Conductive polymer composite and preparation method thereof

A conductive polymer and composite material technology, which is applied in the field of conductive polymer composite materials and its preparation, can solve the problems of complex processing technology, high cost, and decreased mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

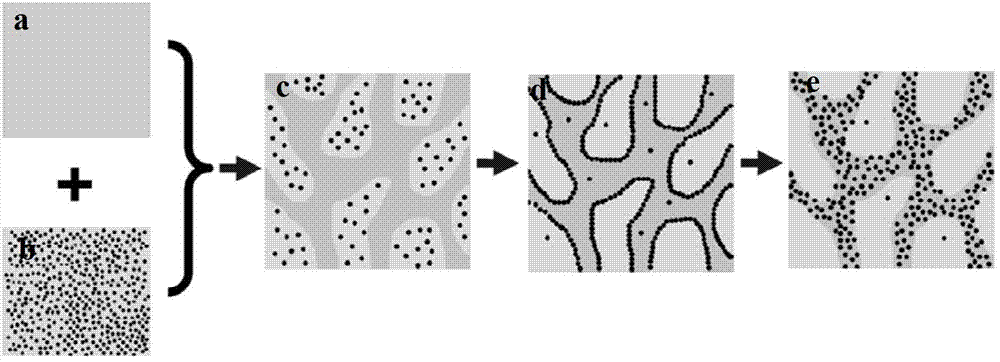

[0039] The present invention also provides a method for preparing a conductive polymer composite material, comprising the following steps: A) heating and co-polymerizing the polymer with poor affinity with the conductive nano-filler in the incompatible polymer blend system and the conductive nano-filler; mixed to obtain a premix; B) heating and blending the premix with the polymer with better affinity with the conductive nanofiller in the incompatible polymer blend system, and the two polymers form a bicontinuous structure, A conductive polymer composite material is obtained; the amount of the incompatible polymer blend system is 100 parts by weight, the amount of the conductive nano filler is 0.01 to 1.5 parts by weight, and the aspect ratio of the conductive nano filler is ≥ 100.

[0040] Wherein, the incompatible polymer blend system is the same as that of the conductive nanofiller, and will not be repeated here.

[0041]The blending temperature in step A is 170-218° C., pr...

Embodiment 1

[0052] 1.1 Blend 0.01 parts by weight of carbon nanotubes and 50 parts by weight of polylactic acid in an internal mixer at a temperature of 180° C., a rotation speed of 120 r / min, and a blending time of 5 minutes to obtain a premix.

[0053] 1.2 Blend 50 parts by weight of polycaprolactone with the premix obtained in 1.1 in an internal mixer, the blending temperature is 180°C, the rotation speed is 50r / min, and the blending time is 4min to obtain a conductive polymer compound Material.

