Electric conductive/ magnetic conductive chemical fiber magnetic field induction spinning assisting forming device and production method thereof

A chemical fiber and molding device technology, applied in conductive/antistatic filament manufacturing, filament/line forming, fiber processing, etc., can solve the problems of poor controllability of magnetic field strength, unfavorable for industrial production, etc., and achieve the processable range The effect of reducing the percolation threshold and improving the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

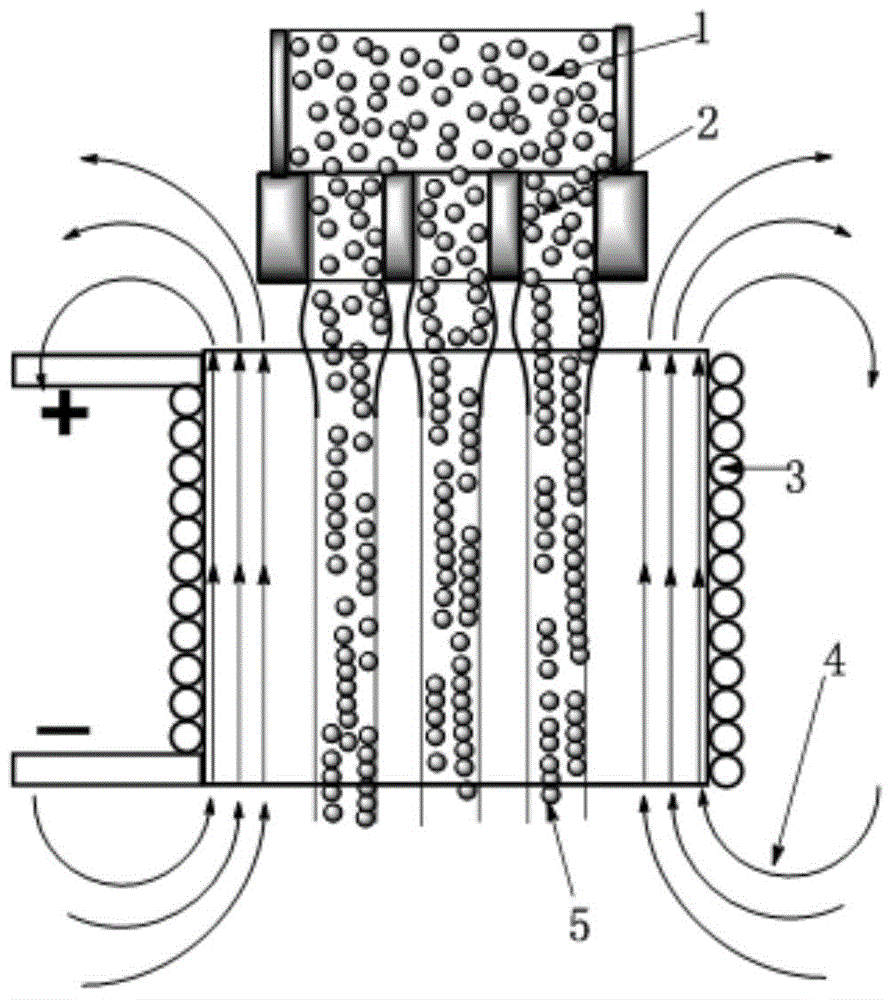

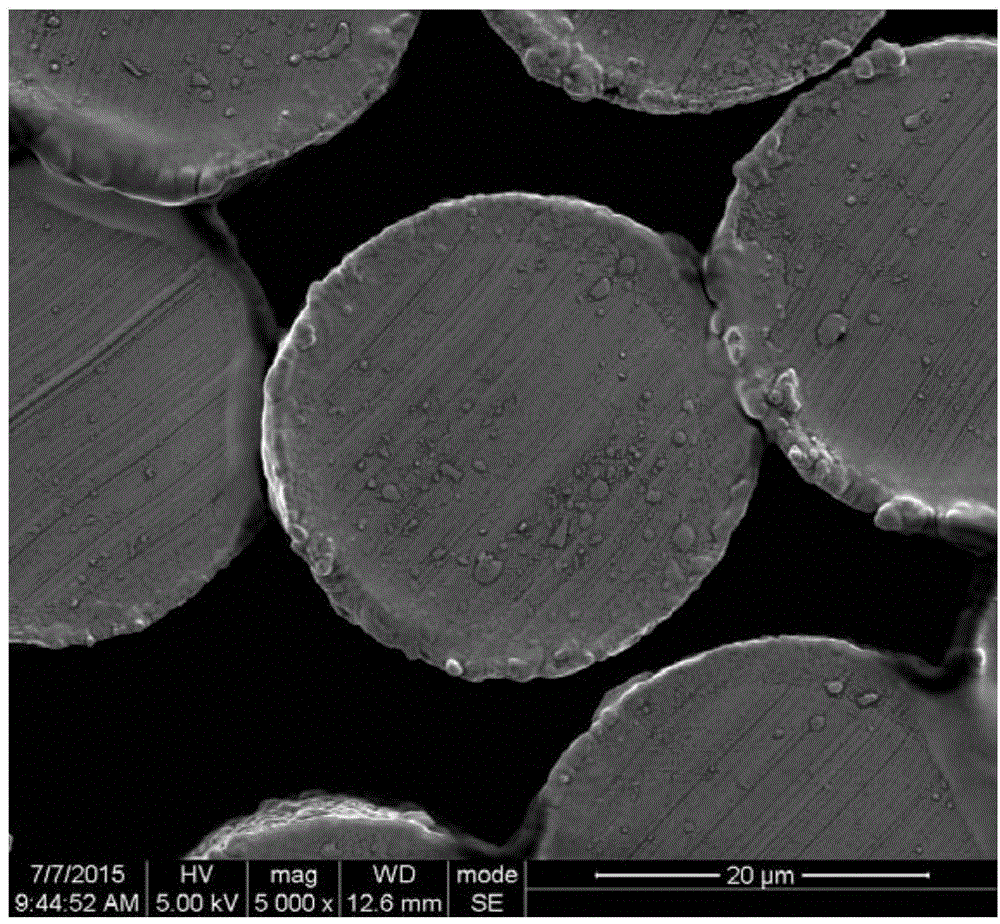

[0030] A magnetic field induction auxiliary spinning forming device for conductive / magnetic conductive chemical fibers, the device contains an electromagnetic coil 3, the electromagnetic coil 3 is vertically connected to the spinneret 2, the spinneret 2 is connected to the melt flow channel 1, and the electromagnetic coil 3 The hollow part of the spinneret is aligned with the center of the spinneret, so that the thread 5 passes smoothly through the hollow part of the electromagnetic coil. When spinning, the coil is connected to a DC power supply to generate magnetic force lines 4. The direction of the magnetic force lines is parallel to the direction of the thread. The silk melt is ejected through the spinneret hole, and passes through the center of the electromagnetic coil. Under the action of the magnetic field of the electromagnetic coil, the magnetic particles are arranged according to the direction of the magnetic force line to form a microfiber or bead structure. The role...

Embodiment 2

[0035] Conductive / magnetic polyethylene fibers were prepared according to the magnetic field-induced assisted spinning device for conductive / magnetic chemical fibers in Example 1. In this example, the commonly used thermoplastic resin polyethylene was selected as the matrix, and Ni powder was used as the magnetic powder.

