Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Solve peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

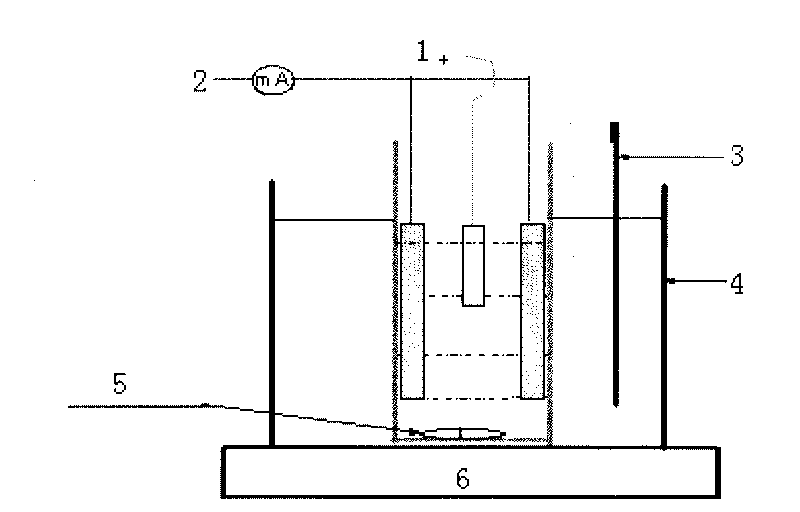

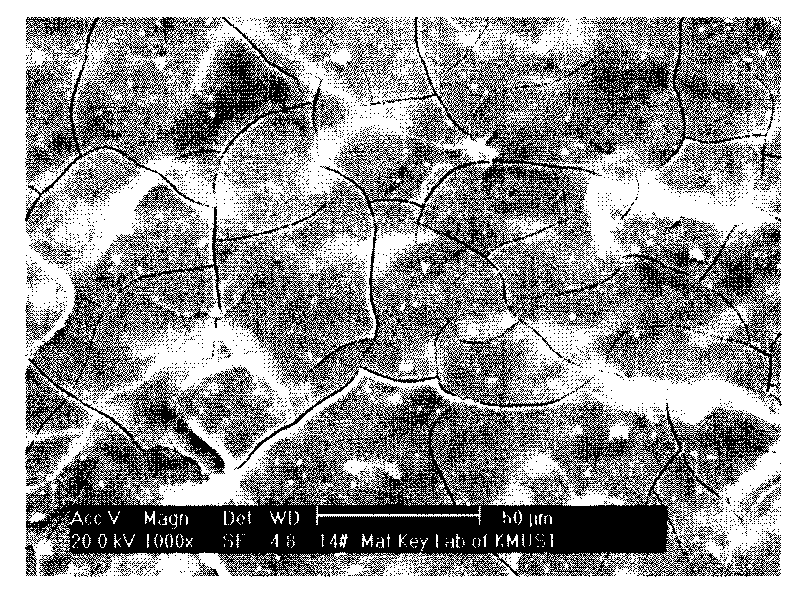

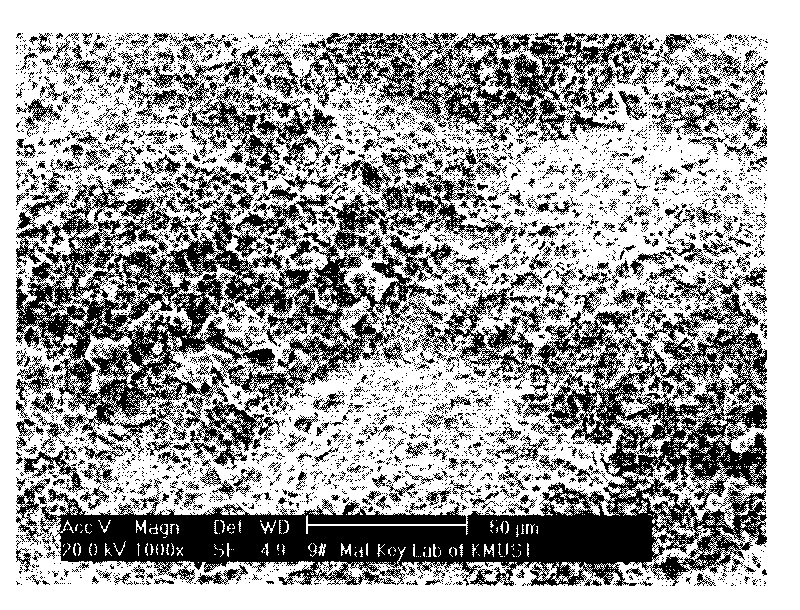

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

Chemical nickel-plating method on magnesium alloy surface

InactiveCN1500910AReduce pollutionUniform thicknessLiquid/solution decomposition chemical coatingFluorideAqueous solution

The present invention relates to magnesium alloy surface treating technology, and is especially chemical nickel plating process for magnesium alloy. The operation process includes the following steps: activating or finishing magnesium alloy through polishing or grinding, degreasing and acid pickling with acid fluoride bearing solution at 20-60 deg.c for 0.5-5 min; pre-treating with water solution containing fluoride bearing compound, iron bearing compound and complex at 15-45 deg.c for 5-30 min; and chemically nickel plating. The said process can make chemical nickel coating with homogeneous thickness, firm combination with substrate, high corrosion resistance and metal appearance. The process of the present invention has low cost and less environmental pollution and is suitable for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

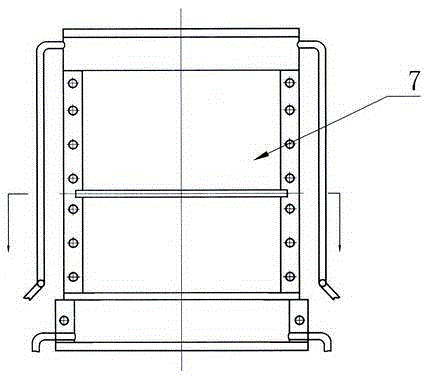

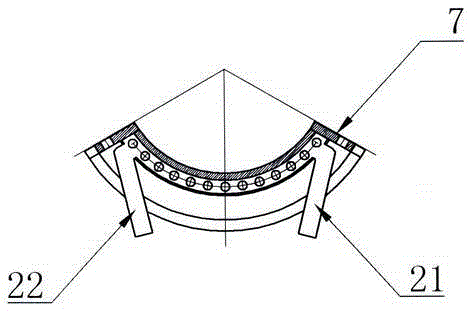

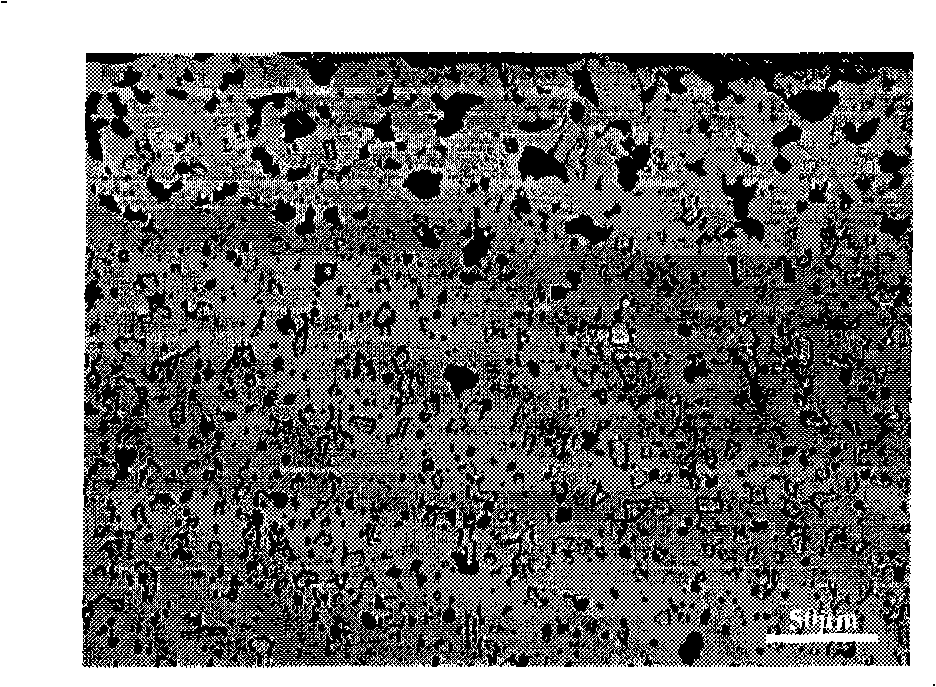

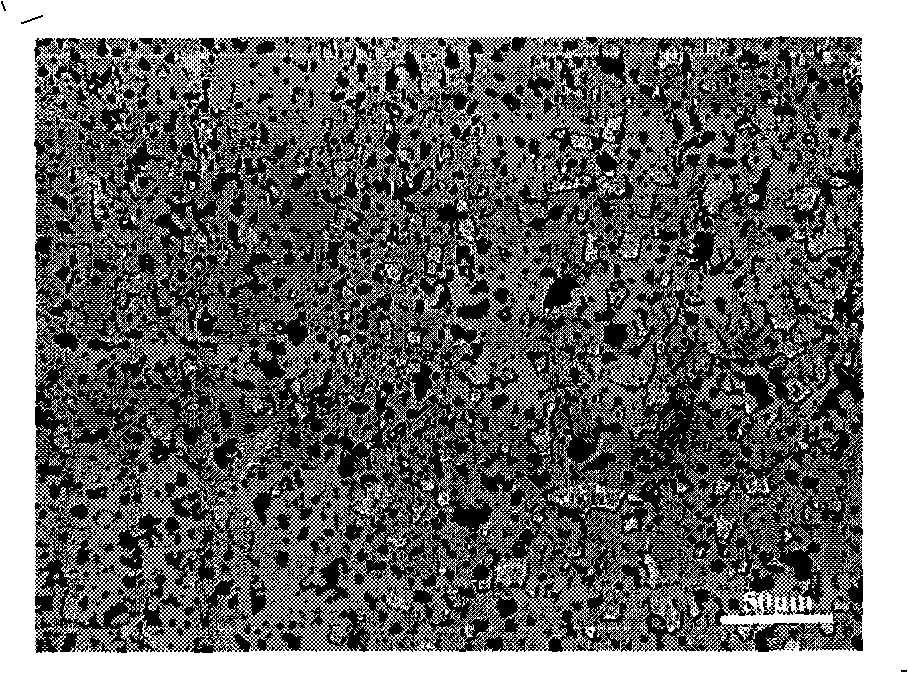

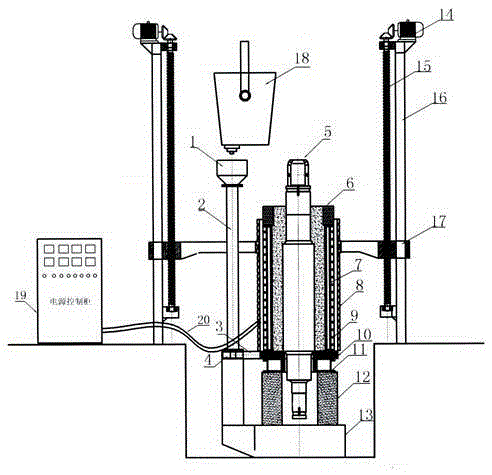

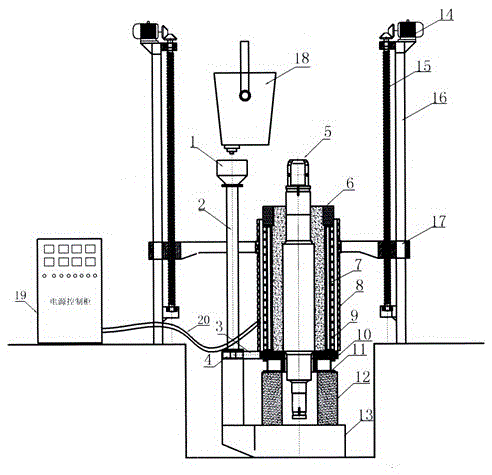

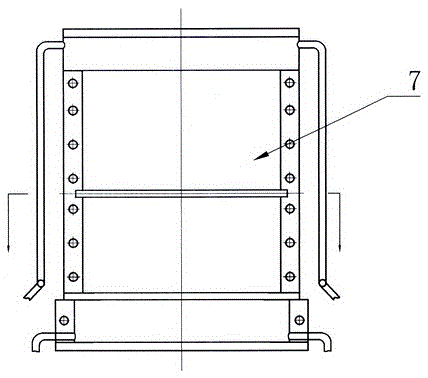

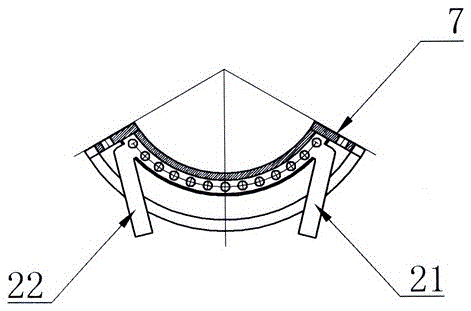

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Metal ceramic inert anode for molten salt electrolysis and preparation method thereof

InactiveCN101255577AAchieve densified sinteringImplementing Continuously Incrementing DistributionsElectrodesRare earthAlloy

The invention relates to a raw material component of cermet inert anode having metallographic phase distributed in gradient from internal side to external side and preparation technology. The material is applied to extracting non-ferrous metal (Al, rare earths and metals with high-melting point) by fused salt electrolytic route. The component comprises the cermet formed by at least one Ca-Fe-Ni-O composite spinel oxide and at least one metallographic phase; wherein the anode material is composed of raw material with following mass prescription: 1% to 5% single metal or alloy, 1% to 99% spinel oxide, 0.1% to 10% other metal oxides; oxidizing the materials selectively in process of sintering the materials by adjusting oxygen content in whole atmosphere to form high strength, high tenacity, high conductivity inner layer (high content of metal) having anticorrosion outer layer (high content of oxides) functional gradient structure. The method of the invention is capable of effectively solving problems that the cermet inert anode is connected with the metal guide and the metallographic phase is dissolved and oxidized selectively in electrolytic process.

Owner:CENT SOUTH UNIV

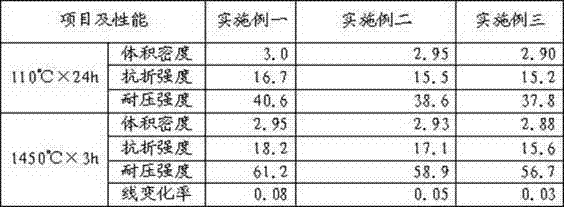

Castable for major iron runner of blast furnace larger than 2500m<3>

InactiveCN102746012AImproved thermal shock stabilityImprove insulation effectCarbon compositesSilicic acid

Owner:JIANGSU DAOJUE GRAND NEW ENERGY VEHICLE

1080 m<3> blast furnace main iron runner castable

InactiveCN102757252AImproved thermal shock stabilityImprove insulation effectCarbon compositesSilicic acid

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Small blast furnace main iron runner castable

InactiveCN103803994AImprove thermal shock resistanceImprove corrosion resistanceStrontium titanateSludge

The invention relates to a small blast furnace main iron runner castable, belonging to the field of refractory castables. The small blast furnace main iron runner castable comprises the following components in parts by weight: 48-56 parts of alumina, 1-8 parts of zirconium mullite hollow sphere, 3-10 parts of metallic silicon powder, 10-25 parts of gahnite powder, 10-15 parts of waste smelting furnace casing, 3-10 parts of strontium titanate powder, 1-2 parts of Gangxi sludge, 1-5 parts of silicon nitride, and additionally 0.1-0.2 part of sodium tripolyphosphate, 0.05-0.2 part of styrene maleic anhydride and 3-8 parts of aluminum sol suspension. The waste smelting furnace casing is a graphite production furnace casing which is mainly composed of 56-68% of SiC, 10-20% of C and 3-10% of SiO2. The blast furnace iron runner prepared from the castable has the characteristics of favorable thermal shock resistance, high corrosion peeling resistance, high iron flux and long service life.

