Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Solve the uniform dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polylactic acid/nano-cellulose composite material

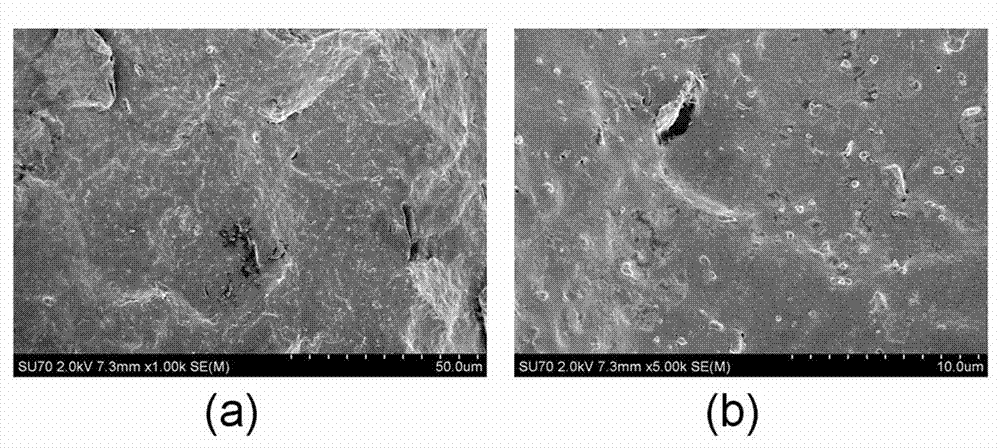

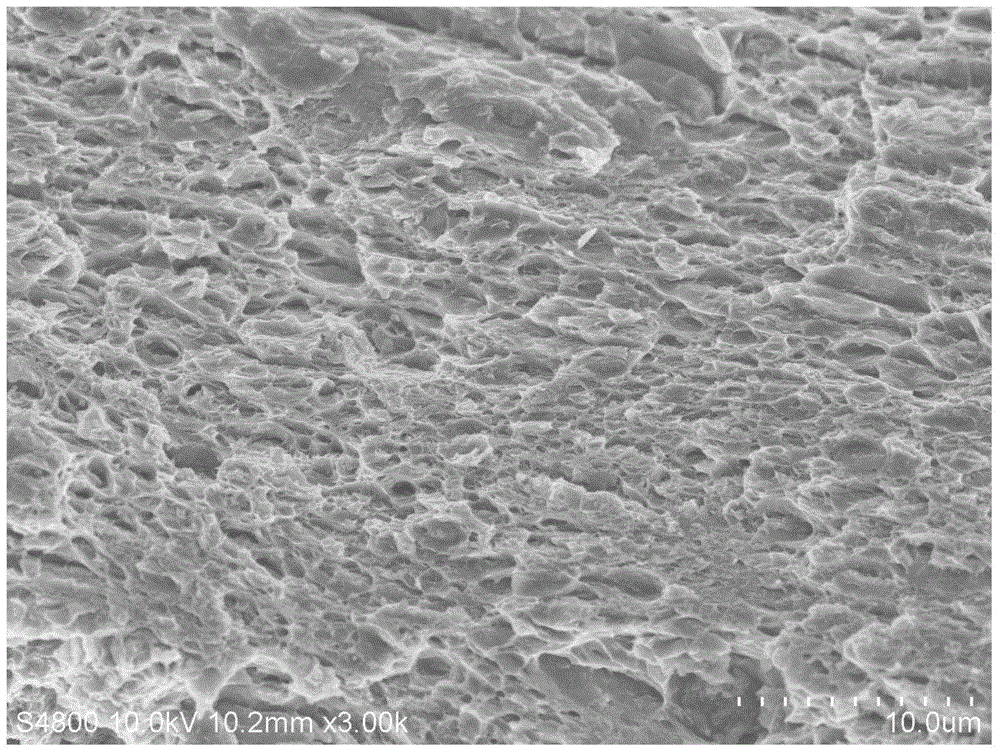

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

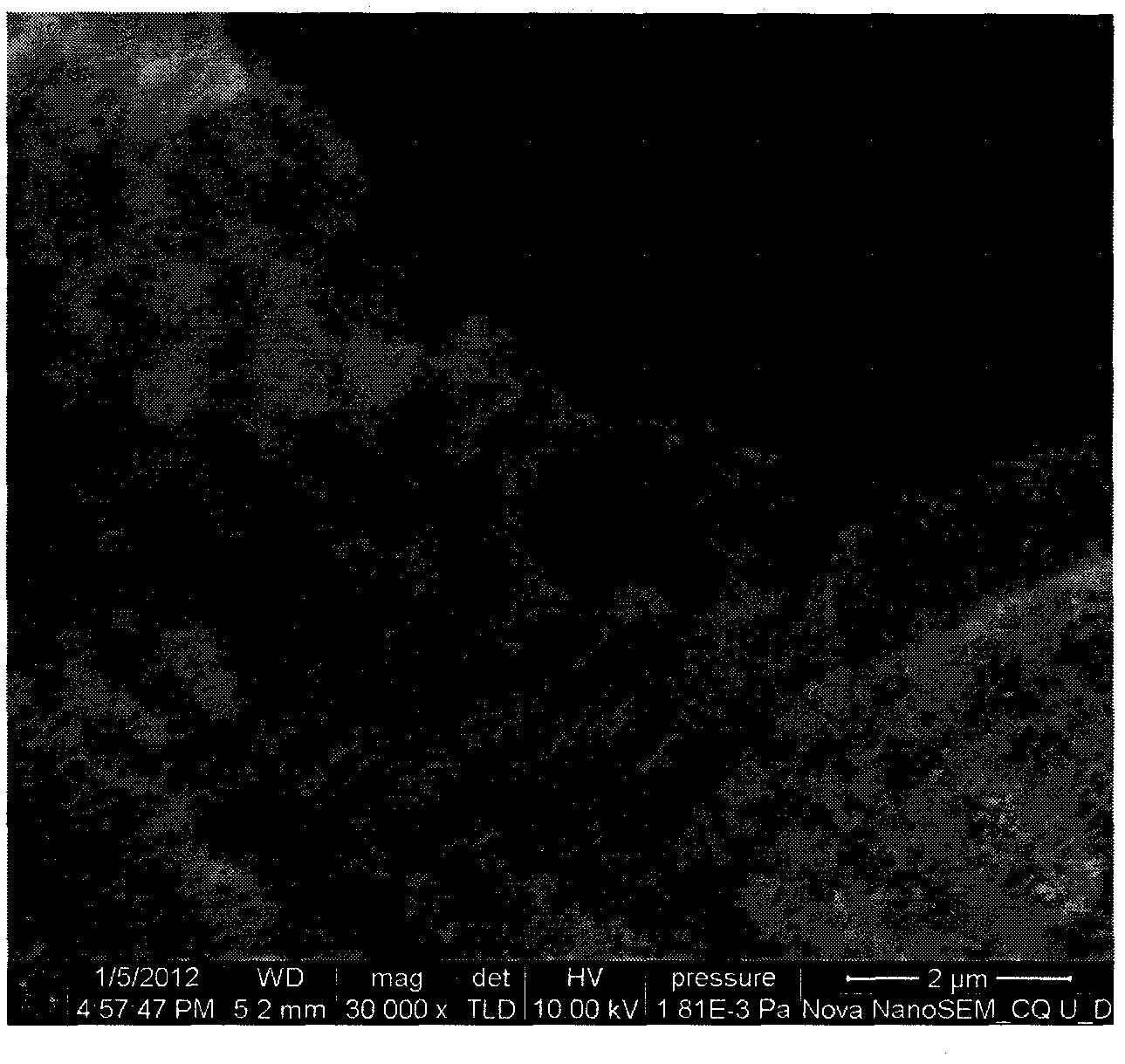

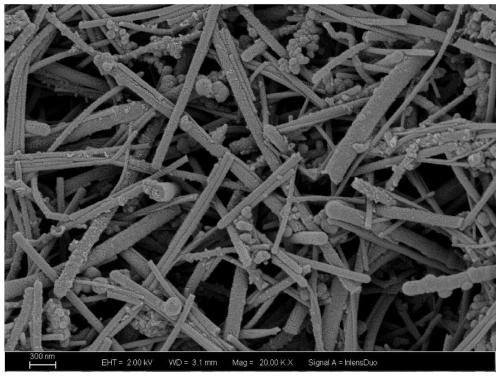

Carbon material-loading manganese dioxide nanowire array composite and method for producing same

The invention provides a carbon material-loading manganese dioxide nanowire array composite and a method for producing the same, and relates to a manganese dioxide nanocomposite and a method for producing the same. According to the invention, the material consists of a carbon material and manganese dioxide; and the method comprises the steps that the carbon material, potassium permanganate and sulfuric acid are taken as raw materials, and after simple technologies of mixing, stirring, oxidation-reduction reaction, solid-liquid separation, washing and drying, the product is obtained. The method is simple, is convenient to operate, is environment-friendly, consumes less energy, and is low in production cost and convenient to popularize and apply; and the product which is produced through the method has the characteristics of high conductivity, high specific surface area, high proton diffusion coefficient, quick charging and discharging capability, excellent electrochemical performance and the like. The method can be widely used for producing manganese dioxide nanocomposite, the product which is produced by adopting the method can be widely applied in lithium ion batteries, solar cells, supercapacitors and other new energy devices, and is particularly suitable for being used as electric and heat conduction materials, catalyst carriers, sensors and other materials.

Owner:重庆锦添翼新能源科技有限公司 +1

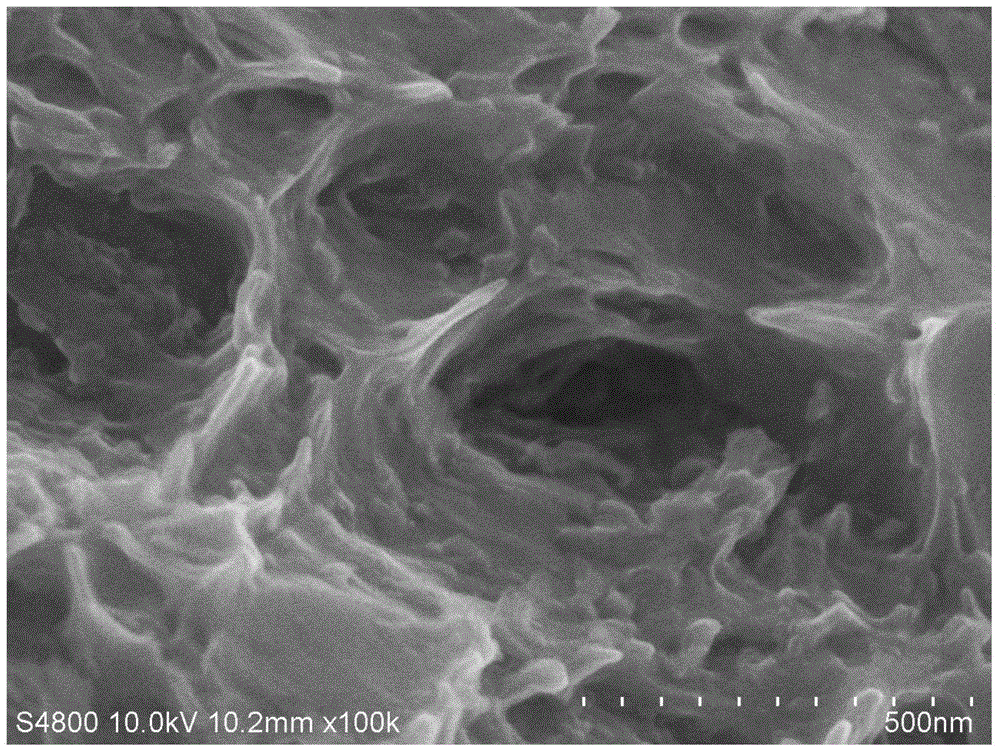

Method for producing carbon nano-tube/composite conducting polymer material

InactiveCN101173051AEvenly dispersedDisadvantages of customer service reunionNon-conductive material with dispersed conductive materialPolymer scienceCarbon nanotube

