Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Specific surface energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific surface energy, also known as surface free energy, is the increase in free energy when the area of a surface increases by every unit area. It can be calculated using Stefan's formula. Specific surface energy is the same as surface tension for isotropic materials, but different for anisotropic materials.

Method for converting traditional paint into superhydrophobic paint

InactiveCN109777260AExcellent superphobic propertiesGood antifoulingAntifouling/underwater paintsPaints with biocidesMicro nanoWeather resistance

The invention discloses a method for converting a traditional paint into a superhydrophobic paint, comprising the following steps: ultrasonically dispersing superhydrophobic particles in a solvent, and then sequentially adding a traditional paint and a low surface energy substance to a dispersion, and performing high-speed stirring and ultrasonic dispersion at room temperature so as to obtain thesuperhydrophobic paint. Excellent film forming property, stability and weather resistance of the traditional paint are utilized, the micro-nano structure and the specific surface energy are provided by the hydrophobic particles and the low surface energy substance to the surface, and then conversion of the traditional paint to the superhydrophobic paint is realized. the coating of the paint has excellent super-hydrophobic performance (water contact angle 150 degrees, and roll angle 10 degrees), shows excellent anti-fouling, waterproof, anti-static, anti-corrosion and anti-icing properties, andhas s broad application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Coating of aluminum substrate for direct plate making of ink-jet printing, production method and use

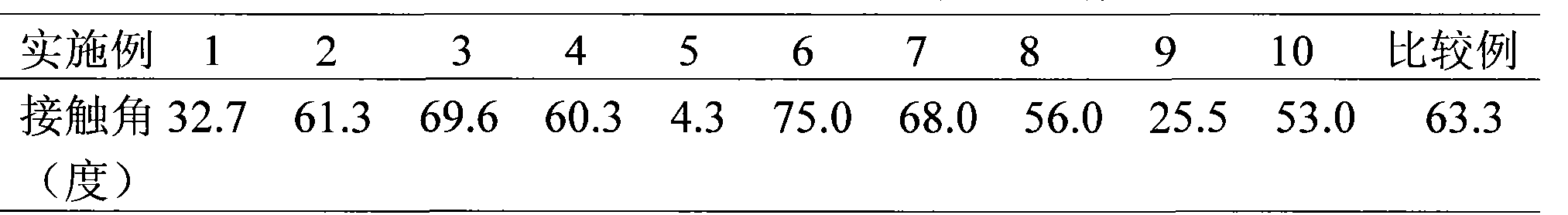

ActiveCN101397438AWith roughnessAvoid pollutionPrinting pre-treatmentProtein coatingsSolventAluminum substrate

The invention relates to a coating for aluminum lithographic supports applied to direct ink jet stencil making, a preparation process and application thereof. The coating is prepared by mixing 0.5-15wt percent of hydrophilic high molecular polymer, 0.5-15wt percent of nanometer or micrometer-sized oxide particles, 0-1wt percent of additive and 80-98wt percent of solvent with agitating at room temperature. The coating can avoid the problem that acid or alkaline waste liquid produced after anodic oxidation treatment of aluminum lithographic supports can cause great pollution to the environment. After thermocuring of the coating, aluminum lithographic supports can absorb ink and can be directly printed after ink jet CTP stencil making, thus reducing the post-treatment process. The coating has good adhesion to aluminum lithographic supports; after the coating is applied to aluminum lithographic supports, due to presence of the nanometer or micrometer-sized oxide particles, the aluminum lithographic supports can have high specific surface energy and satisfy requirements on ink absorbance and environment protection; in addition, surfaces of the aluminum lithographic supports have high wear resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