Owner:占丽青

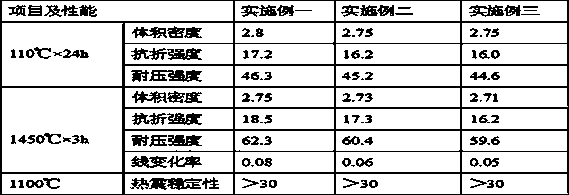

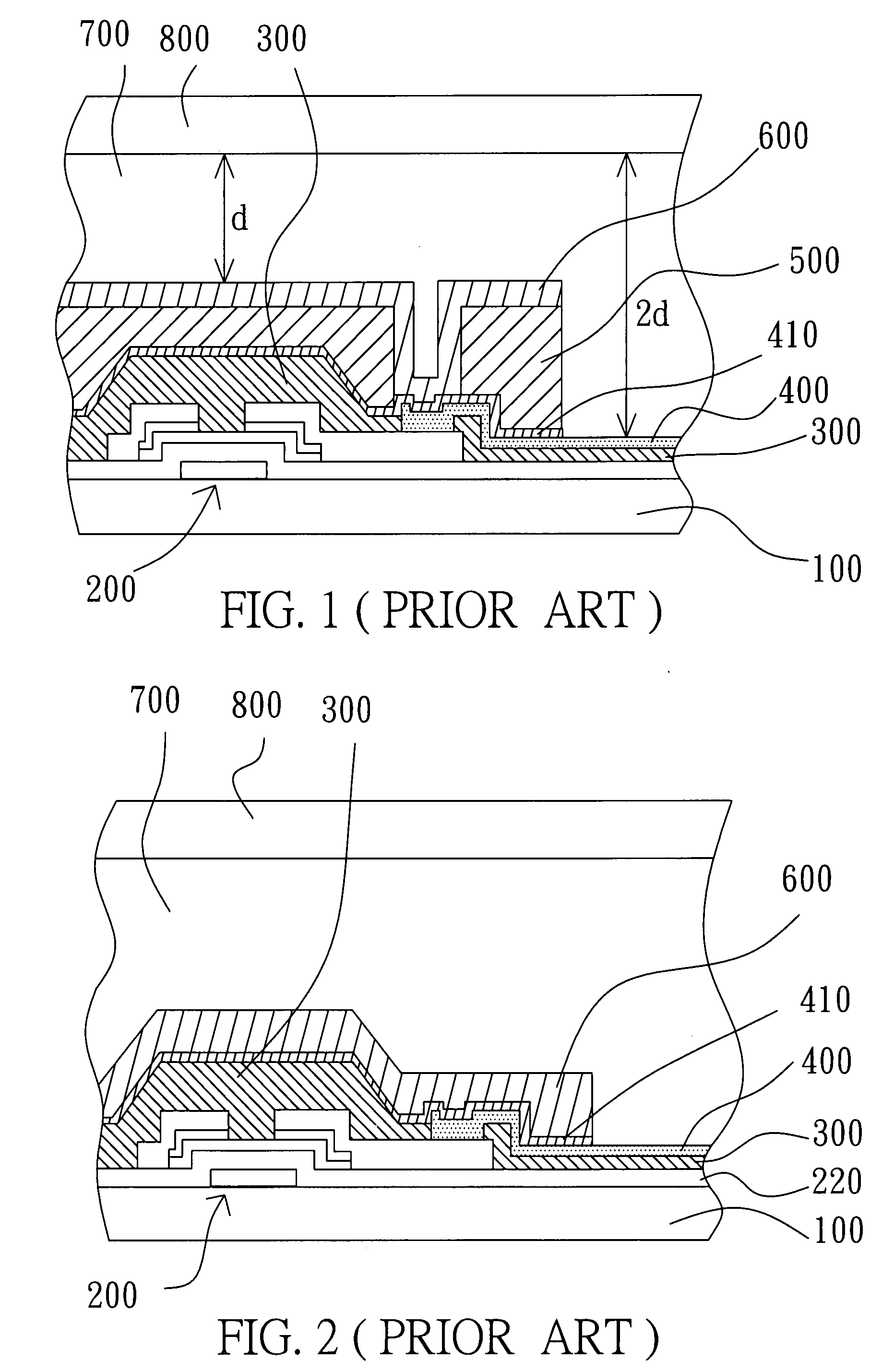

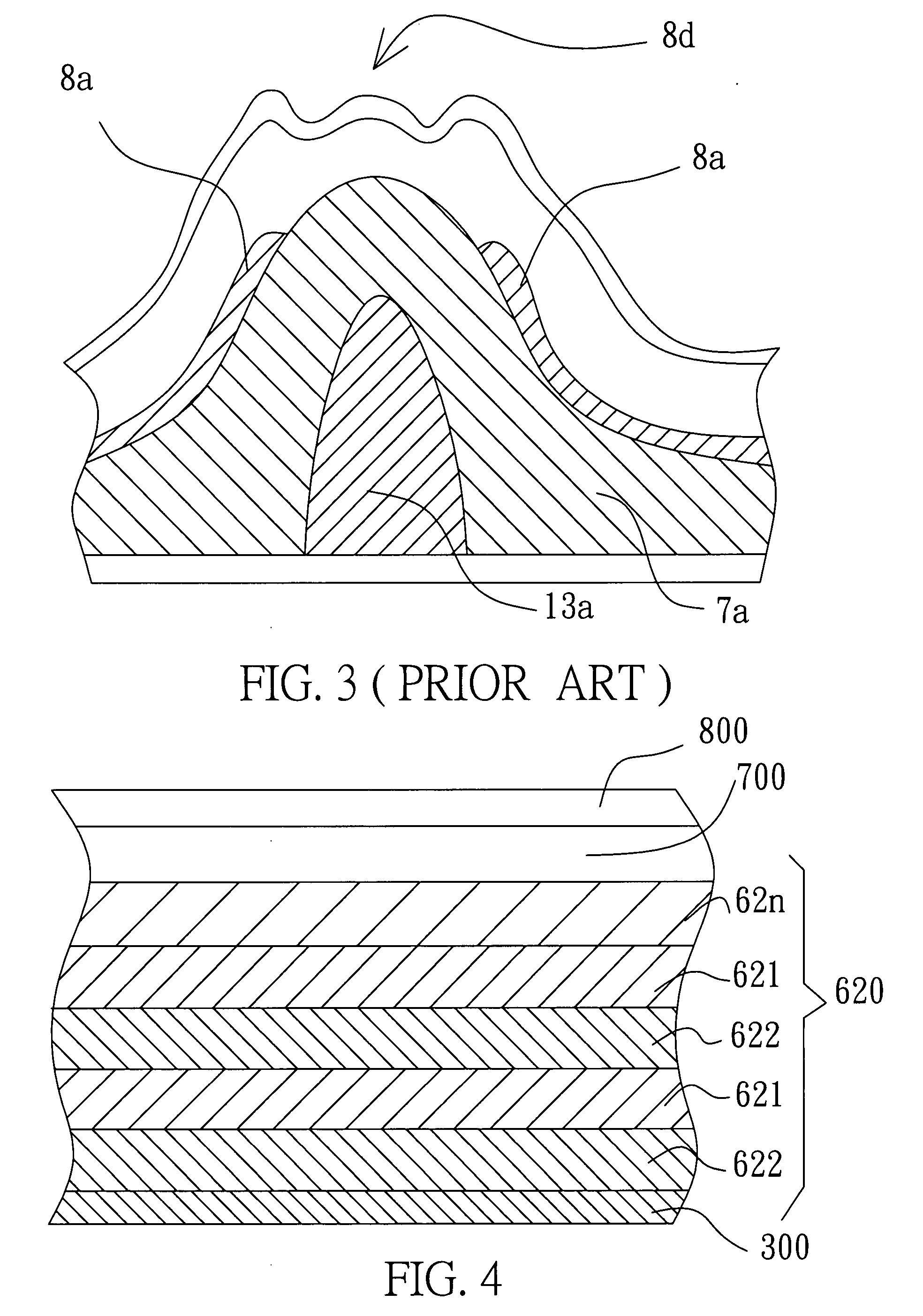

Trans-reflective liquid crystal display and manufacturing method thereof

InactiveUS20080111959A1Increase profitImprove adhesionSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayRefractive index

The structure of a trans-reflective liquid crystal display panel includes stacks in longitudinally and two areas in transversely, which are reflective area and transmissive area. A thin-film-transistor layer and a dielectric layer are formed on a substrate in sequential. For the transmissive area, a transparent conductive film, such as a pixel electrode, is formed. For the reflective area, a reflective film with multi-layer is formed on the dielectric layer and then the thin-film-transistor layer. After assembling, the trans-reflective liquid crystal display is complete. The materials of the reflective film with multi-layer and the dielectric layer are similar to have greater adhesion. Each layer of the reflective film with multi-layer includes two sublayers, the first reflective sublayer and the second reflective sublayer, which have the different refractive indexes. By modifying the temperature, pressure, gas flow and power of emitting in manufacturing process can make the refractive indexes of both layers.

Owner:CHUNGHWA PICTURE TUBES LTD

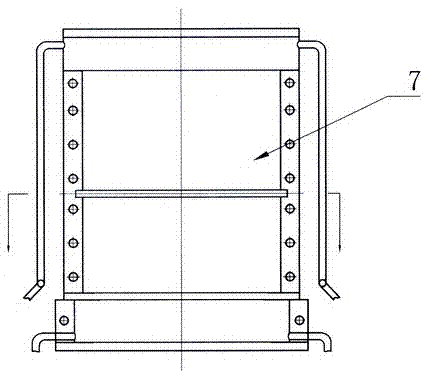

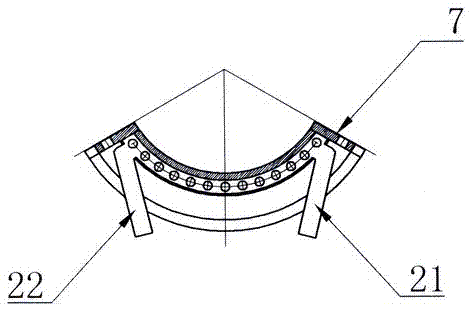

Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Cultivation method for clump planting of arbor

ActiveCN103988651ASolve peelingSolve the problem of slow root growthHorticulture methodsFertilizer mixturesMushroomSeedling

The invention discloses a cultivation method for clump planting of arbor. The method includes the following steps of seedling selection, seedling processing, seedling clump planting, watering for root fixing, spray wet curing and mushroom soil covering. Through the method, in the whole cultivation process of clump planting of arbor, the seedling selection, soil selection, plant water retention and soil water retention are scientifically controlled, and the problems of trunk peeling and slow root system growth easily occurring in the seedling clump planting are effectively solved. Root systems between seedlings planted through the cultivation method for clump planting of arbor are easy to twine to form an integrated root system, so that the problem of uneven seedling growth is solved, and integrity between seedlings is improved. Compared with the natural growing cluster seedling, the manifestation of the whole cluster of seedlings has more shaping advantages and better cost performance ratio.