The invention discloses a preparation method of a carbon nanotube / polymer conductive composite material. 0.3 to 0.8 parts of polymer are added into 18.9 to 57.8 parts of solvent and continuously stirred under the temperature ranging from 110 to 150 DEG C till the polymer is sufficiently dissolved, and then the polymer is cooled to the room temperature; 0.054 to 0.008 parts of carbon nanotube and 80.746 to 41.392 parts of solvent are mixed and put into an ultrasonic mill as ultrasound evenly disperses the carbon nanotube into the solvent; subsequently, the two solutions are mixed and put into the ultrasonic mill as the ultrasound evenly mixes the solution; the slow qualitative filter paper extracts and filters the mixed solution, and the obtained solid mixture is vacuumized and dried under the temperature ranging from 80 to 100 DEG C till the weight is constant; finally, the dried solid material is hot molded, and the carbon nanotube / polymer conductive composite material can be obtained. The invention ensures that the polymer evenly disperses in the carbon nanotube.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fully biodegradable and multi-functional plastic mulch

ActiveCN103289134AFully biodegradableCreate pollutionClimate change adaptationPlant protective coveringsEcological environmentAdditive ingredient

The present invention provides fully biodegradable and multi-functional plastic mulch. The plastic mulch comprises, by weight percent: natural biopolymers of starch or derivatives thereof, biodegradable synthetic polymers, an interfacial reinforcer, a compound plasticizer with urea as a main ingredient, a nitrogen phosphorus and potassium compound fertilizer, pesticides, herbicides and trace fertilizers. The plastic mulch of the present invention not only has heat and moisture preservation functions, and is fully biodegradable after use, eliminating the contamination to soil causes by residual plastic mulch debris; and functional additives of fertilizers and nutrients, pesticides, herbicides etc. in the plastic mulch are sustainedly released as the plastic munch degrading, so the plastic mulch has long lasting effects of weed controlling, pest killing, and sustainedly released fertilizing, significantly reducing the use amount of fertilizers and pesticides, decreasing costs, and protecting the ecological environment. The invention also provides a method for preparing the multi-functional plastic mulch.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

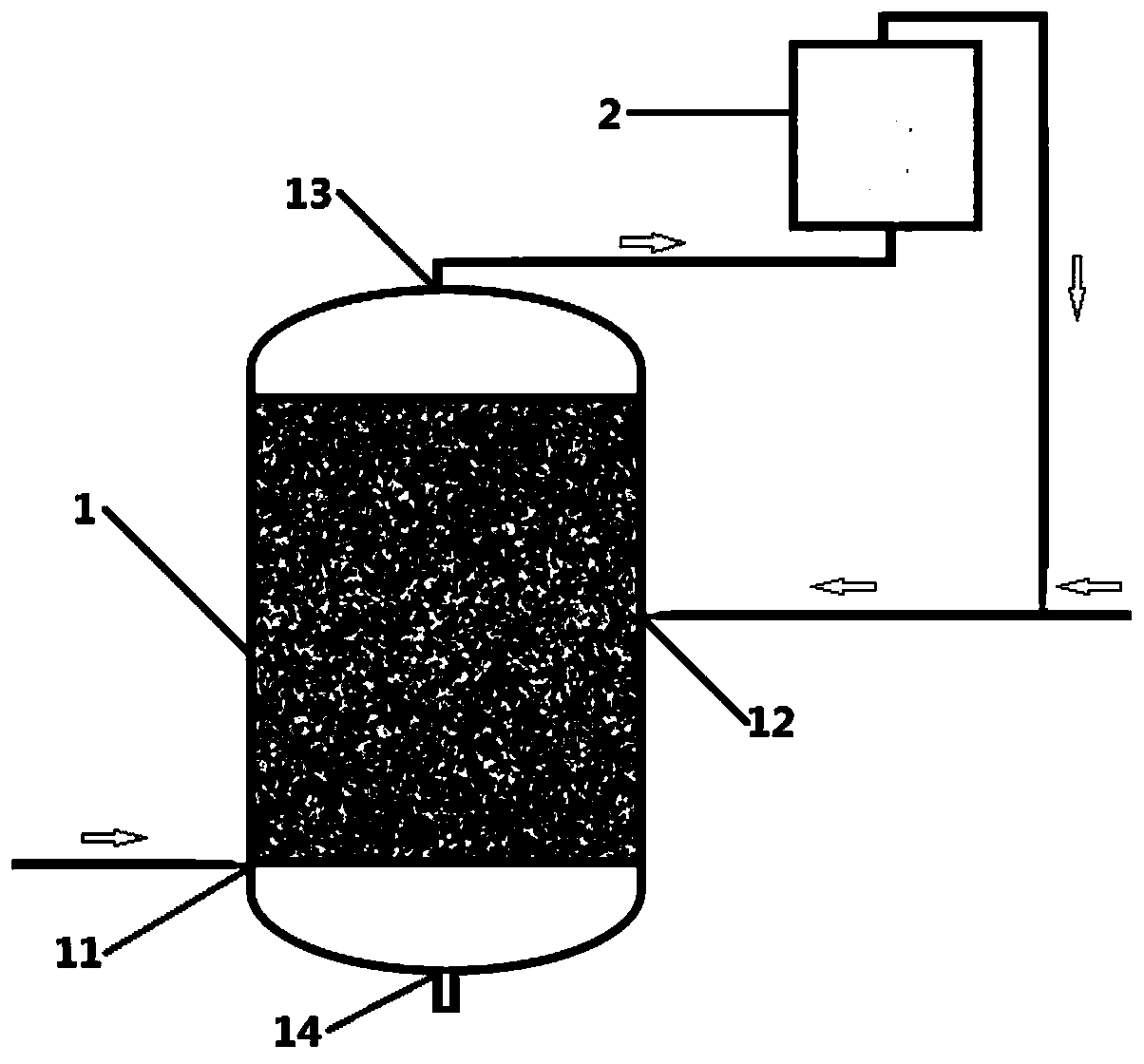

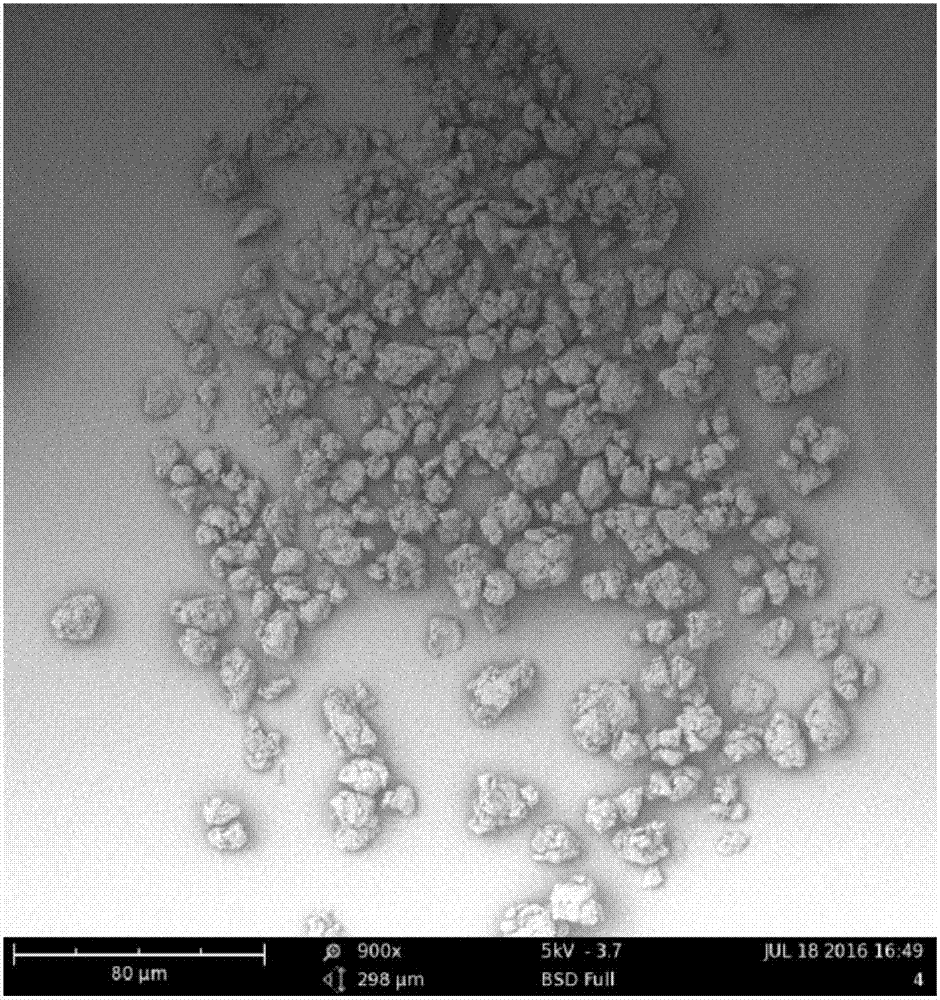

Method for preparing mesocarbon microbeads by copolycondensation

InactiveCN102491307ASolve the uniform dispersionNarrow particle size distributionCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesocarbon microbeads by copolycondensation, which belongs to the technical field of deep processing of coal and is characterized by comprising the following process procedures of: mixing coal tar pitch with coal liquefaction residue pitch in proportion, further heating the mixture at 300-350 DEG C till a low velocity state is obtained, reacting at 390-450 DEG C under a pressure of 0.2-2MPa for 5-12h after stirring uniformly to generate pitch containing the mesocarbon microbeads, subsequently washing with light fraction of coal tar and an organic solvent to obtain the mesocarbon microbeads. According to the invention, the coal tar pitch and the coal liquefaction residue pitch are used as raw materials in copolycondensation reaction; the problems that a large quantity of nucleation promoter needs to be added in preparation of MCMB (mesocarbon microbeads) by using the coal liquefaction residue as the raw material, especially in industrial scale, and the addition of the large quantity of nucleation promoter results in homodisperse are solved; furthermore, no compatilizer needs to be added. The prepared MCMB is narrower in particle size distribution, the yield can reach 30% and the product has good sphericity.

