Preparation method for electromagnetic shielding PP thin film

An electromagnetic shielding and film technology, which is applied in the field of preparation of electromagnetic shielding PP film, can solve the problems of ineffective control of electromagnetic wave reflection, single protective function, and secondary pollution, and achieve cost saving, uniform thickness, and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The name of the main instrument that the present invention adopts, information such as model and place of production are all listed in Table 1 in detail.

[0032] Table 1:

[0033] name

model

Manufacturer

vacuum oven

XMTD-8222

Shanghai Jinghong Experimental Equipment Co., Ltd.

FA2004

Shanghai Precision Scientific Instrument Co., Ltd.

Vacuum Laminator

Y-001 series

Zhengzhou Craftsman Machinery Equipment Co., Ltd.

Vector Network Analyzer

N5242A

Shenzhen Shengteng Instrument Co., Ltd.

Electronic Fabric Strength Tester

YG065

Laizhou Electronic Instrument Co., Ltd.

Melt blown experimental production line

MBCF-I

Hebei Gu'an Shenbao Filter Factory

[0034] The preparation method of electromagnetic shielding PP film of the present invention carries out successively according to the following steps:

[0035] The first step is to use PP as ...

Embodiment 2

[0058] A preparation method of electromagnetic shielding PP film, the steps are as follows:

[0059] (1) Using polypropylene as raw material, PP non-woven fabrics are prepared by melt-blown spinning technology; the process parameters for preparing PP non-woven fabrics by melt-blown spinning technology are: the set temperature of the screw extruder is 175°C in zone 1, Zone 2 is 215°C, Zone 3 is 225°C, Zone 4 is 235°C, Zone 5 is 230°C; the temperature of the meltblown die head is 230°C; the temperature of the metering pump is 230°C, and the speed of the metering pump is 230 r / min; drafting hot air The wind temperature and wind pressure are 230 ℃ and 8 MPa respectively; the moving speed of the net curtain is 1.6 m / min;

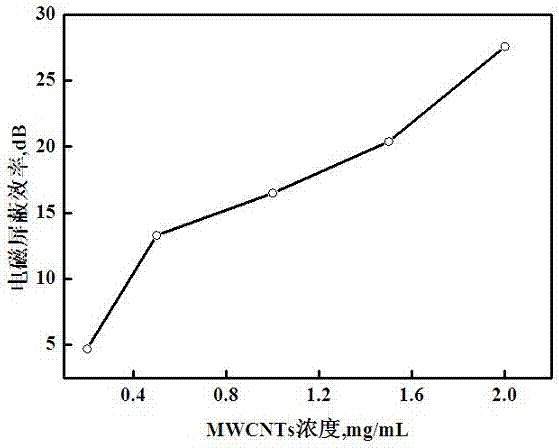

[0060] (2) Add carboxylated multi-walled carbon nanotubes to xylene to prepare a mixed solution with a concentration of 0.1 mg / mL, put the mixed solution into an ultrasonic cleaner, and ultrasonically oscillate in a water bath at 50 °C for 90 min , to obtain a d...

Embodiment 3

[0064] A preparation method of electromagnetic shielding PP film, the steps are as follows:

[0065] (1) Using polypropylene as raw material, PP non-woven fabrics are prepared by melt-blown spinning technology; the process parameters for preparing PP non-woven fabrics by melt-blown spinning technology are: the set temperature of the screw extruder is 180°C in zone 1, Zone 2 is 220°C, Zone 3 is 230°C, Zone 4 is 245°C, Zone 5 is 235°C; the temperature of the meltblown die head is 233°C; the temperature of the metering pump is 240°C, and the speed of the metering pump is 233 r / min; drafting hot air The wind temperature and wind pressure are 240°C and 10 MPa respectively; the moving speed of the net curtain is 2.0 m / min;

[0066] (2) Add carboxylated multi-walled carbon nanotubes to benzene to prepare a mixed solution. The concentration of the mixed solution is 1.6 mg / mL. Put the mixed solution into an ultrasonic cleaner and ultrasonically shake it in a water bath at 70 °C for 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com