Diesel engine post-processing device

A post-processing device and diesel engine technology, applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, exhaust treatment, etc., can solve the problem of low catalyst conversion efficiency and achieve the effect of improving catalytic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

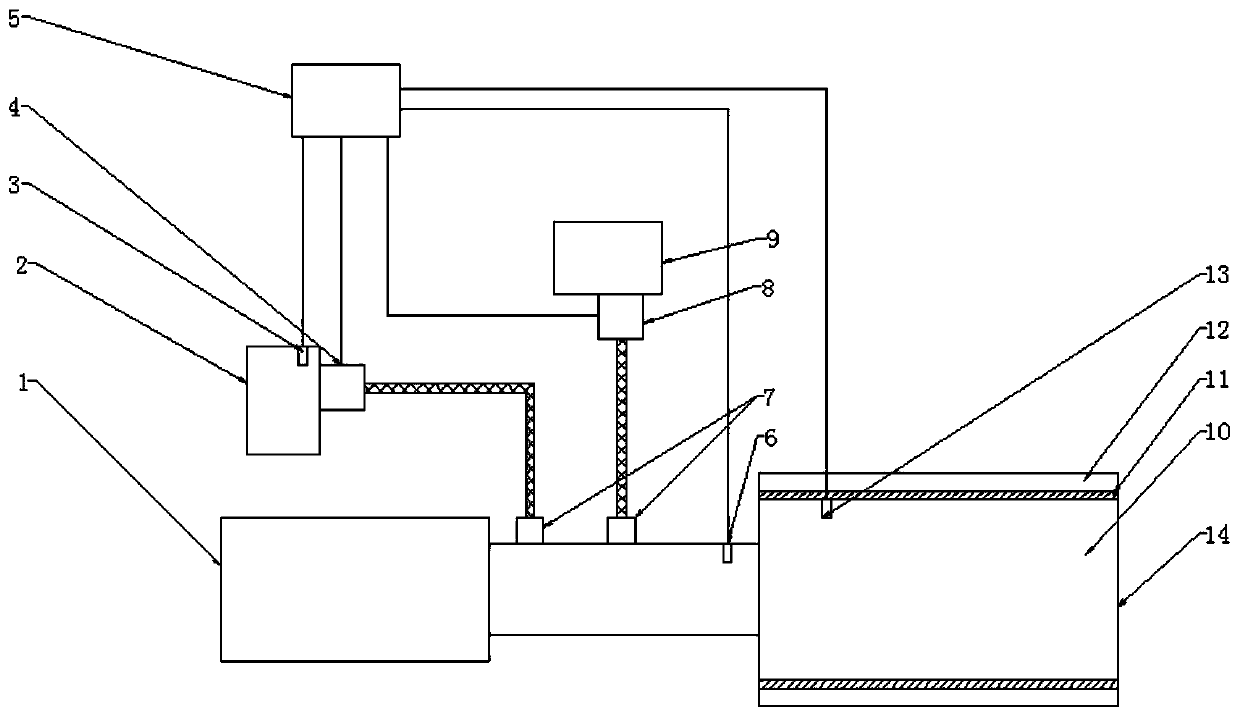

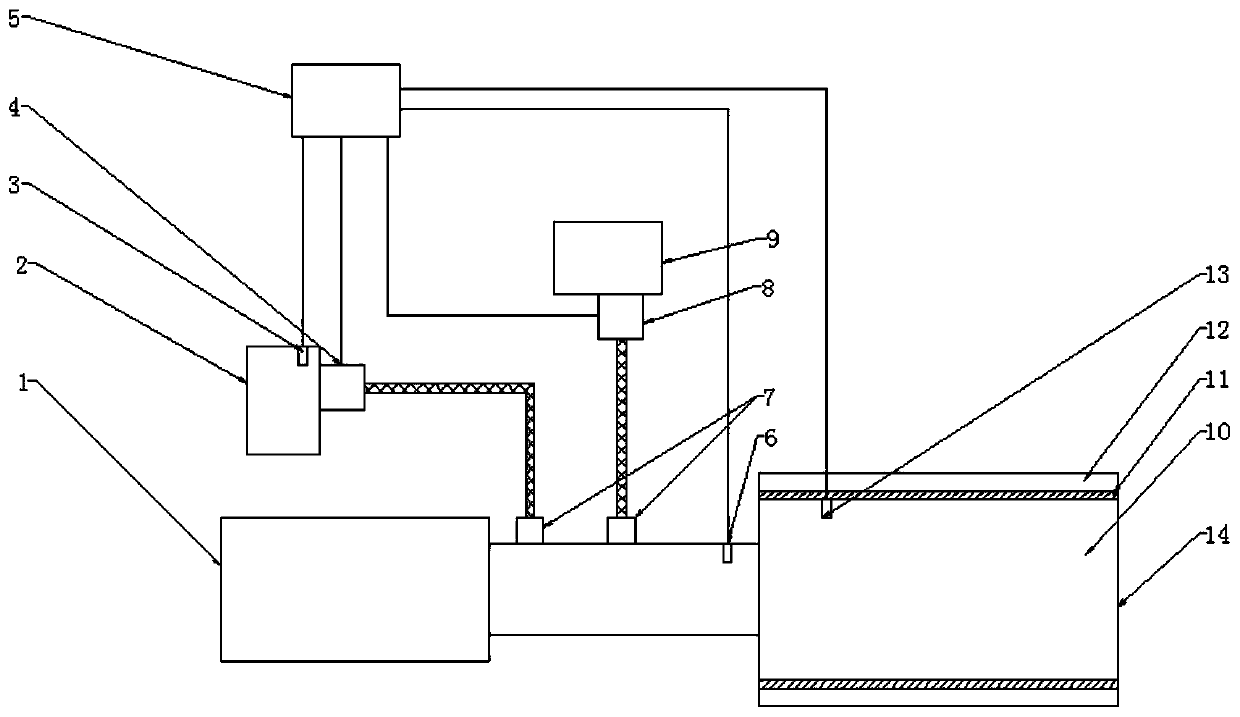

[0022] like figure 1 The diesel engine post-treatment device shown includes a DPF chamber 1 and an SCR catalyst chamber 14, and the exhaust passage between the DPF chamber 1 and the SCR catalyst chamber 14 is equipped with a water jet to the exhaust passage. and two nozzles 7 for urea solution, each nozzle 7 is connected with a separate liquid supply pipeline, one of which is equipped with a metering pump 4 and a water tank 2, and the other is equipped with a selective catalytic reduction for SCR urea pump 8 and urea tank 9.

[0023] The SCR catalyst chamber 14 is provided with a catalyst carrier 10. In order to ensure the catalytic effect, the catalyst carrier 10 is cylindrical. The heater is a PTC heater wrapped around the catalyst carrier 10, and the surface of the tubular electric heater is coated with an insulating layer.