Owner:ZIBO MINING GRP

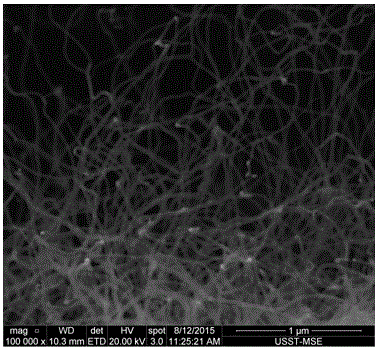

Preparation method of carbon-nanotube-enhanced copper-based composite material

ActiveCN107586981AIntegrity guaranteedEvenly distributedElectrolytic coatingsMaterials preparationComposite film

The invention relates to a preparation method of a carbon-nanotube-enhanced copper-based composite material, and belongs to the technical field of composite material preparation. The method comprises:putting carbon nanotubes in an acid solution, performing ultrasonic dispersion treatment for 20-120 min, performing heating to 50-80 DEG C, maintaining the constant temperature for 5-15 h, and performing filtering, washing, and drying to obtain pre-treated carbon nanotubes; preparing a carbon nanotube and copper salt composite solution with the pre-treated carbon nanotubes; taking a pure titaniumplate as a cathode, a pure copper plate as an anode, the carbon nanotube and copper salt composite solution as a plating solution, performing electroplating at the temperature of 25-50 DEG C with thecurrent density of the cathode being 0.5-20 A / dm2; when the deposition electric quantity is 50-200 C, taking the cathode out, peeling a composite film off, and cleaning and drying the composite filmto obtain carbon-nanotube-enhanced copper-based composite film; laying the composite films layer by layer, and performing compacting molding to obtain a carbon-nanotube-enhanced copper-based compositeblock; and sintering the composite block to obtain the carbon-nanotube-enhanced copper-based composite material. In the composite material, carbon nanotubes are uniformly distributed in the compositefilm layer in a network manner.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for nickel-plated carbon nano tube reinforced aluminum matrix composites

InactiveCN105088110AImprove mechanical propertiesSolve the uniform dispersionCarbon nanotubeMechanical property

The invention provides a preparation method for nickel-plated carbon nano tube reinforced aluminum matrix composites. The method includes the steps that 1, the outer portion of a carbon nano tube is plated with nickel, so that a nickel-coated carbon nano tube is obtained; 2, aluminum powder or aluminum alloy powder, the nickel-coated carbon nano tube and a process control agent are mixed for ball-milling, so that composite powder is obtained; 3, the composite powder is packaged in a metal cover and is rolled after temperature rises, so that a composite material blank is obtained; 4, the metal cover is stripped, burs are removed, and then the nickel-plated carbon nano tube reinforced aluminum matrix composites are obtained. The nickel-plated carbon nano tube is used for improving the interface of the aluminum matrix composites, a high-temperature interface reaction between the carbon nano tube and an aluminum matrix can be avoided, and meanwhile wettability between the carbon nano tube and the aluminum matrix can be improved. Moreover, the nickel layer on the surface of the carbon nano tube can react with the aluminum matrix to generate intermetallic compounds, the interface bonding strength between the carbon nano tube and an aluminum matrix is improved, and accordingly the mechanical properties of the composite materials are improved.

Owner:STATE GRID CORP OF CHINA +1

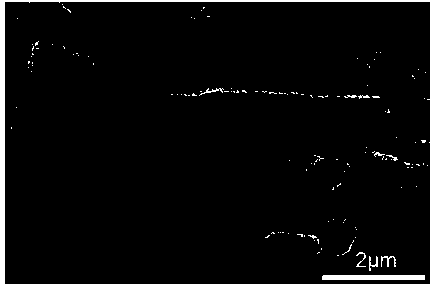

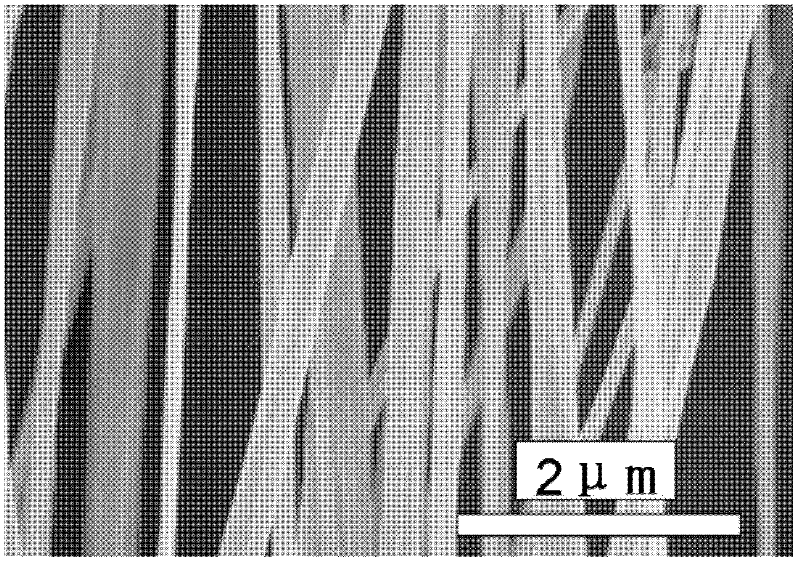

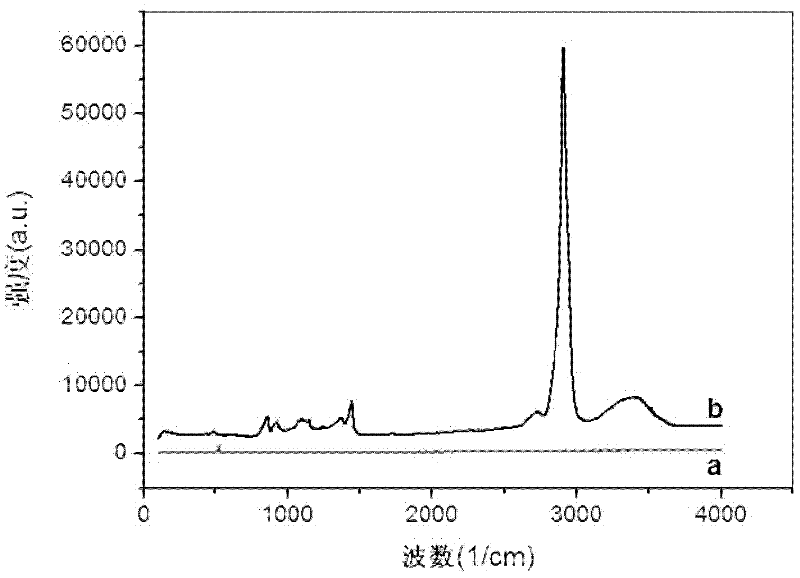

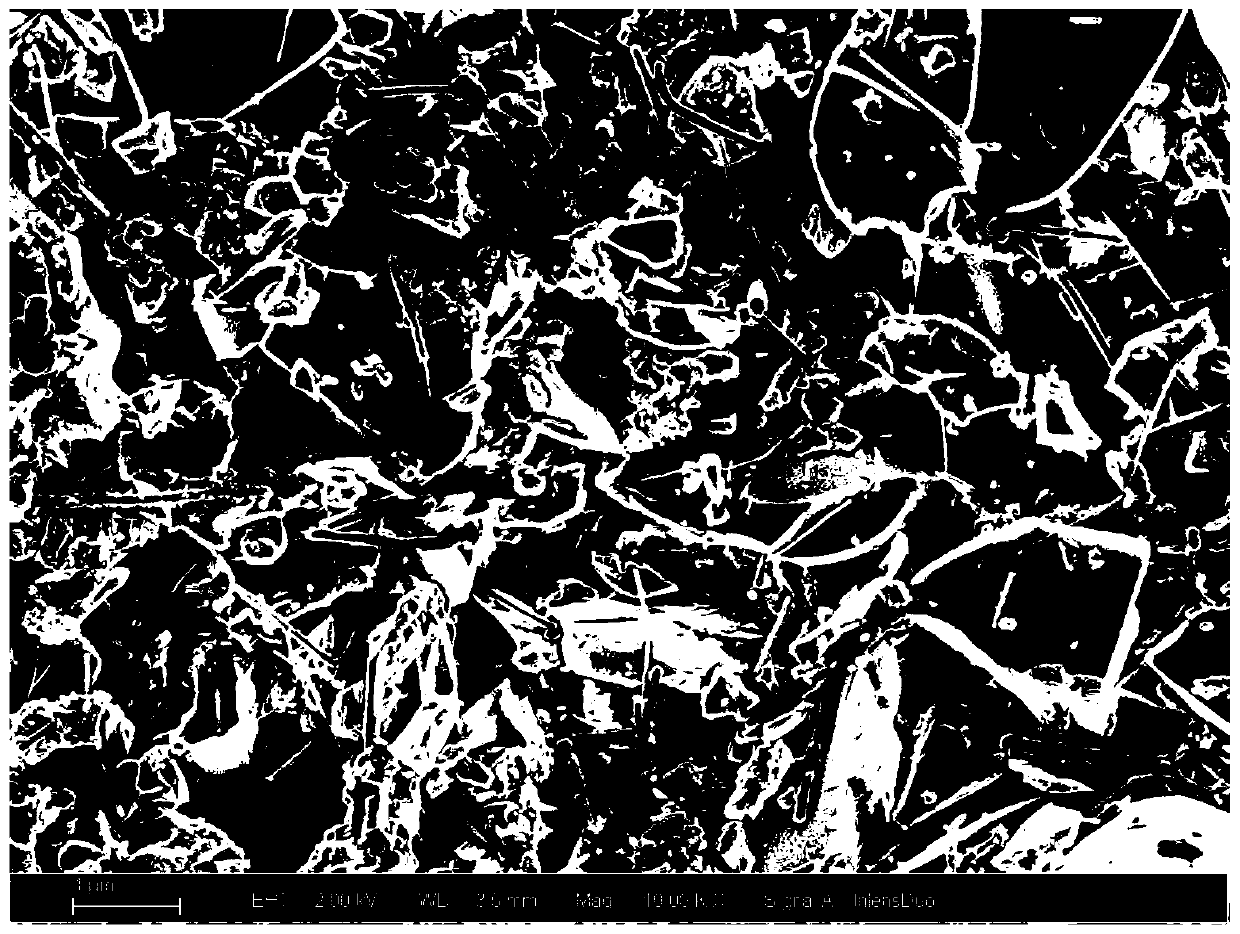

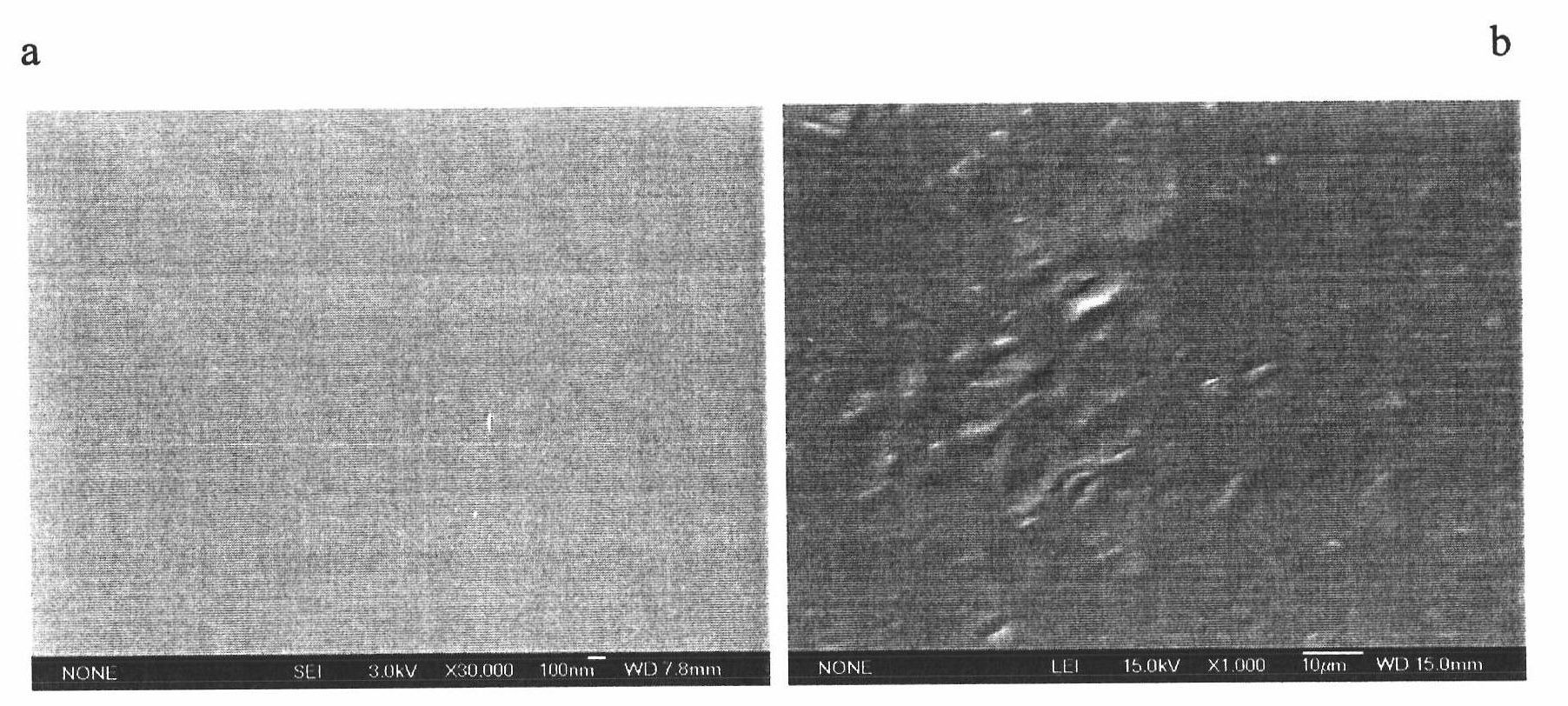

Method for preparing transparent Raman effect film

InactiveCN102642362ADifficult to disperseSolve the uniform dispersionLamination ancillary operationsSynthetic resin layered productsFiberAcetic acid

