Nylon/silica composite microsphere, preparation method and application thereof

A technology of silica and composite microspheres, used in chemical instruments and methods, pharmaceutical formulations, and other chemical processes to achieve the effects of good fluidity, increased bulk density, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

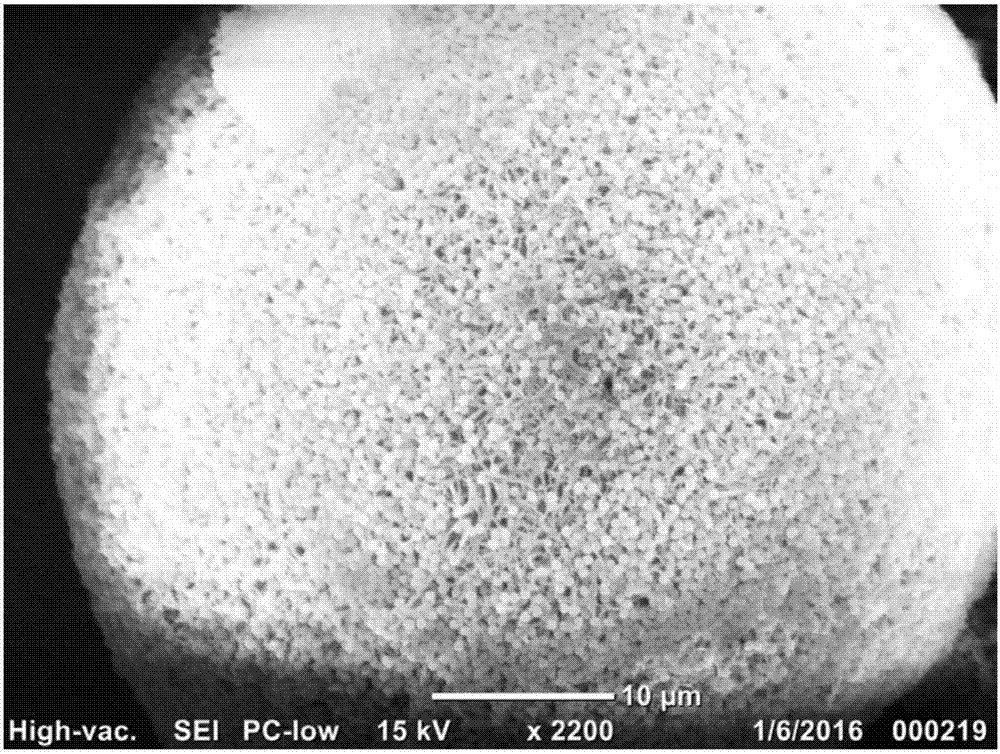

[0044] The preparation method of porous nylon 6 microspheres is:

[0045] Preparation of porous nylon 6 microspheres by the dissolution-precipitation method: add 40g nylon 6 pellets and 240ml formic acid to the reactor and heat up to 80°C, stir for 2h to fully dissolve the material, and then add 400ml of 10% g / ml polyethylene The ethanol solution of pyrrolidone (PVP-K30) was stirred vigorously and then stood still to precipitate a powder. Suction filtration, ethanol washing, and vacuum drying to obtain polyamide porous microspheres; the SEM picture of the obtained pore-containing nylon 6 microspheres is as follows figure 1 Shown; the obtained nylon 6 microspheres have an average particle size of 60μm and a specific surface area of 23m 2 / g, the porosity is 77%, the pore size is 0.1-2μm, and the bulk density is 0.2g / mL.

[0046] The preparation method of porous nylon 12 microspheres is:

[0047] Preparation of porous nylon 12 microspheres by the dissolution-precipitation method: ad...

Embodiment 1

[0050] Take 0.5 g of porous nylon 6 microspheres, 3 mL of 25% ammonia water, and 10 mL of deionized water into a 150 mL three-necked flask, and ultrasonicate for 0.5 h to obtain a dispersion of porous nylon microspheres; add 3 mL of ethyl orthosilicate Dissolved in 30mL ethanol and added to the above dispersion at a dropping rate of 5mL / h, and reacted with rapid stirring at 30°C for 10h; the solution obtained after the reaction was filtered, washed, and dried to obtain nylon / silica composite microspheres with good dispersibility.

[0051] The scanning electron microscope picture of the obtained composite microspheres is as follows image 3 As shown; the particle size of the composite microspheres is 40-60μm, and only a small part of the micropores exist on the surface. The particle size of the nano-silica in the composite microspheres is 200-300nm, and it is uniformly dispersed in the porous nylon 6 microspheres . The specific surface area of the composite microspheres is 11m 2...

Embodiment 2

[0053] Take 0.5 g of porous nylon 12 microspheres, 1 mL of 25% ammonia water, and 5 mL of ethanol into a 150 mL three-necked flask, and ultrasound for 0.5 h to obtain a dispersion of porous nylon microspheres; dissolve 1 mL of ethyl orthosilicate 10 mL of ethanol was added to the above dispersion at a dropping rate of 5 mL / h, and reacted with rapid stirring at 30°C for 10 hours; the solution obtained after the reaction was filtered, washed, and dried to obtain nylon 12 / silica composite microspheres with good dispersibility.

[0054] The scanning electron microscope picture of the obtained composite microspheres is as follows Figure 4 As shown; the particle size of the composite microspheres is 60 μm, and there are only a few micropores on the surface. The particle size of the nano-silica in the composite microspheres is 200-300 nm, and is uniformly dispersed in the porous nylon 12 microspheres. The specific surface area of the composite microspheres is 5m 2 / g, the porosity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com