[0024] A thermal insulation cavity 12 is provided between the cylindrical electric heater 11 and the housing of the SCR catalytic converter chamber ...

Embodiment 2

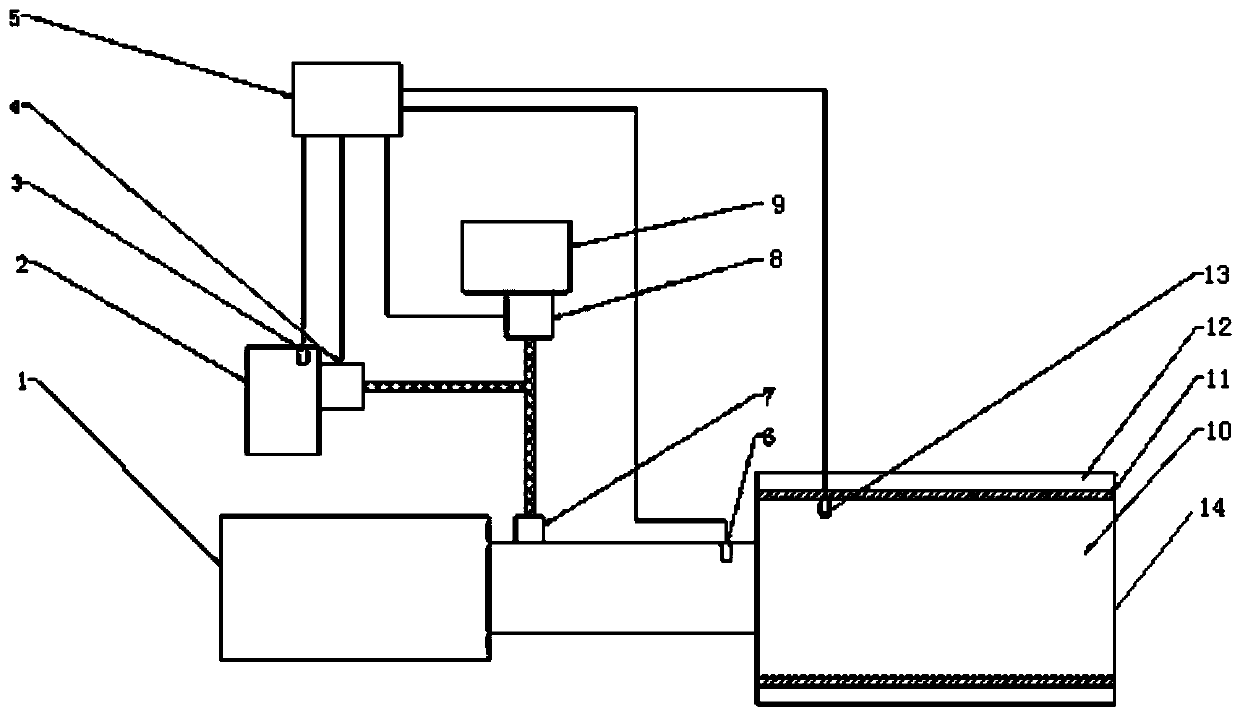

[0052] like figure 2 Another diesel engine post-processing device is shown. On the basis of the diesel engine post-processing device in the first embodiment of the device, the liquid supply pipeline connected to the nozzle 7 includes a main road, which communicates with the water supply branch of the main road and the urea branch. A metering pump 4 and a water tank 2 are provided on the water supply branch, a urea pump 8 and a urea tank 9 are provided on the urea branch, and the controller 5 controls and connects the urea pump 8 . The controller 5 controls the amount of water sprayed by the water tank 2 into the channel through the metering pump 4, and the amount of urea solution sprayed into the channel by the urea tank 9 through the urea pump 8. After the two are mixed in the pipeline, they are sprayed into the exhaust gas pipe to reduce the exhaust temperature.

[0053] When the diesel engine is running at high speed and heavy load or before SCR and DPF regeneration, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com