A method for preparing a transparent Raman effect film relates to preparation of optical fiber films and aims to solve the problems of complicated equipment and difficulty in controlling a production process of an existing method for preparing SERS (surface enhanced Raman scattering) base materials. The method includes the steps: firstly, preparing cellulose acetate solution with acetone, acetic acid and cellulose acetate; secondly, uniformly mixing Ag NPs suspending liquid and the cellulose acetate solution to obtain spinning liquid; thirdly, spinning the spinning liquid into a nano-fiber nonwoven felt by means of electrostatic spinning process; and fourthly, tiling the cut nano-fiber nonwoven felt in a slot of a composite film forming tool, pouring polyvinyl alcohol water solution into the slot, leading the polyvinyl alcohol water solution to be lower than the upper edge of the slot of the composite film forming tool, and maintaining pressure and drying to obtain the transparent Raman effect film. The method is mainly used for preparing the transparent Raman effect film.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method for copper-carbon nano tube (CNT) composite powder

ActiveCN105779962ALow costAddress interfacial wettability issuesNanotechnologyChemical vapor deposition coatingHydrogenWater vapor

The invention discloses a preparation method for copper-carbon nano tube (CNT) composite powder. The method includes the steps that copper-chromium alloy powder is prepared through a water mist method, specifically, through heat treatment, chromium is uniformly dispersed on a copper powder substrate; CNT growing is conducted, specifically, a hyaline-quartz boat is selected as a substrate, the quartz boat substrate is treated and then uniformly covered with a layer of the copper-chromium alloy powder to form a catalyst thin film, the obtained catalyst thin film quartz boat is put in a quartz tube of a water-assistance chemical vapor deposition CNT growing furnace, the temperature is increased to growth temperature, and in the heating process, argon and hydrogen are fed and then the hydrogen, ethylene and water steam are fed so as to perform CNT growing; and after growing is finished, feeding of carbon source gases and the water steam is stopped, the gas flow of the hydrogen and the argon is adjusted, cooling is performed, and then the CNT / copper composite powder is obtained. According to the copper-CNT powder obtained through the preparation method, a copper-CNT bonding interface is good, and CNT distribution is uniform.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

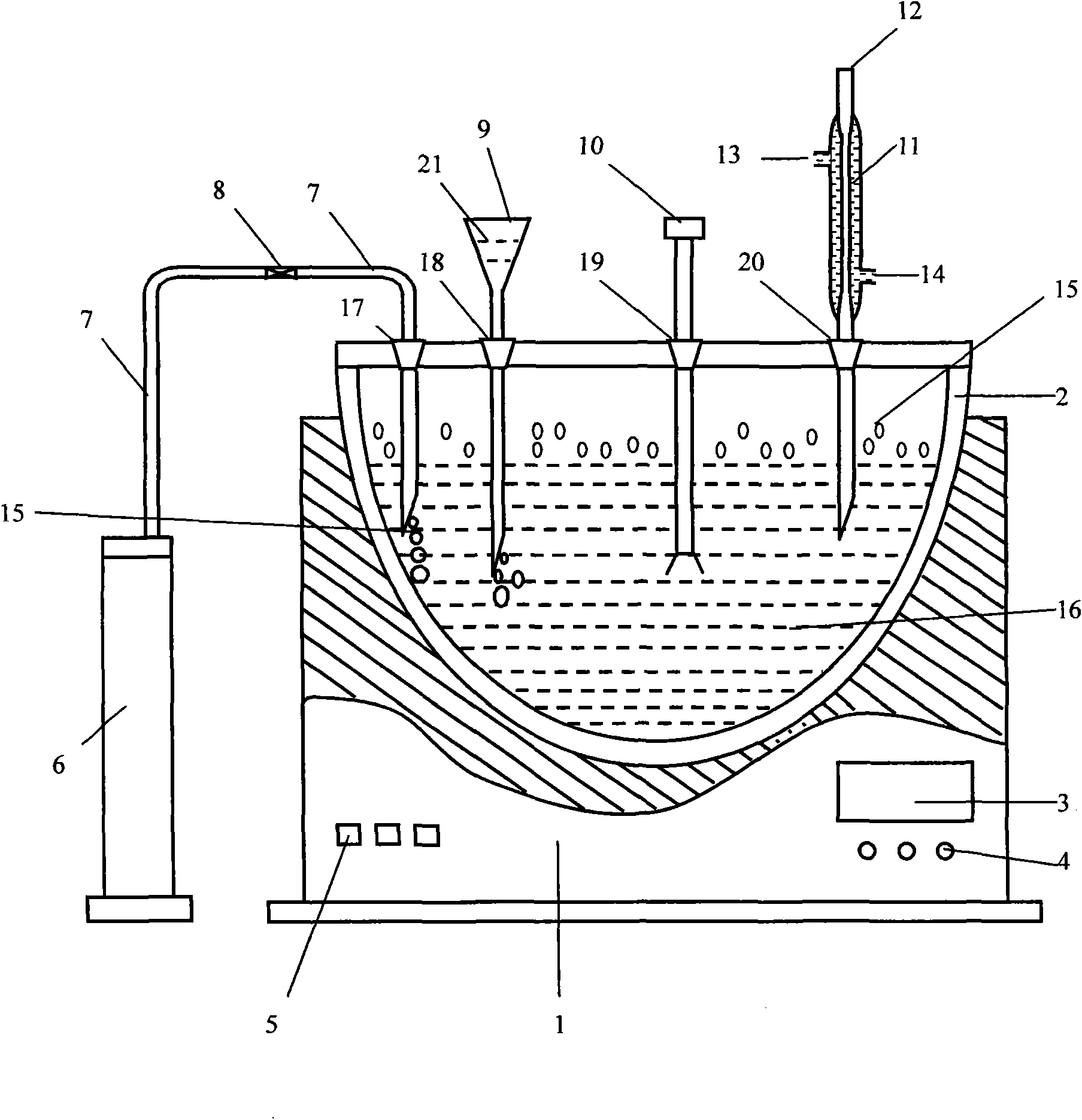

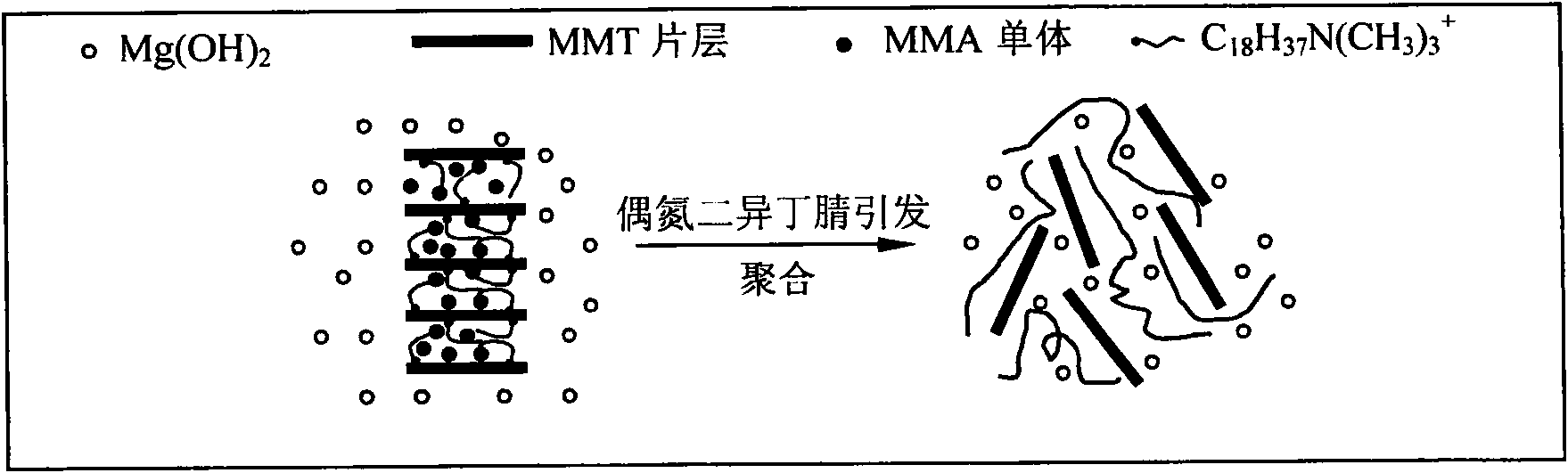

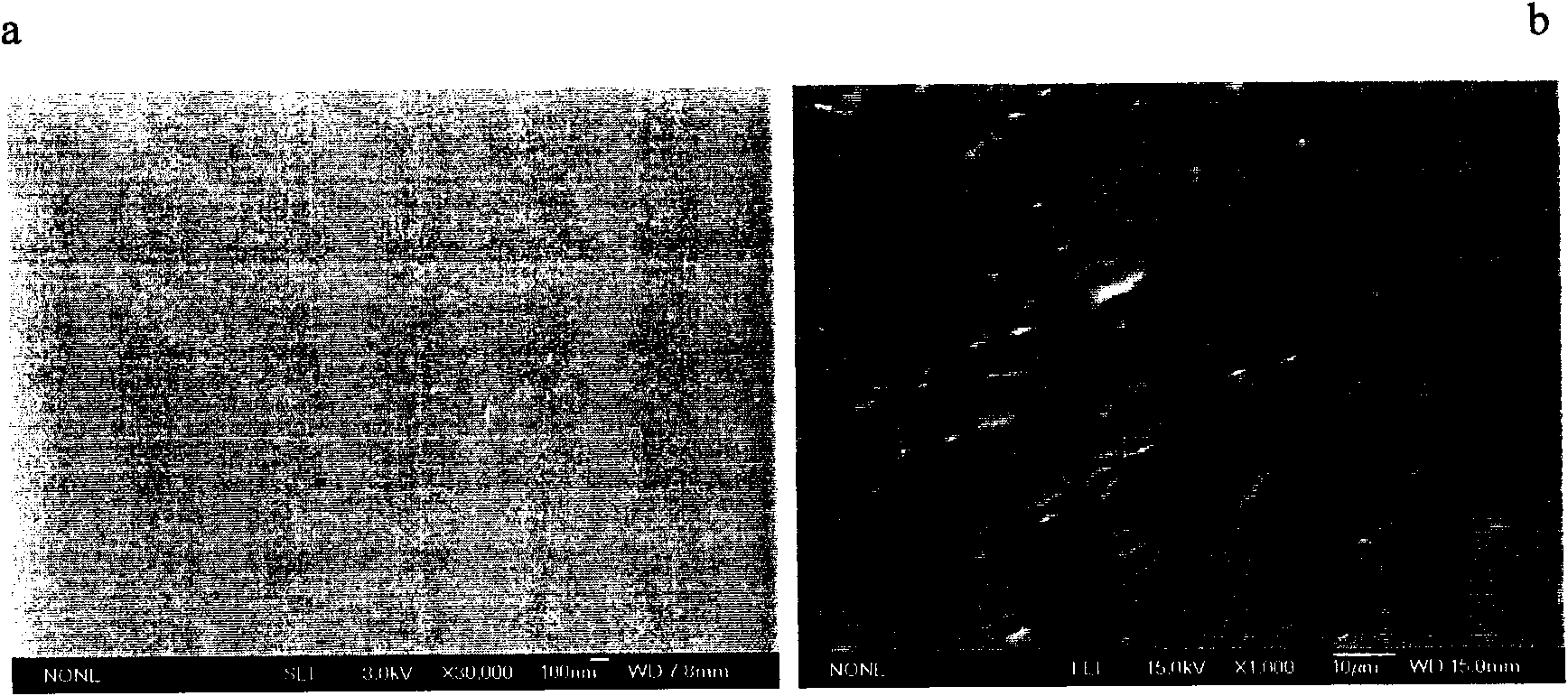

One-step in situ synthesis method for preparing transparent organic inflaming retarding composite material

