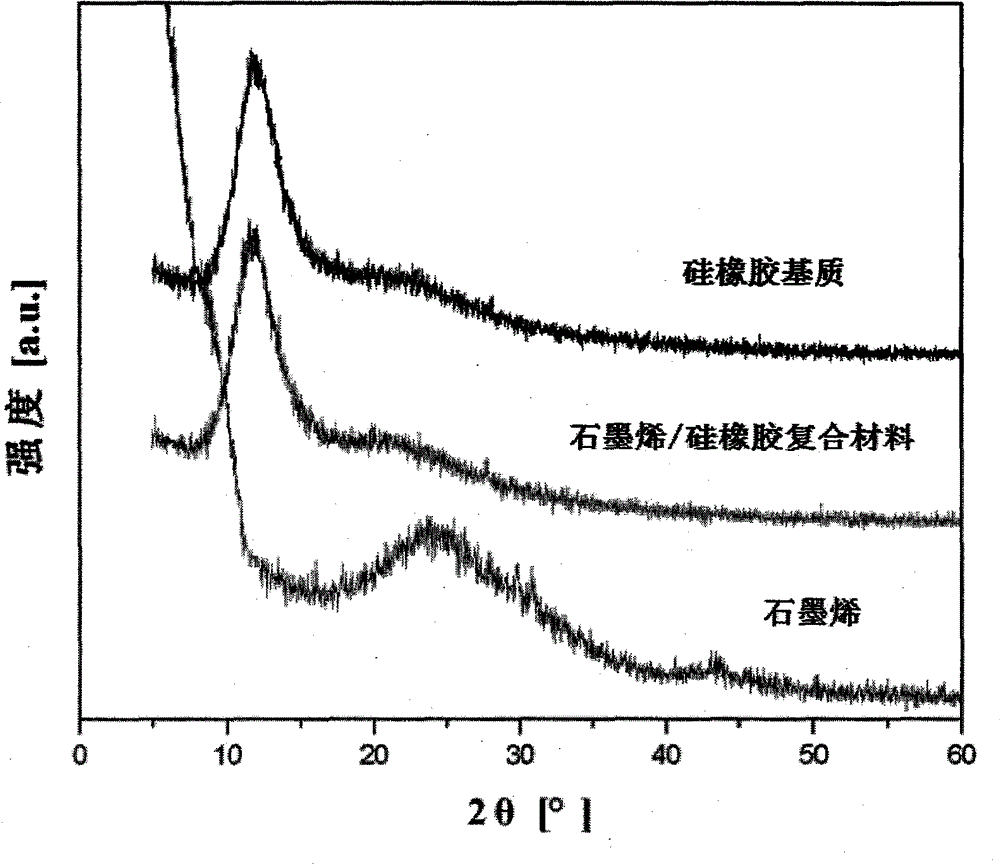

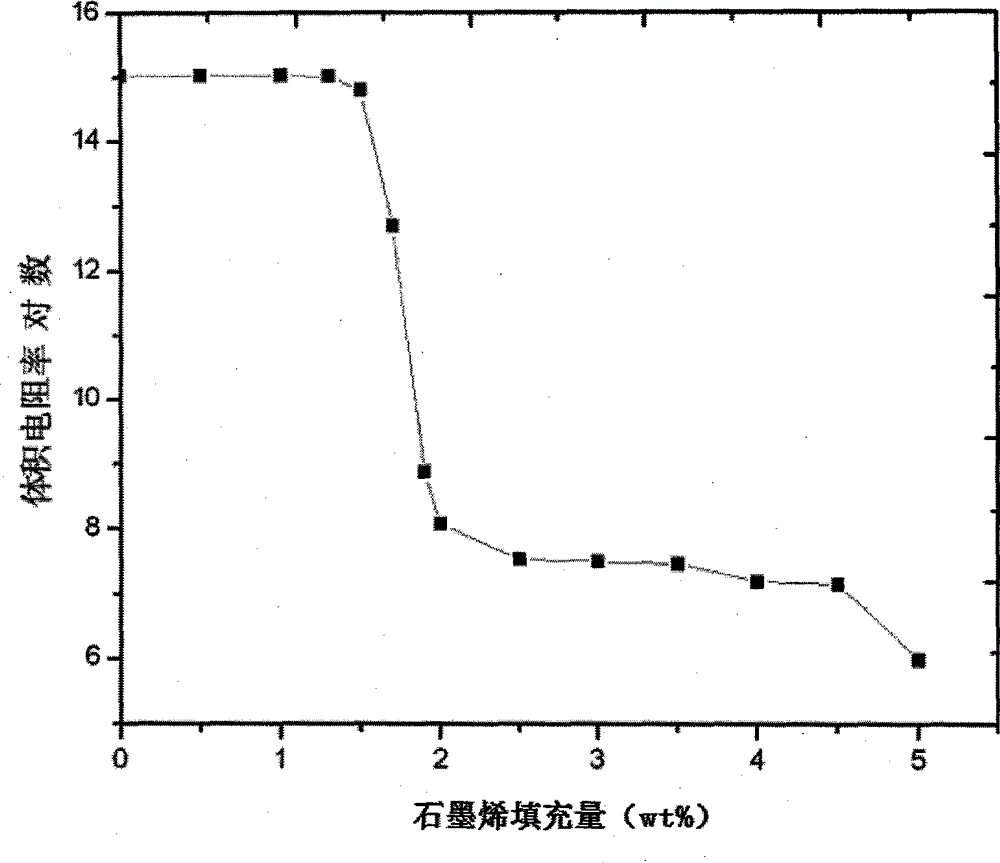

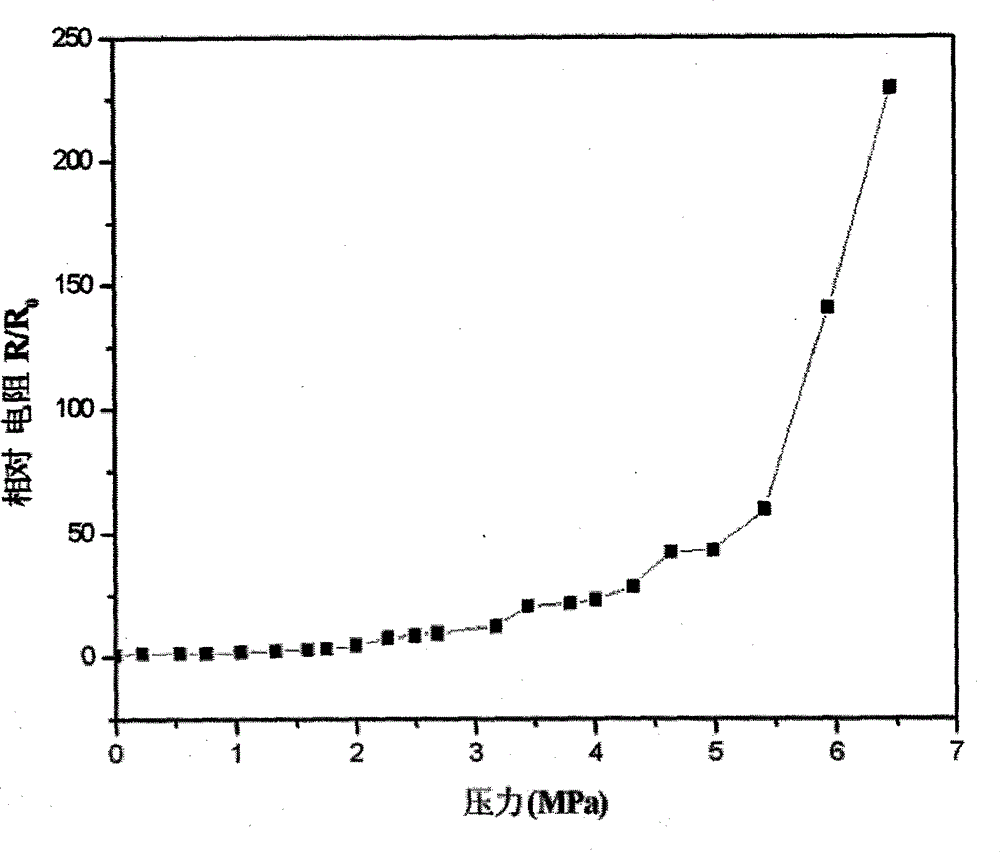

Preparation method of graphene/silicon rubber pressure-sensitive conductive composite

A conductive composite material, graphene technology, applied in the field of composite material preparation, can solve problems such as obvious agglomeration, high cost, and large environmental pollution, and achieve the effects of wide application prospects, pollution avoidance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of graphene / silicone rubber pressure-sensitive conductive composite material, comprising the following steps:

[0033] (1) prepare graphene: comprise:

[0034] (1a) Graphite oxide was prepared by chemical oxidation: adding natural flake graphite, potassium persulfate and phosphorus pentoxide to concentrated sulfuric acid, ultrasonically dispersed for 5 min, and magnetically stirred in an oil bath at 80° C. for 6 h. After vacuum filtration and washing, the filter cake was vacuum-dried and ground. Put the dried ingredients into a beaker, add concentrated sulfuric acid and ultrasonically disperse evenly, slowly add potassium permanganate