Nylon/polystyrene alloy microsphere, preparation method and applications thereof

A polystyrene and styrene technology, applied in the field of nylon/polystyrene alloy materials, can solve the problems of poor dimensional accuracy and mechanical strength of sintered products, and achieve the effects of simple and controllable preparation methods and improved bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

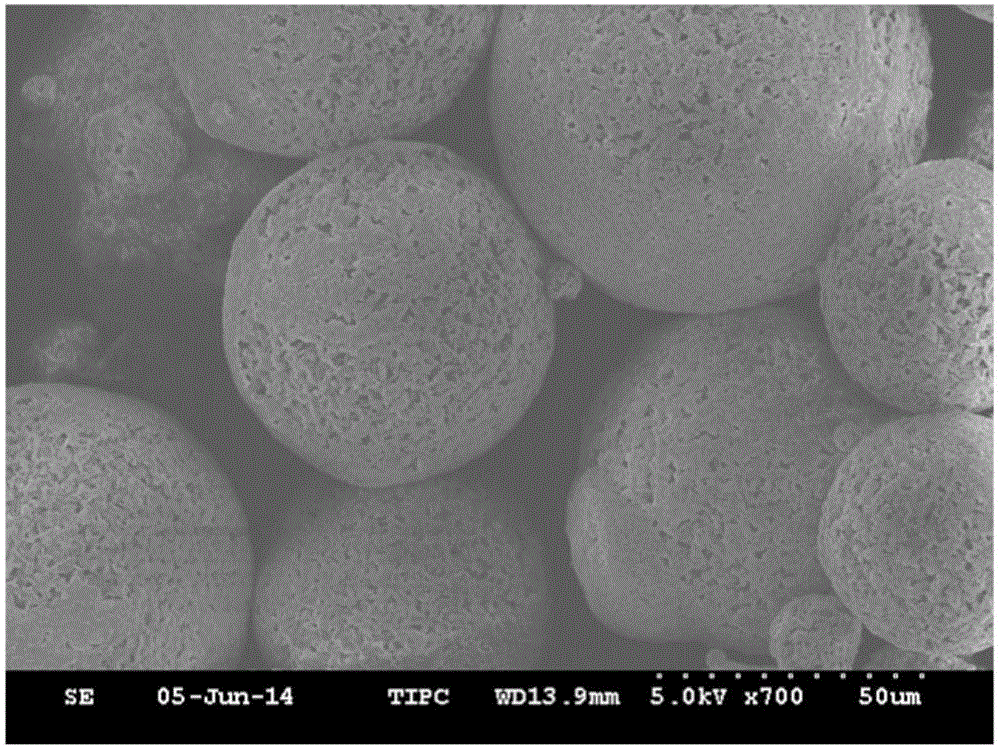

[0037] Embodiment 1: Preparation of porous nylon 6 microspheres

[0038]Preparation of pore-containing nylon 6 microspheres by dissolution-precipitation method: add 40g of nylon 6 pellets and 240ml of formic acid into the reaction kettle and heat up to 80°C, stir for 2 hours to fully dissolve the material, and then add 400ml of polyethylene with a concentration of 10% g / ml Pyrrolidone (PVP-K30) ethanol solution, stirred vigorously and left to stand, precipitated powder. Suction filtration, washing with ethanol, and vacuum drying to obtain polyamide porous microspheres; the average particle diameter of the obtained nylon 6 microspheres is 60 μm, and the specific surface area is 23 m 2 / g, the porosity is 77%, the pore diameter is 0.1-2μm, and the bulk density is 0.2g / mL. SEM pictures see figure 1 .