Owner:FUJIAN SPRING ECOLOGICAL TECH CO LTD

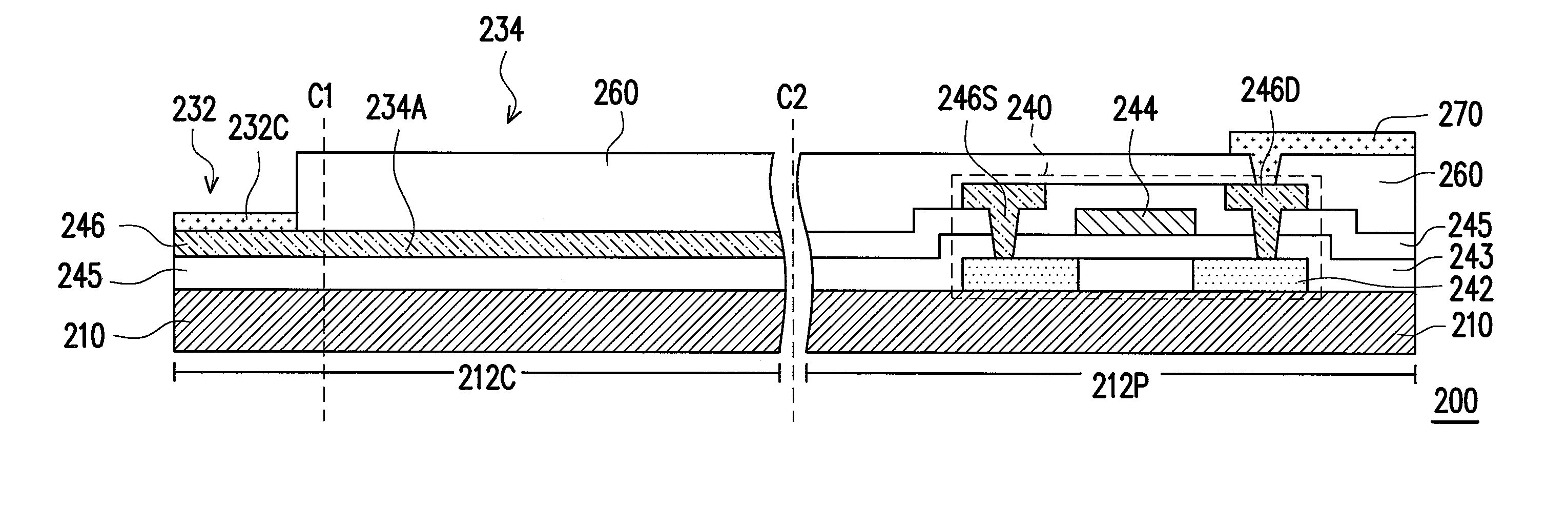

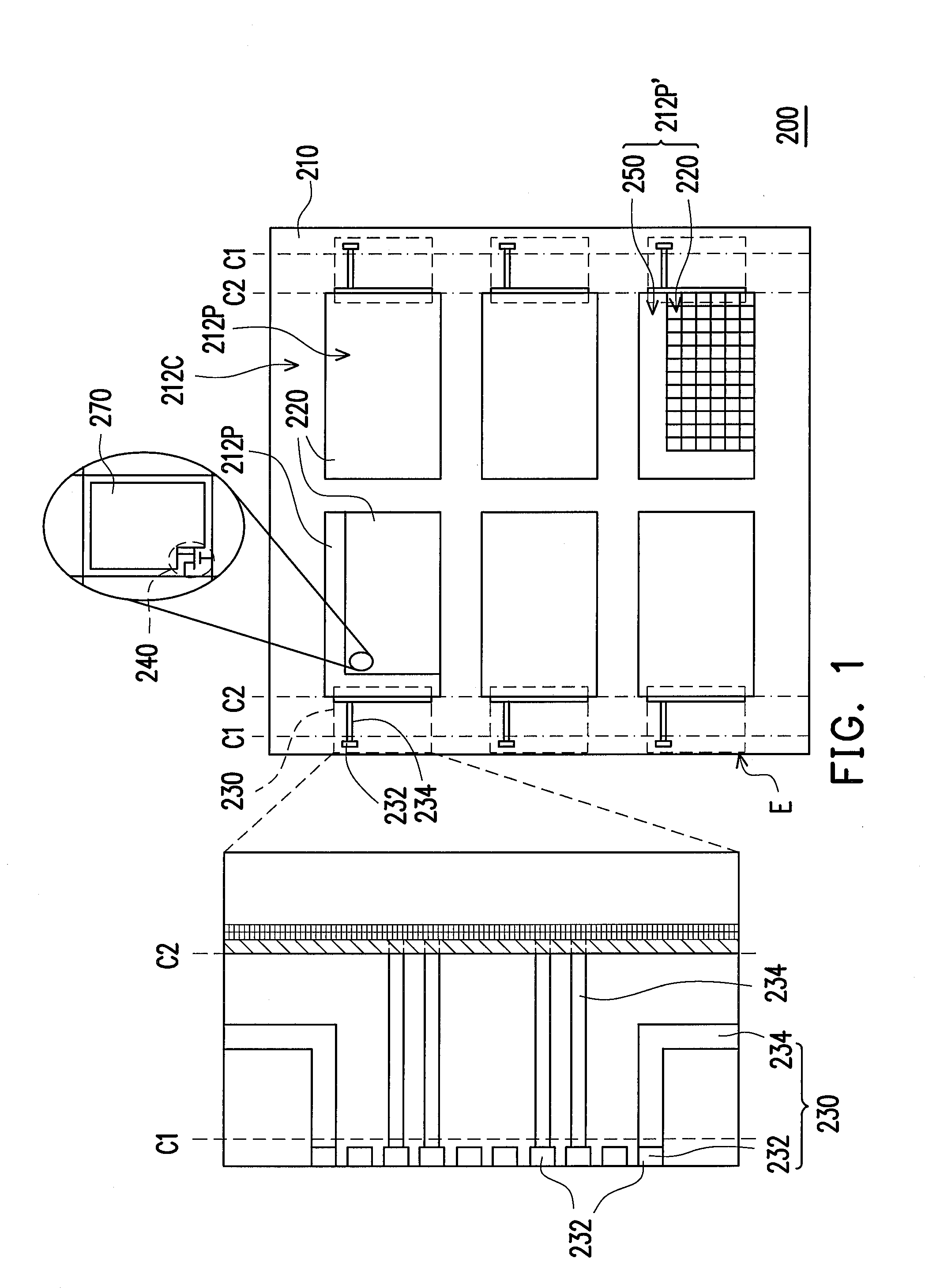

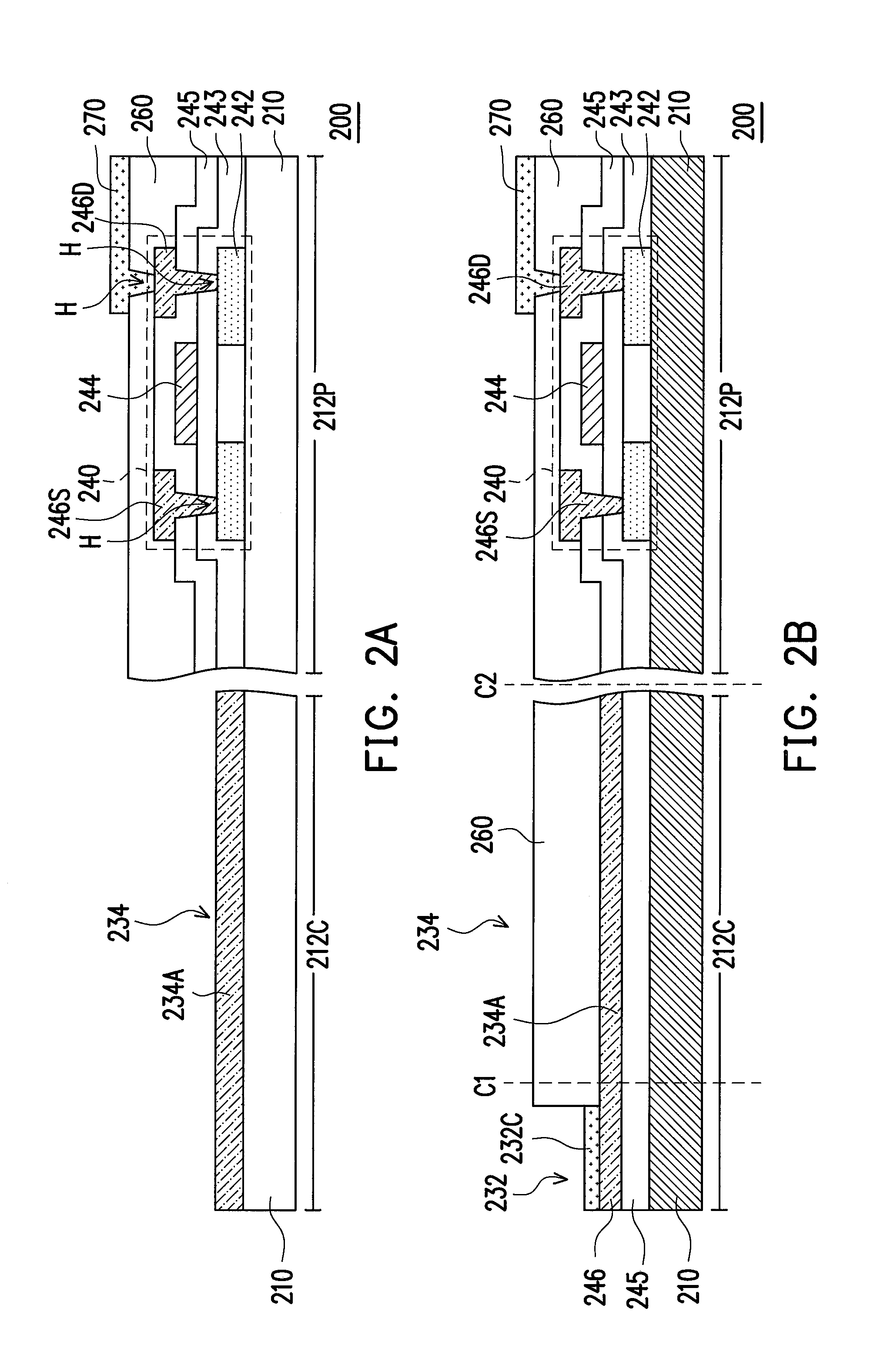

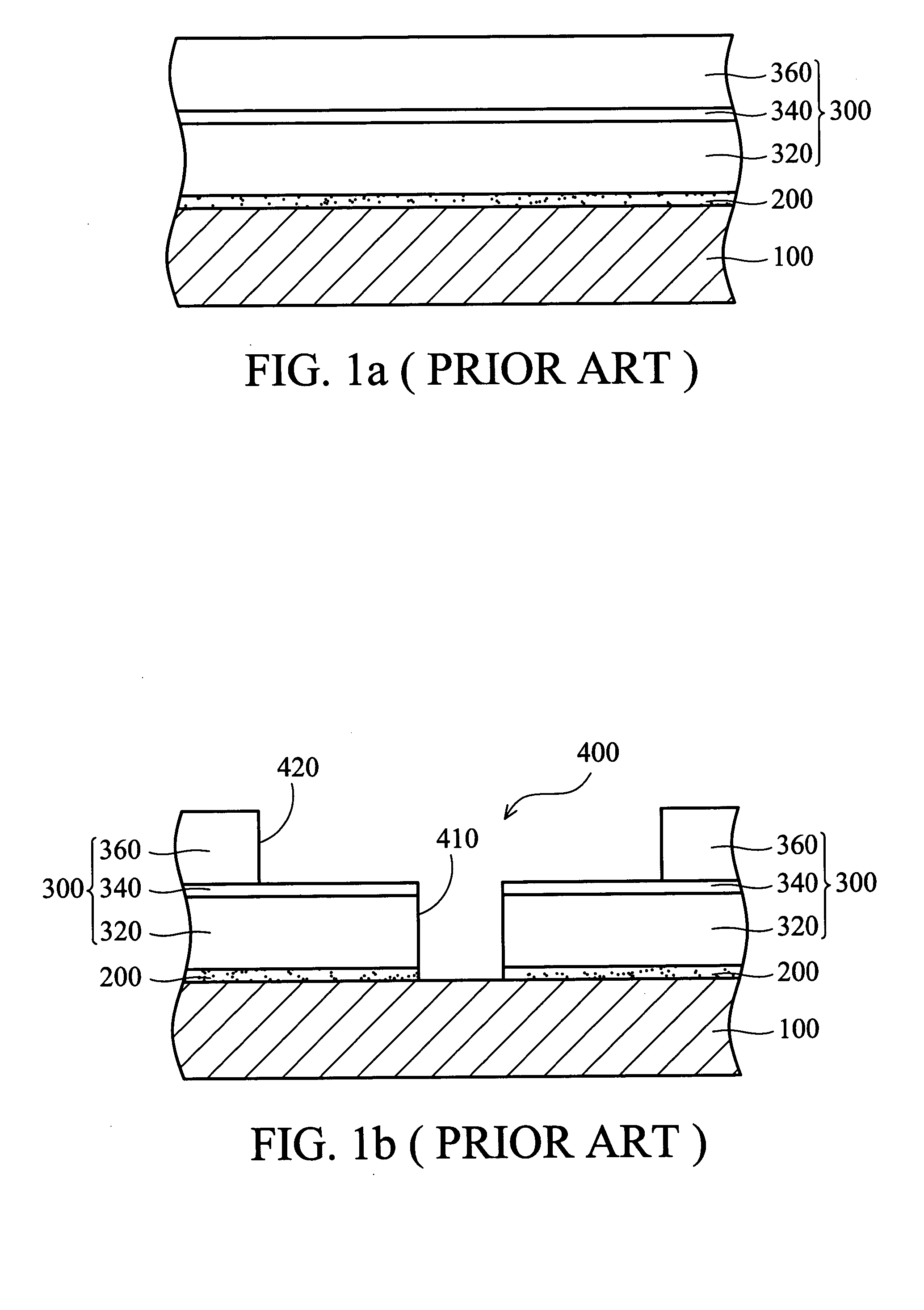

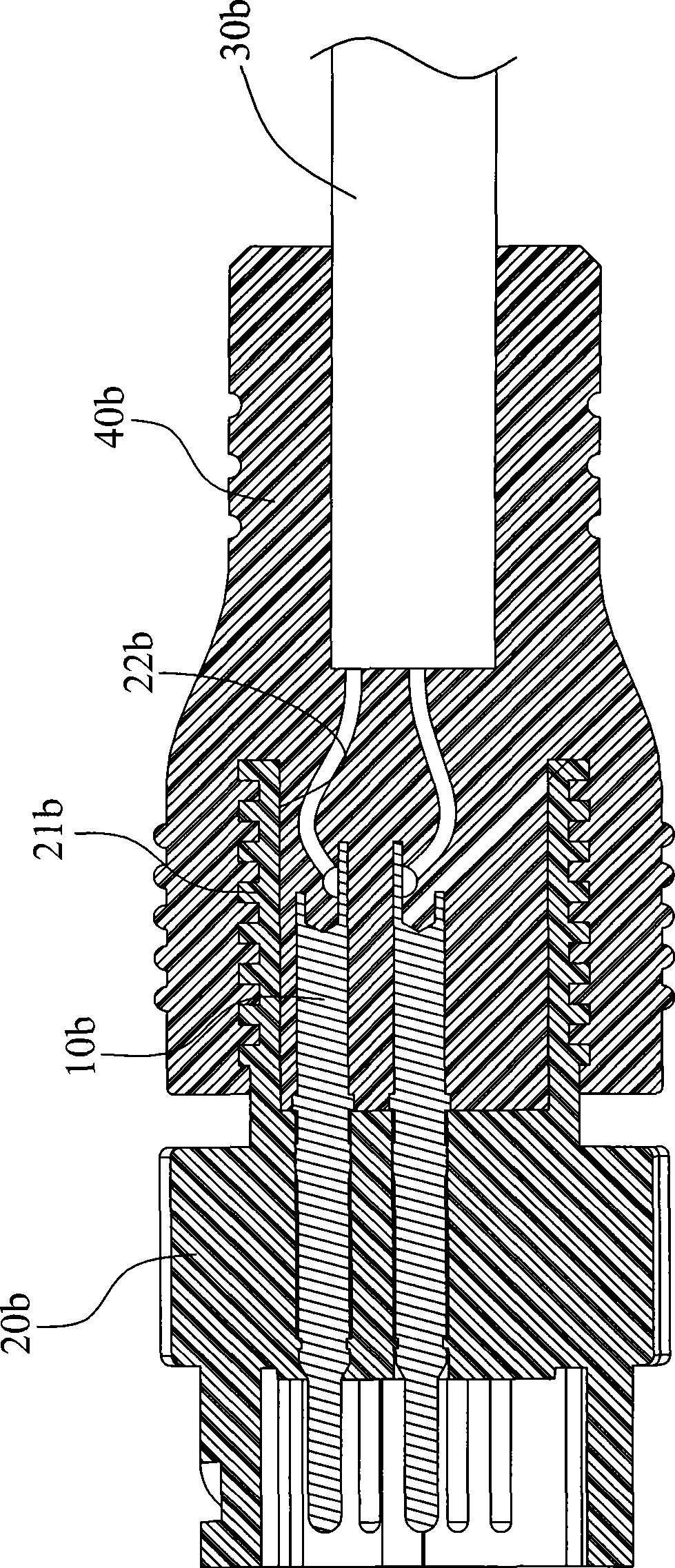

Active device array mother substrate and method of fabricating display panel

ActiveUS20110049521A1Prevent curingSolve peelingSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

An active device array mother substrate including a substrate, pixel arrays, and a polymer-stabilized alignment curing circuit is provided. The substrate has panel regions, a circuit region, a first cutting line, and a second cutting line. The first cutting line is disposed on the circuit region between an edge of the substrate and the second cutting line. The active devices of the pixel arrays have a semiconductor layer. The polymer-stabilized alignment curing circuit disposed on the circuit region includes curing pads disposed between the edge of the substrate and the first cutting line and curing lines having an upper conductive layer connected to the corresponding curing pads and the corresponding pixel array. The upper conductive layer is in the same layer as the source / drain conductor. Therefore, the curing lines are capable of preventing problems such as peeling, so as to keep the polymer-stabilized alignment curing circuit operating normally.

Owner:AU OPTRONICS CORP

Preparation method of nodular cast iron of alloy for roll

The invention discloses a preparation method of nodular cast iron of alloy for a roll. The nodular cast iron comprises the following components in percentage by mass: 3.6-3.8% of C, 1.8-2.0% of Si, 0.5-0.7% of Mn, 0.01-0.04% of P, 0.01% of S, 0.1-0.3% of Cr, 0.11-0.14% of Mo, 1.5-2.0% of Ni, 0.4-0.6% of Mg, 0.04-0.06% of Mo, 0.06-0.1% of Nb, 0.1-0.15% of Ti, 0.2-0.4% of V and the balance of Fe and inevitable trace elements. According to the preparation method, matching of alloy elements is reasonably optimized, the mass percentages of Ni and Cr are optimized and Nb, Ti and V are added for improving the components of the roll, so that the morphology of carbides in the roll can be improved, the bending strength, impact toughness, deflection, area reduction rate, after-fracture elongation percentage and yield strength of the roll can be enhanced further, the problems that the inner surface layer of a hole slot in a finished-rolled roll body is peeled off can be solved, and the single-slot rolling quantity of a rolling mill can be increased.

Owner:QINGDAO LIANGLI PRECISION CASTING

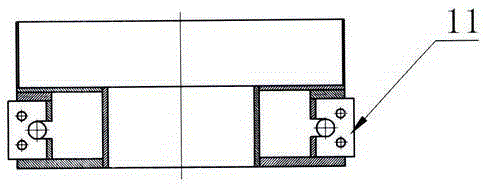

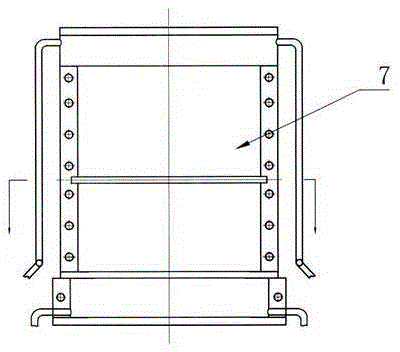

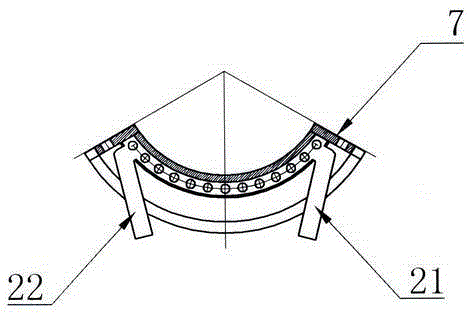

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

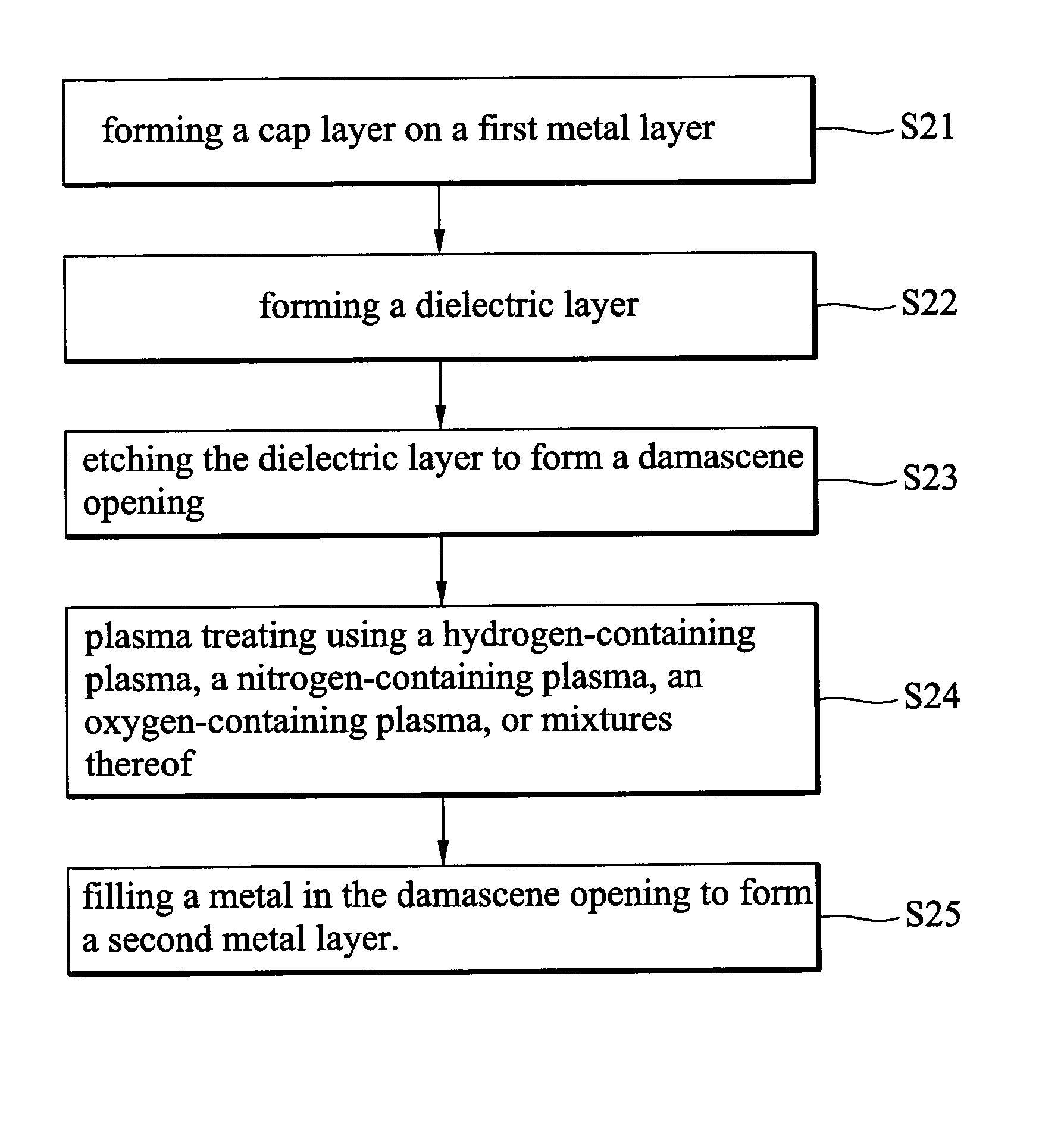

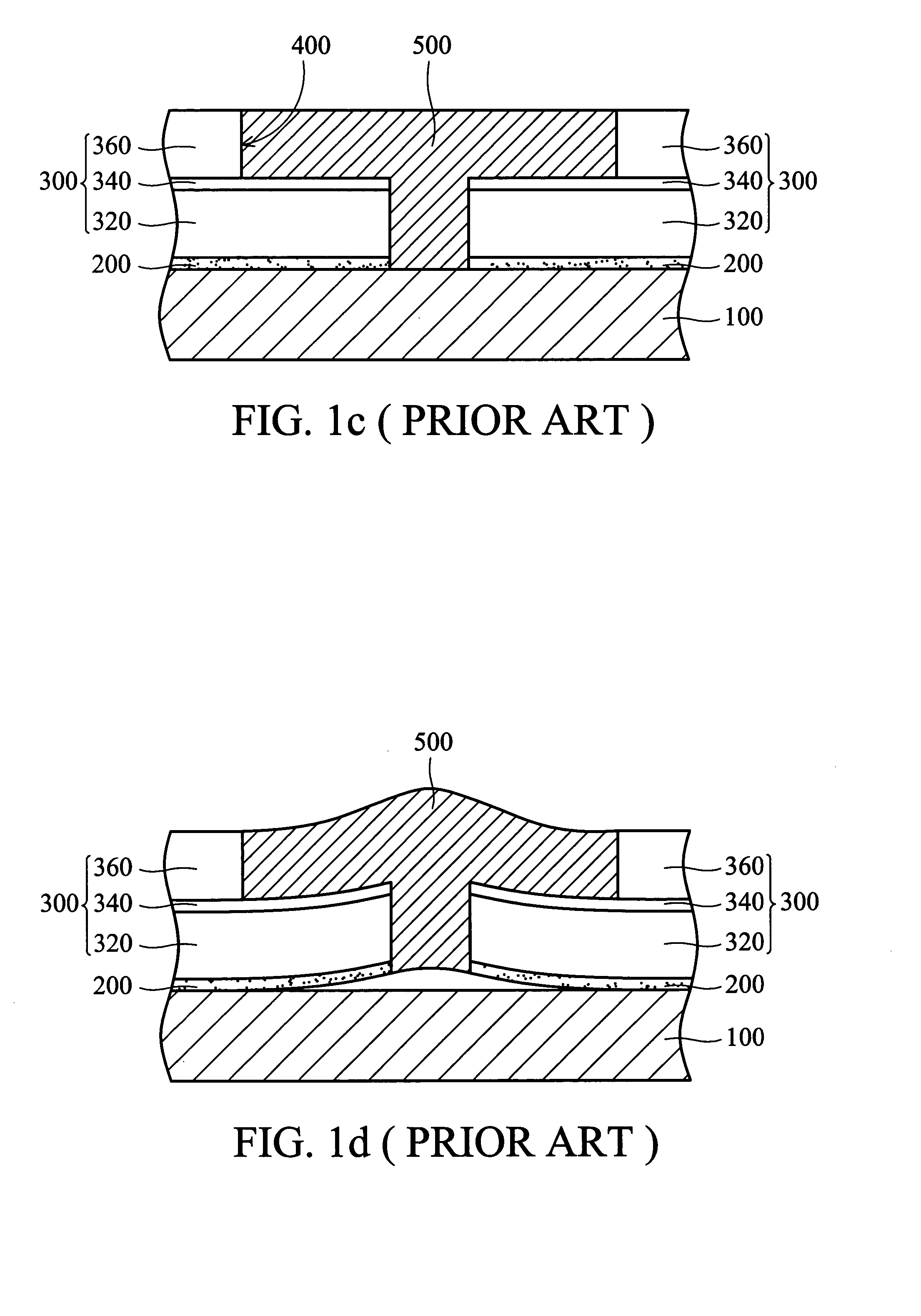

Process for forming metal damascene structure to prevent dielectric layer peeling

InactiveUS20050059233A1Eliminates peelGood adhesionSemiconductor/solid-state device manufacturingSemiconductor devicesPlasma treatmentFiller metal

A process for forming a metal damascene structure. First, a cap layer is formed on a first metal layer, and a dielectric layer is formed on the cap layer. Next, the dielectric layer is etched to form a damascene opening. Next, hydrogen-containing plasma, nitrogen-containing plasma, oxygen-containing plasma, or a mixture thereof is used to perform the plasma treatment. Next, a metal is filled in the damascene opening to form a second metal layer. Peeling of the dielectric layer due to remaining impurities is eliminated by the plasma treatment after etching of the damascene opening.