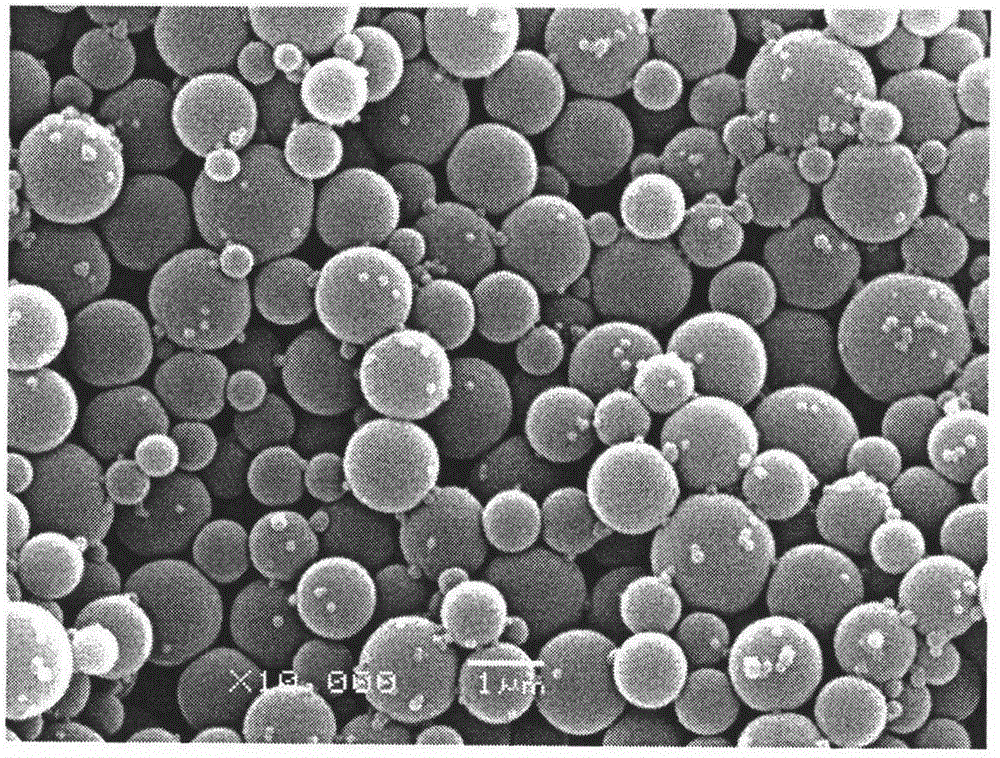

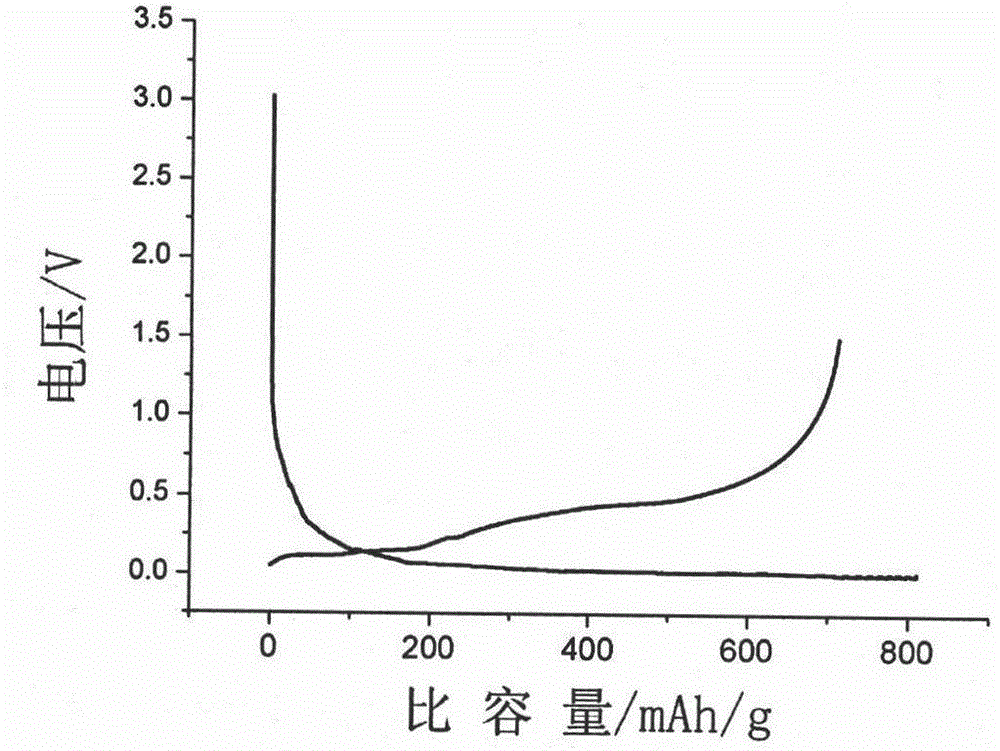

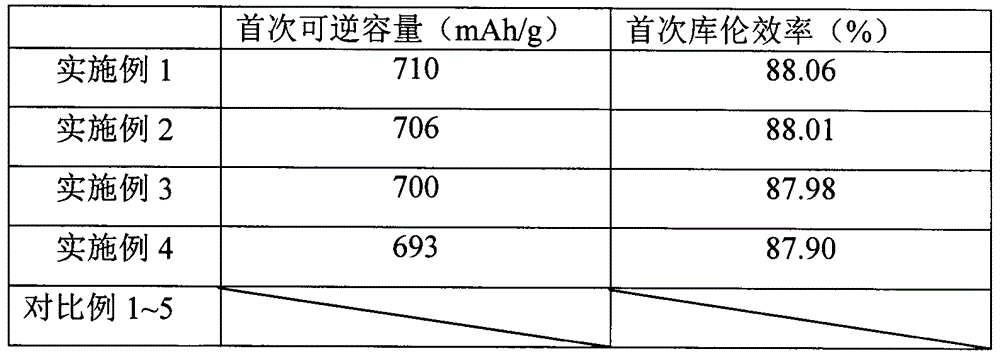

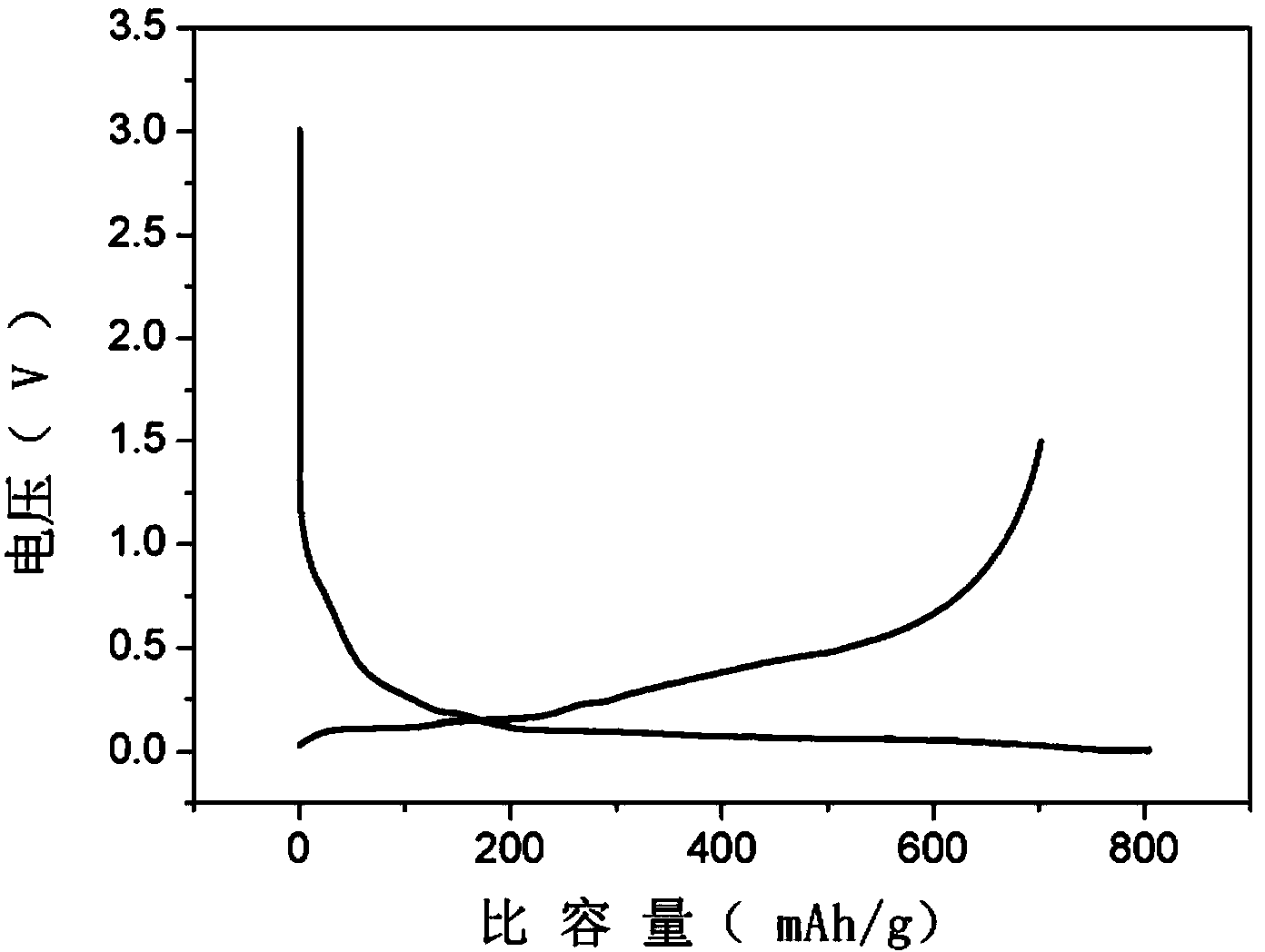

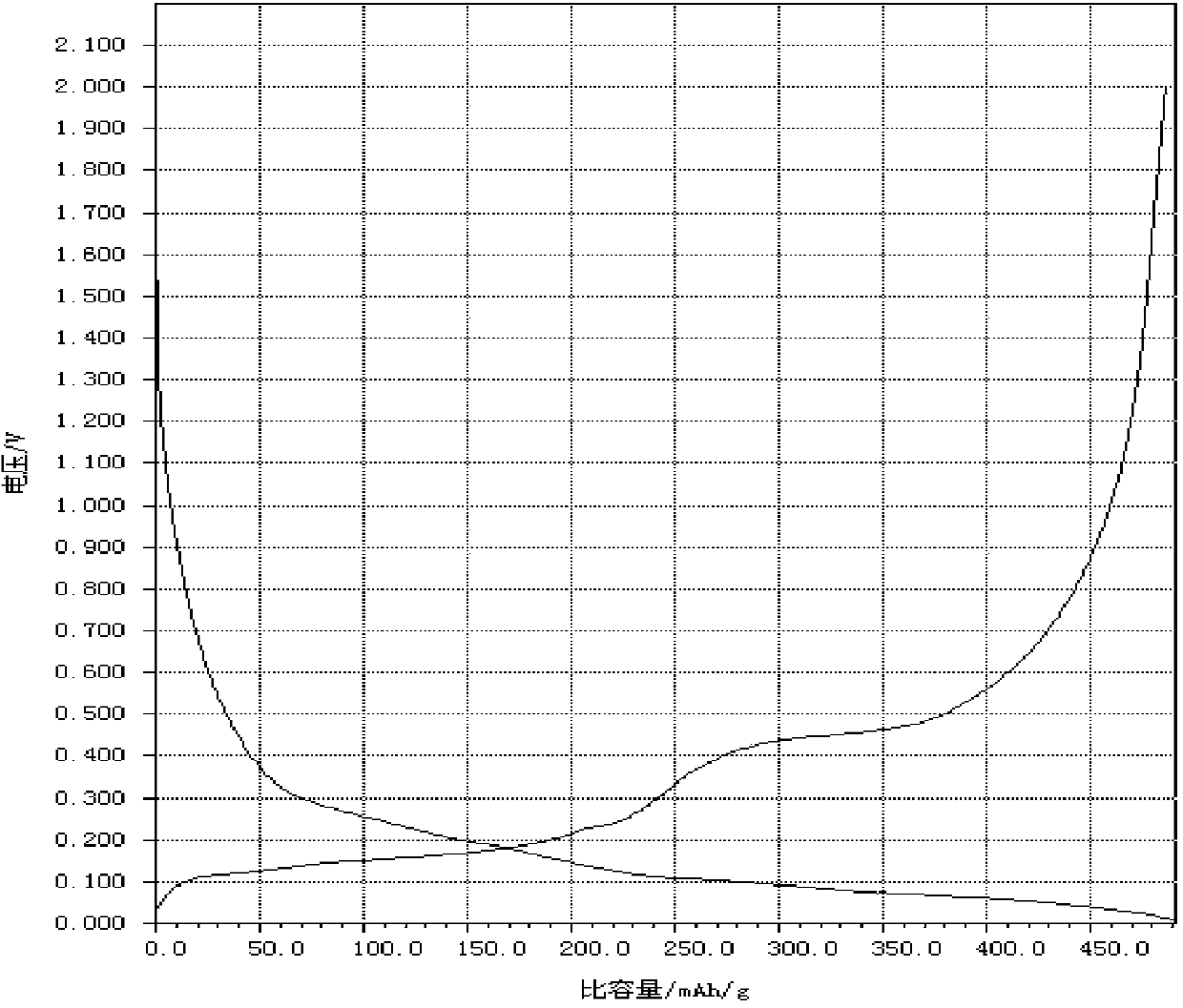

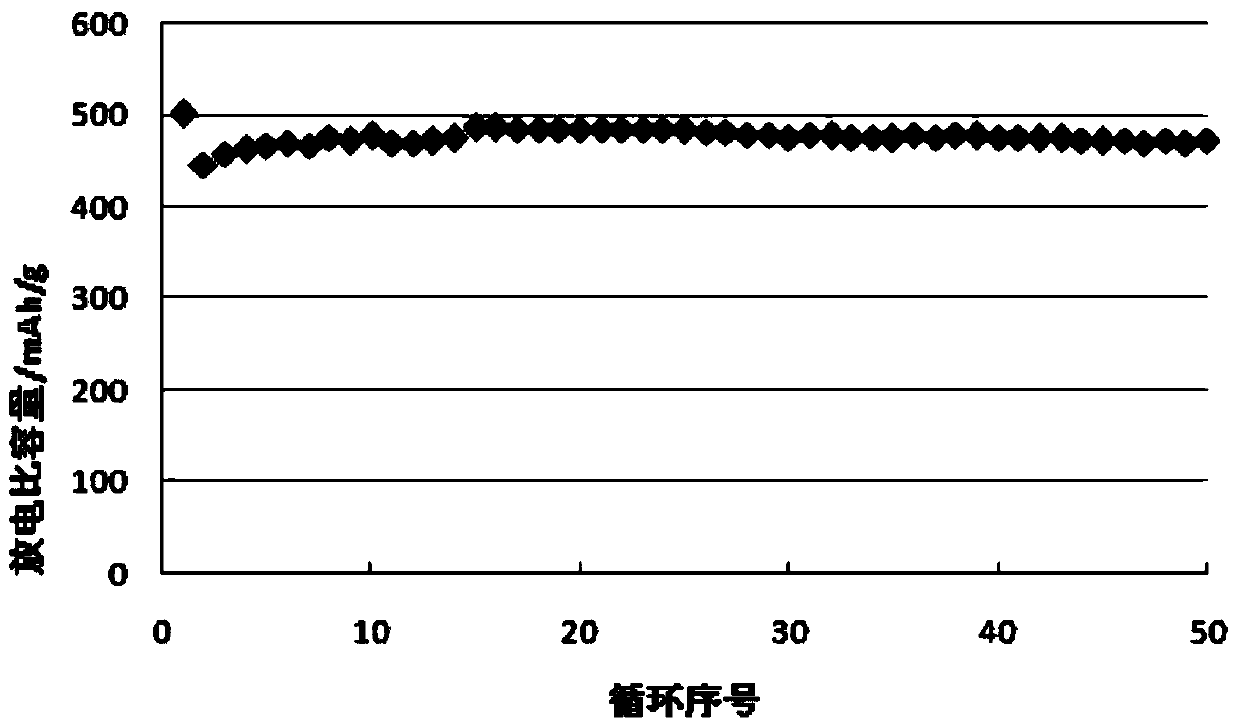

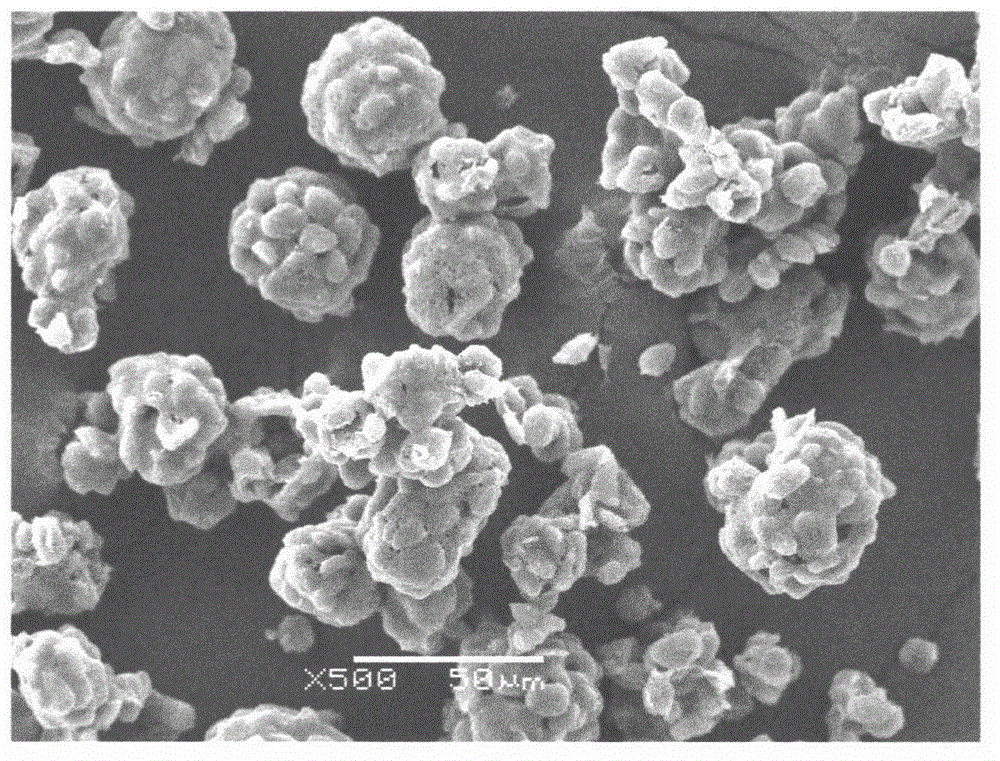

Preparation method of silicon-carbon composite negative electrode material of lithium ion battery and application of silicon-carbon composite negative electrode material

ActiveCN104362300AImprove hydrophilicityEasy to resolve from the oil phaseCell electrodesSecondary cellsCarbon compositesOil phase

The invention provides a preparation method of a silicon-carbon composite negative electrode material of a lithium ion battery. According to the preparation method, an existing silane coupling agent treatment technology is combined and a polymer cladding layer is formed on the surface of nano silicon by dispersion and polymerization processes; then nano silicon dispersion liquid with the polymer cladding layer on the surface is dispersed into an aromatic vinyl monomer; micro-molecular organic alcohol in the dispersion liquid is thoroughly removed by purification treatment so as to finish a nano silicon surface modification process; a condensation product is prevented from being generated by the modification method, and technical supports are provided for formation of oil-in-water type emulsion by micro-suspension polymerization; the problems that the nano silicon has high hydrophily and can easily overflow from an oil phase or a polymer in the dispersion and polymerization processes are solved; and the problems that the nano silicon can be united easily due to small granularity and high specific surface energy are solved. The silicon-carbon composite negative electrode material prepared by the method has high specific capacity (being more than 680Ah / g), high first-time charging and discharging efficiency (being more than 87%) and good circulating stability.

Owner:广东羚光新材料股份有限公司

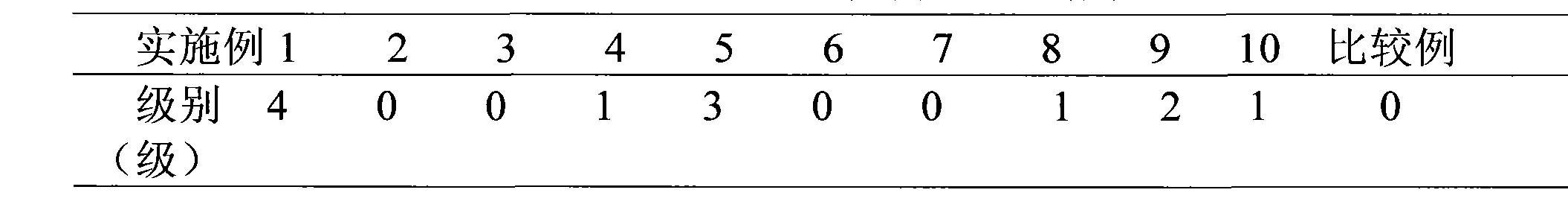

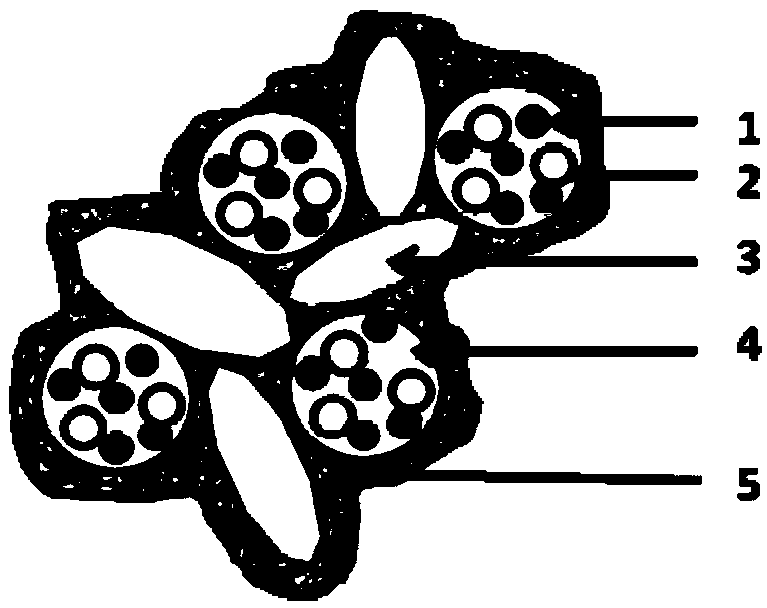

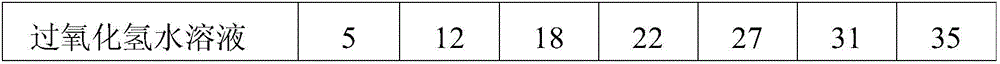

Graphite silicon-based composite anode material and preparation method thereof

InactiveCN104362307ASmall granularityHigh specific surface energyCell electrodesSecondary cellsCarbon compositesHigh carbon

The invention relates to a graphite silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The graphite silicon-based composite anode material comprises a nano-silicon cracked carbon composite material, graphite and a carbon material coating layer. The preparation method comprises the following steps: firstly, nano-silicon is obtained by a high-energy wet mechanical milling method; secondly, nano-silicon and a polymer with high carbon residue are compounded by dispersion polymerization so as to form a polymer / nano-silicon composite microsphere emulsion with nano-silicon inlaid in polymeric microspheres; thirdly, the microsphere emulsion and graphite are compounded; and finally, solid-phase coating is carried out by the use of an organic carbon source, and heat treatment is conducted to obtain the graphite silicon-based composite anode material for a lithium ion battery. By the above method, the problem that nano-silicon is liable to agglomeration, especially agglomeration of nano-silicon from a liquid disperse state to a dry state, due to low granularity and high specific surface energy is solved. The anode material has characteristics of high specific capacity (greater than 550mAh / g), high initial charge discharge efficiency (greater than 80%) and high conductivity.

