Conductive materials

A technology of conductive fillers and compositions, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, metal/alloy conductors, etc., can solve the problems of expensive coatings and adhesives, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

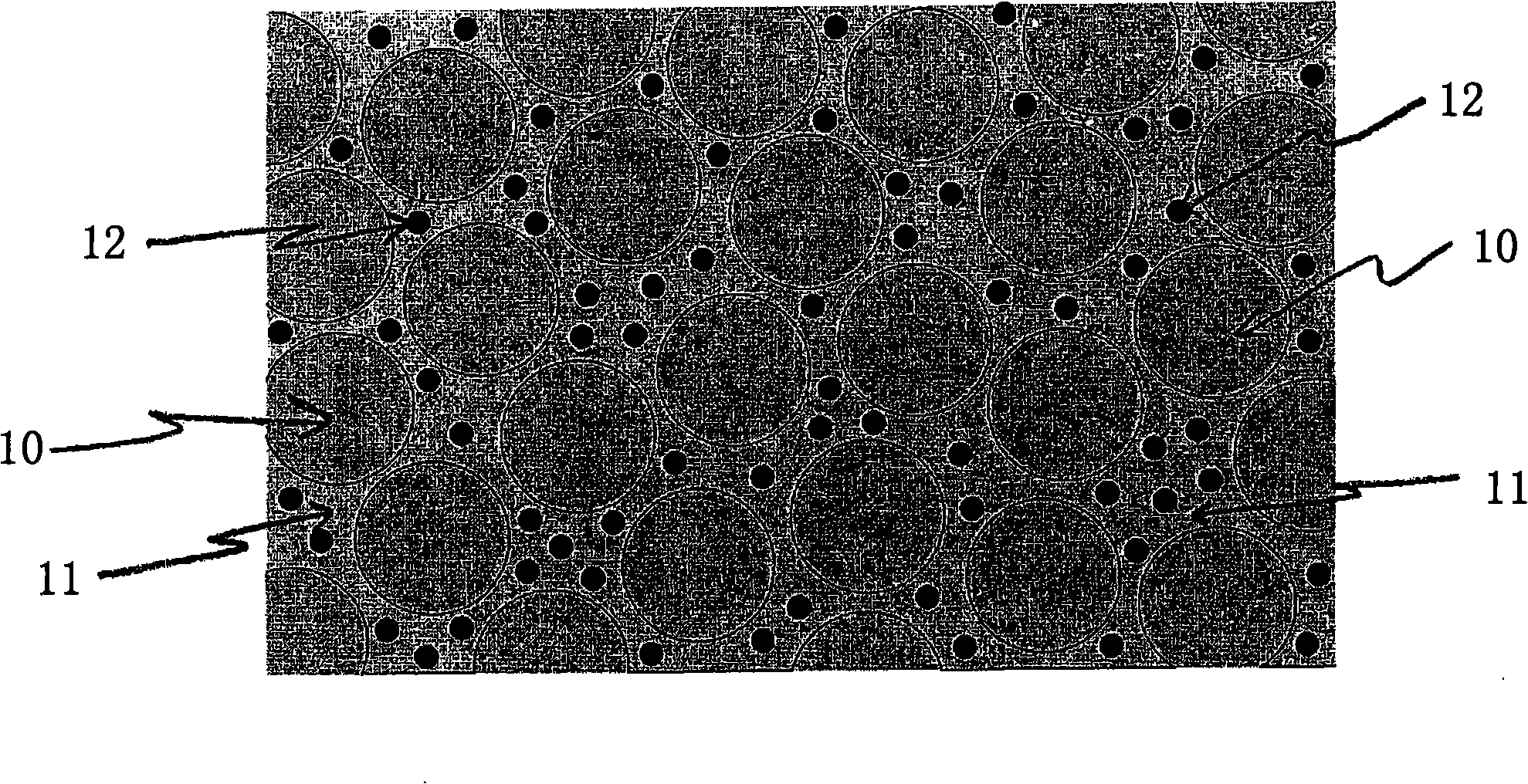

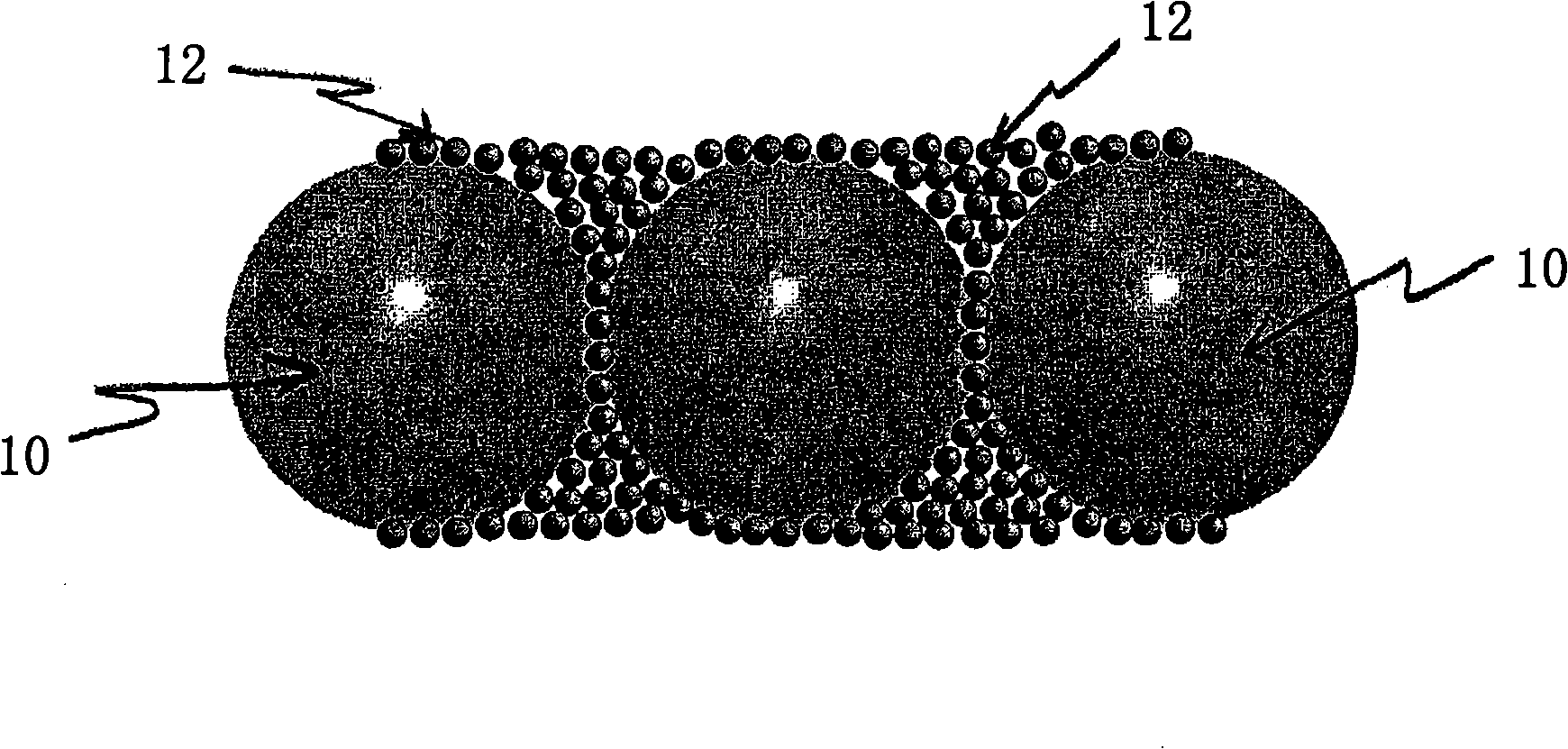

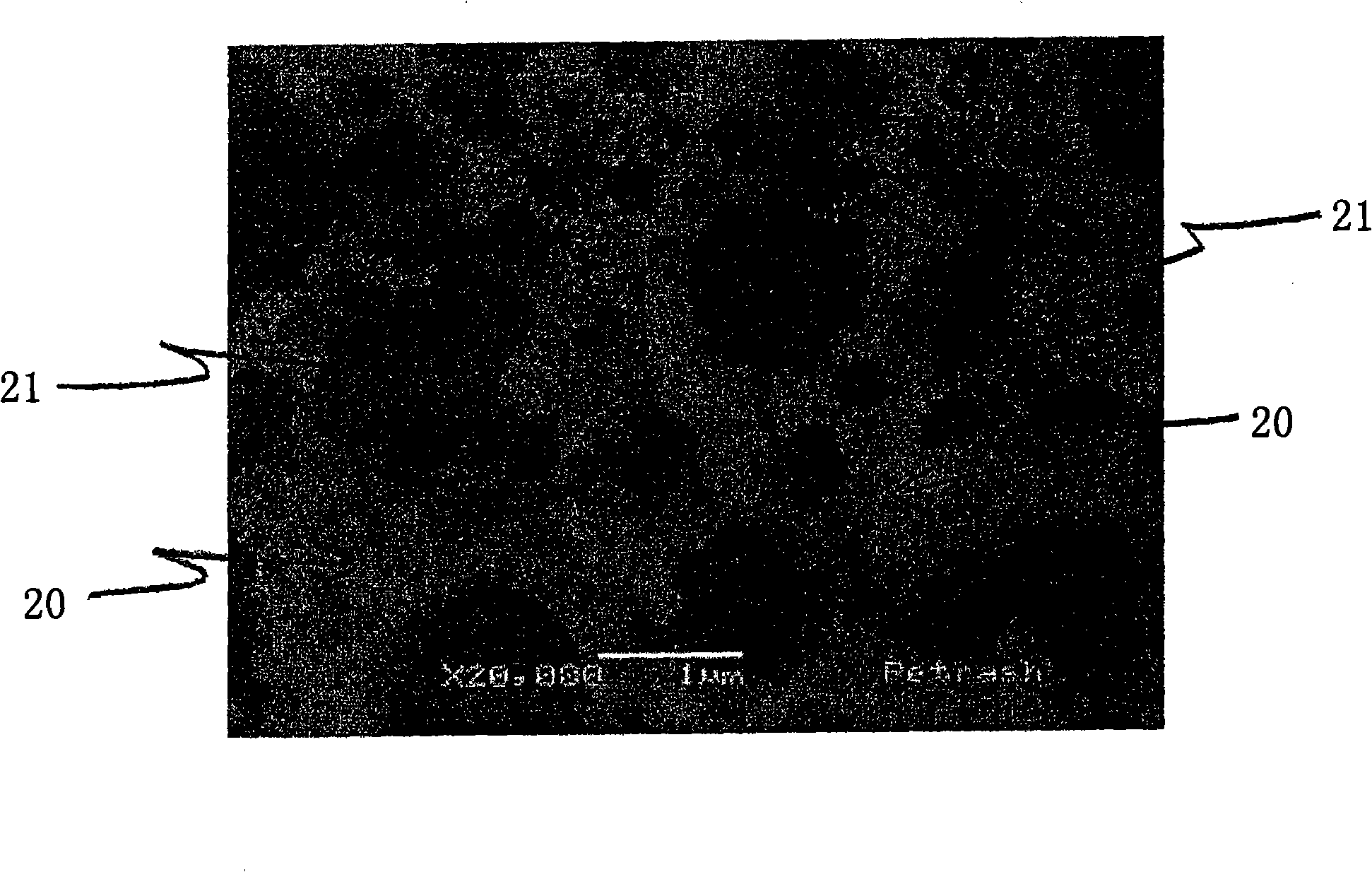

[0026] Three compositions were made according to the method of Example 1. Silver particles with an average particle size in the range of about 0.4 μm to about 1 μm are used, resulting in a polymer particle / nanosilver particle size ratio of about 1.5:1 to about 3.5:1. The ingredients of each composition are shown in Table 3.

[0027] The formula of table 3. compound 5-7

[0028] formula

[0029] 1 Silsphere 514, commercially available from Technic, Inc.

[0030] 2 Dur-O-Set C-325.

[0031] [022] According to the steps of Example 1, formulations 5-7 were coated, dried, heated and measured. Table 4 shows the annealing conditions, silver content, and resistivity of samples 5-7 after annealing.

[0032] After table 4. annealing, the characteristic of formula 5-7

[0033] formula

[0034] [024] Table 4 illustrates that when the silver particles are only slightly smaller than the polymer particles, the silver particles have a percolation threshold of at lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com