The invention relates to a one-step in situ synthesis method for preparing transparent organic flaming retarding composite material. Methyl methacrylate is taken as raw material, Na-montmorillonite and magnesium hydroxide are taken as fire retardant, firstly the Na-montmorillonite is purified, magnesium hydroxide microemulsion is prefabricated, methyl methacrylate monomer is added into a four-opening flask, and initiating agent azodiisobutyronitrile absolute alcohol solution is dripped in under the conditions of protection of nitrogen, water circulation condensation, continuous heating at constant temperature and uniform stirring, thus methyl methacrylate + magnesium hydroxide + Na-montmorillonite three phase composite material, namely the organic flaming retarding nano composite material, is synthesized by one step. The material is in white unconsolidated composite particle power, the average particle size of magnesium hydroxide in base after film forming is 60nm, the Na-montmorillonite is stripped, luminousness of product is 85%, absorption rate of ultraviolet light is 40%, limited oxygen index is improved from 19% to 26%, and hardness can be improved by 10%. The method uses less devices, process flow is short, no environmental pollution is produced, and yield is high.

Owner:TAIYUAN UNIV OF TECH

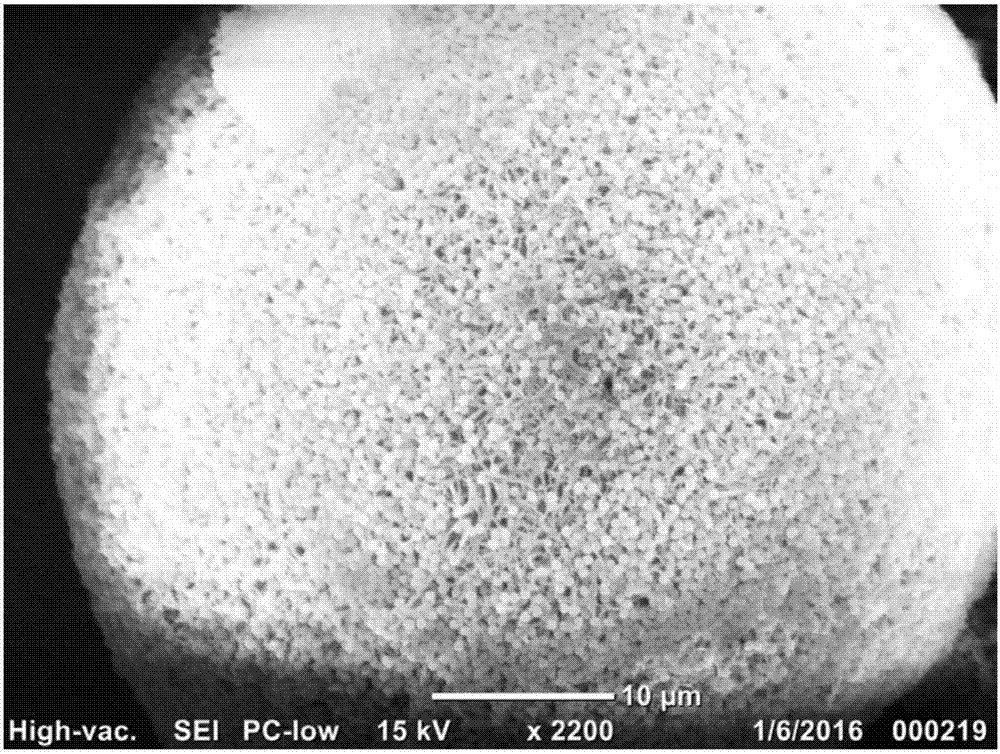

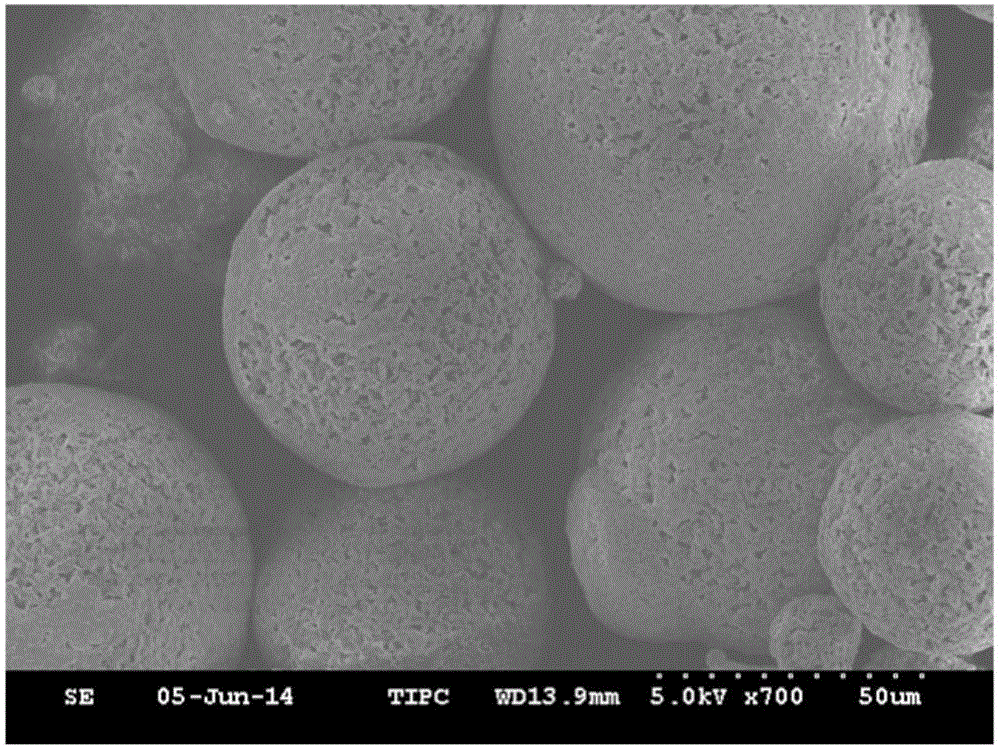

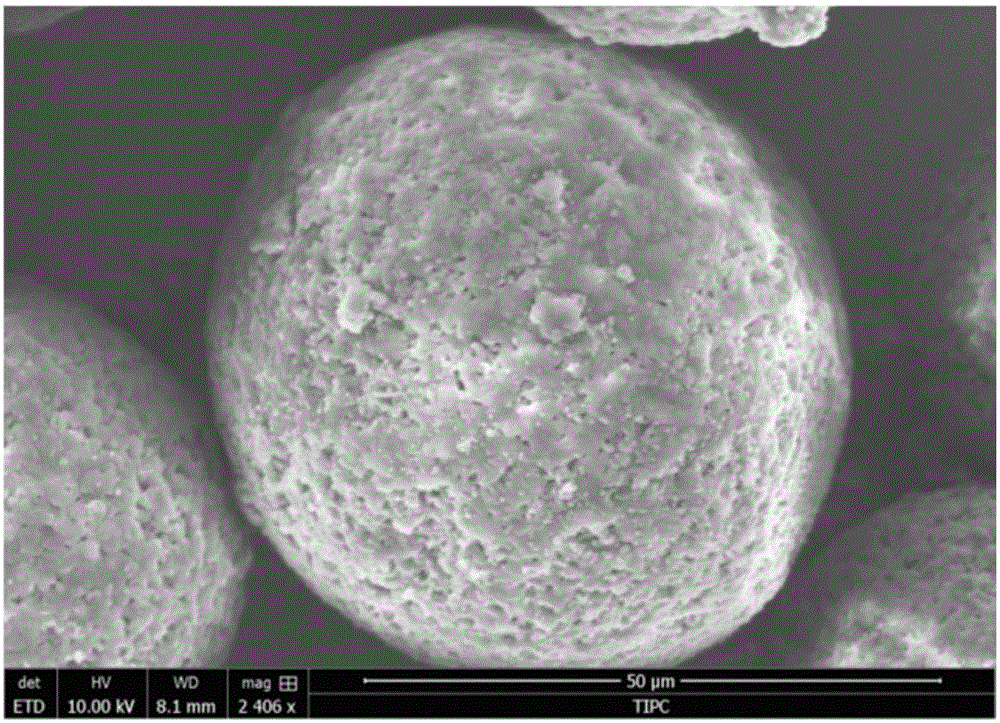

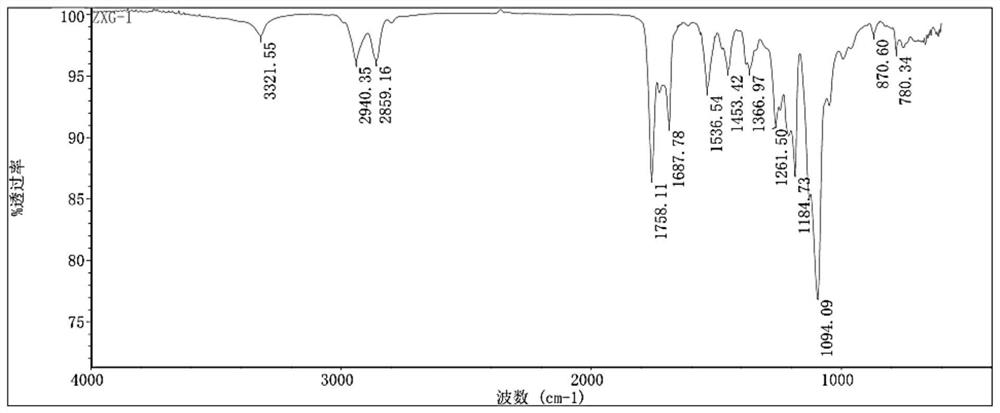

Nylon/silica composite microsphere, preparation method and application thereof

ActiveCN107254163AEvenly dispersedSolve the uniform dispersionAdditive manufacturing apparatusOther chemical processesSelective laser sinteringMicrosphere

The invention discloses a nylon / silica composite microsphere, a preparation method and an application thereof. The composite microsphere is spherical and / or near spherical particles with the particle size of 0.5-300 [mu]m, and is formed by an aperture-containing nylon microsphere matrix and silica uniformly dispersed in the aperture-containing nylon microsphere aperture and / or surface. The content of the aperture-containing nylon microsphere is 10-99.9 wt%, and the content of the silica is 0.1-90 wt%. The composite microsphere is obtained by performing silica in-situ hydrolysation in aperture-containing nylon microsphere dispersion liquid. Addition of silica can effectively reduce the water absorption of the aperture-containing nylon microsphere, and increases the heat stability, crystallization property and mechanical intensity; the composite microsphere can be taken as consumable in a SLS selective laser sintering technology, and widens the application of the SLS technology in the fields of aviation, automobile, medical apparatus, electronic apparatus, machinery die and artwork.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

