Preparation method of ZnO, CuO and ZnS quantum dot film

A technology of quantum dots and colloidal quantum dots, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low yield and complex process, achieve controllable film thickness and simple process , Optimize the effect of separation and compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1) 0.7925g (purity 99.99%) Zn(CH 3 COO) 2 powder and 0.0327g (purity 99.99%) Cu(CH 3 COO) 2 Dissolve the powder in 40 mL of methanol solution, stir well, add 250 μL of deionized water, and reflux in a water bath at 60°C for 30 minutes to obtain a precursor solution;

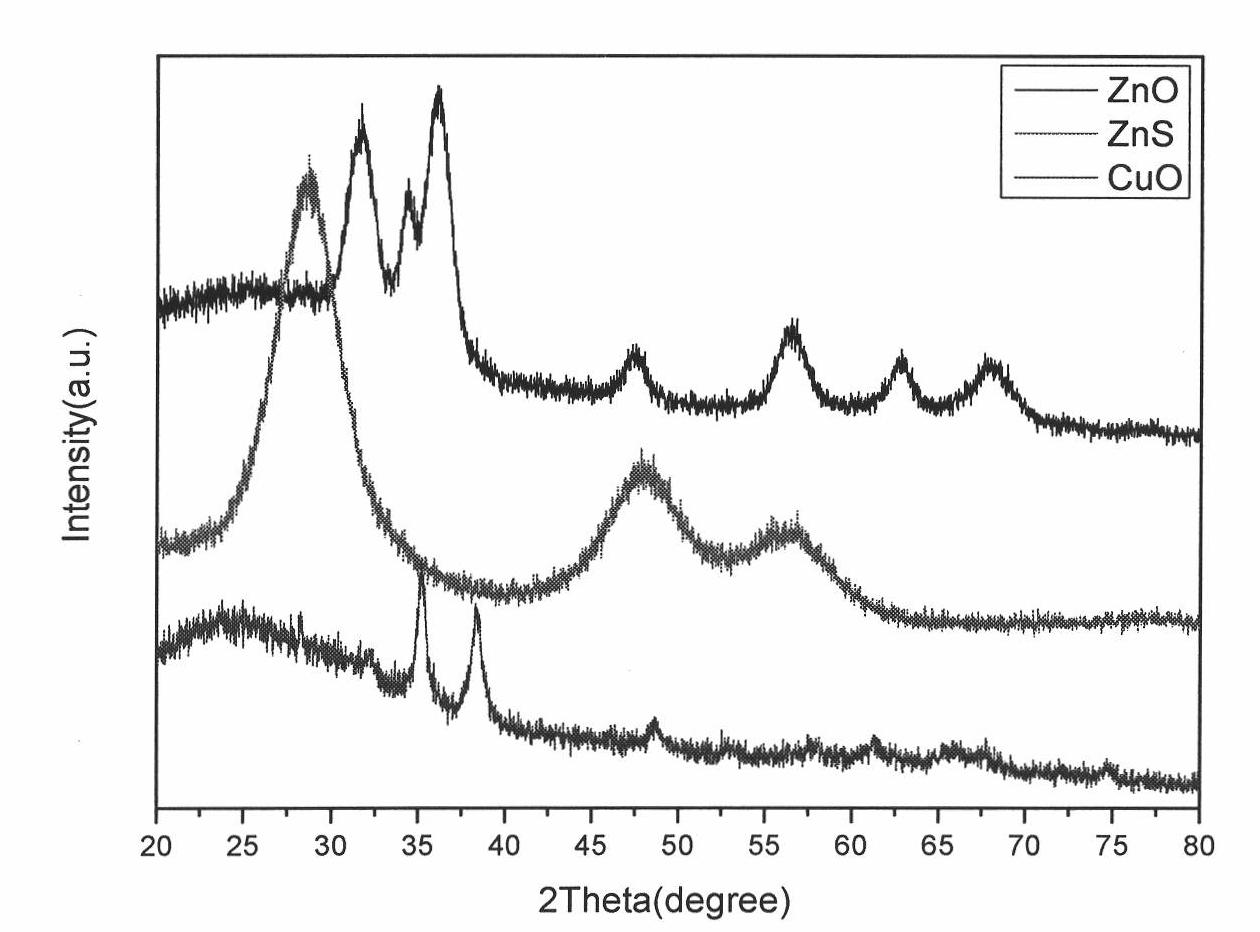

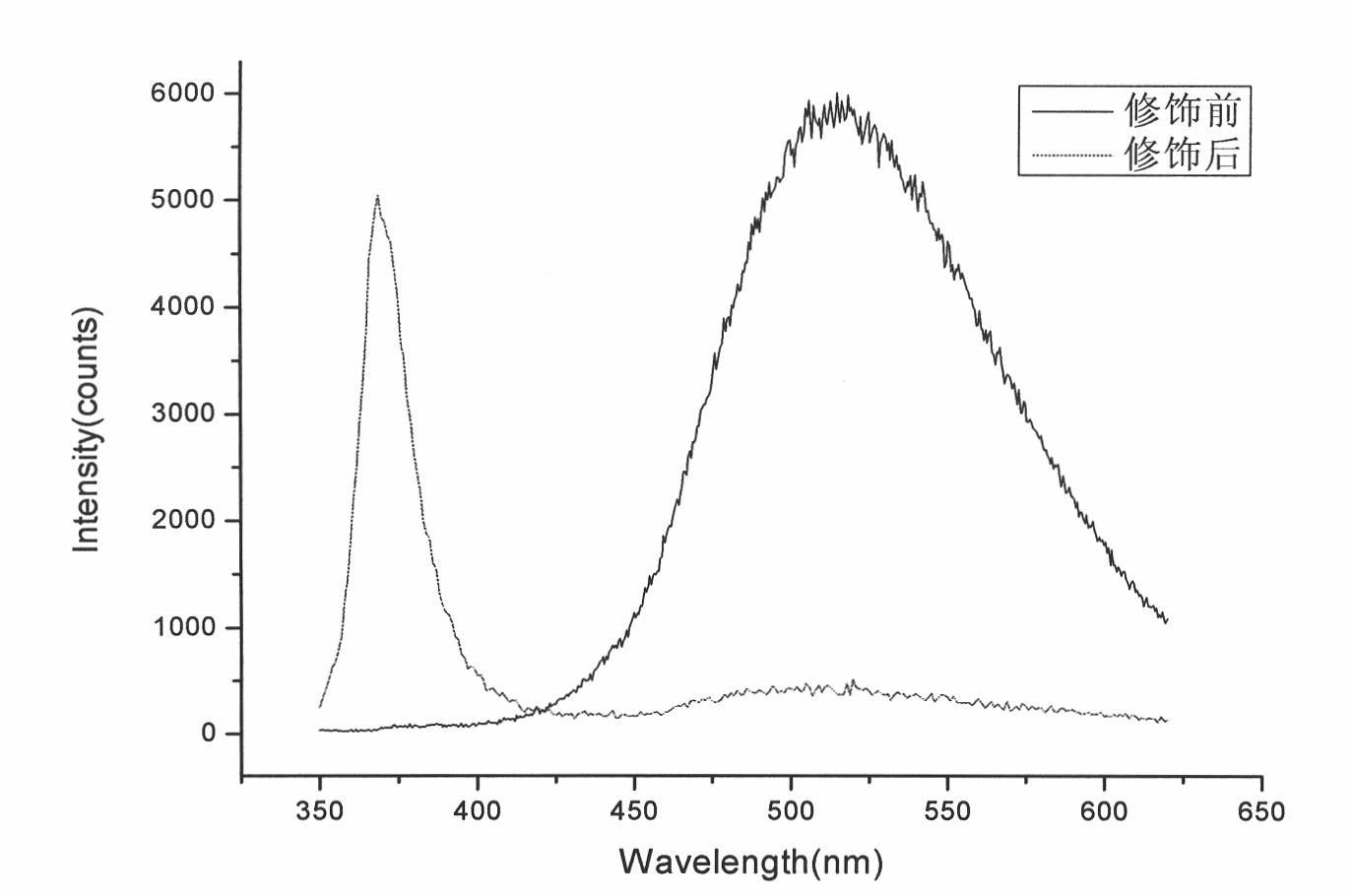

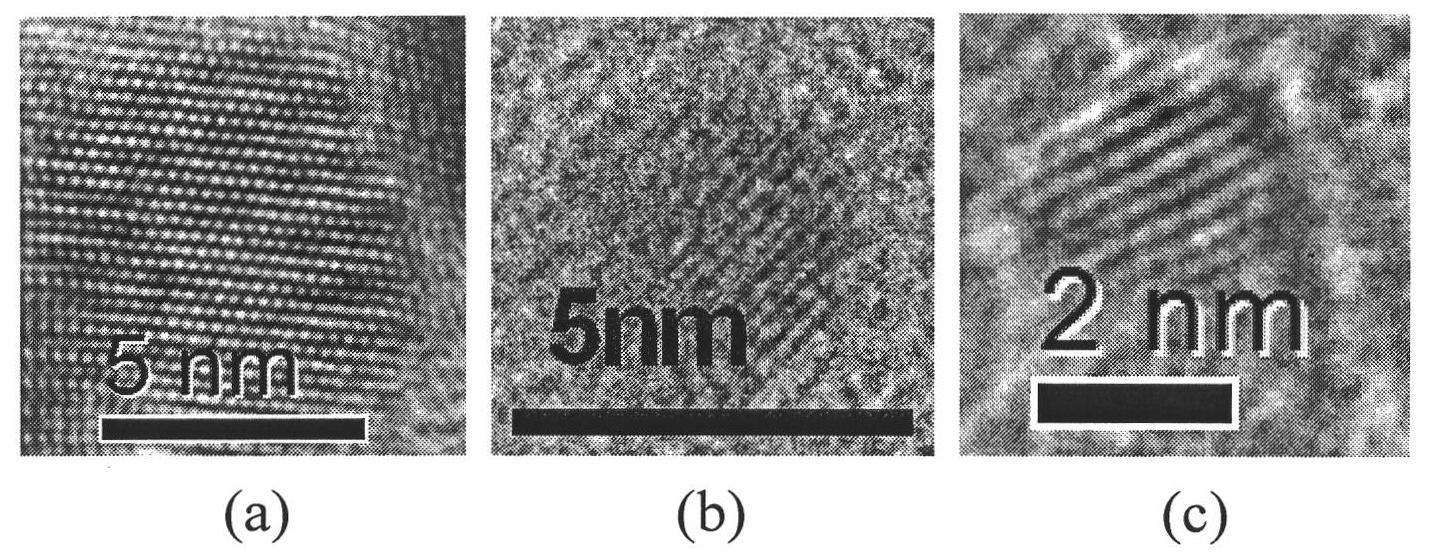

[0031] 2) Add 20 mL of 0.167 mol / L KOH methanol solution dropwise to the precursor solution in step 1), react in a water bath at 60°C for 2.5 hours, cool with ice water, and wash with methanol for 3 times to obtain Cu ion-modified ZnO quantum dots Precipitation, its phase was characterized by XRD (see figure 1 ), PL characterizes its luminescent properties (see figure 2 ), high-resolution transmission electron microscopy to characterize its morphology and size (see image 3 a);

[0032] 3) 0.2724g (purity 99.99%) Cu(CH 3 COO) 2 The powder was dissolved in 60 mL of methanol solution, 100 μL of glacial acetic acid was added, and refluxed in a water bath at 80 ° C for 120 minutes to obtain Cu(CH 3 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com