Embodiment 2

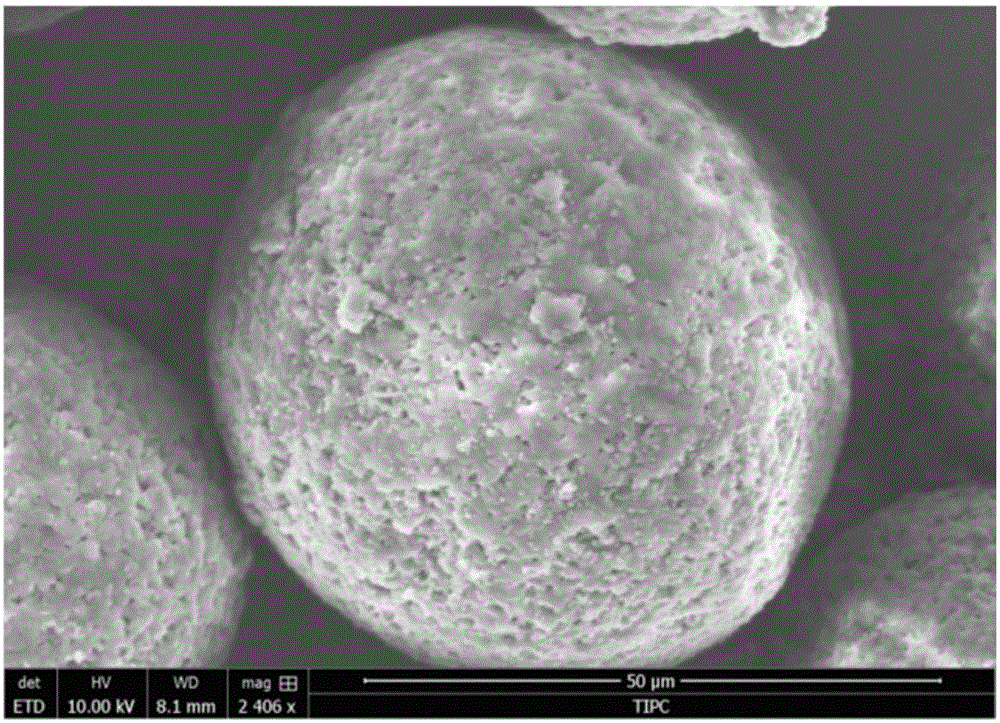

[0039] Embodiment 2: Preparation of porous nylon 12 microspheres

[0040] Preparation of pore-containing nylon 12 microspheres by dissolution-precipitation method: add 40g of nylon 12 pellets and 240ml of acetic acid into the reaction kettle and heat up to 100°C, stir for 2 hours to fully dissolve the material, and then add 400ml of polyethylene with a concentration of 20% g / ml Pyrrolidone (PVP-K30) ethanol solution, stirred vigorously and left to stand, precipitated powder. Suction filtration, washing with ethanol, and vacuum drying to obtain polyamide porous microspheres; the obtained nylon 12 microspheres have a particle size of 60 μm and a specific surface area of 1.1 m 2 / g, porosity 62%, pore diameter 0.1~4μm, bulk density 0.36g / mL. SEM pictures see figure 2 .

[0041] Similarly, other pore-containing nylon 11 microspheres, nylon 1212 microspheres, nylon 612 microspheres, nylon 610 microspheres or nylon 1010 microspheres in the examples of the present invention wer...

Embodiment 3

[0042] Embodiment 3: the preparation of nylon 6 / polystyrene alloy microsphere

[0043] Take 2.5g of nylon 6 porous microspheres and add them to 100g of water and ethanol solution with a mass ratio of 1:1. After ultrasonic dispersion, add 0.1g of ammonium persulfate, pass through nitrogen to discharge oxygen, and when the temperature rises to 45°C, add styrene 7.0 g, and then heated to 75 ° C for 24 hours to stop the reaction, and the obtained product was filtered under reduced pressure, washed with ethanol and dried to obtain microspheres with a mass ratio of nylon 6 to polystyrene of 1:2.80. The particle size of the obtained nylon 6 / polystyrene alloy microspheres remains basically unchanged, the surface is smooth, the porosity is significantly reduced, and there is no obvious phase interface between nylon 6 and polystyrene. SEM pictures see image 3 . The parameters of thermal decomposition temperature, melting temperature and bulk density are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com