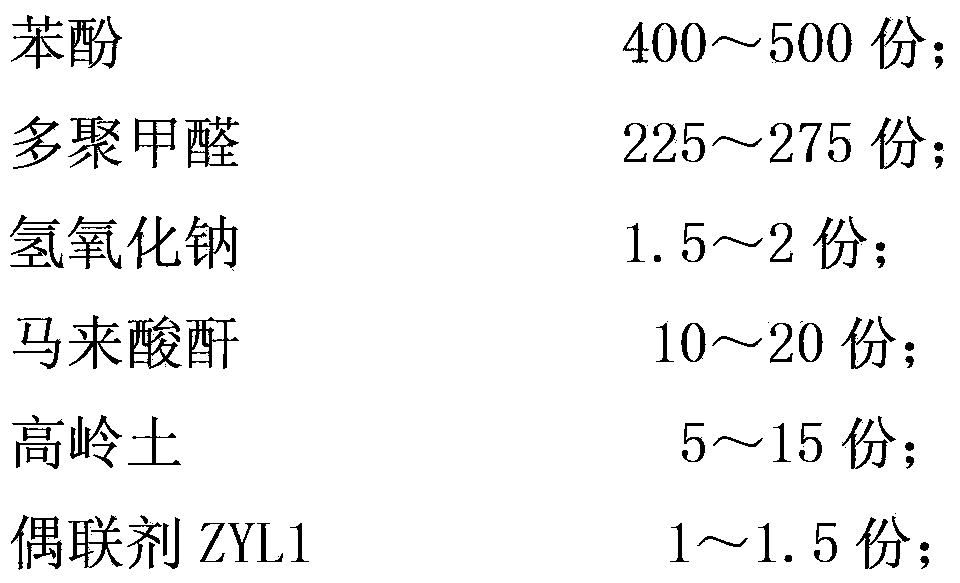

Production method of inorganic soil graft modified phenolic resin foam

ActiveCN103351575AImprove insulation effectImprove fire performanceP-Toluenesulfonic acidFire resistance

The invention discloses a production method of inorganic soil graft modified phenolic resin foam, which comprises the following steps that (1) the following raw materials: phenol, paraformaldehyde, sodium hydroxide, maleic anhydride, kaolin, a coupling agent ZYL1 and water are prepared; (2), phenol, sodium hydroxide and the water are taken, mixed and stirred; (3), paraformaldehyde is taken and put into a reaction kettle; (4), the kaolin and the coupling agent ZYL1 are added, mixed and stirred; (5), dehydration is performed; and (6), kaolin graft modified phenolic resin, BD3088 polyether modified organic polysiloxane, n-pentane and p-toluenesulfonic acid are taken, dissolved in the water and then injected into a die to be foamed to form the inorganic soil graft modified phenolic resin foam. With the adoption of the method, the phenolic resin foam having high flame retardancy, high carbon residue rate, high toughness and high close area percentage can be obtained. The heat preservation performance and the fire resistance of the phenolic resin foam are improved successfully.

Owner:长沙中野机电设备安装有限公司

A kind of preparation method of polylactic acid/nanometer cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

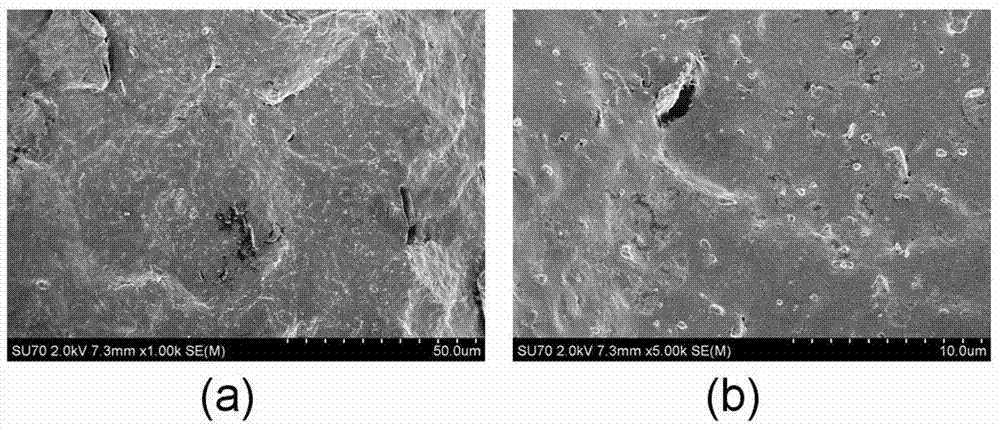

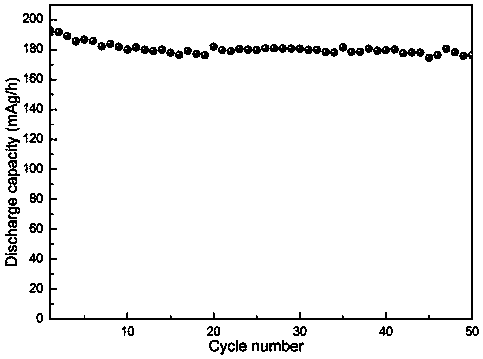

Carbon nanotube modified lithium-rich manganese-based positive electrode material and preparation method thereof

ActiveCN111106337ASolve the uniform dispersionIncrease adsorption sitesCell electrodesSecondary cellsManganeseLithium-ion battery

The invention belongs to the field of lithium ion battery material preparation, and in particular relates to a preparation method of a carbon nanotube modified lithium-rich manganese-based positive electrode material xLi2MnO3. (1-x) LiMO2. According to the preparation method, a precursor and a carbon nanotube are modified at the same time in a pre-oxidation mode; a conductive network combination of the carbon nanotube and the positive electrode material can be formed; and the conductivity of the prepared material is improved. The preparation method comprises the steps of uniformly mixing a transition metal salt solution according to a stoichiometric ratio, dropwise adding a precipitant and a complexing agent, washing and drying to obtain a precursor, stirring, dispersing and drying the precursor and a carbon nanotube aqueous dispersion, adding into an oxidant solution for pre-oxidation, drying, mixing with a lithium source, calcining and cooling to obtain a final product. The lithium-rich manganese-based material disclosed by the invention not only has high specific capacity, but also has excellent rate capability and cycle performance. A lithium ion battery adopting the positive electrode material has huge application potential in the aspect of power batteries.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Preparation and application of silicon nitride coated carbon nano tube

ActiveCN110342494AControllable reaction rateSimple processMaterial nanotechnologyNitrogen compoundsSilane compoundsNitrogen

The invention provides preparation and application of a silicon nitride coated carbon nano tube, and belongs to the technical field of functional materials. A preparation method of the silicon nitridecoated carbon nano tube comprises the following steps that S1, the carbon nano tube is loaded into a whole reaction kettle in a loosening mode and the whole reaction kettle is filled with the carbonnano tube, and then vacuumizing is carried out to 0.1-100Pa; then silicon tetrachloride gas is introduced into the reaction kettle to initial pressure in the reaction kettle being in a range of 1-2atm; then ammonia gas is introduced continuously and reacts with the silicon tetrachloride gas under -20-60 DEG C, and a nitrogenous silane compound generated by the silicon tetrachloride gas and the ammonia gas is deposited on the surface of the carbon nano tube; S2, at an ammonia gas atmosphere, the carbon nano tube attached with the nitrogenous silane compound on the surface in the S1 is heated to500-600 DEG C, and heat treatment is carried out for 1-2 hours; and S3, continuous heating is carried out to 650-1200 DEG C, heat treatment is carried out for 2-8 hours, so that the nitrogenous silane compound is decomposed into amorphous silicon nitride, and the amorphous silicon nitride is uniformly deposited on the surface of the carbon nano tube. According to the preparation and application of the silicon nitride coated carbon nano tube, industrial production requirement and application of the silicon nitride coated carbon nano tube can be realized.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Preparation method of carbon nanotube toughened silicon carbide ceramic

The invention discloses a preparation method of carbon nanotube toughened silicon carbide ceramic, and belongs to the technical field of composite ceramic materials. The preparation method of the carbon nanotube toughened silicon carbide ceramic comprises the following steps: S1, uniformly mixing silicon carbide, carbon black, silicon nitride coated carbon nanotubes, water-soluble phenolic resin and pure water to obtain uniformly dispersed slurry with the solid content of 48-52%; S2, heating the slurry obtained in the step S1, evaporating to remove water to obtain a blocky material, carrying out dry pressing on the blocky material, and carrying out one-step molding to obtain a green body; S3, covering the surface of the green body with monatomic silicon, putting the green body into a vacuum high-pressure sintering furnace, heating to 1300-1400 DEG C, keeping the temperature for a certain period of time, and converting amorphous silicon nitride on the surface of the carbon nano tubes into hexagonal silicon nitride; and heating up to 1450-1500DEG C, and keeping the temperature for a certain period of time to obtain the carbon nanotube toughened silicon carbide ceramic; the fiber structure of the carbon nanotubes can be reserved in the reaction sintering process, the toughening effect of carbon fiber is fully exerted, and the performance of the composite ceramic material is enhanced.

Owner:赛福纳米科技(徐州)有限公司

Alchlor/nucleophilic reagent/catalyst promoter composite catalytic system for synthesizing petroleum resin

The invention provides a composite catalytic system used for synthesizing a petroleum resin, which is a homogeneous transparent solution or a homogeneous disperse system prepared by the following raw materials by weight portion: 1 portion of anhydrous alchlor, 2 to 10 portions of nucleophile and 1 to 20 portions of auxiliary catalyst. Composite catalyst of the composite catalytic system can solvethe problem of homodisperse of solid catalyst AlCl3 during the process of polymerization of the petroleum resin, and can realize stable technique. Moreover, charging is easy; measurement is easy; andcontinuous operation can be realized. The softening point of the resin prepared is between 85 and 135 DEG C; the conversion rate of active ingredients reaches between 60 and 85 percent; and the average molecular weight is between 400 and 700. The synthesized petroleum resin can be widely applied to oil paint, road marking paint and printing ink.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

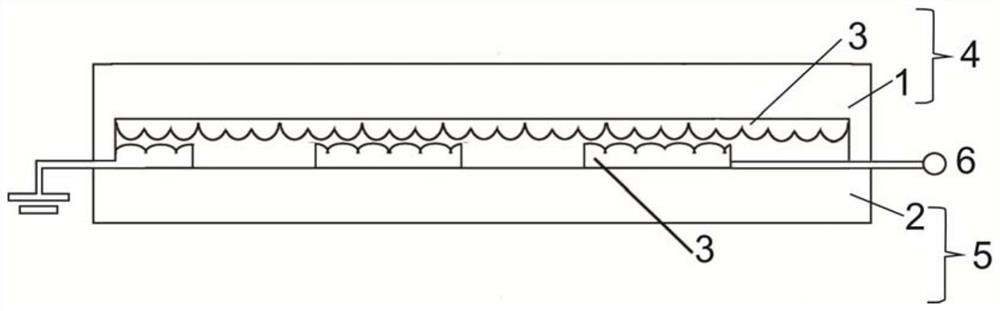

Conductive resin for 3D printing technology, and preparation method and application thereof

ActiveCN113956409AImprove conductivity stabilityHigh tensile strengthFluid pressure measurement using piezo-electric devicesAdditive manufacturing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses a conductive resin for a 3D printing technology, and a preparation method and application thereof, and belongs to the technical field of 3D printing materials. The conductive resin comprises, by weight, 70-95 parts of a polymerization reaction material, 20-35 parts of a conductive material and 0.5-3 parts of a photoinitiator, and the polymerization reaction material comprises hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and modified polydimethylsiloxane. According to the polymerization reaction material disclosed by the invention, the components are mutually cooperated, and a stable three-dimensional network structure is formed through physical crosslinking and chemical crosslinking, so that the mechanical property of the resin can be effectively improved, and the problem that the conductive material dispersed in water is uniformly dispersed in the resin is solved; therefore, the conductive stability of the conductive resin is improved, and the problem that the mechanical property of conductive hydrogel with similar components becomes poor due to water loss is solved. The resin is simple in preparation method, is manufactured through a photocuring 3D printing technology, and has a huge application prospect in the fields of flexible sensing and the like.

