A kind of preparation method of rubber/graphene composite material with isolated structure

A composite material and isolation structure technology, which is applied in the application field of polymer materials, can solve the problems of conductive rubber composite materials that are difficult to build isolation structures, limit the industrial application of conductive rubber composite materials, poor interface interaction, etc., and reduce the threshold value of conductive seepage. , Overcome the effect that it is difficult to form a continuous conductive network and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of functionalized graphene suspension: take 0.2 g of graphene and 0.1 g of polyallylamine, ultrasonically disperse for 1 h, centrifuge, wash, and re-disperse ultrasonically to obtain a uniform functionalized graphene suspension.

[0026] (2) Preparation of styrene-butadiene rubber / graphene composite: ultrasonically disperse the functionalized graphene suspension in the mixed latex of 20.0g carboxylated styrene-butadiene latex and 180.0g styrene-butadiene latex, and add 108.5g of rubber compounding agent aqueous dispersion , under 300W ultrasonic power and 300r / min stirring speed, after ultrasonic stirring and dispersion for 30min, a white styrene-butadiene rubber / graphene composite was obtained.

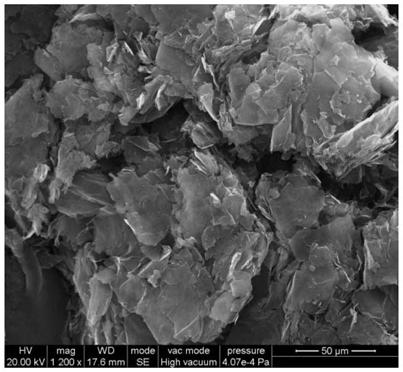

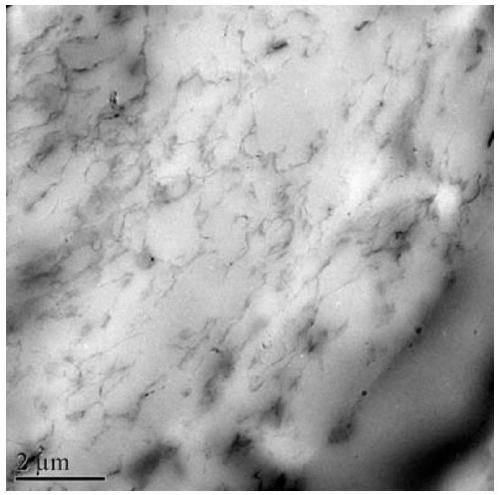

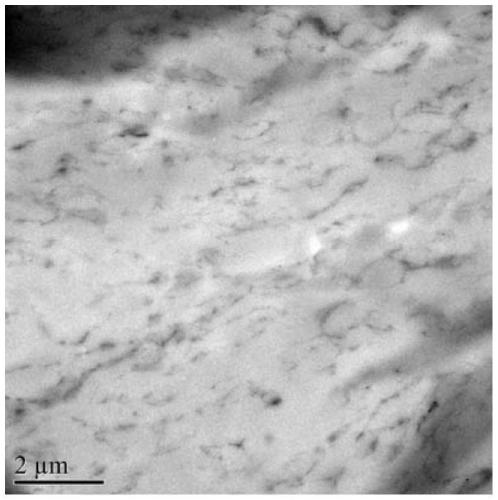

[0027] (3) Preparation of styrene-butadiene rubber / graphene composite material with continuous isolation structure: the styrene-butadiene rubber / graphene composite prepared in step (2) was air-dried at 45°C for 12 hours; finally, the dried composite The materia...

Embodiment 2

[0030] (1) Preparation of functionalized graphene suspension: take 0.2 g of graphene and 0.2 g of polyallylamine, ultrasonically disperse for 1.5 h, centrifuge, wash, and re-disperse ultrasonically to obtain a uniform functionalized graphene suspension.

[0031] (2) Preparation of styrene-butadiene rubber / graphene composite: ultrasonically disperse the functionalized graphene suspension in the mixed latex of 40.0g carboxylated styrene-butadiene latex and 160.0g styrene-butadiene latex, and add 108.5g of rubber compounding agent aqueous dispersion , under 300W ultrasonic power and 300r / min stirring speed, after ultrasonic stirring and dispersion for 30min, a white styrene-butadiene rubber / graphene composite was obtained.

[0032] (3) Preparation of styrene-butadiene rubber / graphene composite material with continuous isolation structure: the styrene-butadiene rubber / graphene composite prepared in step (2) was air-dried at 45°C for 12 hours; finally, the dried composite The mater...

Embodiment 3

[0035](1) Preparation of functionalized graphene suspension: take 0.2 g of graphene and 0.3 g of polyallylamine, ultrasonically disperse for 2 h, centrifuge, wash, and re-disperse ultrasonically to obtain a uniform functionalized graphene suspension.

[0036] (2) Preparation of styrene-butadiene rubber / graphene composite: ultrasonically disperse the functionalized graphene suspension in the mixed latex of 60.0g carboxylated styrene-butadiene latex and 140.0g styrene-butadiene latex, and add 108.5g of rubber compounding agent aqueous dispersion , under 300W ultrasonic power and 300r / min stirring speed, after ultrasonic stirring and dispersion for 30min, a white styrene-butadiene rubber / graphene composite was obtained.

[0037] (3) Preparation of styrene-butadiene rubber / graphene composite material with continuous isolation structure: the styrene-butadiene rubber / graphene composite prepared in step (2) was air-dried at 45°C for 12 hours; finally, the dried composite The material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com