[0036] Step 1: Preparation of conductive / magnetic polyethylene masterbatch, 30 parts by weight of Ni powder, 64 parts by weight of polyethylene chips, 3 parts by weight of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, 2 Parts by weight of polyethylene wax and 1 part by weight of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester are mixed evenly and then mixed by a twin-screw extruder and extruded to granulate , the extrusion temperature is 200°C to obtain conductive / magnetic polyethylene masterbatch.

[0037] Step 2: Preparation of conductive / magnetic conductive vinyl fibers. Blend and spin 30 parts by weight of th...

example 3

[0039] Conductive / magnetic conductive polypropylene fibers were prepared according to the magnetic field induction assisted spinning forming device of conductive / magnetic conductive chemical fibers in Example 1. In this example, commonly used thermoplastic resin polypropylene was selected as the matrix, and Ni powder was used as the magnetic powder.

[0040] Step 1: Preparation of conductive / magnetic polypropylene masterbatch, grafting 35 parts by weight of Ni powder, 60 parts by weight of polypropylene chips, 1.0 parts by weight of γ-aminopropyltriethoxysilane, and 1.0 parts by weight of maleic anhydride Polyethylene, 2.0 parts by weight polyethylene wax, 1.0 parts by weight β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecanyl propionate are mixed evenly and then mixed by a twin-screw extruder And extrusion granulation, the extrusion temperature is 170 ° C, to obtain conductive / magnetic polypropylene masterbatch.

[0041] Step 2: Preparation of conductive / magnetic polypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com