Owner:SOUTHWEST MEDICAL UNIVERISTY

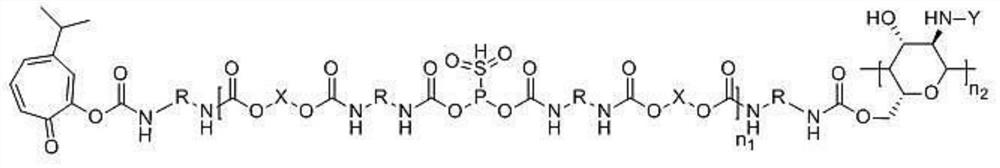

Self-antibacterial lactic acid-based waterborne polyurethane as well as preparation method and emulsion thereof

The invention belongs to the technical field of functional polymer materials, and particularly relates to self-antibacterial lactic acid-based waterborne polyurethane as well as a preparation method and an emulsion thereof. Water-based chitosan and hinokitiol structures are introduced to a side chain of a large polyurethane long chain by self-antibacterial lactic acid-based waterborne polyurethane and are uniformly distributed, so that two substances with different antibacterial and bactericidal mechanisms mutually generate a bactericidal and antibacterial synergistic effect, the drug resistance of bacterial organisms can be effectively reduced, and meanwhile, the two substances are grafted on a polyurethane long chain in a chemical bond manner, so that the antibacterial property is lasting.

Owner:XIAOGAN ESUN NEW MATERIAL +1

Preparation method of high-thermal-conductivity aluminum base graphene composite material

ActiveCN105695804ASimple and fast operationImprove thermal conductivityDistilled waterAqueous solution

The invention relates to a preparation method of a high-thermal-conductivity aluminum base graphene composite material, and belongs to the field of material surface treatment. The method comprises the following steps that an aluminum piece is vertically dipped in dopamine water solution with pH of 8-8.5 for standing by 20-80 min; after the aluminum piece is taken out from the dopamine water solution, water with purity not lower than purity of distilled water is used for cleaning, and the cleaned aluminum piece is vertically dipped in graphene oxide water solution for standing by 2-6 h; and after the aluminum piece is taken out from the graphene oxide water solution, the water with the purity not lower than the purity of the distilled water is used for cleaning, and the cleaned aluminum piece is annealed at 100-300 DEG C by 0.5-3 h to obtain the high-thermal-conductivity aluminum base graphene composite material. The method is simple in process and convenient for instrument equipment operation; and the prepared aluminum base graphene composite material is excellent in thermal conductivity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

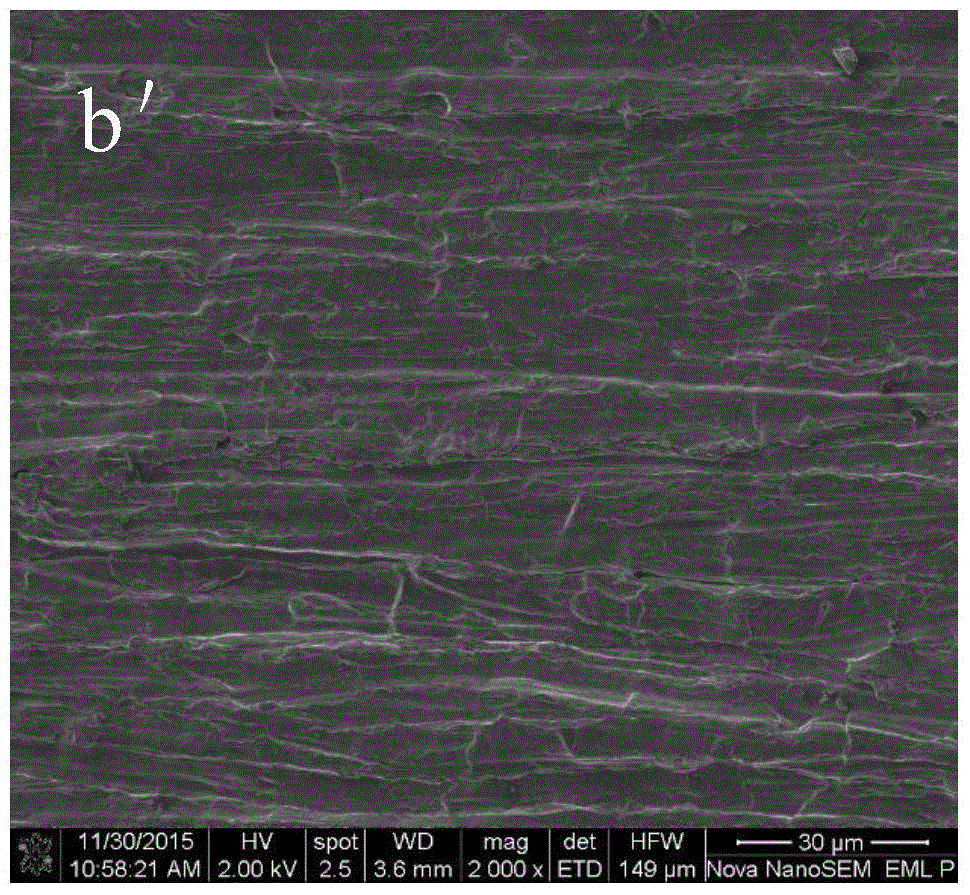

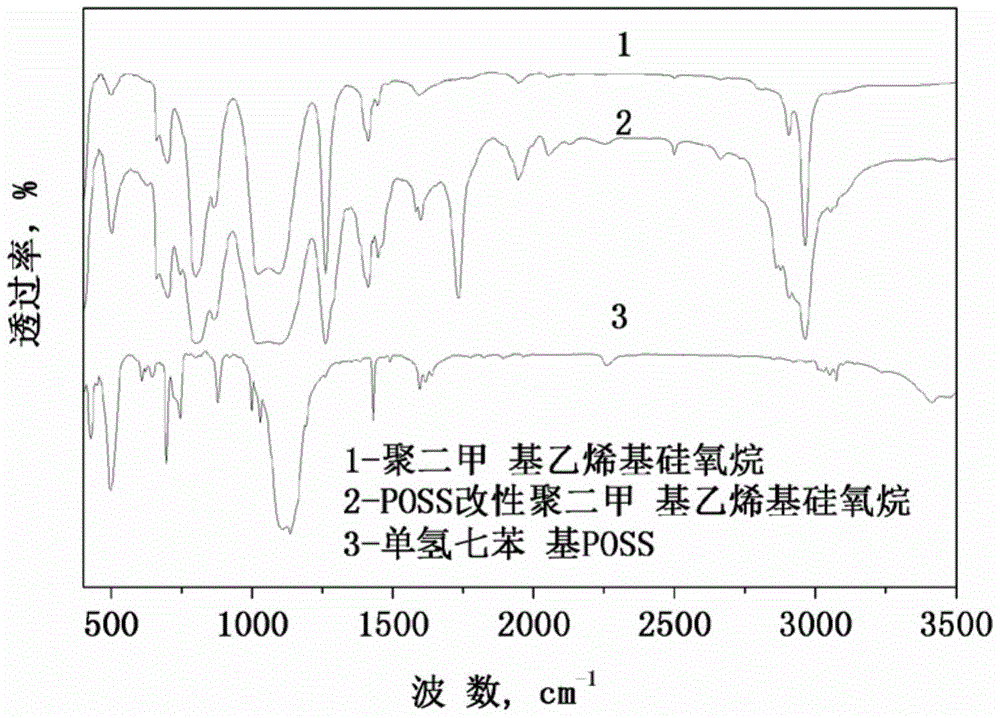

A kind of preparation method of poss modified polysiloxane rubber composite material

The invention discloses a preparation method of a POSS (Polyhedral Oligomeric Silsesquioxane) modified polysiloxane rubber composite material. The preparation method is characterized in that the POSS containing single / double reactive functional groups is introduced into a polysiloxane molecular chain containing a plurality of reactive functional groups by virtue of grafting or blocking in a chemical copolymerization manner, and then a POSS modified polysiloxane oligomer with the POSS as a polysiloxane hanging chain and the POSS as a polysiloxane block chain, next, 0.1-100 parts of POSS modified polysiloxane oligomer is evenly dispersed in 100 parts of polysiloxane raw rubber by virtue of physical blending, and finally, 0-50 parts of white carbon black and 0.2-10 parts of a curing agent are added to the mixture for cross-linking and solidification and then the POSS modified polysiloxane rubber composite material is obtained. The POSS modified polysiloxane rubber composite material has excellent high and low temperature resistance, mechanical properties and dielectric property, and can be applied to the technical fields of automobiles, electronics, building materials as well as national defense and aerospace.

Owner:SICHUAN UNIV

A kind of preparation method of carbon nanotube reinforced copper matrix composite material

ActiveCN107586981BIntegrity guaranteedEvenly distributedElectrolytic coatingsMaterials preparationComposite film

The invention relates to a preparation method of a carbon-nanotube-enhanced copper-based composite material, and belongs to the technical field of composite material preparation. The method comprises:putting carbon nanotubes in an acid solution, performing ultrasonic dispersion treatment for 20-120 min, performing heating to 50-80 DEG C, maintaining the constant temperature for 5-15 h, and performing filtering, washing, and drying to obtain pre-treated carbon nanotubes; preparing a carbon nanotube and copper salt composite solution with the pre-treated carbon nanotubes; taking a pure titaniumplate as a cathode, a pure copper plate as an anode, the carbon nanotube and copper salt composite solution as a plating solution, performing electroplating at the temperature of 25-50 DEG C with thecurrent density of the cathode being 0.5-20 A / dm2; when the deposition electric quantity is 50-200 C, taking the cathode out, peeling a composite film off, and cleaning and drying the composite filmto obtain carbon-nanotube-enhanced copper-based composite film; laying the composite films layer by layer, and performing compacting molding to obtain a carbon-nanotube-enhanced copper-based compositeblock; and sintering the composite block to obtain the carbon-nanotube-enhanced copper-based composite material. In the composite material, carbon nanotubes are uniformly distributed in the compositefilm layer in a network manner.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing transparent Raman effect film

InactiveCN102642362BDifficult to disperseSolve the uniform dispersionLamination ancillary operationsSynthetic resin layered productsFiberAcetic acid

A method for preparing a transparent Raman effect film relates to preparation of optical fiber films and aims to solve the problems of complicated equipment and difficulty in controlling a production process of an existing method for preparing SERS (surface enhanced Raman scattering) base materials. The method includes the steps: firstly, preparing cellulose acetate solution with acetone, acetic acid and cellulose acetate; secondly, uniformly mixing Ag NPs suspending liquid and the cellulose acetate solution to obtain spinning liquid; thirdly, spinning the spinning liquid into a nano-fiber nonwoven felt by means of electrostatic spinning process; and fourthly, tiling the cut nano-fiber nonwoven felt in a slot of a composite film forming tool, pouring polyvinyl alcohol water solution into the slot, leading the polyvinyl alcohol water solution to be lower than the upper edge of the slot of the composite film forming tool, and maintaining pressure and drying to obtain the transparent Raman effect film. The method is mainly used for preparing the transparent Raman effect film.