Owner:南京毕汉特威高分子材料有限公司

Lithium ion battery silicon carbon composite negative electrode material and preparation method thereof

InactiveCN103618074AImprove dispersionEfficient coatingCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention relates to a lithium ion battery silicon carbon composite negative electrode material and a preparation method thereof. The method comprises the following steps: fixing nanometer silicon in a macromolecule microsphere by preparing a micromolecule / silicon / (carbon black) composite microsphere emulsion, then compounding the microsphere emulsion and graphite, asphalt and the like, and carrying out thermal treatment, thereby obtaining the lithium ion battery silicon carbon composite negative electrode material. The macromolecule microsphere in the material has the effects that the macromolecule microsphere not only is a fixer for stabilizing and inlaying the nanometer silicon, but also is a bonding agent between the nanometer silicon and the graphite after being subjected to high-temperature sintering treatment. The method solves the problems that the nanometer silicon is high in specific surface energy and easy to agglomerate because of small granularity. The lithium ion battery silicon carbon composite negative electrode material prepared by the preparation method disclosed by the invention achieves the synergistic effect of graphite, high-dispersion silicon and carbon, and presents an excellent battery performance.

Owner:南京毕汉特威高分子材料有限公司

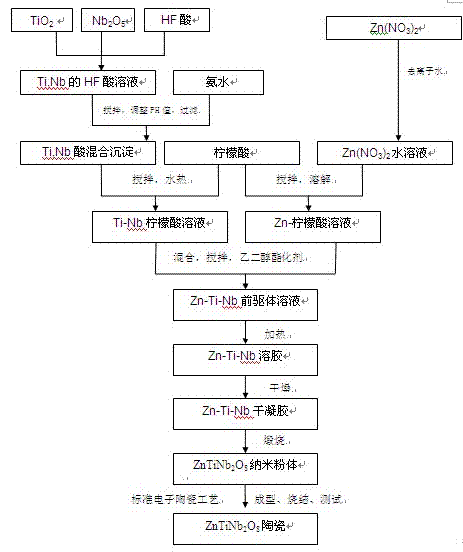

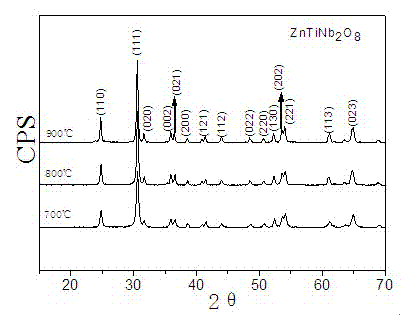

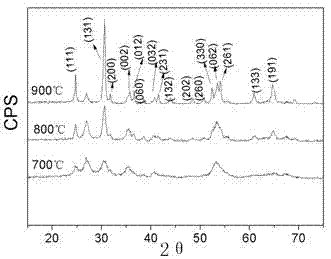

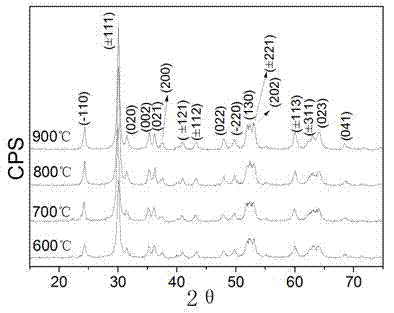

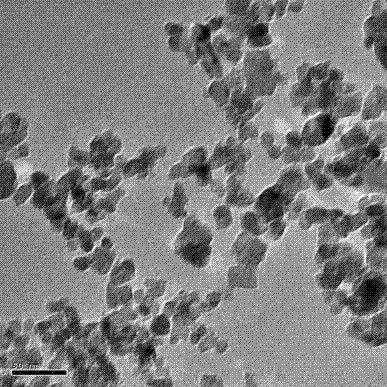

Method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by wet chemical process

InactiveCN102775141ASynthesis temperature is lowImprove sintering propertiesSpecific surface energyMicrowave dielectric properties

The invention belongs to the technical field of preparation and application of electronic ceramics, and particularly relates to a method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by a wet chemical process. The technical scheme is as follows: the method comprises the following steps: 1) preparing a Zn ion citric acid water solution; 2) preparing a Ti and Nb ion citric acid water solution; and 3) synthesizing a ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramic precursor, and preparing the ceramics. The invention has the advantages of low synthesis temperature, uniform ceramic particles, favorable dispersity, pure phase, nano particle size of powder, high specific surface energy, high activity and the like, can implement low-temperature sintering, and maintains favorable microwave dielectric properties, thereby satisfying the application requirements for LTCC (low temperature co-fired ceramic).

Owner:UNIV OF JINAN

Preparation method for functional film capable of simultaneously realizing oil-water emulsion separation and dye removal

PendingCN108905651ANo secondary pollutionPost-processing is simpleSemi-permeable membranesMembranesMatrix solutionOrganic dye

The invention discloses a preparation method for a functional film capable of simultaneously realizing oil-water emulsion separation and dye removal. The method comprises the following steps: (1) preparing a polymer matrix solution; and (2) combining a hydroxyl-containing substrate with the polymer matrix solution, and enabling acceleration of gelation and introduction of charged functional groupsto be realized in one step to obtain the functional film capable of simultaneously realizing the oil-water emulsion separation and the dye removal. According to the method disclosed by the invention,the polymer matrix solution gives high specific surface energy to the hydroxyl-containing substrate, so that super-hydrophilic underwater super-oleophobic performance is obtained, and high-efficiencyseparation of oil and water can be realized; and the charged functional groups are introduced, organic dye is adsorbed through electrostatic interaction, so that the organic dye is removed, and finally dye pollutants are removed while an oil-water emulsion is separated only by gravity.

Owner:石狮市川大先进高分子材料研究中心

Multiwall carbon nanotube-polysilane composite material and preparation method thereof

The invention relates to a multiwall carbon nanotube-polysilane composite material and a preparation method thereof. The invention aims to solve the problems of high specific surface energy, poor dispersity in organic substances, and low combining capacity with organic substances in the existing carbon nanotubes. The multiwall carbon nanotube-polysilane composite material is prepared from silanized multiwall carbon nanotubes, dichlorosilane derivatives, an organic solvent and alkali metals. The method comprises the following steps: 1. preparing purified multiwall carbon nanotubes; 2. preparing acidified multiwall carbon nanotubes; 3. preparing acyl-chlorinated multiwall carbon nanotubes; 4. preparing phenol-derivative-grafted acyl-chlorinated multiwall carbon nanotubes; 5. silanizing to prepare the silanized multiwall carbon nanotubes; and 6. by using alkali metals as the catalyst, polymerizing with dichlorosilane derivatives to obtain the multiwall carbon nanotube-polysilane composite material. The invention is mainly used for preparing the multiwall carbon nanotube-polysilane composite material.