Owner:TAIWAN SEMICON MFG CO LTD

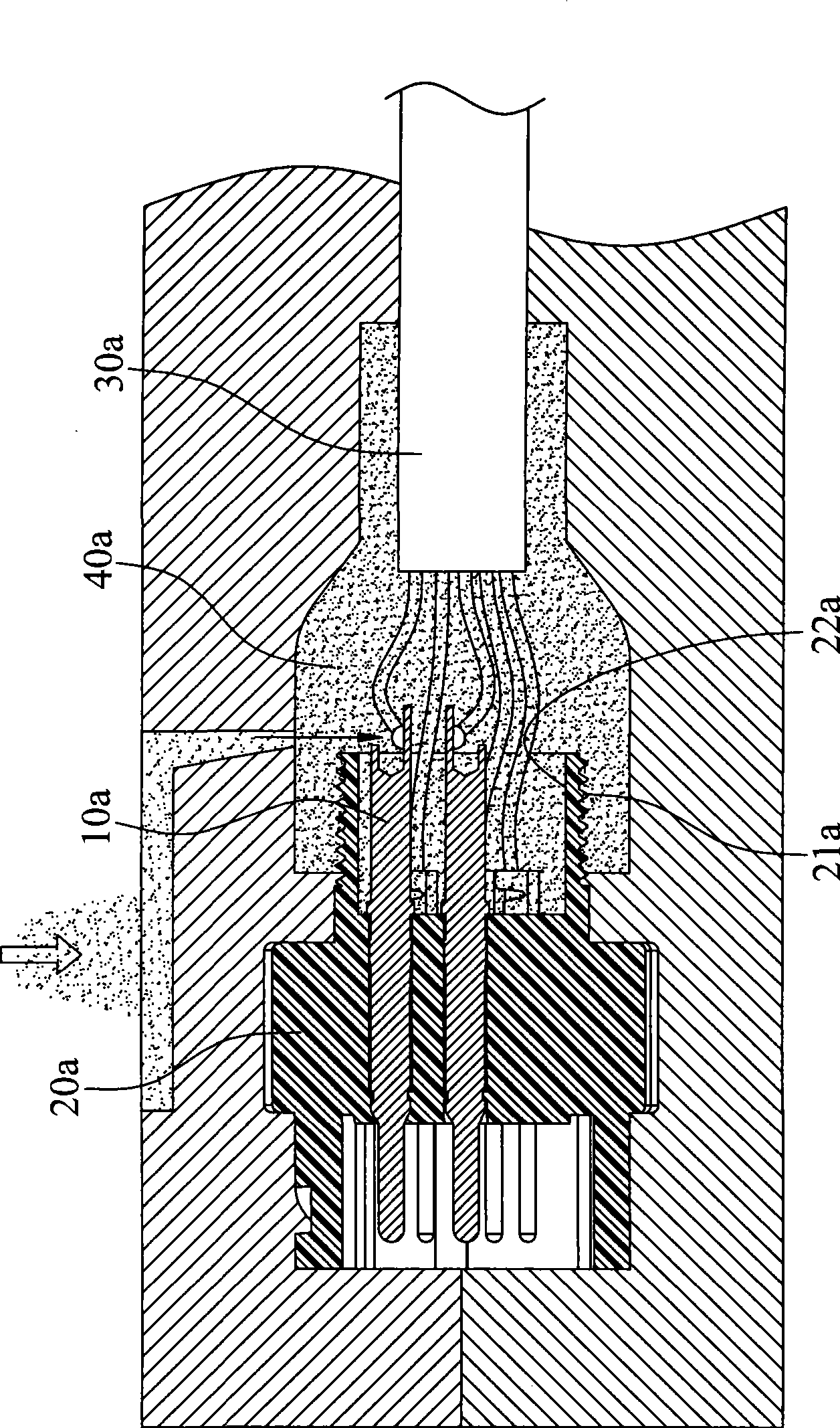

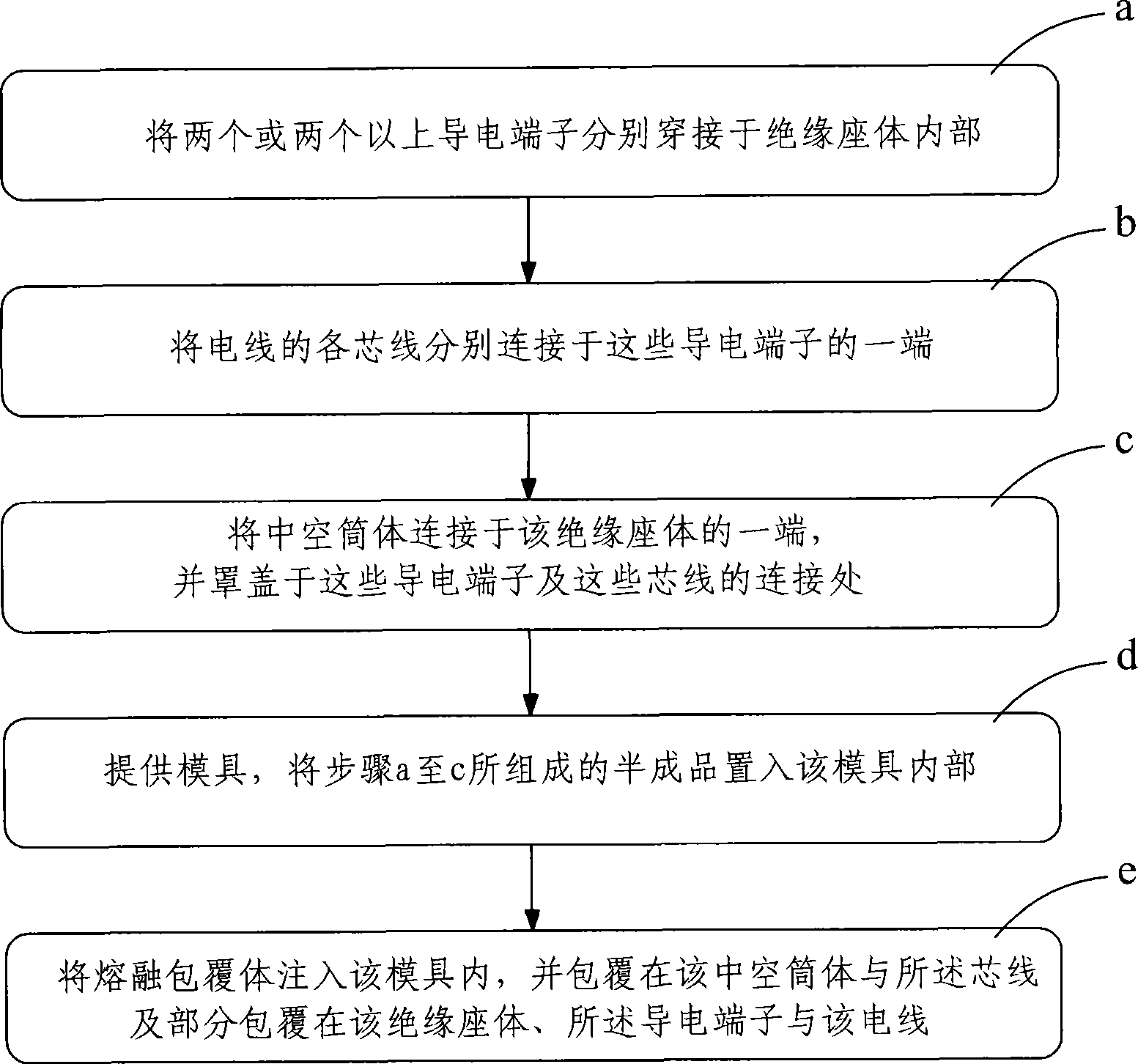

Waterproof connector and producing method thereof

InactiveCN101499585ASolve peelingImprove pass rateContact member cases/bases manufactureCouplings bases/casesWater vaporElectric wire

The invention relates to a waterproof connector and a manufacturing method thereof. The waterproof connector comprises a conductive terminal, an insulation seat, a wire, a hollow cylinder and a coating body; wherein, the conductive terminal fixedly penetrates the insulation seat; the insulation seat is provided with a connection segment; the wire is provided with two or more than two core wires; each core wire is respectively connected with one end of each conductive terminal; the hollow cylinder is connected with the connecting segment and arranged at one side of the wire; and the coating body is coated at one end of the connecting segment, the hollow cylinder, the core wire and the conductive terminal. In addition, the invention also provides a method used for manufacturing the waterproof connector, which can improve the passing rate of products and achieve the effect of preventing the water vapor from infiltrating.

Owner:LIANG TEI

2500 m<3> blast furnace main iron runner castable

InactiveCN102757253AImproved thermal shock stabilityImprove insulation effectCarbon compositesSilicic acid

The invention relates to a 2500 m<3> blast furnace main iron runner castable and belongs to the field of refractory castables. The 2500 m<3> blast furnace main iron runner castable comprises, by weight, 50-55 parts of special grade alumina, 1-8 parts of mullite hollow spheres, 3-10 parts of zirconium silicate, 10-25 parts of zinc-aluminum spinel powders, 10-15 parts of carbon composite materials, 3-10 parts of aluminum oxide micro powders, 1-2 parts of Guangxi mud, 0.1-0.2 part of sodium tripolyphosphate, 0.05-0.2 part of metal aluminum powders and 4-10 parts of silicon dioxide sol suspension liquids. A blast furnace main iron runner prepared by the castable has the advantages of being good in thermal shock stability, anti-stripping and long in service life.

Owner:HENAN POLYTECHNIC UNIV

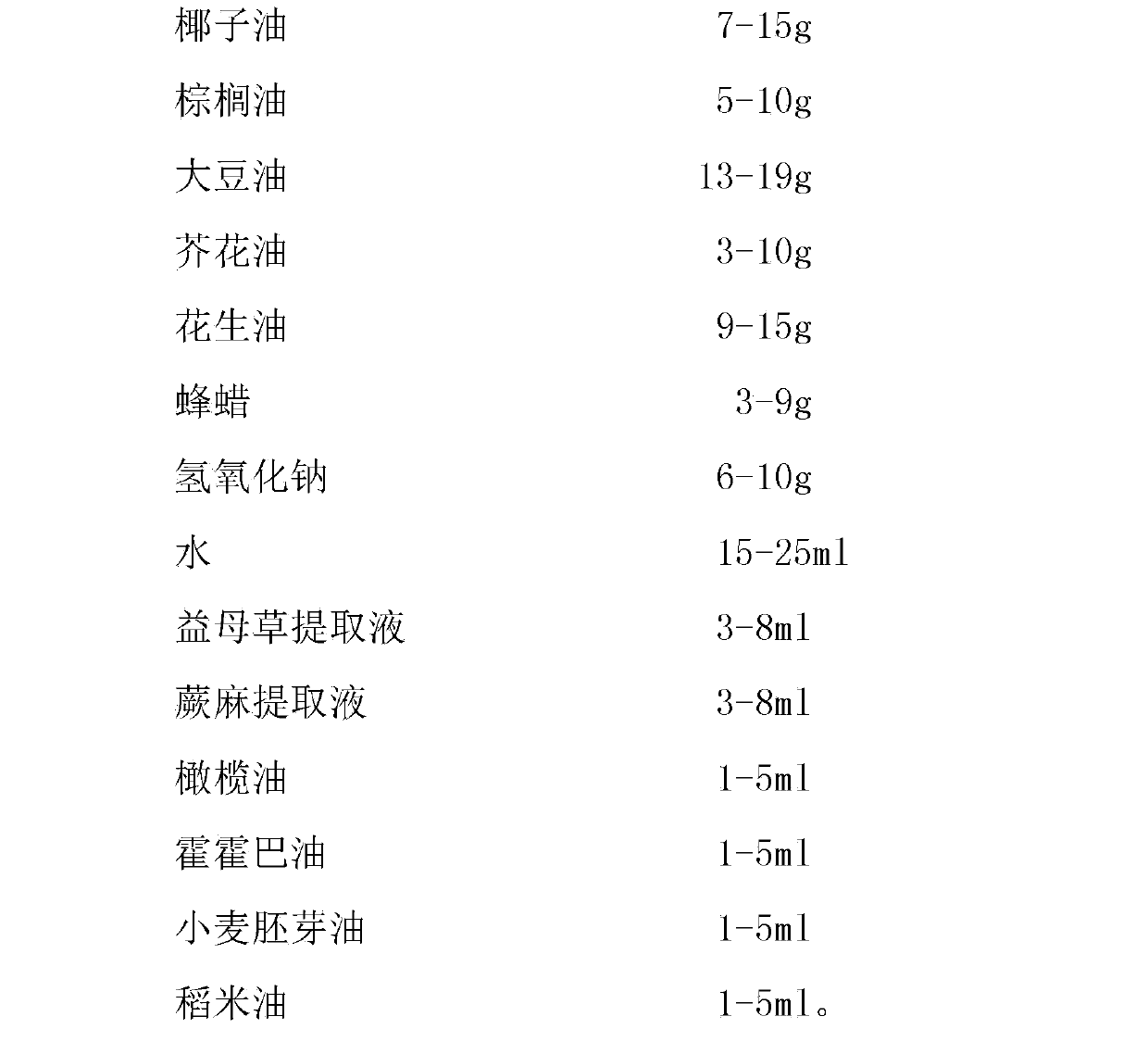

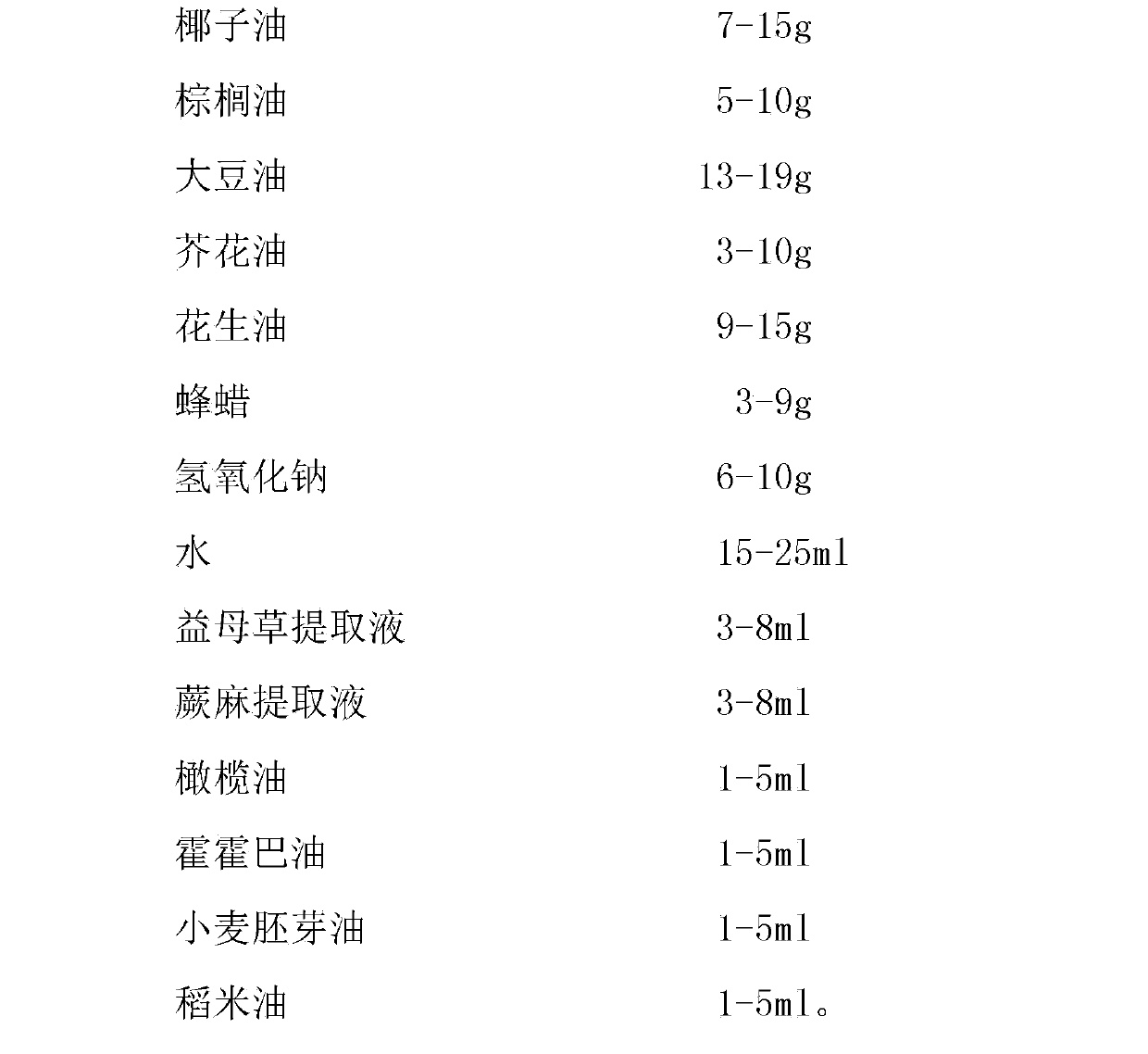

Skin-care whitening beautifying soap and preparation method thereof

InactiveCN103396906AImprove permeabilityImprove beauty effectSkin careDermatological disorderPotentilla anserinaJojoba oil

The invention discloses a skin-care whitening beautifying soap. Per 100 g of the beautifying soap contains the following substances: coconut oil, palm oil, soybean oil, mustard flower oil, peanut oil, beeswax, sodium hydroxide, water, a motherwort extract, a potentilla anserina extract, olive oil, JoJoBa oil,?wheat germ oil and rice oil. The skin-care whitening beautifying soap produced by the method provided by the invention has milk color, good stability, aroma smell, abundant foam, and can supply the skin with nutrients, deeply nourish the skin, and make the skin white, tender, smooth and elastic. Penetration and moistening of a plurality of oriental whitening plant extracts can be effectively absorbed by the skin, so as to effectively improve roughness, water shortage darkness and stains of the skin and make the skin moisturizing and white.

Owner:广州丹葶日用品实业有限公司

Moisturizing lip balm capable of fading lip line

InactiveCN107496214ASolve chappedSolve peelingCosmetic preparationsToilet preparationsSide effectSpermaceti

The invention discloses moisturizing lip balm capable of fading lip lines. The moisturizing lip balm capable of fading the lip lines is prepared from the following components in parts by weight: 25-35 parts of grape seed oil, 15-25 parts of arnebia root oil, 15-20 parts of camellia oil, 5-9 parts of honeysuckle extract, 6-10 parts of chamomile extract, 5-7 parts of lotus extract, 5-7 parts of rose essence, 1-3 parts of peppermint essence, 4-6 parts of scabish, 6-8 parts of rosemary, 8-10 parts of witch hazel, 2-4 parts of liquorice, 8-12 parts of aloe, 3-5 parts of honey, 10-12 parts of beewax, 8-10 parts of spermaceti wax, 0.6-1 parts of multivitamin, 0.3-0.5 part of collagen and 15-25 parts of deionized water. The moisturizing lip balm capable of fading the lip lines is a traditional Chinese medicinal formula composed of pure natural plants, has no toxic or side effect on skin and can be used for solving the problems of lip crack, decrustation and pigment deposition which are caused by long-term use of lipsticks and lip balms on the existing market more or less as well as contact cheilitis of people with sensitive skin.

