Variable geometric turbine nozzle ring

A technology of nozzle ring and geometry, which is applied in the direction of engine components, machines/engines, internal combustion piston engines, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

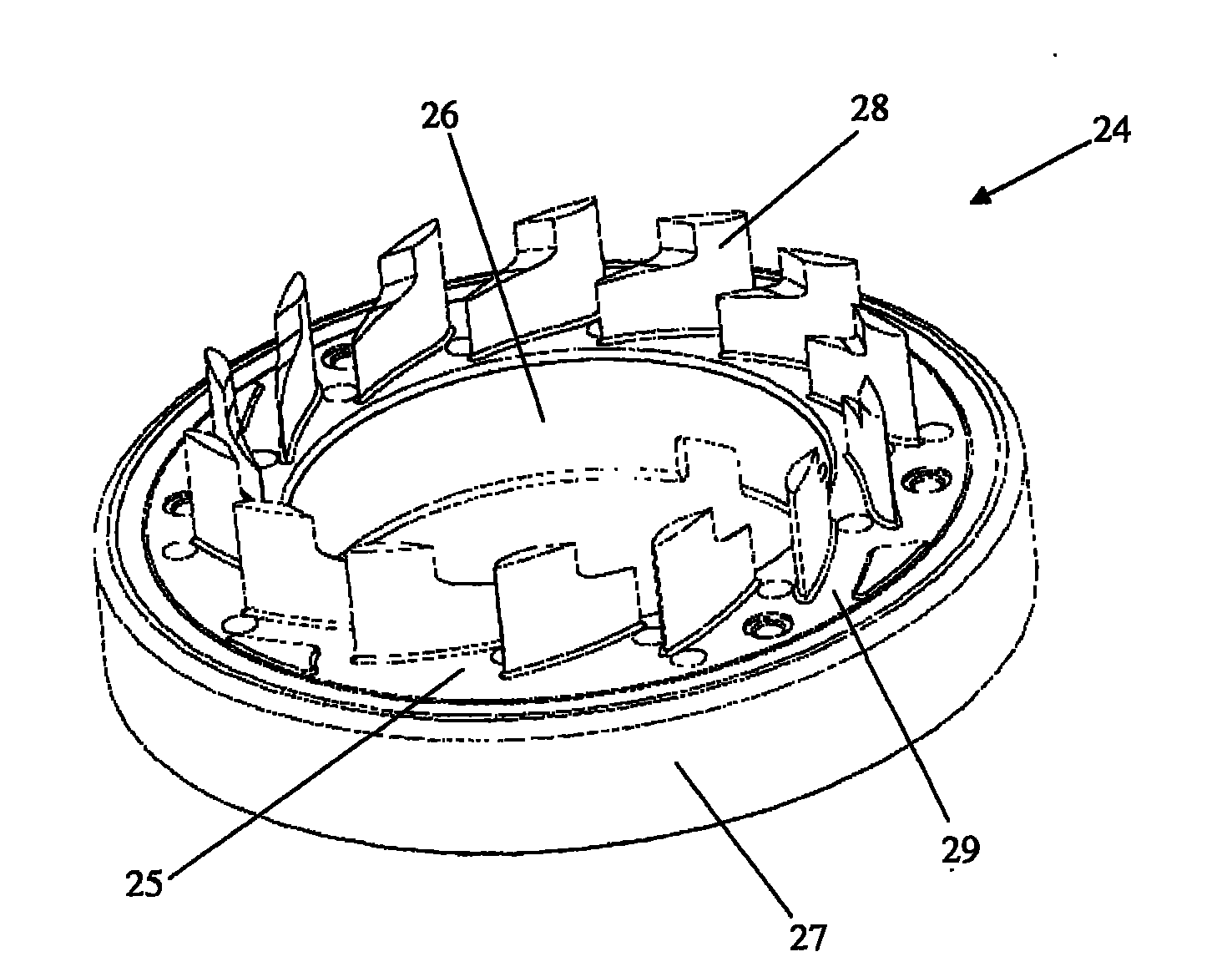

Image

Examples

Embodiment Construction

[0075] refer to figure 1 , which shows a known variable geometry turbocharger comprising a housing consisting of a variable geometry turbine housing 1 and a compressor housing 2 interconnected by a central bearing housing 3 . The turbocharger shaft 4 extends from the turbine housing 1 via the bearing housing 3 to the compressor housing 2 . A turbine wheel 5 is mounted on one end of the shaft 4 to rotate within the turbine housing 1 , and a compressor wheel 6 is mounted on the other end of the shaft 4 to rotate within the compressor housing 2 . The shaft 4 rotates about a turbocharger axis 4 a on a bearing assembly inside the bearing housing 3 .

[0076] The turbine housing 1 defines an inlet volute 7 to which gases from an internal combustion engine (not shown) are conveyed. Exhaust gas flows from the inlet volute 7 to the axial outlet channel 8 via the annular inlet channel 9 and the turbine wheel 5 . The inlet channel 9 is delimited on one side by a face 10 of a radial wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com