Owner:HARBIN UNIV OF SCI & TECH

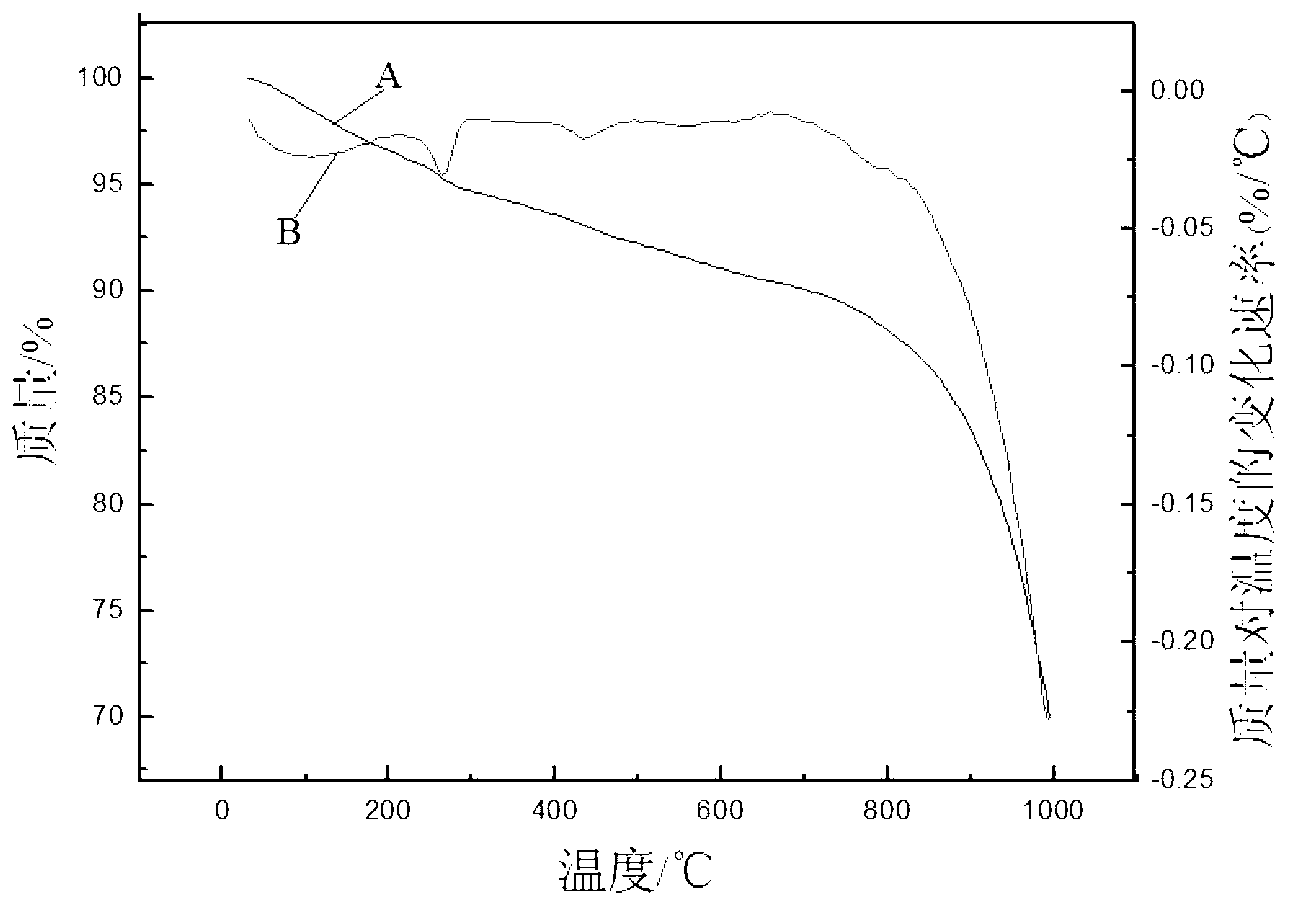

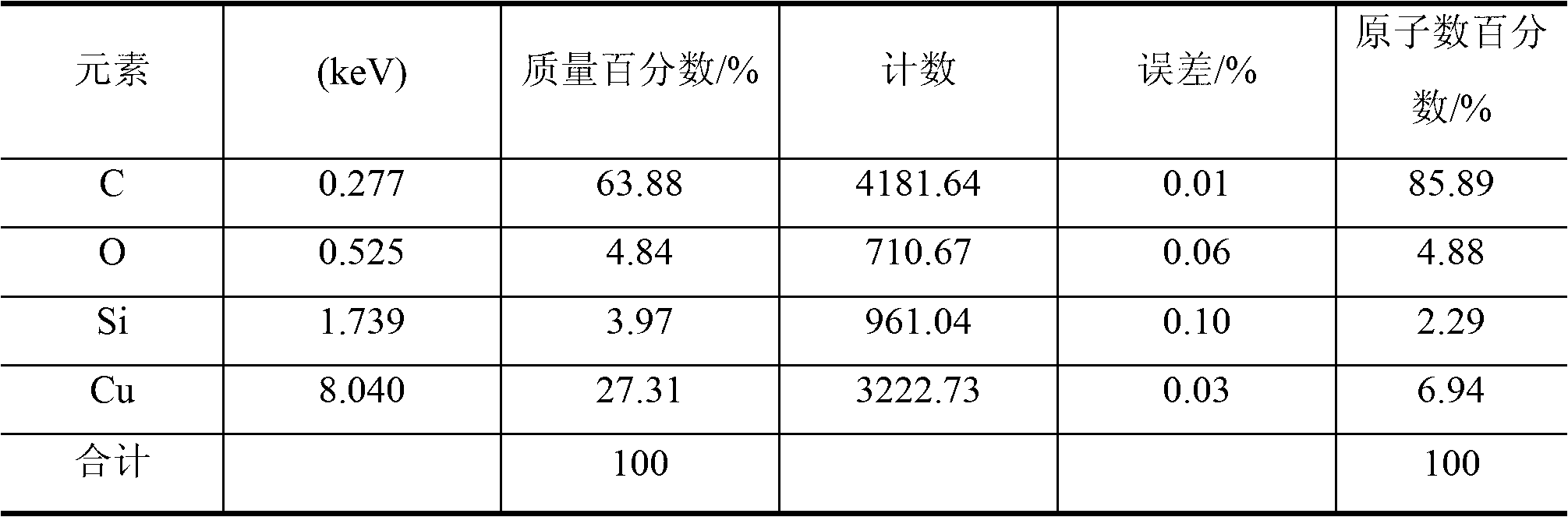

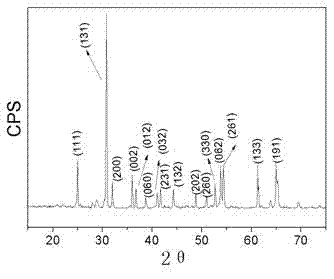

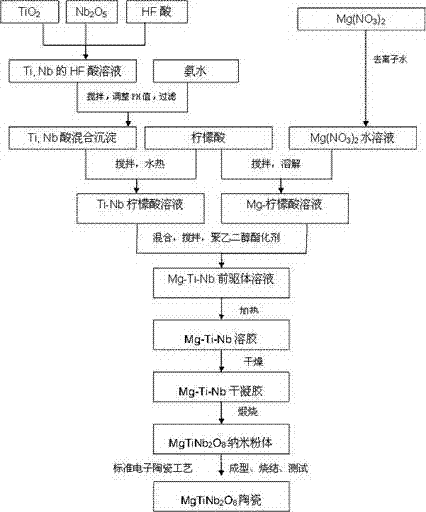

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

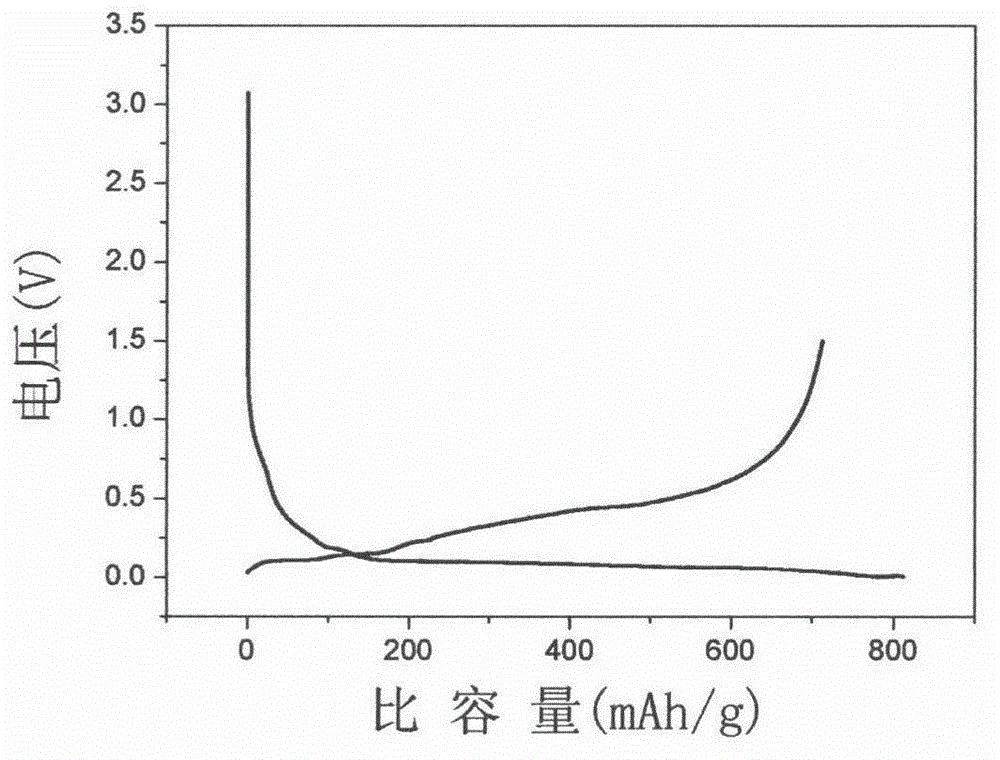

Method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide

ActiveCN106045495AGood chemical stabilityReduce solubilityRadioactive decontaminationCeramicwareEcological environmentPolyethylene glycol

A method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide is characterized by including: using the materials in percent by weight: 50-80% of calcium pyrophosphate, 4-26% of calcium fluoride and 16-45% of calcium carbonate, and mixing, ball-milling, drying, press-forming, calcining, grinding, and screening to obtain fluorapatite powder; mixing the fluorapatite powder with polyethylene glycol solution, methyl cellulose solution and hydrogen peroxide solution, and performing microwave assisted pore-forming, drying and the like to obtain a porous fluorapatite ceramic blank; preparing porous fluorapatite ceramic adsorbing material via normal pressure sintering. The porous fluorapatite ceramic adsorbing material prepared herein has the advantages of high radiation stability, good thermal stability, high mechanical and chemical stability and the like, also has high specific surface energy and nuclide adsorbing capacity and may be used as an efficient adsorbing material for radioactive nuclide in high-radioactive waste liquid, thus effectively protecting human health and ecological environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of nano palladium oxide catalyst

ActiveCN103381364AShape is easy to controlConsistent sizeMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlumina composite

A preparation method of nano palladium oxide catalyst comprises following steps: (1) preparing a nano palladium array and an alumina composite structure; (2) extracting the nano palladium array; (3) subjecting the nano palladium array to a heat treatment to obtain a nano palladium oxide array. The operation of the preparation method is simple. The pH value is adjusted through controlling the ammonia liquor concentration in the electro-deposition solution. The electro-deposition current density, the electro-deposition time, and the temperature and time during the heat treatment process are controlled to prepare a nano-grade palladium oxide array, which has a relatively high specific surface energy and catalyzing ability. The morphology of the nano palladium oxide is controllable, the size of the nano palladium oxide is the same, the application range is wide, and the nano palladium oxide is especially suitable for applications of tailing gas purifying technology in the automobile industry.

Owner:HUNAN JIANTE TECH CO LTD

Preparation method for silicon-carbon composite anode material of lithium ion battery

InactiveCN104916822AImprove cycle performanceHigh bonding strengthCell electrodesSecondary cellsCarbon compositesHigh energy

The present invention relates to a preparation method for a silicon-carbon composite anode material of a lithium ion battery. The method comprises: firstly obtaining nano-silicon dispersion liquid by using a high energy wet mechanical ball milling method; then combining the nano-silicon dispersion liquid with a high-residual-carbon polymer through dispersion polymerization to obtain a polymer / nano-silicon composite micro-sphere dispersion liquid in which flake nano-silicon is embedded in polymer micro-spheres; and finally performing self-assembling, organic carbon sources solid phase coating and heat treatment on the polymer / nano-silicon composite micro-sphere dispersion, the nano-silicon and graphite of the nano-silicon to obtain the silicon-carbon composite anode material of the lithium ion battery. The method solves the problem that nano-silicon is prone to agglomerate as the granularity of the nano-silicon is small and the specific surface energy is high, and adding of elemental silicon greatly improves the capacity of the silicon-carbon composite anode material.

Owner:NANJING UNIV OF TECH

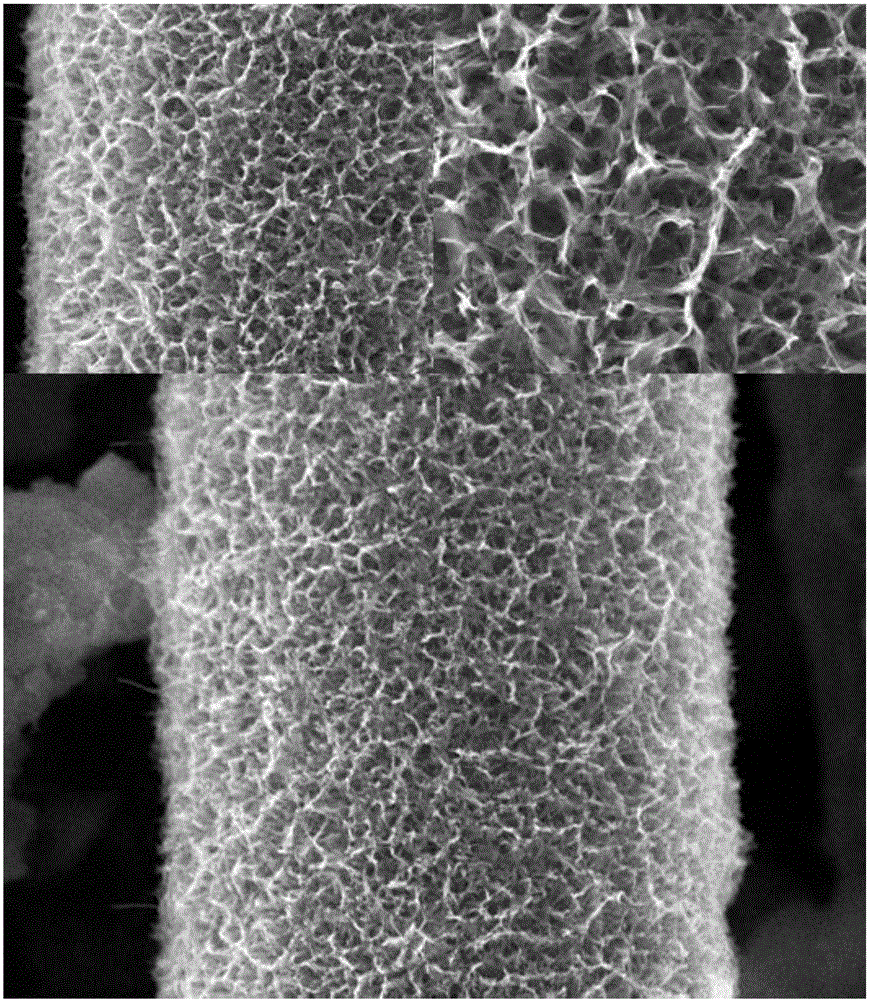

Super-thin-wall honeycomb-shaped structure titanium dioxide nano material and preparation method thereof

The invention discloses a super-thin-wall honeycomb-shaped structure titanium dioxide nano material and a preparation method thereof. The super-thin-wall honeycomb-shaped structure titanium dioxide nano material is of a relatively uniform layered structure, the thickness of a nanosheet is relatively small, gaps are formed among layered nanosheets, specific surface areas, specific surface energy, flame retardancy, conductivity, heat conduction coefficients, impact strength and electron migration capabilities can be remarkably improved, according to the preparation method, a titanium dioxide film layer grows from titanium dioxide gel on the surface of a carbon fiber substrate and a two-dimensional titanium dioxide nano structure layer of which the gap sizes and morphology can be controlled is prepared on a titanium dioxide nano seed layer, defects that a conventional nanosheet is relatively low in generation rate, large in thickness, complex in process and the like can be overcome, the production process is simple, reaction conditions are gentle, the preparation time is short, and further, the industrial application of a titanium dioxide nano-structure material can be accelerated.