Owner:赵宏耀

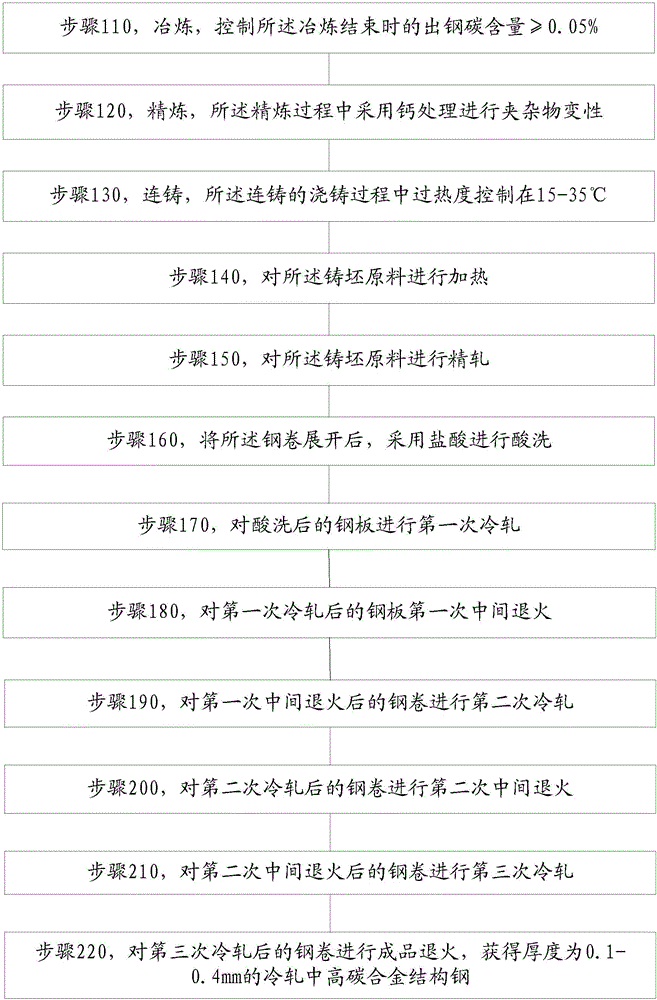

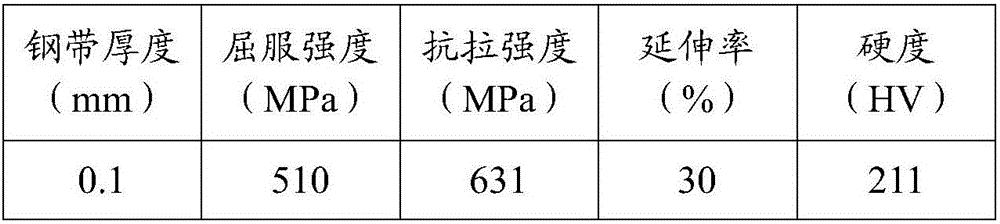

Manufacturing method of cold-rolled medium-high carbon alloy structural steel with thickness ranging from 0.1 mm to 0.4 mm

The invention discloses a manufacturing method of cold-rolled medium-high carbon alloy structural steel with the thickness ranging from 0.1 mm to 0.4 mm. The cold-rolled medium-high carbon alloy structural steel is prepared from components in percentage by weight as follows: 0.25%-0.55% of C, 0.15%-0.35% of Si, 0.10%-2.0% of Mn, 0.10%-2.0% of Cr, 0.010%-0.030% of Alt, less than or equal to 0.015% of P, less than or equal to 0.005% of S, no more than 0.3% of other added alloy elements and the balance of Fe and inevitable impurity elements. The manufacturing method comprises steps as follows: smelting, refining, continuous casting, heating, finish rolling, pickling, cold rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling and finished product annealing. Through control on inclusions in the steel, three times of cold rolling and three times of annealing, a cold-rolled medium-high carbon alloy structural steel strip with the thickness ranging from 0.1 mm to 0.4 mm is obtained. The total reduction rate of first-time cold rolling and second-time cold rolling is controlled to be larger than or equal to 50%, and the single-pass reduction rate is larger than or equal to 10%, so that lamellar carbide in different areas are crushed, the carbide is evenly separated out in the shape of fine particles through long-time low-temperature intermediate annealing, the strength is further reduced, and the plasticity is further improved.

Owner:武汉钢铁有限公司

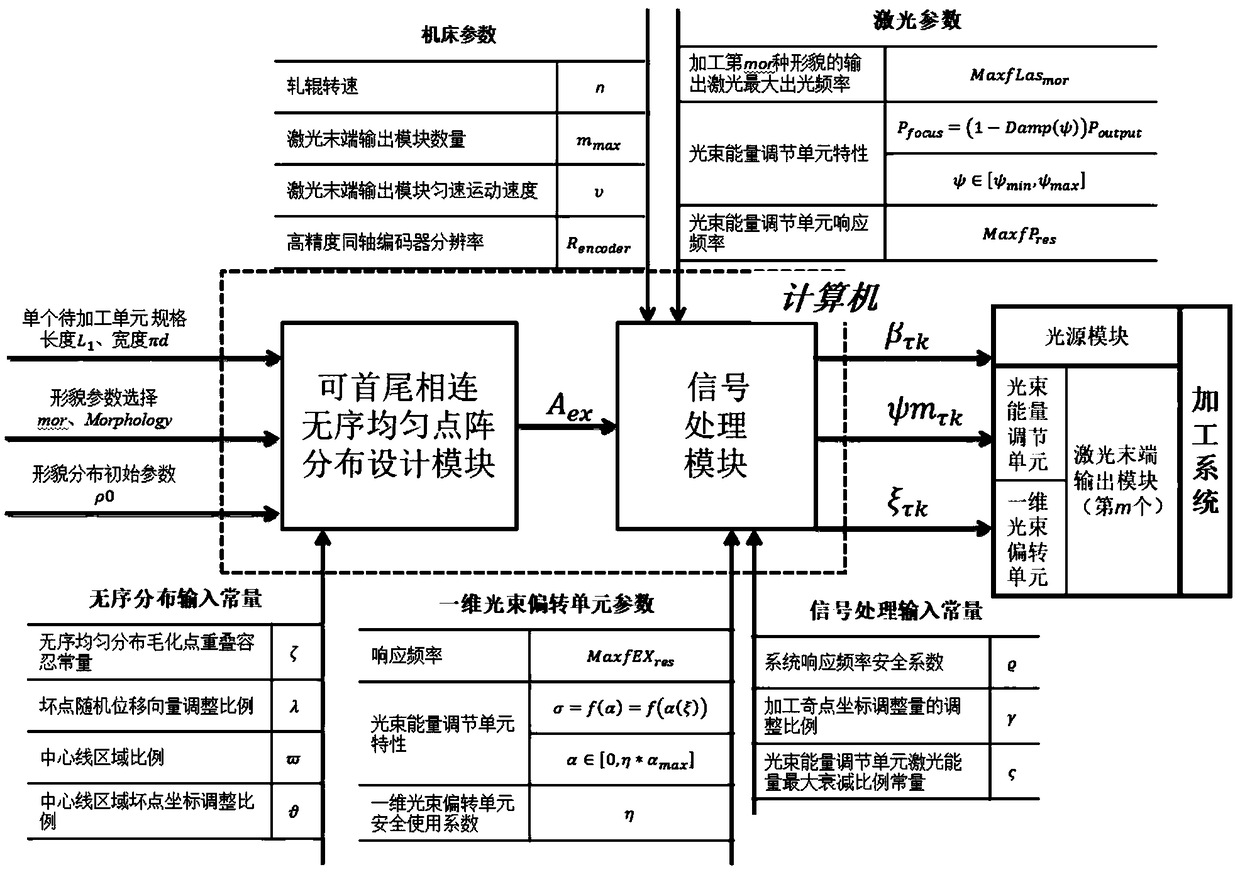

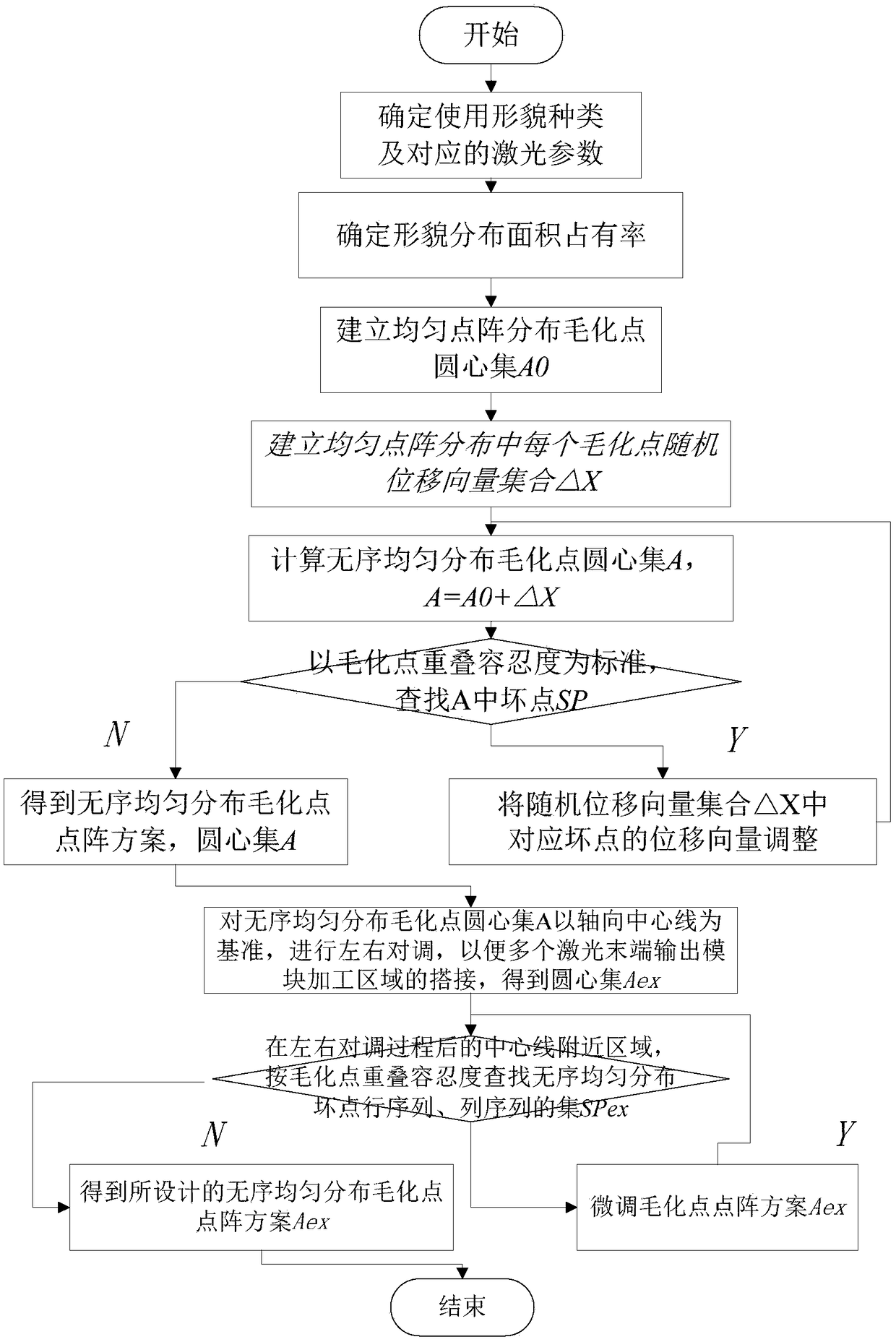

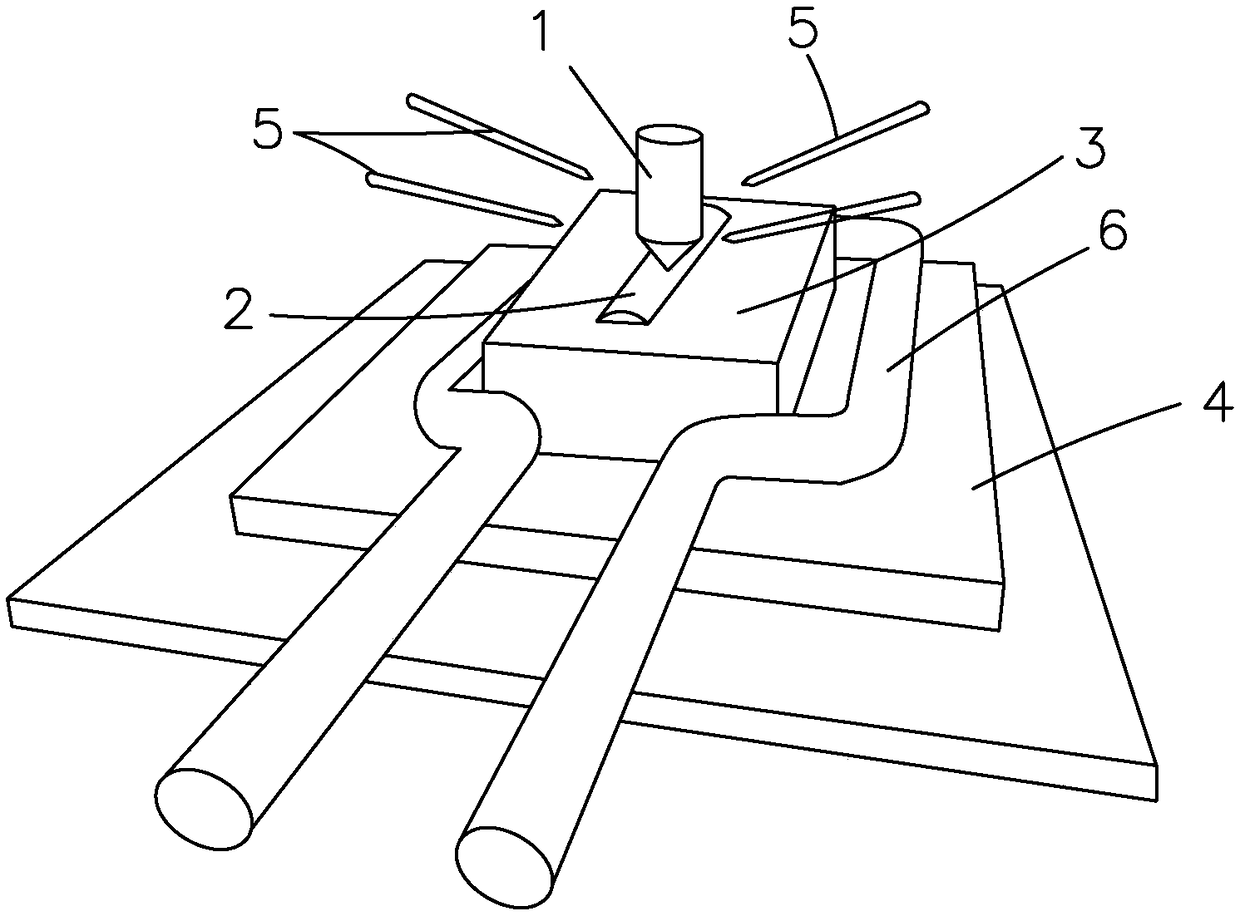

Roller laser roughening machining equipment and machining method thereof

ActiveCN109365993AGuaranteed degree of disorderImprove consistencyWelding/cutting auxillary devicesAuxillary welding devicesOptical beam deflectionLight beam

The invention provides roller laser roughening machining equipment and a machining method thereof. The machining method comprises the following steps that machining area division is conducted; a distribution scheme is determined, and the end-to-end connected disordered uniform distribution roughening lattice distribution scheme can be obtained according to roller machining unit parameters and shape parameters; output signals are determined, and laser light emitting position signals, light beam energy adjusting signals and one-dimension light beam deflection unit deflection signals are obtainedthrough an information processing module; roller laser roughening machining is conducted, and the laser light emitting position signals are used for controlling a light source module to emit lasers;and the light beam energy adjusting signals and the one-dimension light beam deflection unit deflection signals are input into laser tail end output modules for generating disordered laser lattices, and each laser tail end output module is used for machining one roller machining unit. By means of the roller laser roughening machining equipment and the machining method thereof, shape distribution uniformity can be ensured while the roughening point disordered degree is guaranteed, and consistency of the surfaces of produced cold-rolled plates in subsequent coating treatment is better.