and stir electrically for 4 hours under the protection of an ice-water bath; add deionized water and move the mixture into a water bath and keep at 40°C to continue Stir for 2h. Stop stirring and add 5 times the amount of deionized water, and then add hydrogen peroxide to obtain a bright yellow graphite oxide suspens...

Embodiment 2

[0041] A preparation method of graphene / silicone rubber pressure-sensitive conductive composite material, comprising the following steps:

[0042] (1) prepare graphene: method is with embodiment 1.

[0043] (2) Ultrasonic-assisted solution mixing method to prepare silicone rubber base material:

[0044] 100 parts by weight of methyl vinyl silicone rubber (brand 110-2) was dissolved in tetrahydrofuran to obtain silicone rubber solution A, 2.0 parts by weight of graphene was ultrasonically dispersed in tetrahydrofuran for 1 h to obtain graphene dispersion B, and A was mixed with B is mixed, and the mixture is ultrasonically dispersed for 30 minutes. Use a temperature-adjustable ultrasonic cleaner to replace the water bath of the rotary evaporator, and rotate the tetrahydrofuran in the mixed solution while ultrasonically dispersing to separate the rubber from the tetrahydrofuran, and then vacuum-dry the obtained rubber for future use.

[0045] (3) Preparation of the target comp...

Embodiment 3

[0047] A preparation method of graphene / silicone rubber pressure-sensitive conductive composite material, comprising the following steps:

[0048] (1) prepare graphene: method is with embodiment 1.

[0049] (2) Ultrasonic-assisted solution mixing method to prepare silicone rubber base material:

[0050] 100 parts by weight of methyl vinyl silicone rubber (brand 110-2) was dissolved in tetrahydrofuran to obtain silicone rubber solution A, 3.0 parts by weight of graphene was ultrasonically dispersed in tetrahydrofuran for 1 h to obtain graphene dispersion B, and A and B is mixed, and the mixture is ultrasonically dispersed for 30 minutes. Use a temperature-adjustable ultrasonic cleaner to replace the water bath of the rotary evaporator, and rotate the tetrahydrofuran in the mixed solution while ultrasonically dispersing to separate the rubber from the tetrahydrofuran, and then vacuum-dry the obtained rubber for future use.

[0051] (3) Preparation of the target composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com