Owner:NORTHEAST FORESTRY UNIVERSITY

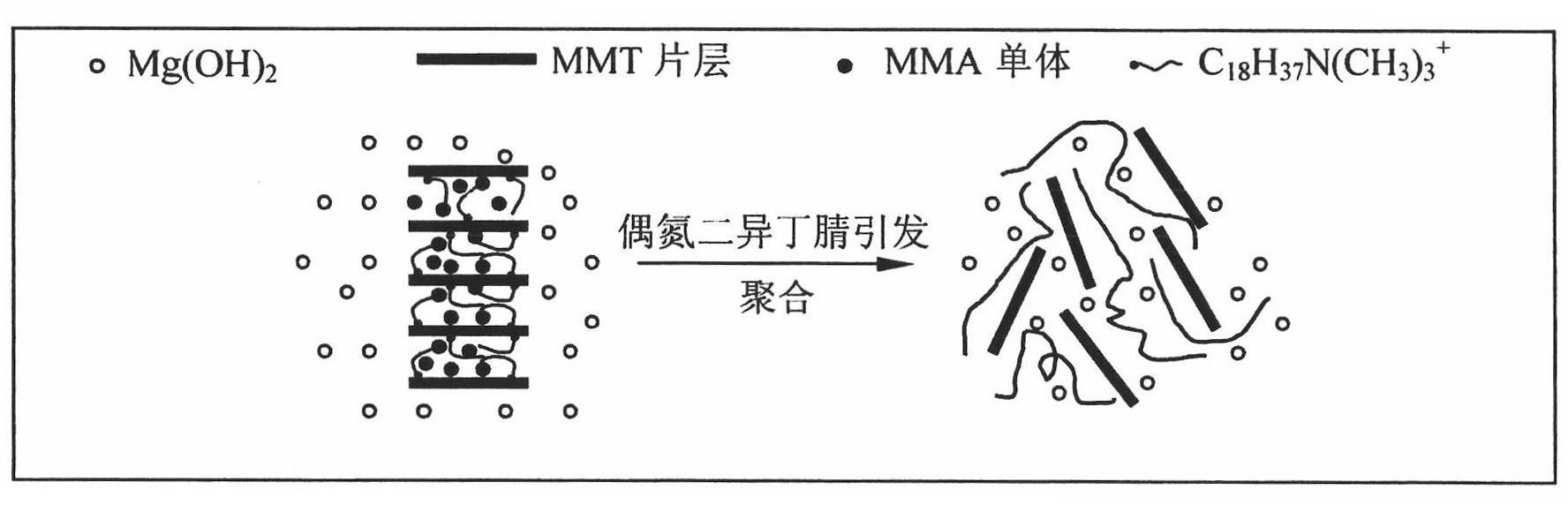

One-step in situ synthesis method for preparing transparent organic inflaming retarding composite material

The invention relates to a one-step in situ synthesis method for preparing transparent organic flaming retarding composite material. Methyl methacrylate is taken as raw material, Na-montmorillonite and magnesium hydroxide are taken as fire retardant, firstly the Na-montmorillonite is purified, magnesium hydroxide microemulsion is prefabricated, methyl methacrylate monomer is added into a four-opening flask, and initiating agent azodiisobutyronitrile absolute alcohol solution is dripped in under the conditions of protection of nitrogen, water circulation condensation, continuous heating at constant temperature and uniform stirring, thus methyl methacrylate + magnesium hydroxide + Na-montmorillonite three phase composite material, namely the organic flaming retarding nano composite material, is synthesized by one step. The material is in white unconsolidated composite particle power, the average particle size of magnesium hydroxide in base after film forming is 60nm, the Na-montmorillonite is stripped, luminousness of product is 85%, absorption rate of ultraviolet light is 40%, limited oxygen index is improved from 19% to 26%, and hardness can be improved by 10%. The method uses less devices, process flow is short, no environmental pollution is produced, and yield is high.

Owner:TAIYUAN UNIV OF TECH

Colored toner prepared by adopting mini-emulsion polymerization and ball-milling compounding and method

The invention discloses a colored toner prepared by adopting mini-emulsion polymerization and ball-milling compounding and a method. The method comprises the following steps: adopting a mini-emulsion polymerization method to prepare core-shell compound emulsion particles of a resin coated pigment and polyethylene wax, wherein the particle sizes of the prepared compound emulsion particles are 100 to 200 nm; then, preparing composite particles with the particle sizes of 7 to 12 microns through an electrolyte agglomeration compound method, and then compounding a charge control agent onto the micron composite particles through mechanical milling. Charge stabilization is provided for monomer droplets by using a negative (positive) ionic type polyethylene wax emulsion, and the addition of an ionic type emulsifier is avoided, so that the technology is simpler; the charge control agent is compounded to the particle surface of the colored toner through the mechanical milling method, and the charge control agent is uniform in arrangement, simple in technology and simple in operation, so that the particle charges of the finally obtained colored toner is uniformly distributed.

Owner:NANJING UNIV OF SCI & TECH

Nylon/polystyrene alloy microsphere, preparation method and applications thereof

ActiveCN107434891ASolve the uniform dispersionLow water absorptionChromatographic separationPolymer science

The invention discloses a nylon / polystyrene alloy microsphere, a preparation method and applications thereof, wherein the nylon / polystyrene alloy microsphere comprises, by weight, 25-95 wt% of pore-containing nylon microsphere, and 5-75 wt% of polystyrene uniformly dispersed in the pores and / or on the surface of the pore-containing nylon microsphere in a nanometer or micro particle manner or / and in a micro-scale continuous state manner, wherein the alloy microsphere is spherical or nearly spherical particle with a particle size of 0.05-500 [mu]m. According to the present invention, the nylon / polystyrene alloy microsphere can be used in the fields of chromatographic separation, drug delivery and sustained-release, functional coating materials and 3D printing selective laser sintering.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of nylon/silicon dioxide composite microsphere, preparation method and application

ActiveCN107254163BSolve the uniform dispersionSolve water absorptionAdditive manufacturing apparatusOther chemical processesSelective laser sinteringMicrosphere

The invention discloses a nylon / silica composite microsphere, a preparation method and an application thereof. The composite microsphere is spherical and / or near spherical particles with the particle size of 0.5-300 [mu]m, and is formed by an aperture-containing nylon microsphere matrix and silica uniformly dispersed in the aperture-containing nylon microsphere aperture and / or surface. The content of the aperture-containing nylon microsphere is 10-99.9 wt%, and the content of the silica is 0.1-90 wt%. The composite microsphere is obtained by performing silica in-situ hydrolysation in aperture-containing nylon microsphere dispersion liquid. Addition of silica can effectively reduce the water absorption of the aperture-containing nylon microsphere, and increases the heat stability, crystallization property and mechanical intensity; the composite microsphere can be taken as consumable in a SLS selective laser sintering technology, and widens the application of the SLS technology in the fields of aviation, automobile, medical apparatus, electronic apparatus, machinery die and artwork.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Self-bacterial lactic acid-based waterborne polyurethane, its preparation method and its emulsion

The invention belongs to the technical field of functional polymer materials, and in particular relates to a self-bacterial lactic acid-based aqueous polyurethane, a preparation method thereof and an emulsion thereof. In the present invention, water-based chitosan and juniper alcohol structures are introduced into the side chain of the large polyurethane long chain from the antibacterial lactic acid-based water-based polyurethane and evenly distributed, so that the two substances with different antibacterial and biocidal mechanisms can produce synergistic effects of biocide and antibacterial. It can effectively reduce the drug resistance of bacterial organisms, and at the same time, the two are grafted on the long chain of polyurethane in the form of chemical bonds, and the antibacterial is durable.

Owner:XIAOGAN ESUN NEW MATERIAL +1

Stable nanometer oxidate dispersion solution, preparation method and application thereof

ActiveCN101362859BImprove performanceEasy to preparePlastic/resin/waxes insulatorsSilanesDimethyl acetamide

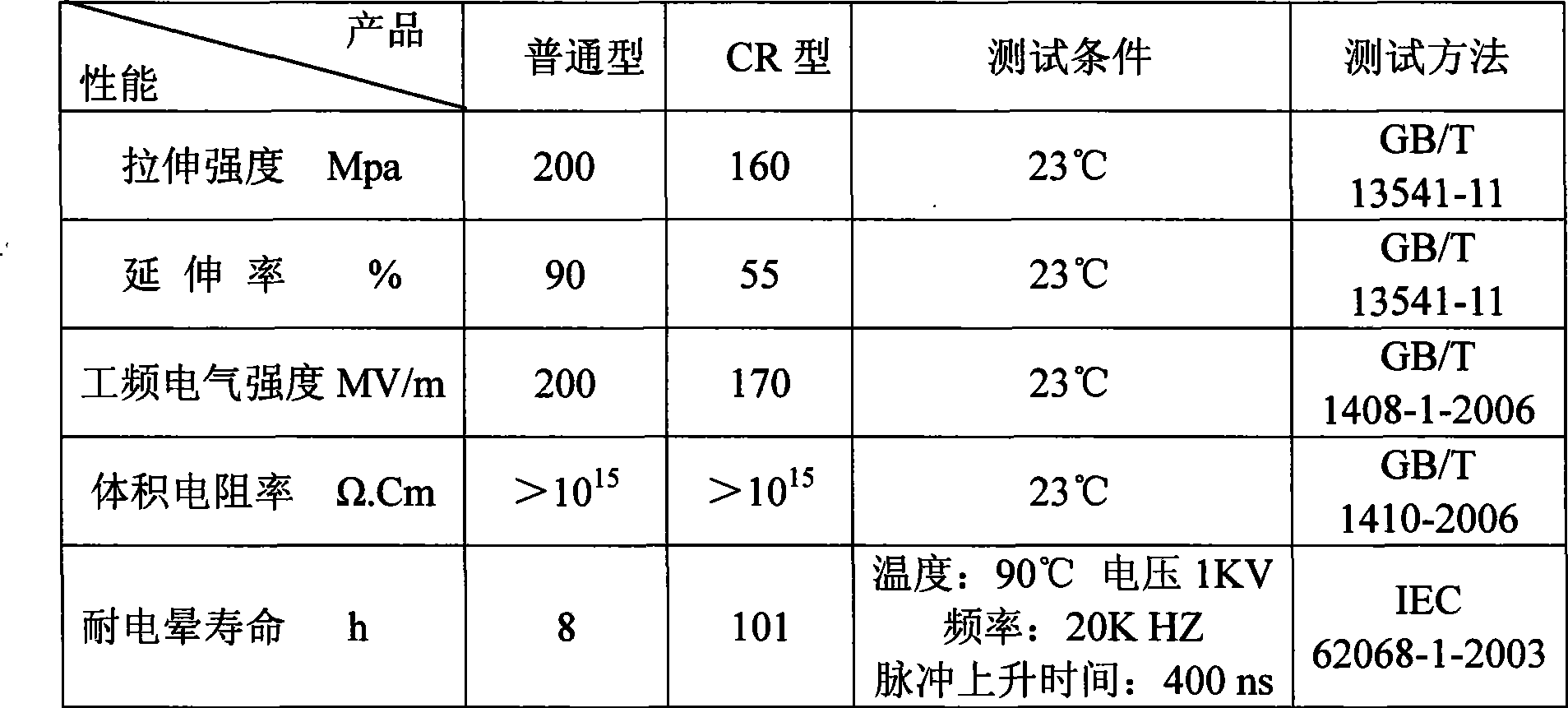

Owner:无锡高拓新材料股份有限公司

Fully biodegradable multifunctional mulch film and preparation method thereof

ActiveCN103289134BFully biodegradableCreate pollutionClimate change adaptationPlant protective coveringsEcological environmentAdditive ingredient

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com