Owner:梁厚栋

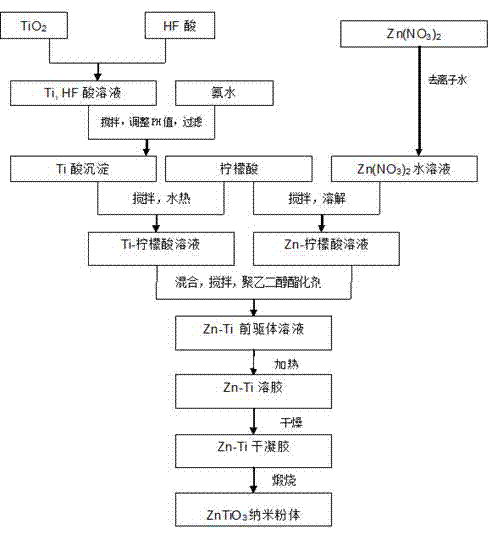

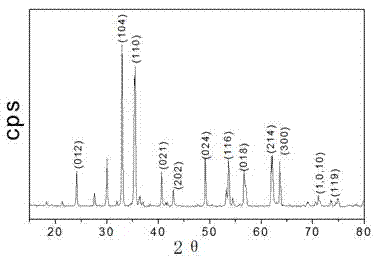

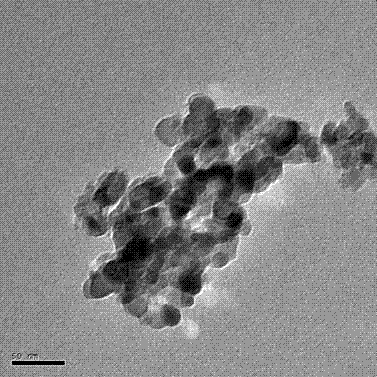

Method for finely synthesizing ilmenite structure ZnTiO3 nanometer powder by using water-soluble sol-gel process

InactiveCN103708537ASimple processPrecise stoichiometric controlMaterial nanotechnologyTitanium compoundsHigh activitySpecific surface energy

The invention belongs to the technical field of electronic ceramic preparation and application, and particularly relates to a method for finely synthesizing ZnO-TiO2 system microwave dielectric ceramic nanometer powder by using a sol-gel method. The technical scheme comprises adopting a water-soluble sol-gel method to finely synthesize ZnO-TiO2 system microwave dielectric ceramic nanometer precursor powder, and specifically comprises: 1) preparing a citric acid aqueous solution of Zn ions; 2) preparing a citric acid aqueous solution of Ti ions; and 3) synthesizing a ZnTiO3 microwave dielectric ceramic nanometer precursor. According to the present invention, the low price oxide and the inorganic nitrate are adopted as the raw materials, use of the expensive metal alkoxide is avoided, and the synthesized powder has significant advantages of low synthesis temperature, uniform ceramic particles, good ceramic particle dispersity, pure phase, easy performing of fine doping modification of various elements, nano-scale powder (particle size of about 30 nm), high specific surface energy, high activity and the like. In addition, the method has the following characteristics that: the subsequent low temperature sintering can be achieved, and the LTCC application requirements can be met.

Owner:UNIV OF JINAN

Manufacture method of metal plate substrate for computer-to-plate of inkjet printing

ActiveUS20120021129A1High surface energyReduce diffusePretreated surfacesSpecial surfacesSpecific surface energyMetallic substrate

A method for preparing a metal substrate for inkjet CTP, comprising: treating a metal substrate by anodizing or non-anodizing (such as sandpaper burnishing, sand blasting, polishing, or brushing), and then applying a hydrophilic polymer paint on the surface of the metal substrate. Due to the existence of nano-size or micron-size oxide particles in the hydrophilic polymer paint, the metal substrate has high specific surface energy, while the metal substrate has a certain roughness, therefore the metal substrate has ink absorbency and good abrasive resistance. The metal substrate can reduce the spread of ink droplets and produces print image having better resolution and definition. The non-anodizing method can avoid environmental pollution which is caused by waste acid and waste alkali discharge of anodizing method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

New method for preparing monoclinic structure ZnZrNb2O8 microwave dielectric ceramic through low temperature sintering

The invention belongs to the technical field of electronic ceramic preparation and application, and particularly relates to a method for fine synthesis of a ternary monoclinic structure ZnZrNb2O8 microwave dielectric ceramic by using a sol-gel method. The technical scheme comprises adopting a sol-gel method to finely synthesize a ternary monoclinic structure ZnZrNb2O8 microwave dielectric ceramic, and specifically comprises: 1) preparing a citric acid aqueous solution of Zn ions and Zr ions; 2) preparing a citric acid aqueous solution of Nb ions; and 3) synthesizing a ternary ZnZrNb2O8 nanometer precursor, and preparing the dielectric ceramic. The ternary monoclinic structure ZnZrNb2O8 microwave dielectric ceramic has significant advantages of low synthesis temperature, uniform ceramic particles, good ceramic particle dispersity, pure phase, nano-scale powder (particle size of about 30 nm), high specific surface energy, high activity and the like. In addition, compared with the conventional solid-phase method, the method of the present invention has the following characteristics that: the sintering temperature can be significantly reduced by 100-200 DEG C so as to achieve low temperature sintering, maintain the good microwave dielectric property, and meet the LTCC application requirements.

Owner:UNIV OF JINAN

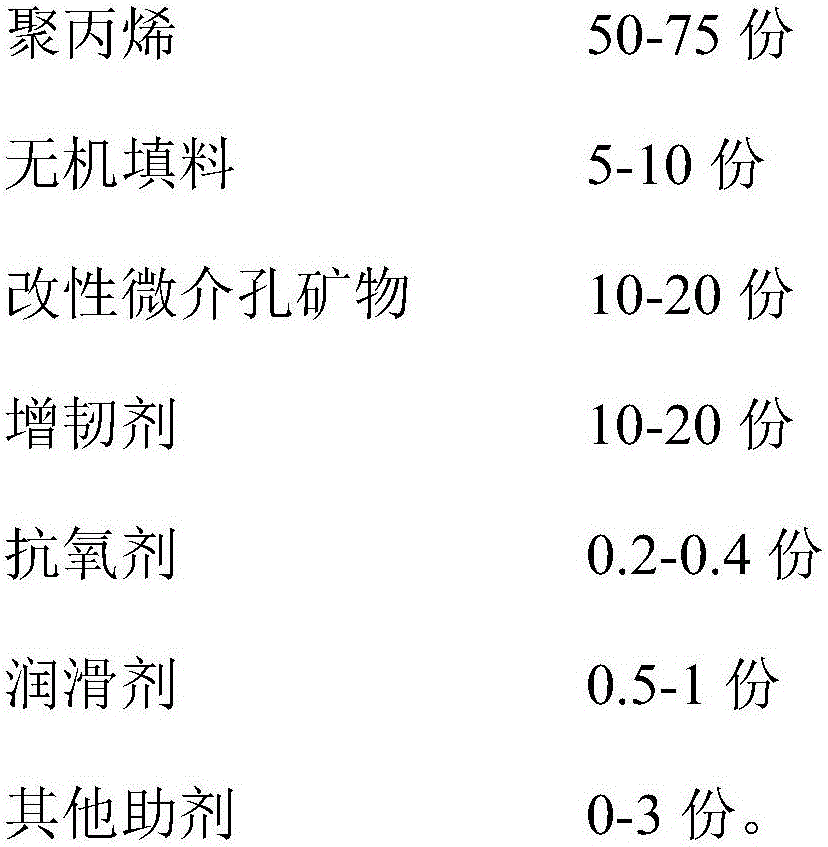

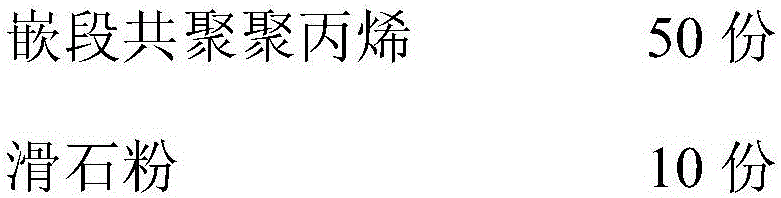

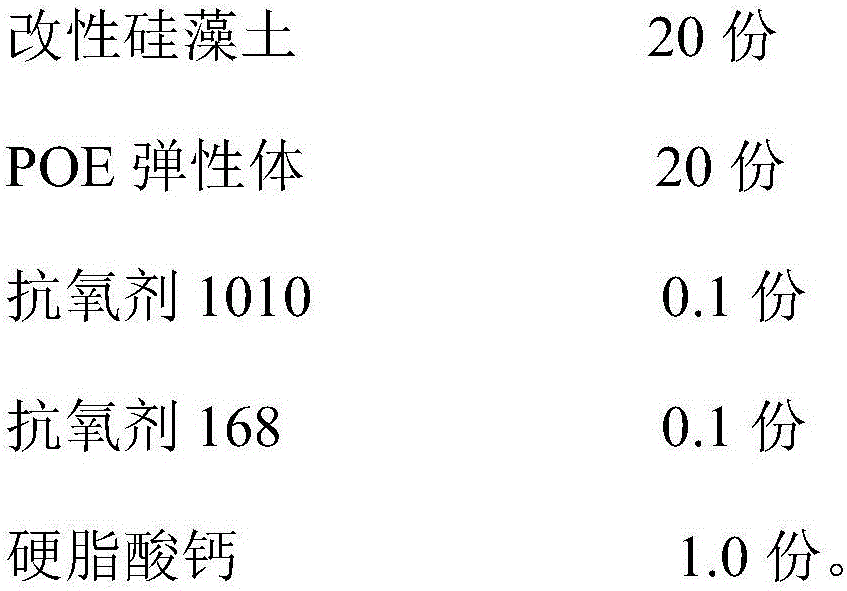

Highly filled low-density polypropylene composite material and preparation method thereof

The invention discloses a highly filled low-density polypropylene composite material and a preparation method of the highly filled low-density polypropylene composite material, wherein the highly filled low-density polypropylene composite material comprises the following raw materials in parts by weight: 50 to 75 parts of polypropylene, 5 to 10 parts of inorganic fillers, 10 to 20 parts of modified micro-mesoporous minerals, 10 to 20 parts of toughening agents, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 3 parts of other additives. According to the invention, sodium bicarbonate and citric acid are compounded to process opening micro-mesoporous minerals so as to replace a part of mineral filling; the modified micro-mesoporous minerals are heated to be decomposed in the process of injection moulding, so as to produce a large number of cells of which the sizes are several microns to tens of microns; the cells are adhered to channel surfaces with high specific surface energy inside the minerals; gases occupy micro-mesoporous channels, so that a matrix melt is unlikely to enter for filling. The method effectively reduces the density and weight of highly filled polypropylene, and performance and comprehensive properties of the highly filled polypropylene are not lost; and the material is endowed with good mechanical properties, and further has the functions of sound insulation, noise reduction and the like, and can be widely used in automotive interior materials.

