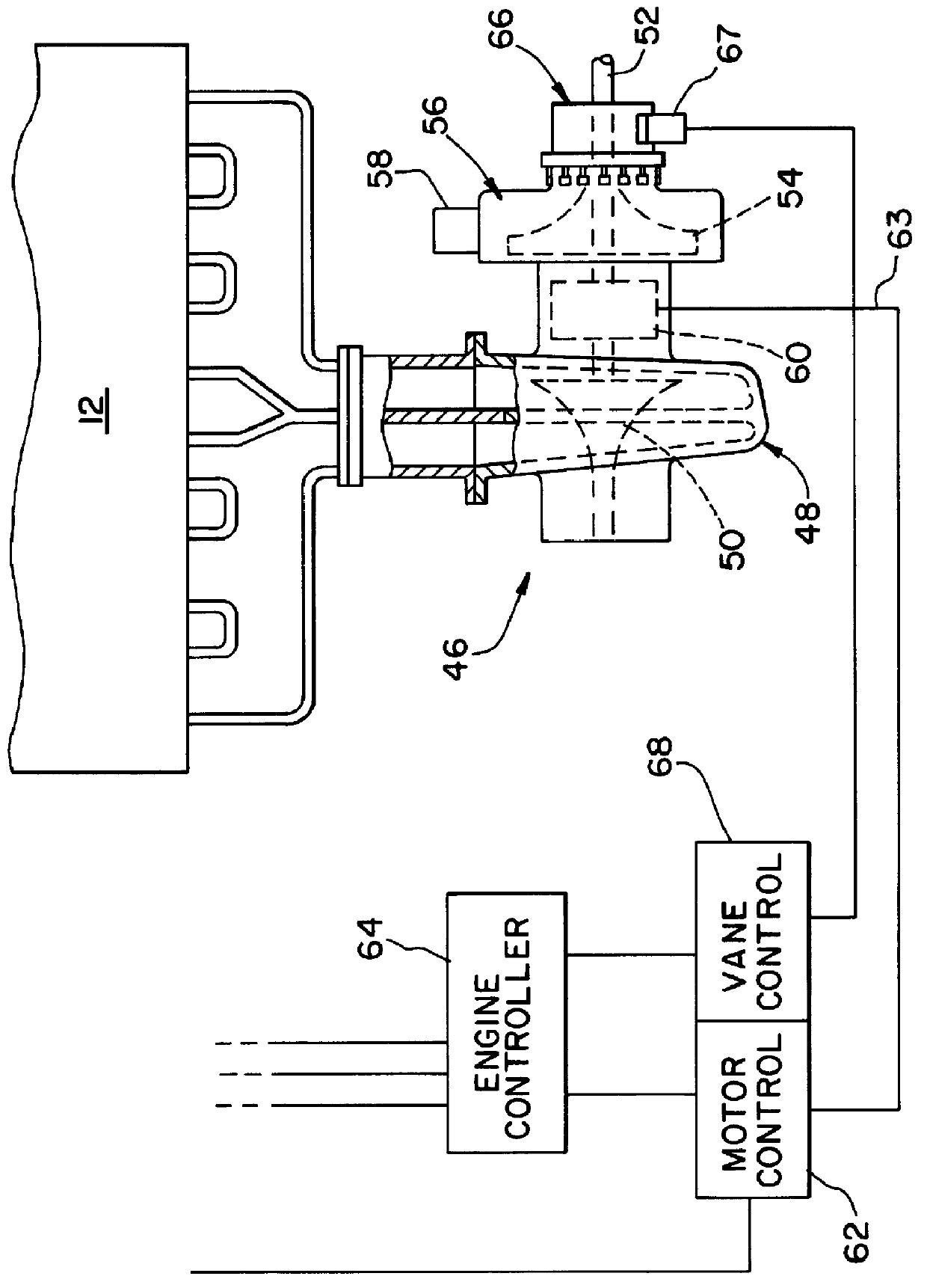

Motor-assisted variable geometry turbocharging system

InactiveUSRE36609E1Improve variable performanceImprove performanceInternal combustion piston enginesGearingVariable geometry turbineTurboexpander

The motor-assisted variable geometry turbocharging system has a motor to add power to the turbocharging shaft, especially at low exhaust gas volume. Additionally, the turbocharger has control over compressor air inlet direction and / or control of exhaust gas to a two-volute expander. These are individually controlled directly or indirectly from an engine controller to enhance turbocharger performance. In a preferred embodiment, the motor is an electric motor, mounted directly on the turbocharger shaft intermediate the turbo expander and turbo compressor and within the main housing.

Owner:HALIMI EDWARD MAYER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com