Preparation method for secondarily-silver-plated highly-conductive filling material

A high conductivity, secondary plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of low conductivity, low density of graphene oxide, and increased density of composite materials, etc., to achieve excellent Conductivity, easy operation, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

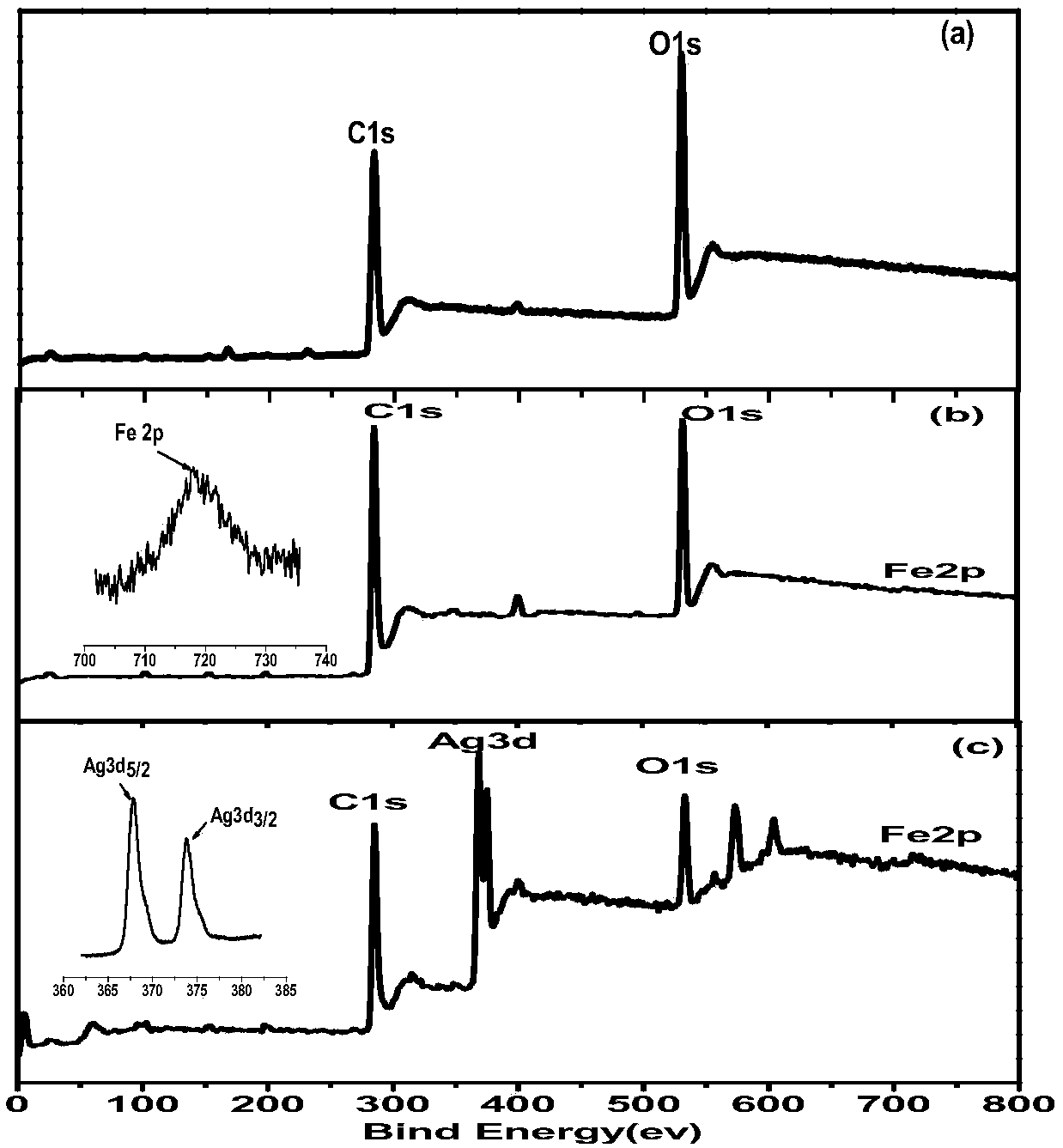

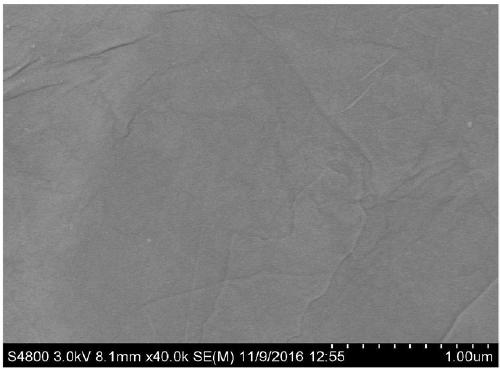

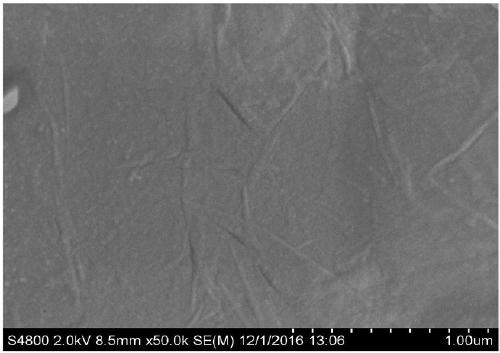

[0054] 1) Add 2g of graphene oxide to 100ml of deionized water, stir evenly, and then configure 3.6g / L tannic acid and 1.2g / L ferric chloride aqueous solution, tannic acid and trichloride The iron molar ratio is 3:1, respectively added to the matrix solution, and after adjusting the pH to 8.5 with Tris-HCl buffer solution, stirred at a stirring rate of 60 rpm for 1 minute, filtered, then added to 100mL deionized water, and then added 6g / L silver nitrate solution, and 25mL ethylene glycol, and then quickly add 450uL octylamine, stirring at 60 rpm; the total reaction time does not exceed 1h. Graphene oxide with silver nanoparticles deposited on the surface is obtained. After the stirring is completed, the graphene oxide deposited with silver nanoparticles is filtered out, washed with absolute ethanol at least three times, and dried;

[0055] 2) configure a silver nitrate solution with a concentration of 10g / L, titrate with ammonia water until the precipitate just disappears, an...

Embodiment 2

[0063] Process is the same as embodiment 1, changes the mol ratio of tannic acid and iron trichloride into 1:2, 1:3, 2:1 and 3:1 in step 1), can obtain the graphite oxide that surface is coated with silver layer alkene.

[0064] It has been determined that the graphene oxide / silver core-shell composite microbeads can conduct electricity, with a conductivity of 1.5—2.0×10 6 Between S / m.

Embodiment 3

[0066] The process is the same as in Example 1, and the pH of the tannic acid-ferric chloride solution in step 1) is adjusted to 7, 7.5, 8, 9, 9.5 and 10 respectively to obtain graphene oxide coated with a silver layer on the surface.

[0067] It has been determined that the graphene oxide / silver core-shell composite microbeads can conduct electricity, with a conductivity of 1.5—2.0×10 6 Between S / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com