Owner:JIANGSU UNIV

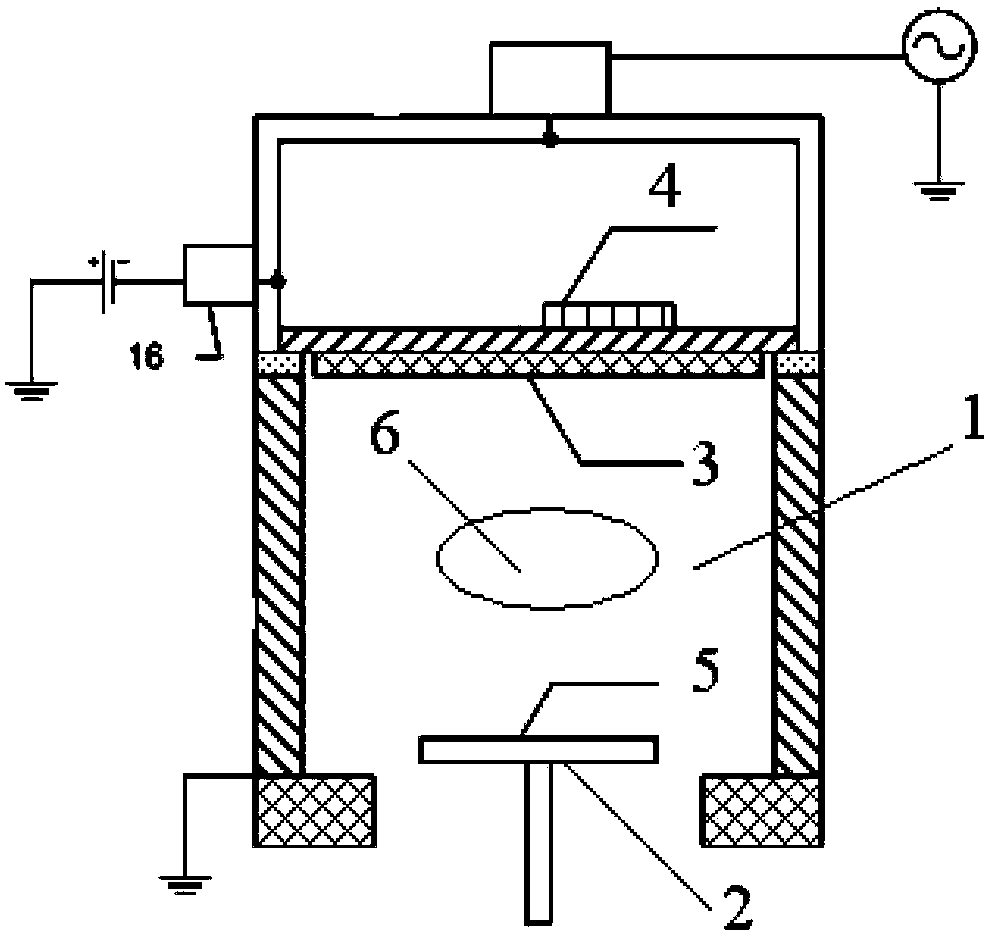

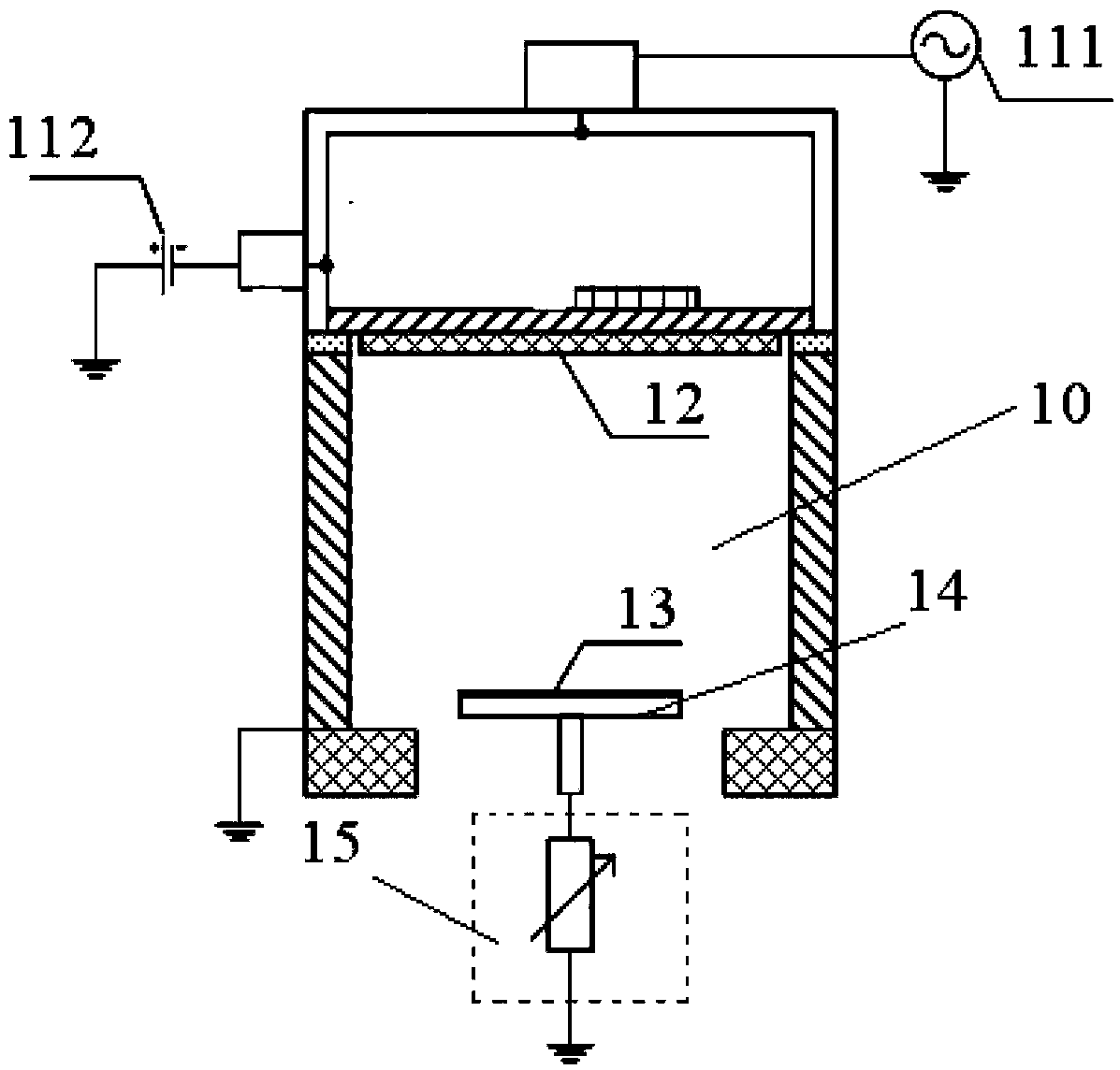

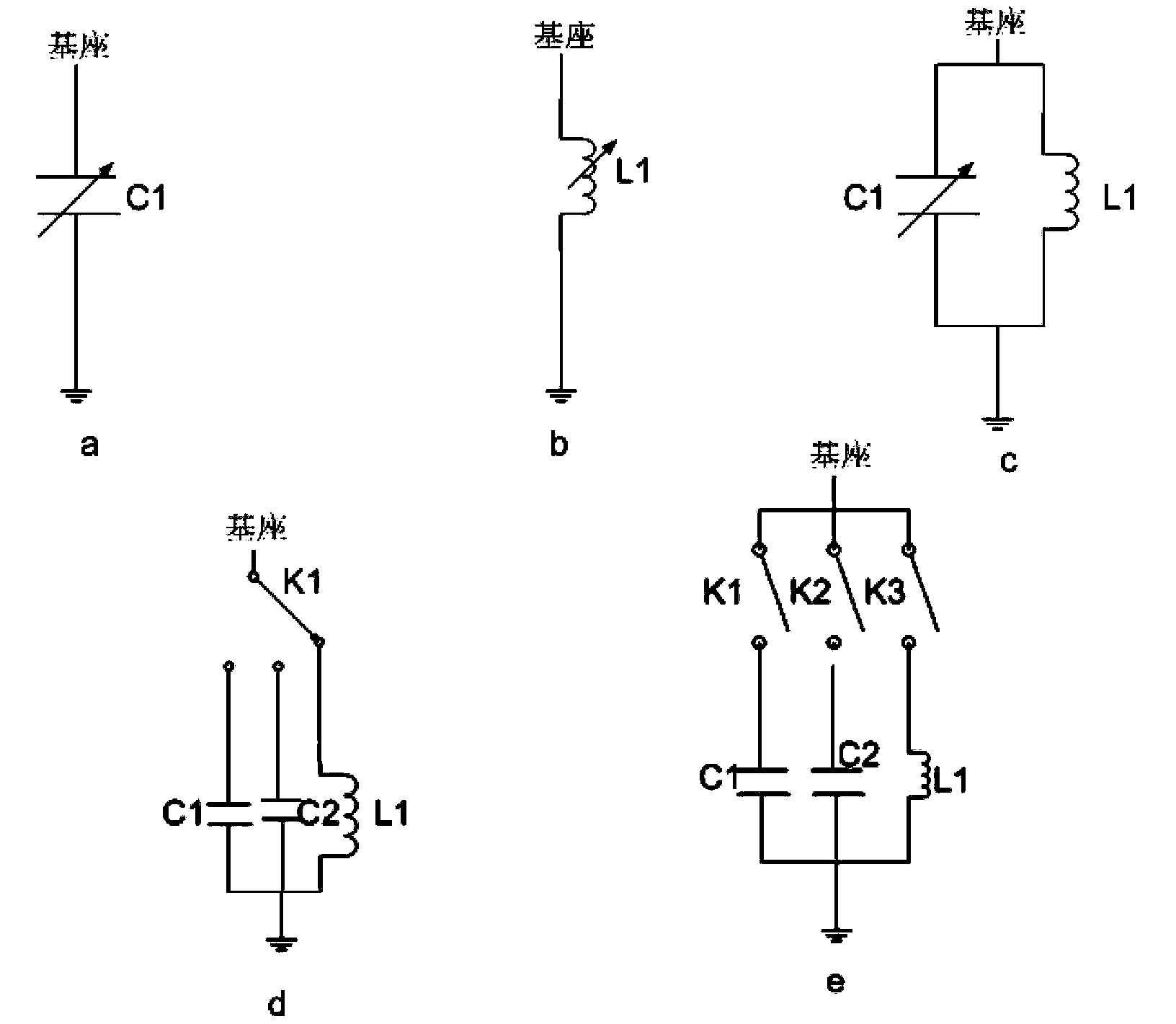

Magnetron sputtering equipment and method

ActiveCN104164653APrevent peelingSolve peelingVacuum evaporation coatingSputtering coatingBack biasSputter deposition

The invention provides magnetron sputtering equipment and method. The equipment and method are used for bombarding a thin film layer surface deposited on a machined workpiece surface after magnetron sputtering deposition, and therefore the thin film layer surface is made to be roughened. The magnetron sputtering equipment comprises a reaction cavity, a sputtering power source, a base, a target material, a bombardment gas source and a bias voltage unit, the sputtering power source is electrically connected with the target material, and is used for outputting sputtering power to the target material, and after magnetron sputtering deposition is completed, the bombardment gas source is used for leading bombardment gas which does not react with a thin film deposited on the machined workpiece surface into the reaction cavity, and the bombardment gas is excited by the bias voltage unit and / or the sputtering power source to form plasmas. The bias voltage unit is used for loading back bias voltages to the base so as to enable the plasmas to bombard the thin film surface, formed after magnetron sputtering deposition, of a machined workpiece. The magnetron sputtering equipment can solve the metal electrode layer peeling problem, the production investment cost is low, and the original technological process can be kept basically unchangeable.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

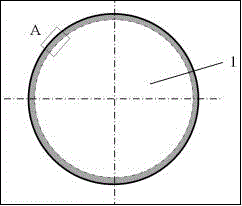

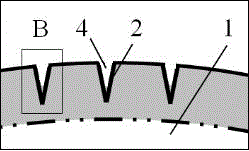

Hot-rolling work roll with micron-grade tungsten carbide enhancement layers and manufacturing method thereof

ActiveCN106040744AImprove surface strengthHigh surface hardnessSolid state diffusion coatingFurnace typesWork rollMegasonic cleaning

The invention discloses a hot-rolling work roll with micron-grade tungsten carbide enhancement layers. The hot-rolling work roll comprises a hot-rolling work roll body. The surface of the hot-rolling work roll body is provided with multiple sunken pipe-like bodies. The surface of the hot-rolling work roll body is provided with the micron-grade tungsten carbide enhancement layer. The inner surface of each pipe-like body is provided with one micron-grade tungsten carbide enhancement layer. According to the manufacturing method of the hot-rolling work roll, surface treatment is carried out on the hot-rolling work roll body; then laser drilling, acid pickling and ultrasonic cleaning are carried out; the cleaned hot-rolling work roll body with the sunken pipe-like bodies is subjected to carburizing in a vacuum carburizing furnace, and a composite body with the micron-grade tungsten carbide enhancement layers is obtained; finally, aftertreatment is carried out to obtain the hot-rolling work roll with the micron-grade tungsten carbide enhancement layers. The hot-rolling work roll solves the problem that roll surface spalling of an existing hot-rolling work roll occurs under the severe working condition, the overall mechanical property, the heat-resisting property and the wear-resisting property of the composite material are improved, and the manufacturing method is simple and easy to implement.

Owner:湖北广力轧辊有限公司

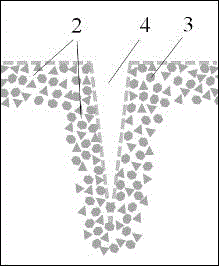

Osteoid structure biological ceramic composite material with adjustable coating thickness

The invention discloses an osteoid structure biological ceramic composite material with adjustable coating thickness, which is prepared from the following raw materials in weight percentage: 1-3% of rare earth, 70-74% of Ca.HPO4.2H2O, and 23-29% of CaCO3. The thickness of a coating prepared by adopting the osteoid structure biological ceramic composite material can achieve 3mm. The invention has the advantages as follows: the rare earth is added into the composite biological material, so that the stability of a HAP phase structure is improved. The coating prepared by adopting the composite material mainly contains hydroxyapatite with stable property, tertiary calcium phosphate, degradable calcium pyrophosphate and calcium titanate, so that the biocompatibility is excellent; the coating and a matrix are combined in a chemical metallurgic manner, so that the combination strength is high and the problem that the biological ceramic coating drops off during clinic application can be solved. Meanwhile, the raw materials are low in price, convenient to buy and easy to store, so that the osteoid structure biological ceramic composite material has favorable market application prospect and commercial value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment

ActiveCN105562647AAchieve regulationMeet manufacturingFurnace typesProcess efficiency improvementTrace elementInduction heater

The invention discloses a forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment. A material comprises the following components in percentages by mass: 3.1-3.5% of C, 0.70-1.20% of Si, 0.40-1.20% of Mn, 3.0-4.8% of Ni, 1.0-2.0% of Cr, 0.40-1.1% of Mo, 0.1-2% of W, 0.5-1.0% of Cu, less than or equal to 0.05% of P, less than or equal to 0.03% of S, 1-3% of Sb, 0.02-0.18% of N, 0.1-0.3% of Ce, and the balance Fe and inevitable trace elements; rare earth Ce and silicon iron are subjected to compound inoculation, Sb and N are added to carry out grain refinement, mechanical properties of a roll are improved, the strength of the roll is improved by a forced steel roll journal, a mandrel is subjected to internal integral heating fusion casting by an induction heater, forming is implemented by a water-cooled crystallizer, an interface of a composite layer can be controlled dynamically, the process is simple, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

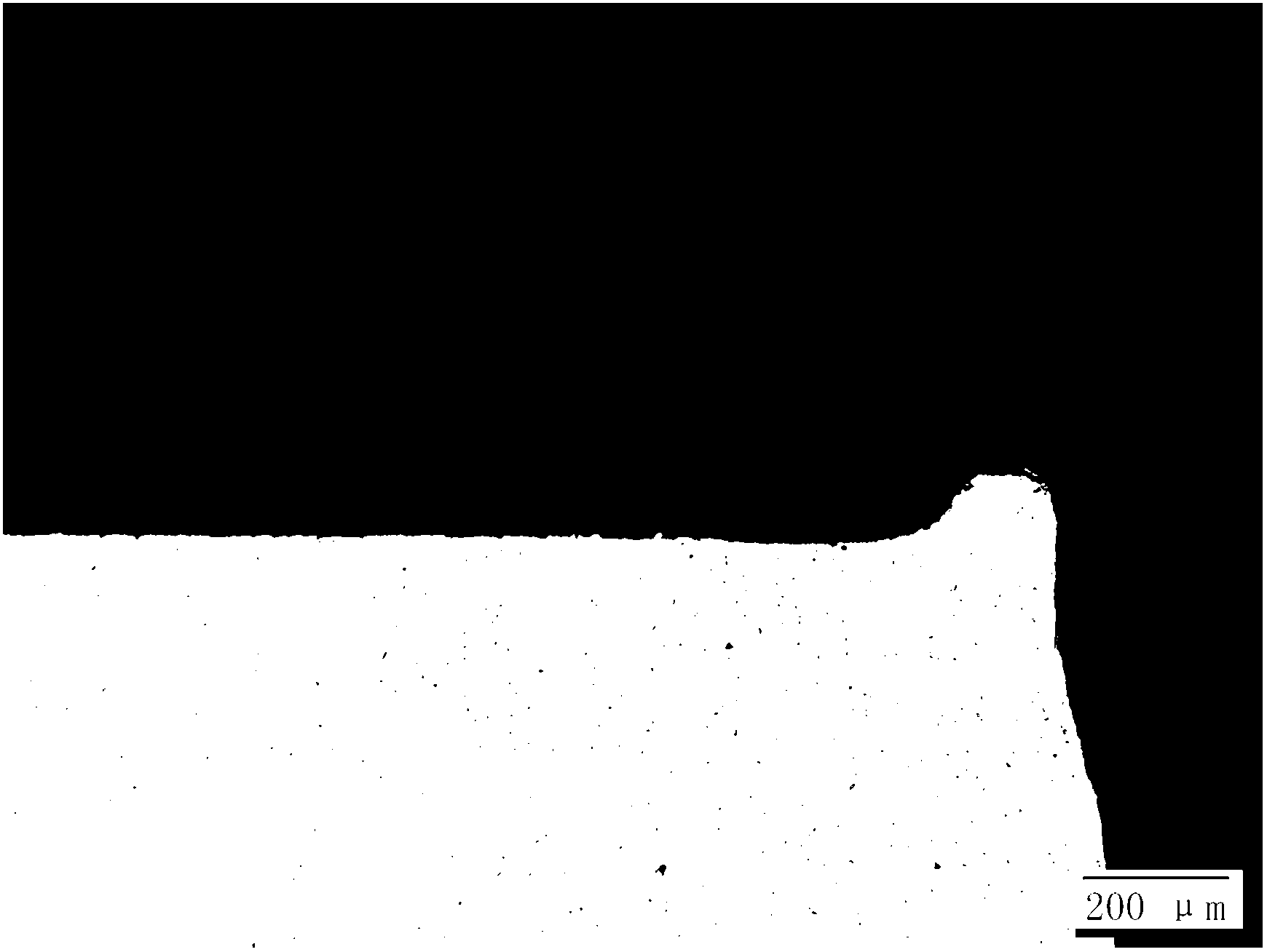

Brass dezincification-resistance sample preparation method

ActiveCN103063496APrevent precipitationDepth is clearly visiblePreparing sample for investigationCorrosionSandpaper

The invention discloses a brass dezincification-resistance sample preparation method. The method comprises the following steps: inlaying a brass sample to be tested, grinding, polishing, and corroding in a 75DEG C CuCl2.2H2O solution for 24h; slicing the corroded brass sample to be tested, and corroding and cleaning the surface of the obtained slice with anhydrous ethanol; coating the cleaned slice surface with a glue to form a protection layer, wherein the protection layer fully contacts with the brass sample surface; carrying out resin inlaying of the slice surface; grinding the inlaid slice surface with metallographic sandpaper; polishing the ground slice surface on a polishing machine; and corroding the polished slice surface in a solution composed of 1-3g of ferric trichloride, 10-20ml of hydrochloric acid and 80-150ml of alcohol. The preparation method solves the dezincification layer chamfering and spalling problems, effectively prevent the water stain from appearing, and makes the dezincification layer depth be clear; and the concentrations and the proportions of the above corrosion solutions are adjusted to improve the corrosion effect in order to make the dezincification layer depth be clearly displayed in the corrosion state.

Owner:上海宝冶工程技术有限公司

Metallic water-based paint

InactiveCN104559601AGood instant solubilitySolve peelingAnti-corrosive paintsEmulsionWeather resistance

The invention relates to a metallic water-based paint and a preparation method thereof. The metallic water-based paint comprises the following components in percentage by weight: 35-40% of an acrylic emulsion, 2-3% of propylene glycol, 3-6% of rock powder, 0.1-0.4% of a wetting agent, 0.05-0.3% of a dispersant, 8-12% of a color paste, 0.1-0.4% of a defoaming agent, 0.1-0.4% of a neutralizing agent, 4-6% of a film coalescing aid, 0.1-0.3% of a leveling agent, 0.05-0.3% of a preservative, 3-5% of bentonite, 1-4% of a thickening agent, 0.2-0.5% of a coupling agent and 1-3% of acrylic resin. Compared with the prior art, the metallic water-based paint provided by the invention has the advantages of good weathering resistance, strong ageing resistance, strong adhesive power and capability of reducing product corrosion.

