Hot-rolling work roll with micron-grade tungsten carbide enhancement layers and manufacturing method thereof

A technology of work rolls and tungsten carbide, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as roll surface peeling, achieve the effect of not easy to fall off, improve surface strength and hardness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

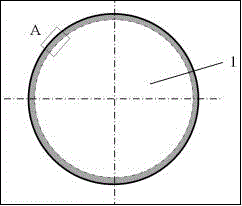

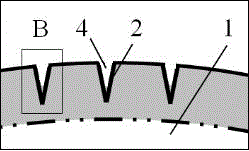

[0032] The preparation method of above-mentioned hot rolling work roll specifically comprises the following steps:

[0033] Step 1: cleaning the surface of the hot-rolled work roll body with acetone to obtain a surface-treated hot-rolled work roll body;

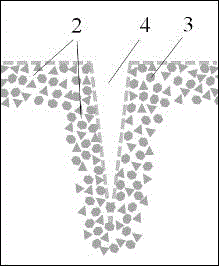

[0034] Step 2: Use a laser drilling machine to carry out laser drilling on the surface-treated hot-rolled work roll body obtained in step 1 under vacuum conditions or under the protection of an inert gas, and then carry out pickling. The acid solution used for pickling has a volume concentration of 300ml / L of hydrochloric acid, 60ml / L of phosphoric acid, 120ml / L of hydrogen peroxide, 300ml / L of hydrofluoric acid or 200ml / L of sulfuric acid, then rinse with water until neutral, and finally use ethanol or acetone Ultrasonic cleaning to obtain the cleaned hot-rolled work roll body with a concave tubular body;

[0035] Step 3: Put the cleaned hot-rolled work roll body with a depressed tubular body obtained in Step 2 into a vacuu...

Embodiment 1

[0049] Step 1: cleaning the surface of the hot-rolled work roll body with acetone to obtain a surface-treated hot-rolled work roll body;

[0050] Step 2: Using a laser drilling machine to laser drill holes on the surface-treated hot-rolled work roll body obtained in step 1 under vacuum conditions, the hole diameter is 30 μm, the hole depth is 20 μm, and the hole spacing is 1000 μm; then pickling, The acid solution used for pickling is hydrochloric acid with a volume concentration of 300ml / L, then rinsed with water until neutral, and finally ultrasonically cleaned with ethanol to obtain the cleaned hot-rolled work roll body with a depressed tubular body;

[0051] Step 3: Place the cleaned hot-rolled work roll body with the depressed tubular body obtained in step 2 in a vacuum carburizing furnace for carburizing at a temperature of 920° C., the carbon mass concentration in the vacuum carburizing furnace being 0.9%, The vacuum degree is not greater than 1×10 4 Pa, the carburizi...

Embodiment 2

[0055] Step 1: cleaning the surface of the hot-rolled work roll body with acetone to obtain a surface-treated hot-rolled work roll body;

[0056] Step 2: Use a laser drilling machine to perform laser drilling on the surface-treated hot-rolled work roll body obtained in step 1 under the protection of inert gas argon, with a hole diameter of 20 μm, a hole depth of 18 μm, and a hole spacing of 25 μm; and then carry out Pickling, the acid solution used for pickling is hydrofluoric acid with a volume concentration of 300ml / L, then rinsed with water until neutral, and finally ultrasonically cleaned with acetone to obtain the cleaned hot-rolled work roll body with a depressed tubular body;

[0057] Step 3: Place the cleaned hot-rolled work roll body with a depressed tubular body obtained in step 2 in a vacuum carburizing furnace for carburizing at a temperature of 930° C. The carbon mass concentration in the vacuum carburizing furnace is 1.0%. The vacuum degree is not greater than 1×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com