Owner:重庆会通科技有限公司

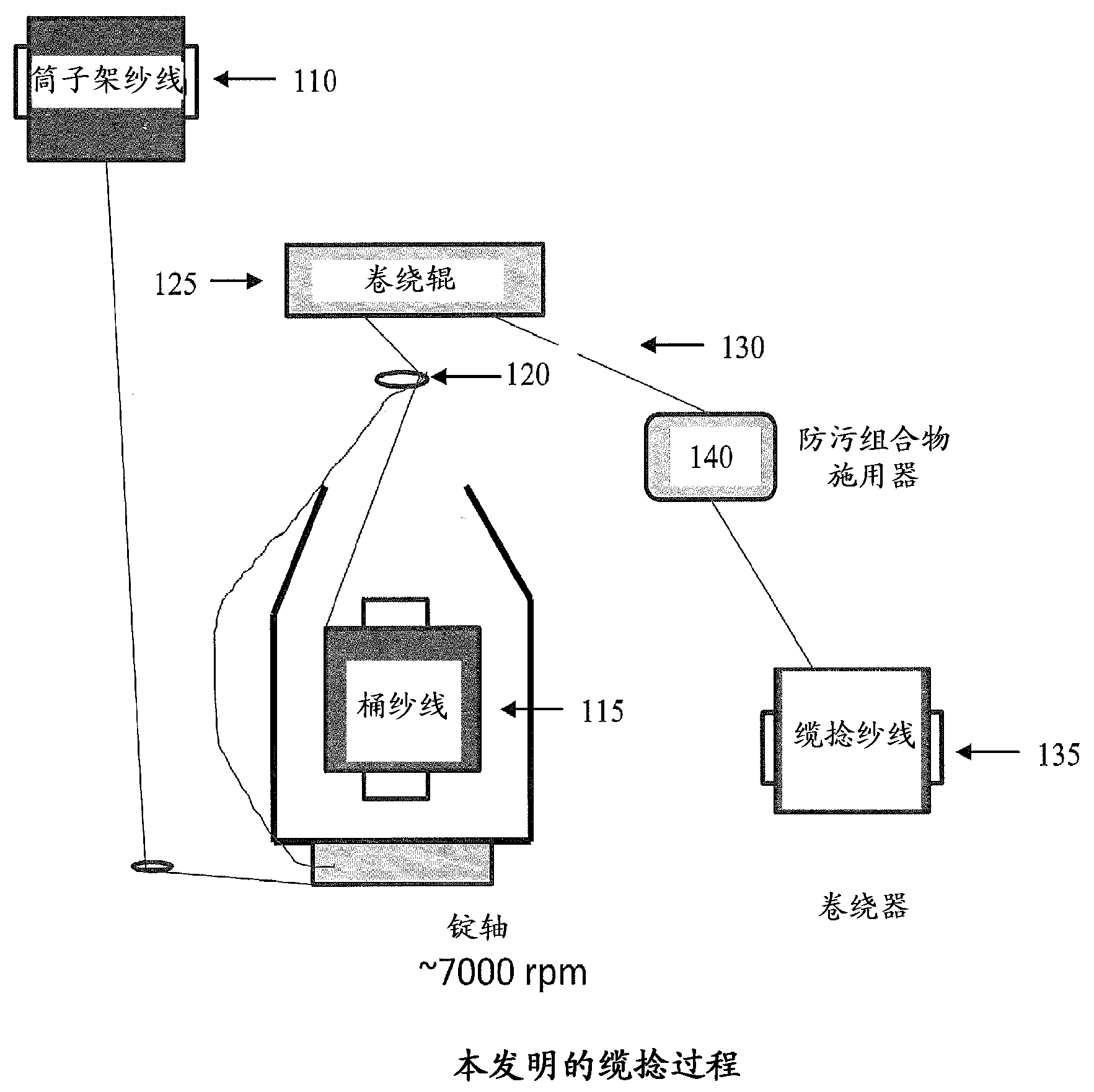

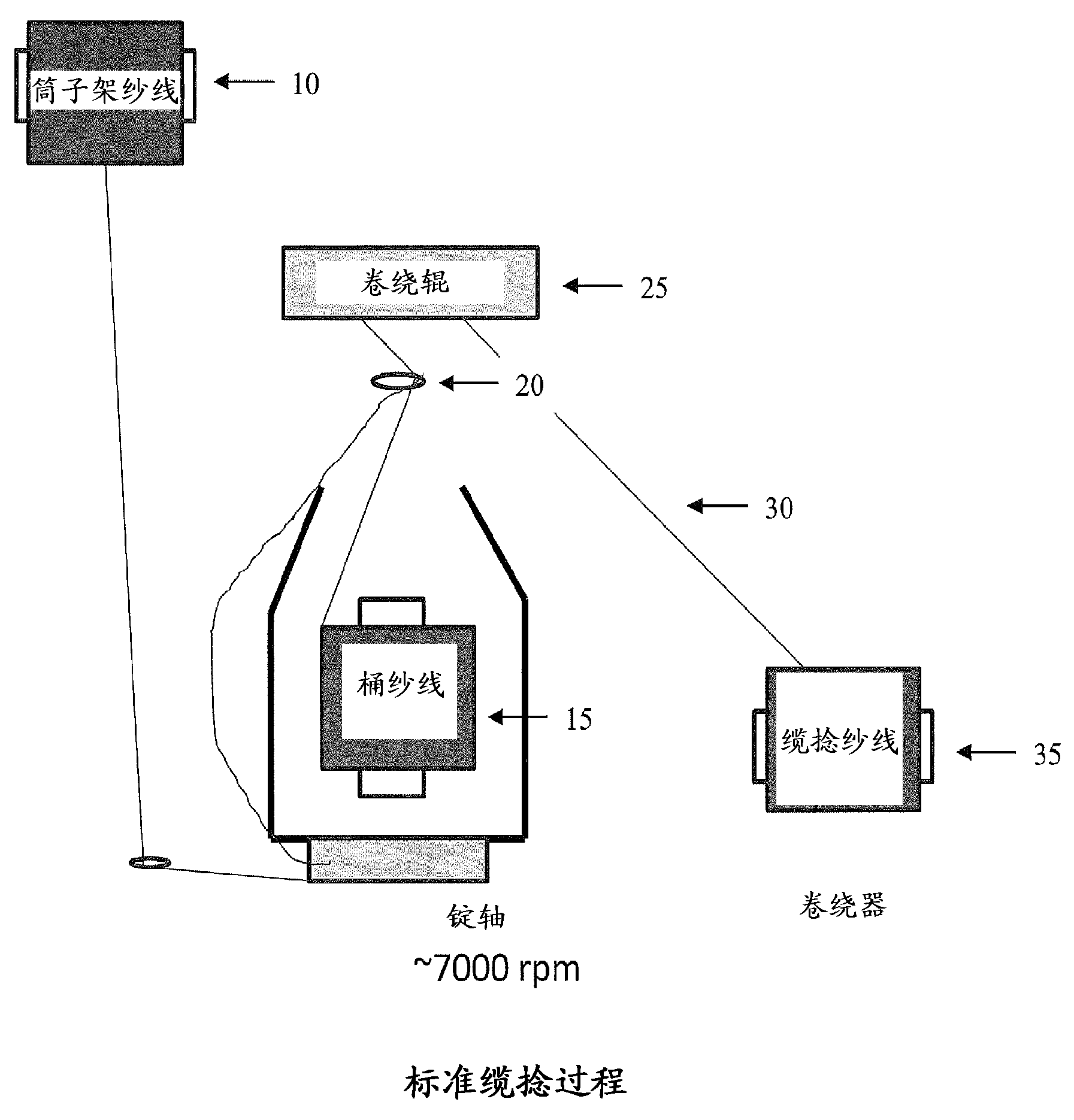

Processes to make water and oil repellent bcf yarn

InactiveCN103415661ALow costExcellent antifouling propertiesStain/soil resistant fibresLiquid repellent fibresChemical treatmentEngineering

Owner:INVISTA TECHNOLOG IES S A R L

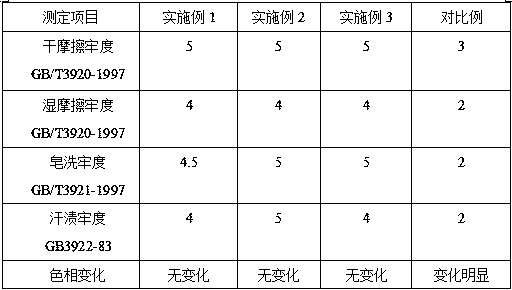

Preparation method of aldehyde-free textile color fixing agent

The invention relates to a preparation method of an aldehyde-free textile color fixing agent, and belongs to the technical field of textiles. The aldehyde-free textile color fixing agent is prepared by adding carboxymethyl cellulose hydrogel; hydrogen bonds, coordination bonds and van der waals force can be formed among groups of the carboxymethyl cellulose, a dye and fibers, and the color fixation rate of the dye is improved; the carboxymethyl cellulose is high in molecular weight so that a layer of thin film can be easily formed on the surface of a fabric and wrap dye molecules and water-soluble groups thereof, the difficulty is increased for the dye when the dye is dissolved and falls off from the surface of the fabric during washing, and the wet treatment fastness is improved; the carboxymethyl cellulose, metal salt and inorganic salt can form sol through hydrolysis or decondensation, the micro sol particles have a large specific surface area and relatively high specific surface energy, the particles are made to form a three-dimensional net structure, a layer of oxide thin film is formed on the fabric and wraps the dye molecules and the water-soluble groups thereof, the difficulty is increased for the dye when the dye is dissolved and falls off from the surface of the fabric during washing, and the wet treatment fastness is improved.

Owner:陈桂川

Adsorption composite material with magnetic inflation, and preparation method thereof

InactiveCN106732453AImprove stabilityLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesFiberCarbon nanotube

The invention discloses an adsorption composite material with magnetic inflation. The adsorption composite material is prepared from the following raw materials in parts by weight: 20-40 parts of adsorbent resin, 8-15 parts of ceiba base activated carbon fiber, 8-15 parts of carbon nanotube, 8-15 parts of graphene oxide, 5-10 parts of metal-organic framework material, 20-30 parts of ferrite type magnetic solution, 15-25 parts of magnetic powder body, 3-8 parts of active ingredient, 1-3 parts of sodium dodecylbenzene sulfonate and 20-30 parts of solvent. The adsorption composite material with the magnetic inflation, which is put forward by the invention, has the advantages of good stable performance, large specific surface area, high specific surface energy, high adsorption ability, high applicability, low requirement on the water body and high adsorption efficiency, can be widely applied to acid solution and alkaline solution and does not cause the secondary pollution of the water body. The preparation method has the advantages of simpleness, low preparation cost and high degree of expansion and is worth popularizing.

Owner:MOBAO CO LTD

Preparation method of monodispersed nano-calcium carbonate with low surface energy

ActiveCN109850931ATo achieve the purpose of disaggregating secondary aggregatesLower surface energyCalcium/strontium/barium carbonatesMaterial nanotechnologyDepolymerizationFiltration

The invention provides a preparation method of monodispersed nano-calcium carbonate with low surface energy and relates to the technical fields of preparation and processing of nano-calcium carbonatepowder. The preparation method comprises the following steps: S1, preparing boiled nano-calcium carbonate pulp; S2, adding an aging agent into the boiled nano-calcium carbonate pulp prepared in S1, and carrying out aging treatment to obtain a nano-calcium carbonate aging suspension; and S3, adding a surface treating agent into the nano-calcium carbonate aging suspension prepared in S2 to carry outsurface treatment, and then, carrying out filtration pressing dehydrating, drying and smashing to obtain the monodispersed nano-calcium carbonate with low surface energy. According to the preparationmethod, due to the addition of the aging agent, secondary aggregate depolymerization is realized, meanwhile, the specific surface energy of a powder is greatly reduced, and a monodispersed nano-calcium carbonate product is achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

Preparation method of high-performance glass fiber

The invention discloses a preparation method of high-performance glass fiber. The preparation method comprises the following steps: weighing a compound of silicon, aluminum, magnesium, calcium, zirconium, titanium, ferrum, cerium, yttrium, niobium, lithium, bismuth and boron, wherein the water-soluble compound is not less than 10% of the total molar quantity of all the compounds; then adding deionized water, and by taking zirconium oxide grinding balls as a grinding medium, sequentially performing ball grinding, spray drying, calcination, isostatic pressing treatment, fusing, wire drawing and other processes. The water-soluble compound evenly coats the surfaces of other compounds in a manner of ions through ball grinding mixing and spray drying, then nanoscale particles can be obtained after calcination. Under the high specific surface energy action of the nanoparticles and isostatic pressing, all the components are closely contacted, and the fusion temperature and fusion time of the glass can be obviously reduced, so that the energy consumption needed in the production of the glass fiber can be reduced.

Owner:CHINA JILIANG UNIV

Preparation method of nano calcium carbonate capable of stably suspending and dispersing in aqueous solution

ActiveCN109879303AStable suspension dispersionCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideCentrifugation

The invention discloses a preparation method of nano calcium carbonate capable of stably suspending and dispersing in an aqueous solution. The preparation method uses a carbonization method to preparethe nano calcium carbonate, and includes the steps that carbon dioxide gas is introduced into calcium hydroxide suspension liquid, nano calcium carbonate paste is obtained, nano calcium carbonate boiled paste is obtained after overcarbonization for 5-10 min, a hydrophilic treatment agent is added, when the room temperature is up to 120 DEG C, the stirring modification time is 1-24 h, and the nanocalcium carbonate capable of stably suspending and dispersing in the aqueous solution is obtained after centrifugation or filter pressing, drying, and crushing. According to the preparation method ofthe nano calcium carbonate capable of stably suspending and dispersing in the aqueous solution, through overcarbonization after carbonization of calcium hydroxide prime paste, thus bicarbonate radicals are uniformly distributed on the surfaces of nano calcium carbonate grains, a hydrophilic surface modifier is then added to modify the surface of calcium carbonate, the specific surface energy is lowered, thus the nano calcium carbonate is in a monodisperse state, and stably suspends in the aqueous solution.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

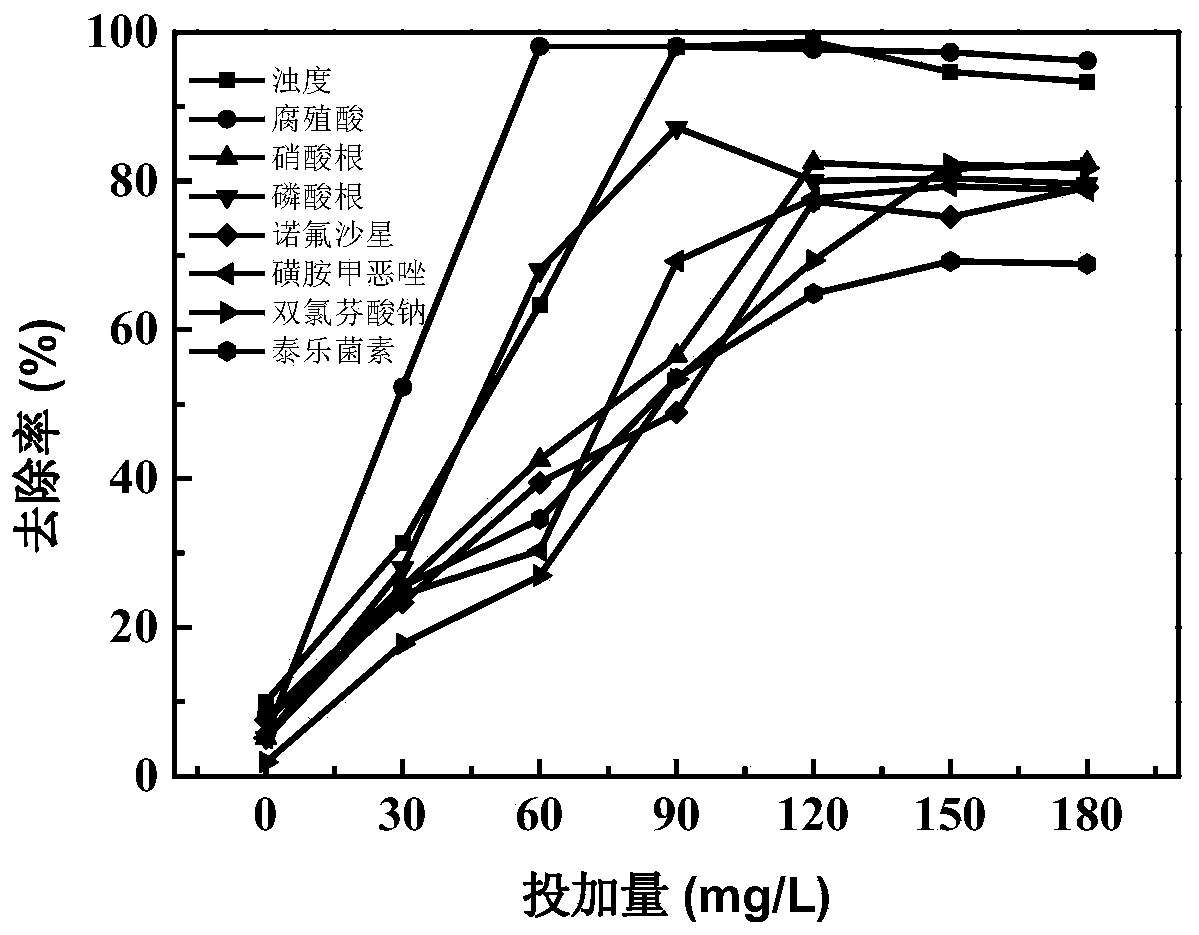

Hydrophobic modified organic/inorganic composite flocculant and preparation method and application thereof

ActiveCN111573802AIncrease electropositivityMeet different environmental conditionsEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationFlocculationOrganic group

The invention discloses a hydrophobic modified organic / inorganic composite flocculant and a preparation method and application thereof. The structural formula of the hydrophobic modified organic / inorganic composite flocculant is as follows: R1 is Al or Fe or Ti, R2 is-NH (CH2) 2CH3 or-NHCH (CH3) 2, n ranges from 4.012 to 19.47, and the value range of x: y is (3.1 to 12.4): 1. The flocculant has both inorganic groups and organic groups, improves the defect of insufficient charge density of a single flocculating agent, and improves the electric neutralization characteristic so that the flocculation speed of the composite flocculating agent is increased, the effective flocculation range is widened, and the floc settling performance is good; the nanocrystallization flocculant has the advantages of multiple surface atoms, large particle specific surface area, high specific surface energy and the like, and the flocculation performance of the flocculant on pollutants is further improved; in addition, the flocculating agent subjected to moderate hydrophobic modification has excellent flocculation performance on micromolecular organic pollutants containing hydrophobic functional groups in awater body, and is wide in application range.