Owner:ZIBO WATERMASTER ENVIRONMENTAL TEHNOLOGY CO LTD

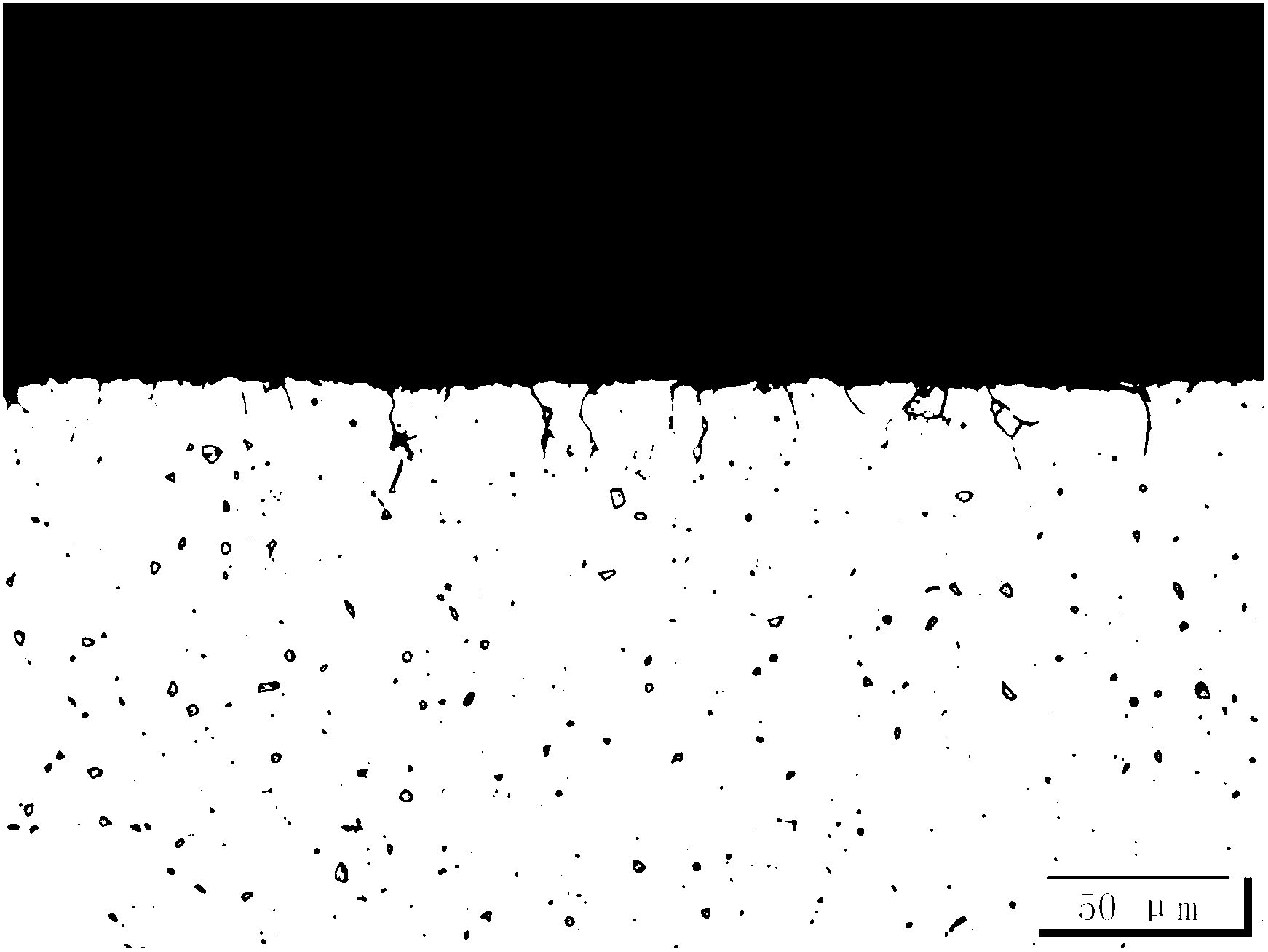

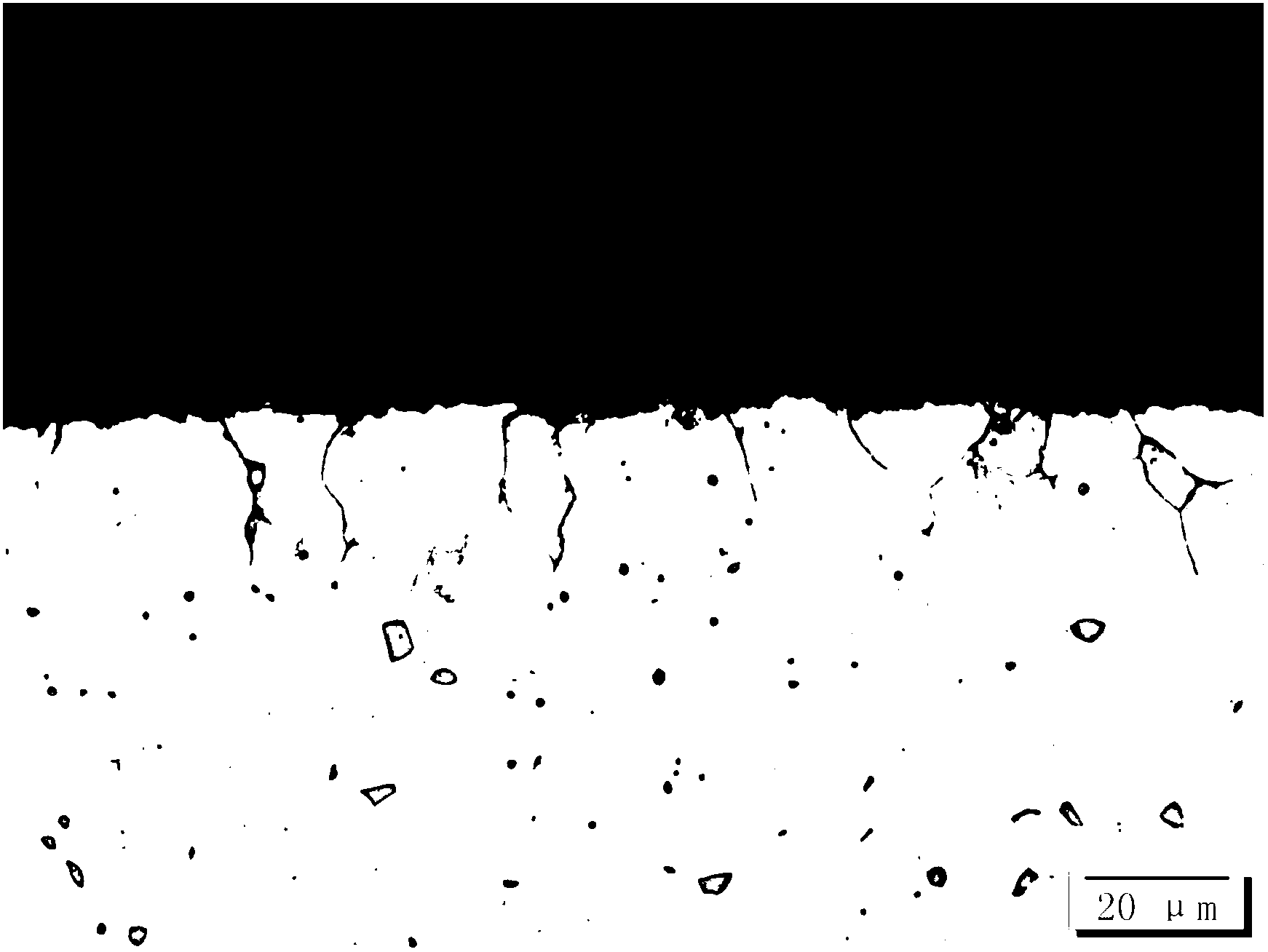

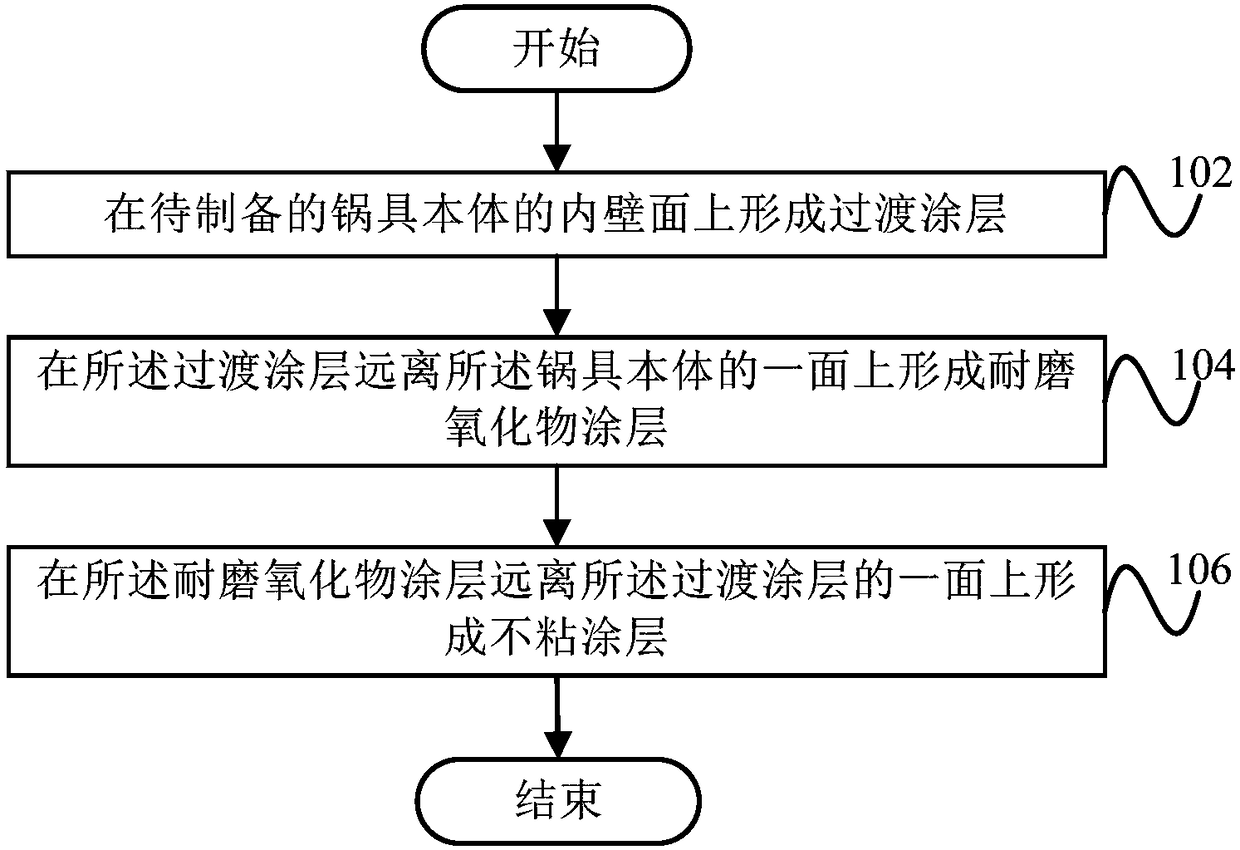

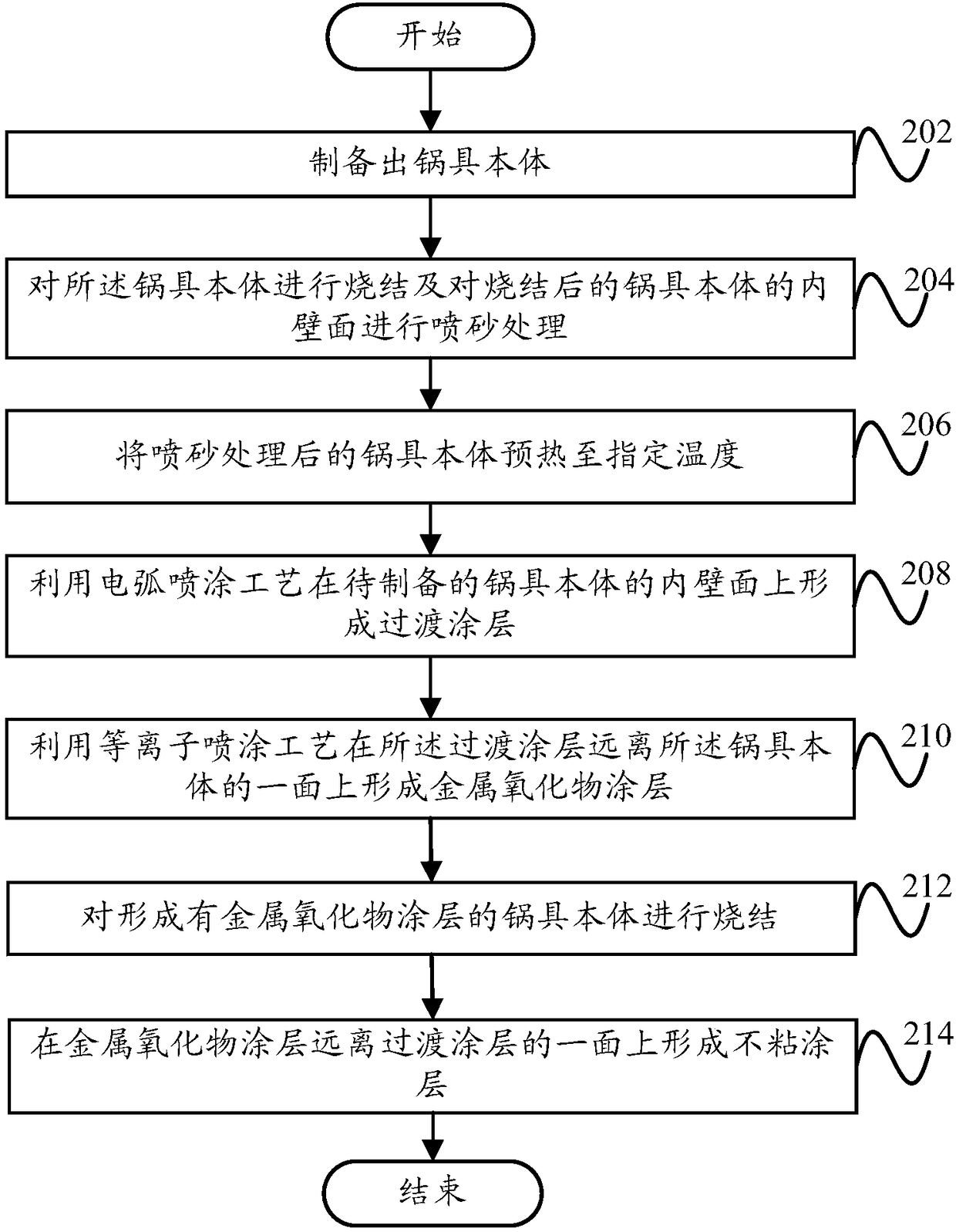

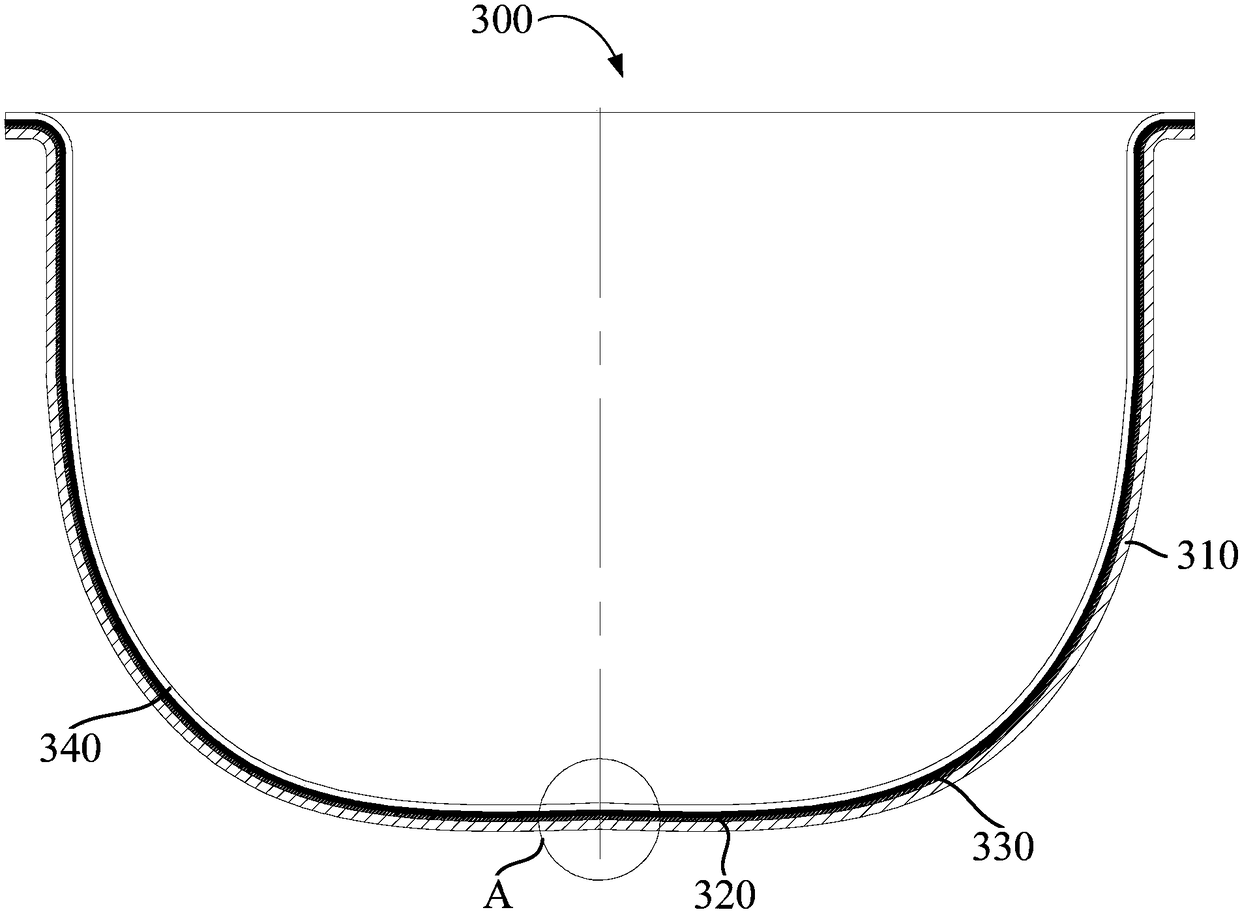

Making method of cooker, cooker and cooking appliance

PendingCN108324081AExtended service lifeImprove stabilityCooking-vessel materialsMolten spray coatingFatigue damageBiochemical engineering

The embodiment of the invention provides a making method of a cooker, a cooker and a cooking appliance. The making method of the cooker includes the steps that a transitive coating is formed on the inner wall face of a cooker body to be made; an abrasion-resistance oxide coating is formed on the face, away from the cooker body, of the transitive coating; a non-adhesive coating is formed on the face, away from the transitive coating, of the abrasion-resistant oxide coating. In the technical scheme, by arranging the transitive coating, the abrasion-resistant oxide coating is more firmly attachedto the cooker body; by arranging the abrasion-resistant oxide coating, the deformation of the non-adhesive coating under the action of external pressure can be reduced, then the fatigue damage degreeof the non-adhesive coating can be decreased, the service life of the non-adhesive coating is greatly prolonged, then the stability and health of the coatings of the whole cooker can be promoted, andthe problem that coatings are prone to being scratched or stripped off is solved. With the non-adhesive coating, the cooker has non-adhesive performance, and can be a cooker without adhesion, and then the using experience of a user can be improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

