Preparation method for copper-carbon nano tube (CNT) composite powder

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of nanomaterials, can solve the problems of interaction between carbon nanotubes and matrix copper catalyst and matrix, and achieve the effects of easy control and implementation, uniform distribution of CNTs and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

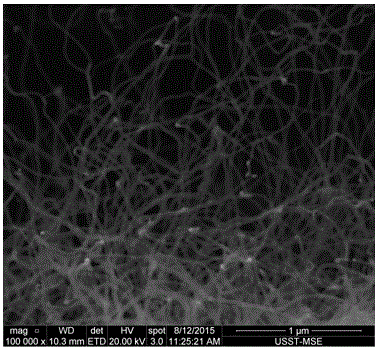

Image

Examples

Embodiment 1

[0022] A preparation method of copper-carbon nanotube composite powder is carried out according to the following steps:

[0023] 1) A step of preparing copper-chromium alloy powder by water mist method, weighing chromium and copper powder matrix according to mass percentage, the mass percentage of described chromium is 0.6wt% of copper-chromium alloy powder, and the particle size of described chromium is in 400 mesh, the balance is the copper powder matrix, and then heat treatment is carried out. In the heat treatment process, Ar gas protection is selected, and hydrogen protection of 100 to 500 ccm is introduced at the same time. The heat treatment temperature is 800 ° C. The chromium in the copper powder Solid solution in the matrix for 1 hour, then aging treatment at 450°C for 1 hour, so that chromium is uniformly dispersed on the copper powder matrix, and a copper-chromium composite powder with catalytic activity is prepared, and then cleaned in alcohol for 24 hours, and ele...

Embodiment 2

[0028] A preparation method of copper-carbon nanotube composite powder is carried out according to the following steps:

[0029] 1) A step of preparing copper-chromium alloy powder by water mist method, weighing chromium and copper powder matrix according to mass percentage, the mass percentage of described chromium is 0.4wt% of copper-chromium alloy powder, and the particle size of described chromium is in 200 mesh, the balance is the copper powder matrix, and then heat treatment is carried out. In the heat treatment process, Ar gas protection is selected, and hydrogen protection of 100 to 500 ccm is introduced at the same time. The heat treatment temperature is 800 ° C. The chromium in the copper powder Solid solution in the matrix for 1 hour, then aging treatment at 450°C for 2 hours, so that chromium is uniformly dispersed on the copper powder matrix, and a copper-chromium composite powder with catalytic activity is prepared, and then cleaned in alcohol for 24 hours, and el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com