Owner:NANJING NORMAL UNIVERSITY

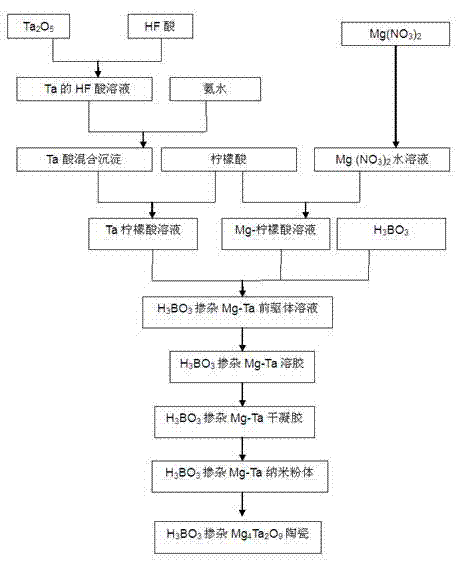

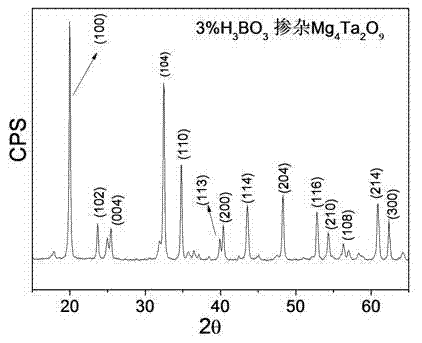

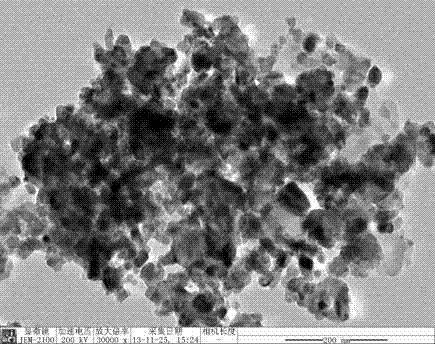

Novel method for lowering sintering temperature of corundum-type Mg4Ta2O9 microwave dielectric ceramic by doping H3BO3

InactiveCN104119075AImprove sintering propertiesLower sintering temperatureCeramic sinteringHigh activity

The invention belongs to the technical field of preparation and application of electronic ceramic, and particularly relates to a novel method for lowering sintering temperature of corundum-type Mg4Ta2O9 microwave dielectric ceramic by doping H3BO3. The technical scheme is as follows: the method for lowering sintering temperature of corundum-type Mg4Ta2O9 microwave dielectric ceramic by doping H3BO3 is based on a wet chemical technique. The method comprises the following steps: 1) preparing a Mg ion citric acid water solution; 2) preparing a Ta ion citric acid water solution; 3) preparing a H3BO3-doped Mg-Ta precursor by a sol-gel process, synthesizing a dielectric ceramic nano precursor, and sintering the ceramic. The H3BO3-doped Mg4Ta2O9 ceramic precursor powder is firstly synthesized, so that the ceramic has the advantages of low synthesis temperature, uniform ceramic particles, favorable dispersity, pure phase, nano size, high specific surface energy, higher activity and the like; and in the subsequent sintering process, the function of the H3BO3 as the sintering fluxing agent is highlighted, thereby obviously lowering the sintering temperature by 200-300 DEG C and maintaining favorable microwave dielectric properties.

Owner:UNIV OF JINAN

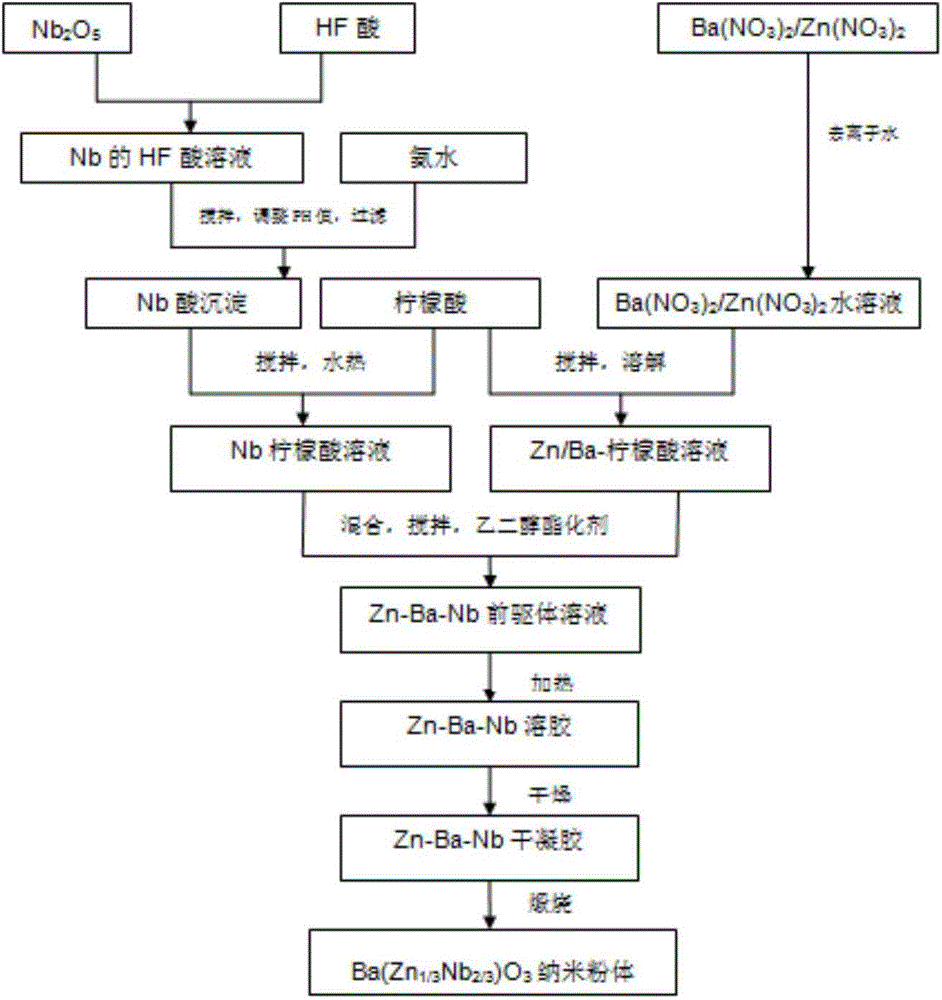

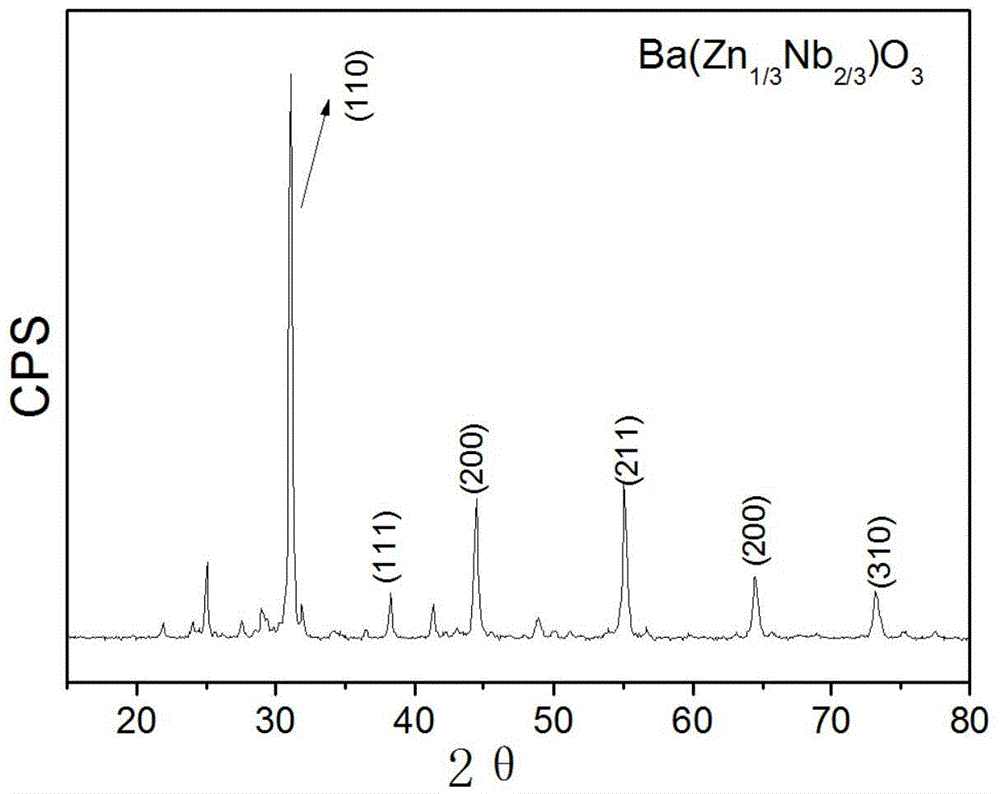

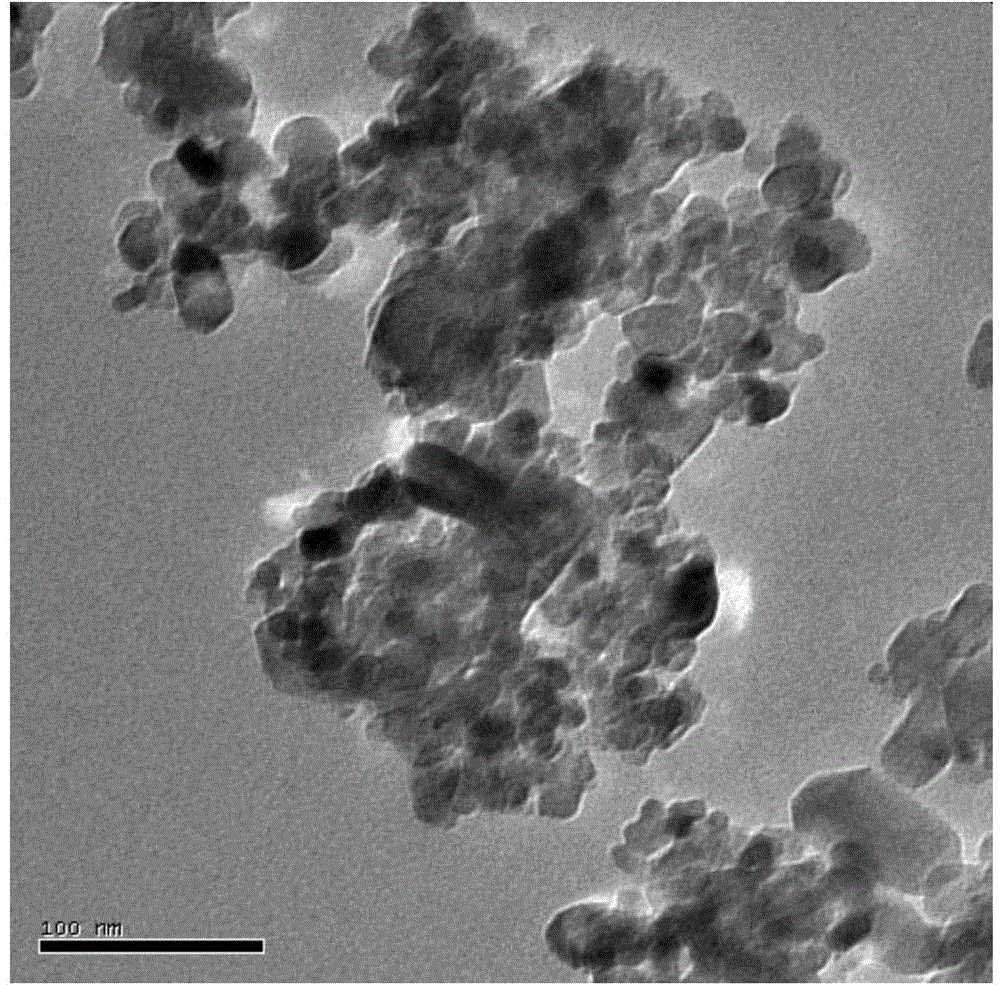

Method for fine synthesis of Ba(Zn1/3Nb2/3)O3 dielectric ceramic nano-powder through utilizing water-soluble sol-gel method

The invention belongs to the technical field of electronic ceramic preparation and application, and discloses a method for fine synthesis of Ba(Zn1 / 3Nb2 / 3)O3 dielectric ceramic nano-powder through utilizing the sol-gel method. The method for fine synthesis of Ba(Zn1 / 3Nb2 / 3)O3 dielectric ceramic nano-powder includes the following steps: (1), preparing a citric acid water solution with Zn and Ba ions; (2), preparing a citric acid water solution with Nb ions; (3) synthesizing Ba(Zn1 / 3Nb2 / 3)O3 ceramic nanometer precursor. According to the invention, oxides and inorganic nitrate with lower price are used as raw materials, so that expensive metal alkoxide is not used, the synthesized powder is low in synthesis temperature, uniform in ceramic particles, good in dispersity and pure in phase, fine doping modification of various elements can be implemented easily; the obtained powder has the remarkable advantages of the nano particle size lower than 100 nm, high specific surface energy, higher activity, and the like, follow-up low temperature sintering is realized, and the LTCC application requirements are expected to be met.

