Waterproof connector and producing method thereof

A technology of waterproof connector and manufacturing method, which is applied in the manufacture of contact box/base, base/housing, etc., and can solve the problems of physical property difference and peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The detailed description and technical content of the present invention are described below with the accompanying drawings. However, the accompanying drawings are only provided for reference and illustration, and are not used to limit the present invention.

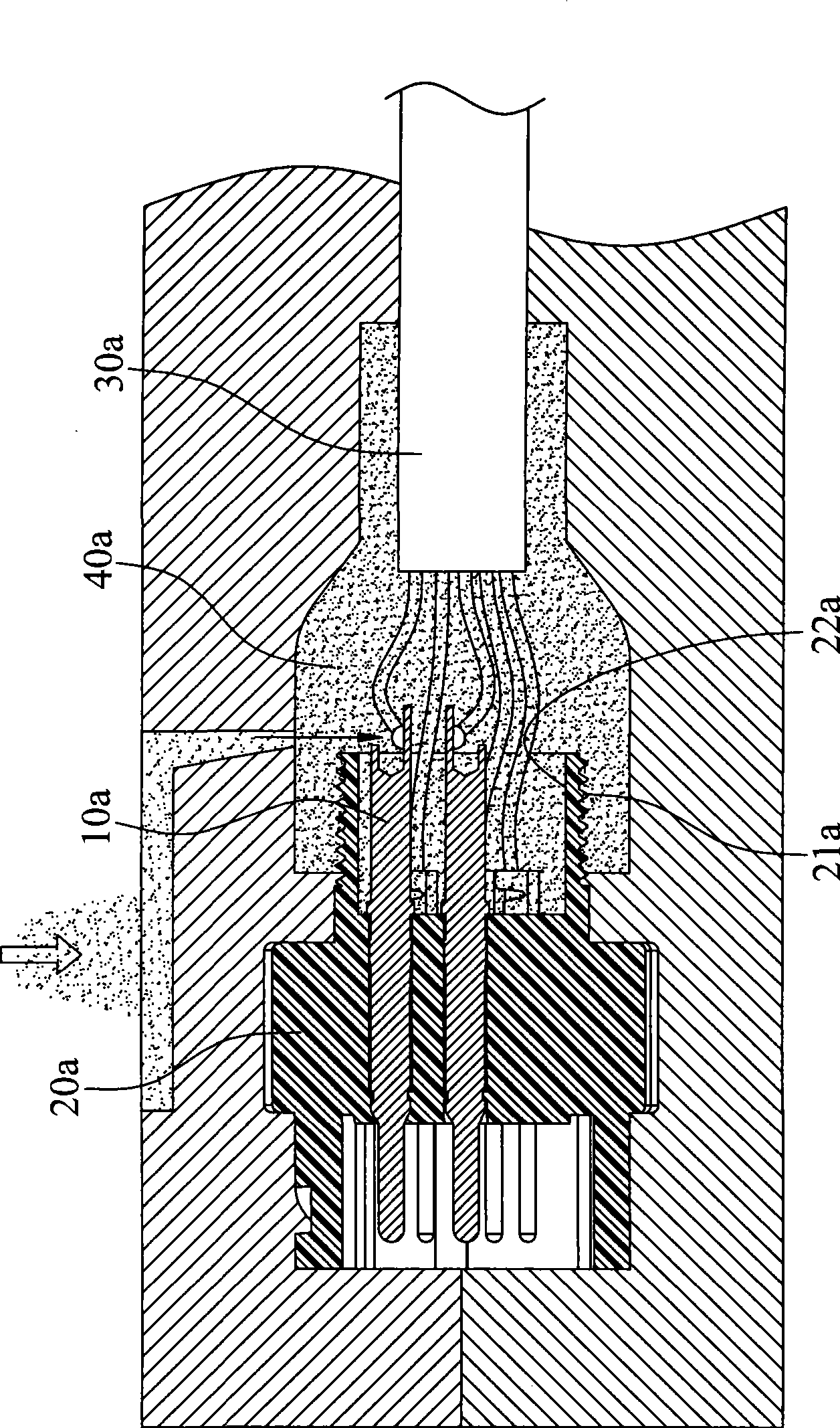

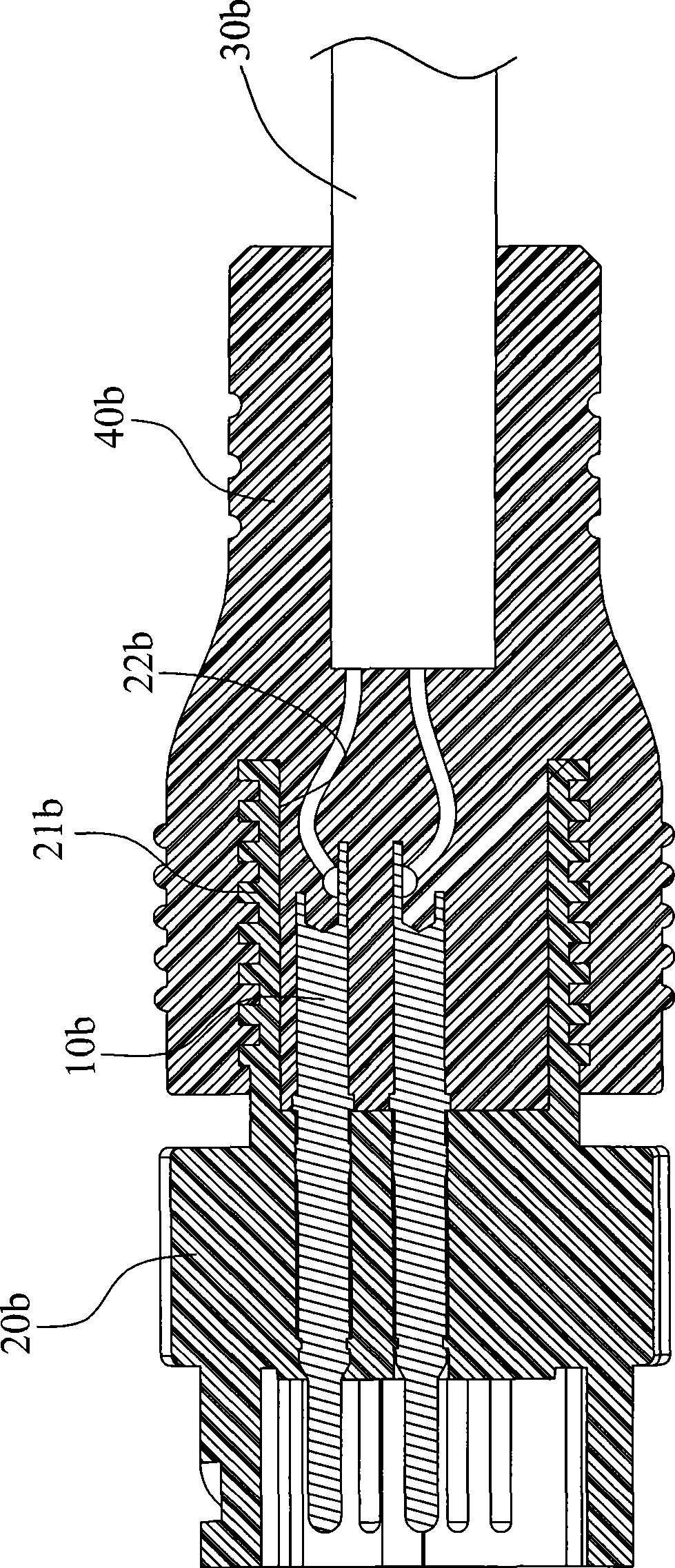

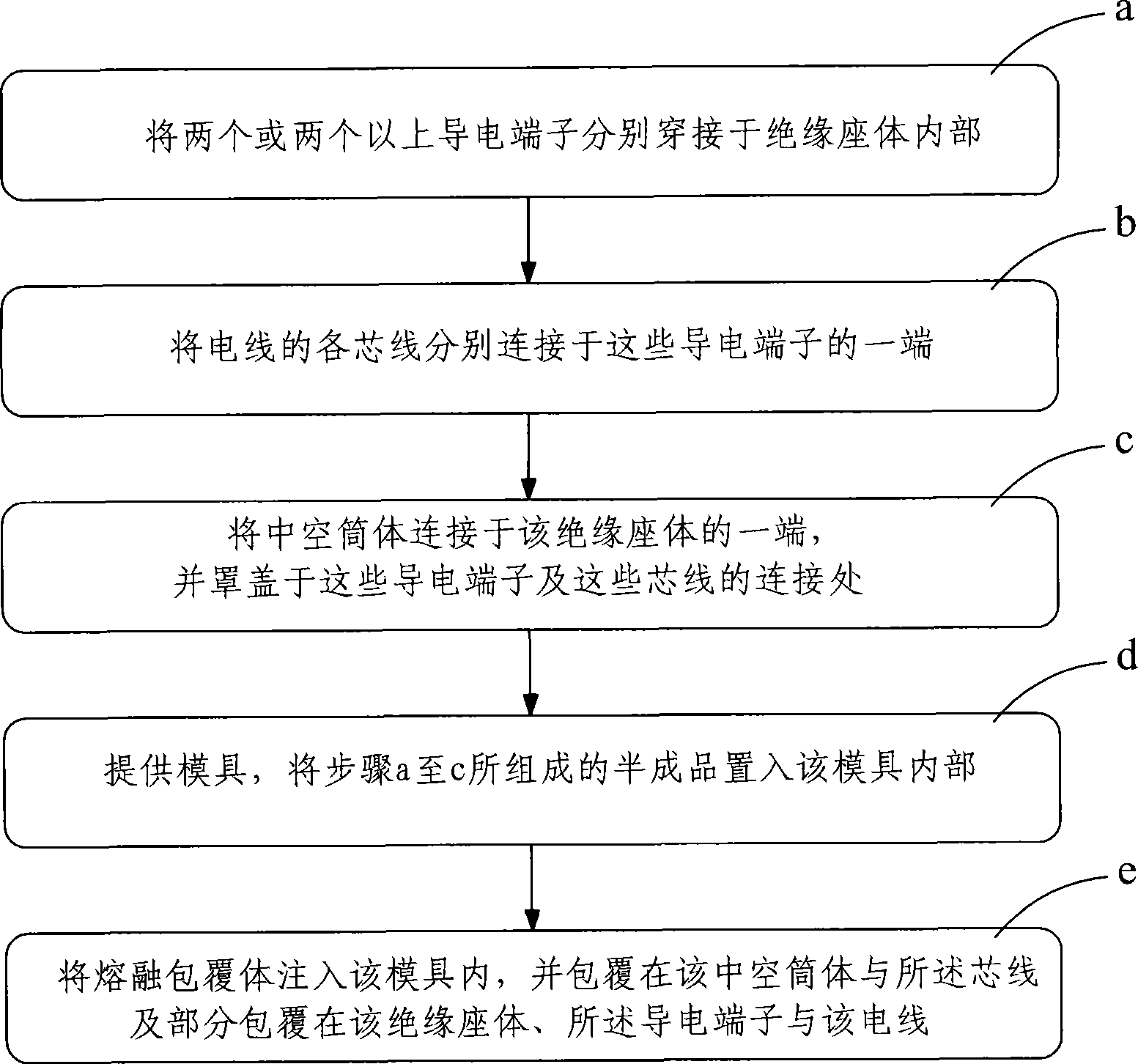

[0051] Please refer to Figure 4 to Figure 7 As shown, the waterproof connector provided by the present invention includes:

[0052] Two or more conductive terminals 10;

[0053] A fixed insulating base body 20 for the conductive terminal 10 to pass through, the insulating base body 20 having a receiving section 21;

[0054] The electric wire 30 has two or more core wires 31, and the core wires 31 are respectively connected to one end of the conductive terminal 10;

[0055] The hollow cylinder 40 is connected to the receiving section 21 and located on one side of the electric wire 30; and

[0056] The covering body 50 covers one end of the receiving section 21, the hollow cylinder 40, the core wire 31 and the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com