Preparation method of carbon nanotube toughened silicon carbide ceramic

A technology of carbon nanotubes and tough silicon carbide is applied in the field of preparation of carbon nanotube toughened silicon carbide ceramics. High performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment includes the following steps:

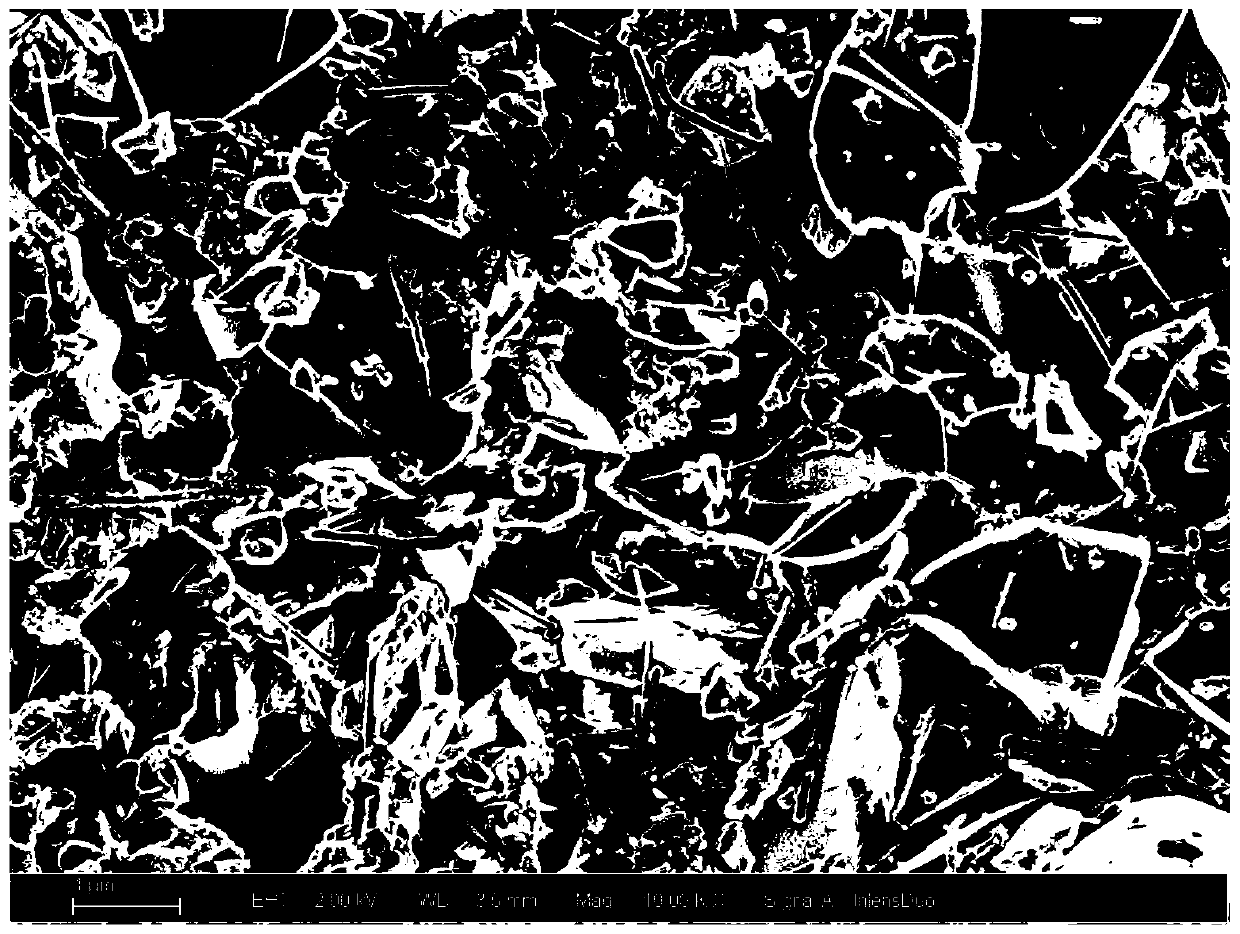

[0025] S1, mix 1kg of silicon carbide, 0.1kg of carbon black, 0.1kg of silicon nitride-coated carbon nanotubes, 0.06kg of water-soluble phenolic resin and 1.2kg of pure water to obtain a uniformly dispersed slurry with a solid content of 50%. The SEM photos of figure 2 shown;

[0026] S2, heating the slurry obtained in step S1, evaporating and removing water to obtain a block material, dry pressing the block material, and forming a green body at one time;

[0027] S3, cover the surface of the green body with elemental silicon, put it into a vacuum high-pressure sintering furnace, raise the temperature to 1400°C and keep it for 30 minutes, and convert the amorphous silicon nitride on the surface of the carbon nanotube into hexagonal silicon nitride; then raise the temperature to 1500°C Insulated for 1h, carbon nanotube toughened silicon carbide ceramics were obtained, the SEM photo of which is as follows image 3 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com