Owner:JINAN WEIBO NEW MATERIAL

Method for producing activated carbon using hickory shells as raw material

InactiveCN106276890AIncrease char formationIncrease in sizeOther chemical processesPhosphoric acidZno nanoparticles

The invention discloses a method for producing activated carbon using hickory shells as raw material. The method comprises the steps of raw material selecting, drying, shredding, extruding to form blocks, forming carbon in a carbonization furnace, crushing into granules, activating to forma rough product of activated carbon, acid pickling, water washing, drying and mixing; according to the method disclosed by the invention, an acid source generates metaphosphoric acid or poly metaphosphoric acid when heated, so that the carbon yield of the organic matter Chinese chestnut shells is increased; the volume of the carbon is increased byusing an air source so as to increase the specific surface area of the activated carbon; the particle strength of expanded carbon is increased by inorganic silicon; nano zinc oxide has the characteristics of large specific surface area and specific surface energy, so that the adsorbability and the antibacterial property of the material can be increased; and self-researched modified dolomite is added to further reinforce the adsorption capacity of the produced activated carbon.

Owner:旌德县龙强净化材料厂

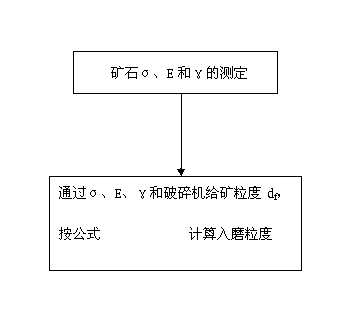

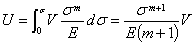

Method for determining grinding granularity of ores based on ore properties

ActiveCN102706784AAvoid blindnessReduce grinding energy consumptionParticle size analysisGrain treatmentsGranularitySpecific surface energy

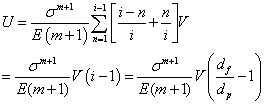

The invention relates to a method for determining the grinding granularity of ores based on ore properties. In order to solve the problem that appropriate grinding granularity is difficult to determine in the dressing plant designing process, the appropriate grinding granularity is calculated through a theoretical calculation formula of the grinding granularity by testing the limit stress, elastic modulus and specific surface energy of the ores, so that a theoretical basis is provided for the selection of crushing equipment and ore grinding equipment, and a condition is created for grinding energy conservation of a designed dressing plant. By the method, a small number of ore mechanical parameters are referred, the grinding granularity can be measured by the conventional detection method,and a calculation method is simple; and the method is high in practicability and has an important effect on energy-saving levels of dressing plants.

Owner:KUNMING UNIV OF SCI & TECH

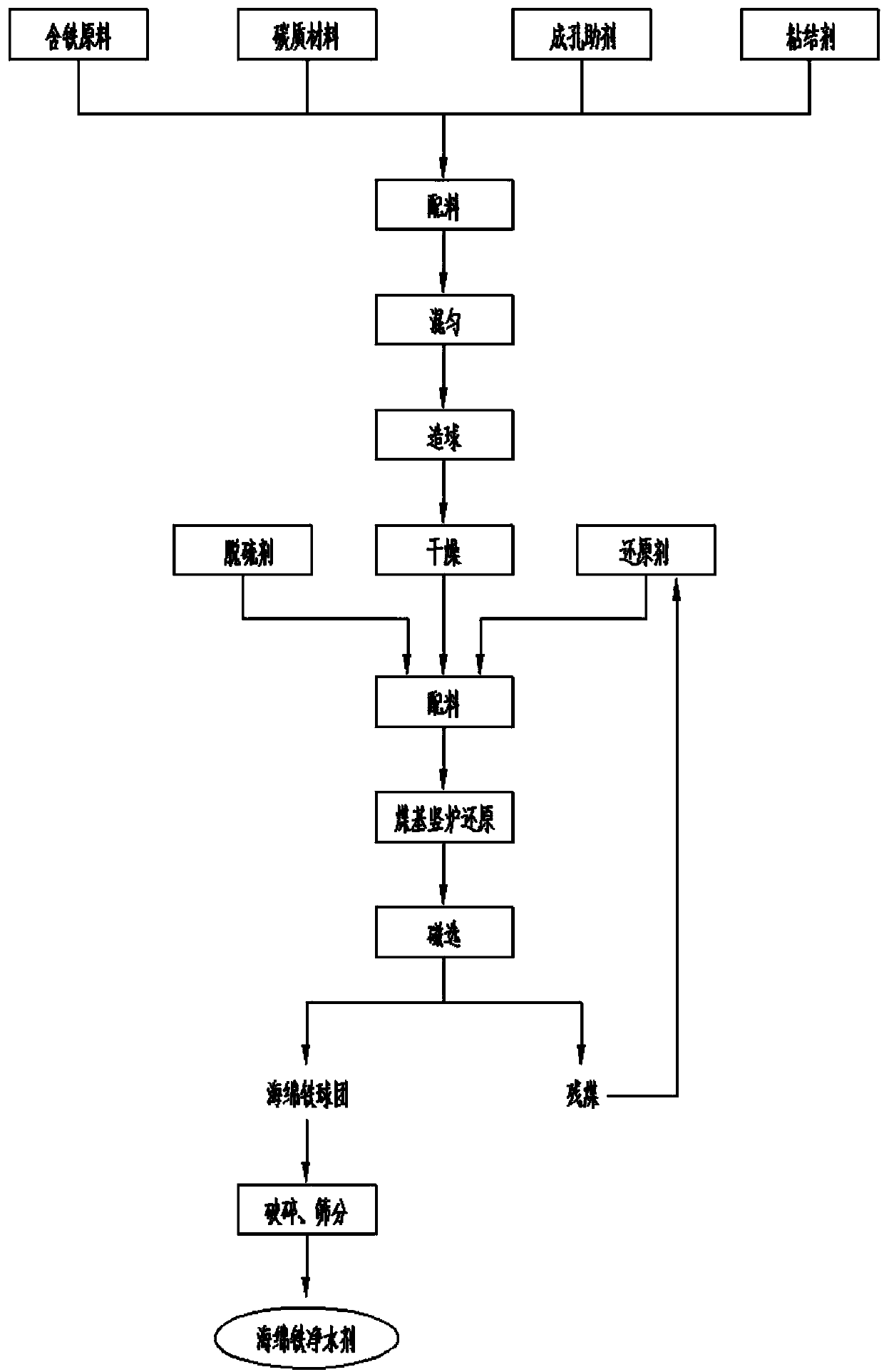

Production technology of sponge iron for water purifying agent

ActiveCN107827197AThe production process is simple and reliableRealize large-scale productionWater contaminantsWater/sewage treatment by flocculation/precipitationFlocculationWastewater

The invention relates to a production technology of sponge iron for a water purifying agent. The production technology comprises steps as follows: (1), a dried and finely ground iron-containing raw material is mixed uniformly with a carbonaceous material, a pore-forming auxiliary and binder components, and a mixture is pressed into balls; (2), green balls are dried and mixed uniformly with a reducing agent and a desulfurizing agent, preheating, reducing and cooling are performed in a coal shaft furnace, and a sponge iron mixture is obtained; (3), after the sponge iron mixture is subjected to magnetic separating, sponge iron metallized pellets and residual coal are obtained; sponge iron particles obtained after crushing and screening of the sponge iron metallized pellets are used as the water purifying agent. The production technology has the remarkable advantages of being advanced, reliable, stable in product quality, low in production cost, high in production efficiency and environmentally friendly, and large-scale production can be realized; the produced sponge iron water purifying agent has the advantages of large specific surface area, high specific surface energy, higher electrochemical enrichment, physical absorption and flocculation precipitation and the like, and can be widely used for treating various kinds of wastewater with difficulty in biochemical degradation.

Owner:WUHAN COSRED SCI & TECH LTD

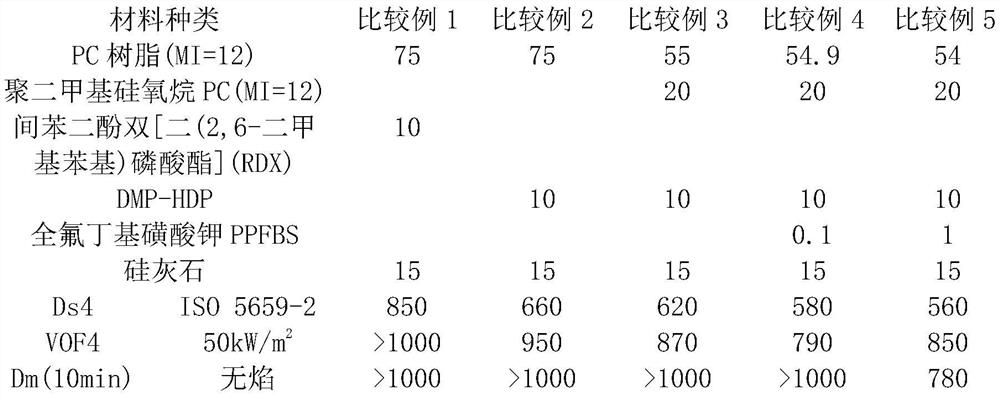

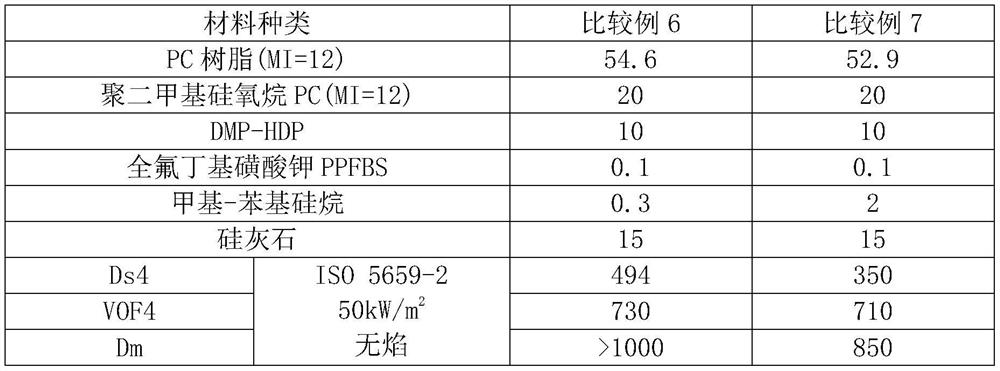

Low-smoke-density flame-retardant PC composition

The invention discloses a low-smoke-density flame-retardant PC composition. The low-smoke-density flame-retardant PC composition is prepared from the following raw materials in parts by weight: 10 to 85 parts of PC resin, 5 to 50 parts of organic silicon PC, 0.1 to 2 parts of sulfonate flame retardant, 0 to 10 parts of phosphorus flame retardant, 0.3 to 5 parts of organic silicon flame retardant, 2 to 40 parts of reinforced filler and 0.5 to 5 parts of nano material. According to the low-smoke-density flame-retardant PC composition disclosed by the invention, by compounding a flame-retardant system and adding an inorganic nano material, the efficiency of a flame retardant can be improved and the release of combustible gas during degradation of the material is slowed down and reduced by virtue of a relatively large nano specific surface energy, so that smoke formation and combustion of the material are slowed down, and a low-smoke-density flame-retardant effect is achieved while the additive amount of the flame retardant is low; the low-smoke-density flame-retardant PC composition disclosed by the invention can be applied to the fields of rail transit, aerospace, buildings and the like which have strict requirements on the combustion smoke density of materials.

Owner:上海品诚控股集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com