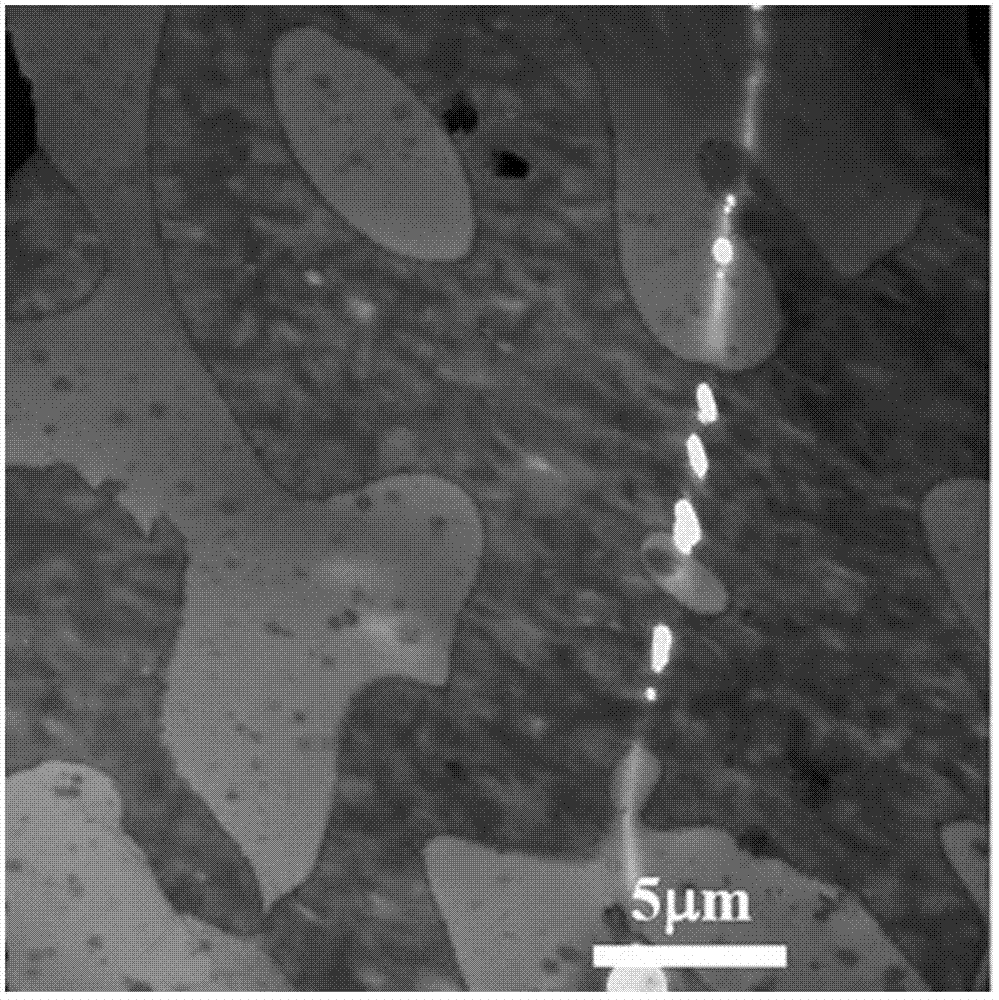

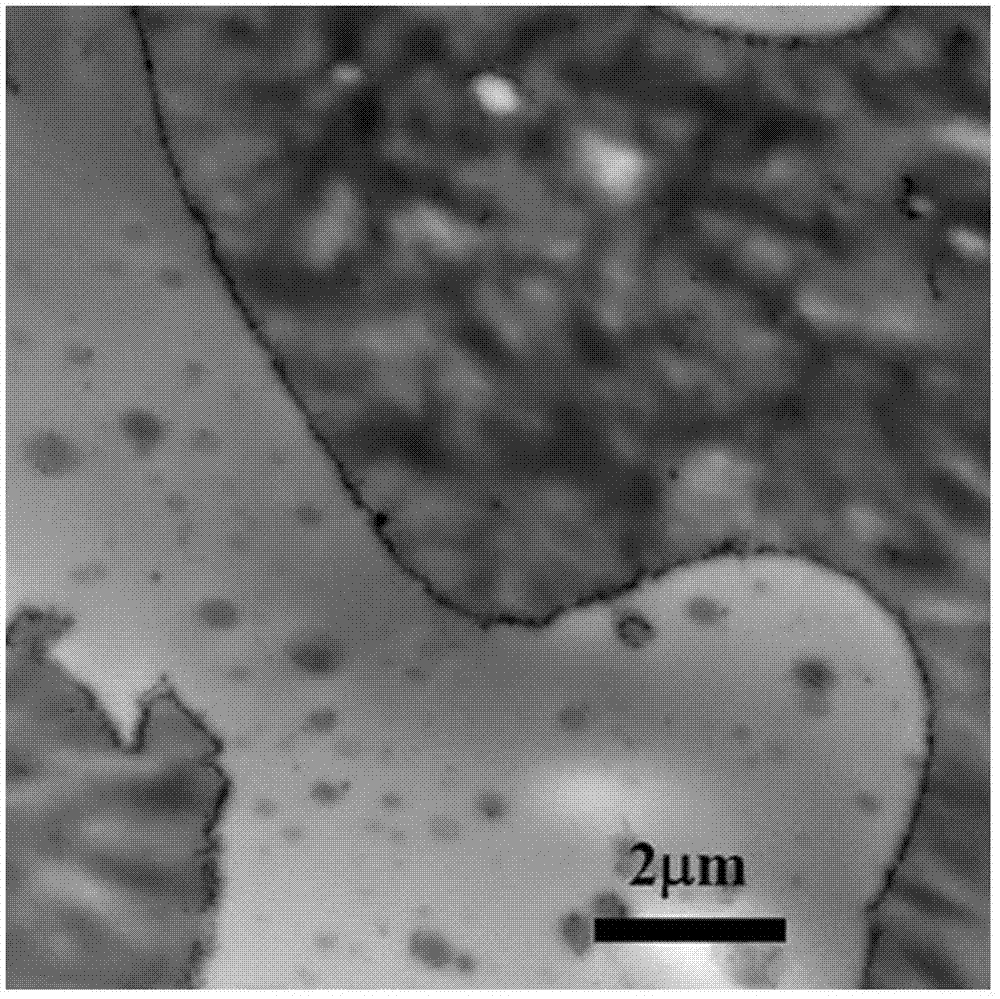

[0054] Utilize the transmission electron microscope to test the conductive polymer composite material obtained in 1.2, and obtain the transmission electron microscope photos of different magnification ratios, such as Figure 2-4 shown, where image 3 for figure 2 A partial enlargement of the Figure 4 for image 3 A partial enlargement of the .

[0055] The conductive polymer composite material obtained in 1.2 was tested using a broadband dielectric impedance spectrometer (Concept80), a...

Embodiment 2

[0057] 2.1 Blend 0.02 parts by weight of carbon nanotubes and 50 parts by weight of polylactic acid in an internal mixer at a temperature of 180° C., a rotation speed of 120 r / min, and a blending time of 5 minutes to obtain a premix.

[0058] 2.2 Blend 50 parts by weight of polycaprolactone with the premix obtained in 2.1 in an internal mixer, the blending temperature is 180°C, the rotation speed is 50r / min, and the blending time is 4min to obtain a conductive polymer compound Material.

[0059] The conductive polymer composite material obtained in 2.2 was tested with a broadband dielectric impedance spectrometer (Concept80), and its electrical conductivity (conductivity at a frequency of 0.1 Hz) is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com