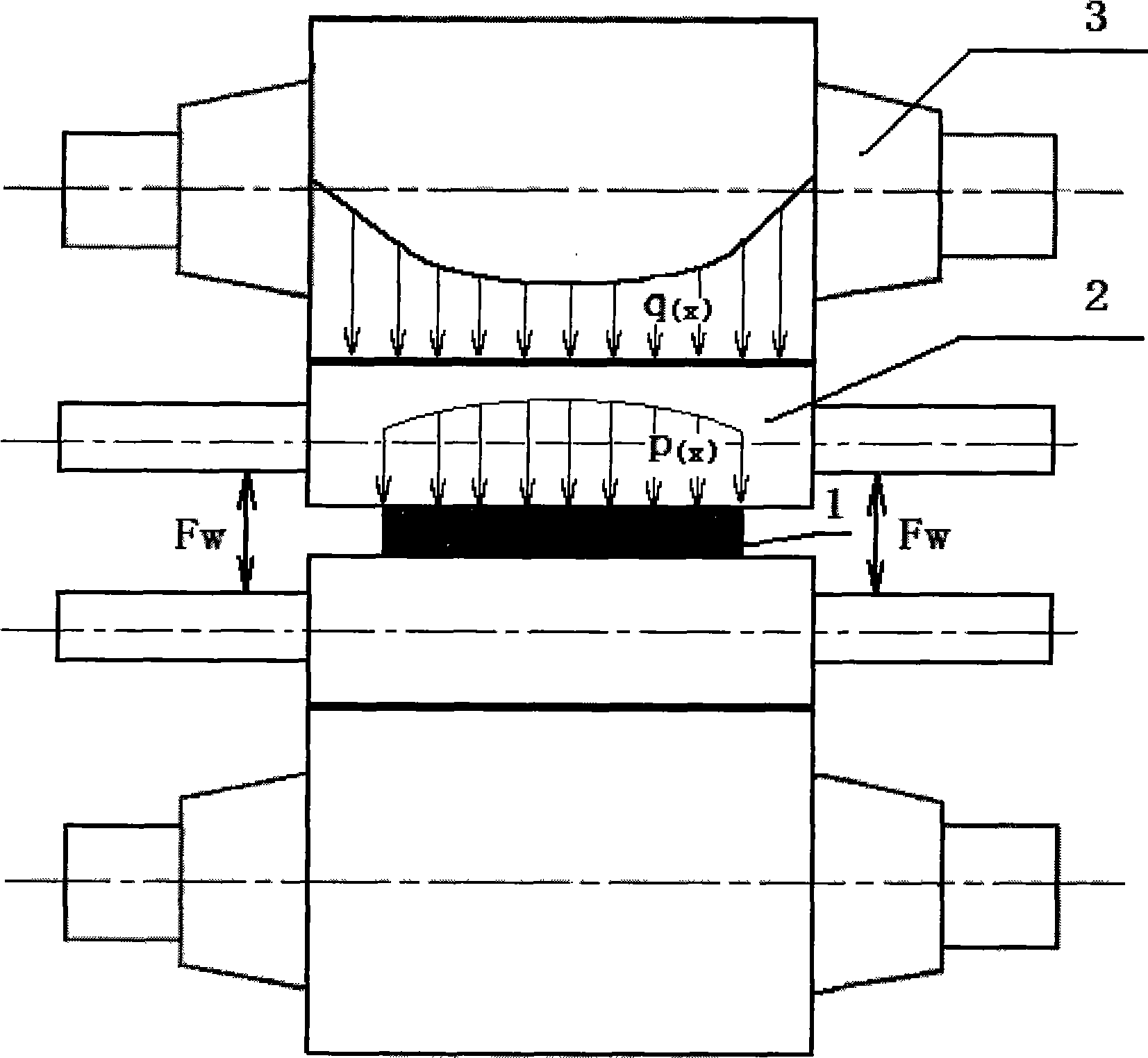

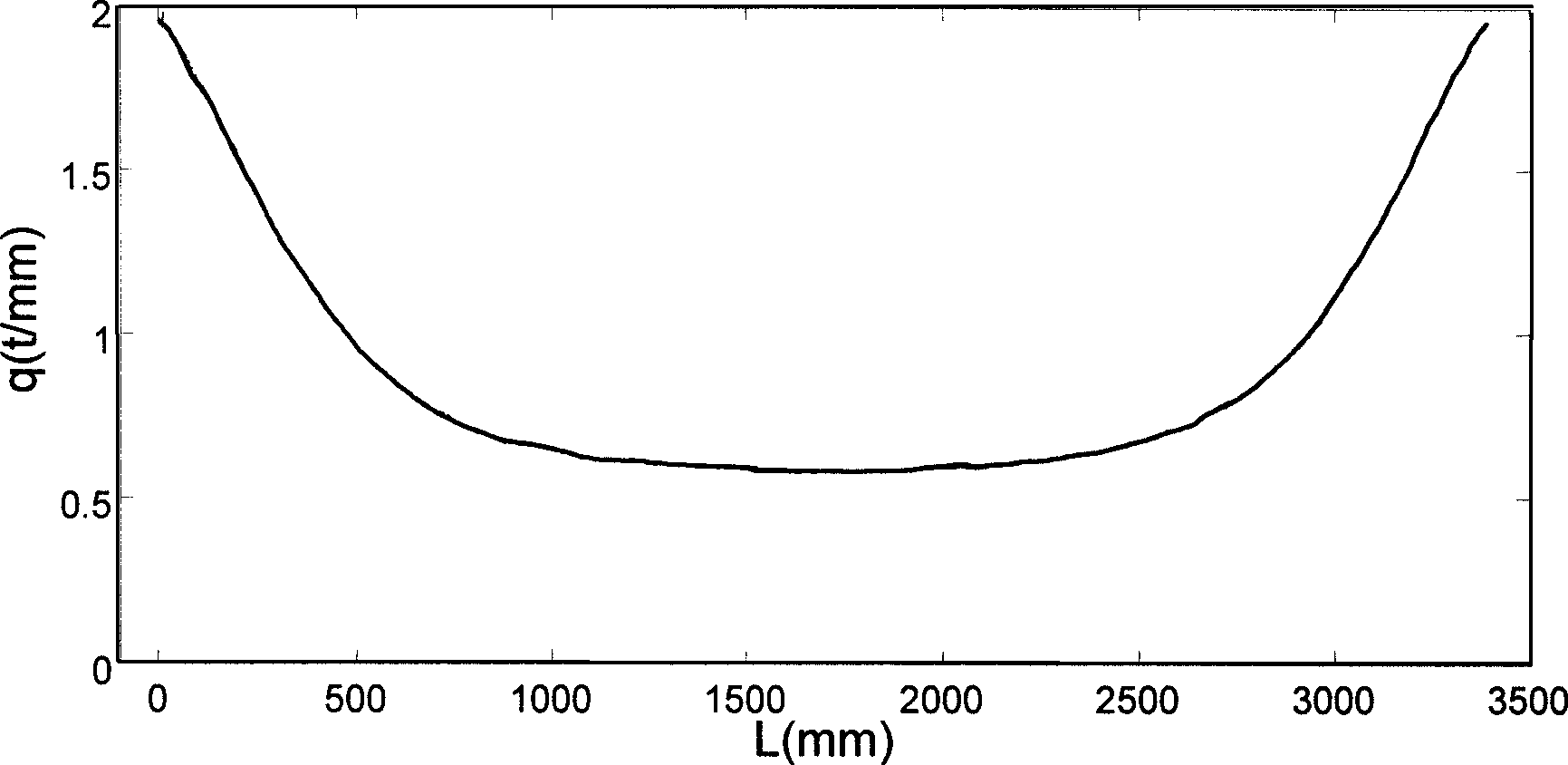

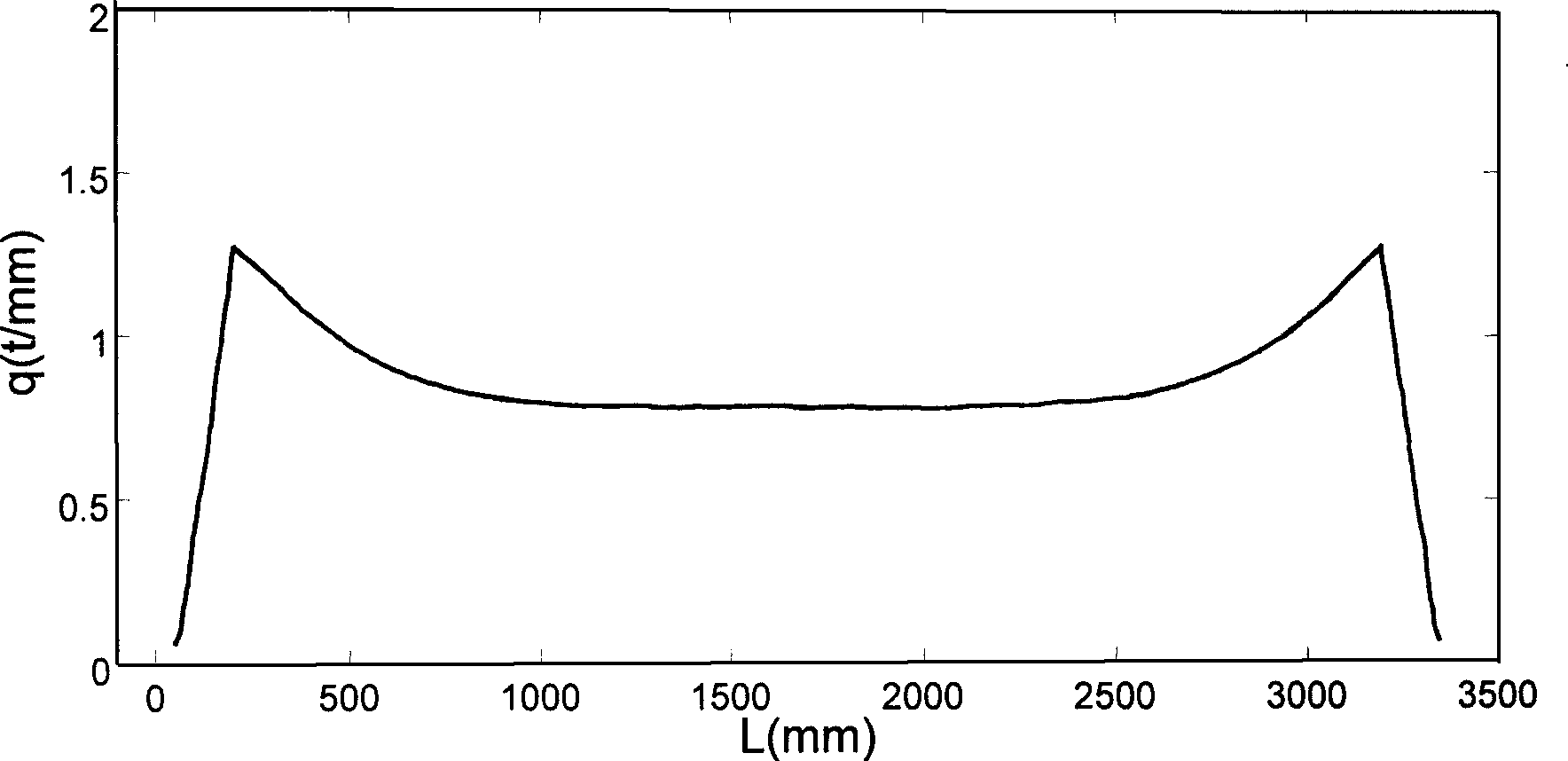

Computing method for roll profile of steckel mill

InactiveCN101477353AInhibit flakingAccurately reflect the stress situationNumerical controlEngineeringFinite element method

The invention relates to a method for calculating the roll shape in the field of metallurgy, in particular to a method for calculating the roll shape of a steckel mill. The invention adopts the calculation method which influences a function method or a finite element method, and considers designing the original roll shape of rolls on the basis of abrasion and thermal expansion of the rolls under the condition of certain rolling procedures. The method calculates the rolling force and the deflection and wafering of working rolls and supporting rolls according to the rolling procedures, and then calculates the rolling force, the contact pressure between the rolls and the thickness distribution conditions of rolling pieces so as to obtain reasonable roll shape of which the pressure between the rolls is reasonably distributed and the plate convexity meets the requirements, of the supporting rolls and the working rolls, and the roll bending force. By adoption of the method to design the supporting rolls and the working rolls, the pressure distribution state between the rolls of the supporting rolls and the working rolls can be obviously improved, spallation of the rolls is inhibited, and simultaneously the plate convexity requirement can be met.

Owner:NANJING IRON & STEEL CO LTD

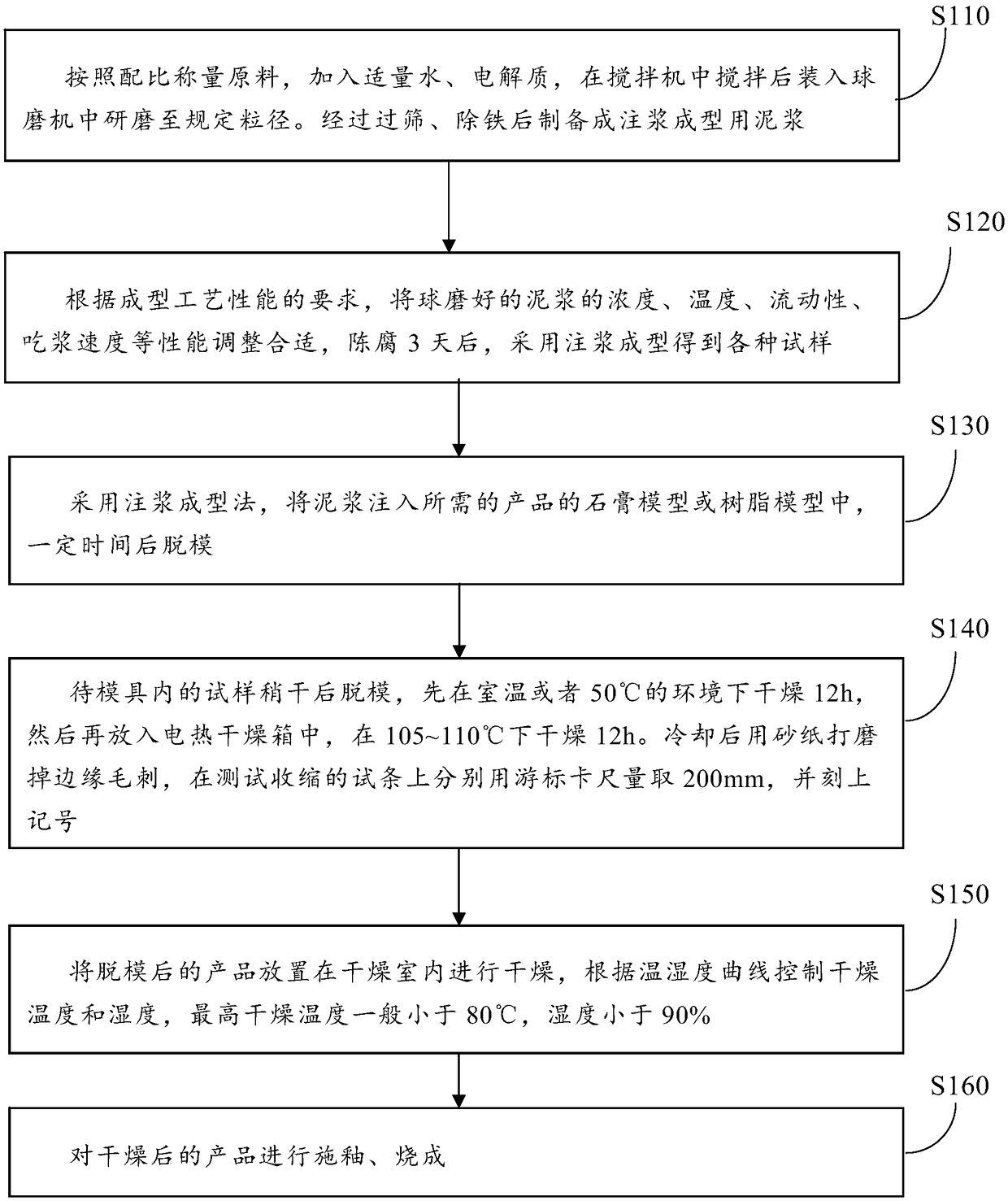

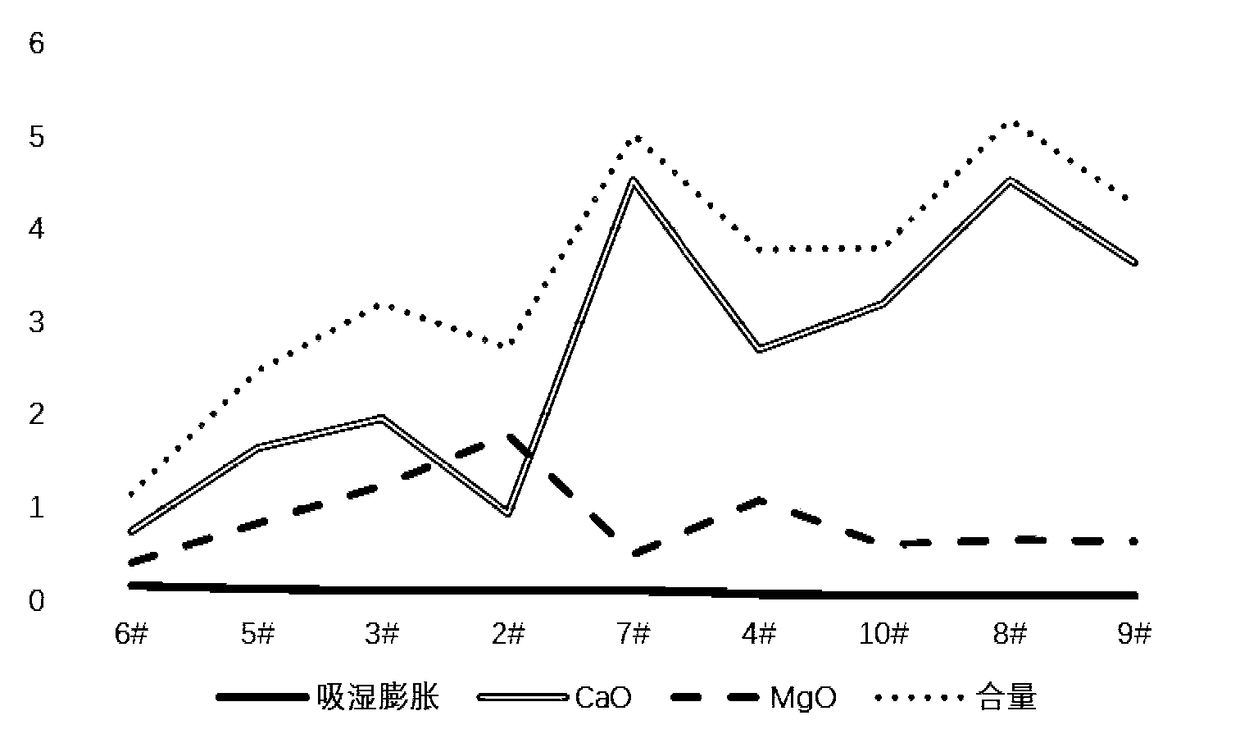

Earthen sanitary ware blank and preparation method thereof

PendingCN108975865AResolve shrinkageSmall overall deformationCeramic materials productionClaywaresThermal expansionQuartz

The invention provides an earthen sanitary ware blank and a preparation method thereof. A proper quantity of raw materials such as kaolin and quartz are introduced; the crystalline phase content of mullite, quartz and the like in the blank is controlled; the glass phase content of potassium oxide and sodium oxide is reduced; the high-temperature plastic deformation is reduced; the low deformationof earthen sanitary ceramics is realized. The thermal expansion coefficient of the blank at 200 to 300 DEG C is regulated, so that the thermal expansion coefficient of the blank is matched with the thermal expansion coefficient of glaze. The problem that the earthen sanitary ware blank cannot overcome shrinkage and great deformation is solved, so that the earthen sanitary ware does not use engobeand does not generate glaze checking; qualified products are produced according to an earthen sanitary ware production method.

Owner:平潭海创智汇科技有限公司

Ultrasonic and induction heating-assisted laser cladding method of composite nanometer coating

ActiveCN108588708ASolve the problem that it is easy to generate tensile stress and greatly increase the crack sensitivitySolve the problem of greatly increased crack susceptibilityMetallic material coating processesUltrasonic assistedOptoelectronics

The invention provides an ultrasonic and induction heating-assisted laser cladding method of a composite nanometer coating. A laser, a precoated layer, a base body, a working table, an ultrasonic vibrator and an induction heating coil are arranged. The ultrasonic and induction heating-assisted laser cladding method of the composite nanometer coating comprises the following concrete steps of (10) after preprocessing the base body, placing the precoated layer on the base body, placing the base body with the precoated layer onto the working table, and moving a laser head of the laser to a position to be cladded of the base body; (20) starting the induction heating coil, and using the induction heating coil for heating the base body and the precoated layer to 200 to 400 DEG C; (30) switching on the laser and the ultrasonic vibrator, wherein the laser is used for laser-cladding the base body through the laser head, and the ultrasonic vibrator is used for ultrasonic-assisting the laser cladding process; (40) after finishing laser cladding, switching off the ultrasonic vibrator and the laser; (50) switching off the induction heating coil; and (60) taking out the base body subjected to laser cladding.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com